Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Meet molding needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

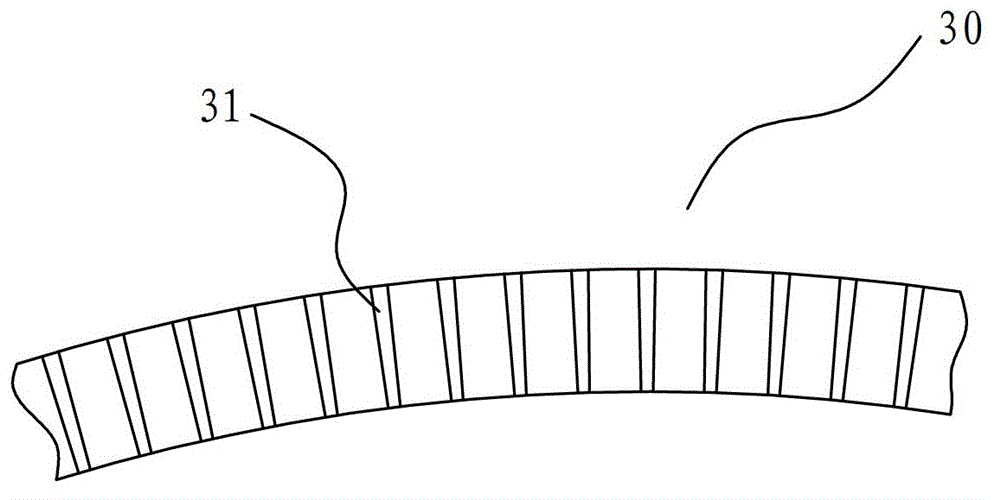

Processing technology of arc-shaped spring

ActiveCN102501009ASmall thermal relaxation rateLarge momentary torqueFurnace typesHeat treatment furnacesStress reliefMaterials science

The invention relates to a processing technology of a large-radian arc-shaped spring. The processing technology is characterized by comprising the following procedures of: spring coiling: primary stress relief annealing; spring grinding; spring bending into an arc-shaped spring; secondary stress relief annealing; shot blasting; hot-strong pressing; sorting; angular rigidity and torque test; fatigue life test; and surface antirust treatment. According to the forming technology of the arc-shaped spring provided by the invention, the arc-shaped spring with the free angle of being more than 45 degrees can be effectively formed, the thermal relaxation rate of the spring is less than 2%, the instantaneous torque is large, the fatigue life is 1 million times, and the technical problems of low finished product rate and incapability for normal use of the large-radian arc-shaped spring in the prior art are solved.

Owner:HANGZHOU FUCHUN SPRING

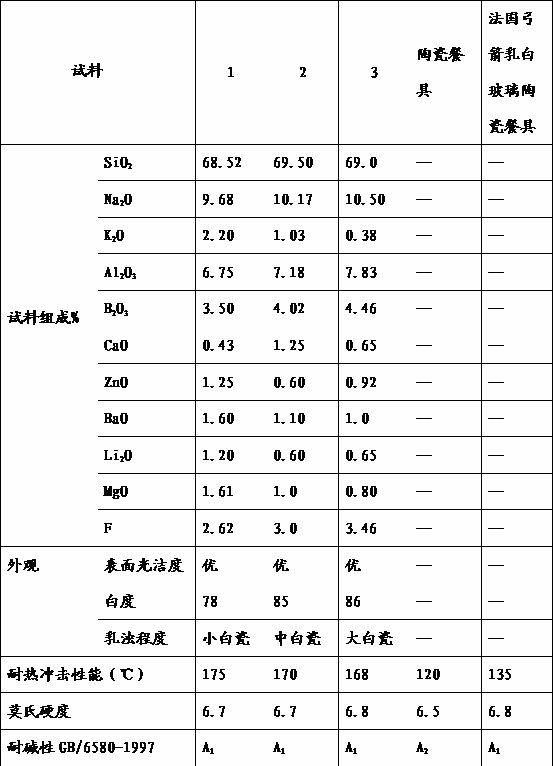

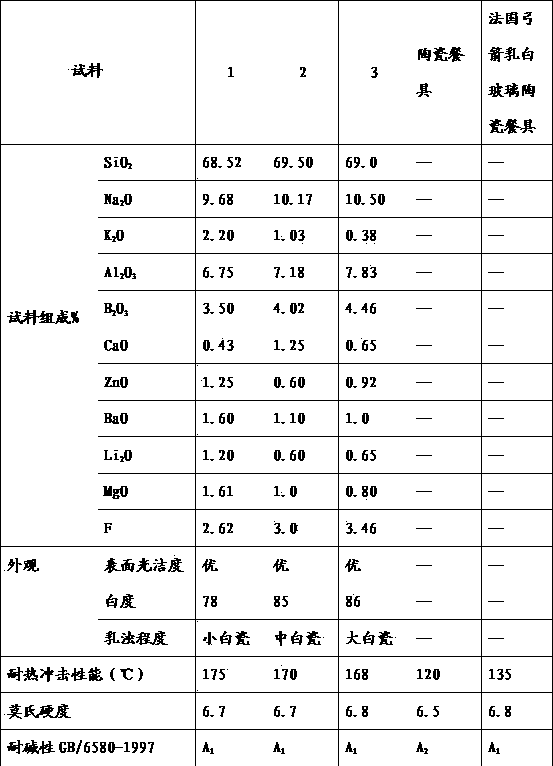

Milky white glass ceramic suitable for all electric melting and preparation process for milky white glass ceramic

The invention provides a milky white glass ceramic material and a preparation process thereof. The milky white glass ceramic material contains the following components: 67 to 74 percent of SiO2, 8.0 to 12 percent of Na2O, 0.3 to 2.5 percent of K2O, 6 to 9 percent of Al2O3, 3 to 5 percent of B2O3, 0.3 to 2 percent of CaO, 0.3 to 2 percent of ZnO, 0.5 to 2.5 percent of BaO, 0.3 to 2 percent of MgO, 2.5 to 4.8 percent of F and 0.5 to 2 percent of Li2O. The material is prepared by the following steps of: (1) weighing the following raw materials in part by weight: 4 to 9 parts of alumina powder, 0.5 to 3 parts of barium carbonate, 0.15 to 3.5 parts of calcium carbonate, 0.5 to 3 parts of fluorite, 0.5 to 4 parts of dolomite, 0.5 to 5 parts of potassium nitrate, 0.3 to 2 parts of magnesium oxide, 5 to 11 parts of borax pentahydrate, 5 to 10 parts of soda ash, 3.5 to 9 parts of sodium fluosilicate, 7 to 20 parts of albite, 1 to 5 parts of sodium nitrate, 50 to 70 parts of quartz sand, 0.25 to 2 parts of zinc oxide and 1 to 5 parts of lithium carbonate, and mixing the raw materials to obtain a batch; (2) putting the batch into an electric melting furnace, and performing all electric melting at the temperature of between 1,320 and 1,520 DEG C to obtain molten glass; (3) adjusting the temperature of the molten glass, and molding in a mould by a pressing or centrifugal method; (4) putting a molded product into an annealing kiln, and annealing at the temperature of between 530 and 620 DEG C for more than 60 minutes; and (5) performing toughening treatment after annealing.

Owner:WENZHOU HUISHUNDA IND TRADE

Medium-strength and high-ductility titanium alloy

InactiveCN101476059AReduced cold workabilityImproved cold working propertiesForeign matterElectric arc furnace

The invention belonging to a low cost titanium alloy for sports products and other civil industries, relates to mezzo-forte high-ductility titanium alloy.The invention is characterized in that the components of the mezzo-forte high-ductility titanium alloy are aluminum of 2-4.5% by weight, molybdenum is 0.1-1.5% by weight, zirconium is 0.5-2% by weight, Fe is 0.1-1.5% by weight, and the rest is Ti and ineluctable foreign matters; the sum of each component content of the raw material is 100%. The manufacturing process comprises the following steps: batching according to a certain weight percentage, batch mixing and pressing to form consumable electrodes, performing a second smelting in the vacuum consumable arc furnace, and then making casting ingot into casting ingot boards.Because of the solution strength effect of aluminum, zirconium, molybdenum, vanadium, iron and the like, the titanium alloy of the invention can remain a definite strength level, the cost of the raw materials of the alloy can be reduced, cold working performance of the alloy is improved, the cold deformation amount is increased, the process flow is shortened, and correspondingly, the processing cost of the materials is reduced, processing performances of winding, bending, press forming and the like of the materials are improved, and shaping requirements of users can be further satisfied.

