Long pipe surface thermal spraying device

A thermal spraying, long-pipe technology, applied in coating, fusion spraying, metal material coating process, etc., can solve spraying leaks or uneven coating, uneven coating thickness, easy to produce beating and swinging, etc. problem, to achieve the effect of automatic spraying process, complete spraying process and smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

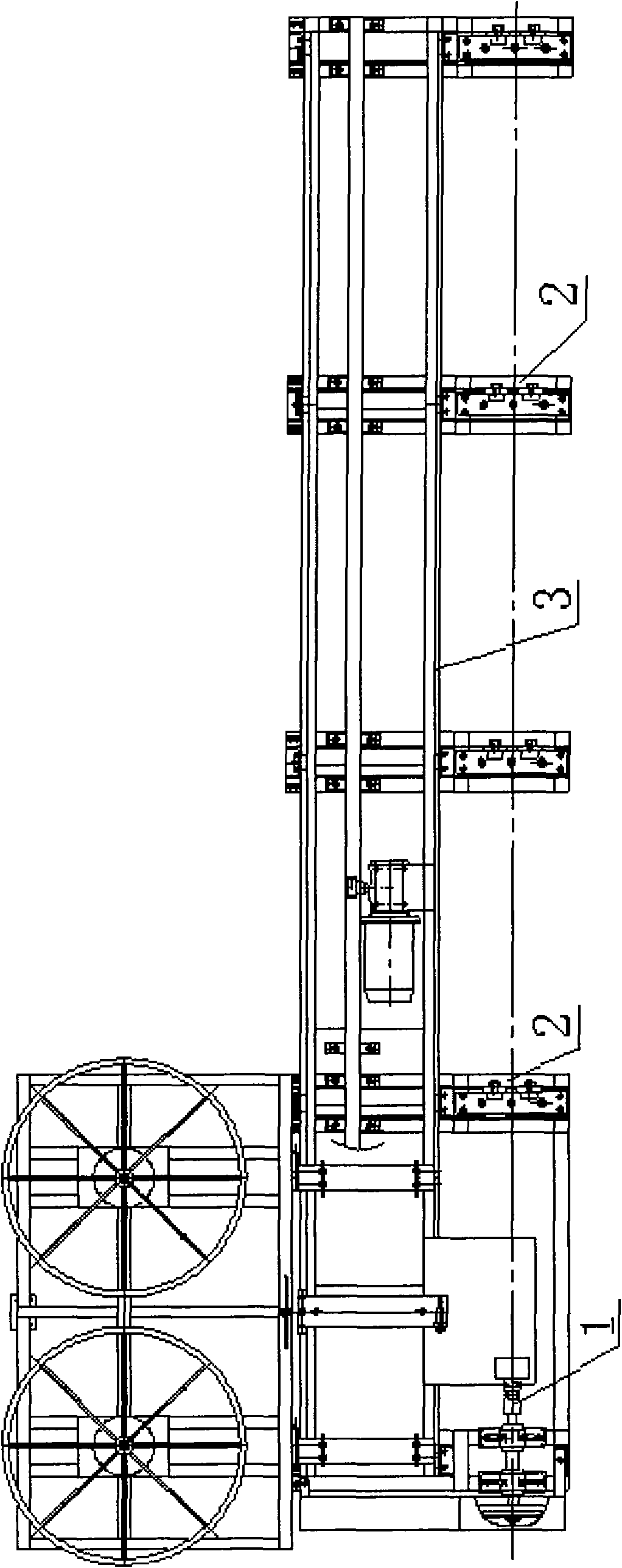

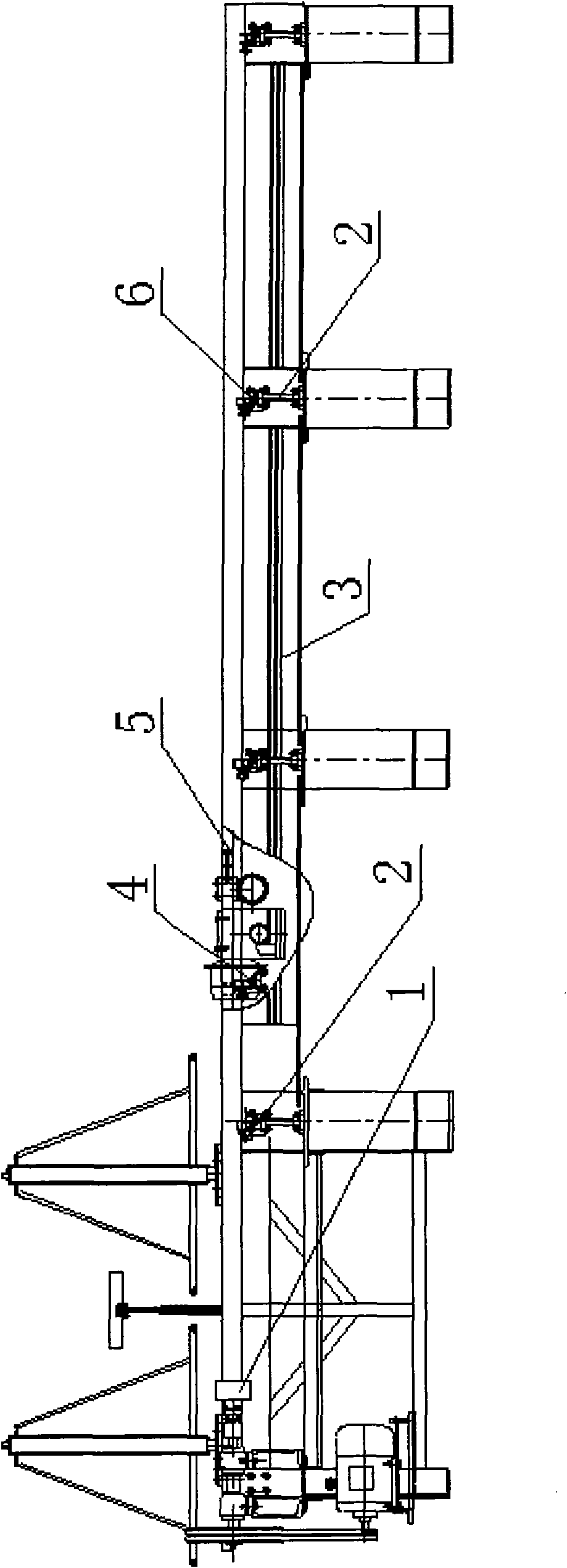

[0037] Embodiment 1: Taking the 27 / 8 "oil pipe spraying aluminum as an example, the long pipe fitting surface thermal spraying device of the present invention is described in further detail. Refer to figure 1 and figure 2 .

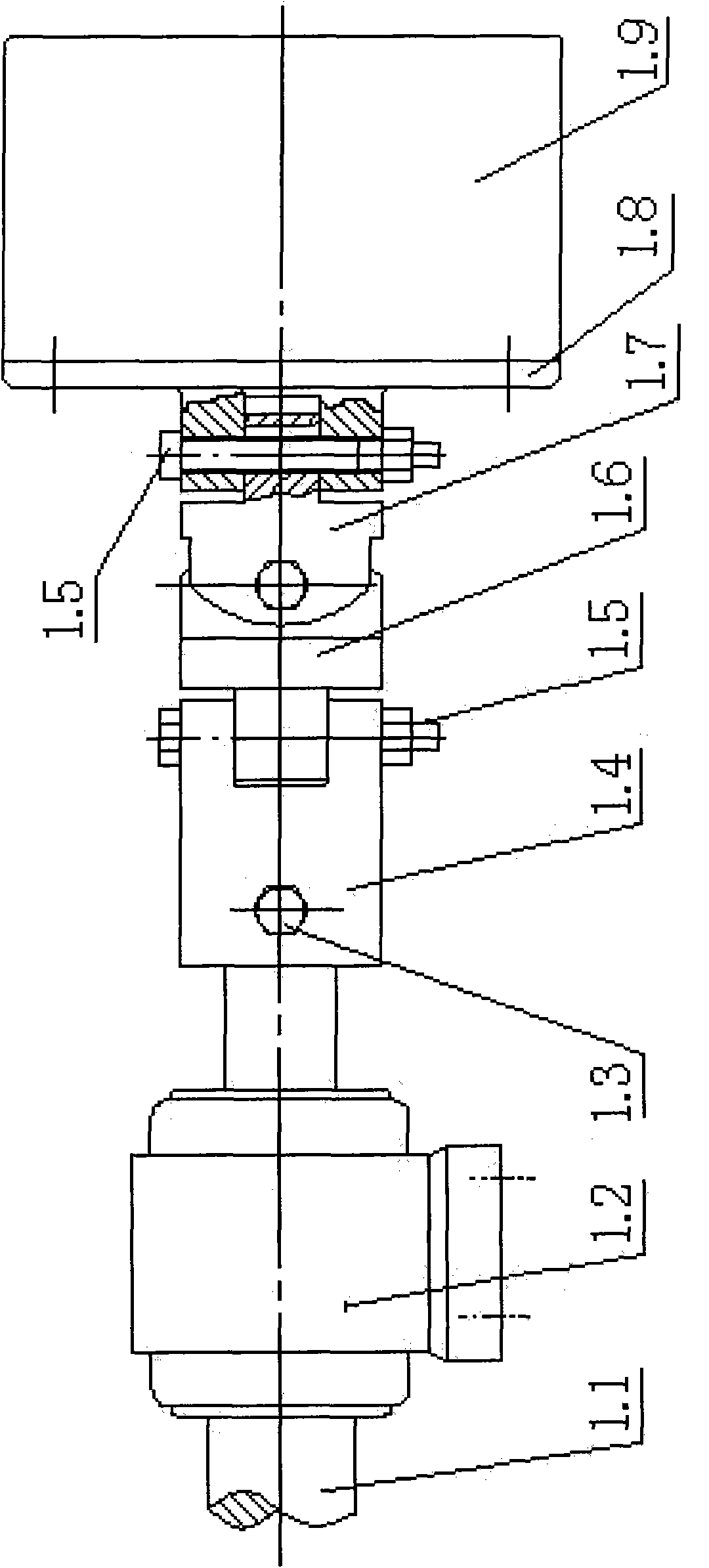

[0038] The thermal spraying device on the surface of long pipes is mainly composed of a clamping and rotating mechanism 1, a cylinder type lifting mechanism 2, a track 3, a walking trolley 4, a thermal spraying system 5 and a control mechanism 6. There is a walking trolley 4; a thermal spraying system 5 is fixed on the walking trolley 4.

[0039] One side of the track 3 is fixed with a support, and the cylinder type lifting mechanism 2 is fixed on the support. The number of the cylinder type lifting mechanism 2 is four, and the cylinder type lifting mechanism 2 is arranged in parallel with the track 3 and evenly distributed. One end of the support of the cylinder type lifting mechanism 2 is fixed with a clamping and rotating mechanism 1 .

[0040] Ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com