Gantry movable type multifunctional numerical-control drilling and milling machine

A mobile, multi-functional technology, applied in the direction of driving devices, large fixed members, maintenance and safety accessories, etc., can solve the problem of only one set of drilling and milling mechanisms, and achieve the goal of reducing labor intensity, ensuring stability and ensuring machining accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

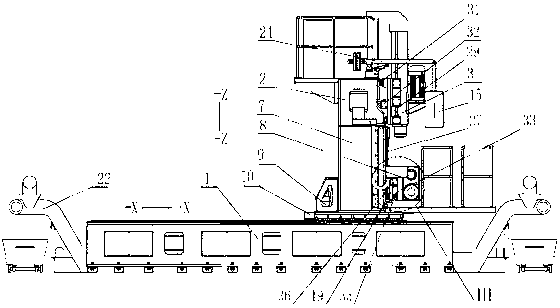

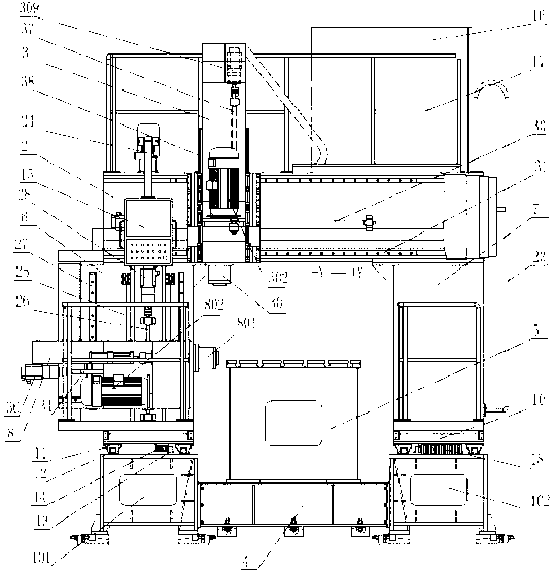

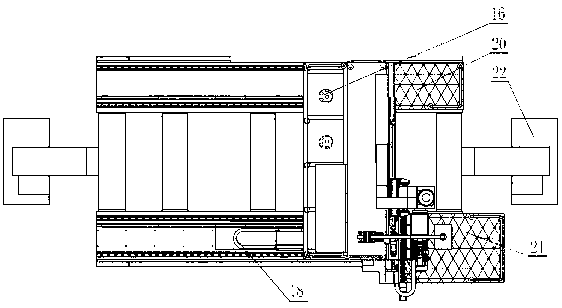

[0046] See figure 1 , figure 2 , image 3 , Figure 4 , the present invention includes a bed 1, an operation box 15 and an electric control cabinet 16, a column is slidably supported on the bed 1, a beam mechanism 2 is fixed on the column, and an upper drilling and milling mechanism 3 is slidably supported on the beam On the mechanism 2, the electric control cabinet 16 is fixed on the beam mechanism 2. The bed 1 is a split structure, including the left bed 101 and the right bed 102. The left bed 101 and the right bed 102 are connected by the middle The connecting frame 4 is connected, and the workbench 5 is fixed on the connecting frame 4; the left column 6 and the right column 7 are slidably supported on the left bed 101 and the right bed 102 respectively through the sliding mechanism; the beam mechanism 2 spans And fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com