Inductance encapsulating machine

A packaging machine and inductance technology, applied in packaging and other directions, can solve problems that affect the correct use of components by end users, wrong polarity of packaged components, unstable pulling force of packaging machines, etc., to achieve accurate counting without errors, avoid errors, and solve problems Unsteady effect of pressing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

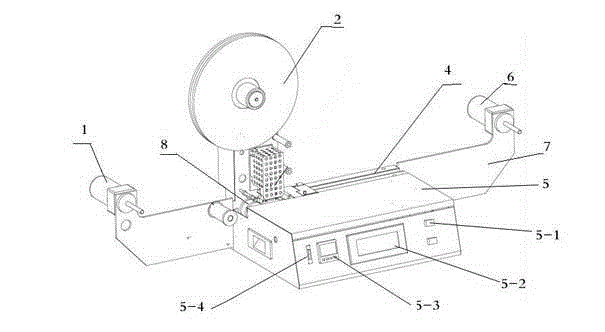

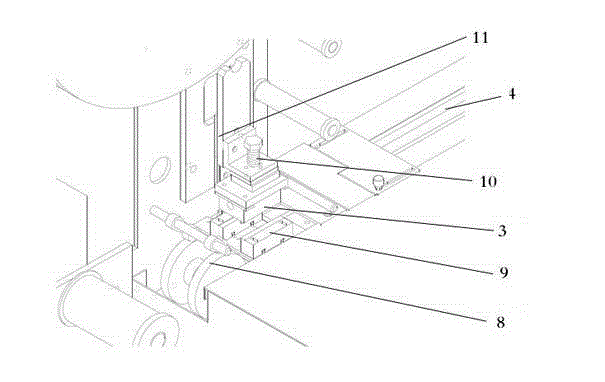

[0014] figure 1 with figure 2 The shown inductance packaging machine includes a control box 5 and a frame 7, on which a take-up shaft driven by the take-up motor 1 and a tape feed shaft driven by the tape feed motor 6 are installed on the frame 7; 2 and the carrier tape guide wheel 8; The lower paper tape conveying path is arranged between the said take-up shaft and the tape feeding shaft, the said lower paper tape conveying path is provided with a carrier tape guide groove 4, and said lower paper tape conveying A base 9 is provided at the end of the track, and a heat-sealing head 3 installed on a vertical guide rail 11 is arranged above the base 9 , and an electromagnetic driver is connected between the frame 7 and the heat-sealing head 3 .

[0015] The upper packing paper tape is placed on the upper paper tape reel 2, and the lower packing paper ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com