Owner:BAOJI TITANIUM IND CO LTD

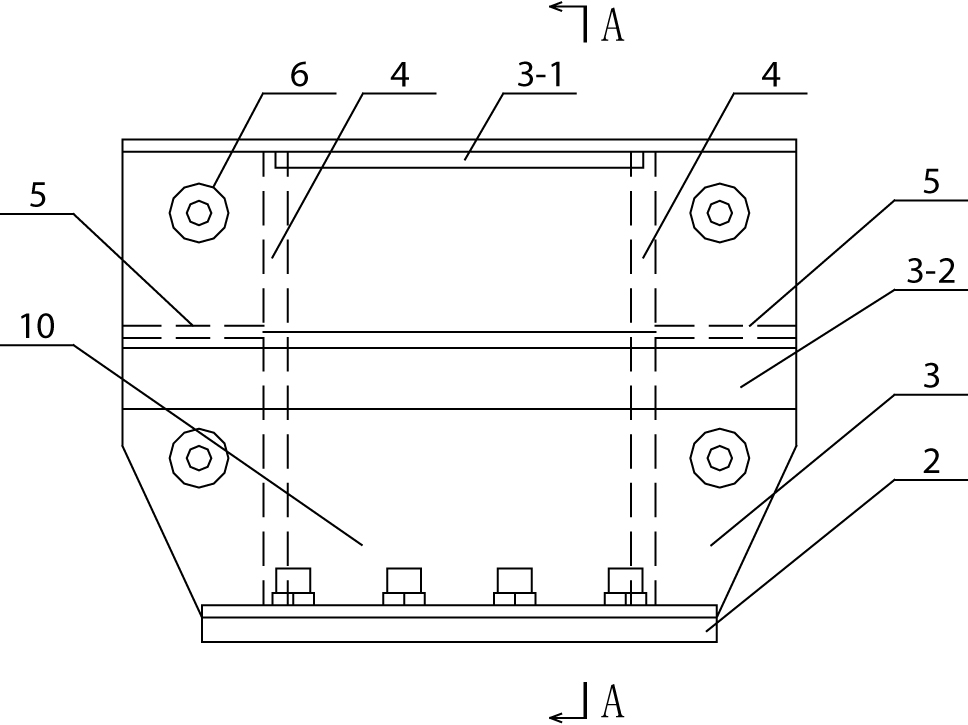

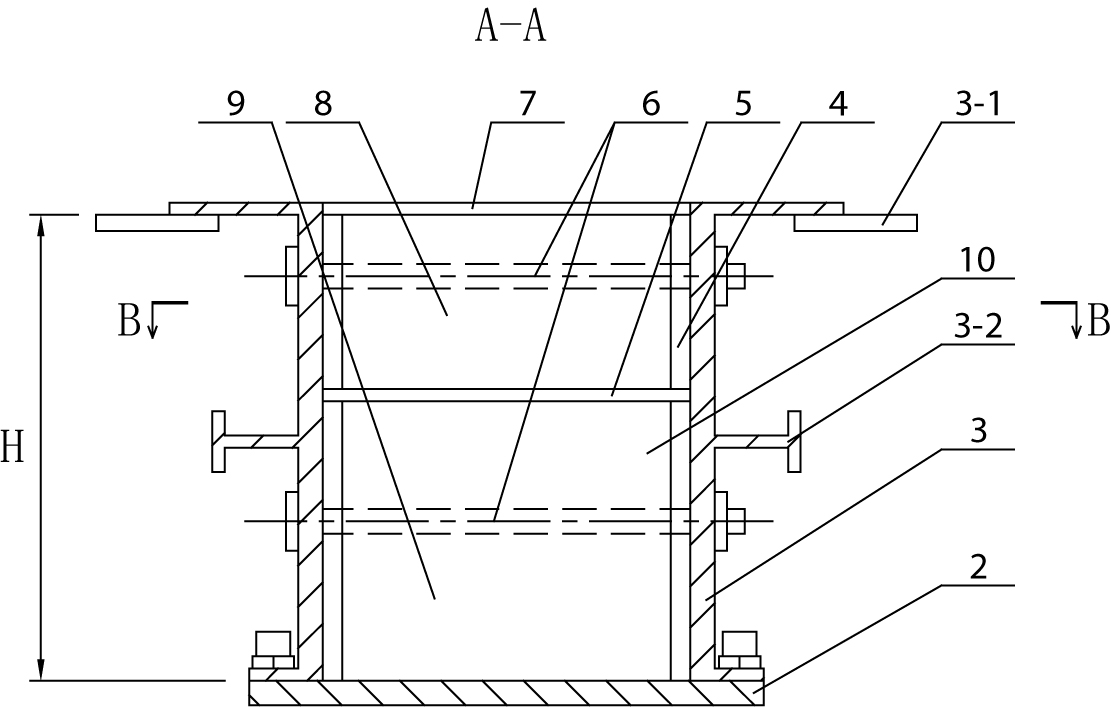

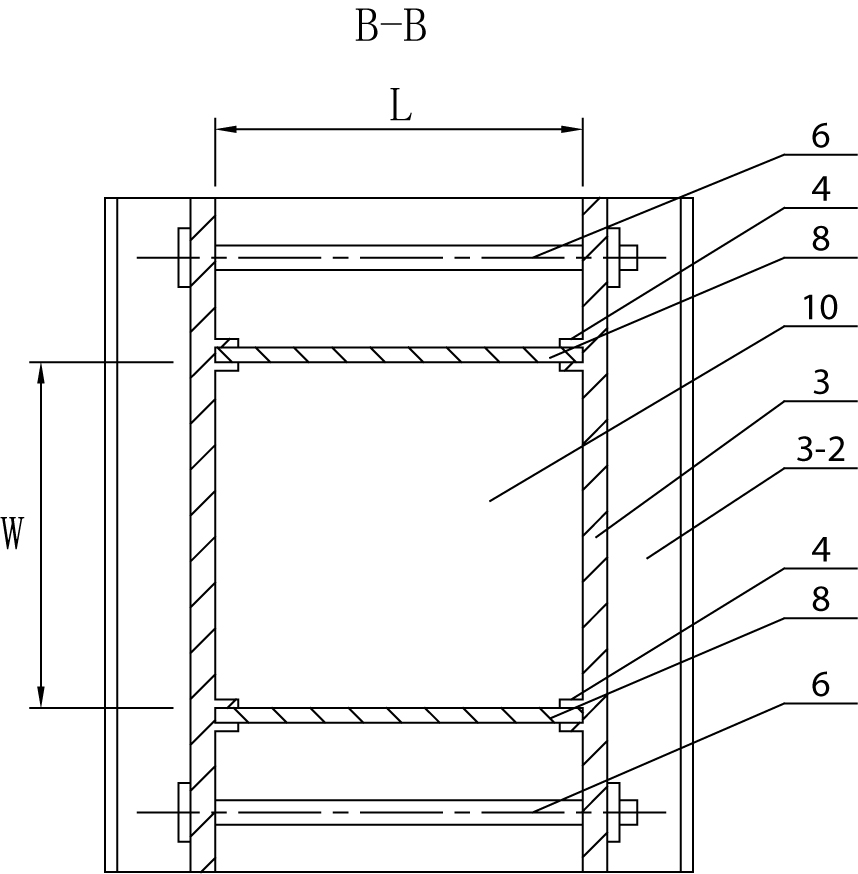

Test piece preparation mould special for shearing test and preparation method thereof

InactiveCN101871863AEasy to disassembleSatisfy IntegrityPreparing sample for investigationStrength propertiesEngineeringSurface layer

The invention discloses a test piece preparation mould special for a shearing test and a preparation method thereof, and relates to the technical field of road inter-layer binding performance tests. The invention solves the problems that no special forming mould for preparing a test piece is available and in the conventional method, the uniformity of the structures at the middle base and the surface layer is poor, the strength of the cut base layer of the test piece is reduced and the accuracy of the test result is affected. Two parallel side plates in the mould are connected with the two ends of a supporting bottom plate; two pairs of slots are oppositely formed in the inner walls of the two side plates; split bearing baffles are symmetrically inserted between two bearing baffles through the slots; the method comprises the following steps of: 1, uniformly stirring broken stones, water and cement and pouring the mixture into a mould provided with a second split bearing baffle; 2, controlling the speed of a pressure head so that the distance between the pressure head and the upper end of the second split bearing baffle is 40 mm; 3, coating priming oil on the test piece and then standing for 24 hours; 4, after the priming oil penetrates, arranging a first split bearing baffle, sealing with the broken stone and placing the sealed first split bearing baffle on the test piece for 4 hours; 5, pressing and forming; and 6, demoulding and preserving. The test piece preparation mould is used for a shearing test for measuring the road interlayer binding performance.

Owner:HARBIN INST OF TECH

Novel copper conductive printing ink

The invention provides a novel copper conductive printing ink. The novel copper conductive printing ink is prepared from following main raw materials: 45 to 55% of copper powder, 20 to 25% of an adhesive, 10 to 15% of a solvent, 4 to 6% of a coupling agent, and the balance an additive. IIngredient supplement of the novel copper conductive printing ink is reasonable; preparation cost is low; and the novel copper conductive printing ink is excellent in conductive performance and adhesive force, possesses excellent high temperature oxidation resistance, and is capable of satisfying moulding demands of a plurality of printed circuits.

Owner:SUZHOU ZHONGYA INK

Machining process of arc spring

InactiveCN108747218ASmall thermal relaxation rateLarge momentary torqueWire springsLife testingControl theory

The invention relates to a machining process for an arc spring. The machining process for the arc spring is characterized by comprising the following working procedures of spring coiling, first-time stress relieving, spring grinding, bending for the arc spring, second-time stress relieving, shot blasting, hot stressing, sorting, angle rigidity and torque testing, fatigue life testing and surface rust-proof treatment. The forming process of the arc spring is provided, and by means of the forming process, the arc spring with the free angle larger than 45 degrees can be effectively formed, it isguaranteed that the hot relaxation rate of the spring is smaller than 2 %, the instantaneous torque is large, and the fatigue life is one million times or above; and the technical problems that in theprior art, the yield of the large-angle arc spring is low, and the large-angle arc spring cannot be normally used are solved.

Owner:JIANGSU XIANGYING HARDWARE SPRING CO LTD

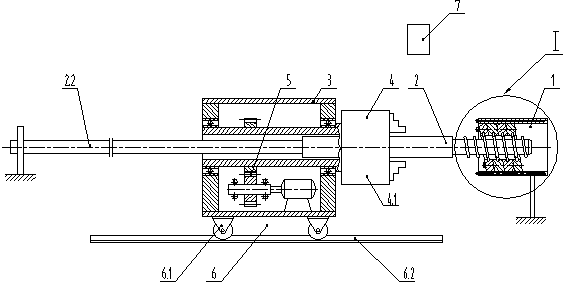

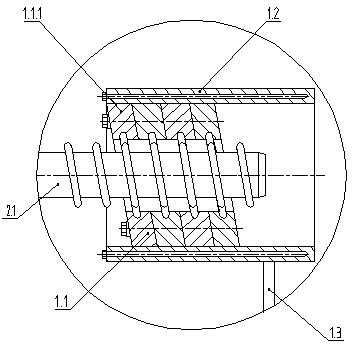

Spiral polytetrafluoroethylene bellows forming machine

The invention discloses a spiral polytetrafluoroethylene bellows forming machine, which includes an inner mold component, an outer mold component, a rack, a clamping component, a transmission mechanism, a movement component, and a circuit control system. The clamping component is supported by the rack and is driven by the transmission mechanism. The clamping component includes a chuck with a horizontal axis and an inner hole. The inner mold component includes an inner mold sleeve, the inner wall of the inner mold sleeve's inner hole is provided with spiral corrugated grooves. The outer mold component includes an outer mold shaft and a fixedly disposed outer mold shaft connecting rod. The outer wall of the outer mold shaft is provided with spiral corrugated projections. The outer mold shaft connecting rod or outer mold shaft runs through the chuck inner hole and is in butt joint connection. The inner mold sleeve is disposed on the right side of the chuck, the spiral corrugated grooves of the inner mold sleeve is in coaxial nesting connection with the spiral corrugated projections of the outer mold shaft, and is coaxial with the chuck axis. The forming machine provided by the invention has the characteristics of simple structure, small volume and low cost. The outer mold shaft and the inner mold sleeve are convenient to adjust, and can be rapidly adjusted for forming products. Through control of the heating temperature, a good forming effect can be acquired.

