Vertical force floating powder laying scraper device for metal additive manufacturing

A scraper device and metal additive technology are applied in the directions of additive manufacturing, additive processing, and process efficiency improvement, which can solve the problems of reducing the surface quality of molded products and increasing surface defects, and achieve the effect of simple structure and stable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

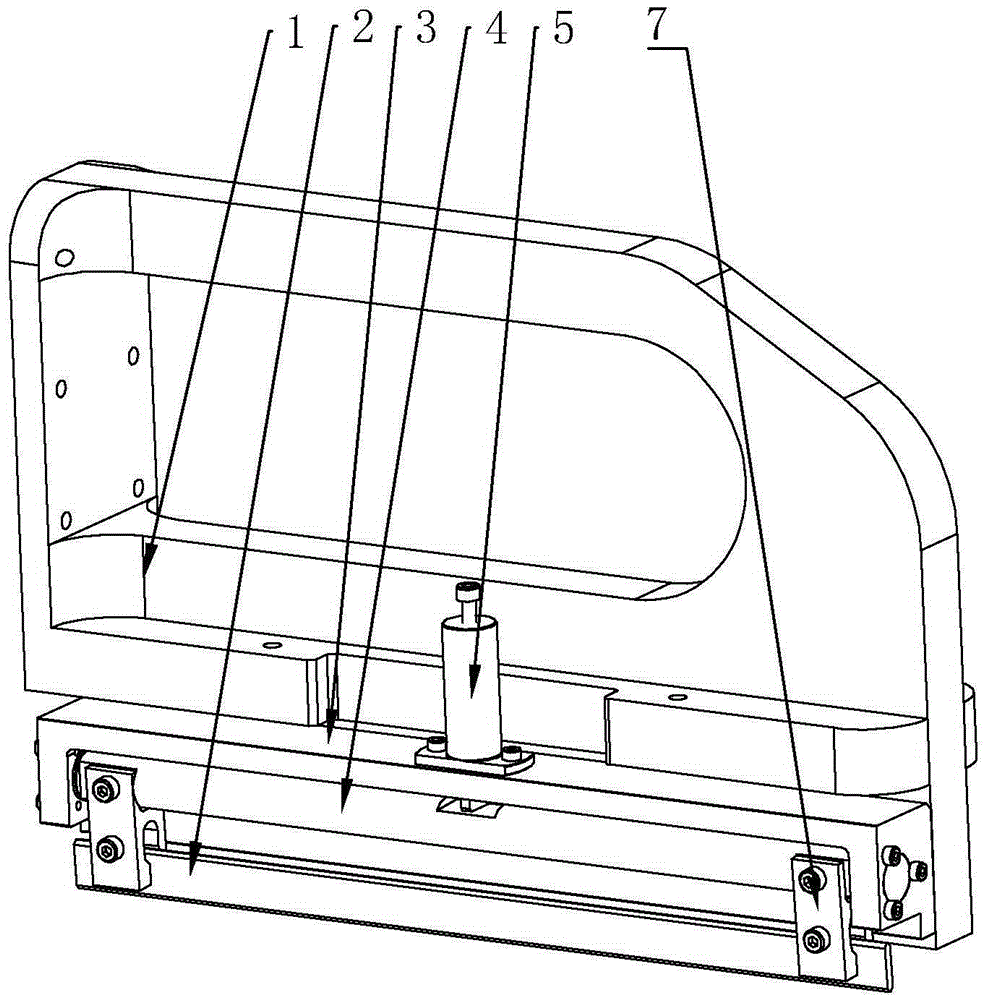

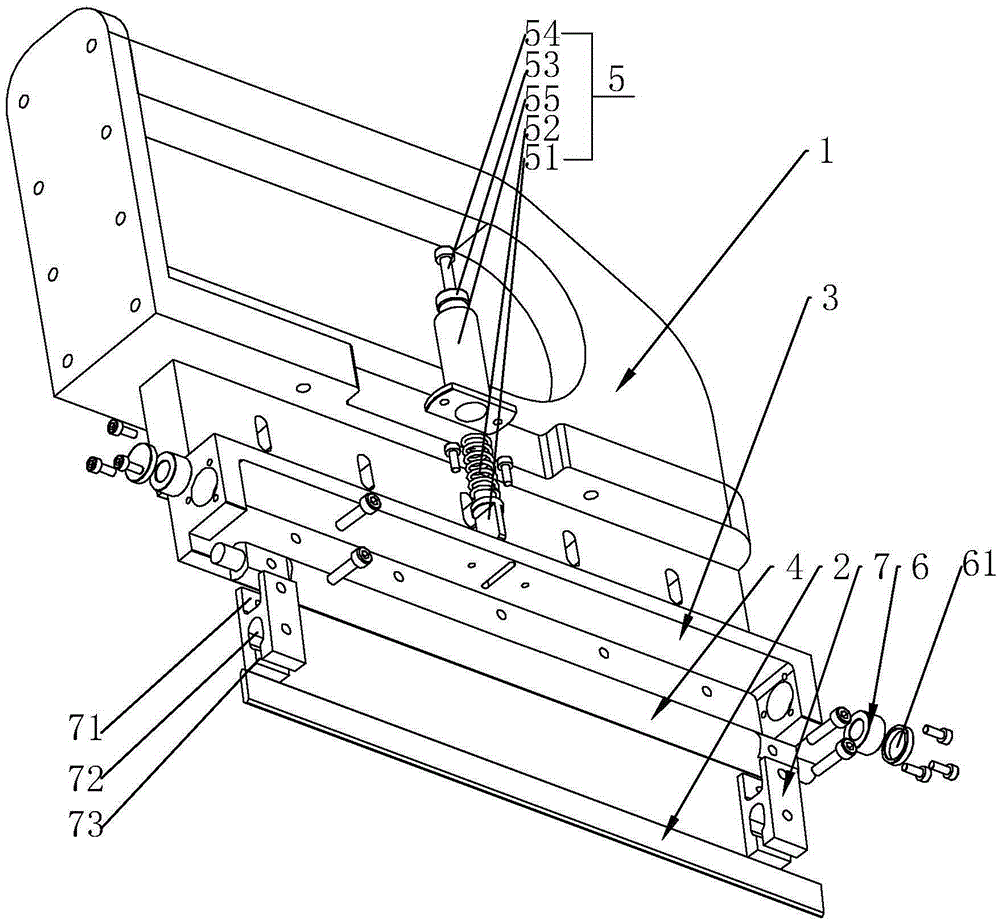

[0035] refer to Figure 1 to Figure 7 And embodiment the present invention is described further.

[0036] A vertical force floating powder spreading scraper device for metal additive manufacturing, such as figure 1 The three-dimensional structural view shown in