Material discharging and ejecting mechanism

An ejector mechanism and ejector technology, applied in the field of presses, can solve problems such as unstable operation, jumping of ejector rods, and complicated adjustment of ejector mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

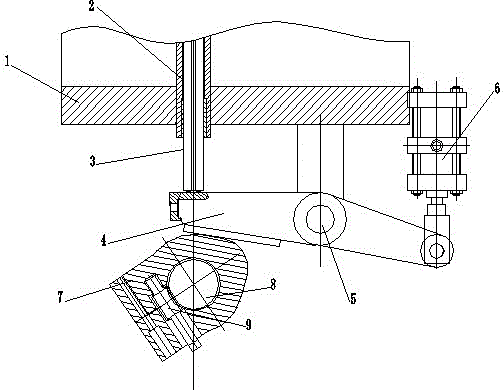

[0014] The present invention includes a mold base 1, and a material hole 2 of the mold base 1 is provided with an ejector rod 3 penetrating from its lower part;

[0015] The lower part of the ejector rod 3 is provided with a lever 4, the two sides of the lever 4 are free ends, and the middle part is provided with a fixed turning point 5;

[0016] One side of the lever 4 is arranged under the ejector rod 3 to form contact with the ejector rod 3, and the lower part of the lever 4 is provided with an eccentric mechanism 6;

[0017] A fixed air cylinder 6 is arranged on the upper part of the other side of the lever 4 , and the cylinder 6 drives the other side of the lever 4 .

[0018] The eccentric mechanism 6 includes a material ejector cam 61 in contact with the material ejector rod 3, a material ejector shaft 62 arranged in the material ejector cam 61 to drive the material ejector cam 61 to operate, and an adjustment to adjust the initial position of the material ejector cam 61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com