Micro line segment dynamic prospect control method and micro line segment dynamic prospect control device

A control method and line segment technology, which are applied in digital control, program control, electrical program control, etc., can solve the problems of lack of fitting and low processing efficiency, and achieve the effect of reducing storage space, improving interpolation accuracy, and improving machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

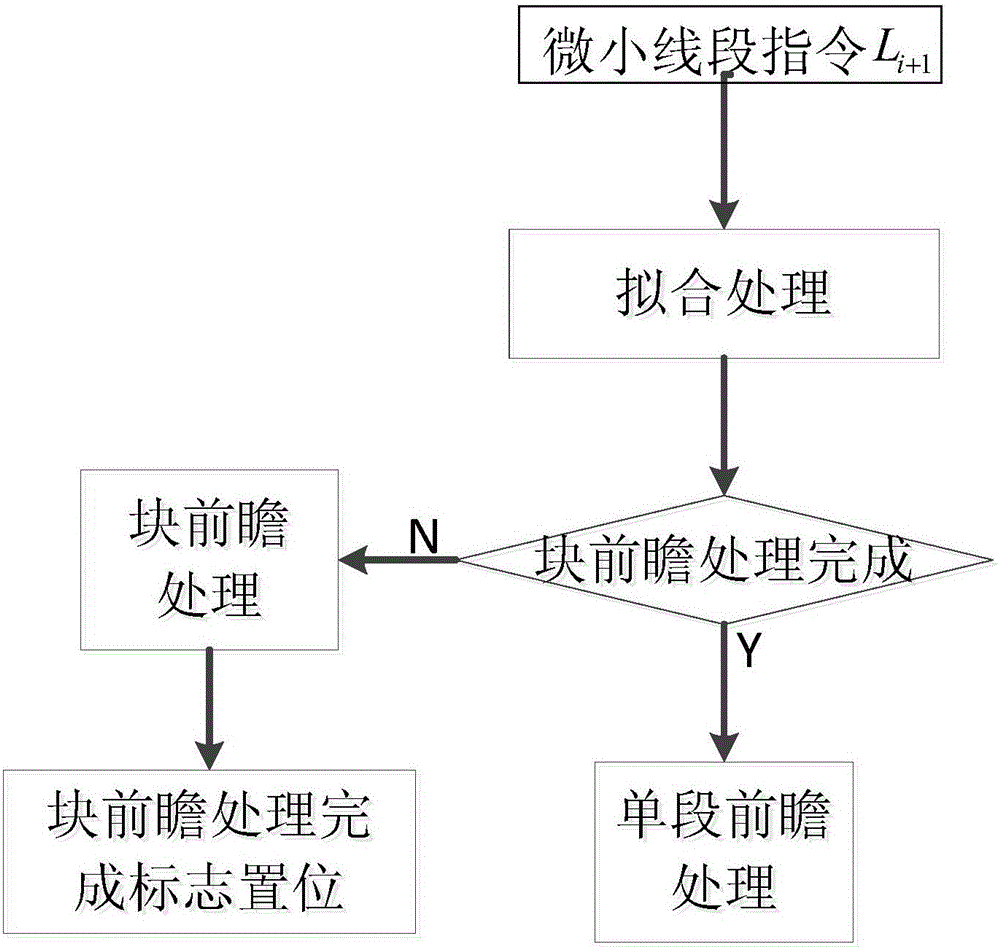

[0063] like figure 1 Shown is a timing logic of fitting processing, block forward processing and segment forward processing, that is, the fitting process is performed first, and then it is judged whether the block forward processing is completed. If it is not completed, the block forward processing is performed, and if it is completed, the segment Lookahead processing.

[0064] In the actual control, other different sequential logics can also be used, or one or two kinds of processing can be omitted, such as only fitting processing and block forward processing, etc. are performed. Various sequential logics based on the above three processes are within the protection scope of the present invention.

[0065] The logic of Embodiment 1 will be described below. After the motion control system receives the tiny line segment instruction, it includes the following processing steps:

[0066] 1. Fitting processing

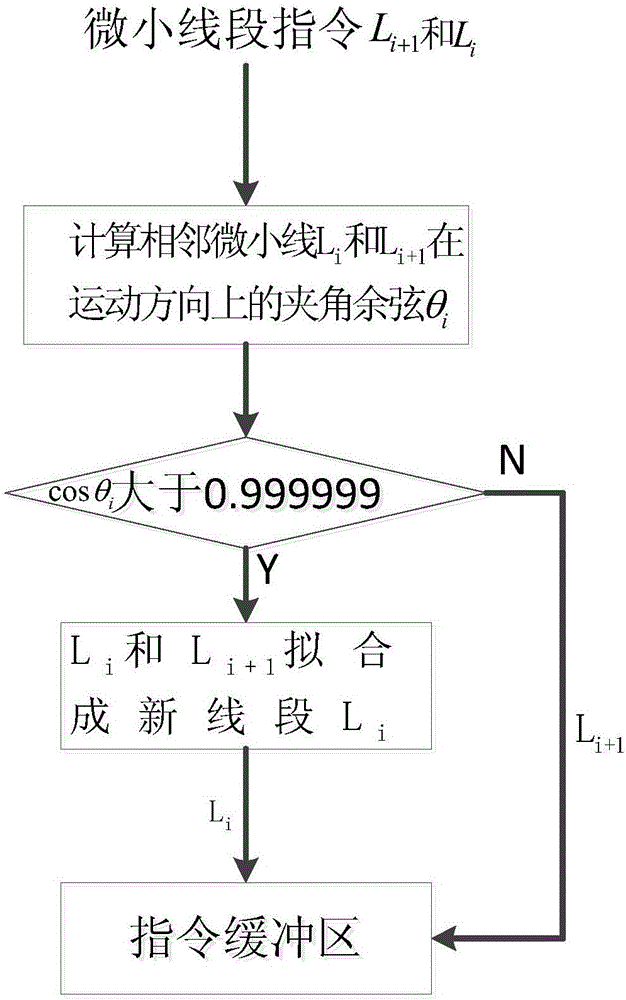

[0067] The principle of fitting processing is to do corresponding f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com