Improved solar heat exchange water storage tank

A technology of solar energy and water storage tanks, applied in the field of improved solar heat exchange water storage tanks, to achieve the effects of reducing volume, ensuring water temperature, and optimizing the internal structure of the box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings.

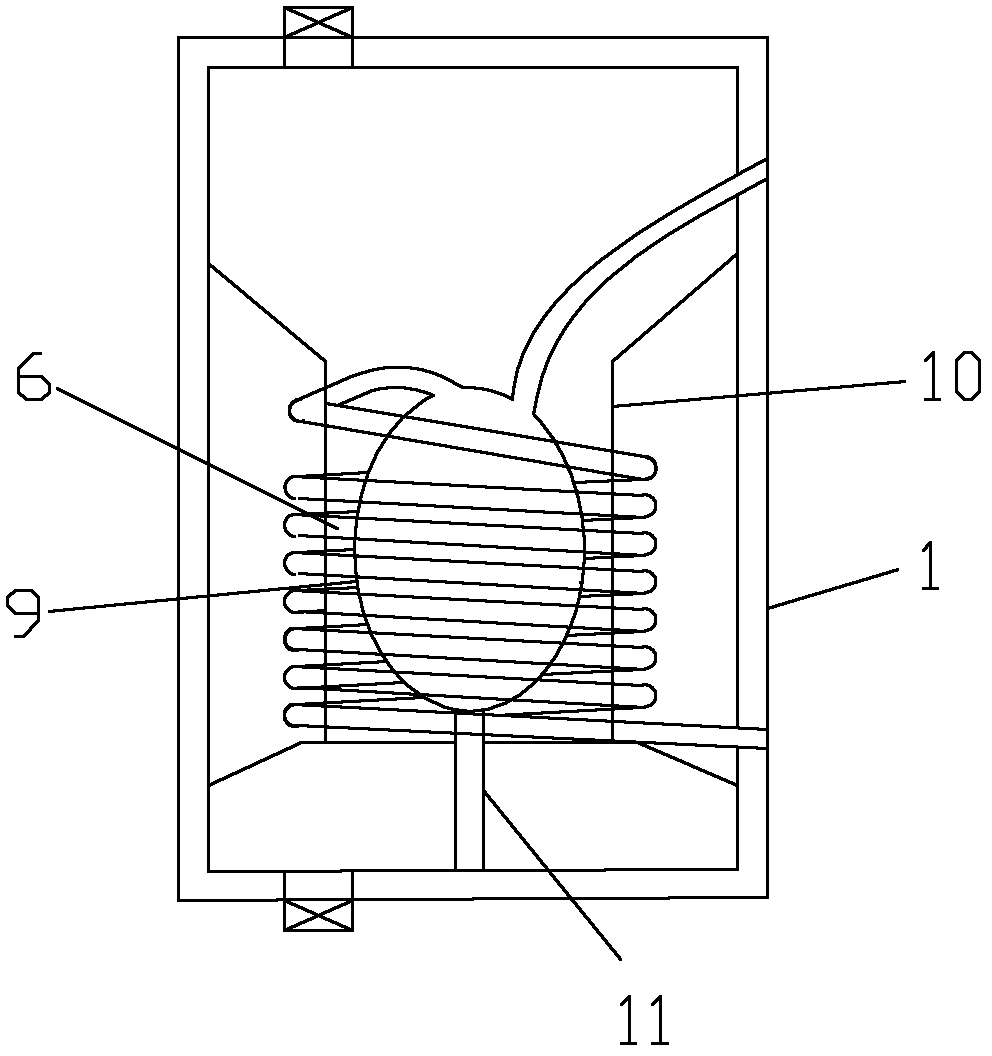

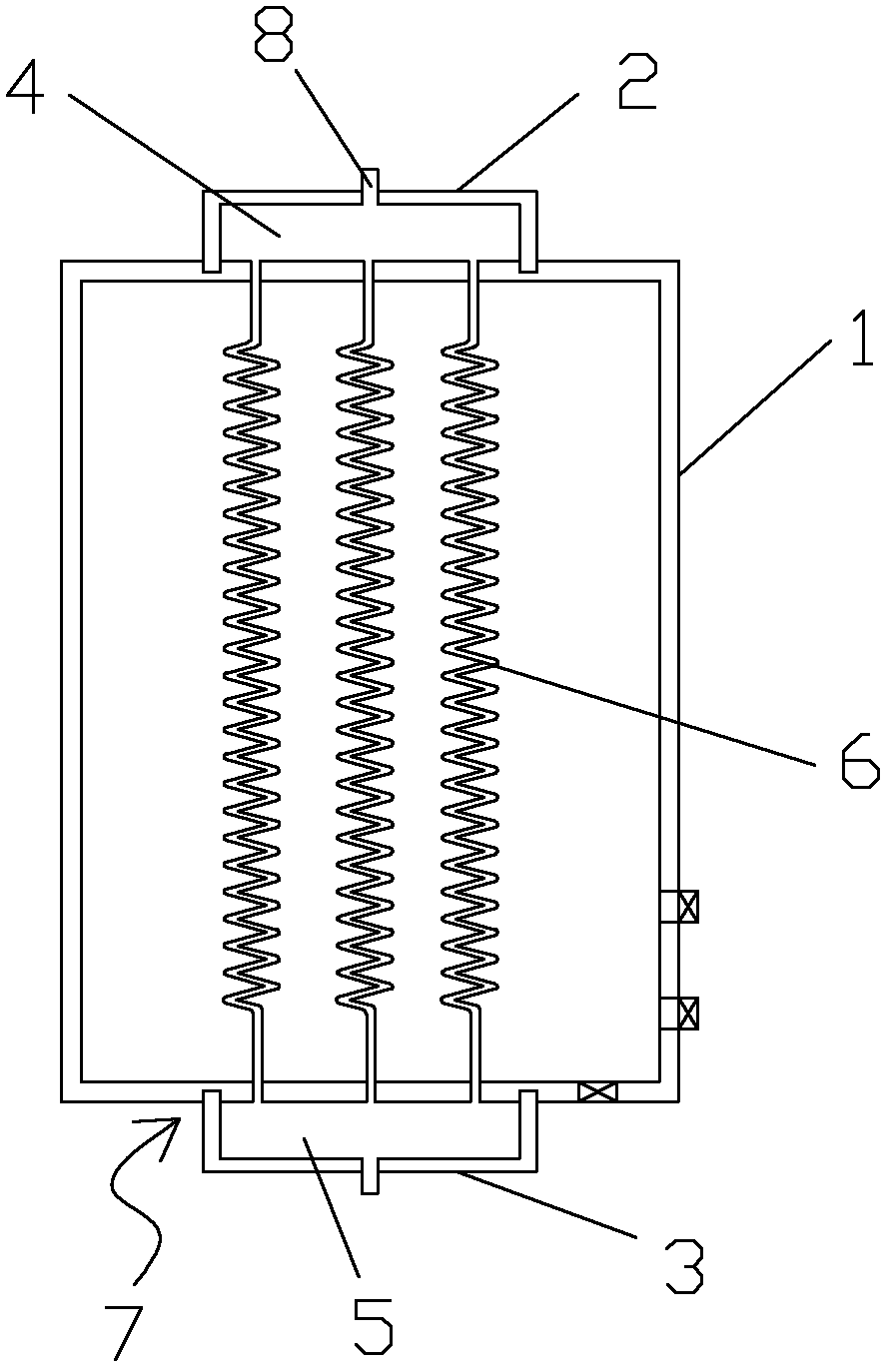

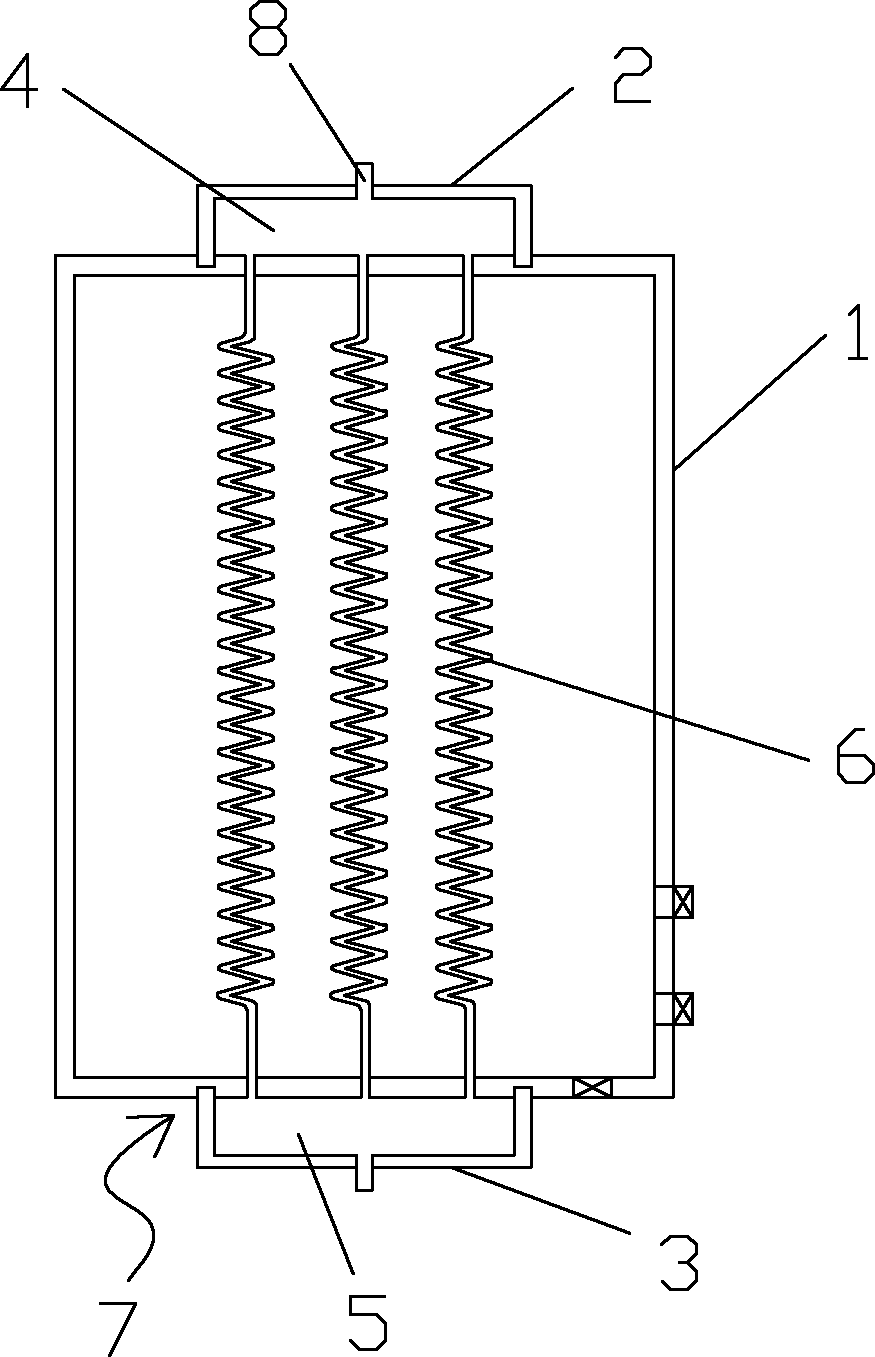

[0019] Such as figure 2 As shown, an improved solar heat exchange water storage tank described in this embodiment includes a hollow box body 1, and the upper and lower ends of the box body 1 are respectively provided with an upper end cover 2 and a lower end cover 3. Both the upper end cover 2 and the lower end cover 3 are recessed and respectively cooperate with the upper surface and the lower surface of the box body to form an upper cavity 4 and a lower cavity 5, and the upper cavity 4 and the lower cavity 5 pass through the box body through at least one The heat exchange tubes 6 communicate with each other, and the upper end cover 2 and the lower end cover 3 are both provided with connecting ports 8 communicating with their respective cavities. On the upper surface and the lower surface of the box body 1, a recessed ring 7 is preset, and the outer edge size of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com