Semiconductor component test carrier, test apparatus thereof and equipment

A technology for component testing and conductor components, applied in the direction of single semiconductor device testing, measuring devices, measuring electricity, etc., can solve problems such as easy displacement or jumping out of the carrier plate 97, and achieve convenient feeding and discharging efficiency, fast feeding. The effect of feeding and discharging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

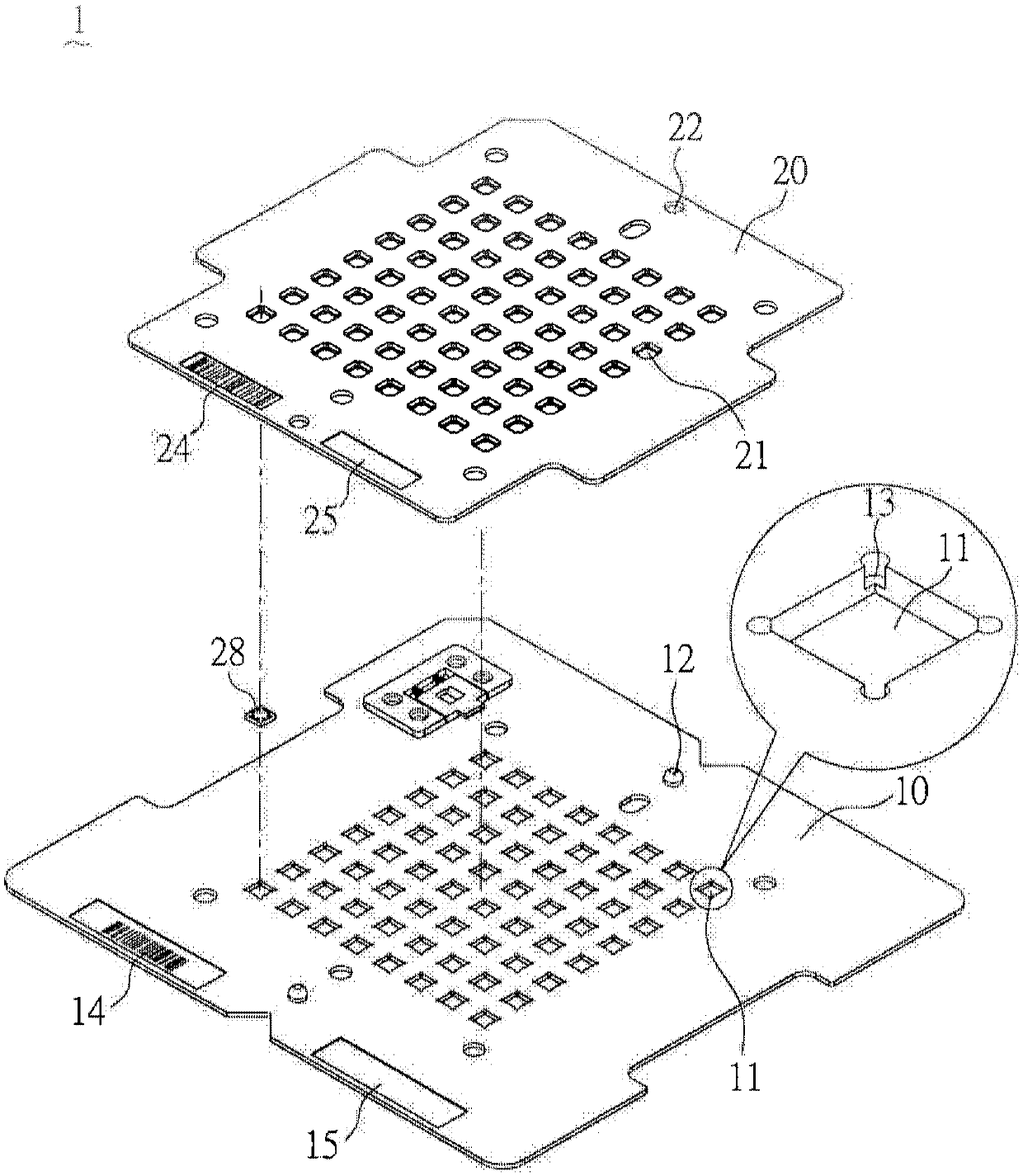

