Rotating pipe feed positioning mechanism for large-caliber pipes

A positioning mechanism and large-diameter technology, applied in metal processing, transportation and packaging, roller tables, etc., can solve the problems of large machine size, long adjustment time, and heavy fixtures, etc., and achieve flexible and convenient adjustment of the overall structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

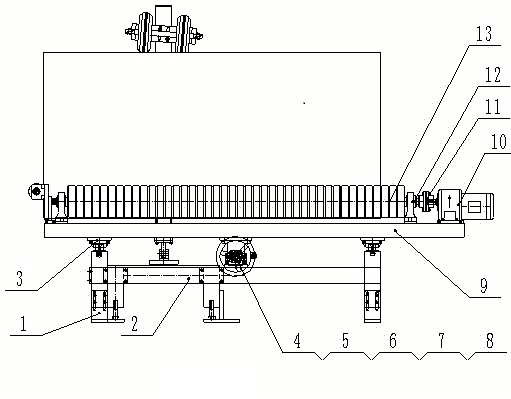

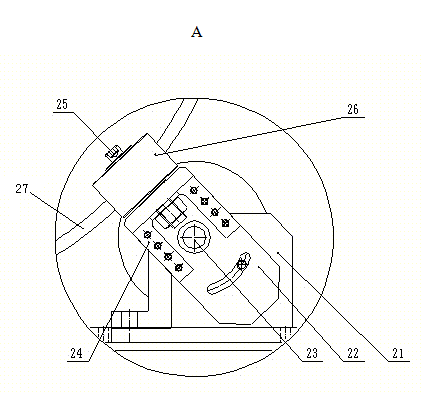

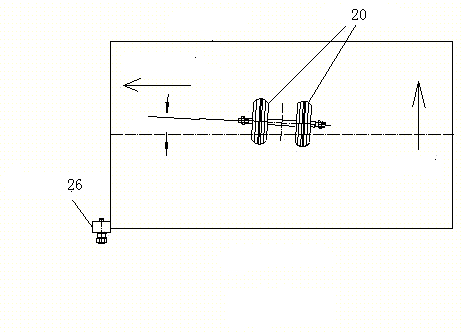

[0023] Such as figure 1 , figure 2 As shown, the present invention includes a machine foot 1 and an installation frame 2, the machine foot 1 supports and fixes the installation frame 2, and the installation frame 2 is successively provided with a rotating pipe mechanism and a rotating pipe feed limiting mechanism, and the rotating pipe A pipe pressing mechanism is provided on one side of the pipe mechanism, and the pipe pressing mechanism extends upward to the top of the pipe transfer mechanism, so that the pipe transfer mechanism, the transfer pipe feed limit mechanism and the pipe compression mechanism form a triangle to fix the pipe.

[0024] Among them, the pipe transfer mechanism includes linear guide rail 3, left and right screw rods 4, left screw sleeves 5, right screw sleeves 6, screw rod installation and fixing columns 7, hand wheels 8, rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com