Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "No jumping phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

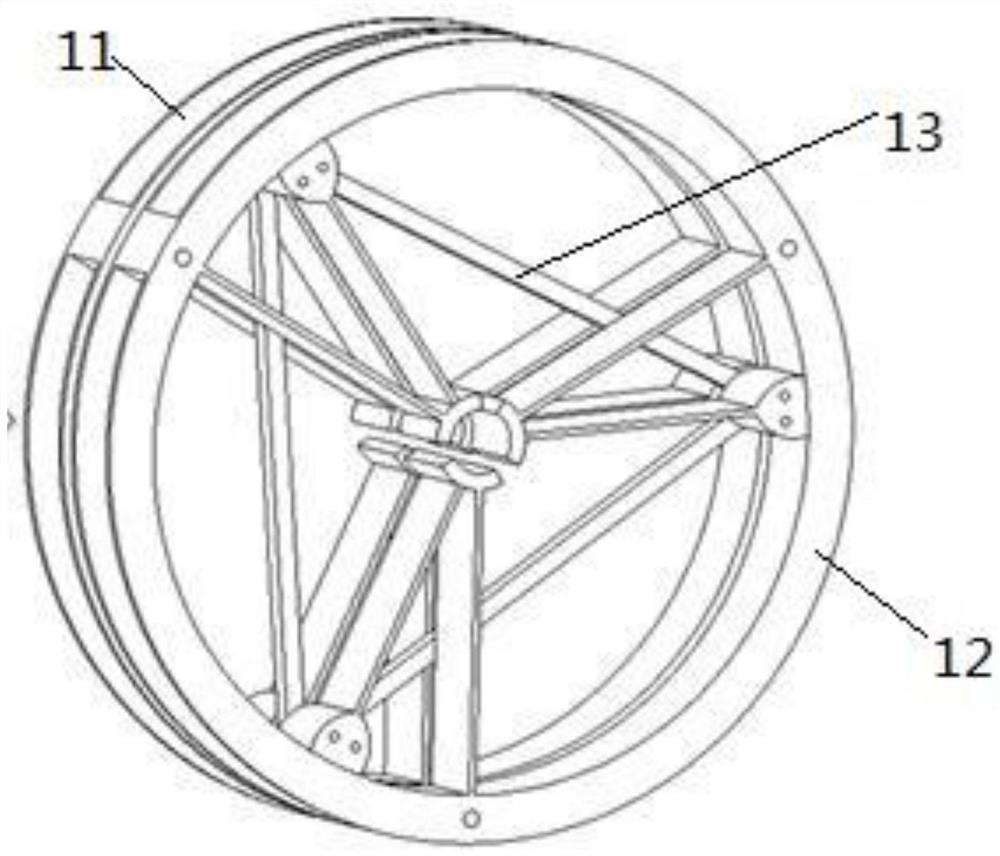

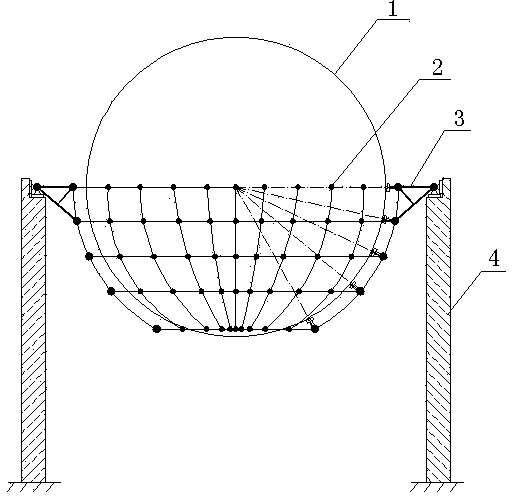

Reticulated shell-annular truss frame-irregular-shaped combination column combined support spherical tank system capable of slightly moving

InactiveCN103306531AGood energy dissipation and shock absorptionGood wind resistanceBulk storage containerShock proofingRebarReinforced concrete

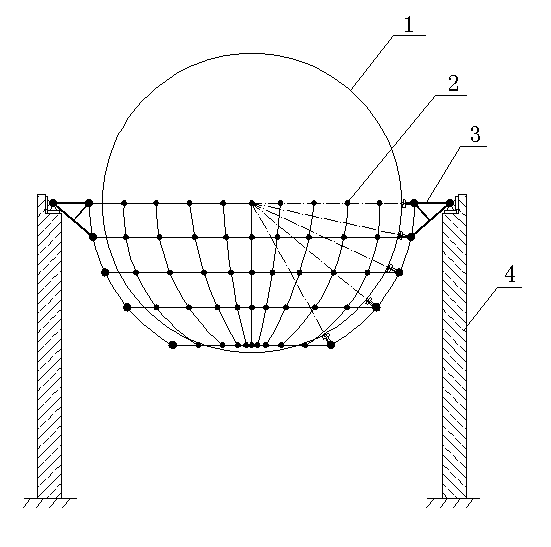

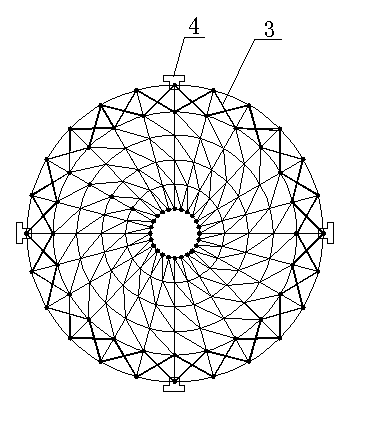

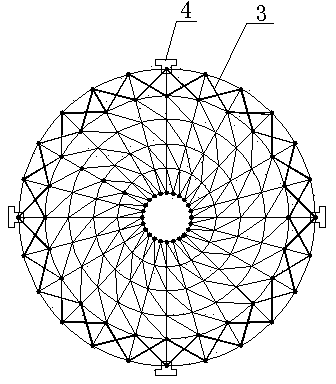

The invention relates to a reticulated shell-annular truss frame-irregular-shaped combination column combined support spherical tank system capable of slightly moving. The system comprises combined spherical tanks, reticulated shell-annular truss frame-irregular-shaped combination column combined supports, a rubber ball-damper shock-absorbing energy consumption device, wherein annular truss frames are encircled outside the reticulated shells, and are connected with the irregularly-shaped combination columns; the combined spherical tanks are arranged on the reticulated shell-annular truss frame-irregularly-shaped combination column combined supports; the rubber ball-damper shock-absorbing energy consumption device is arranged between the reticulated shell pitch points and the combined spherical tanks; the rubber ball- damper shock-absorbing energy consumption device is composed of dampers and rubber balls; the rubber balls are arranged at one ends of the dampers; concave slide tracks are arranged on the outer walls of the combined spherical tanks; the rubber balls are positioned in the concave slide tracks; the other ends of the dampers are fixed with the pitch points of the reticulated shells; the irregularly-shaped combination columns are composed of solid-web section steel and reinforced concrete; the solid-web section steel is placed in the reinforced concrete; an L-shaped support seat is arranged at the top ends of the combination columns. The system can move slightly in any direction under the strong shock or the strong wind, and has excellent energy consumption shock-absorbing performance and wing resistance.

Owner:NORTHEAST GASOLINEEUM UNIV

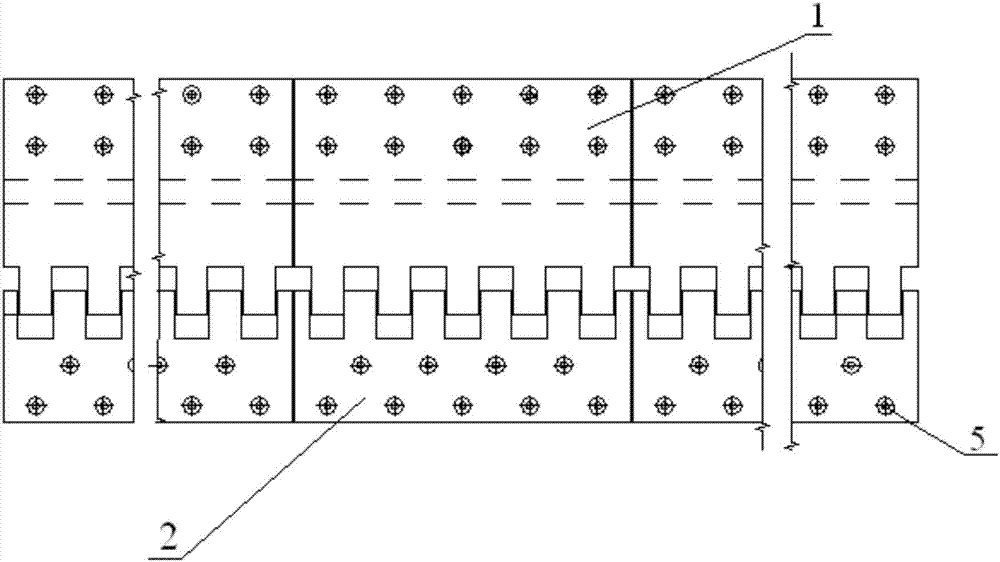

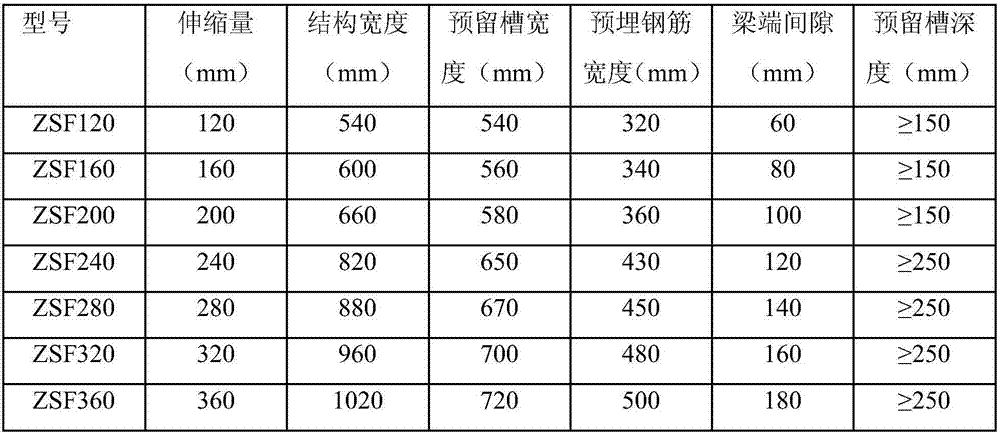

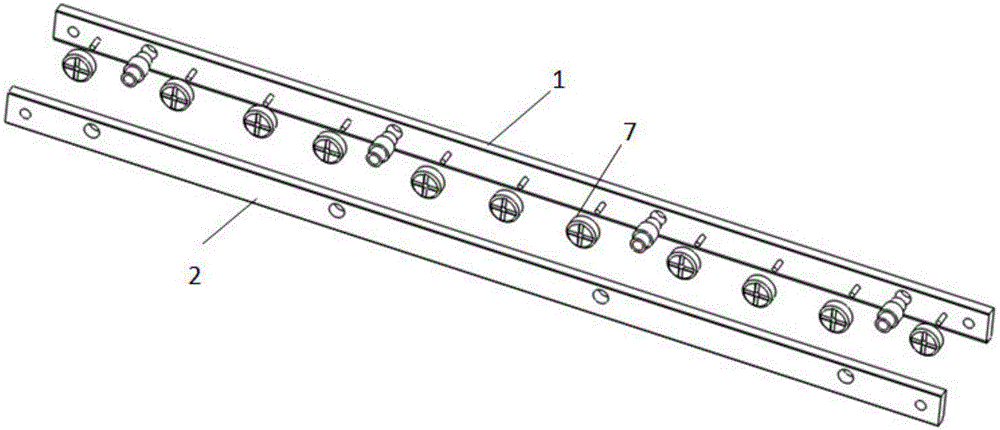

SF steel comb-teeth-shaped telescopic device and installing construction method thereof

InactiveCN107974935ANo jumping phenomenonNo noiseBridge structural detailsBridge erection/assemblyEpoxyEngineering

The invention discloses an SF steel comb-teeth-shaped telescopic device and an installing construction method thereof. The SF steel comb-teeth-shaped telescopic device includes a comb-teeth-shaped steel plate, a comb teeth plate anti-abrasion layer, a figured steel seal, a rubber sealing tape, a high strength bolt and a post-cast strip concrete layer. The installing construction method includes the steps of preparatory work before installing, line drawing and cutting, groove opening digging and cleaning, expansion joint fixing fixed bolt set positioning, centering and leveling, temporary fixing, detecting, welding and fixing, cleaning, concrete pouring below the comb teeth plate, comb teeth plate installing, surface finishing and maintenance and nut fixing and epoxy resin infusing. The SFsteel comb-teeth-shaped telescopic device and the installing construction method thereof have the beneficial effects that the disadvantages that fashioned iron type expansion joint concrete damaging and fashioned iron deformation can be solved, the maintenance charge is reduced, the disadvantage that garbage and sundries enter the expansion joint to affect expansion of a bridge before is improved,and the problem of running safety of the bridge is solved.

