SF steel comb-teeth-shaped telescopic device and installing construction method thereof

A telescopic device, comb-type technology, used in the erection/assembly of bridges, bridge parts, bridges, etc., can solve the problems of concrete cracking in the anchoring area, generating noise, affecting the surrounding environment, etc., to avoid sun exposure and prolong use. Longevity and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The SF steel comb-tooth type telescopic device and the installation and construction method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

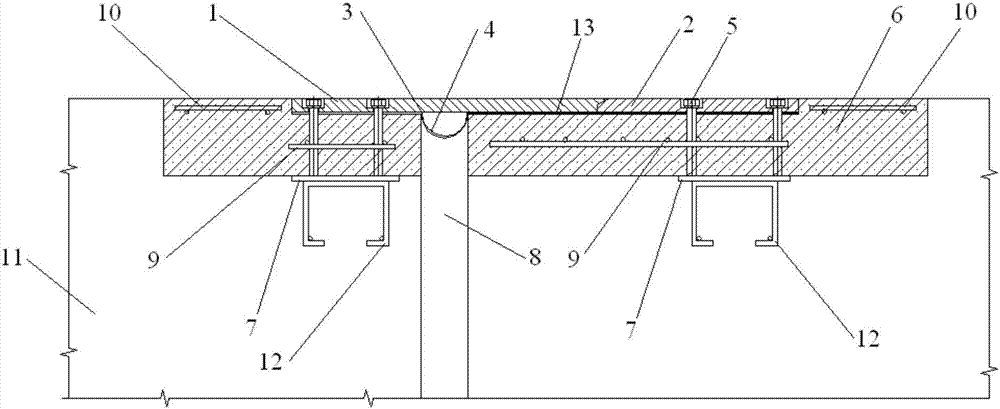

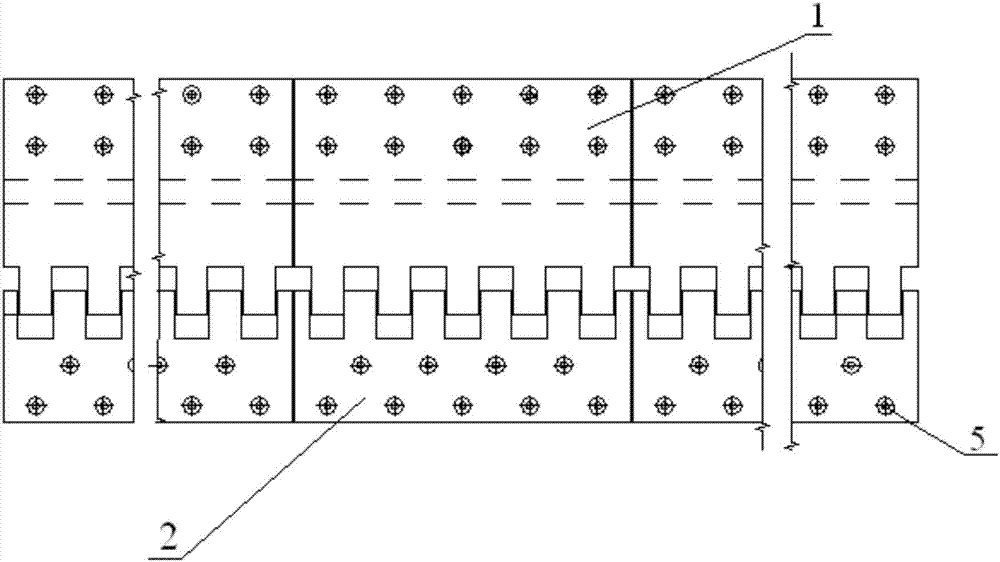

[0060] Such as figure 1 , 2 As shown, an SF steel comb-shaped telescopic device, the device includes a left comb-shaped steel plate 1 and a right comb-shaped steel plate 2, a comb-toothed plate wear-resistant layer 13, a stainless steel slide plate 3, a rubber sealing tape 4, and high-strength bolts 5. Post-cast concrete layer 6, embedded parts 7, bridge expansion joints 8, positioning steel plates 9, compression steel plates 10, concrete box girder 11 and pre-embedded steel bars 12, wherein the embedded parts 7 are fixed on the concrete box girder 11 On the pre-embedded steel bars 12, the two ends of the post-cast concrete layer 6 are respectively provided with compression steel plates 10, and the middle part of the concrete box girder 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com