Owner:JIANGSU MAITENG PIPELINE EQUIP

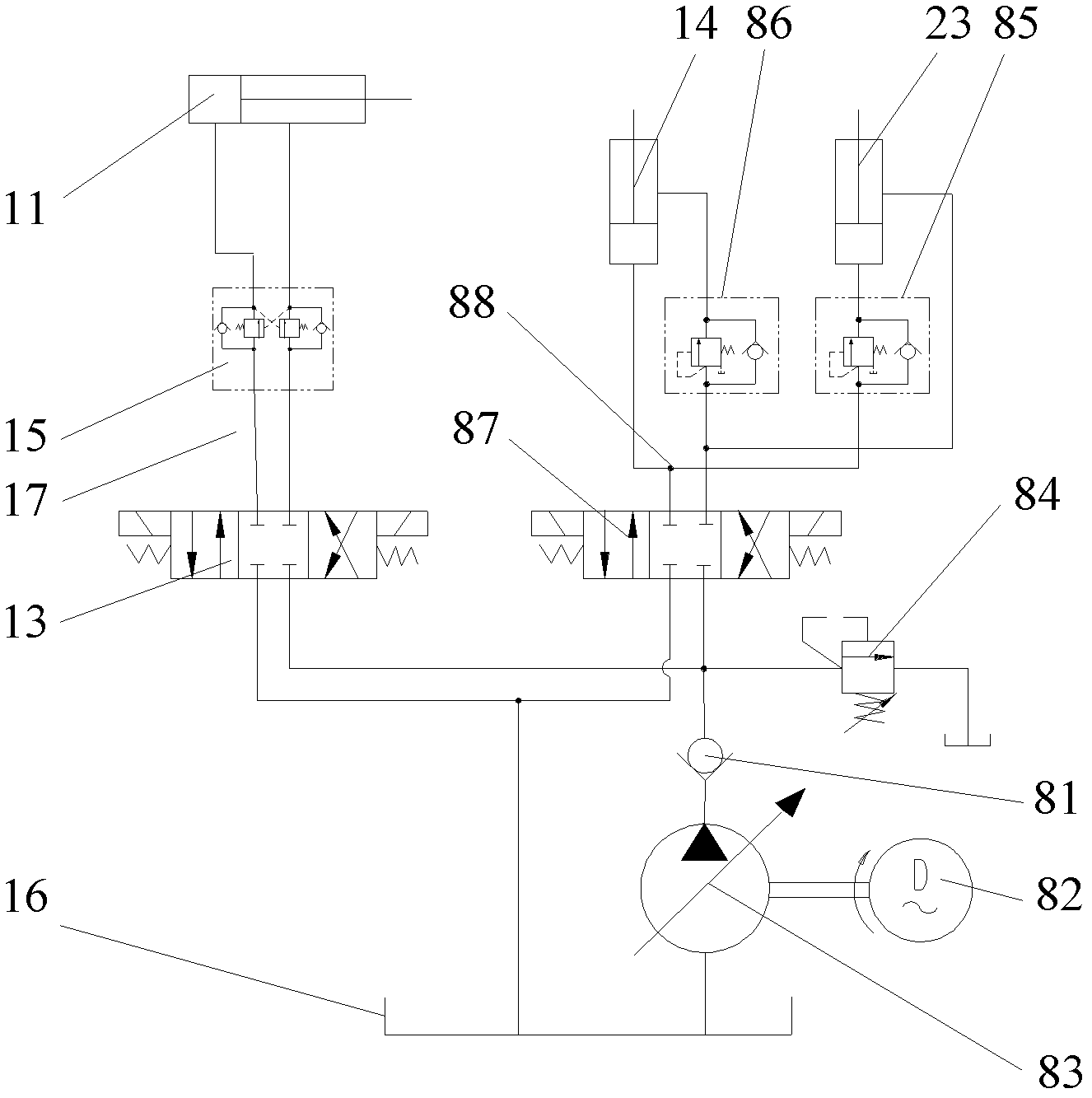

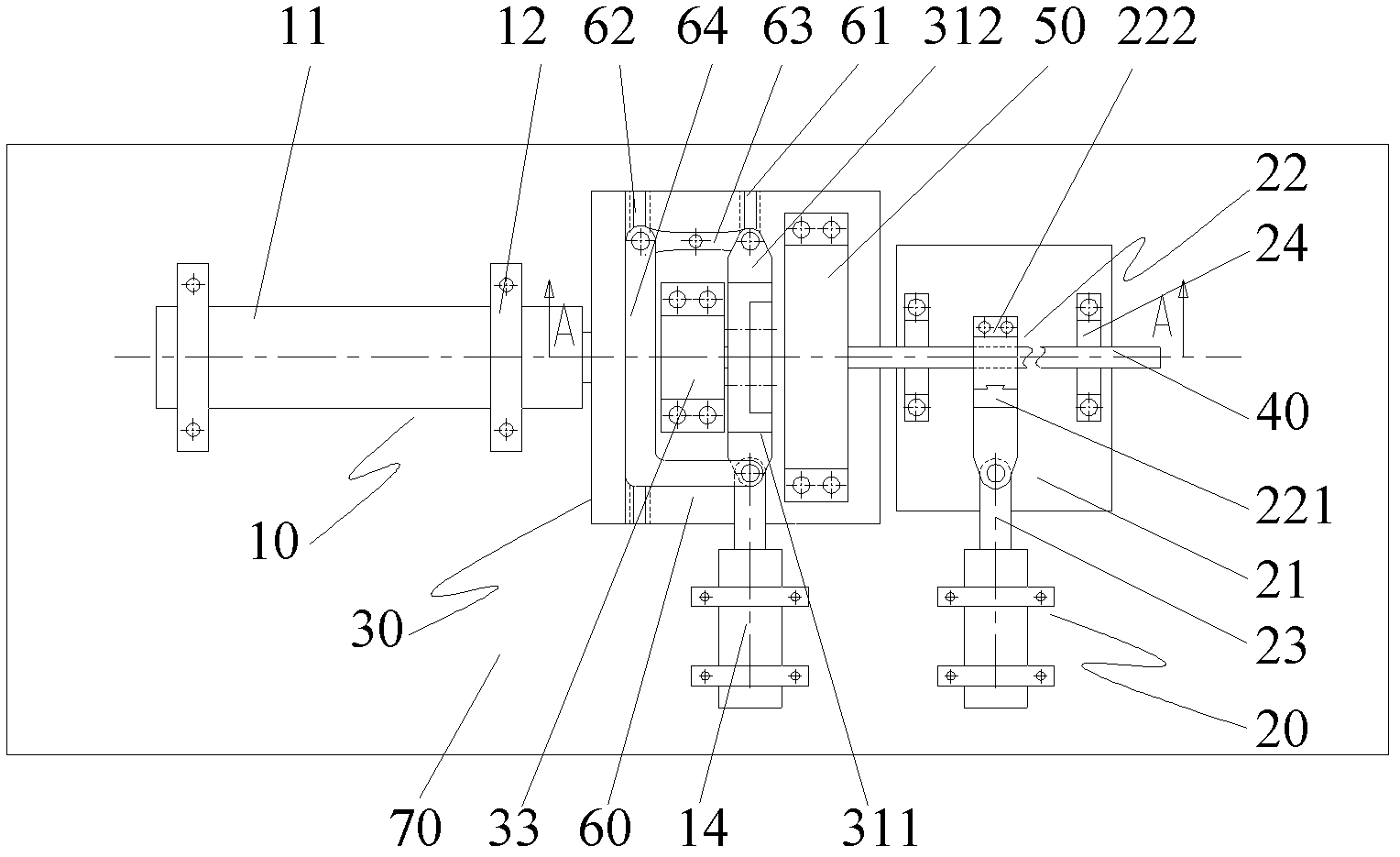

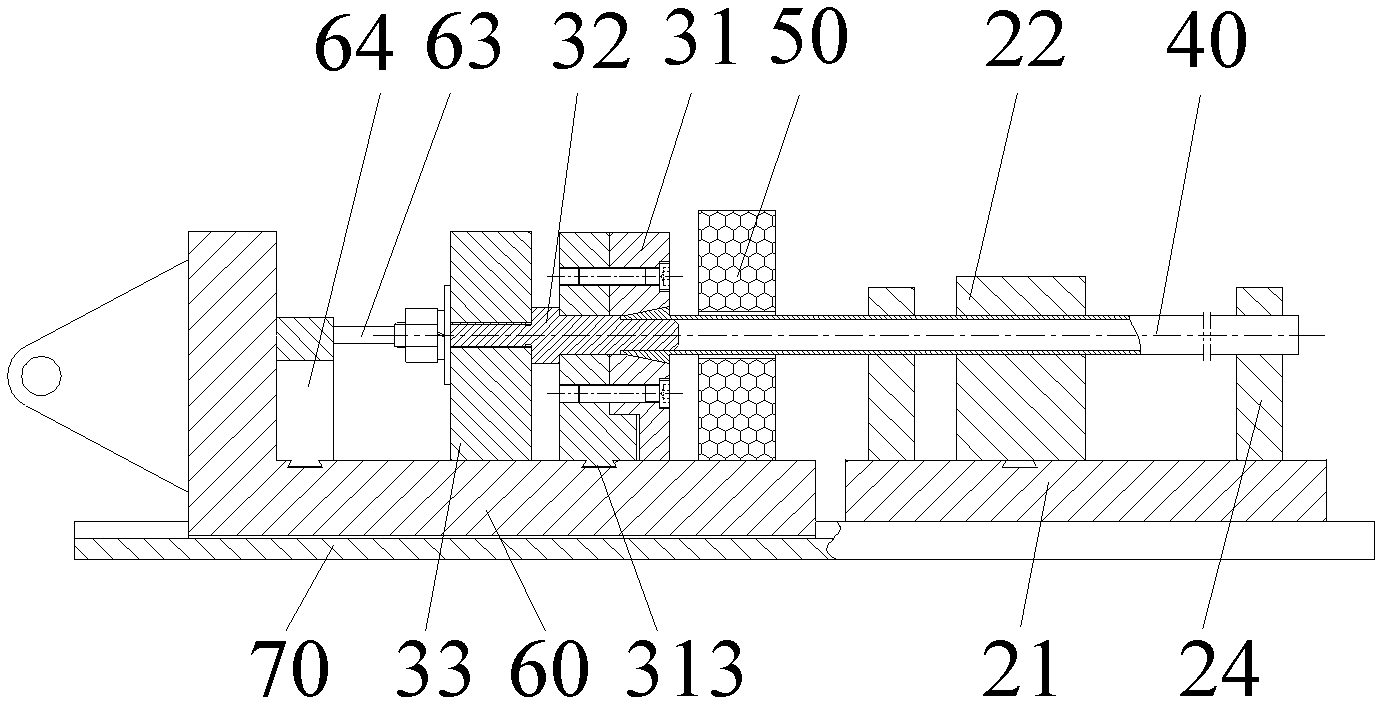

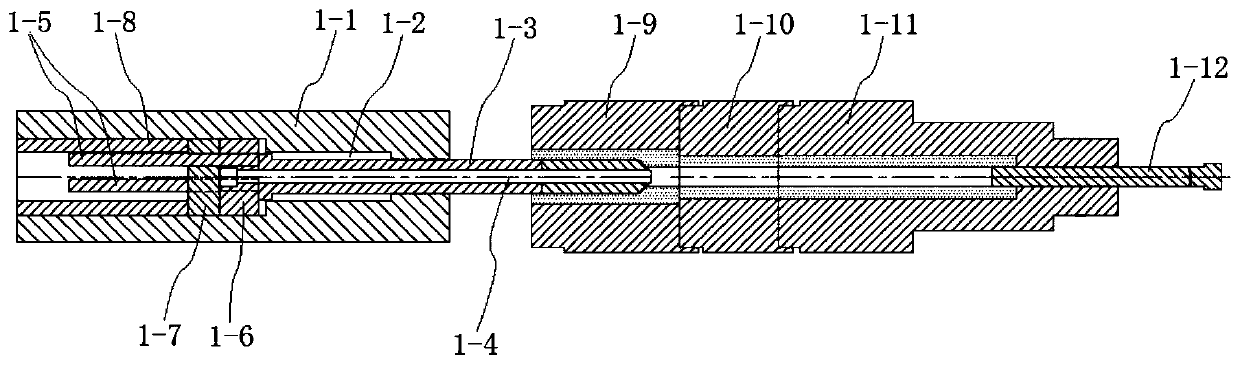

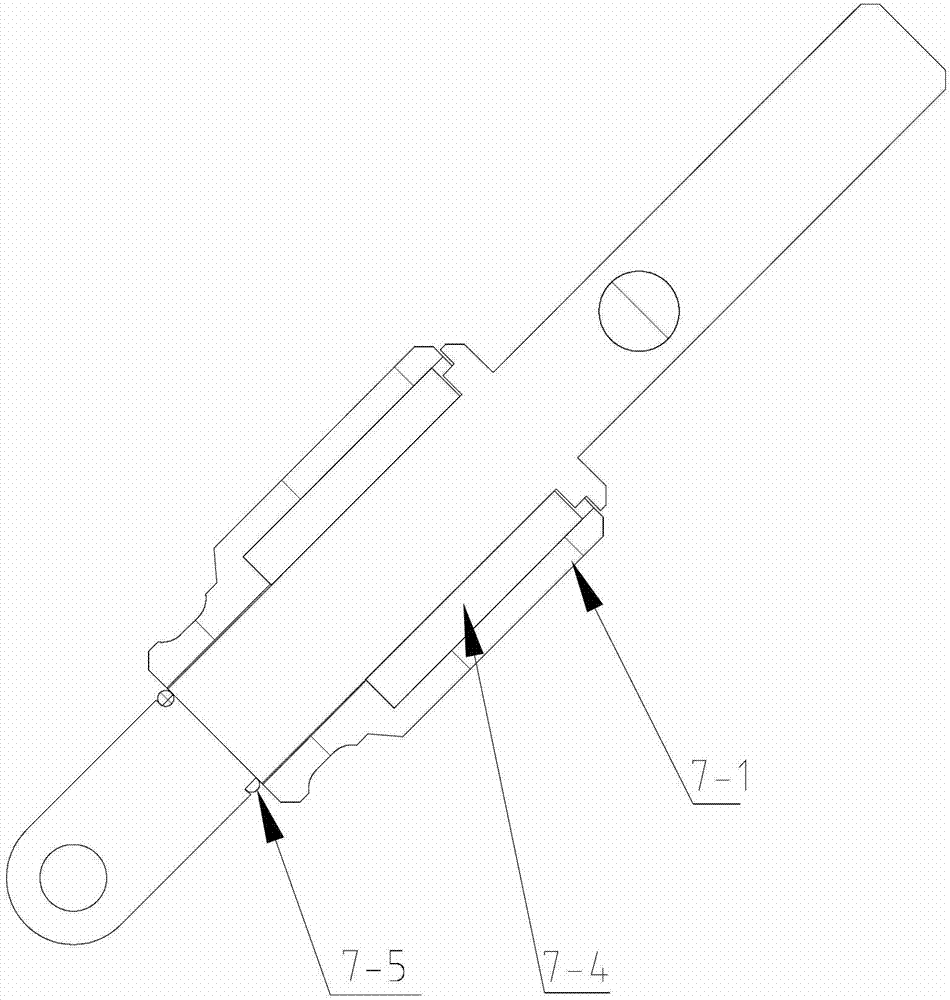

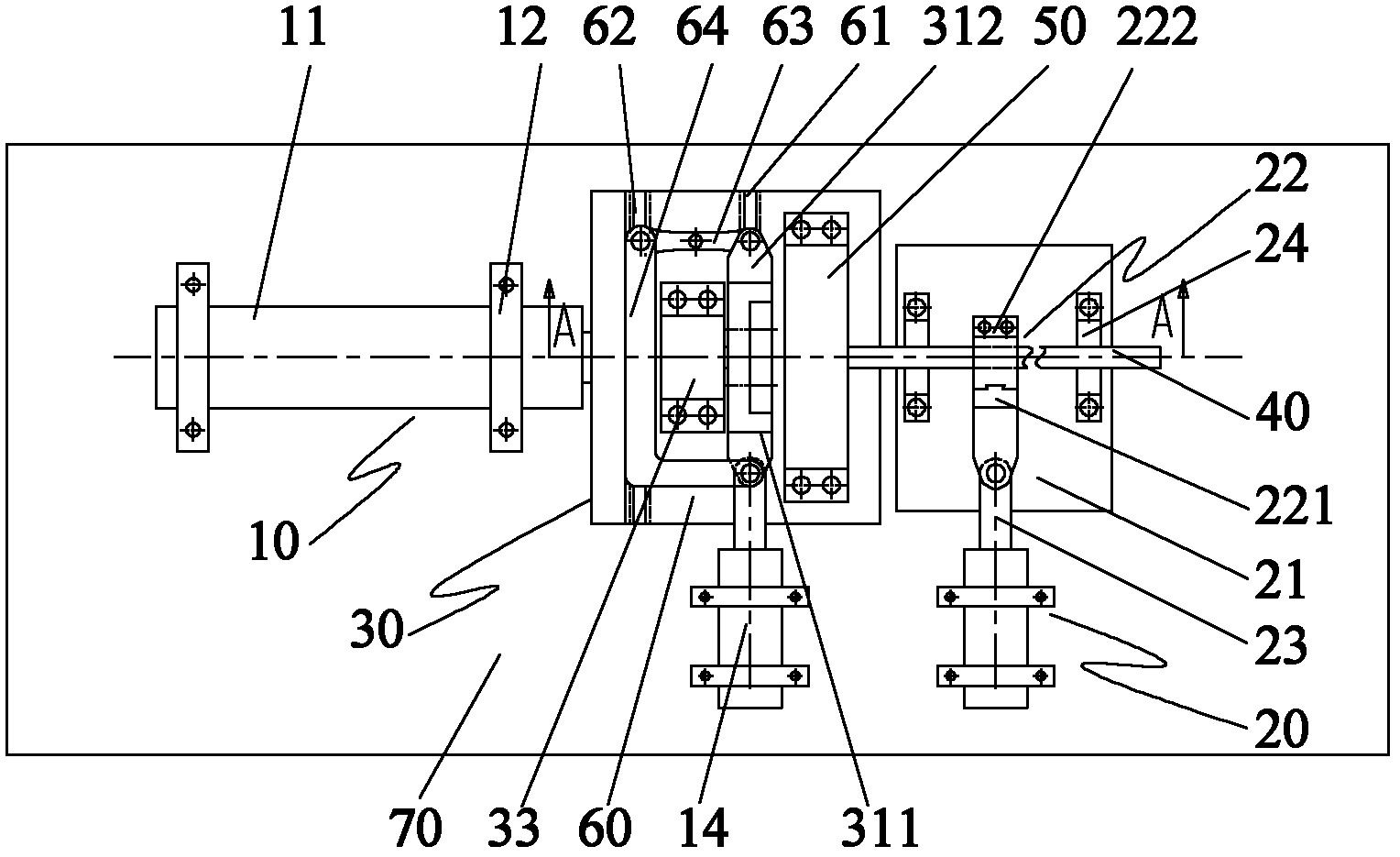

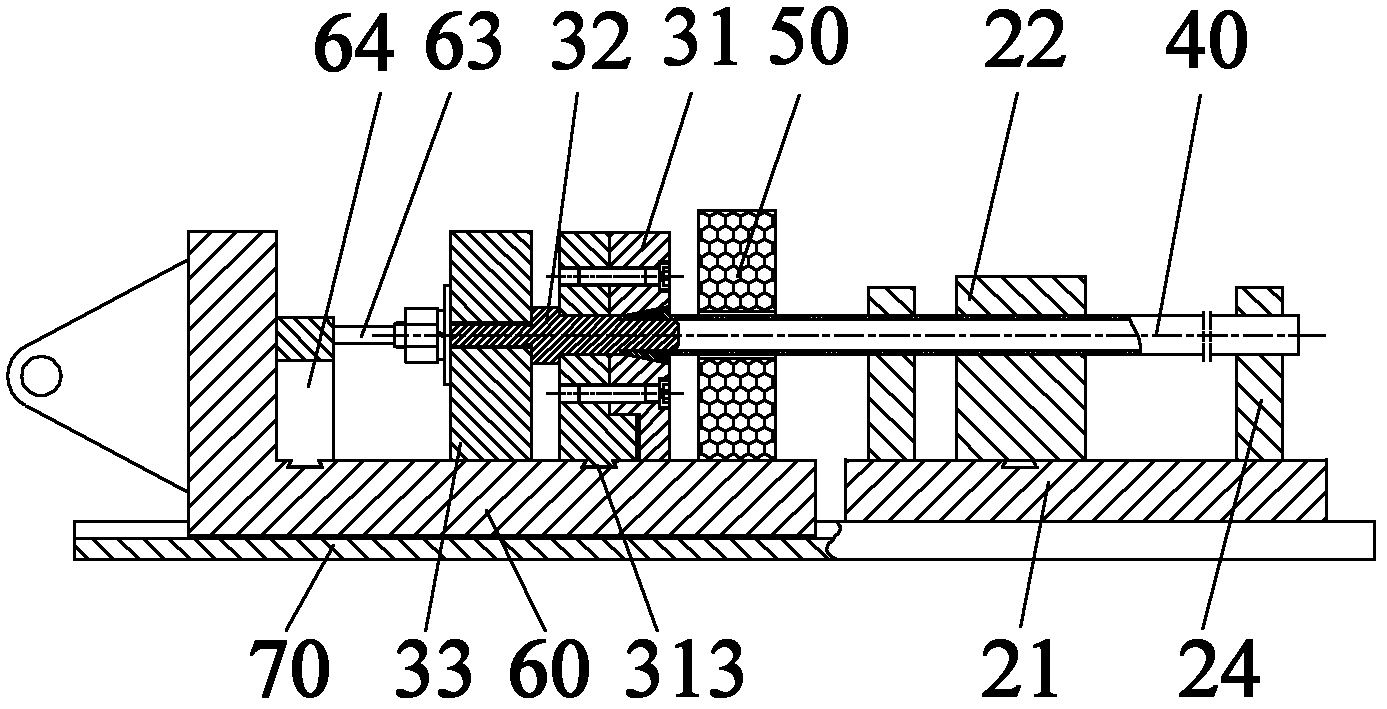

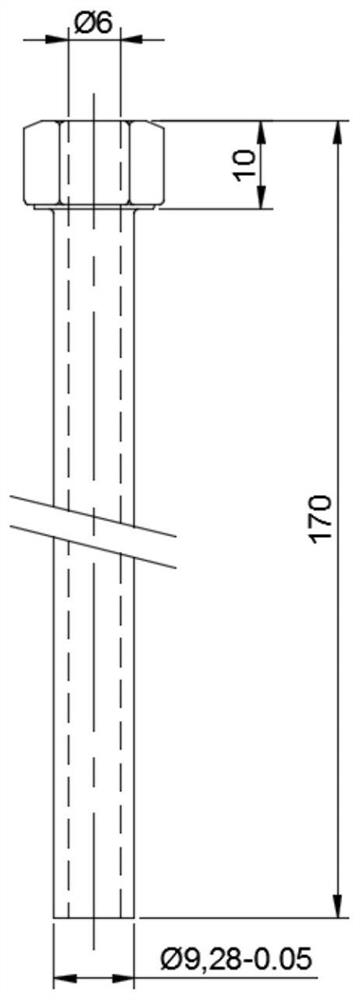

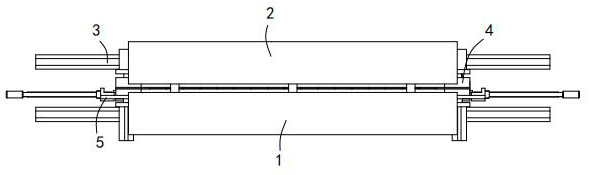

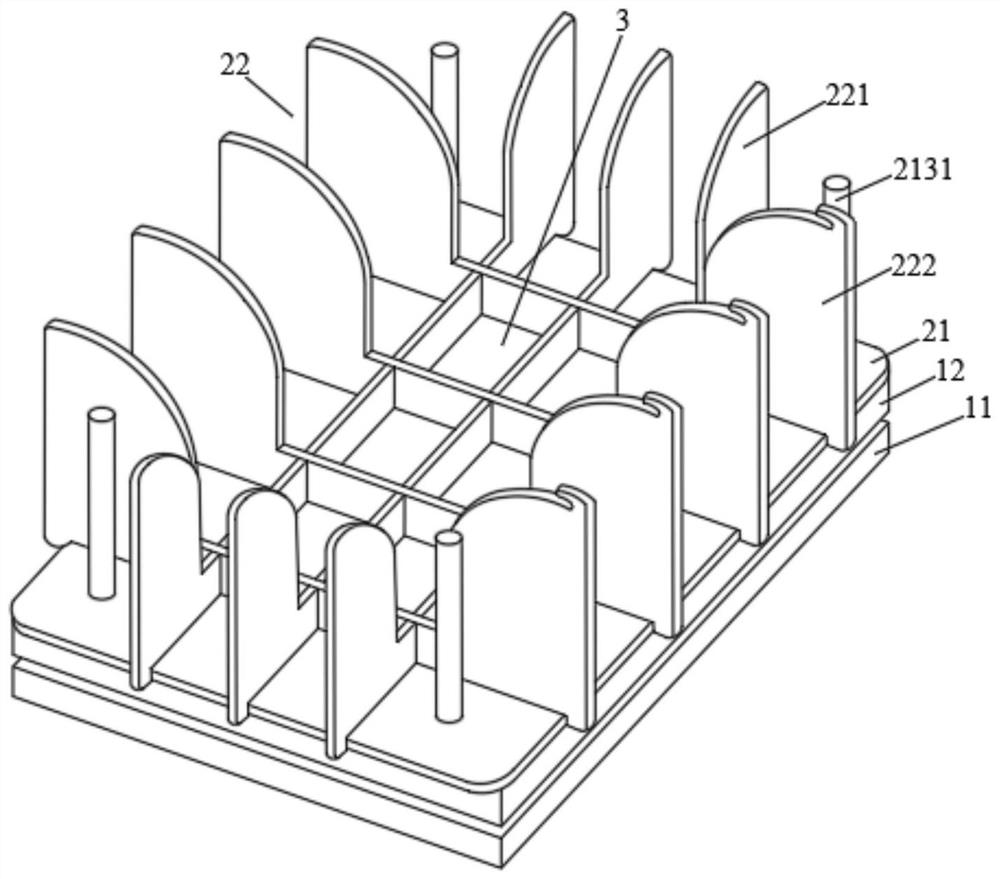

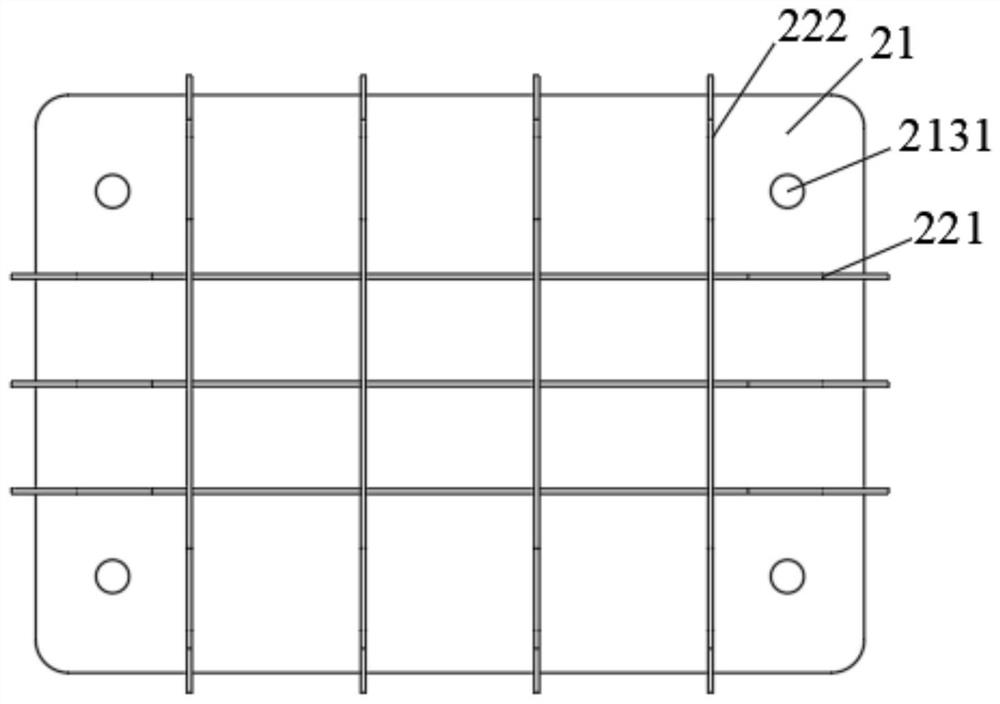

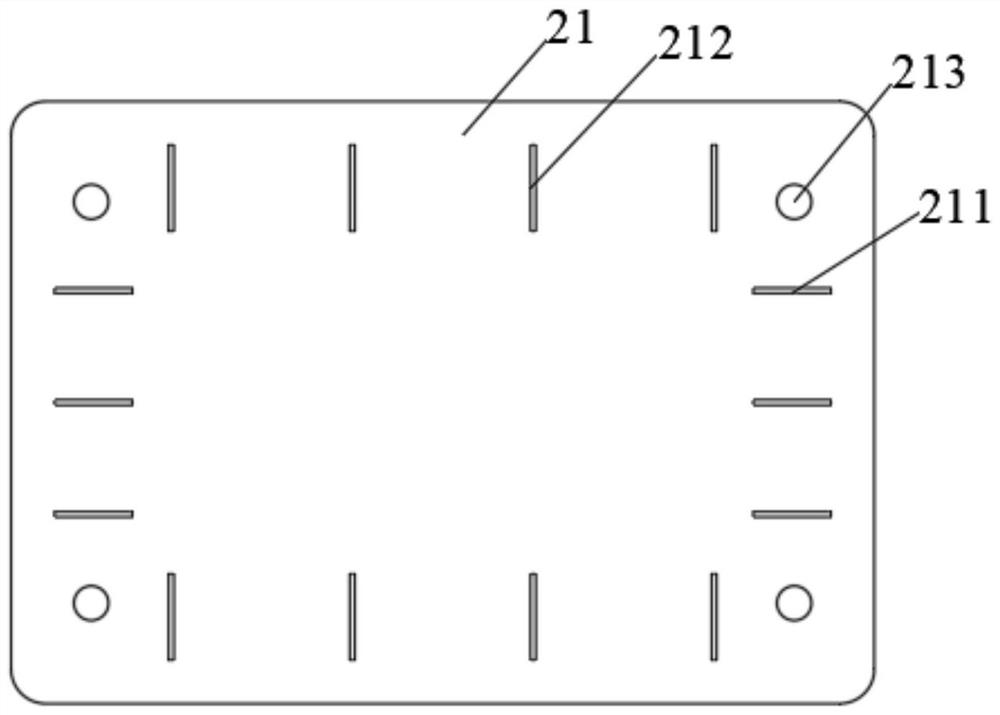

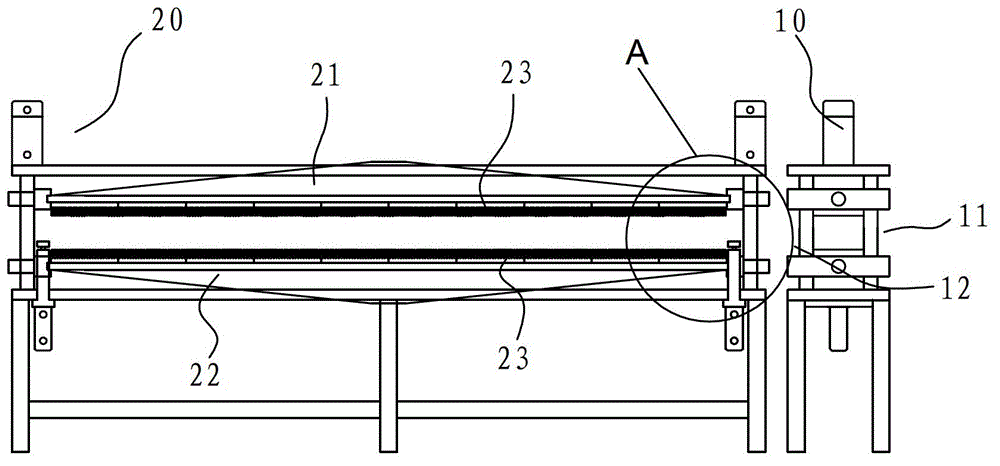

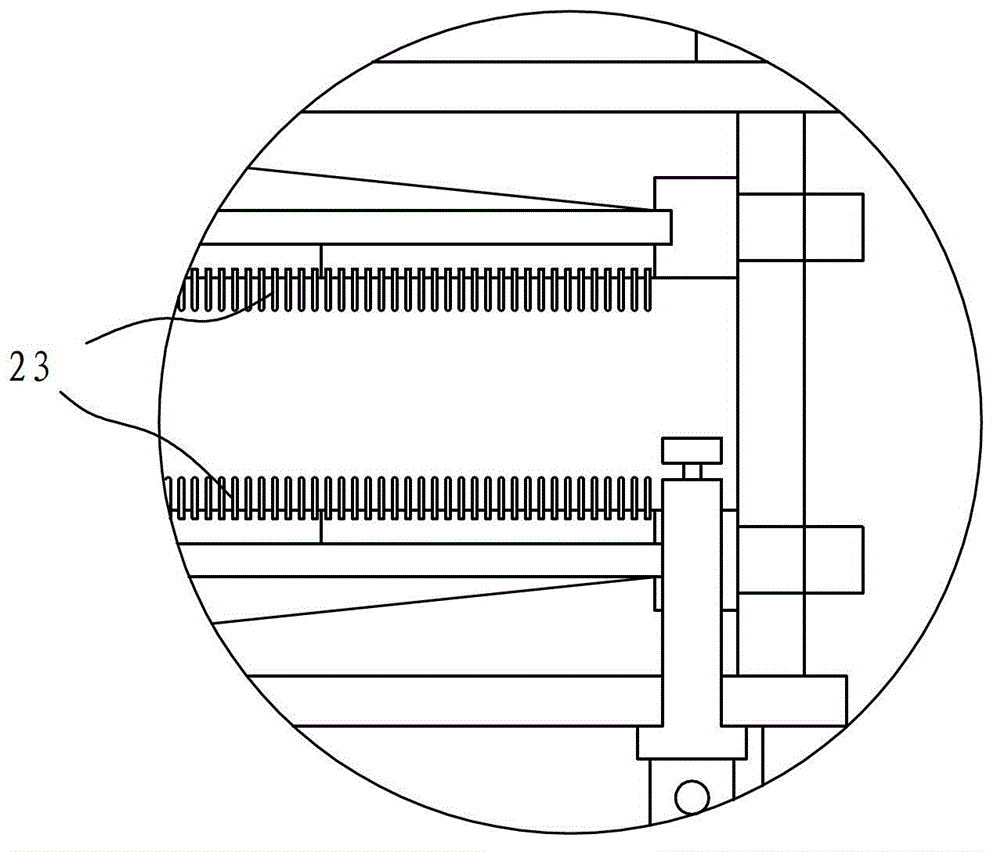

Hard tube end forming equipment and forming method

The invention provides hard tube end forming equipment and a forming method. The hard tube end forming equipment comprises a feeding portion (10), a clamping portion (20) and an extrusion forming portion (30), wherein the clamping portion (20) is used for fixing a hard tube (40) to be formed, and the extrusion forming portion (30) is used for forming a tube end structure of the hard tube (40) to be formed. The hard tube end forming equipment is characterized in that a heating portion (50) is further arranged between the clamping portion (20) and the extrusion forming portion (30). The hard tube end forming equipment is stable in structure, high in reliability, low in cost, high in production efficiency, high in positioning precision and fine in forming quality.

Owner:ZOOMLION HEAVY IND CO LTD

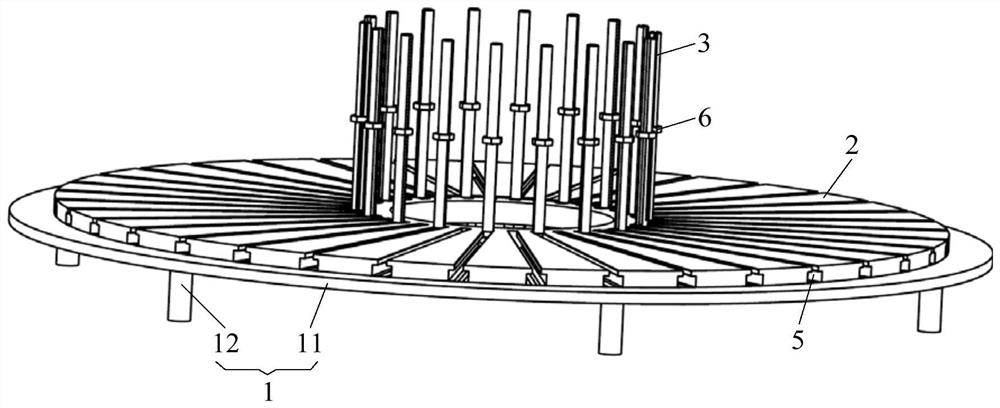

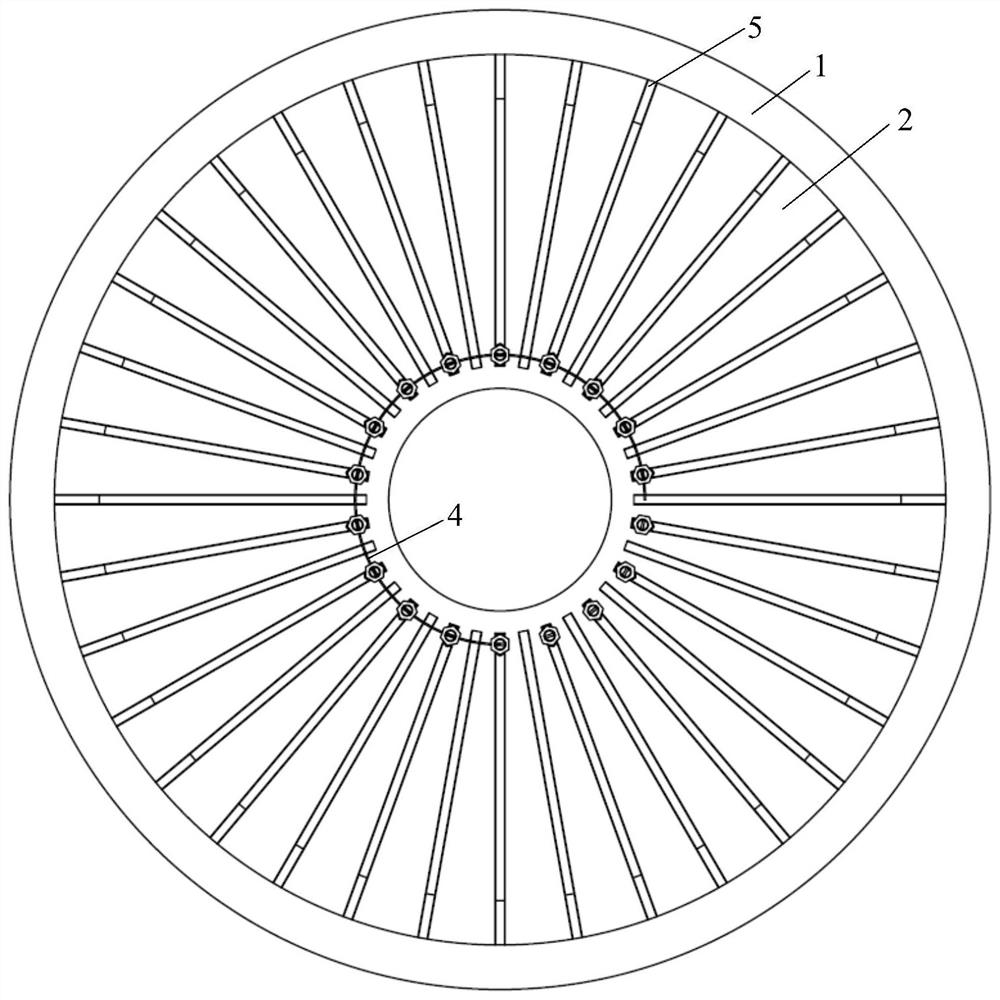

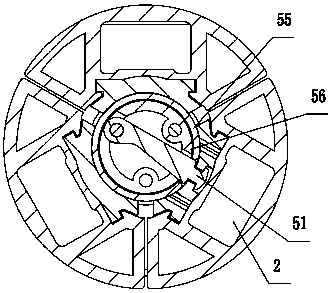

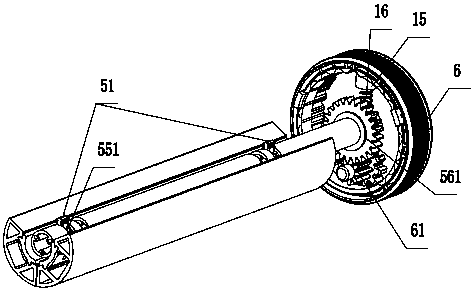

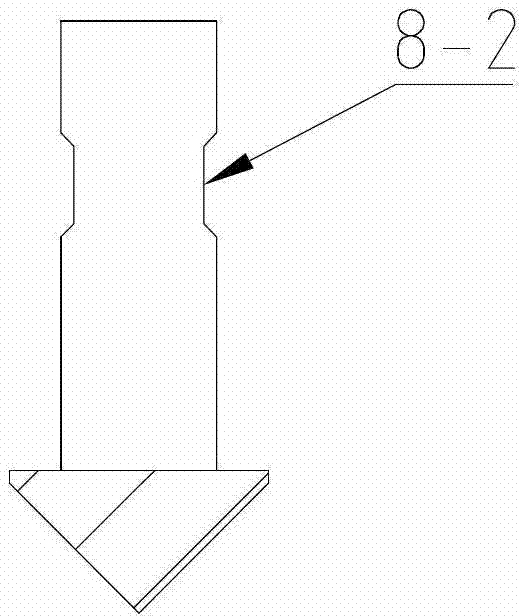

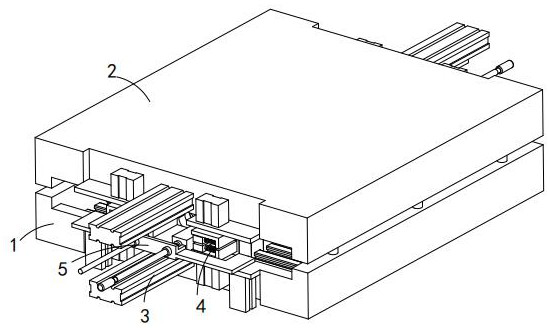

Adjustable micropipe forming tooling

ActiveCN113858064AImprove molding efficiencyMeet molding needsWork holdersGlass productionEngineeringTube forming

The invention discloses an adjustable micropipe forming tooling. The adjustable micropipe forming tooling comprises a base, an adjusting disc and a plurality of adjusting rods; the adjusting disc is fixedly installed on the base and provided with a plurality of adjusting rails distributed in the circumferential direction; the adjusting rails extend in the radial direction of the adjusting disc; the adjusting rods are used for fixedly installing a micropipe, the bottom ends of the adjusting rods can be installed on the adjusting rails in a sliding fit mode, and the adjusting rods can be switched between a locking state and an unlocking state; when the adjusting rods are in the locking state, the bottom ends of the adjusting rods are fixedly connected to the adjusting disc; and when the adjusting rods are in the unlocking state, the adjusting rods can slide in the extending direction of the adjusting rails. The adjustable micropipe forming tool can meet the forming requirements of pipelines in different shapes, and can form a plurality of micropipes at a time, so that the forming efficiency is greatly improved.