Owner:SINOHYDRO BUREAU 11 CO LTD

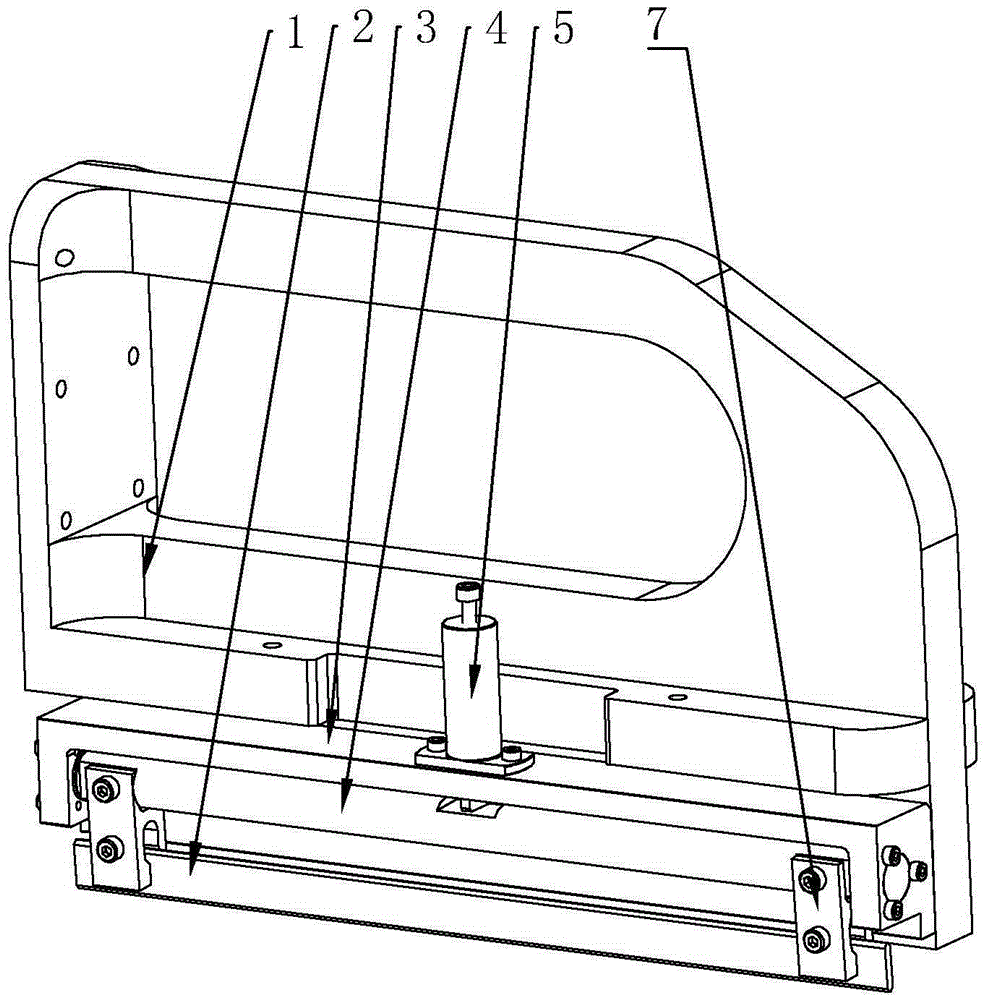

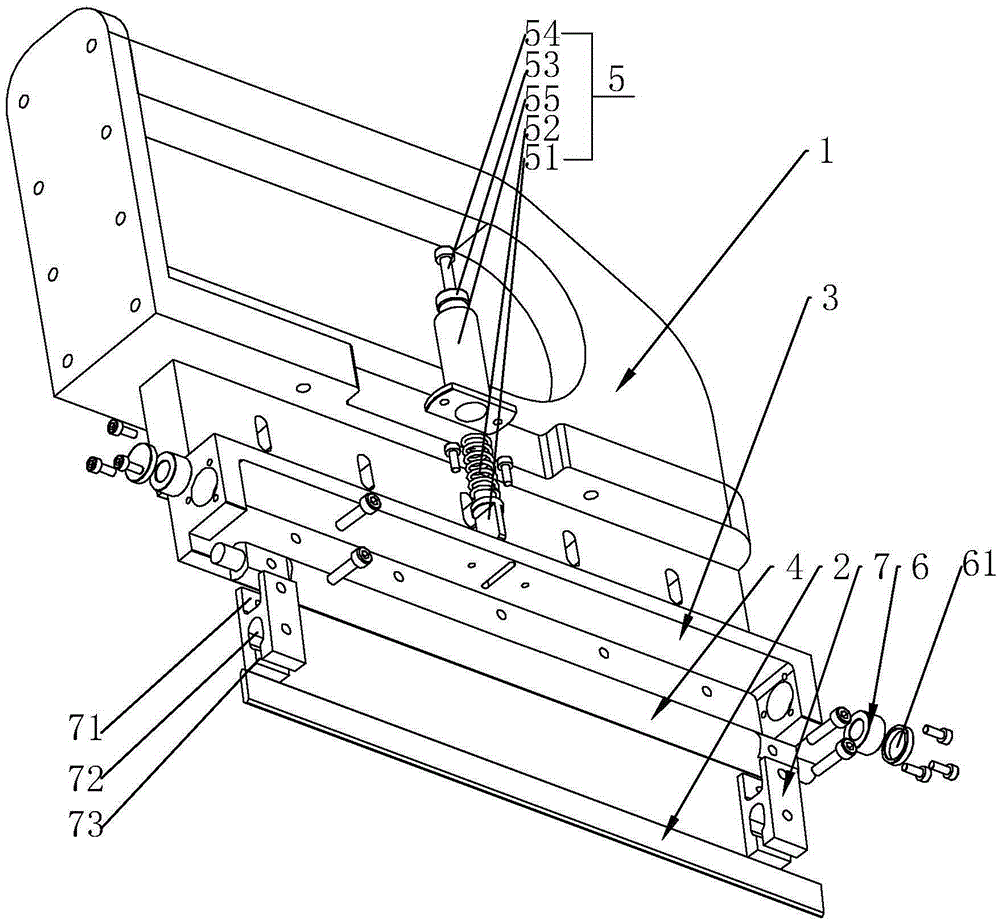

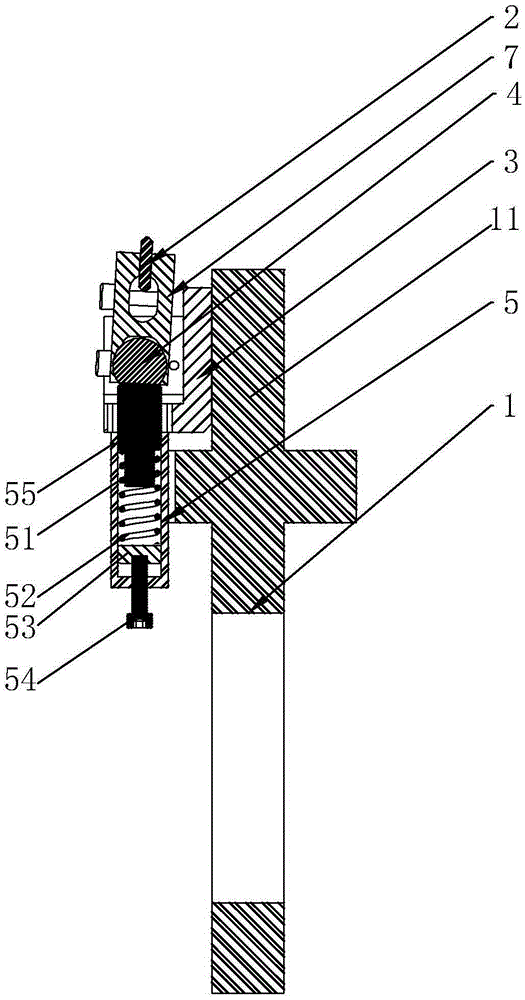

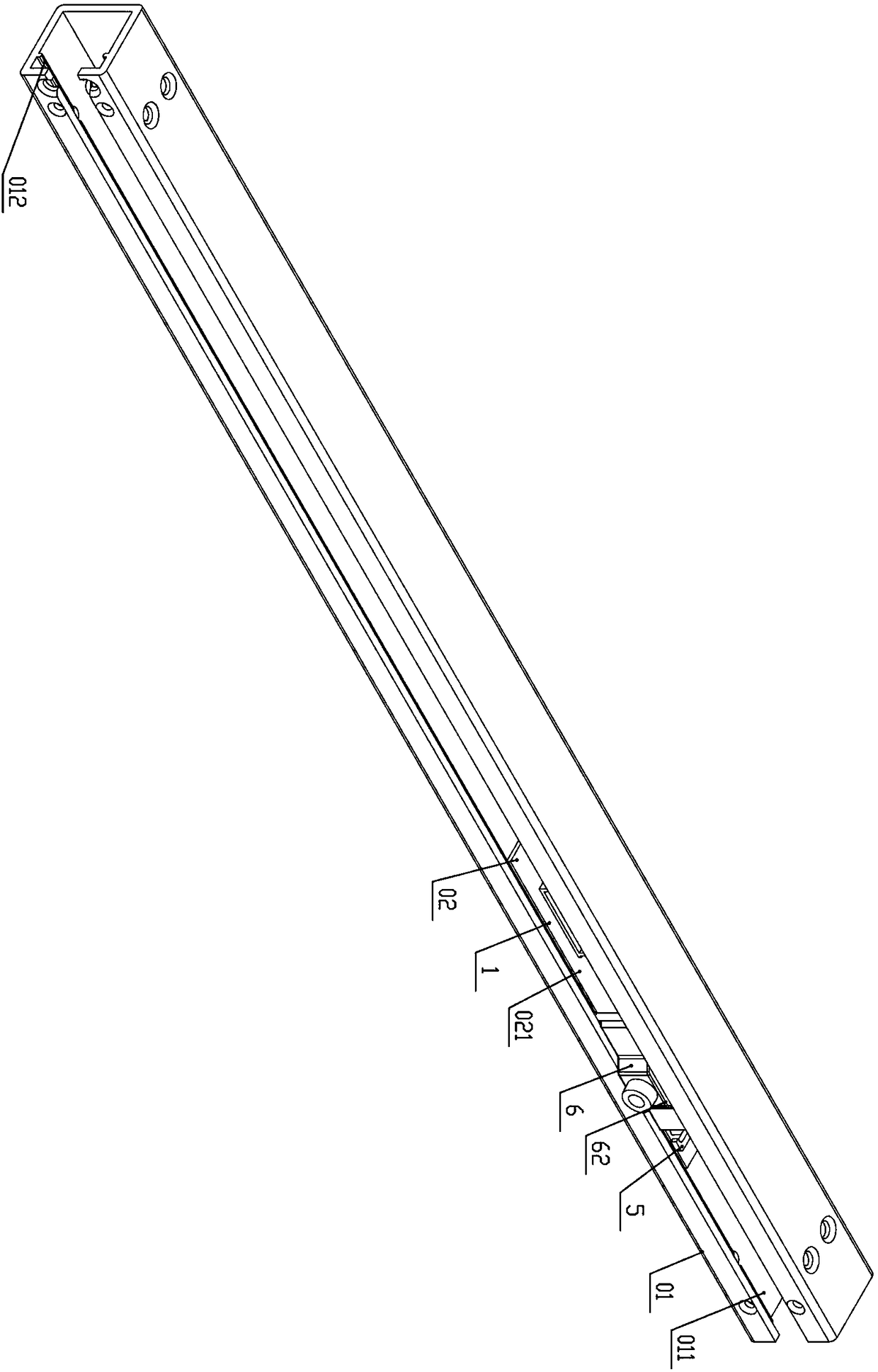

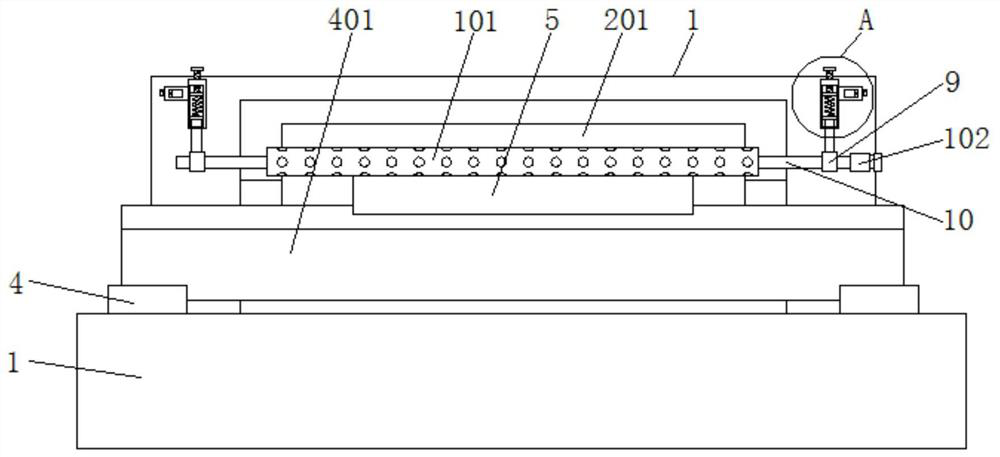

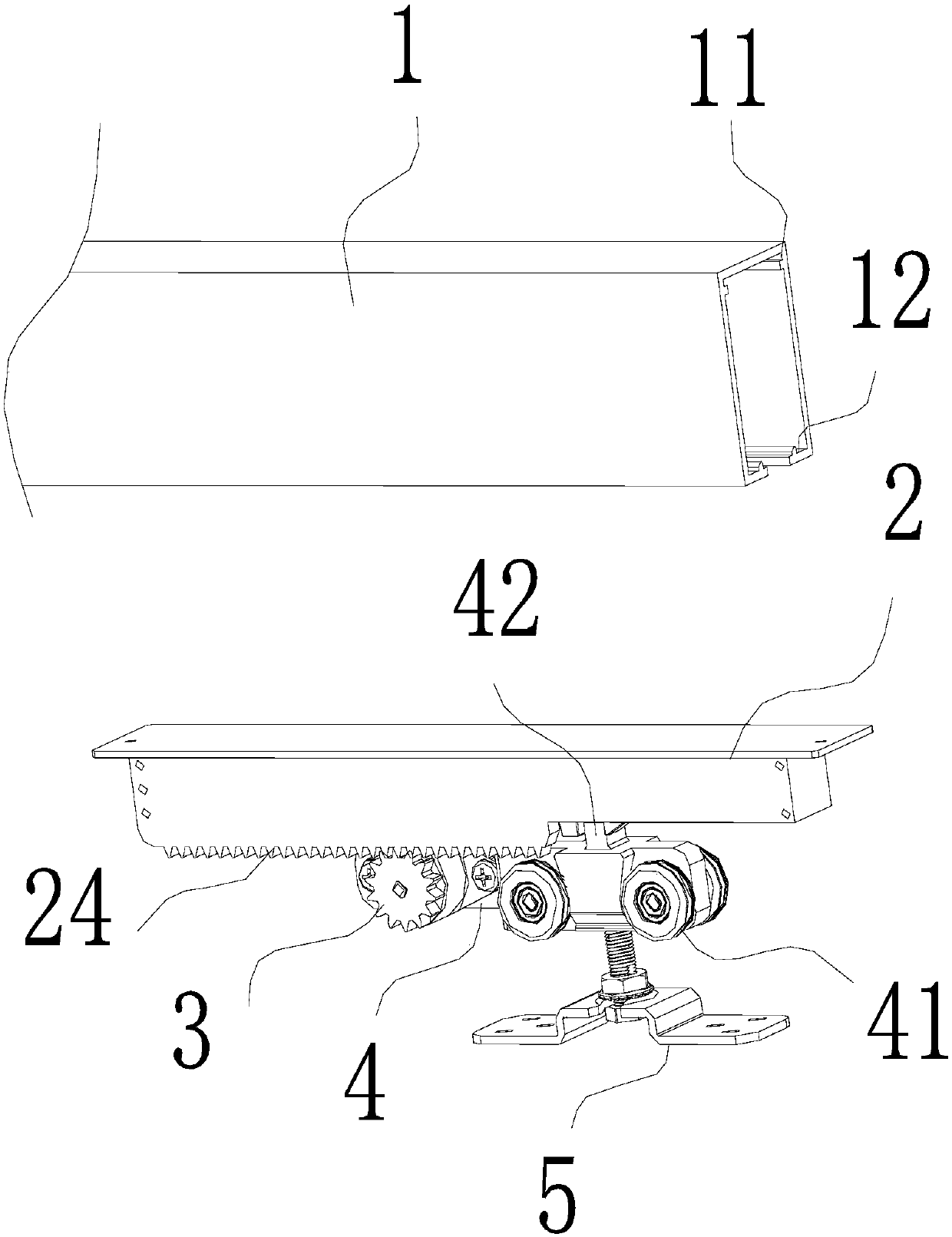

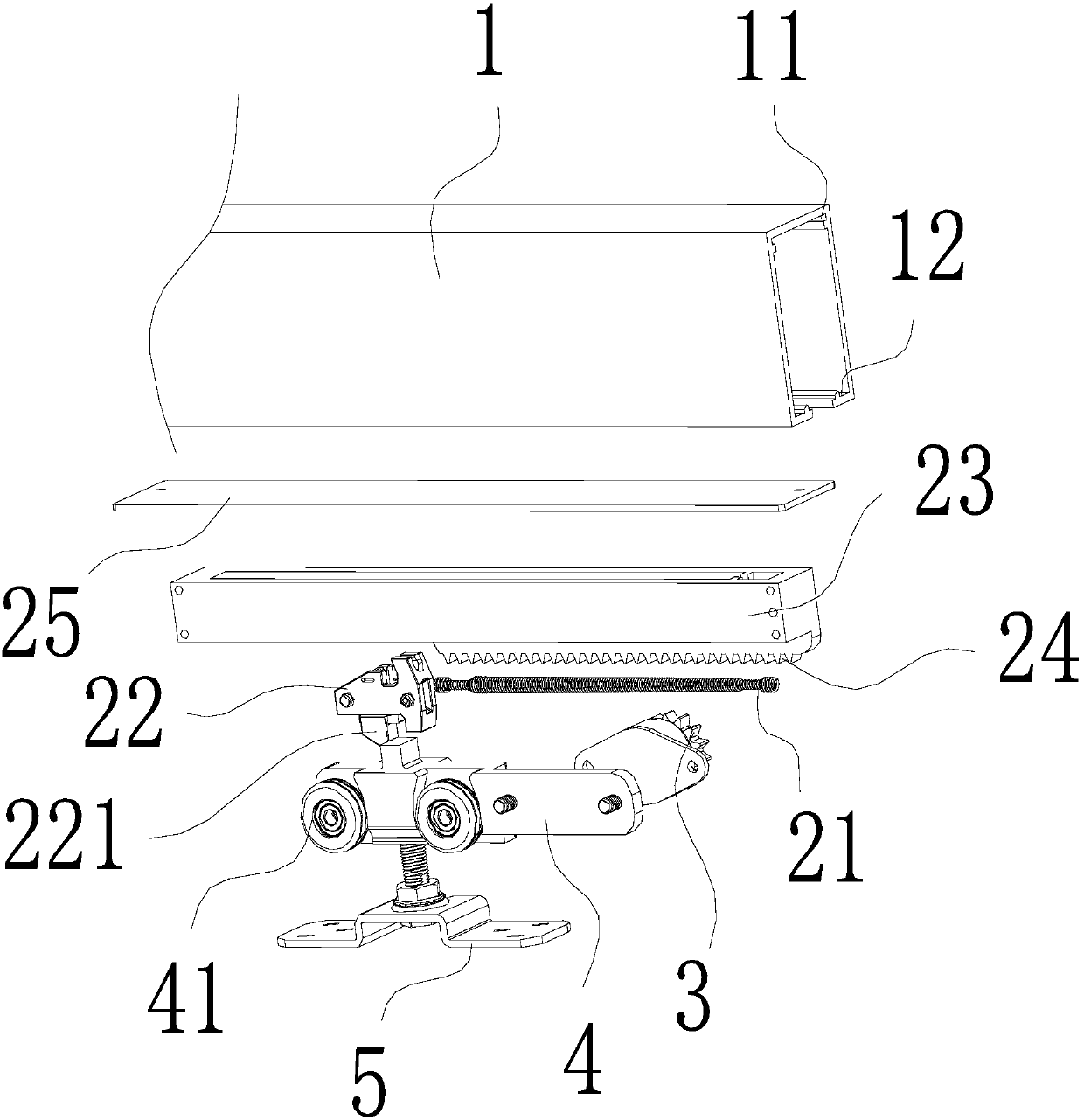

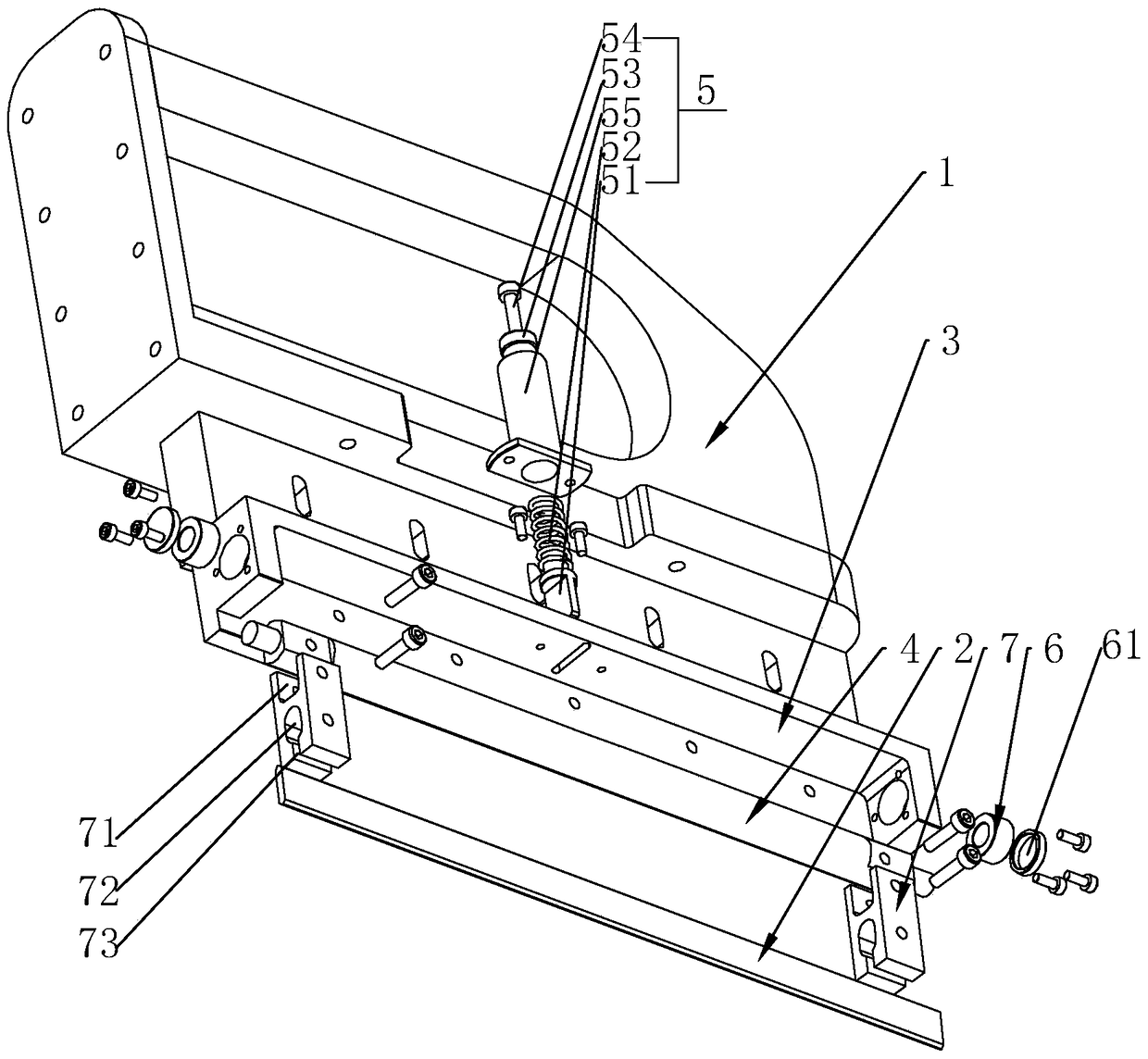

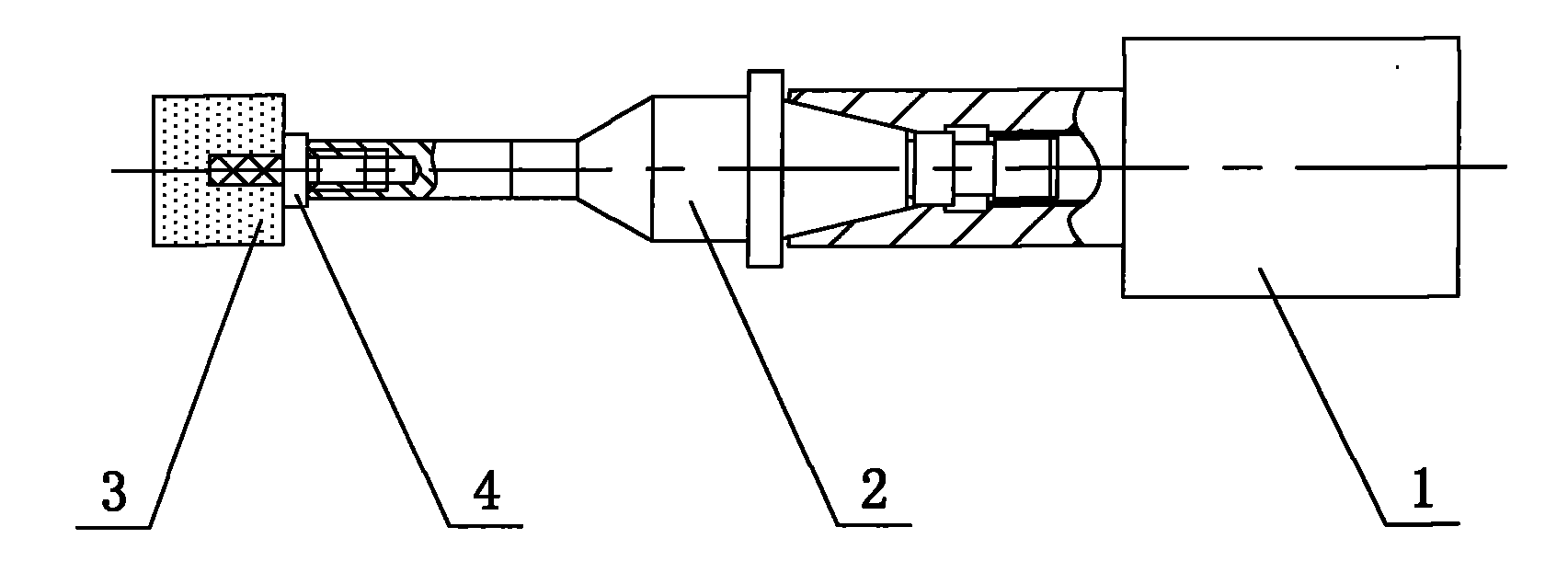

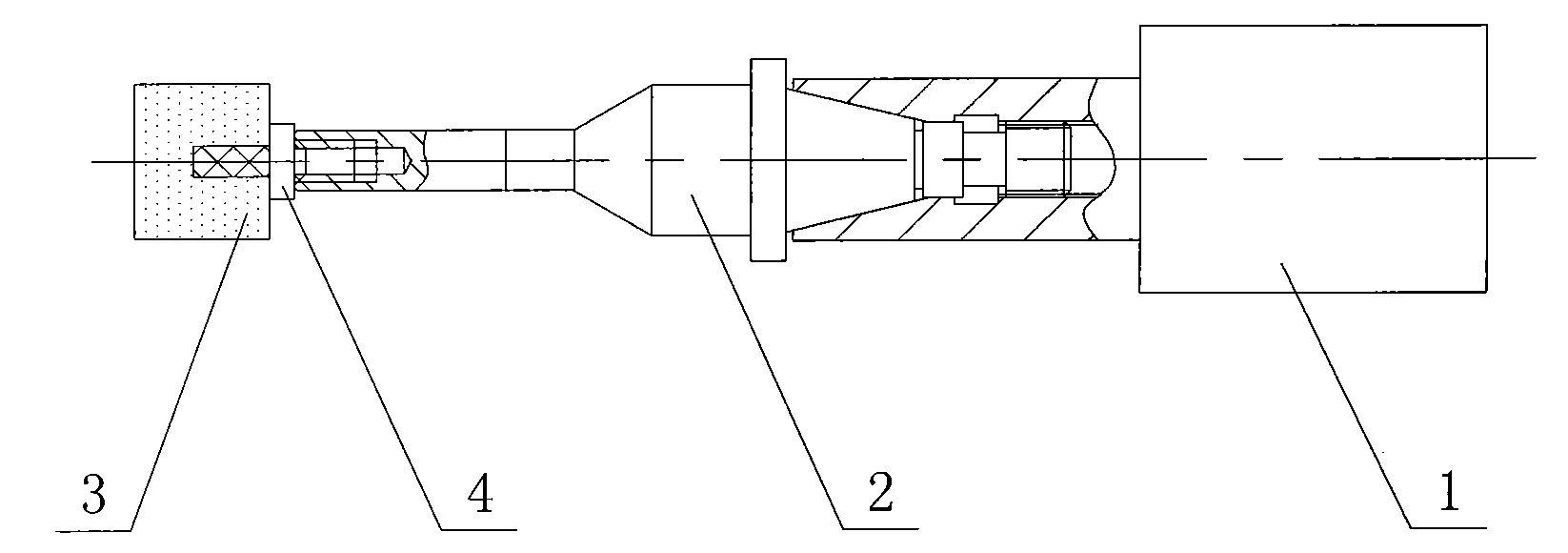

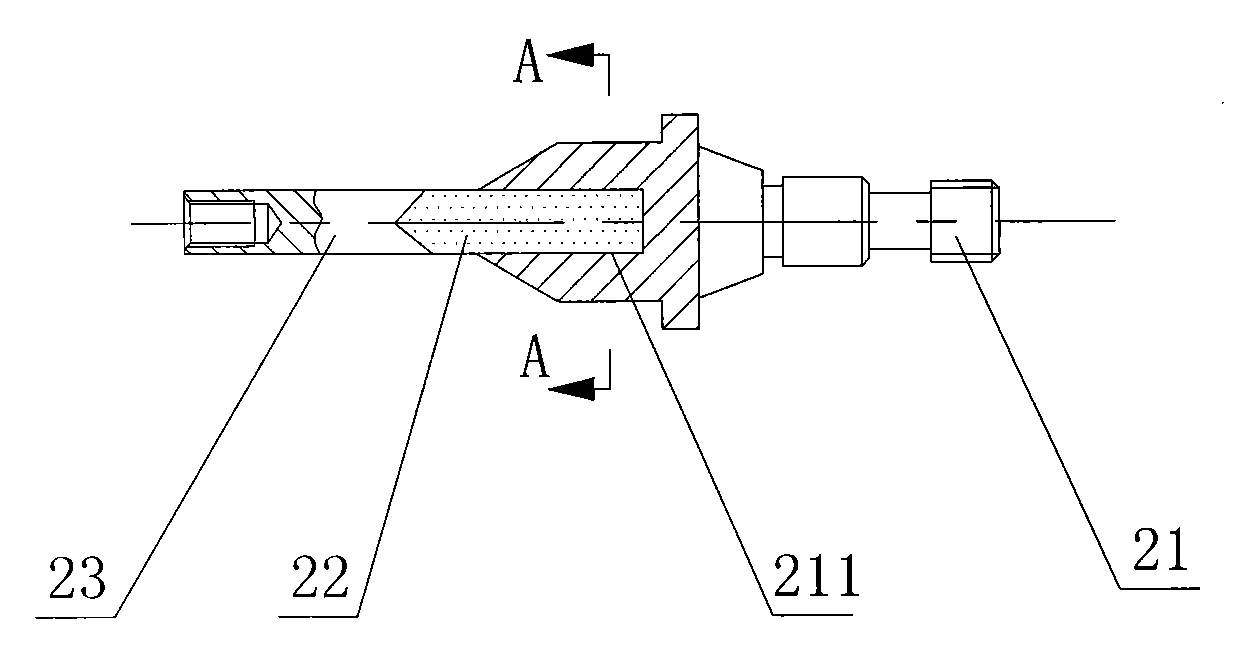

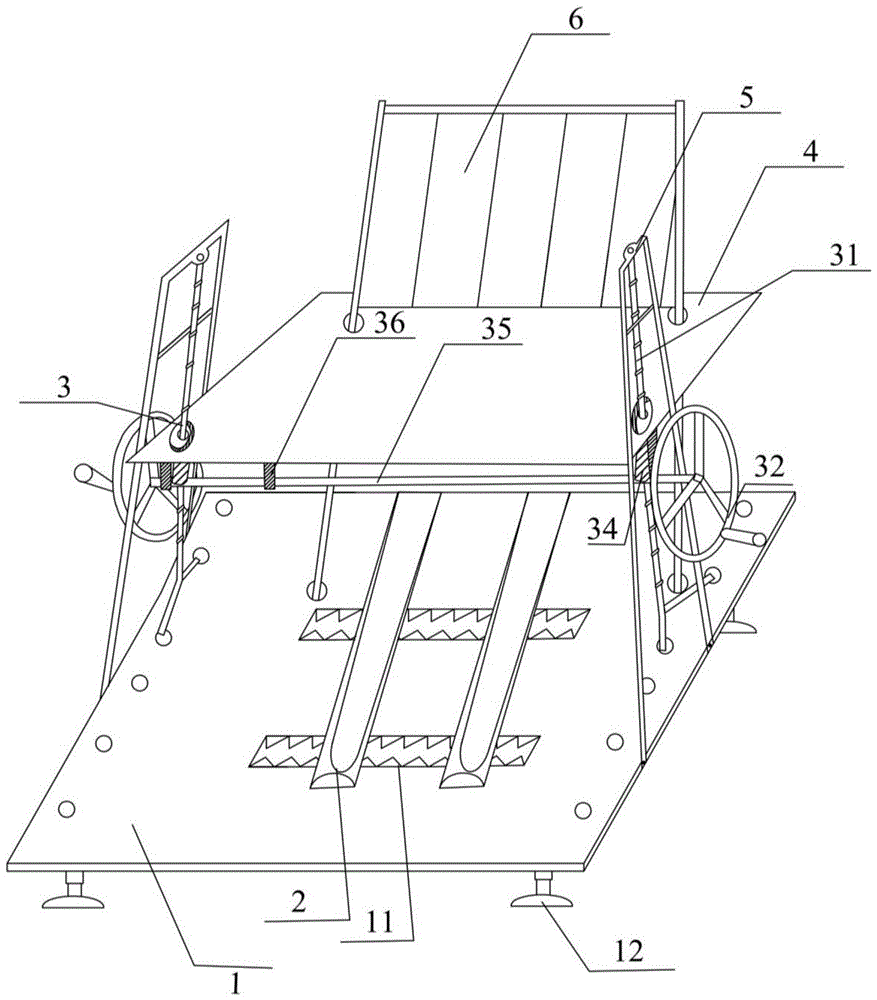

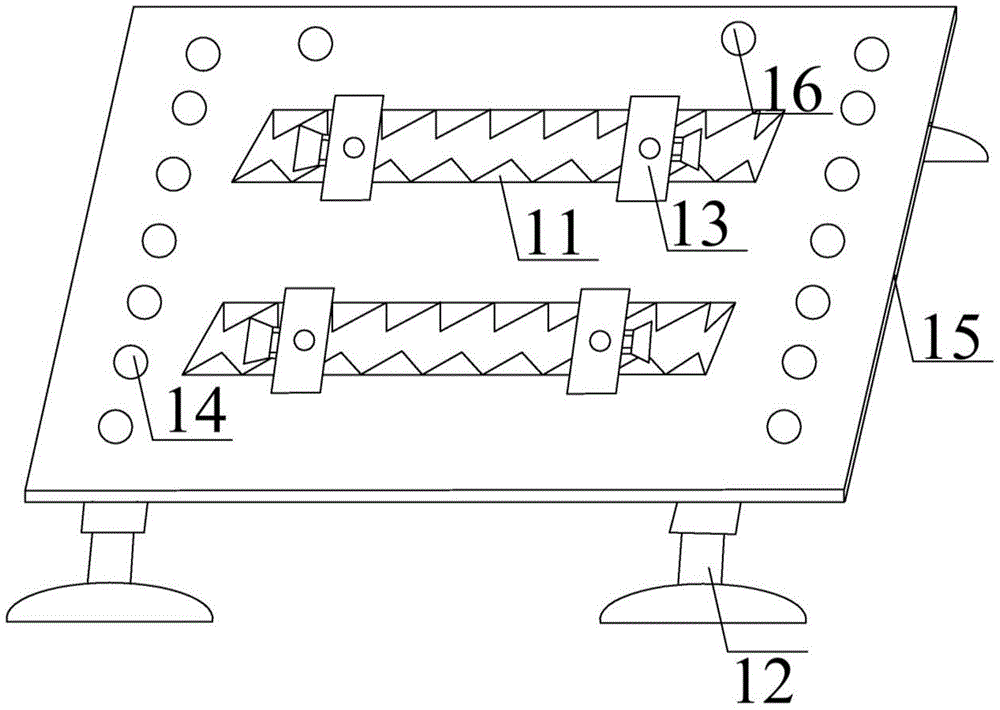

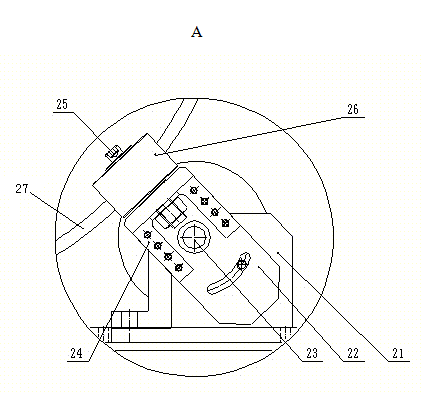

Vertical force floating powder laying scraper device for metal additive manufacturing

ActiveCN105397089ANo jumping phenomenonRealize simple structureAdditive manufacturing apparatusIncreasing energy efficiencySelective laser sinteringEngineering

The invention discloses a vertical force floating powder laying scraper device. The technical problems in the process that a scraper avoids nodulizing protruding points of defects on a selective laser sintering surface in the prior art are solved. According to the technical scheme, the vertical force floating powder laying scraper device is characterized by comprising a scraper support externally connected with a drive source and a scraper connected between the scraper support and a powder bed; the end, close to the scraper, of the scraper support is provided with a floating scraper frame; the scraper is rotationally connected to the floating scraper frame; and when the scraper meets sintering defect protruding points in the powder laying direction, the floating scraper frame drives the central axis of the upper end face of the scraper to swing to bypass the sintering defect protruding points, and the technical effects that the scraper rotates to avoid the protruding points on the powder bed, a movement member causing destructiveness to structural functions due to direction collisions, shearing and the like of the scraper and the sintering defect protruding points is avoided, the critical defects that powder laying is uneven, a powder laying bed is loosened, and defects are moved backwards and transferred in other scraper powder laying manners are overcome, the yield of products is greatly increased, the mechanism is simple, and occupied space is small are achieved.