includes a scraper bracket 1, a scraper 2 and a floating knife holder 3, wherein the scraper bracket 1 is externally connected with a power source that drives it to spread powder along a predetermined track on the powder bed, and the floating knife holder 3 is fixedly connected On the lower end face of the scraper support 1, a scraper 2 is fixedly connected at its lower end.

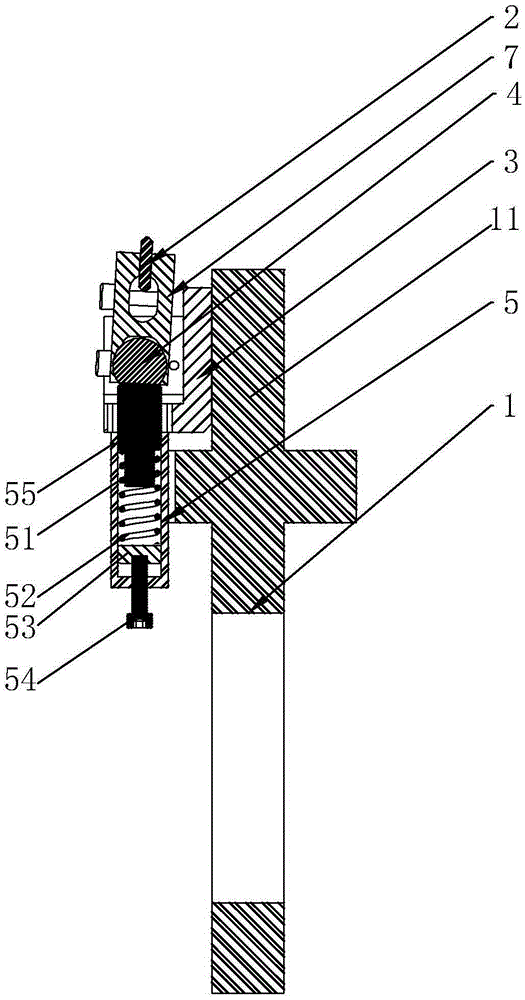

[0037] Specifically, as figure 2 As shown in the exploded view, the lower end of the scraper bracket 1 is provided with a mounting plate 11 along the extending direction of the scraper 2, and one end surface of the floating knife rest 3 is mounted on the mounting plate 11 and fixed to each other. There are a pair of supporting rotary holes 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com