Vacuum box body of vacuum touch roll for papermaking machine

A vacuum box and paper machine technology, applied in paper machine, papermaking, textiles and papermaking, etc., can solve the problems of expensive manufacturing and use, unsatisfactory vacuuming effect, complex vacuum box structure, etc., to improve smoothness, Reduce the number of downtimes, and the effect of good economic benefits for the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, the present invention will be further described in detail based on the drawings and embodiments.

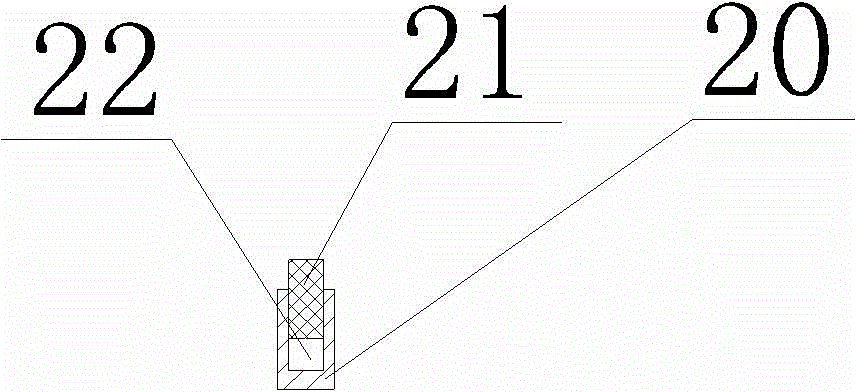

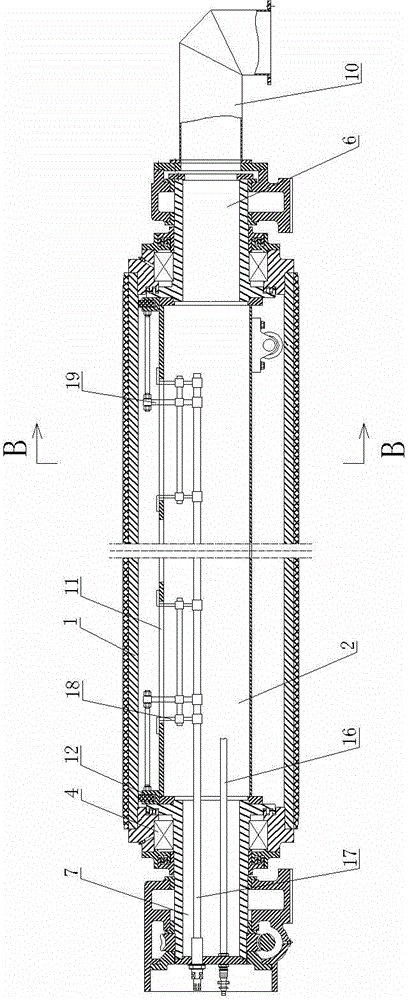

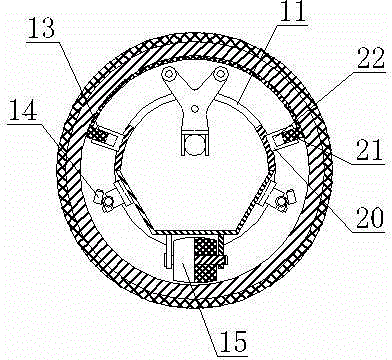

[0012] Such as figure 1 , figure 2 , image 3 As shown, the vacuum box of the vacuum roller of the paper machine according to the embodiment of the present invention includes a vacuum box 2. The vacuum box is arranged in the roll body 1, and two ends of the vacuum box 2 are respectively connected with a transmission side vacuum box head 6 A vacuum suction port 10 is connected to one end of the vacuum box head 7 on the transmission side and the vacuum box head 6 on the transmission side. A number of suction ports 11 are uniformly arranged on the vacuum box 2 along the axial direction. The vacuum box is provided with a sealing device near the inner wall of the roller. The device includes an end sealing device 12 and an axial sealing device 13. The end sealing device 12 is arranged at both ends of the vacuum box 2 along the arc of the vacuum box 2, and the axial se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com