Owner:BEIJING E PLUS 3D TECH CO LTD

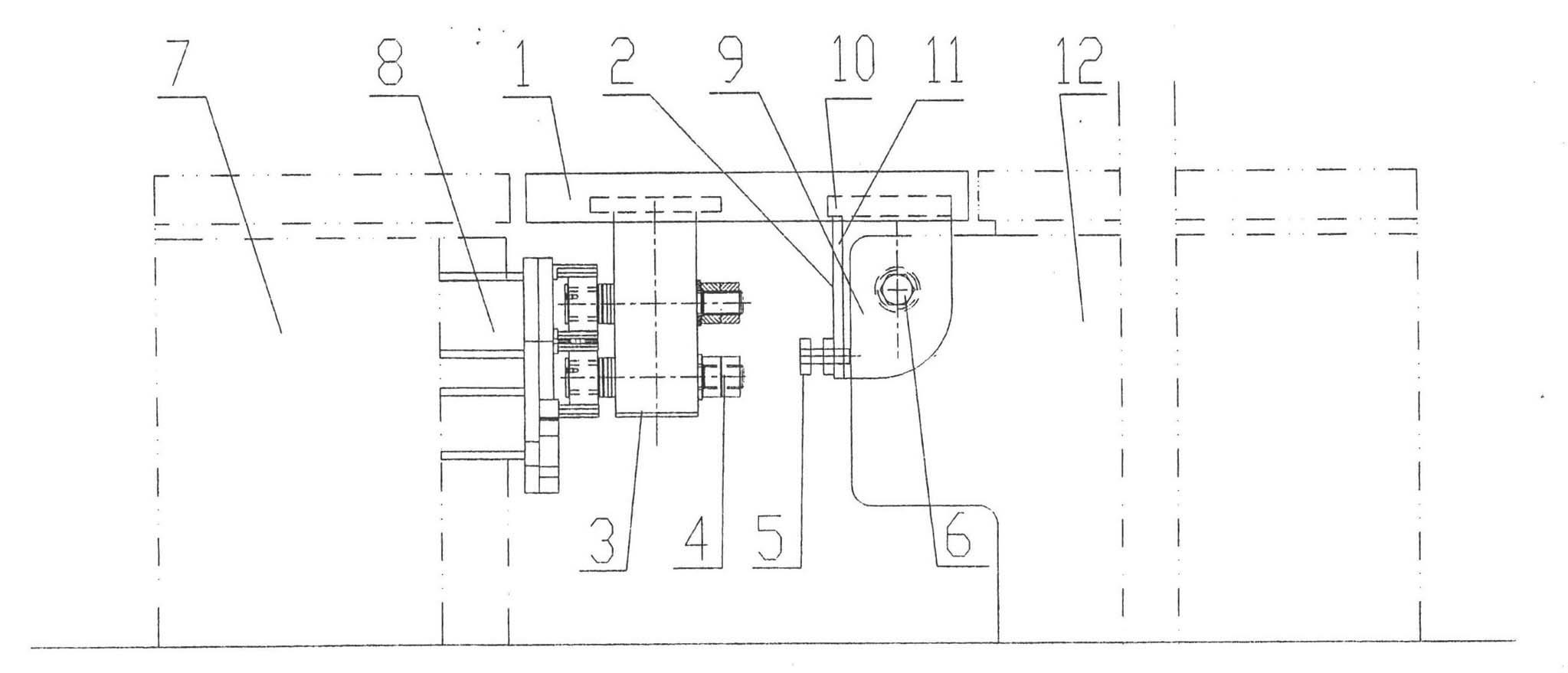

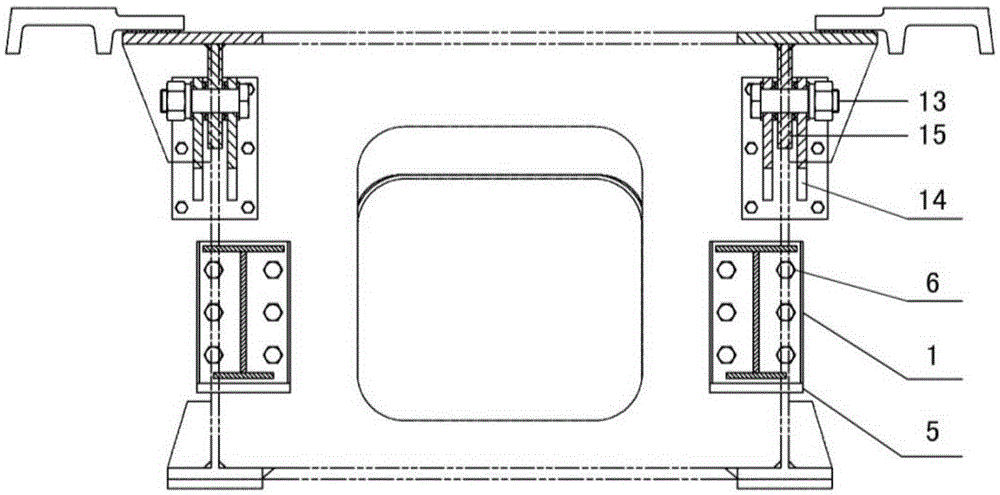

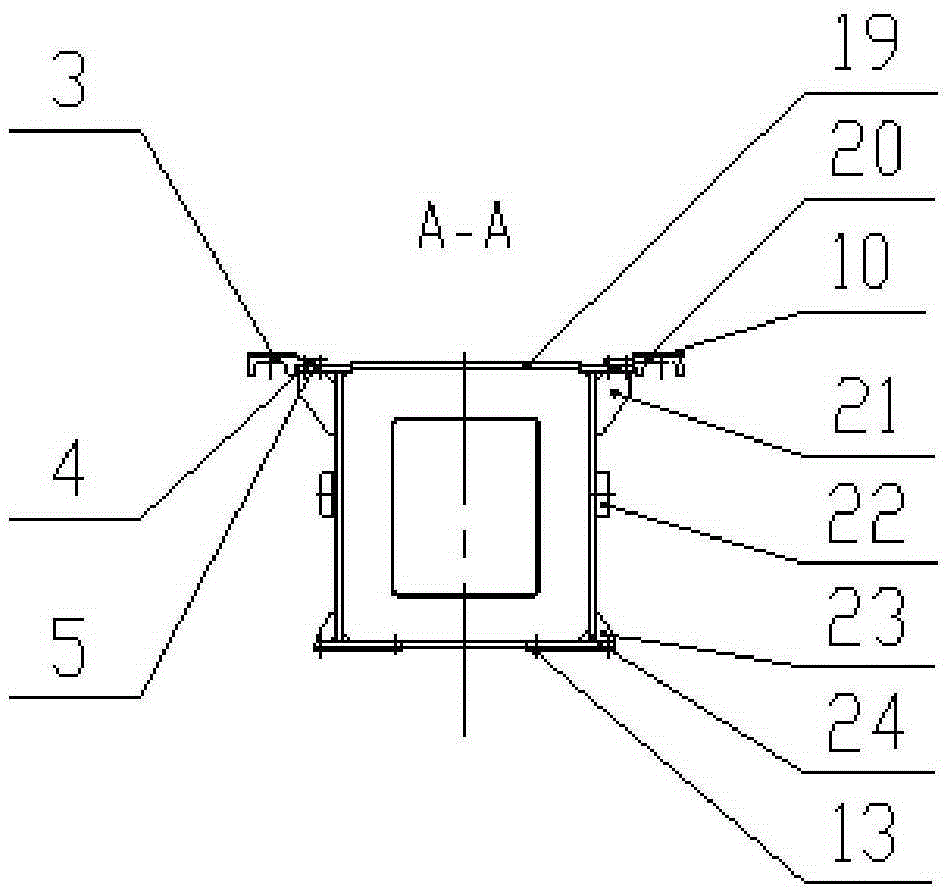

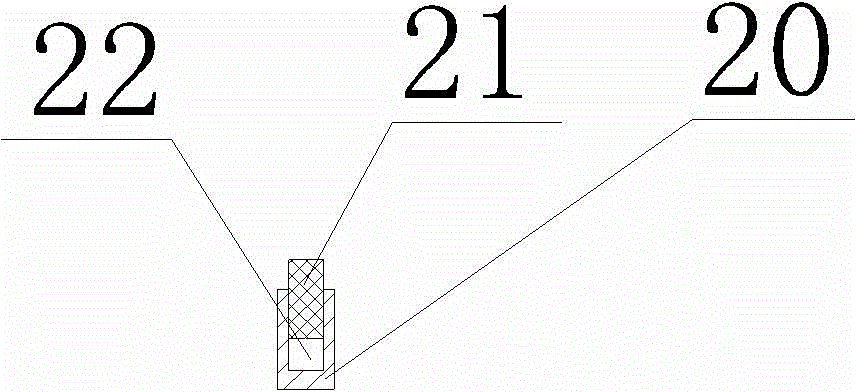

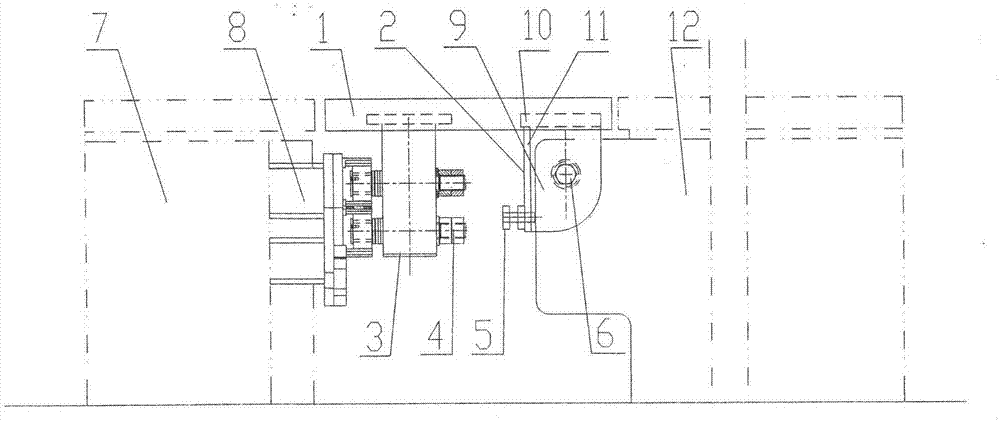

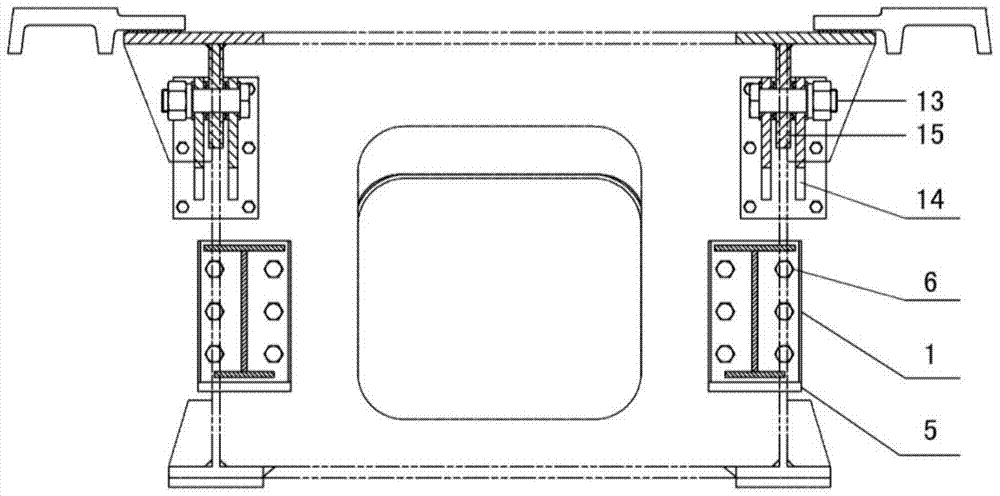

F-track movable end positioning and connection device for medium-and-low-speed magnetic suspension turnout

The invention discloses an F-track movable end positioning and connection device for a medium-and-low-speed magnetic suspension turnout. The F-track movable end positioning and connection device comprises two sections of F-track movable ends which are symmetrical left and right. A movable hinged support is fixedly connected with the lower part of the rear end of each of the two sections of F-track movable ends which are symmetrical left and right; each movable hinged support consists of a pair of ear plates, an upper connection plate, a front side plate and a pin roll; the upper connection plate is fixedly connected with the upper ends of the pair of the ear plates and the lower part of the F-track movable end, and the front side plate is fixedly connected with the front end of the pair of the ear plates and the lower part of the upper connection plate; and the pair of the ear plates are inserted into two sides of an extension end of a turnouttrack web of the turnout and are hinged with two sides of the extension end of the turnouttrack web of the turnout through the pin roll, each front side plate is provided with an adjusting screw and the front end of the adjusting screw is pressed against the extension end of the turnouttrack web of the turnout. The left and right freedom degree of the F-track movable end positioning and connection device is limited on the premise that thevertical freedom degree of the device is limited, and the turnout is prevented from swinging left and right and jumping in a vertical direction.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +1

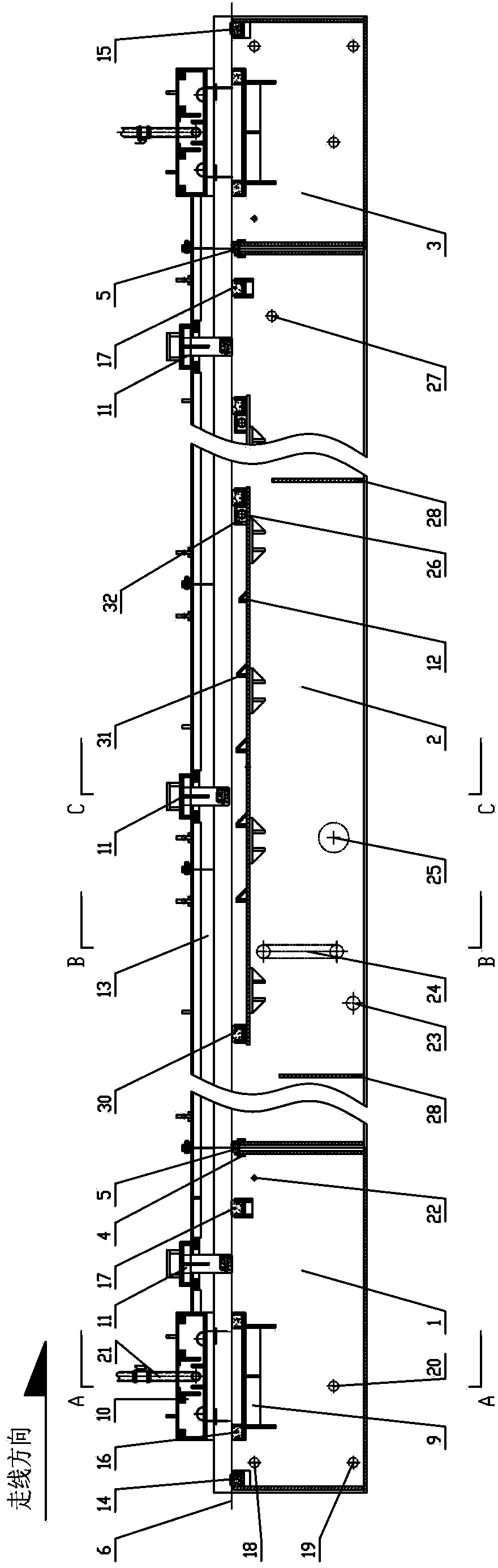

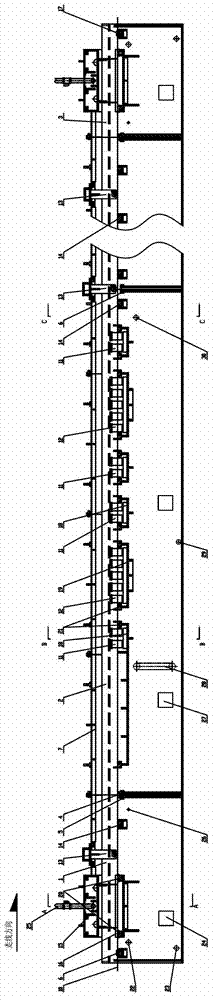

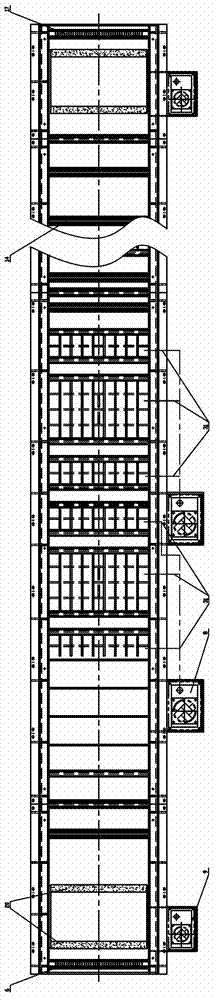

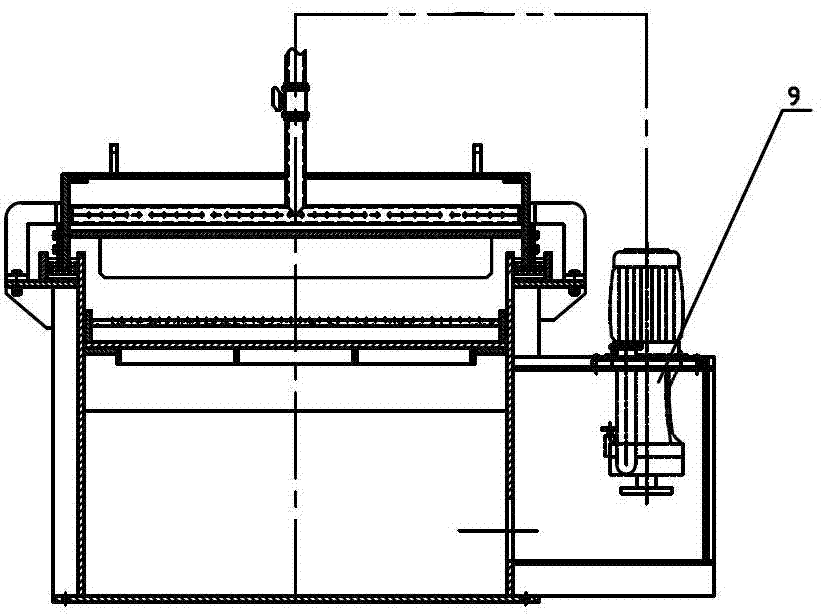

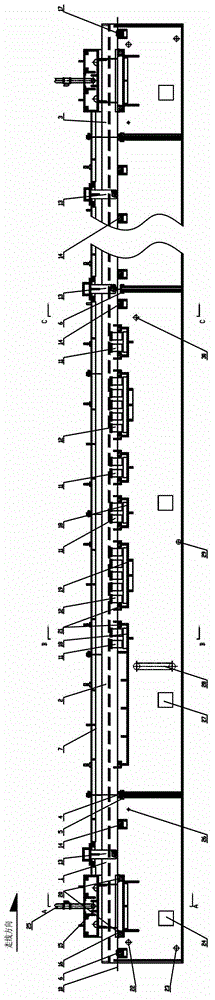

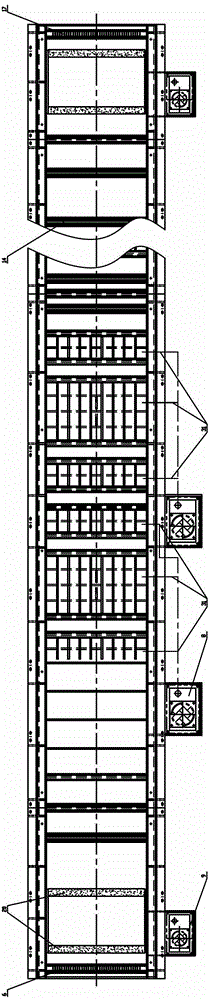

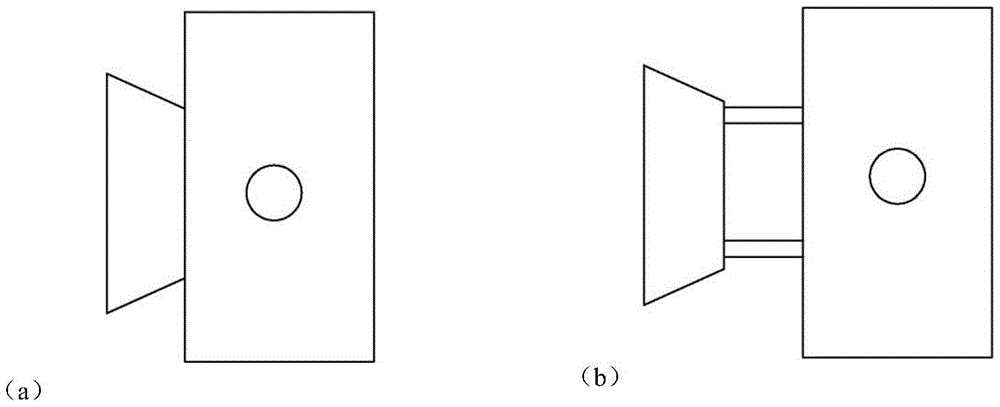

Steel wire sealing type smokeless pickling line

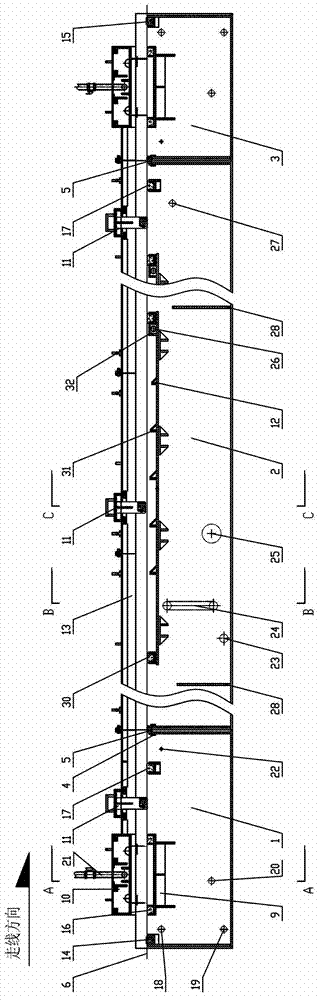

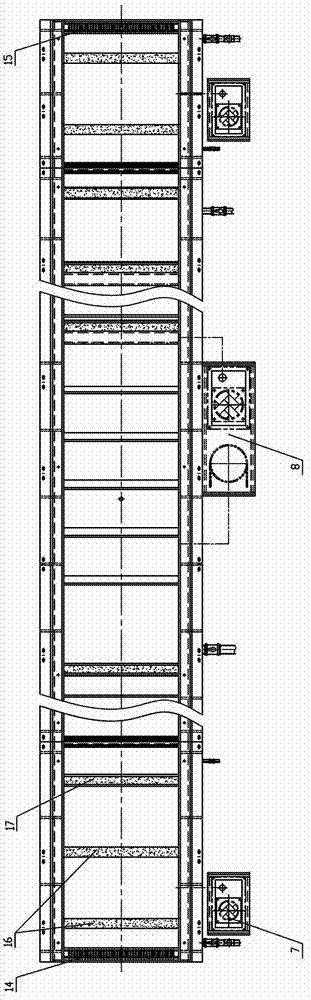

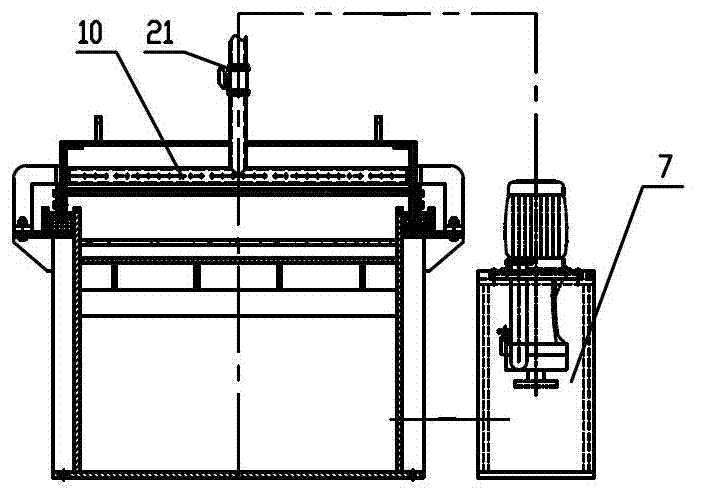

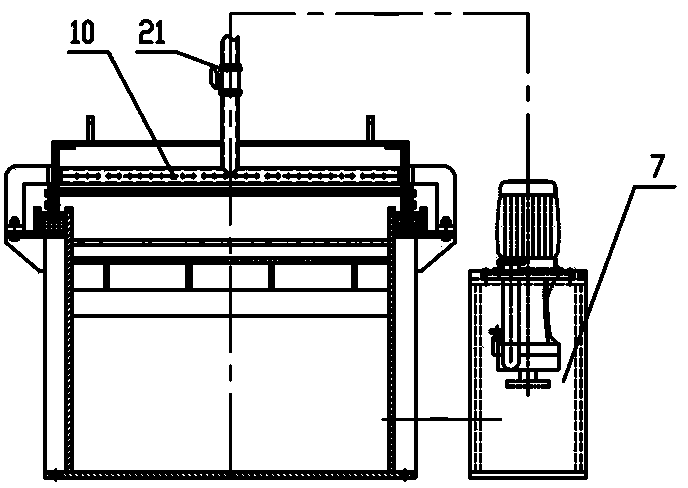

The invention relates to a steel wire sealing type smokeless pickling line. The pickling line comprises a wire inlet water curtain groove, at least one pickling groove and a wire outlet water curtain groove, wherein the wire inlet water curtain groove, the pickling groove and the wire outlet water curtain groove are arranged sequentially along a steel wire routing direction. The pickling line is characterized in that a wire inlet sealing device and a wire outlet sealing device are respectively arranged at two ends of the cover plate of the pickling groove, steel wires can penetrate through the wire inlet sealing device and the wire outlet sealing device, the wire inlet sealing device and the wire outlet sealing device can prevent pickling solutions in the pickling groove from volatilizing from two ends, a pickling working groove is arranged inside the pickling groove, a pickling solution chamber is arranged at the rear end of the pickling working groove and connected with a liquid outlet of a steam heating acid pump box through an acid inlet pipe, a liquid inlet of the steam heating acid pump box is communicated with the interior of the pickling groove through an acid drawing pipe, and the upper surface of the pickling working groove is provided with a plurality of turbulent flow retaining bars. The pickling line is ingenious and reasonable in structure, steel wires can work stably in the pickling solutions, a jumping phenomenon cannot occur, the cleaning effect is good, the acid consumption is low, and the pickling line is environment-friendly and beneficial to improvement of product quality.