Owner:BEIJING POWER MACHINERY INST

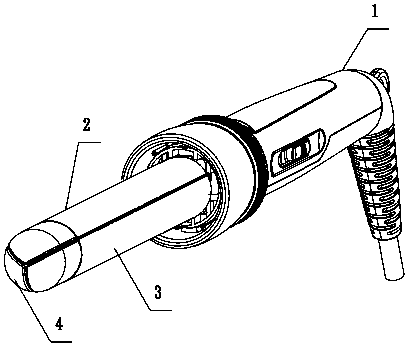

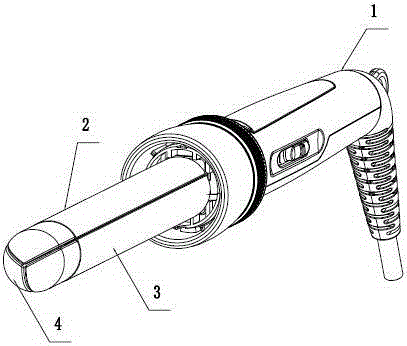

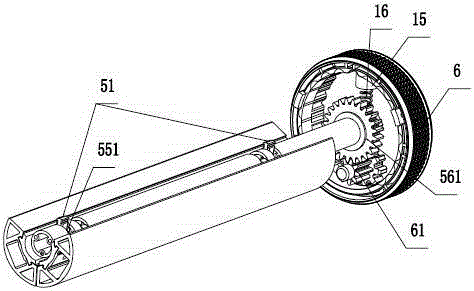

a curling iron

A curling iron. It mainly solves the problem that most of the traditional ones are not adjustable or the structure is complicated although it can be adjusted, but this structure cannot meet the needs of different shapes in actual use. The present invention provides a hair curler, the corresponding position of the heating rod is provided with a telescopic device; the first movable part is driven by the rotation of the telescopic device to adjust the distance between the first heating rod and the second heating rod, thereby meeting the shaping requirements of different hairstyles , simple in structure and easy to use.

Owner:ZHEJIANG MEISEN ELECTRICAL APPLIANCE

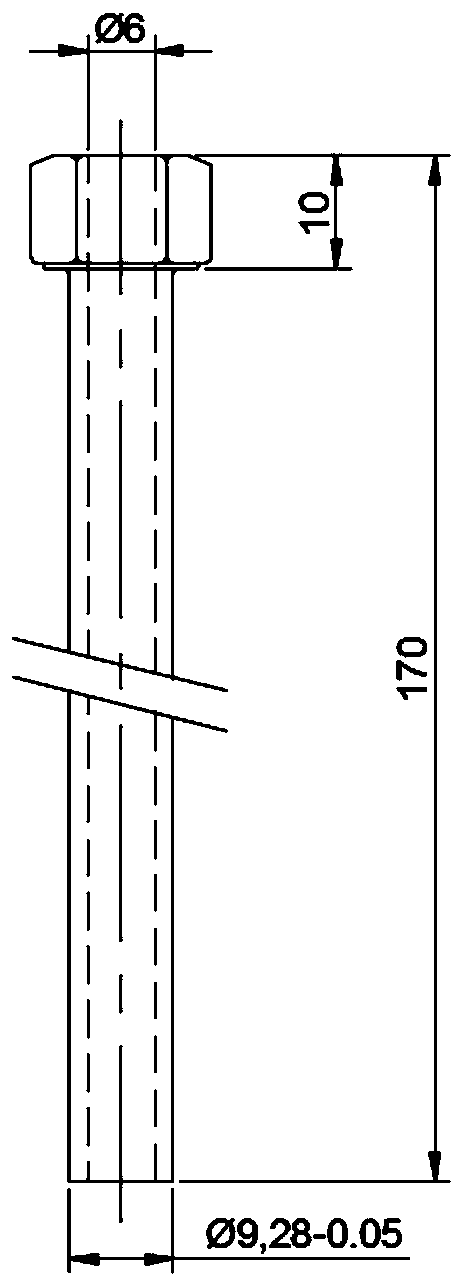

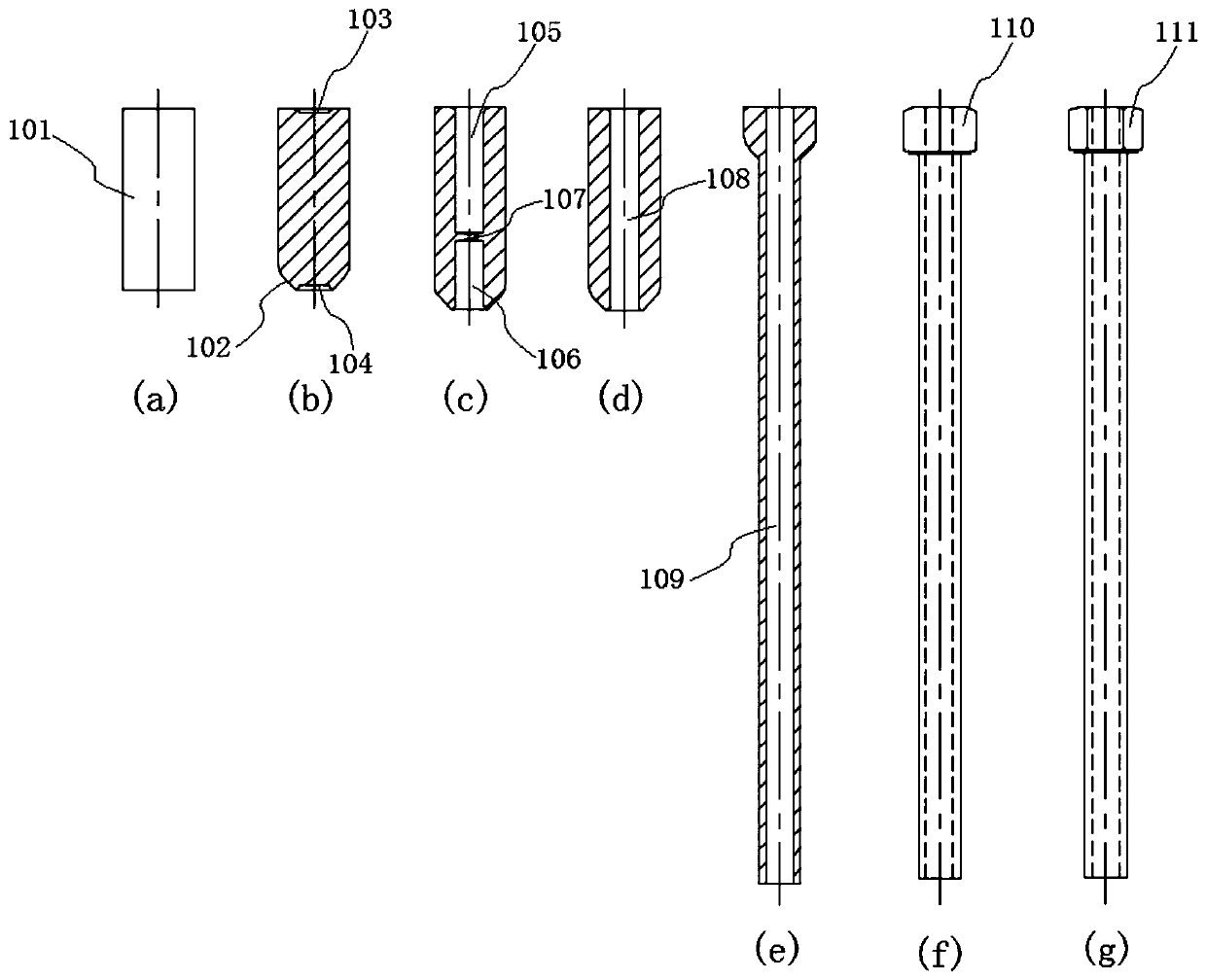

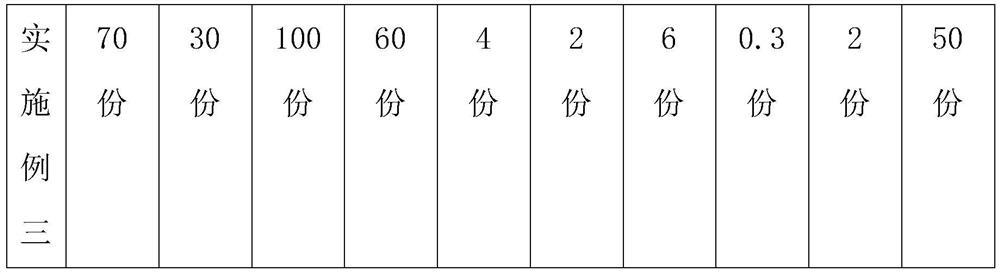

Cold machining process of ultradeep-hole long and thin part and cold extruding stretching mold

The invention discloses a cold machining process of an ultradeep-hole long and thin part and a cold extruding stretching mold, and belongs to the technical field of cold extruding. According to the cold machining process, the bar is subjected to alramenting according to part needs, and a hollow short pipe blank is formed; and then a hole protection needle stretches into a center through hole of the hollow short pipe blank, the hollow short pipe blank is cold-extruded and stretched to the length needed by the part and an ultradeep hole of the long and thin part is molded. The invention furtherdiscloses a cold extruding stretching mold for the cold machining process of the ultradeep-hole long and thin part. According to the cold machining process of the ultradeep-hole long and thin part andthe cold extruding stretching mold, the problem that an existing ultradeep-hole long and thin part is large in molding difficulty, poor in precision, low in machining efficiency and the like is solved, the machining efficiency and quality of the ultradeep-hole long and thin part are greatly improved, and the machining adaptability to the part is high; and the cold machining process can be used for cold machining molding of various ultradeep-hole long and thin parts, is theoretically not limited by the draw ratio of the parts, and is especially suitable for machining the ultradeep-hole parts large in draw ratio.

Owner:常州永茂特种紧固件有限公司

Composite material for solving paint bottom biting phenomenon

The invention provides a composite material for solving a paint bottom biting phenomenon. The composite material is prepared from the following components in parts by mass: 30-40 parts of PC1; 35-45 parts of SAN; 5-15 parts of PC2; 5.5-6.5 parts of ABS high rubber powder; 4.5-5.5 parts of a maleic anhydride graft; 2.5-3.5 parts of a compatilizer; 0.5-1.5 parts of black masterbatch; 0.1 part of a main antioxidant; 0.2 part of an auxiliary antioxidant; 0.3 part of an internal lubricant; and 0.3 part of an external lubricant. According to the composite material for solving the paint bottom bitingphenomenon, by using the formula, the problem of paint bottom biting can be effectively solved, a fracture phenomenon is avoided, the tensile strength is high, and mechanical properties such as the bending strength and the bending modulus are excellent.

Owner:TIANJIN KINGFA NEW MATERIAL

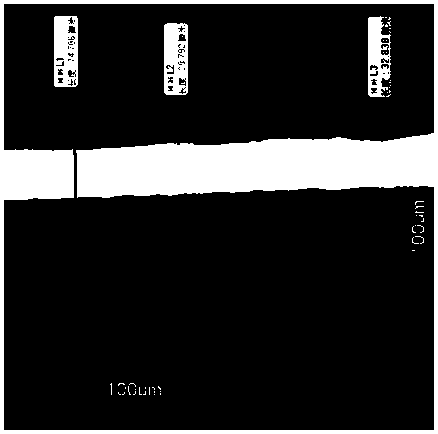

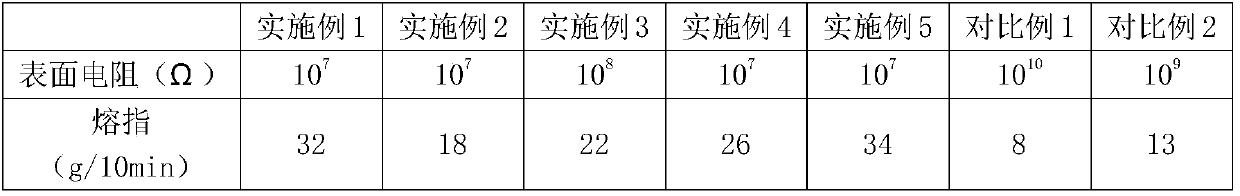

Conductive polypropylene composite material and preparation method thereof

The invention discloses a conductive polypropylene composite material and a preparation method thereof. The conductive polypropylene composite material is prepared from, by mass, 69-85.5% of polypropylene, 12-24% of conductive carbon black, 2-5% of 1-allyl-3-methylimidazolium chloride and 0.5-2% of heat stabilizers. Conductive carbon black is subjected to surface treatment through 1-allyl-3-methylimidazolium chloride so that dispersity and existence form of the conductive carbon black in the polypropylene matrix can be improved; the composite material has good conductivity on the premise of adding a small amount of carbon black, its surface resistance is lower then 190 Ohm, and accordingly the composite material can be applied to field such as packaging and electronic devices having requirements on electrostatic protection and industrial fields having requirements on electromagnetic shielding.

Owner:HEFEI GENIUS NEW MATERIALS

Milky white glass ceramic suitable for all electric melting and preparation process for milky white glass ceramic

The invention provides a milky white glass ceramic material and a preparation process thereof. The milky white glass ceramic material contains the following components: 67 to 74 percent of SiO2, 8.0 to 12 percent of Na2O, 0.3 to 2.5 percent of K2O, 6 to 9 percent of Al2O3, 3 to 5 percent of B2O3, 0.3 to 2 percent of CaO, 0.3 to 2 percent of ZnO, 0.5 to 2.5 percent of BaO, 0.3 to 2 percent of MgO, 2.5 to 4.8 percent of F and 0.5 to 2 percent of Li2O. The material is prepared by the following steps of: (1) weighing the following raw materials in part by weight: 4 to 9 parts of alumina powder, 0.5 to 3 parts of barium carbonate, 0.15 to 3.5 parts of calcium carbonate, 0.5 to 3 parts of fluorite, 0.5 to 4 parts of dolomite, 0.5 to 5 parts of potassium nitrate, 0.3 to 2 parts of magnesium oxide, 5 to 11 parts of borax pentahydrate, 5 to 10 parts of soda ash, 3.5 to 9 parts of sodium fluosilicate, 7 to 20 parts of albite, 1 to 5 parts of sodium nitrate, 50 to 70 parts of quartz sand, 0.25 to 2 parts of zinc oxide and 1 to 5 parts of lithium carbonate, and mixing the raw materials to obtain a batch; (2) putting the batch into an electric melting furnace, and performing all electric melting at the temperature of between 1,320 and 1,520 DEG C to obtain molten glass; (3) adjusting the temperature of the molten glass, and molding in a mould by a pressing or centrifugal method; (4) putting a molded product into an annealing kiln, and annealing at the temperature of between 530 and 620 DEG C for more than 60 minutes; and (5) performing toughening treatment after annealing.

