New energy vehicle battery frame base transfer loading shelf

A technology for new energy vehicles and battery frames, which is applied to external frames, assembled vehicles, special packaging objects, etc., can solve the problems of small transportation volume of material racks, large logistics costs, and inappropriate frames, and achieve the effect of easy operation by manipulators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

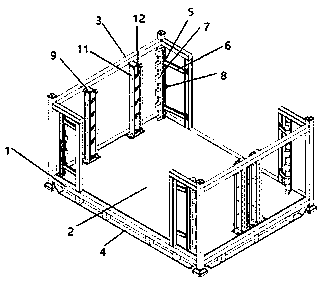

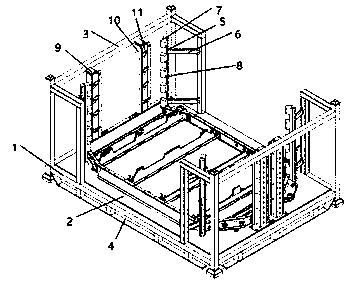

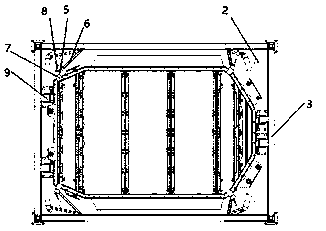

[0024] according to Figure 1 to Figure 4 , a new energy vehicle battery frame base turnover on-line material rack, comprising: a material rack main body 1, the material rack main body 1 is composed of a rectangular base 2 and two U-shaped ribs 3, and the two U-shaped ribs 3 Installed on the base 2, the two U-shaped ribs 3 are installed on two opposite short sides of the base 2, so that the rack has openings at the front and rear, so that the manipulator can grab the battery frame base from the opening. On both sides of 2, place and pick up in the up and down direction in the material rack.

[0025] A stabilizing bracket 4 is installed on each side of the lower end of the base 2, and the both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com