Owner:WUXI XINKE METALLURGICAL EQUIP

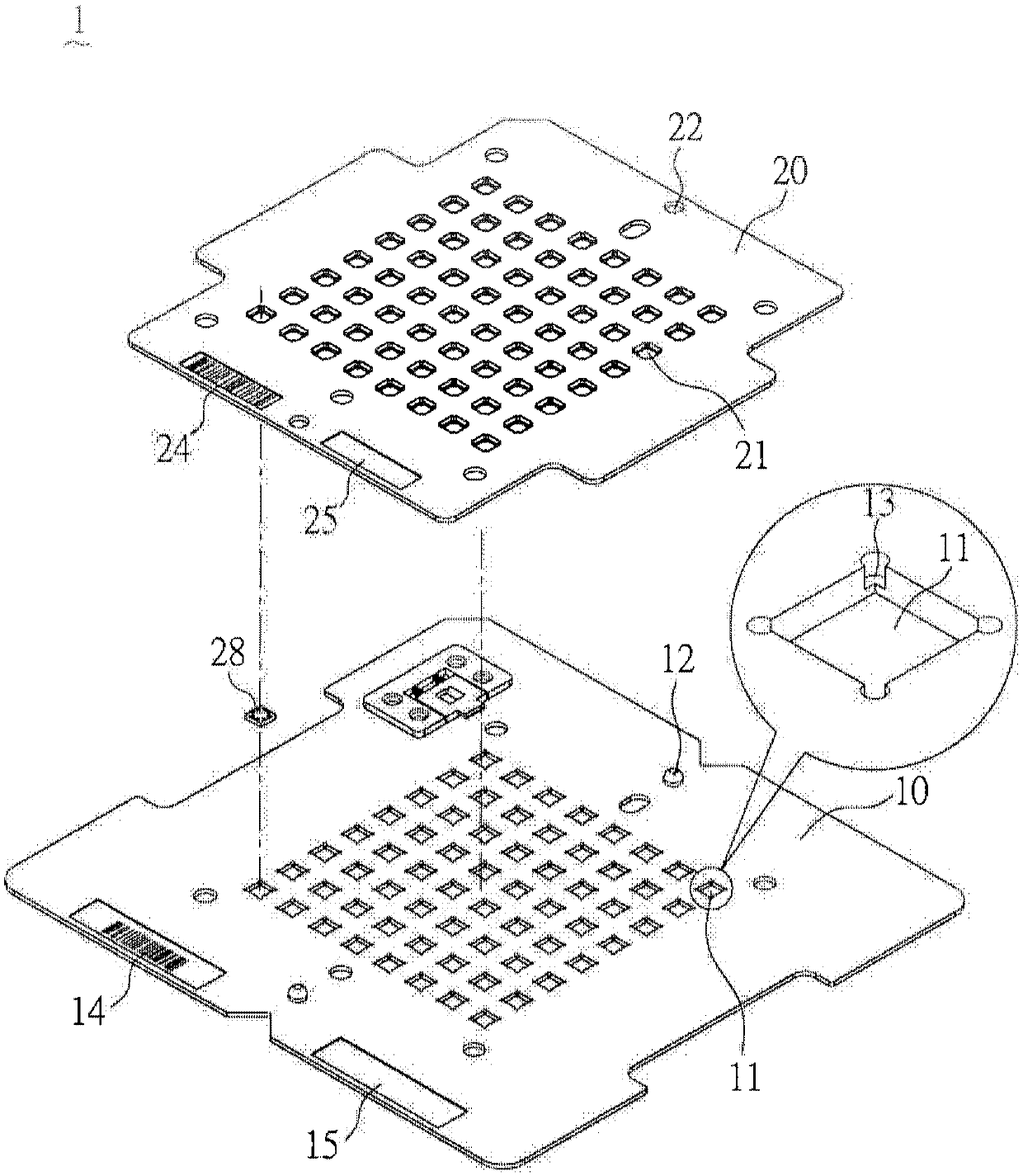

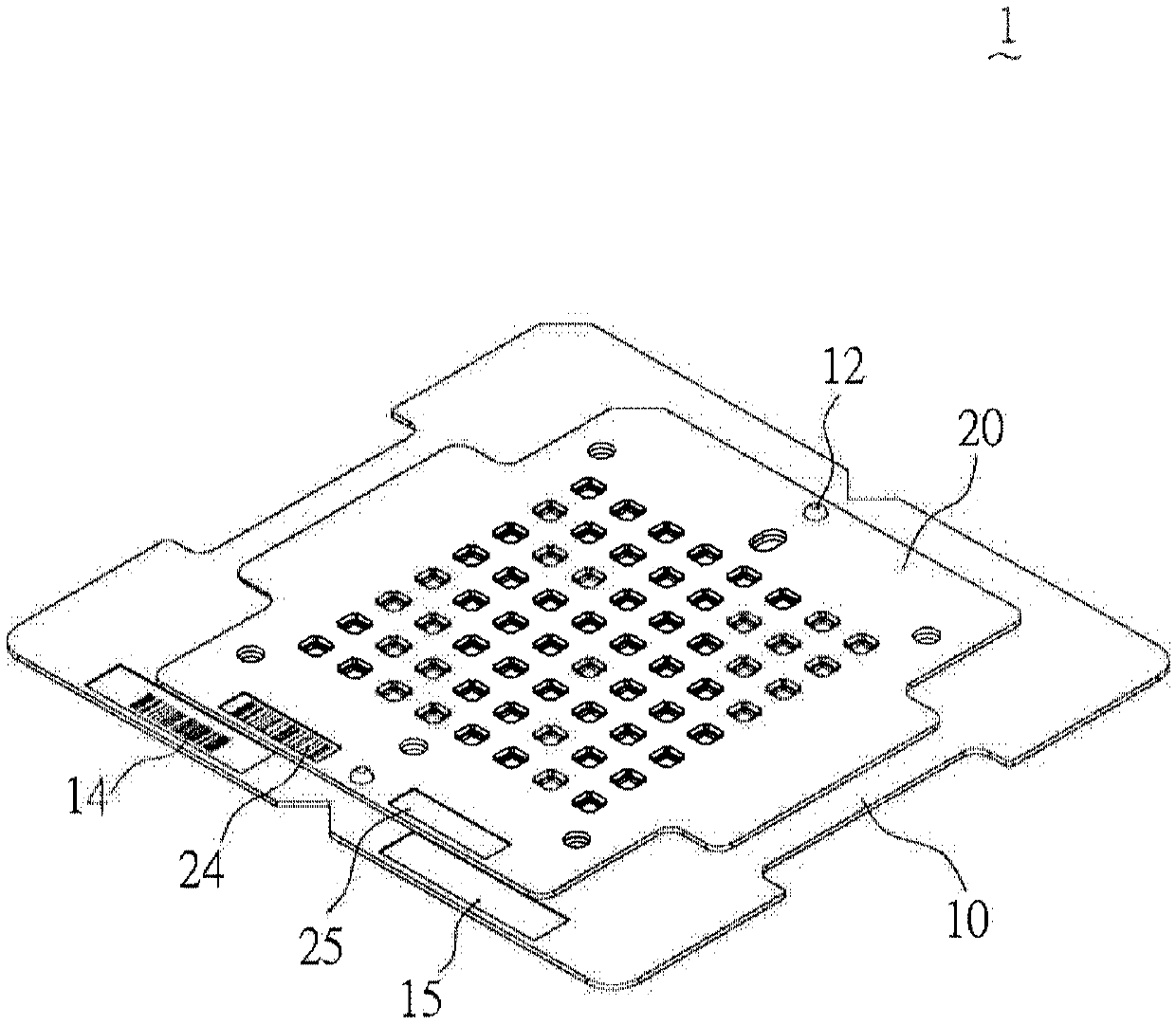

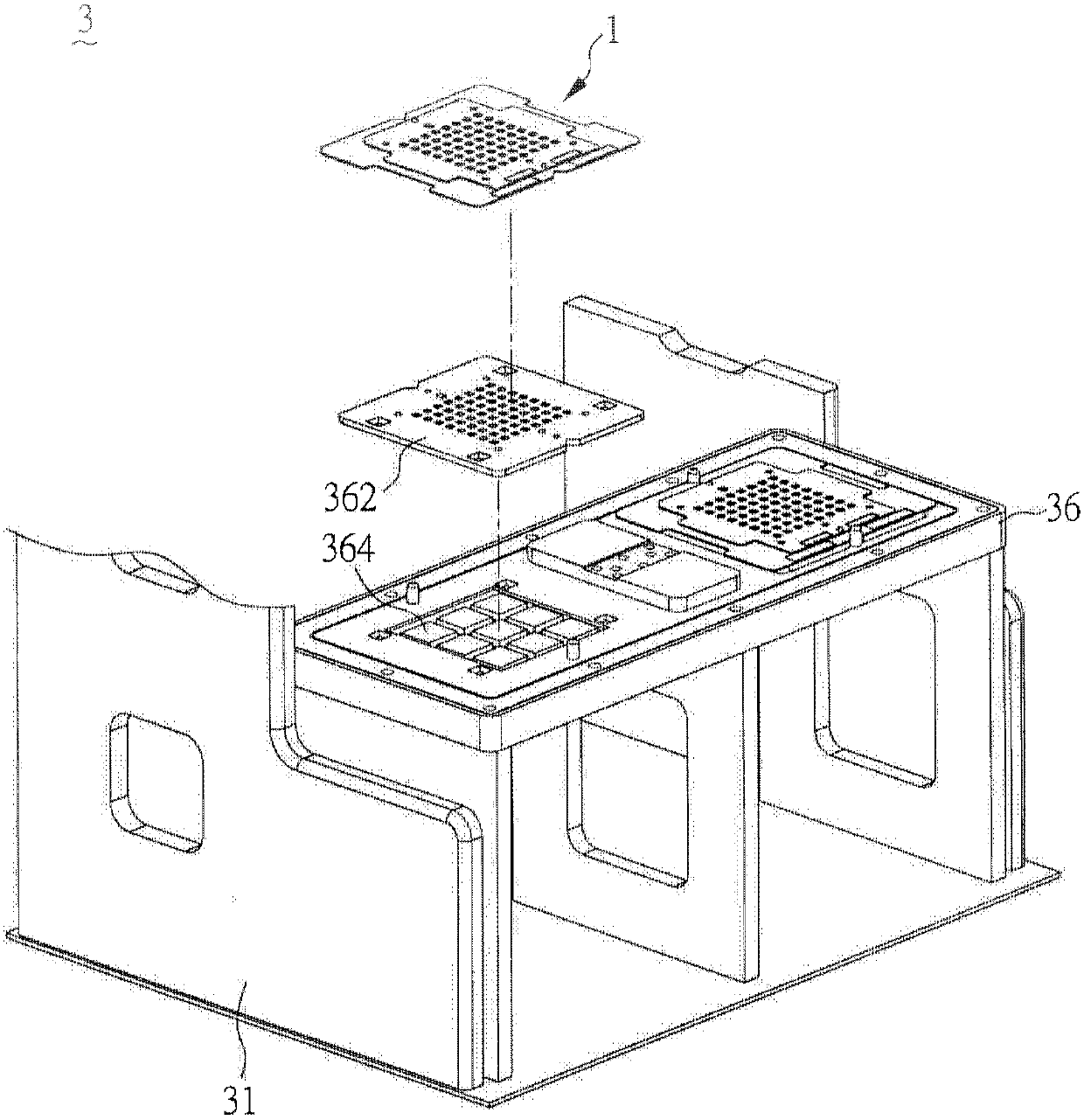

Semiconductor component test carrier, test apparatus thereof and equipment

ActiveCN110018405ANo displacementNo jumping phenomenonSortingIndividual semiconductor device testingElectrical conductorEngineering

The invention relates to a semiconductor component test carrier, a test apparatus thereof and equipment. The semiconductor component test carrier comprises a carrying seat and an upper cover, whereinthe carrying seat is provided with a plurality of through holes and at least one positioning post; the upper surface of the carrying seat is provided with at least one groove at the periphery of eachthrough hole for carrying a semiconductor component; the upper cover covers the carrying seat; the upper cover is provided with a plurality of through holes and at least one positioning hole; each through hole in the upper cover corresponds to each through hole in the carrying seat; and the at least one positioning hole of the upper cover also corresponds to at least one positioning post of the carrying seat. Thus, during a sliding process of the test carrier, the semiconductor component does not shift or jump on the carrying seat.

Owner:KING YUAN ELECTRONICS

Steel wire sealing type smokeless pickling line

The invention relates to a steel wire sealing type smokeless pickling line. The pickling line comprises a wire inlet water curtain groove, at least one pickling groove and a wire outlet water curtain groove, wherein the wire inlet water curtain groove, the pickling groove and the wire outlet water curtain groove are arranged sequentially along a steel wire routing direction. The pickling line is characterized in that a wire inlet sealing device and a wire outlet sealing device are respectively arranged at two ends of the cover plate of the pickling groove, steel wires can penetrate through the wire inlet sealing device and the wire outlet sealing device, the wire inlet sealing device and the wire outlet sealing device can prevent pickling solutions in the pickling groove from volatilizing from two ends, a pickling working groove is arranged inside the pickling groove, a pickling solution chamber is arranged at the rear end of the pickling working groove and connected with a liquid outlet of a steam heating acid pump box through an acid inlet pipe, a liquid inlet of the steam heating acid pump box is communicated with the interior of the pickling groove through an acid drawing pipe, and the upper surface of the pickling working groove is provided with a plurality of turbulent flow retaining bars. The pickling line is ingenious and reasonable in structure, steel wires can work stably in the pickling solutions, a jumping phenomenon cannot occur, the cleaning effect is good, the acid consumption is low, and the pickling line is environment-friendly and beneficial to improvement of product quality.

Owner:WUXI XINKE METALLURGICAL EQUIP

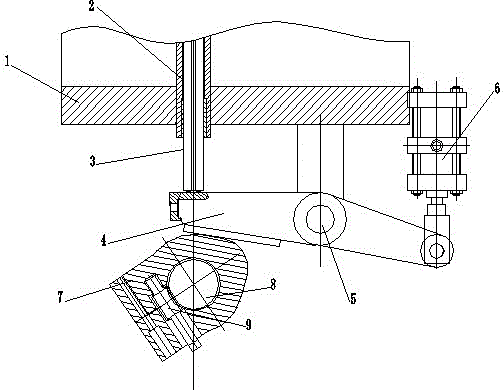

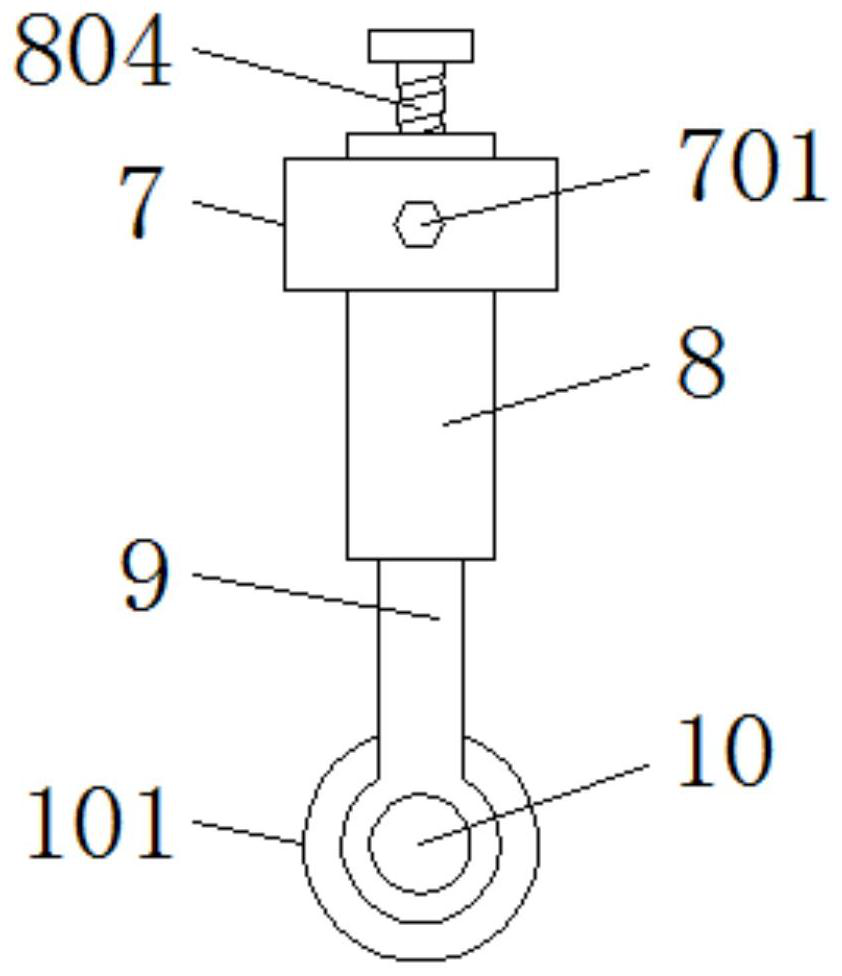

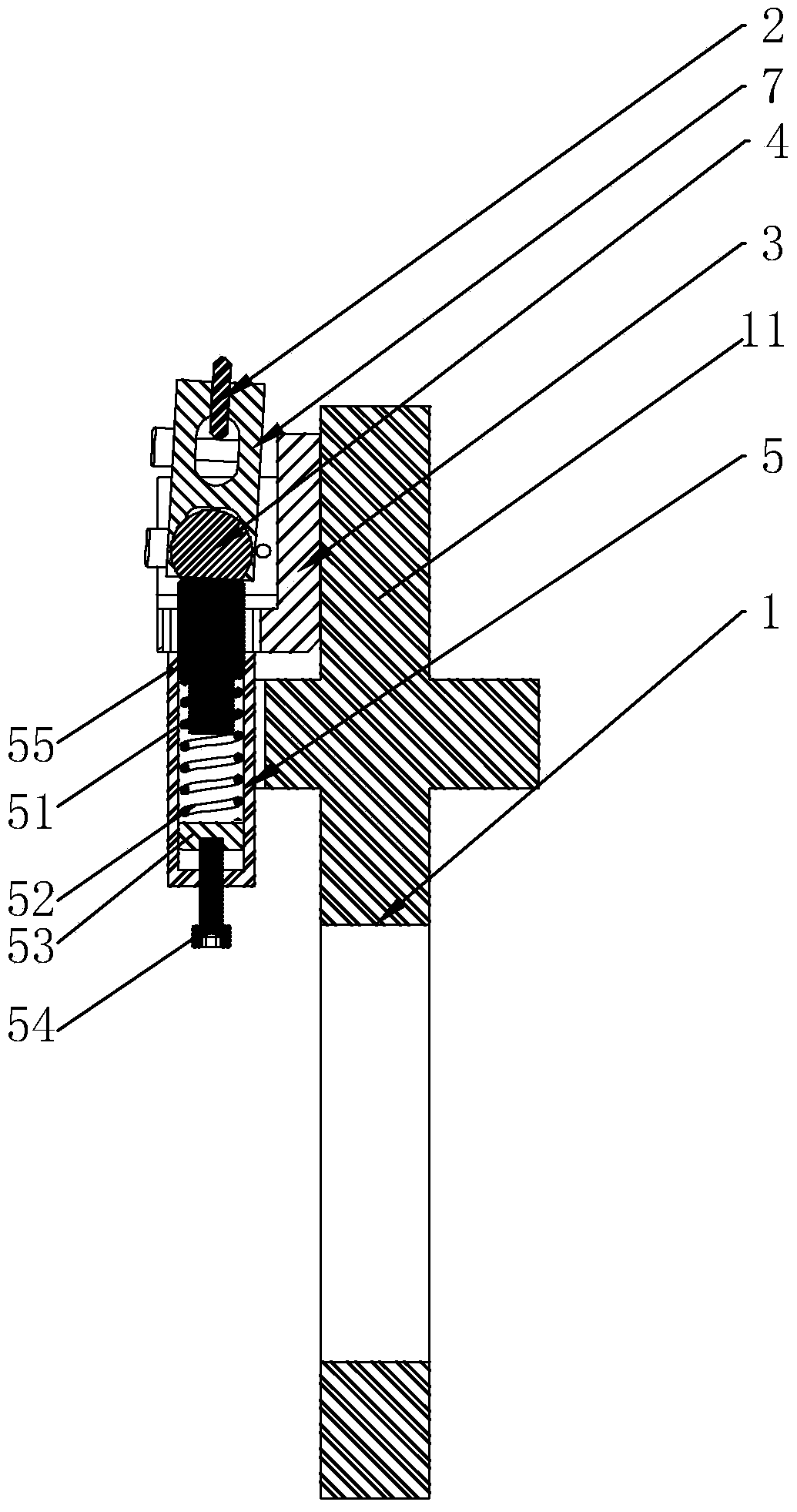

Material discharging and ejecting mechanism

The invention relates to a material discharging and ejecting mechanism which comprises a die seat (1). A material hole (2) of the die seat (1) is internally provided with a material ejecting rod (3) penetrating out of the lower portion of the material hole (2). A lever (4) is arranged on the lower portion of the material ejecting rod (3), the two sides of the lever (4) are free ends, and the middle portion of the lever (4) is provided with a fixed rotating point (5). One side of the lever (4) is arranged below the material ejecting rod (3) to make contact with the material ejecting rod (3), wherein the lower portion of the side of the lever (4) is provided with an eccentric mechanism (6). The upper portion of the other side of the lever (4) is provided with an air cylinder (6) which is fixedly arranged, and the air cylinder (6) is used for driving the other side of the lever (4). According to the material discharging and ejecting mechanism, due to the action of a material ejecting cam on the lever, material ejecting is achieved through the material ejecting rod; and meanwhile due to the air cylinder on the other side of the lever, the lever is restrained, the lever cannot jump in the movement process, the material ejecting rod cannot jump, and the material ejecting process can be stable.