Owner:WENZHOU HUISHUNDA IND TRADE

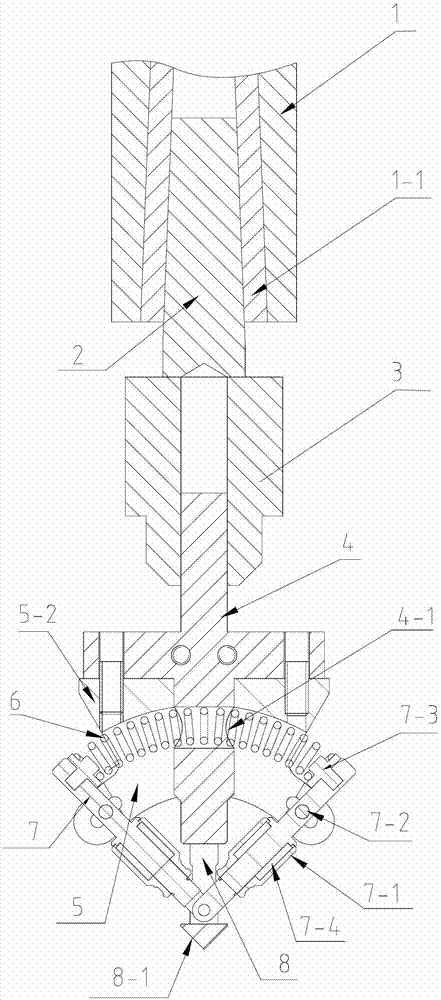

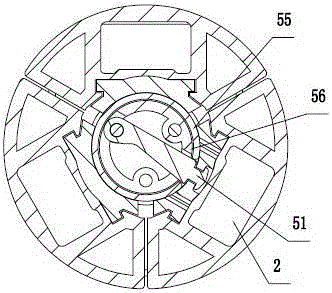

R-angle stamping fixture for flexible milled-surface-painted plastic material

ActiveCN103111672AGuaranteed to be smoothMeet molding needsMilling equipment detailsEngineeringPlastic materials

The invention relates to the technical field of flexible material milling fixtures and particularly relates to an R-angle stamping fixture for a flexible milled-surface-painted plastic material. The R-angle stamping fixture is characterized in that gaps are respectively formed in the two ends of the arc-shaped closure of the upper part of an arc-shaped shell body; the lower plane of the connecting end face of a transmission and locating main shaft is fixedly connected with the upper surface of the top of the arc-shaped shell body, the bottom end of the lower connecting shaft part of the transmission and locating main shaft penetrates through the middle of the top of the arc-shaped shell body and is then located below the arc-shaped shell body, and the bottom face of the lower connecting shaft part of the transmission and locating main shaft is connected with the top end of a center locating column; the bottom ends of two cylindrical rollers are respectively pinned to the front side of the lower part of the center locating column, the top ends of the two cylindrical rollers are respectively embedded in the gaps of the left and right ends of the arc-shaped shell body, the left end of a spring is fixed to the top of a left cylindrical roller, and the right end of the spring penetrates through a spring hole of the transmission and locating main shaft and is then fixed to the top of a right cylindrical roller; and rolling balls are sleeved outside the middle parts of the cylindrical rollers. Compared with the prior art, the R-angle stamping fixture has the advantage that the defects caused by the surface yielding and deformation stress of workpieces can be overcome.

Owner:YANFENG PLASTIC OMNIUM AUTOMOTIVE EXTERIOR SYST

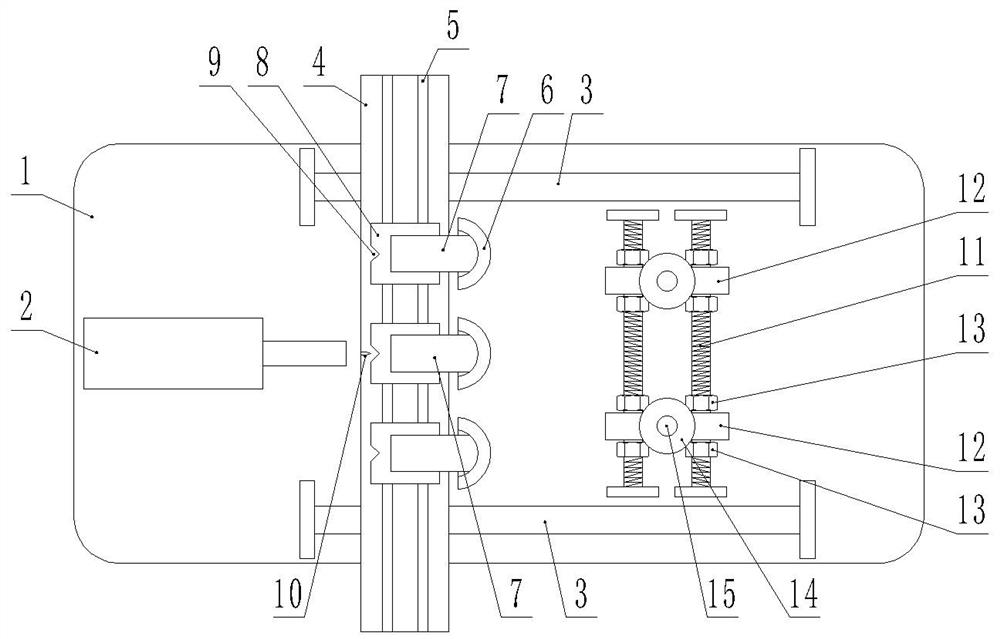

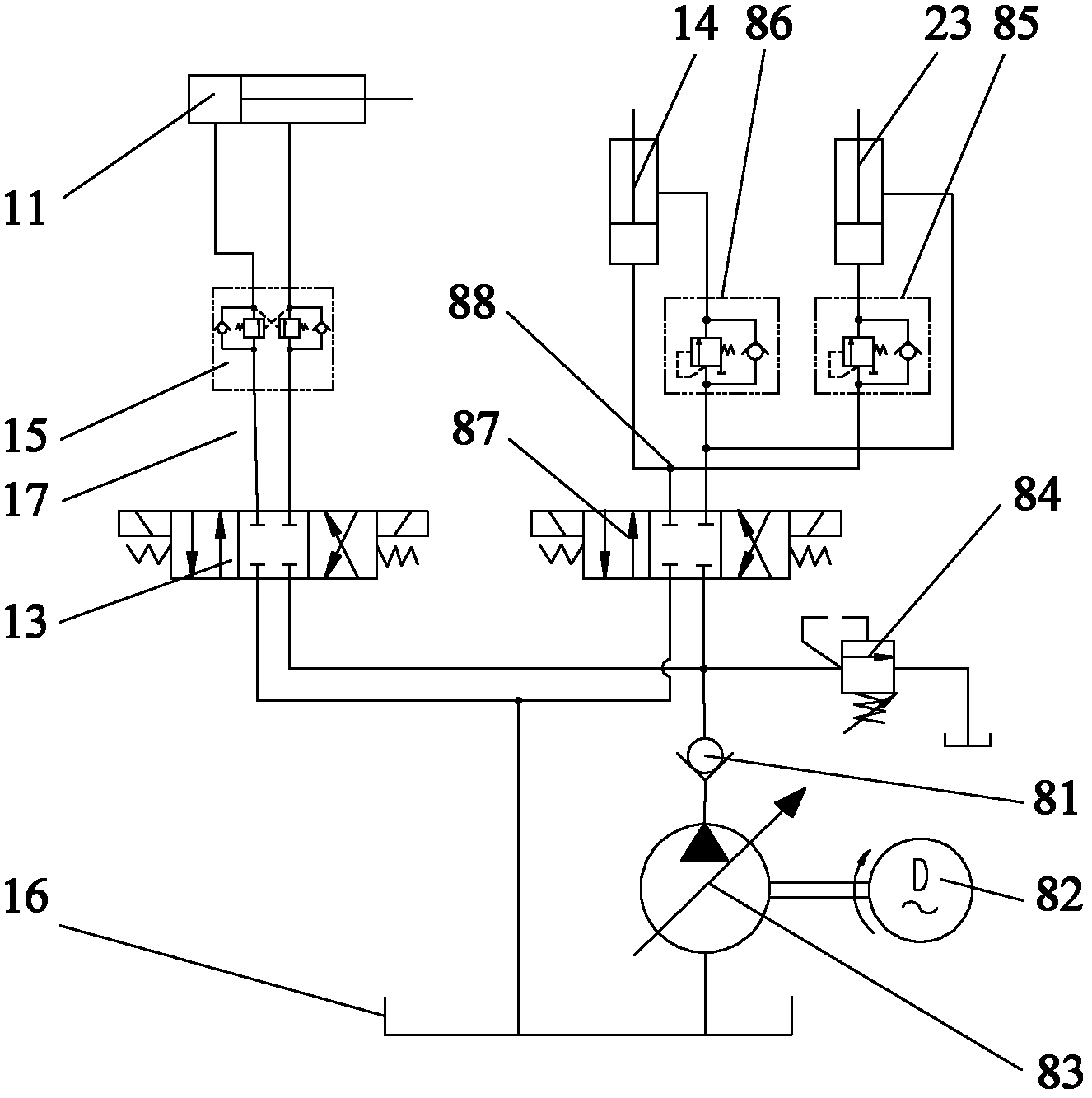

Pipe bender with various processing radians

The invention relates to a pipe bender with various processing radians. The pipe bender comprises a processing table, a power mechanism, a forming die head mounting structure and a limiting roller mounting mechanism are arranged on the upper surface of the processing table, the power mechanism is a hydraulic cylinder, the hydraulic cylinder is arranged in the long axis direction of the processingtable, the forming die head mounting structure comprises a sliding plate sliding in the long axis direction of the processing table, a plurality of sliding blocks are connected to the sliding plate ina sliding mode, each sliding block slides in the short axis direction of the processing table, a die head is installed on each sliding block, and the radians of the die heads connected to the different sliding blocks are different. The pipe bender can meet the forming requirements of multiple radians of a pipe body, the space is saved, and the equipment purchase cost is also saved.

Owner:HUANENG LAIWU POWER GENERATION CO LTD

Hard tube end forming equipment and forming method

The invention provides hard tube end forming equipment and a forming method. The hard tube end forming equipment comprises a feeding portion (10), a clamping portion (20) and an extrusion forming portion (30), wherein the clamping portion (20) is used for fixing a hard tube (40) to be formed, and the extrusion forming portion (30) is used for forming a tube end structure of the hard tube (40) to be formed. The hard tube end forming equipment is characterized in that a heating portion (50) is further arranged between the clamping portion (20) and the extrusion forming portion (30). The hard tube end forming equipment is stable in structure, high in reliability, low in cost, high in production efficiency, high in positioning precision and fine in forming quality.

