Water refrigerating device of exterior brake of grab bucket type grasping and digging crane

A technology of water cooling device and brake, applied in the direction of brake type, brake parts, hoisting device, etc., can solve the problems of reducing the service life of the friction belt, affecting production efficiency, friction belt wear, etc., to improve production efficiency and cool down Friction effect, effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

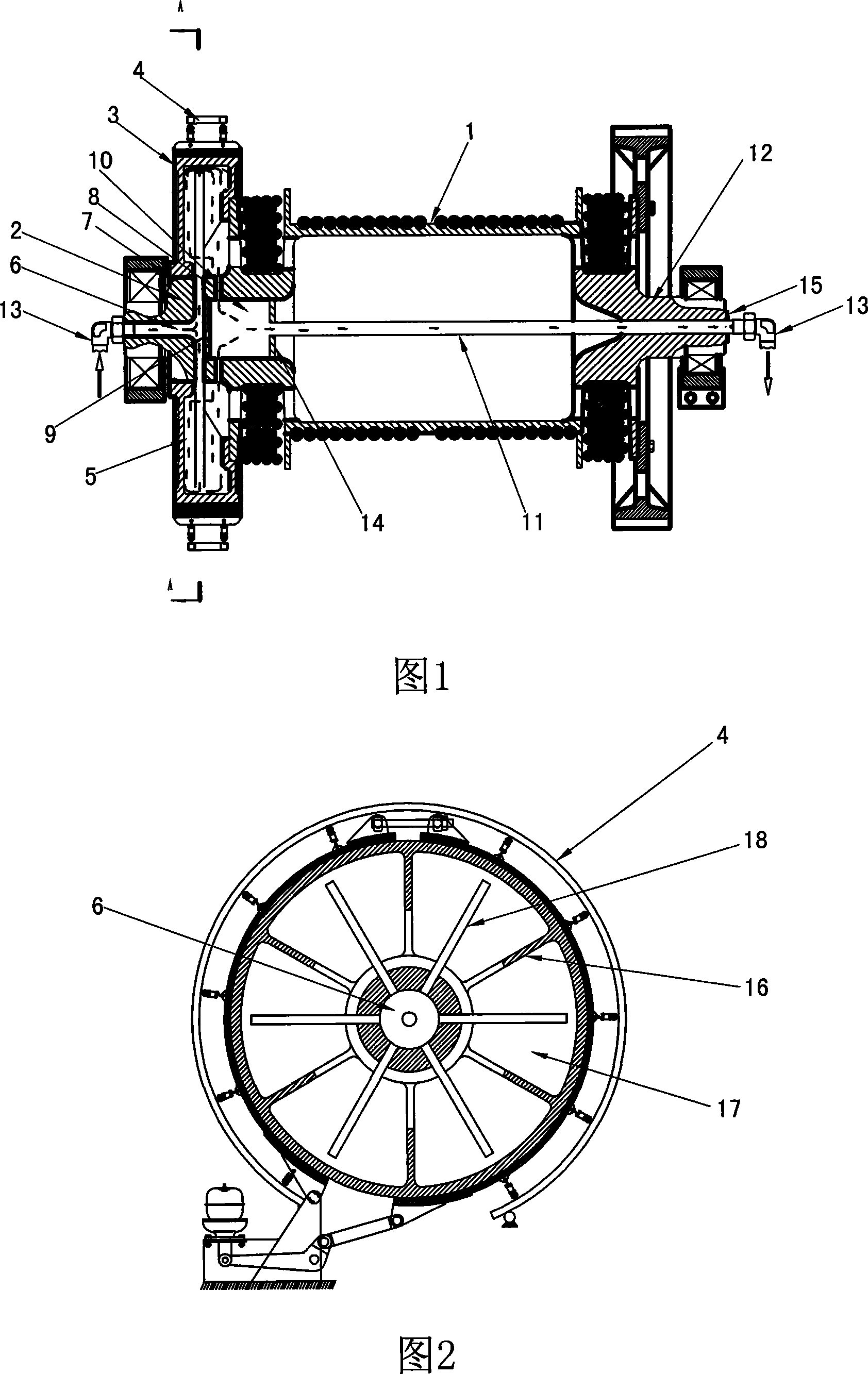

[0014] Referring to Fig. 1, an external brake is installed on the wheel hub 2 on one side of the wire rope drum 1 of the grab-type grabbing crane, wherein the external brake includes a brake 3 mounted on the drum hub 2 and an external brake mounted on the brake 3. Brake assembly 4.

[0015] As shown in the figure, a cooling chamber 5 is provided in the wire rope drum brake 3, a water inlet chamber 6 communicating with the cooling chamber 5 is provided in the hub 2 of the drum 1, and a Sealing ring 7. A water outlet chamber 8 is also arranged in the hub 2, and a water chamber partition 9 is arranged between the water outlet chamber 8 and the water inlet chamber 6. The cooling chamber 5 and the water outlet chamber 8 communicate through the water outlet hole 10 arranged on the hub 2, and the water The cavity partition 9 can prevent the cooling water from being disturbed in the whole cooling process, so that it flows according to the route of cold in and hot out, so as to achiev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com