Owner:YANGZHOU FORGING MACHINE TOOL

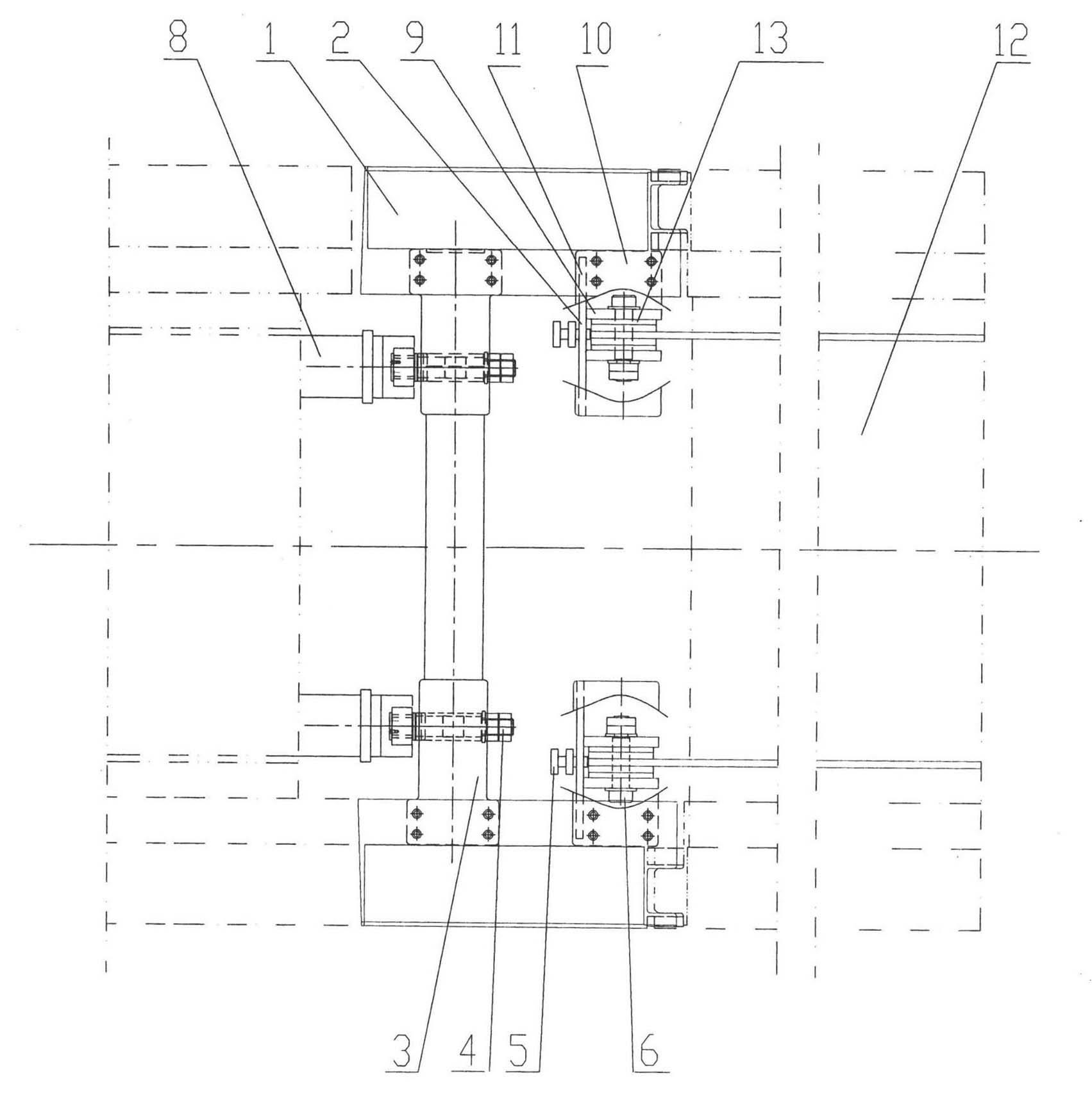

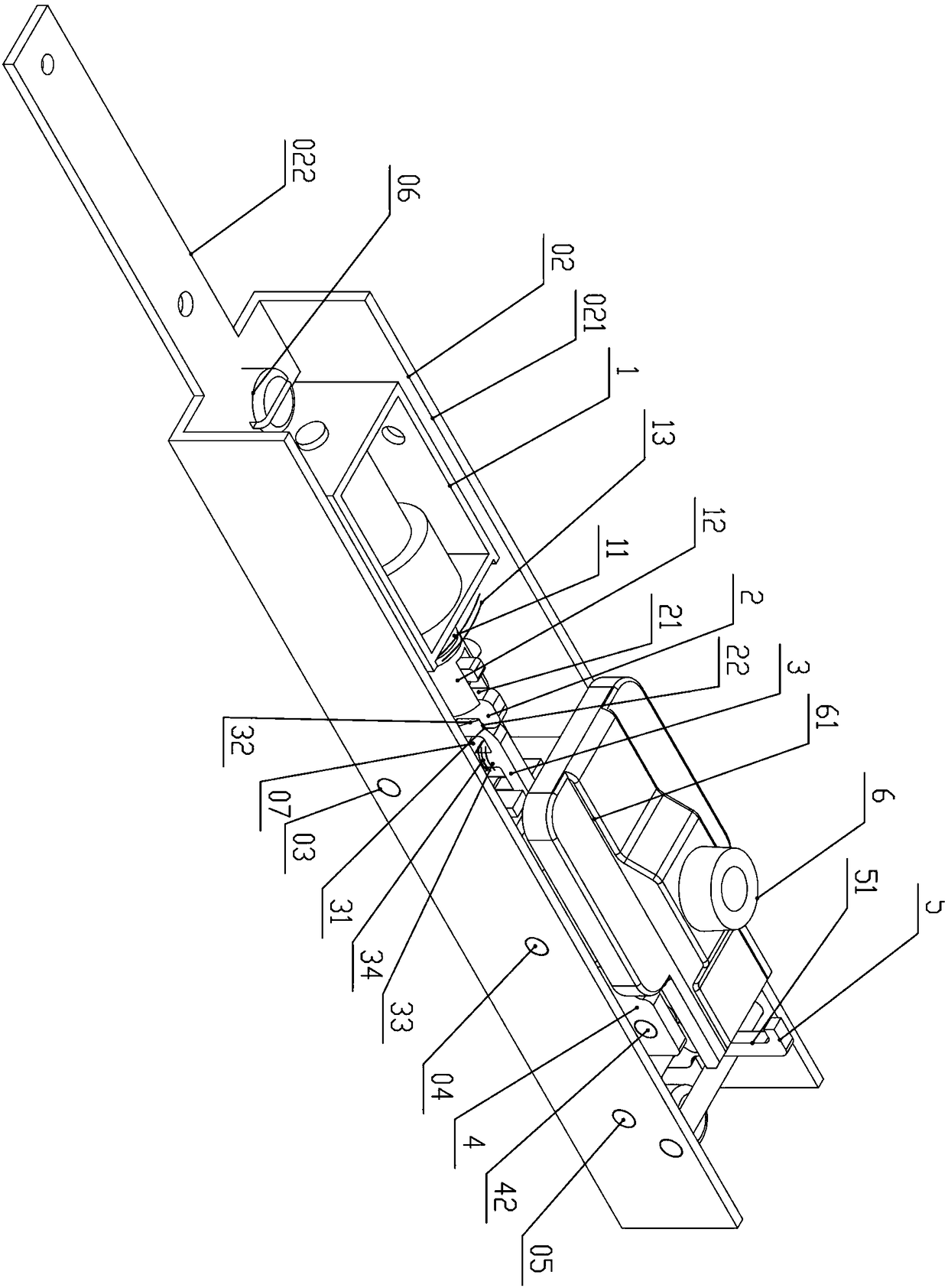

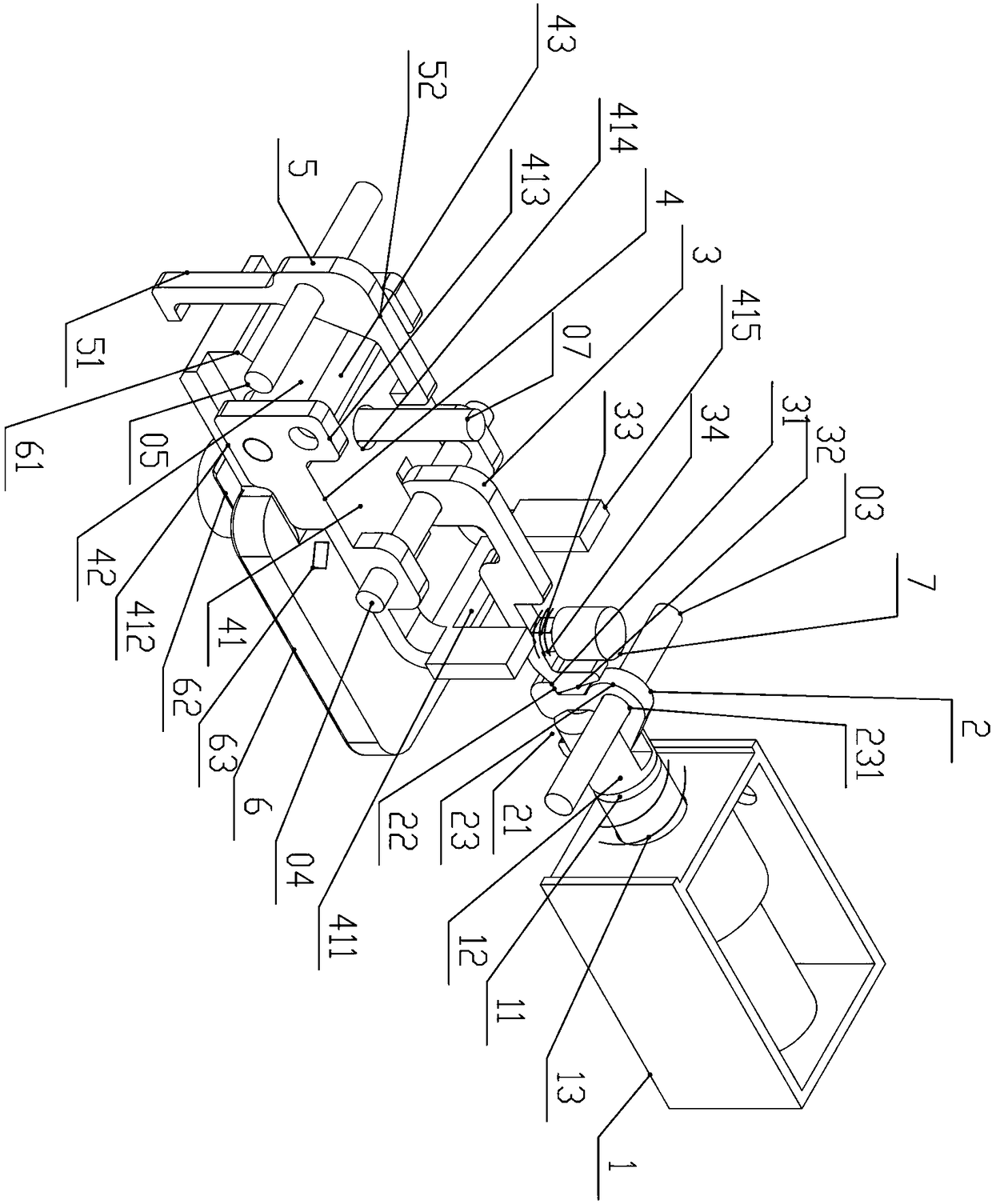

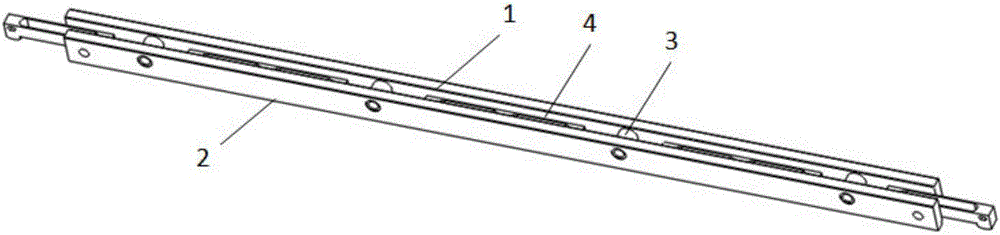

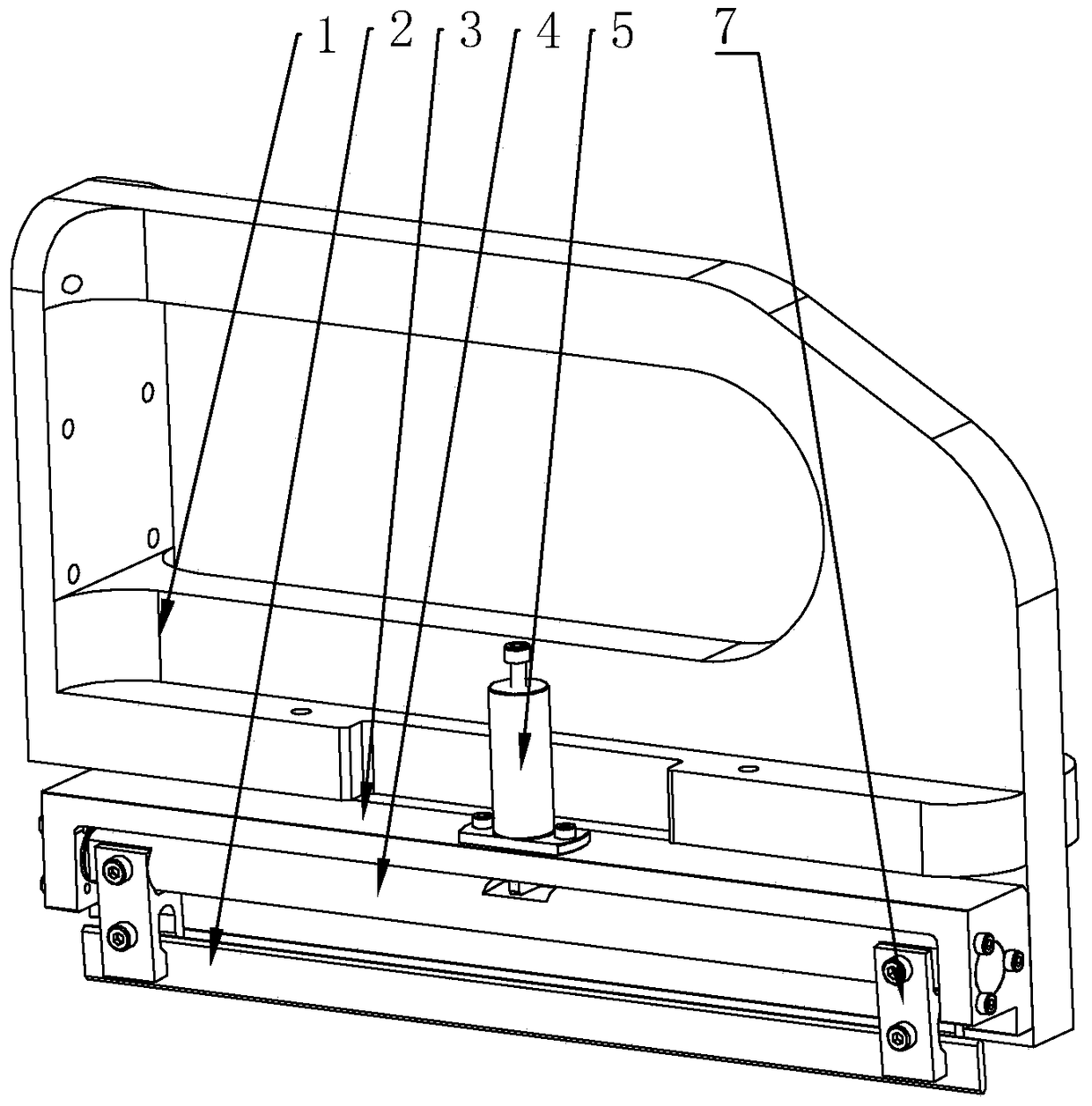

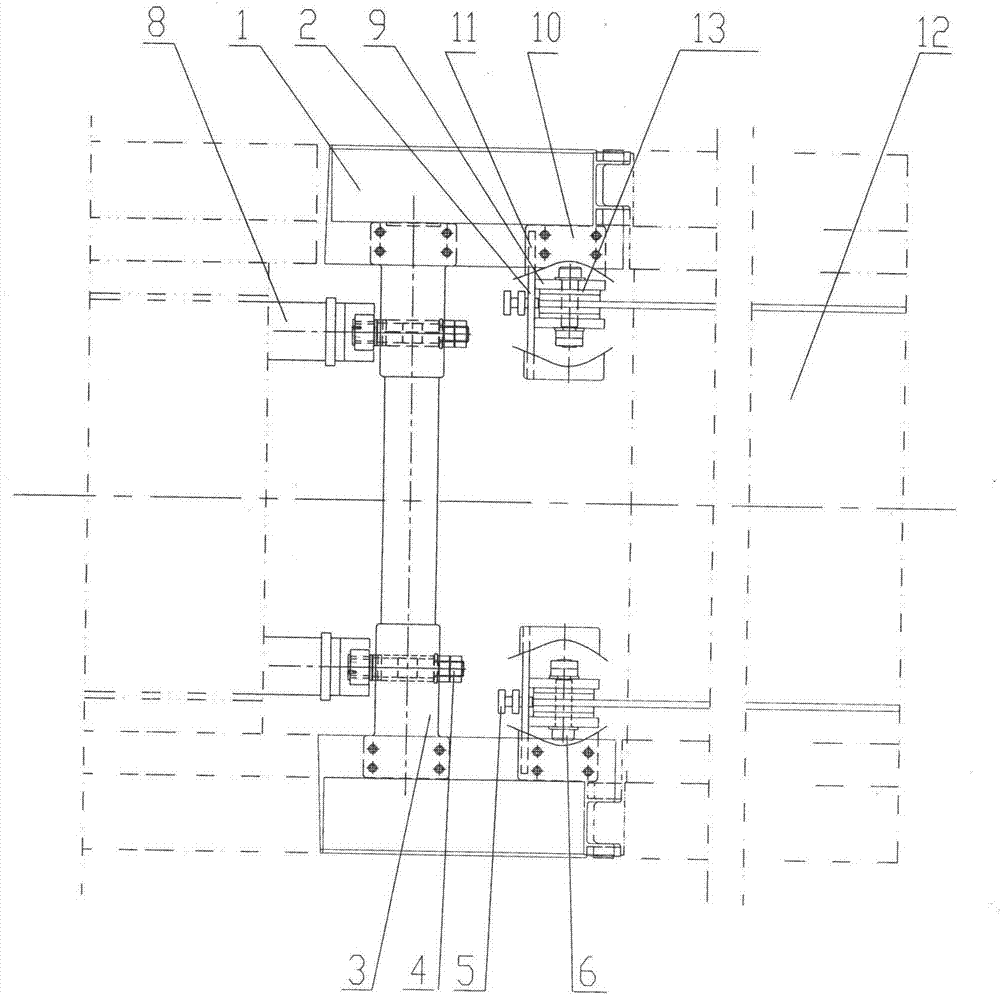

Connecting device for active beam and buttress beam of turnout

ActiveCN105386372AThe line is stable and smoothAvoid shaking from side to sideRailway tracksDeflection angleEngineering

The invention discloses a connecting device for an active beam and a buttress beam of a turnout. The connecting device comprises two moving F rails, connecting cross beams, angle adjusting mechanisms and supporting beams, wherein the two moving F rails are transversely symmetrically arranged along a track; the connecting cross beams are fixedly arranged on the lower surfaces, close to the buttress beam end, of the two moving F rails along the track line direction, and are used for connecting the two moving F rails; each angle adjusting mechanism is arranged at the other end, opposite to the corresponding connecting cross beam, of each moving F rail, and is used for properly adjusting relative deflection angle of the corresponding moving F rail and the active beam of the turnout; the supporting beams are arranged at the bottom parts of the connecting cross beams; one end of each supporting beam is fixed to a supporting beam base which is mounted on the active beam of the turnout, and the other end of each supporting beam extends toward one end of the corresponding cross beam, and the extending end is fixed to the bottom end of the corresponding connecting cross beam. With the adoption of the connecting device, the vertical stiffness of the connecting device between the active beam and the buttress beam can be improved on the premise that the degree of vertical freedom and the degree of left and right freedom of the active beam of the turnout are limited after the active beam moves in place, and the stability of the connecting device of the turnout is improved, so that a train can be prevented from jumping while running through a connecting part, and a route is stable and smooth.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

