Active Beam of a Segmental Turnout

An active beam and segment technology, applied in the field of rail transit system, can solve problems such as easy failure, increase failure sources, and difficult installation, save manufacturing costs and construction costs, reduce the type and number of parts, and simplify turnouts. The effect of beam structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

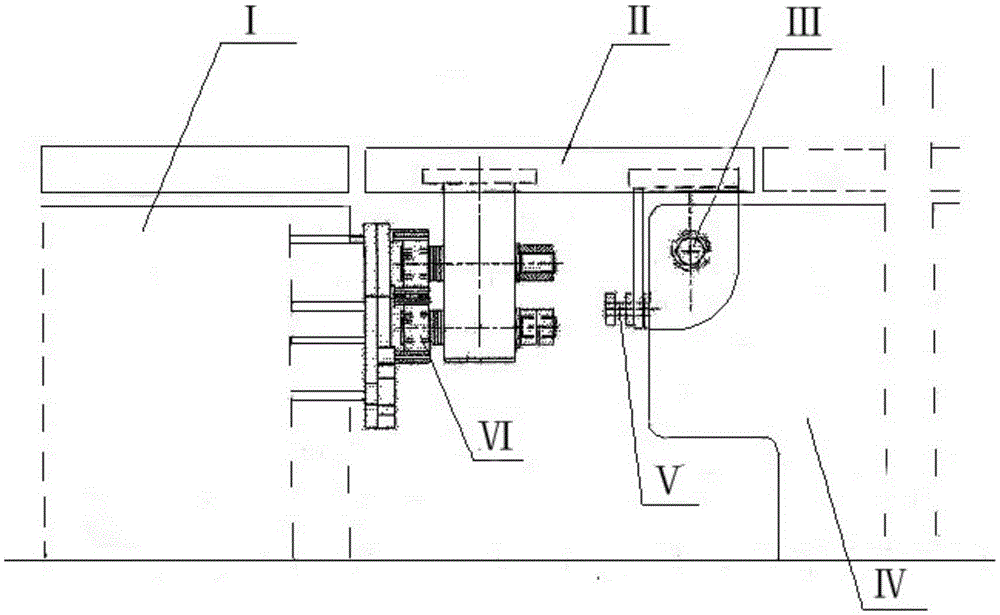

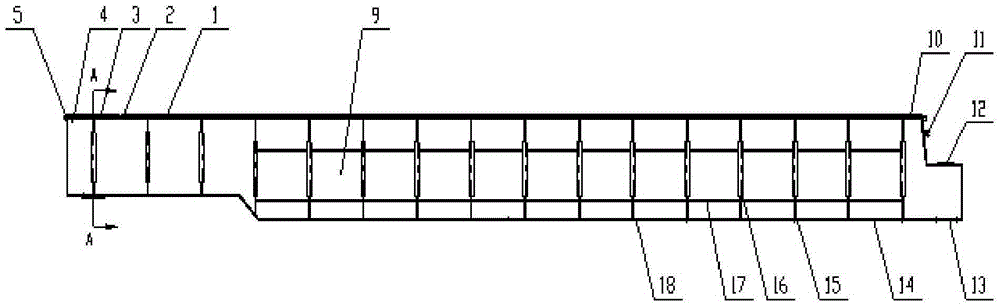

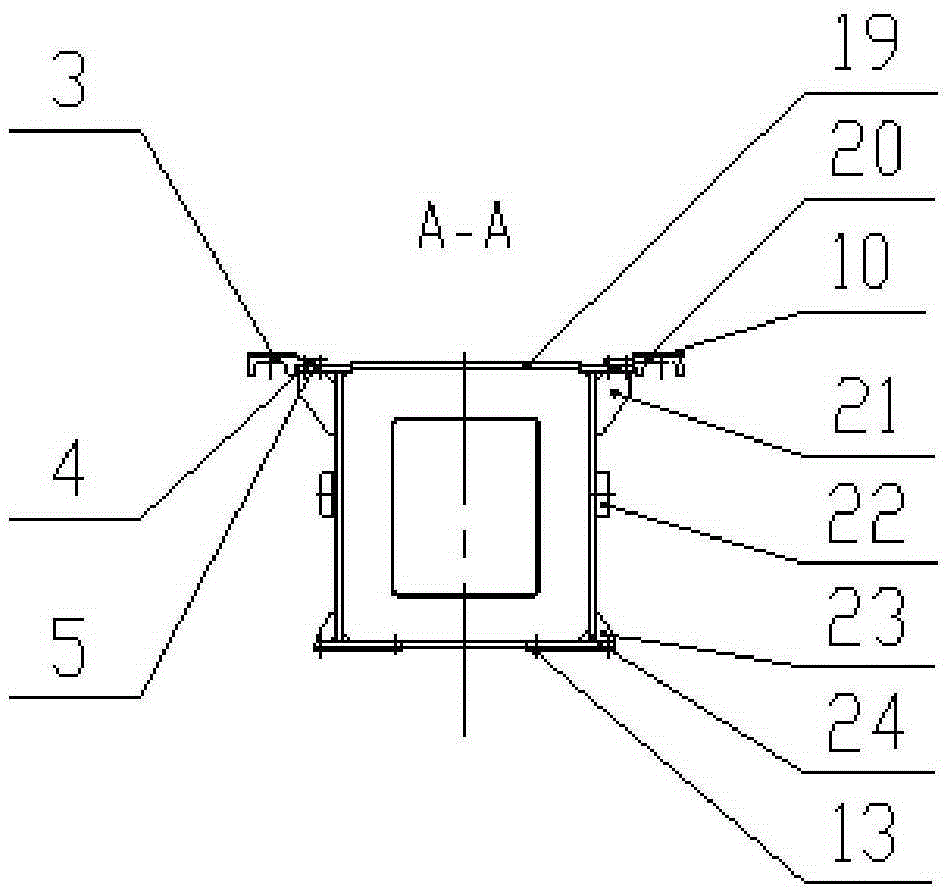

[0022] Figure 2-5 The active beam of a segmental turnout provided by the present invention is shown in the figure, comprising a main beam body 9, a main beam upper flange plate 10, a main beam F rail 1 above the main beam upper flange plate 10, an adjustment rail 3, and an F rail Mounting plate 2, mounting plate 5 and adjustment assembly 4, described adjusting rail 3 is used for main girder F rail 1 and is positioned at movable end stacking beam F rail 6 above the upper flange plate 8 of movable end stacking beam joint (connecting flat), described One end of the adjustment rail 3 and one end of the main beam F rail 1 are all fixedly arranged on the upper flange plate 10 of the main beam through the same F rail mounting plate 2, and the two are arranged to be flush in the height direction, and the adjustment rail The other end of 3 and / or its middle are fixedly connected to the upper flange plate 10 of the main girder through the adjustment assembly 4 and the installation plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com