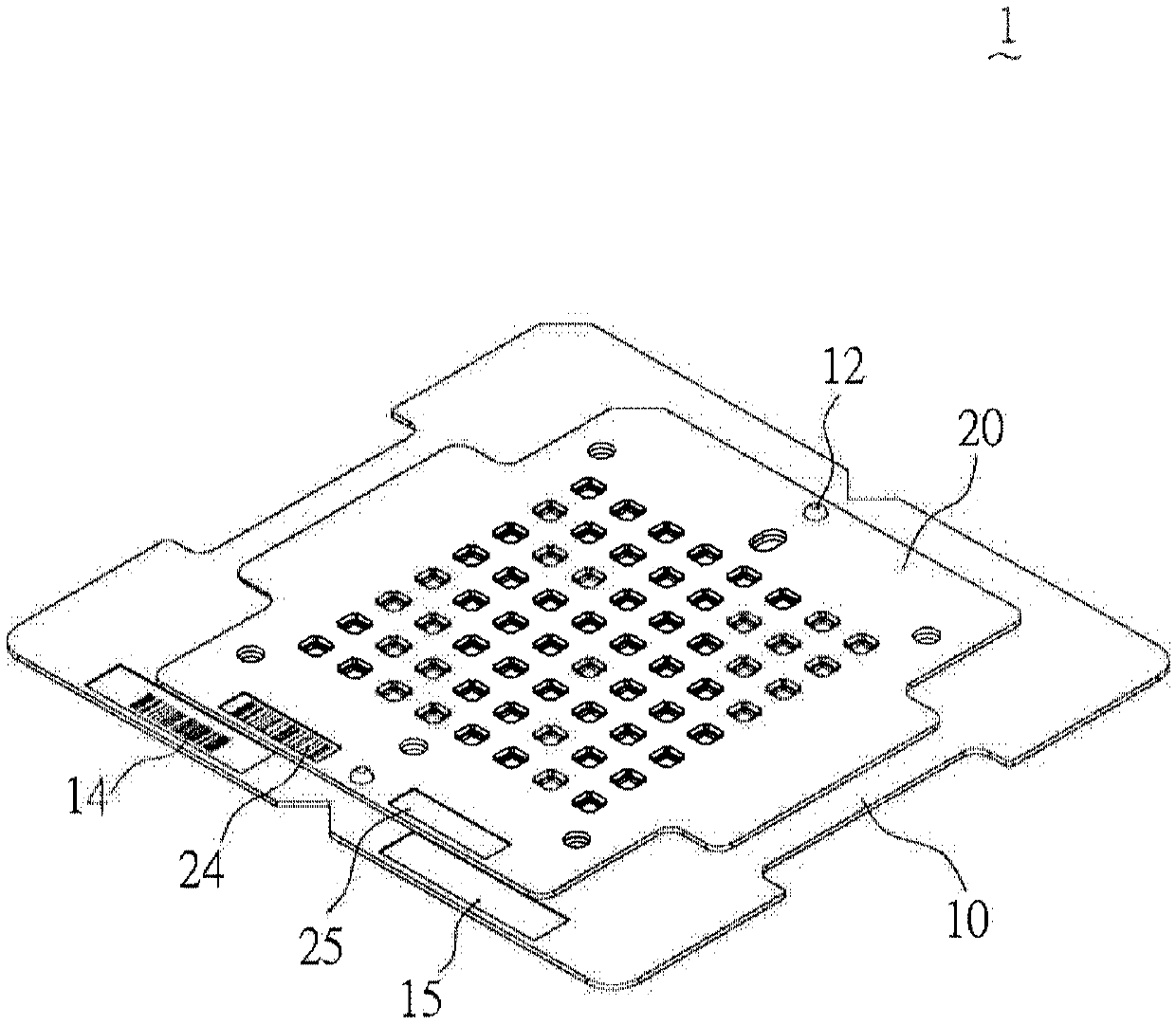

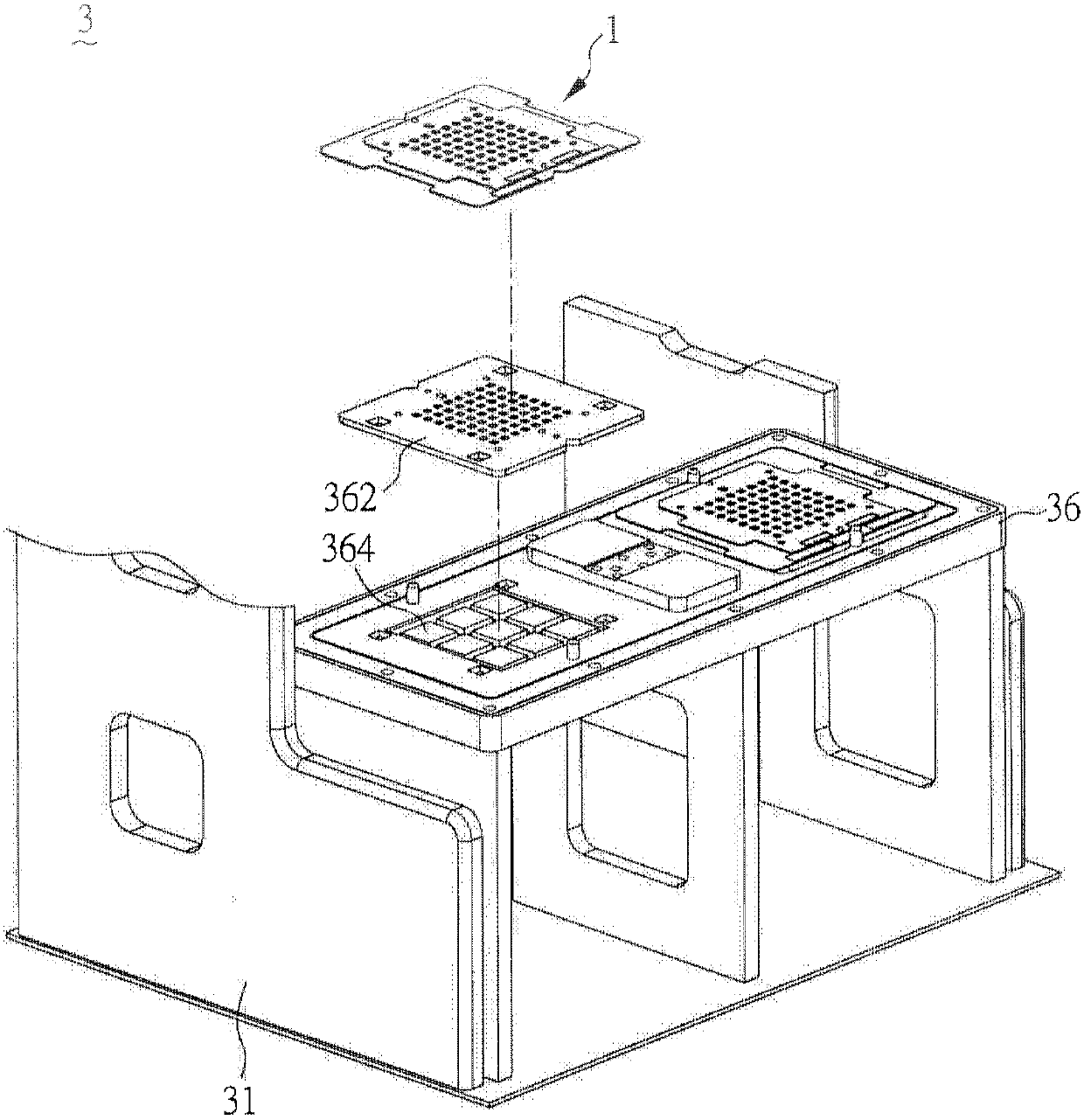

[0079] see figure 1 and figure 2 , which are respectively an exploded view and a perspective view of the semiconductor device test carrier according to the first preferred embodiment of the present invention. Shown in the figure is a semiconductor element test tray 1. The test tray 1 includes a bearing seat 10 and an upper cover 20. The bearing seat 10 has a plurality of through holes 11 and at least one positioning column 12. The upper surface of the bearing seat 10 is The surface has at least one groove 13 on the periphery of each through hole 11 for supporting a semiconductor element 28 . The upper cover 20 is covered on the bearing seat 10, and the upper cover 20 has a plurality of through holes 21 and at least one positioning hole 22, each through hole 21 corresponds to each through hole 11, and the at least one positioning hole 22 corresponds to the each through hole 11. At least one positioning column 12 is corresponding.

[0080] In this embodiment, the bearing ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com