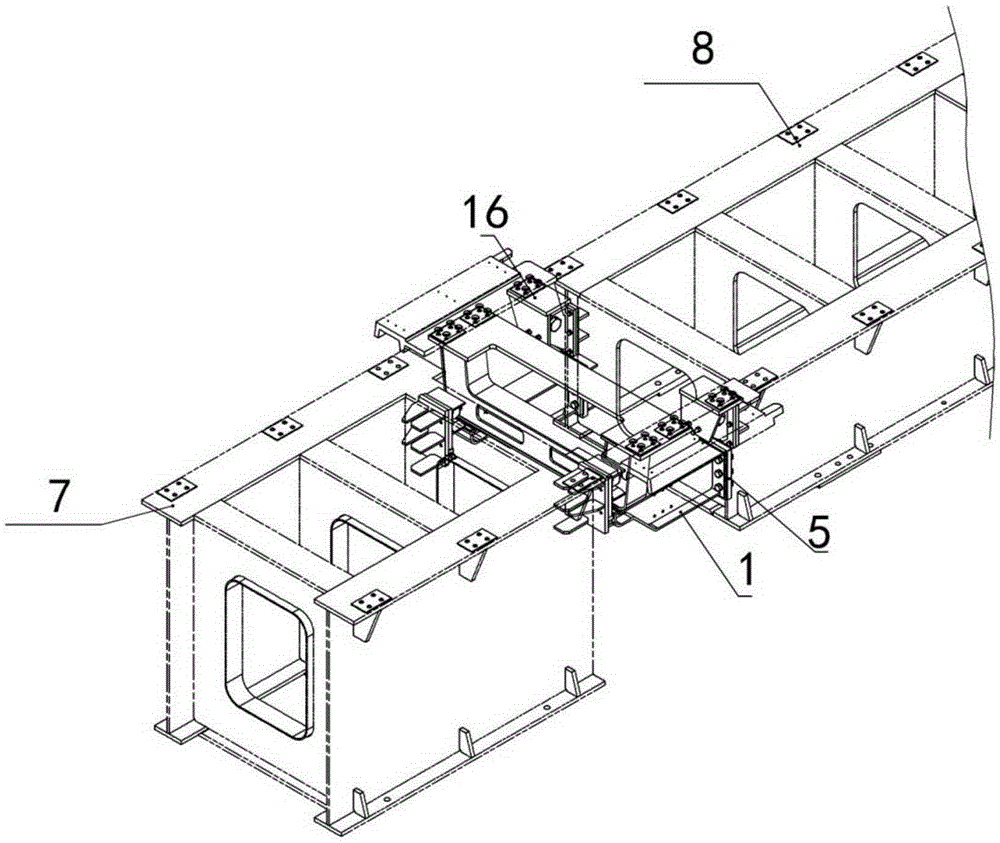

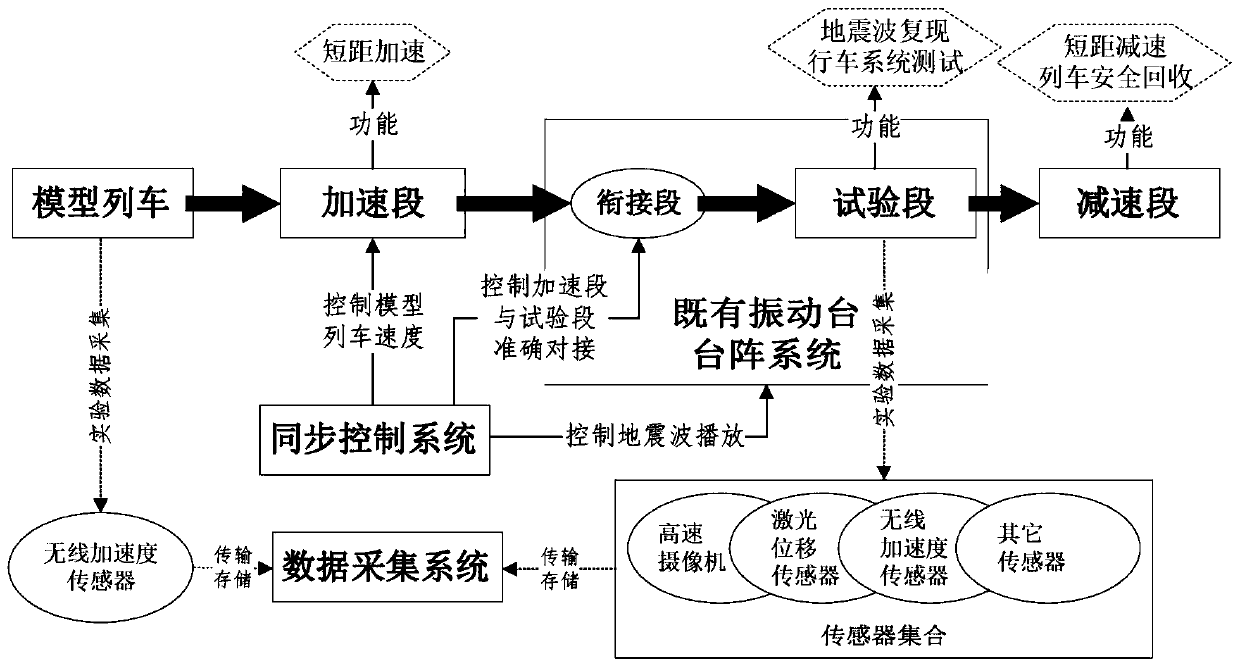

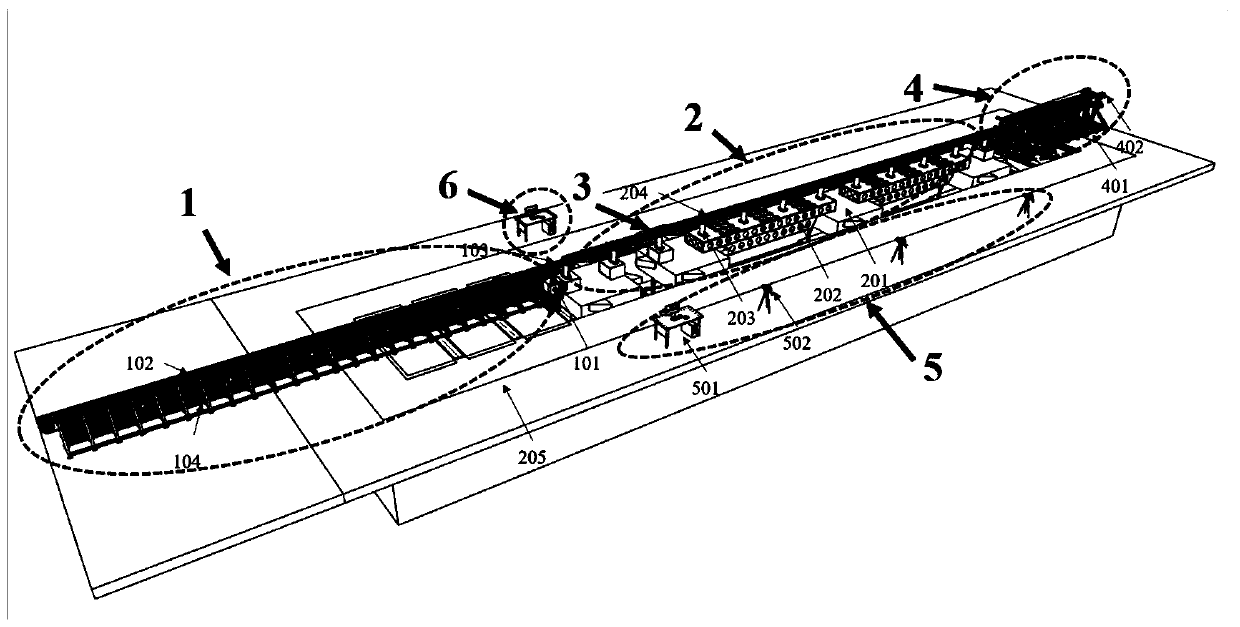

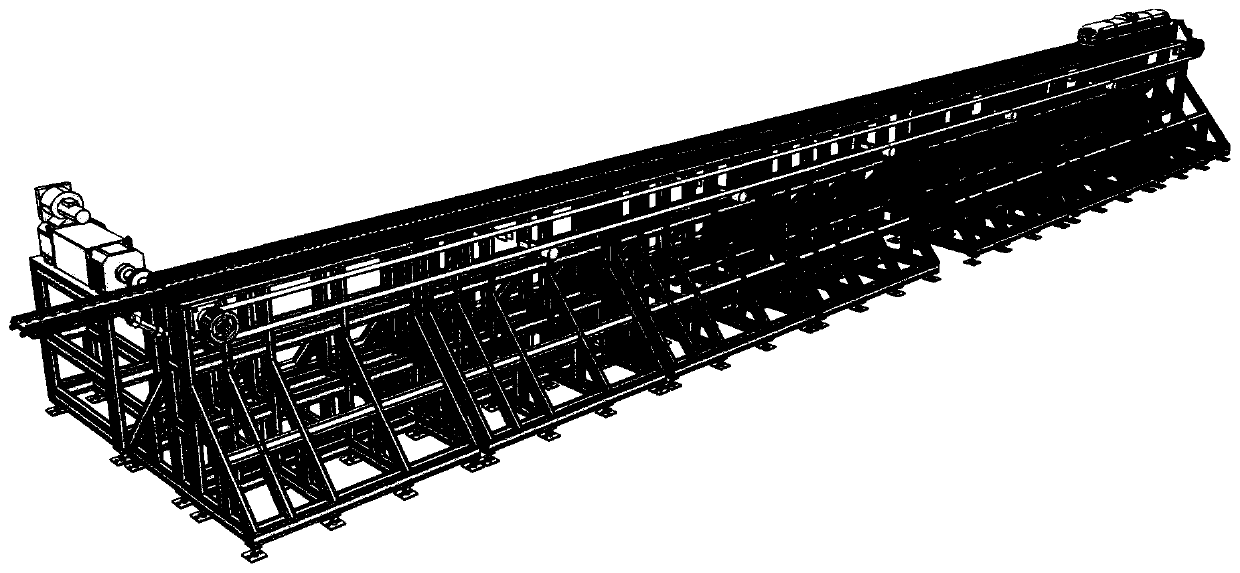

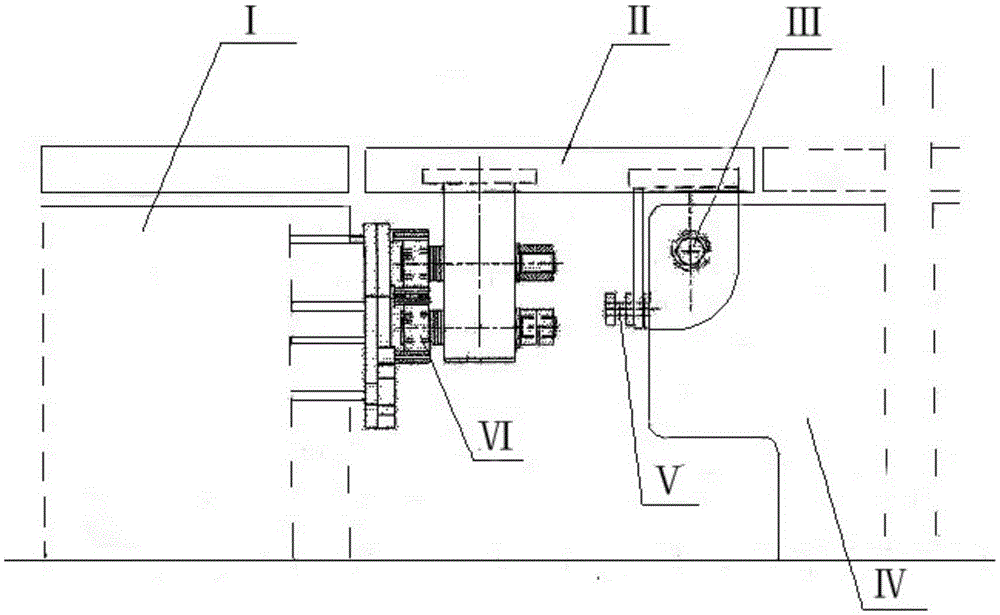

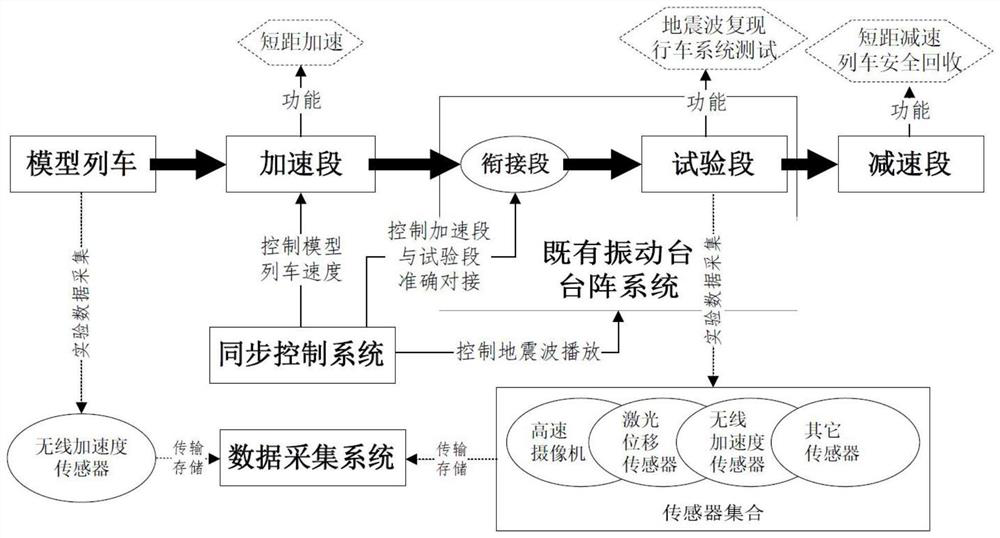

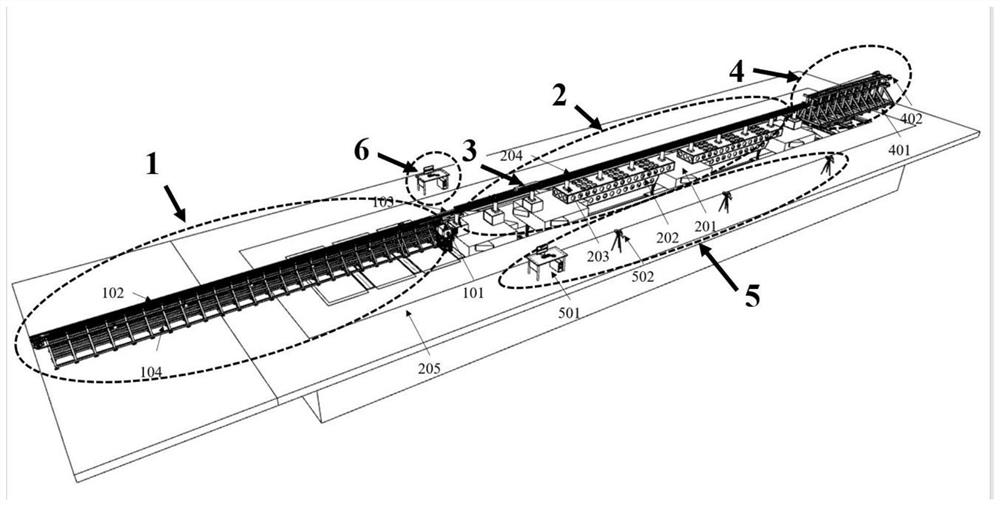

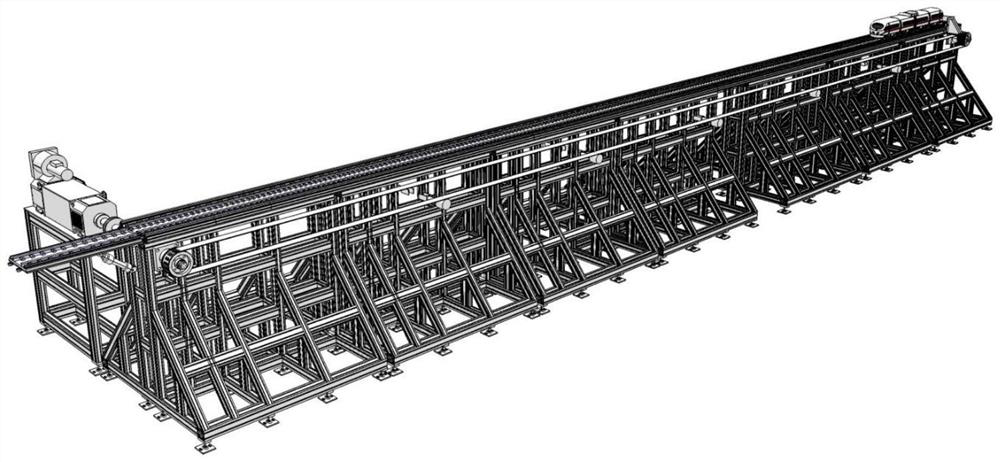

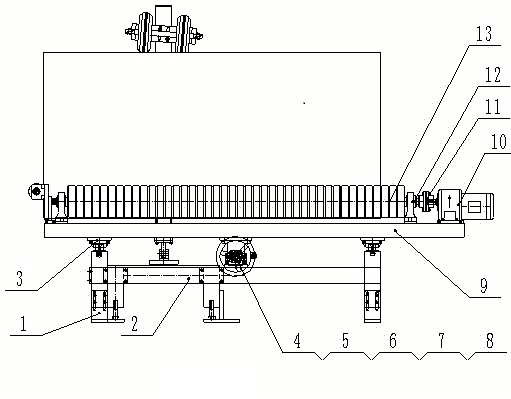

Driving safety testing system on high-speed railway bridge under earthquake

ActiveCN111537246ANo jumping phenomenonRun fastRailway vehicle testingVibration testingSynchronous controlControl system

The invention, which relates to the train safety performance testing field, discloses a driving safety testing system on a high-speed railway bridge under an earthquake. The system comprises a drivingtesting system comprising an acceleration segment, a testing segment, and a deceleration segment that are connected successively. A model train is arranged on the driving testing system; a data acquisition system is arranged on one side of the testing segment, and the data acquisition system and the driving testing system are respectively connected with a synchronous control system; the acceleration segment can accelerate the model train to a test speed greater than 20m / s; the testing segment can adopt a vibration table to input seismic excitation; and the deceleration segment can deceleratethe model train to a static state. According to the invention, the functions of short-distance acceleration of the model train to a test speed, on-bridge high-speed driving test, seismic excitation synchronous reproduction, short-distance deceleration braking and the like can be realized in a laboratory, and the system has the advantages of millisecond-level synchronous control, millimeter-level configuration control and the like.

Owner:NAT ENG RES CENT OF HIGH-SPEED RAILWAY CONSTR TECH +1

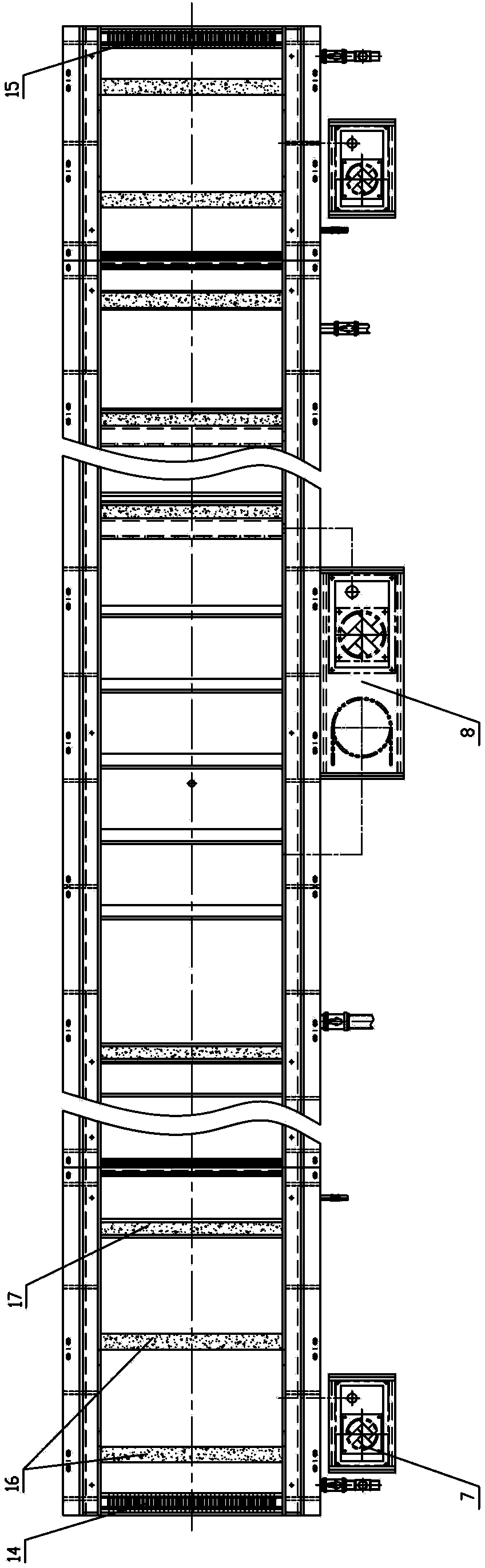

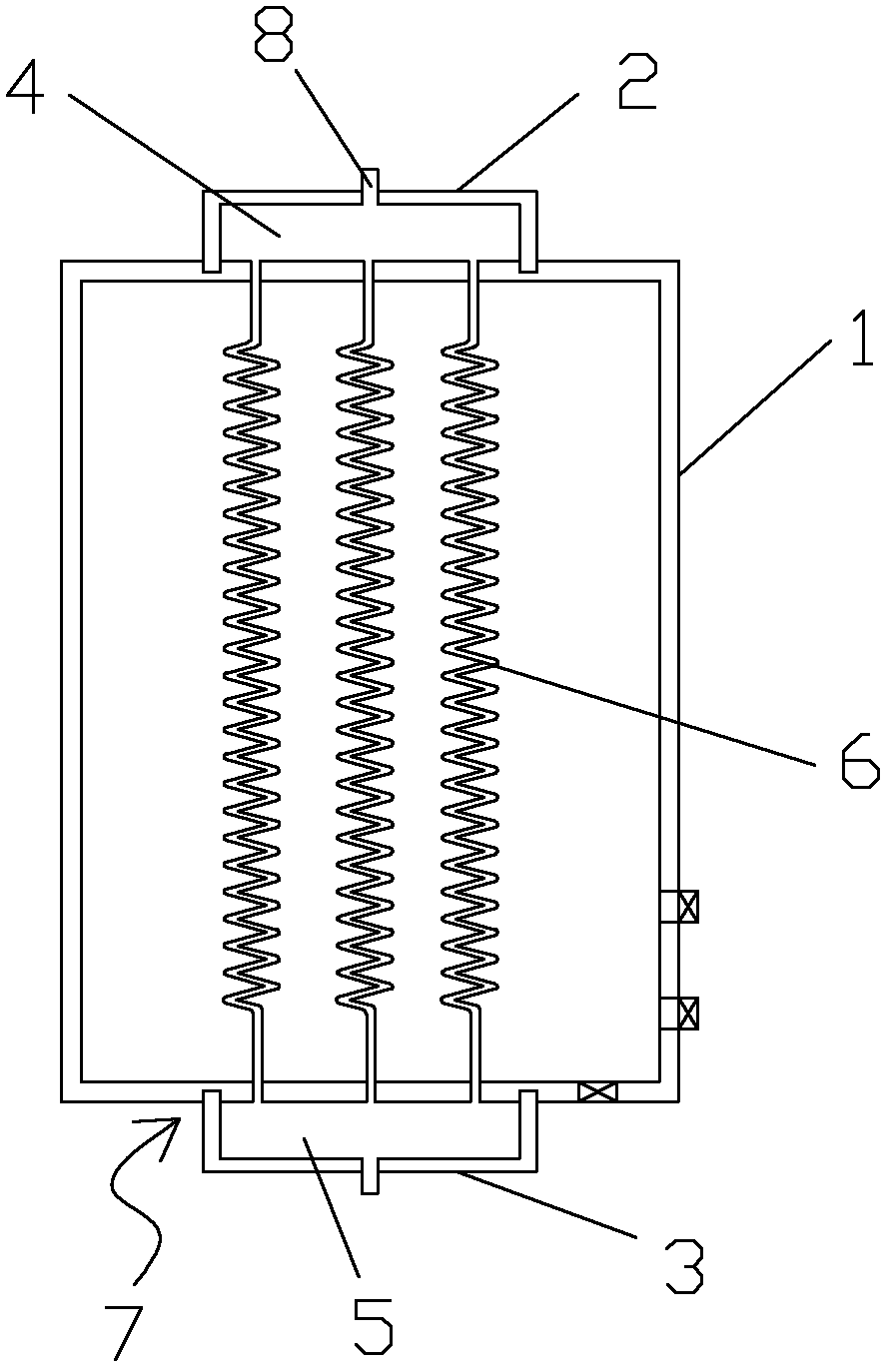

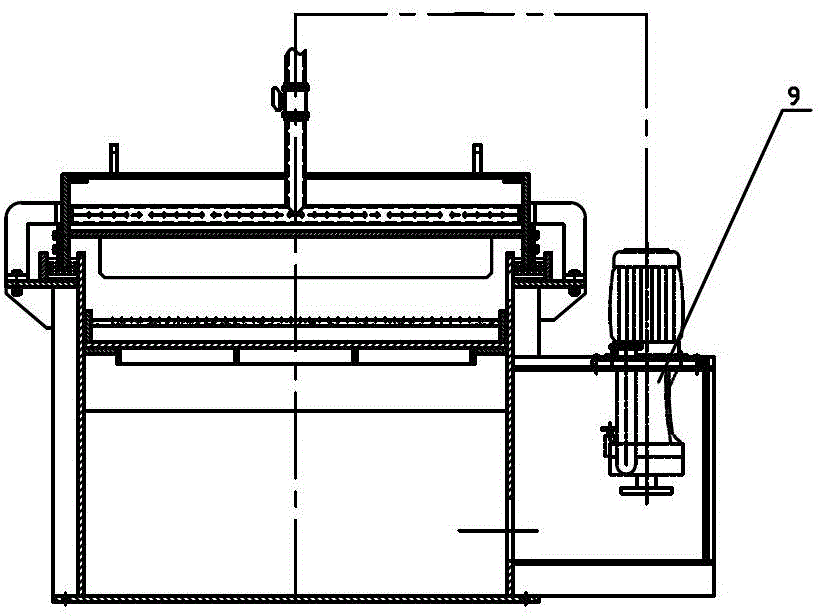

Closed electrolytic pickling machine set

The invention relates to a closed electrolytic pickling machine set which comprises an inlet wire water curtain groove, at least one electrolytic pickling grooves and an outlet wire water curtain groove which are arranged in sequence along the wiring direction of a steel wire. The closed electrolytic pickling machine set is characterized in that two ends of cover plates of the electrolytic pickling grooves are provided with inlet wire sealing devices and outlet wire sealing devices respectively, the inlet wire sealing devices and the outlet wire sealing devices can be penetrated by the steel wire, and can prevent pickling solutions in the electrolytic pickling grooves from escaping from two ends; positive work grooves and negative work grooves are arranged in the electrolytic pickling grooves, the steel wire penetrates above the positive work grooves and the negative work grooves, positive plates are mounted in positive work grooves, and negative plates are mounted in the negative work grooves; and the positive work grooves and the negative work grooves are connected with a liquid outlet of an acid pump box through an acid inlet pipe respectively, and a liquid inlet of the acid pump box is communicated with the interiors of the electrolytic pickling grooves through an acid pimping pipe. The closed electrolytic pickling machine set has the advantages of being ingenious and reasonable in structure, good in sealing performance, free of pickling solution leakage, and environment friendly.

Owner:WUXI XINKE METALLURGICAL EQUIP

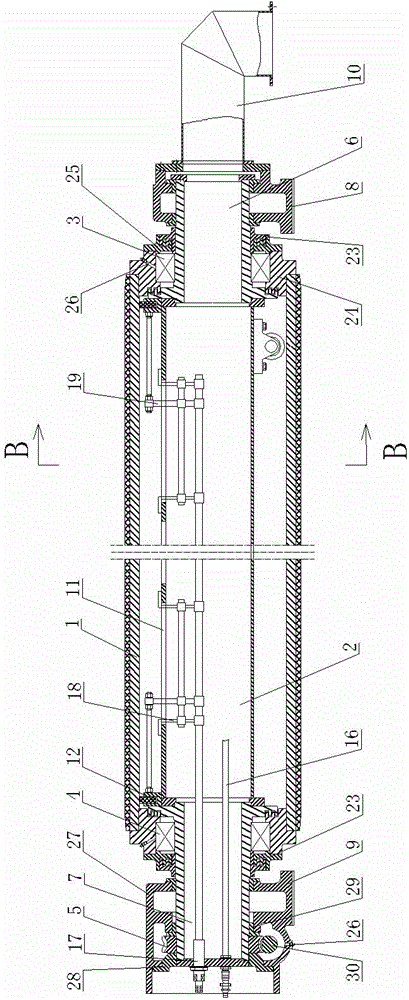

Vacuum carrier roller of papermaking machine

The invention provides a vacuum carrier roller of a papermaking machine. According to the vacuum carrier roller of the papermaking machine, the structure is simple, the maintenance is convenient, and the dehydration is stable and fruitful. The vacuum carrier roller comprises a roller body, a vacuum box, bearings and a worm and gear adjusting device, wherein the two ends of the vacuum box are separately connected with vacuum box heads, the outer end of the vacuum box head at one side is connected with a vacuum suction port, water suction holes are uniformly distributed in the surface of the roller body, a plurality of water suction openings are uniformly formed in the vacuum box along the axial direction, sealing devices are arranged at the internal wall end, close to the roller body, of the vacuum box, the sealing devices and the vacuum box are in fit so as to form vacuum chambers, the vacuum box comprises a semicircular top and a semi-regular-hexagon bottom, and an adjusting lead screw is further arranged in the vacuum box, is separately connected with water suction opening adjusting rods and end part sealing device adjusting rods and is separately used for adjusting sizes of the water suction openings and adjusting positions of end part sealing devices.

