Efficient motor shaft

A motor shaft, high-efficiency technology, applied in the direction of shafts, shafts and bearings, mechanical equipment, etc., can solve problems that affect work efficiency, offset, gear or bearing beating, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

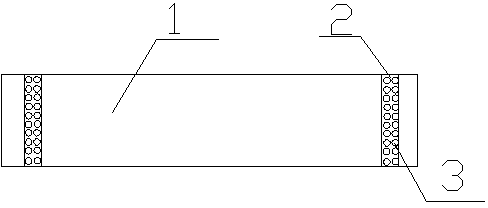

[0010] Such as figure 1 It is a structural schematic diagram of the present invention, a high-efficiency motor shaft, including a motor shaft body 1, a sleeve 2 is respectively provided on the motor shaft body 1 near the front end and the rear end, and there are several raised convex surfaces on the sleeve 2 3. Preferably, the material of the sleeve 2 is elastic rubber.

[0011] In the present invention, a sleeve 2 is sheathed on the motor shaft body 1, and the sleeve 2 has a raised convex surface 3, which can prevent the gears sleeved on the motor shaft from bouncing and shifting during operation, greatly improving work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com