Owner:WUXI HONGCHENG PAPER MAKING MACHINERY

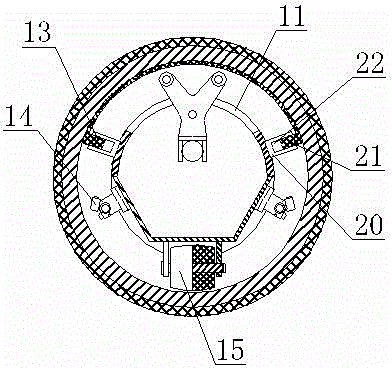

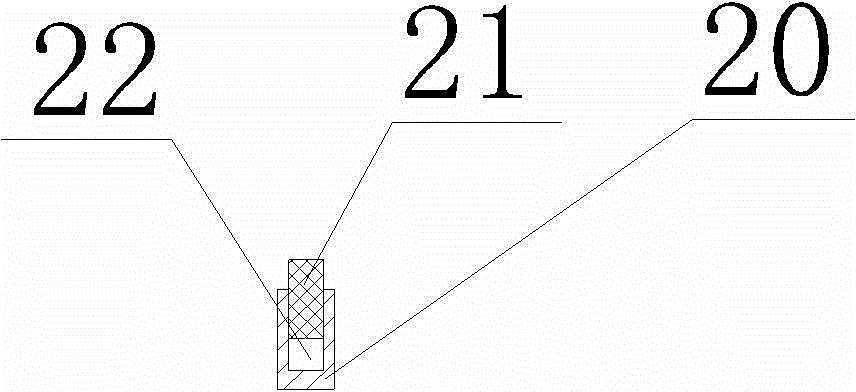

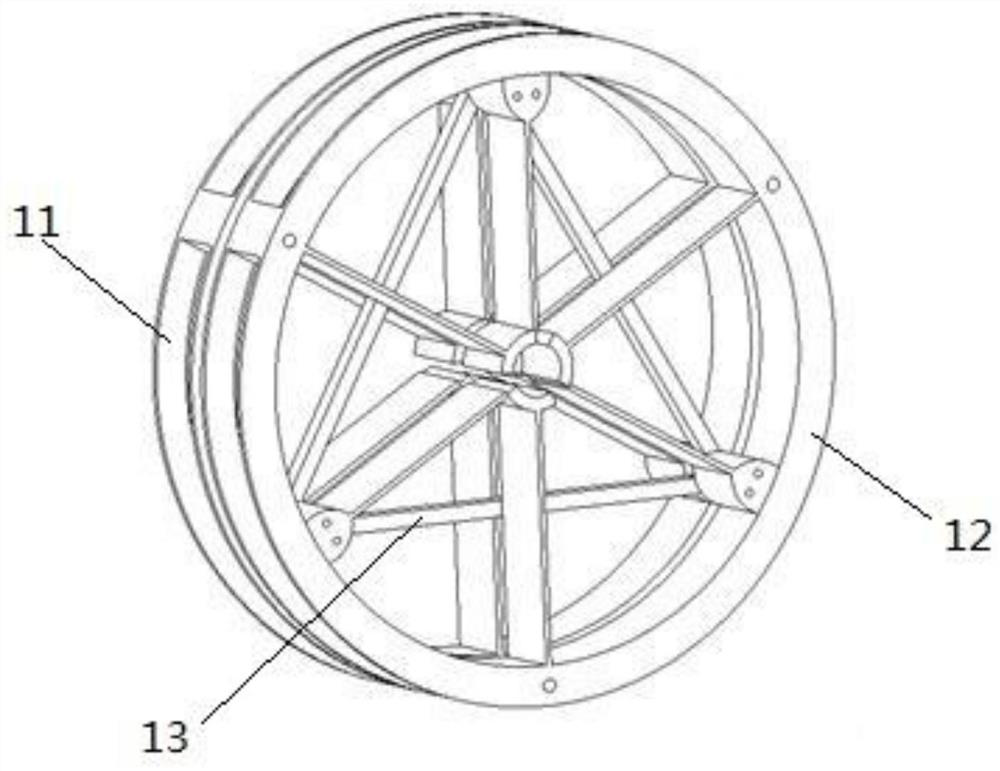

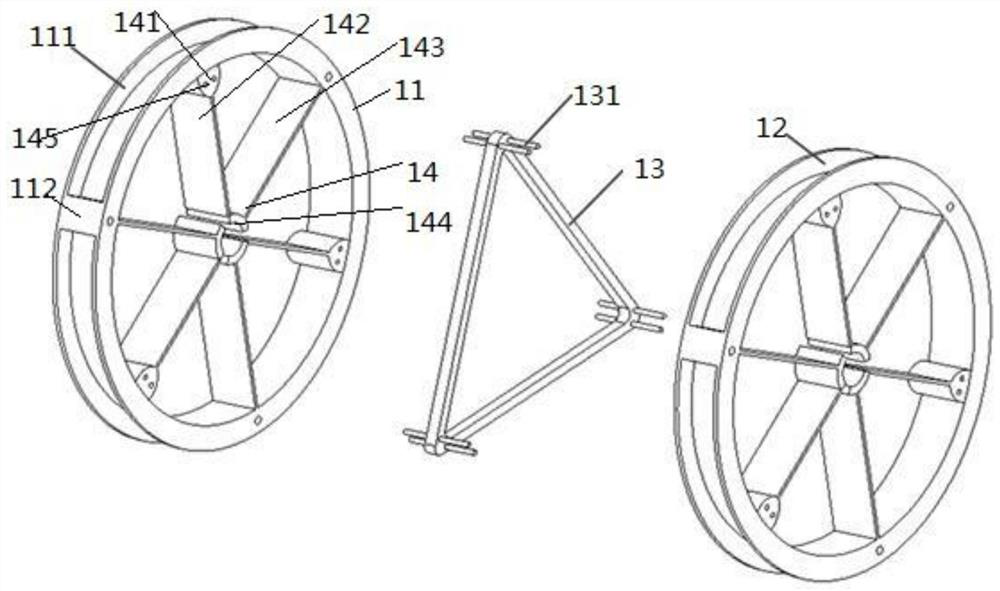

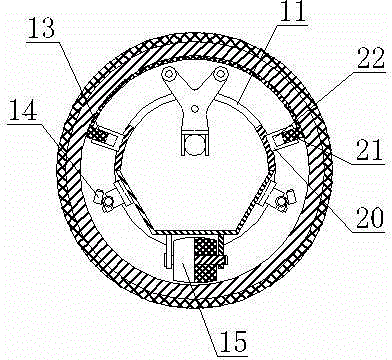

Large-angle flexible supporting device

PendingCN112460447AReduce coefficient of frictionImprove support stiffnessRotating vibration suppressionStands/trestlesPhysicsLubrication

The invention provides a large-angle flexible supporting device. The large-angle flexible supporting device comprises a first side ring, a second side ring and a triangular frame, three first supporting assemblies are arranged on the inner surface of the circumference of the first side ring, three second supporting assemblies are arranged on the inner surface of the circumference of the second side ring, first sliding heads of the three first supporting assemblies are connected to second sliding heads of the three second supporting assemblies through the triangular frame, and connection between the first side ring and the second side ring is achieved. The device has the advantages of no lubrication, few parts, good heat dissipation and the like, and can effectively support space rotation motion.

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

Door closing device

ActiveCN108547529AGuaranteed to be used multiple timesGuaranteed straightnessPower-operated mechanismToggle switchEngineering

The invention discloses a door closing device. The door closing device comprises a rectangular tubular shell, a slideway is formed in the center of the upper surface of the shell, a stop sliding blockis installed on the slideway, the outer end of the stop sliding block is connected with the closing end of a door, and an installing frame is fixed to the inner surface of the shell. An electromagnetis connected with one end of a metal buckle, the metal buckle is provided with an upper clamping portion, a releasing part is provided with a lower clamping portion, and the middle of the releasing part is connected with the installing frame through a second spring. A stop buckle is provided with a bottom plate, one end of the bottom plate extends to form a bearing surface in the vertical direction, the bearing surface is attached to the middle of the releasing part, a stop portion is further arranged at the upper end of the bottom plate, a clamping connection portion is arranged at the lowerend of the stop sliding block, and the stop portion and the clamping connection portion are clamped. A toggle switch is provided with an upper arm and a lower arm, a reset portion is further arrangedat the lower end of the stop portion, the lower arm is located at the lower end of the reset portion, and the upper arm is located on the outer side of the stop portion and stretches out of the slideway. The door closing device has the effects of simple structure, high response speed, stable operation and high safety.

Owner:SHANGHAI RYNON AUTOMATION TECH

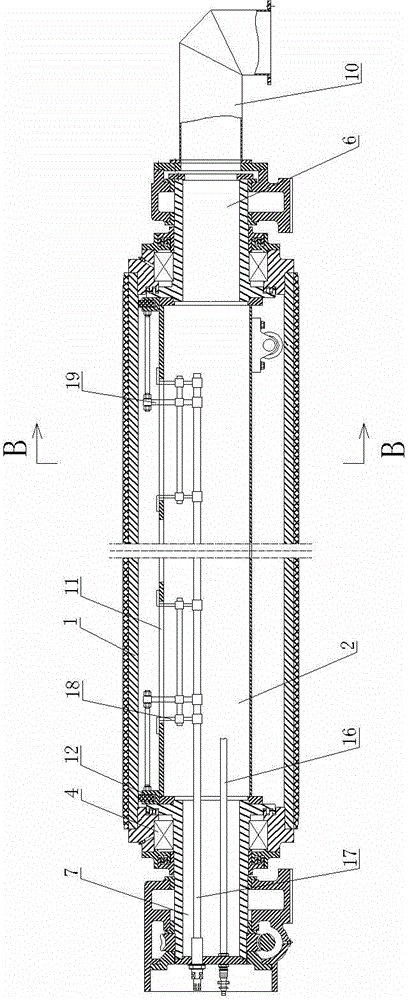

Axial-flow type water control reducing valve

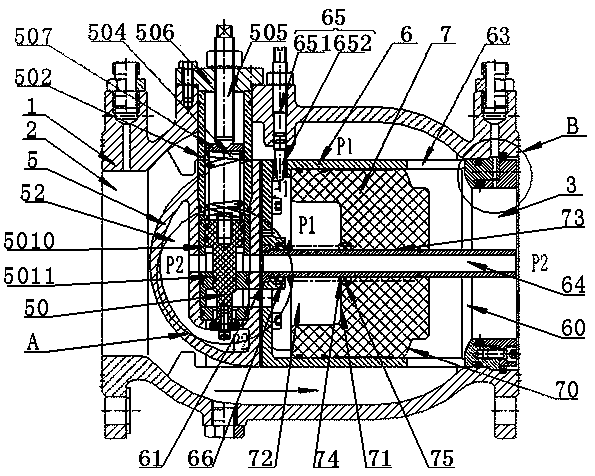

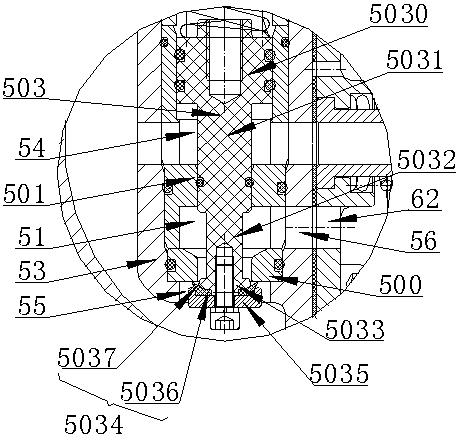

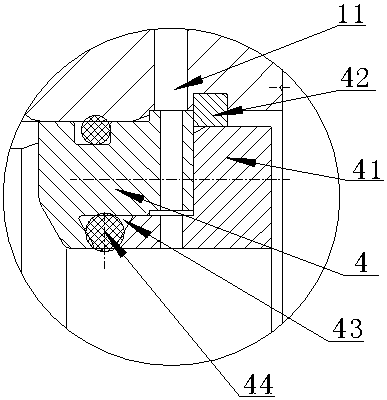

PendingCN107806524AMedium flow state is goodAccurate opening and closing strokeValve members for absorbing fluid energyEqualizing valvesPiston ringEngineering

The invention provides an axial-flow type water control reducing valve. The axial-flow type water control reducing valve comprises a valve body, a water inlet and a water outlet which are formed in the two ends of the valve body, a first valve seat arranged at the water outlet, a pressure releasing body arranged in the valve body, a pressure releasing valve arranged in the pressure releasing body,a piston ring arranged on the pressure releasing body and a piston which is arranged in the piston ring and is in sealed fit with the first valve seat. The piston and the piston ring form a piston inner cavity. The piston ring is provided with a pressure guide pipe and a water inlet needle valve. The pressure releasing body is divided into an upper pressure releasing cavity and a lower pressure releasing cavity by the pressure releasing valve. The water inlet communicates with the piston inner cavity through the water inlet needle valve. The water outlet communicates with the lower pressure releasing cavity through the pressure guide pipe. When the pressure releasing valve is closed, the upper pressure releasing cavity communicates with the piston inner cavity. When the pressure releasingvalve is opened, the lower pressure releasing cavity communicates with the piston inner cavity. By means of the axial-flow type water control reducing valve, the control precision of opening and closing of the piston can be improved, and the gas etching and vibration borne by parts in the valve body can be weakened.

Owner:ANHUI REDSTAR VALVE

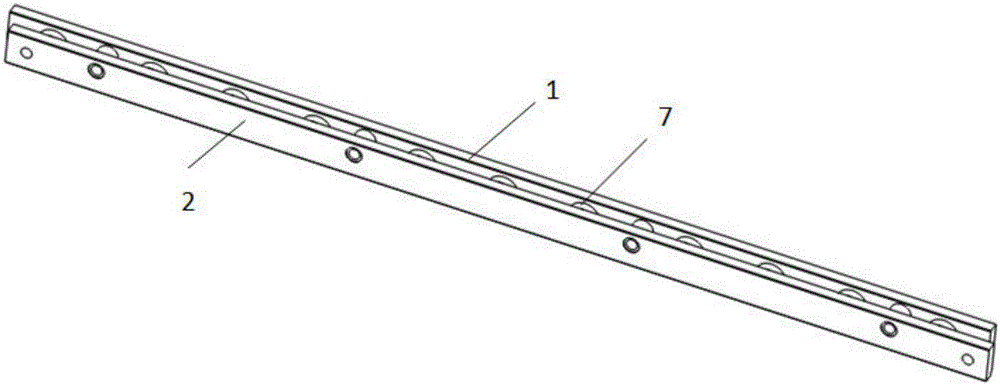

Cut tobacco suction band guide rail device of cigarette making machine

InactiveCN105768207AIncrease the support areaStable supportCigarette manufacturePulp and paper industry

The invention discloses a cut tobacco suction band guide rail device of a cigarette making machine. The cut tobacco suction band guide rail device comprises multiple guide rail units, each guide rail unit comprises an inner guide rail piece and an outer guide rail piece which are arranged in a relatively parallel manner, multiple cut tobacco suction band supporting blocks are arranged between each inner guide rail piece and the corresponding outer guide rail piece, each cut tobacco suction band supporting block comprises a long-strip-shaped body, multiple supporting convex blocks which protrude downward and are positioned on a same horizontal plane are arranged at the bottom of each body, the bottom of each supporting convex block is minor-arc-shaped, the supporting convex blocks are arranged along the length direction of the corresponding bodies, multiple first through holes which are up-down through are formed in each body, each two adjacent guide rail units are connected through a connection supporting block, two first convex blocks which protrude downward are arranged at two ends of the bottom of each connection supporting block, the bottom of each first convex block is minor-arc-shaped, and the first convex blocks and the corresponding supporting convex blocks are positioned on a same horizontal plane. The cut tobacco suction band guide rail device has the advantages that the cut tobacco band supporting blocks of special structure are arranged between each inner guide rail piece and the corresponding outer guide rail piece, so that uniformity in thickness of a cut tobacco layer below a cut tobacco suction band is guaranteed.

Owner:CHINA TOBACCO ANHUI IND CO LTD

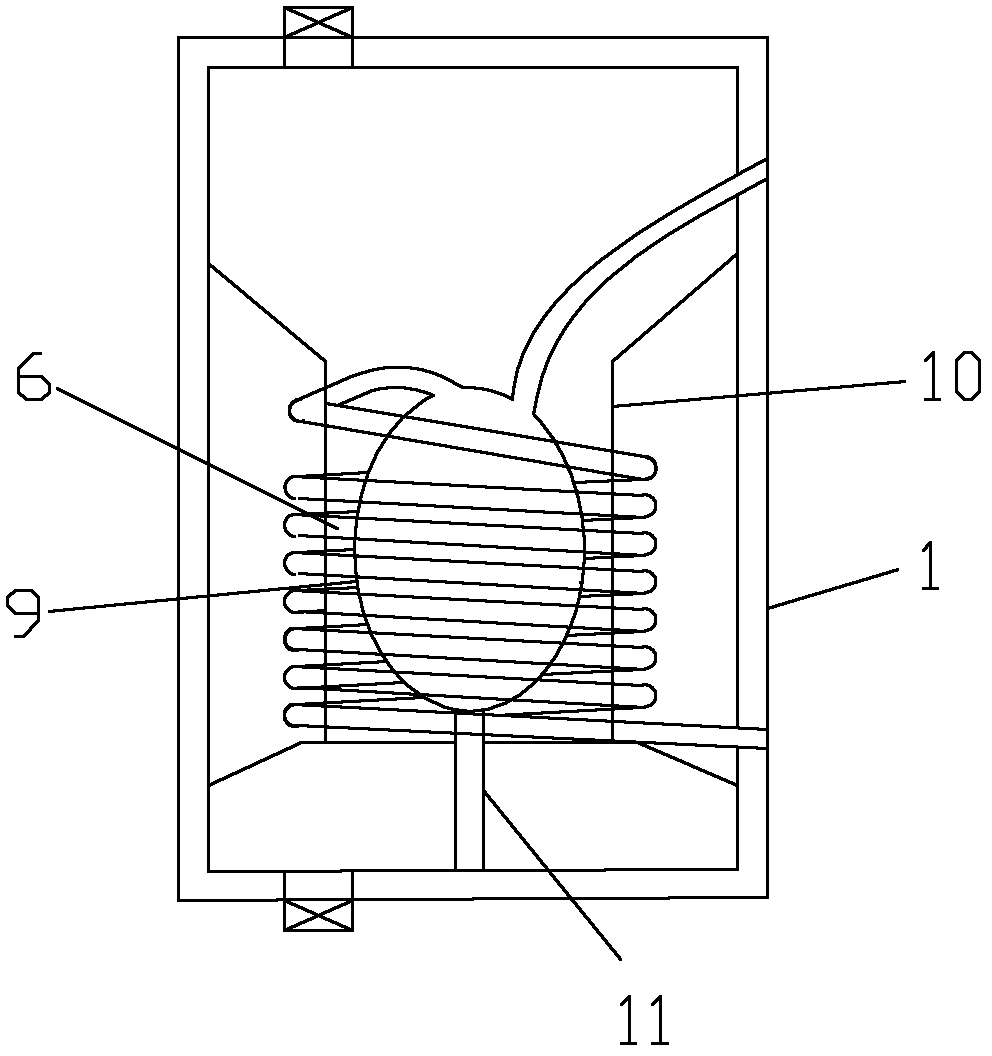

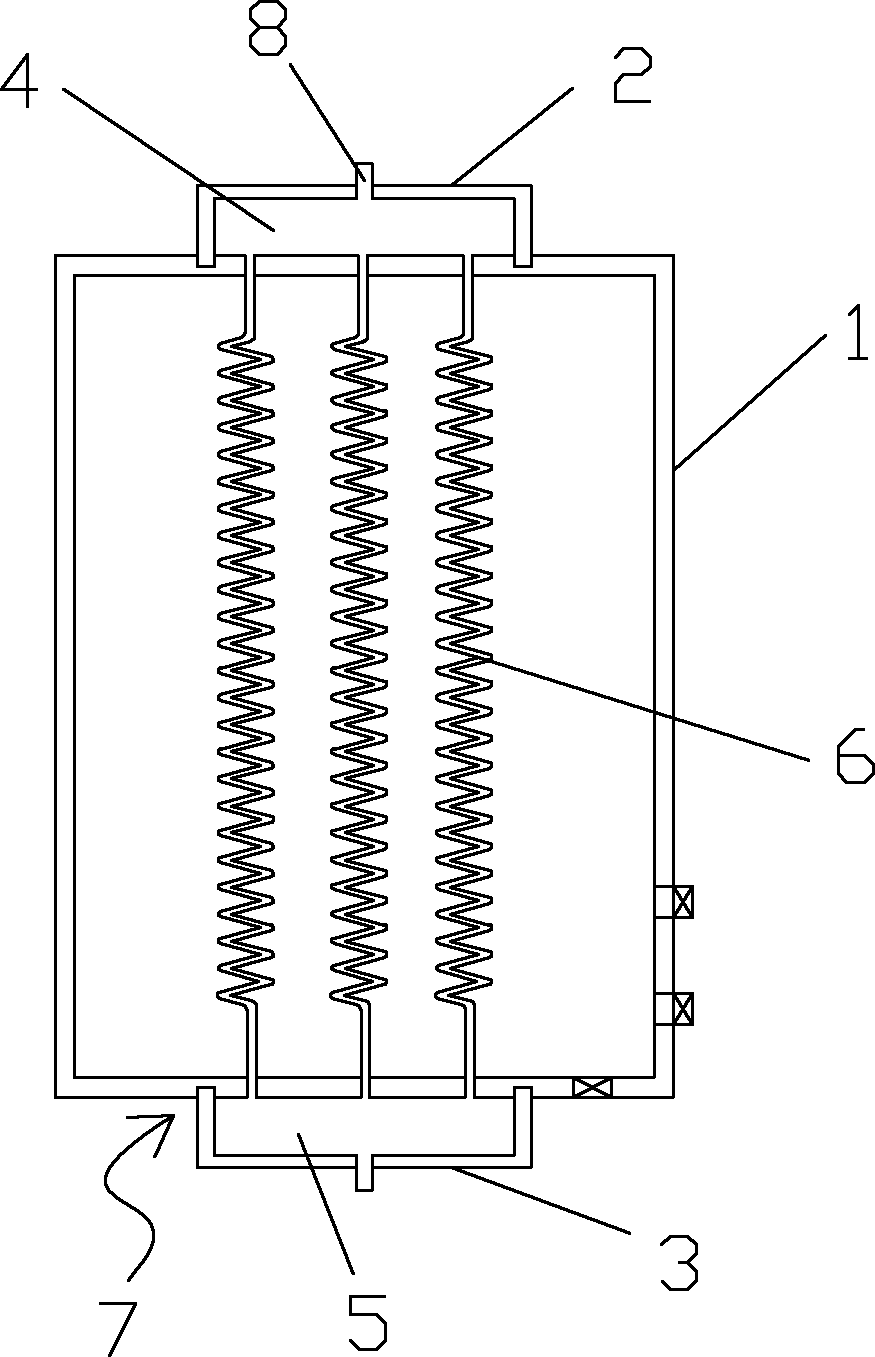

Improved solar heat exchange water storage tank

InactiveCN102401498ACooperate wellEasy to installSolar heat devicesSolar thermal energy generationThermodynamicsWater storage tank

The invention discloses an improved solar heat exchange water storage tank, which relates to a heat exchange water storage tank and solves the technical problem of flashover or sealing-off in the machining or transportation of the conventional water storage tank. The improved solar heat exchange water storage tank comprises a hollow tank body, and is characterized in that: the upper and lower ends of the tank body are provided with an upper end cover and a lower end cover respectively; the upper and lower end covers are inwards sunken and matched with the upper and lower surfaces of the tank body to form an upper cavity and a lower cavity respectively; the upper and lower cavities are communicated with each other through at least one heat exchange tube passing through the tank body; and each of the upper and lower end covers is provided with a connecting pipe orifice communicated with own cavity. In the improved solar heat exchange water storage tank, the arrangement of a fluid reservoir is canceled, and a heat transfer medium is diffused into vertical fixed heat exchange tubes which are highly stationary, thereby avoiding potential safety hazards such as the flashover, sealing-off and the like which may be caused in mounting or transportation in the tank body; and the improved solar heat exchange water storage tank is convenient to mount and low in cost.

Owner:冯卓林

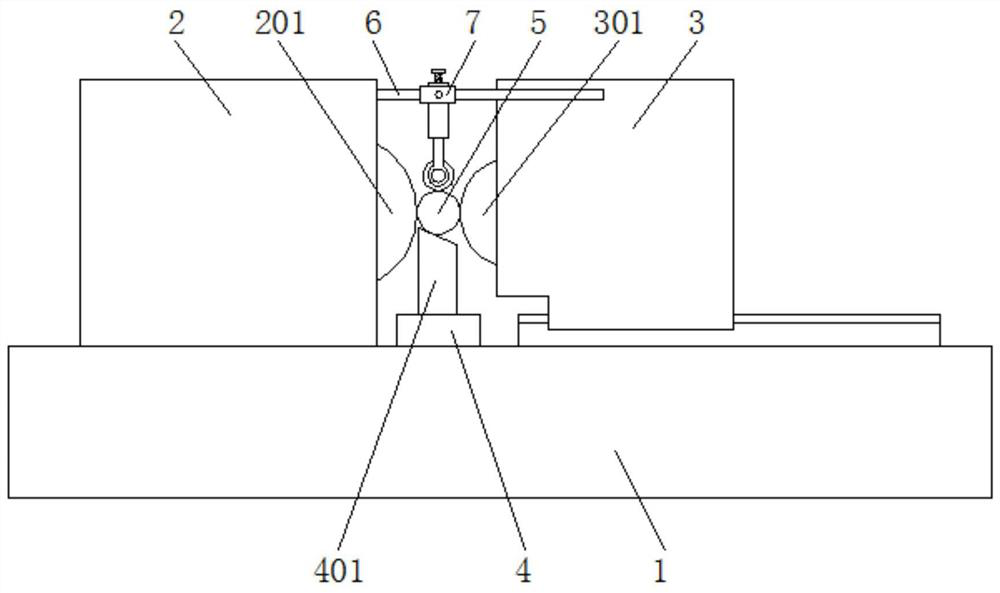

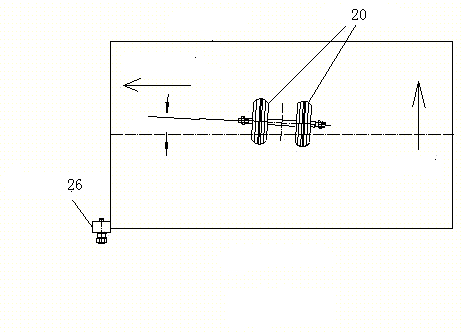

Cylindrical grinding equipment for tungsten steel rods and anti-running method thereof

ActiveCN110802448BNo jumping phenomenonGuarantee the quality of external grindingGrinding carriagesRevolution surface grinding machinesEngineeringStructural engineering

The invention relates to the technical field of grinding equipment for tungsten steel rods, and discloses a cylindrical grinding equipment for tungsten steel rods, including a machine table, a grinding wheel frame, a grinding wheel, a guide wheel frame, a guide wheel, a fixed frame, plate, tungsten steel rod to be polished, the side of the machine table is fixedly connected with two positioning horizontal shafts located outside the guide wheel frame, and the two positioning horizontal shafts are provided with moving blocks, and the moving blocks can move laterally. The outer cylindrical grinding equipment for tungsten steel rods uses the limit roller to limit the position of the tungsten steel rods to be polished, so as to ensure that the tungsten steel rods will not jump when grinding, and ensure that the grinding parts are always in contact with the grinding wheel, effectively guaranteeing The grinding quality of the outer circle of the tungsten steel bar is improved, and at the same time, the cold water evenly flowing out of the water hole of the limit roller is used to cool down, so as to ensure that the tungsten steel bar is cooled evenly during grinding, and there will be no local overheating of the grinding wheel, which effectively improves the grinding wheel. service life.

Owner:湖南镕耀有色金属有限公司

Closed electrolytic pickling unit

Owner:WUXI XINKE METALLURGICAL EQUIP

Reticulated shell-annular truss frame-irregular-shaped combination column combined support spherical tank system capable of slightly moving

InactiveCN103306531BEfficient deliveryImprove shock absorptionBulk storage containerShock proofingReinforced concreteRebar

The invention relates to a reticulated shell-annular truss frame-irregular-shaped combination column combined support spherical tank system capable of slightly moving. The system comprises combined spherical tanks, reticulated shell-annular truss frame-irregular-shaped combination column combined supports, a rubber ball-damper shock-absorbing energy consumption device, wherein annular truss frames are encircled outside the reticulated shells, and are connected with the irregularly-shaped combination columns; the combined spherical tanks are arranged on the reticulated shell-annular truss frame-irregularly-shaped combination column combined supports; the rubber ball-damper shock-absorbing energy consumption device is arranged between the reticulated shell pitch points and the combined spherical tanks; the rubber ball- damper shock-absorbing energy consumption device is composed of dampers and rubber balls; the rubber balls are arranged at one ends of the dampers; concave slide tracks are arranged on the outer walls of the combined spherical tanks; the rubber balls are positioned in the concave slide tracks; the other ends of the dampers are fixed with the pitch points of the reticulated shells; the irregularly-shaped combination columns are composed of solid-web section steel and reinforced concrete; the solid-web section steel is placed in the reinforced concrete; an L-shaped support seat is arranged at the top ends of the combination columns. The system can move slightly in any direction under the strong shock or the strong wind, and has excellent energy consumption shock-absorbing performance and wing resistance.

Owner:NORTHEAST GASOLINEEUM UNIV

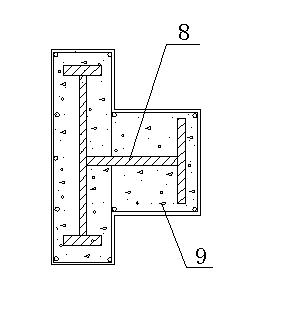

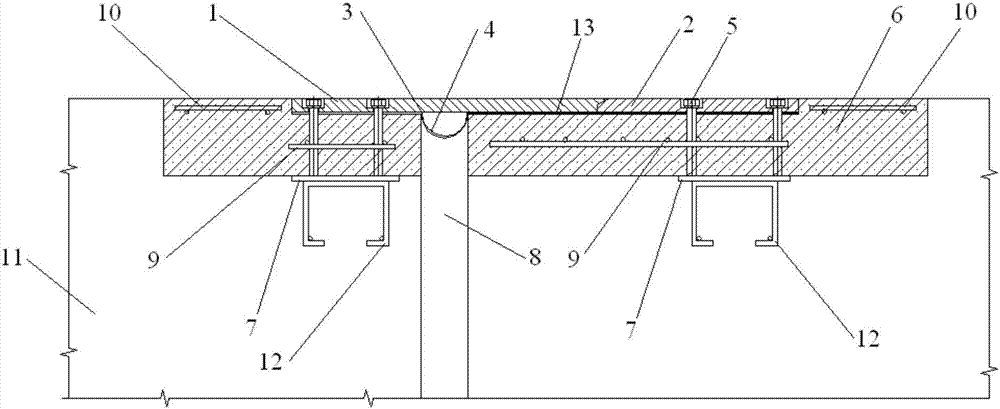

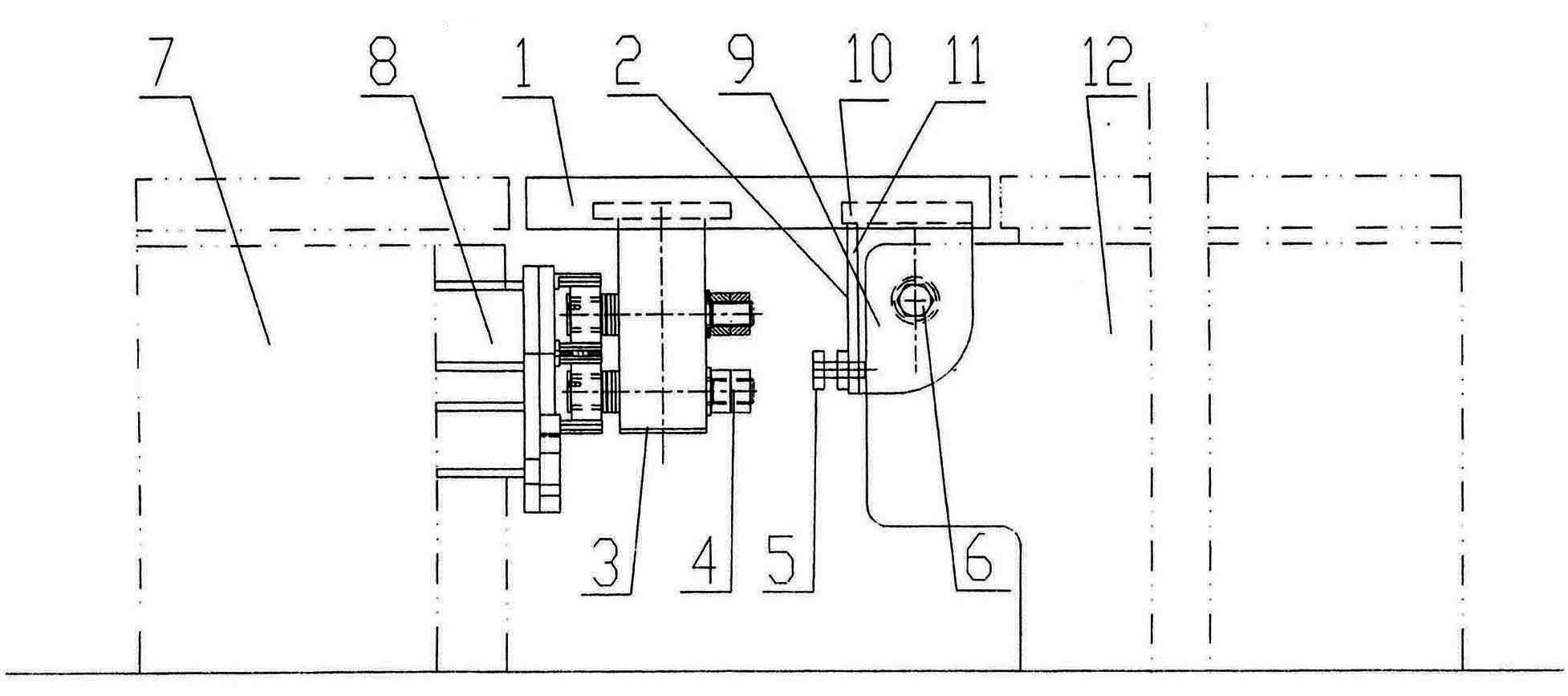

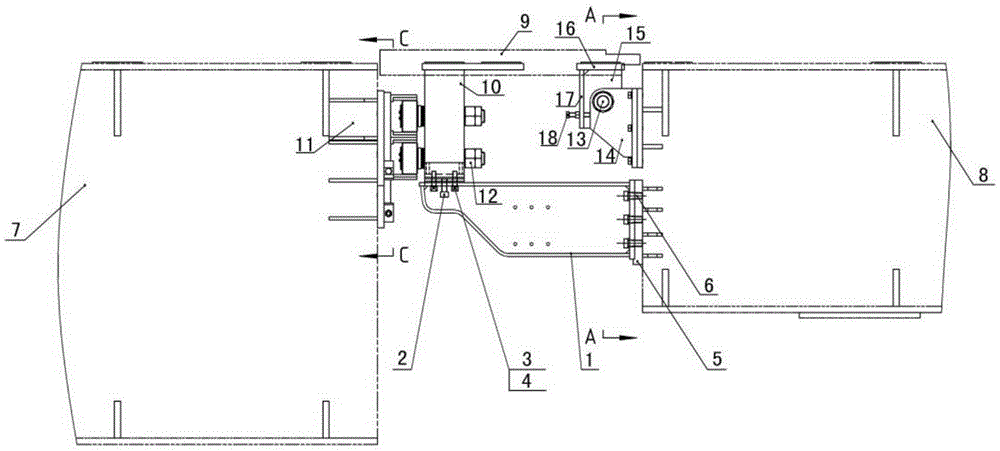

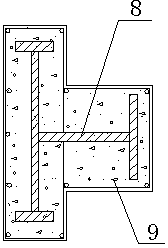

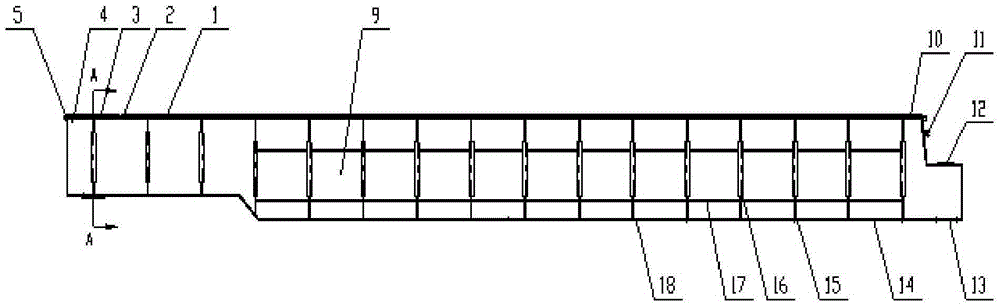

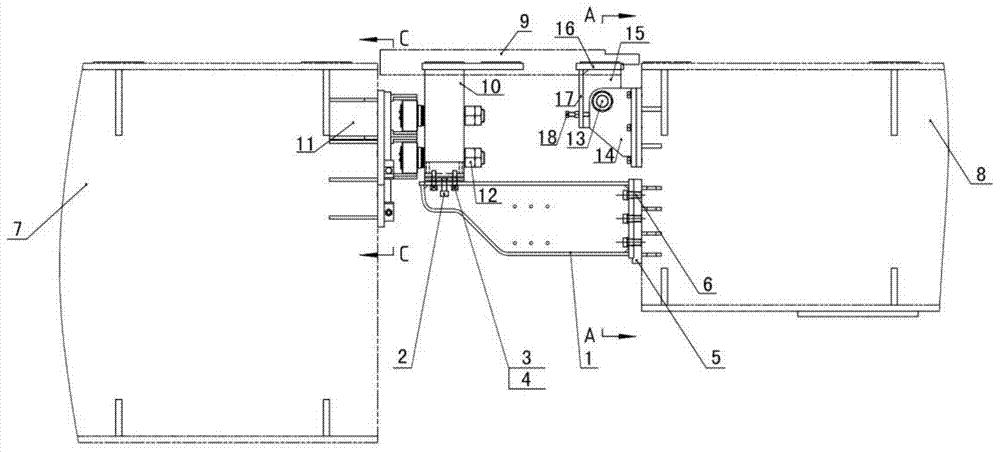

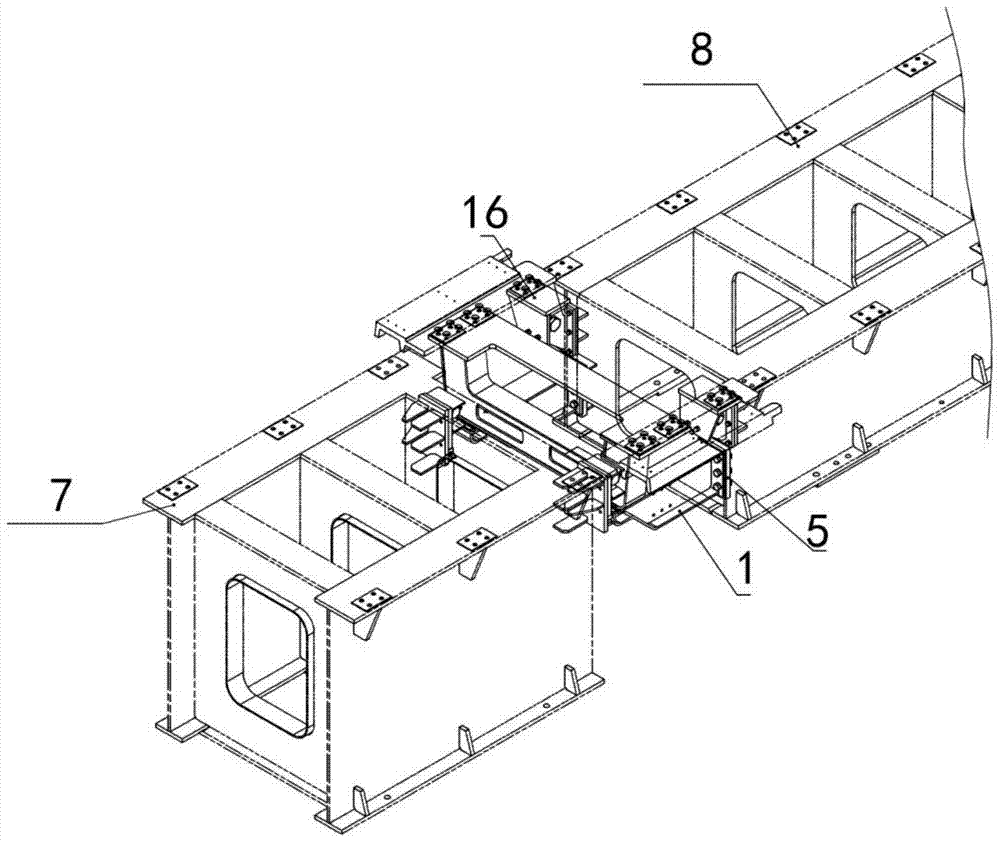

Active Beam of a Segmental Turnout

The invention provides a driving beam of a segmental turnout. The driving beam comprises a main beam body 9, a main beam upper flange plate 10, a main beam F-rail 1 located above the main beam upper flange plate 10, an adjusting rail 3, an F-rail mounting plate 2, a mounting plate 5 and an adjusting component 4. The adjusting rail 3 is used for flatly connecting the main beam F-rail 1 and a moving end butt beam F-rail 6 located above a moving end butt beam upper flange plate 8. The driving beam allows a turnout beam to be switched in place, with left-right and vertical degrees of freedom both limited, the moving end F-rail and a fixed end F-rail are flatly connected, and no leap occurs when a train passes by. Compared with the prior positioning techniques, the driving beam has the advantages that complex positioning connectors for use at the moving end of the F-rail of the turnout are omitted, a weak and fragile link is omitted, safety is improved at the premise of ensuring service performance; the whole turnout beam structure is simplified, fewer parts of fewer varieties are used, mounting is simplified, and manufacturing cost and construction cost are saved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Rotational damping buffering lifting wheel

PendingCN107701002ASimple structureReduce manufacturing costWing suspension devicesGear wheelIndustrial engineering

Owner:GUANGDONG MINGMEN LOCKS IND

A vertical force floating powder coating scraper device for metal additive manufacturing

ActiveCN105397089BNo jumping phenomenonSimple structureAdditive manufacturing apparatusIncreasing energy efficiencySelective laser sinteringEngineering

The invention discloses a vertical force floating powder spreading scraper device for metal additive manufacturing, which solves the technical problems in the prior art that the scraper avoids surface defects in selected areas of laser sintering and spheroidizes bumps, and the main points of the technical scheme It includes a scraper bracket with an external drive source and a scraper connected between the scraper bracket and the powder bed. A floating knife holder is arranged on the scraper bracket near the scraper. The scraper is rotatably connected to the floating knife holder. When the sintering defect bump is reached, the floating knife holder drives the central axis of the upper end surface of the scraper to swing around the sintering defect bump, so that the scraper rotates to avoid the bump on the powder bed, and there is no direct collision between the scraper and the sintering defect bump. Cutting and other moving components that are destructive to the structure function eliminate the fatal defects of uneven powder spreading, loose powder bed, and backward transfer of defects in other forms of scraper powder spreading. The product yield rate is greatly improved, and the mechanism is simple and takes up space. Small technical effect.

Owner:BEIJING E PLUS 3D TECH CO LTD

Vacuum box body of vacuum touch roll for papermaking machine

The invention provides a vacuum box body of a vacuum touch roll for a papermaking machine. The vacuum box body has the advantages of simple structure, convenient maintenance, and stable and good dehydration effect. The vacuum box body comprises a vacuum box which is arranged inside a roll body; two ends of the vacuum box are respectively connected with a vacuum box head; and one end of one side of vacuum box heads is connected with a vacuum suction port. The vacuum box body is characterized in that a plurality of water suction ports are uniformly and axially arranged on the vacuum box; the vacuum box close to the inner wall end of the roll body is provided with sealing devices which can enclose the water suction ports and cooperate with the vacuum box to form a vacuum chamber; the vacuum box comprises a semi-circular top part and a semi-hexangular bottom part; the side wall of the vacuum box is provided with water jets used for spraying water to the inner wall of the roll body; the water jets are respectively arranged on two side walls of the bottom part of the vacuum box; water-jet pipes are arranged on an operation-side vacuum box head and connected with water jets; and a rolling wheel device is arranged under the bottom part of the vacuum box.

Owner:WUXI HONGCHENG PAPER MAKING MACHINERY

Manufacture method of high-speed grinding head for processing precise hole and high-speed grinding head

InactiveCN101456168BEasy to processGuaranteed machining accuracyGrinding devicesHigh-speed grindingCarbide

The invention relates to a method for manufacturing a high-speed grinding bit used for processing precise small holes. The method comprises: a grinding wheel connecting part, a transition rod of carbide and a motor connecting part are assembled into a grinding wheel lengthening shaft; one end of the transition rod of carbide is connected with the motor connecting part through hot extrusion, whilethe other end is connected with the grinding wheel through welding; after manufacturing the grinding wheel lengthening shaft, the motor connecting part of the grinding wheel lengthening shaft is connected with the output end of a drive motor; and the grinding wheel connecting part is connected with the grinding wheel through a grinding wheel nail. The method has the advantages of improving the rigidity of the grinding wheel lengthening shaft and saving the resetting and balancing working procedure. The high-speed grinding bit manufactured by the method comprises the drive motor, the grinding wheel lengthening shaft, the grinding wheel nail and the grinding wheel; the grinding wheel lengthening shaft consists of the transition rod of carbide, the motor connecting part and the grinding wheel connecting part; and one end of the transition rod of carbide is welded with the grinding wheel connecting part, while the other end is connected with an accommodating hole of the transition rod on the motor connecting part through the hot extrusion. The high-speed grinding bit has the advantages of improving the grinding quality of the precise small holes and improving the grinding production efficiency.

Owner:HUNAN IND POLYTECHNIC +2

F-track movable end positioning and connection device for medium-and-low-speed magnetic suspension turnout

ActiveCN102304883BMeet the needs of vertical positioningMeet the needs of left and right positioningRailway tracksRear quarterLow speed

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +1

Driving safety test system on high-speed railway bridge under earthquake

ActiveCN111537246BNo jumping phenomenonRun fastRailway vehicle testingVibration testingSynchronous controlControl system

Owner:NAT ENG RES CENT OF HIGH-SPEED RAILWAY CONSTR TECH +1

It is used for the connection device between the active beam of the turnout and the stacking beam

ActiveCN105386372BNo jumping phenomenonAvoid shaking from side to sideRailway tracksVertical stiffnessDeflection angle

A connection apparatus used between an active beam (8) and a buttress beam (7) of a turnout, comprising: two moving F rails transversely symmetrically arranged along a track; a connecting crossbeam (10) fixedly arranged on the lower surfaces, close to the buttress beam (7) end, of the two moving F rails along the track line direction, used for connecting the two moving F rails; and an angle adjusting mechanism disposed at the other end, opposite to the connecting crossbeam (10), of the two moving F rails, used for properly adjusting a relative deflection angle of the moving F rails and the active beam (8) of the turnout; and further comprising a supporting beam (1) disposed at the bottom of the connecting crossbeam (10), one end of the supporting beam being fixed to a supporting beam base (5) which is mounted on the active beam (8) of the turnout, the other end of the supporting beam extending toward one side of the crossbeam (10), and the extending end being fixed to the bottom of the connecting crossbeam (10). The connection apparatus can improve the vertical stiffness of the connecting apparatus between the active beam (8) and the buttress beam (7), and improve the stability of the connecting apparatus of the turnout.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A kind of knee joint post-rehabilitation training chair

InactiveCN105147501BFully consider training needsEasy to useChiropractic devicesBall screwKnee Joint

The invention discloses a knee joint later-period rehabilitation training chair which comprises a base, two guide grooves, two lifting devices, a base plate, assisting armrests and a backrest. The two guide grooves are fixed to the upper side face of the base. The left side and the right side of the upper side face of the base are each provided with a row of lead screw fixing holes at equal intervals. Two long slots transversely distributed in parallel are formed in the middle of the upper side face of the base. The guide grooves and the long slots are distributed in a crossed mode. Four corners of the lower side face of the base are each provided with an antiskid leg. Each lifting device comprises a nut type ball screw and a transmission rod. The two lifting devices are connected through the transmission rods. The base plate is located on the base. Insert connection is adopted for the backrest, the two sides of the backrest are provided with metal rods, and the two metal rods penetrate through penetrating holes of the base plate and are inserted in backrest fixing holes in the base. The knee joint later-period rehabilitation training chair has the advantages of being user-friendly in design, simple in structure, easy to operate, low in price and the like and is suitable for a patient who rests at home and has a knee joint bending problem.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

Rotating pipe feed positioning mechanism for large-caliber pipes

ActiveCN103659883BRealize positioning feedPromote structural adjustmentMetal working apparatusRoller-waysMechanical engineeringEngineering

The invention discloses a rotating pipe feed positioning mechanism for large-caliber pipes. The rotating pipe feed positioning mechanism for the large-caliber pipes comprises machine legs and a mounting rack. The mounting rack is sequentially provided with a rotating pipe mechanism and a rotating pipe feed limiting mechanism. A pipe pressing mechanism is arranged on one side of the rotating pipe mechanism, the pipe pressing mechanism extends upwards to the position above the rotating pipe mechanism, so that the rotating pipe mechanism, the rotating pipe feed limiting mechanism and the pipe pressing mechanism are in a triangle shape to fix the pipes. A three-point positioning mode is used in the rotating pipe feed positioning mechanism for large-caliber pipes, adjusting is flexible, reliable and stable, and the large-caliber pipes can be conveniently machined on the mechanism.

Owner:HESHAN LESSO IND DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com