Owner:ZOOMLION HEAVY IND CO LTD

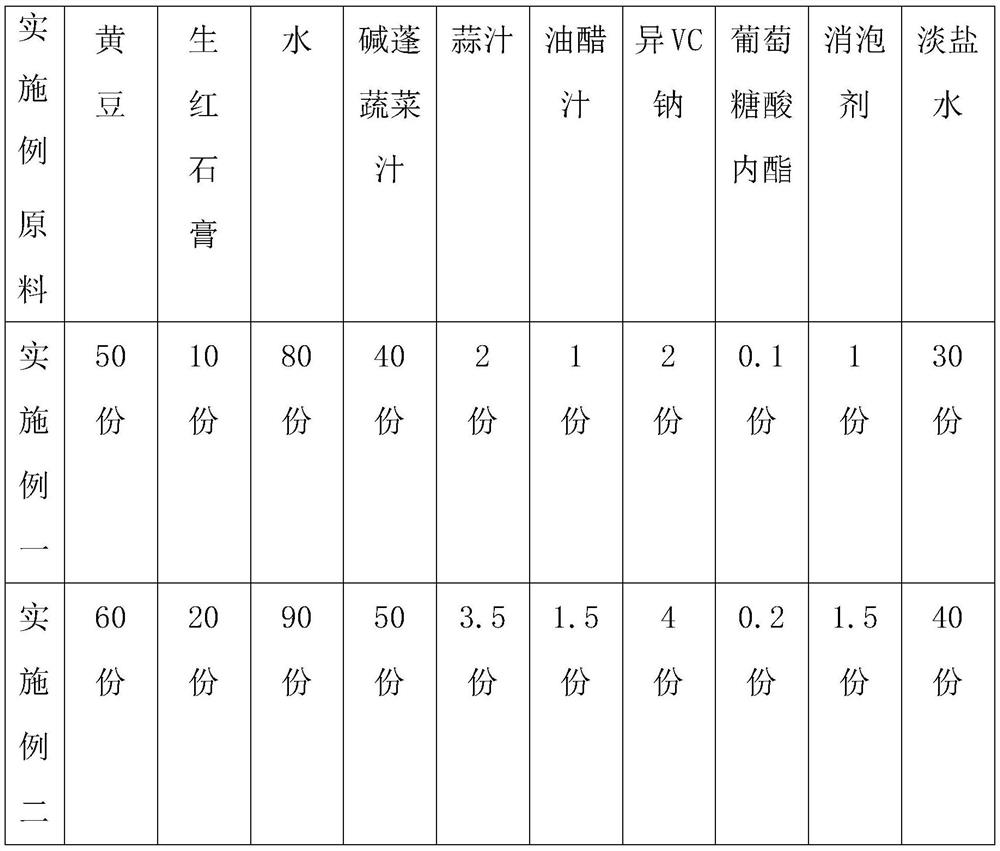

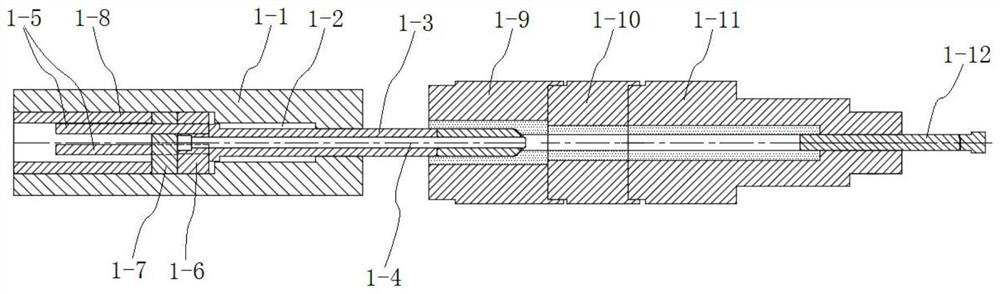

Weight-losing health-preserving bean curd and preparation technology thereof

PendingCN113854490AStrong bean flavorGreat tasteFood thermal treatmentClimate change adaptationBiotechnologyDelta-gluconolactone

The invention discloses weight-losing health-preserving bean curd and a preparation technology thereof, and relates to the technical field of bean curd. The weight-losing health-preserving bean curd comprises the following raw materials in parts by weight: 50-70 parts of soybeans, 10-30 parts of raw red gypsum, 80-100 parts of water, 40-60 parts of suaeda glauca juice, 5-10 parts of garlic juice, 1-2 parts of oil vinegar juice, 5-15 parts of sodium D-isoascorbate, 1-3 parts of glucolactone, 1-2 parts of a defoaming agent and 30-50 parts of light salt brine. The preparation technology can easily control tenderness of the weight-losing and health-preserving bean curd through the gypsum slurry and the glucolactone, effectively improves putrefaction resistance, a preservation function and a water-retaining property of the bean curd, and enables the texture of the bean curd to be finer and smoother, and the taste and the quality of the bean curd to be more stable. Suaeda glauca is added in the bean curd and the bean curd helps eaters to delay cardiovascular aging diseases and prevent blood pressure rise, has great benefits for maintaining cardiovascular health, and accelerates permeability of blood vessels.

Owner:达州合得拢食品有限公司

A cold processing technology of ultra-deep hole slender parts and cold extrusion elongation die

ActiveCN110434186BImprove processing efficiencyImprove processing qualityExtrusion diesThermodynamicsMachining process

The invention discloses a cold processing technology of an ultra-deep hole slender part and a cold extrusion elongation die, belonging to the technical field of cold extrusion processing. In the cold working process of the present invention, the surface phosphating treatment is first carried out on the bar according to the needs of the parts to form a hollow short tube blank; The hollow short tube blank is cold extruded and stretched to the required length of the part, and the ultra-deep hole of the slender part is formed. The invention also discloses a cold extruding elongating die for the cold working process of the ultra-deep hole slender parts. The invention solves the problems of the existing ultra-deep hole slender parts such as high difficulty in forming, poor precision, and low processing efficiency, greatly improves the processing efficiency and processing quality of the ultra-deep hole slender parts, and has strong processing adaptability to the parts. It can be used for cold forming of various ultra-deep hole slender parts, theoretically not limited by the length-to-diameter ratio of the part, especially suitable for processing ultra-deep hole parts with a large length-to-diameter ratio.

Owner:常州永茂特种紧固件有限公司

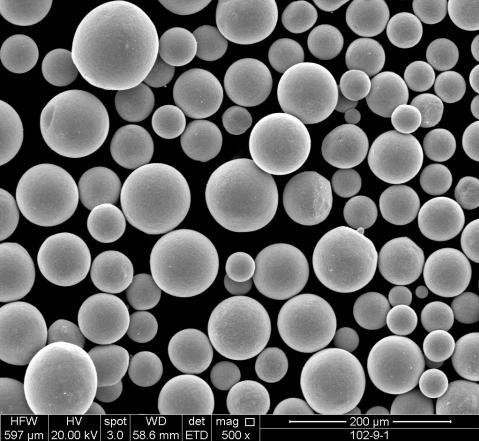

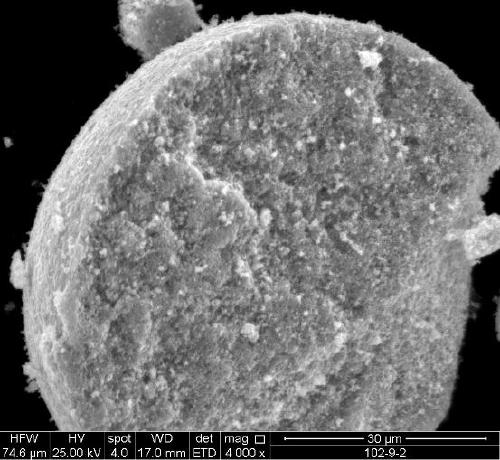

A method for preparing high-performance ito granulated powder

The invention provides a high-performance ITO granulation powder preparation method, which comprises: weighing indium oxide nanometer powder with a purity of more than 99.99% and tin oxide nanometer powder with a purity of more than 99.99% according to a mass ratio of 9:1, adding deionized water and a dispersing agent to prepare a slurry with a certain solid content, and carrying out ball milling with a sand mill to achieve a certain fineness; adding a binder and an antifoaming agent, and carrying out spray drying to obtain powder; adding cyclone powder, a certain amount of a dispersing agent and water to the powder to prepare a slurry with a certain solid content; and carrying out high speed dispersing, and carrying out spray drying to obtain the final granulation powder. According to the present invention, the prepare granulation powder has the solid sphere shape and the large bulk density, and the prepared indium tin oxide has the single-phase micro-particle dispersed state, has the characteristics superior to the agglomerated powder, has good fluidity and good gradation, and is beneficial for meeting the molding requirement of the high-end ITO target.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

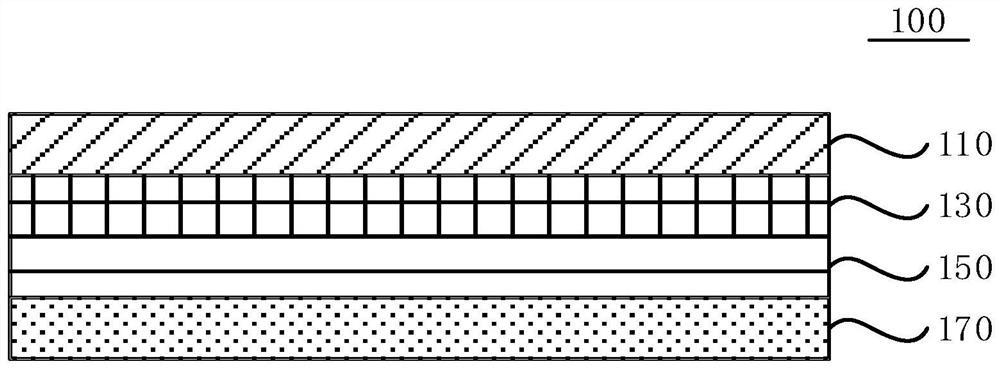

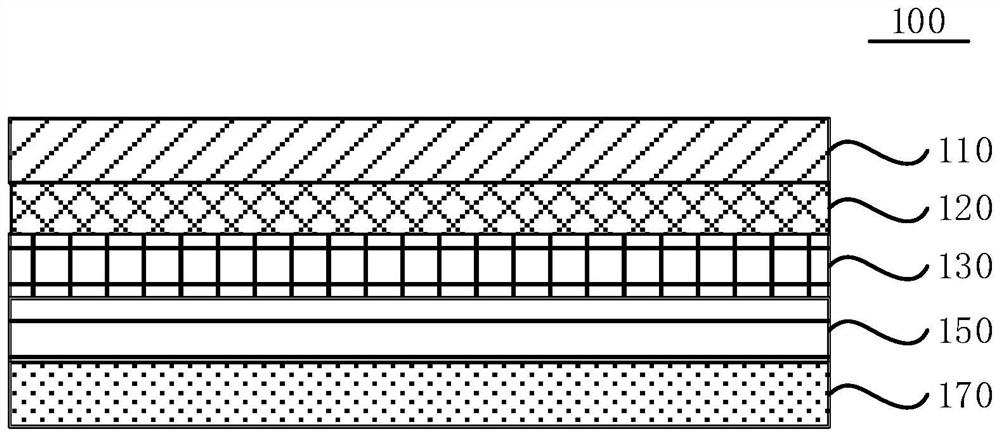

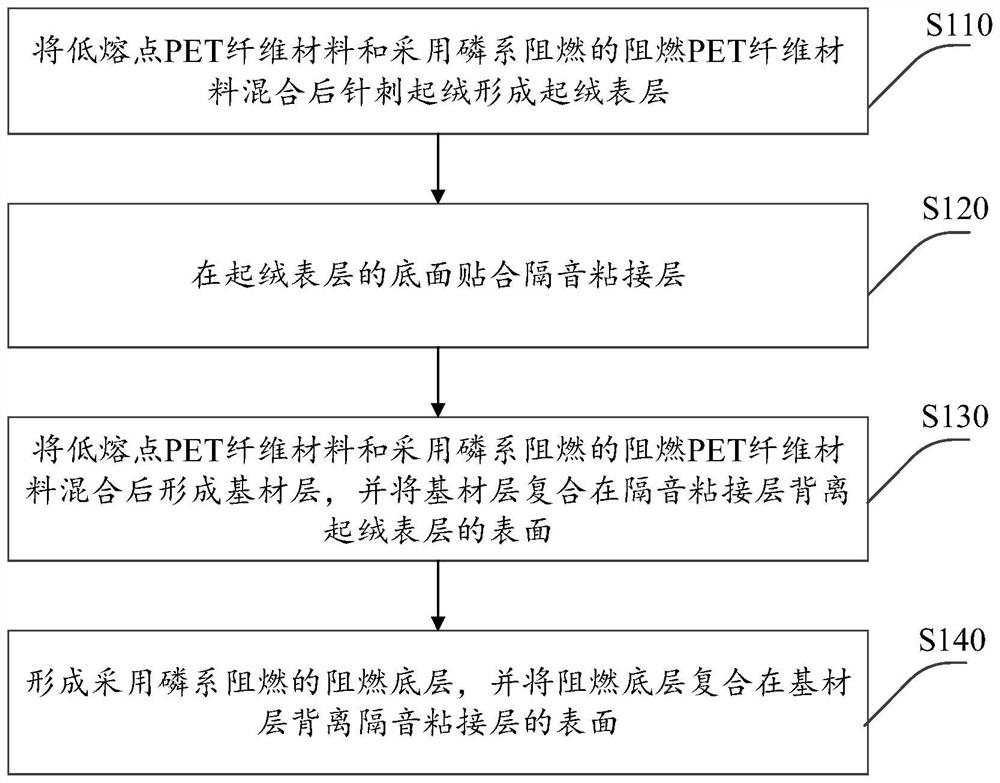

Flame-retardant carpet and manufacturing method thereof

PendingCN114474907ASatisfies the requirements of needle-punch raising processImprove flame retardant performanceVehicle arrangementsSynthetic resin layered productsFiberAviation

The invention provides a flame-retardant carpet and a manufacturing method of the flame-retardant carpet, the flame-retardant carpet comprises a raising surface layer, a sound insulation bonding layer, a base material layer and a flame-retardant bottom layer which are sequentially stacked and arranged, the raising surface layer and the base material layer both comprise a flame-retardant PET fiber material and a low-melting-point PET fiber material, and the flame-retardant PET fiber material and the flame-retardant bottom layer both adopt phosphorus flame retardance. According to the flame-retardant carpet provided by the invention, the flame retardance can be improved by the flame-retardant PET fiber material, and the low-melting-point PET fiber material plays a role in forming, so that the flame-retardant carpet not only can meet the flame-retardant requirement of an aviation carpet, but also can meet the forming requirement, and therefore, the flame-retardant carpet can be suitable for air-ground amphibious manned aircrafts.

Owner:GUANGDONG HUITIAN AEROSPACE TECH CO LTD

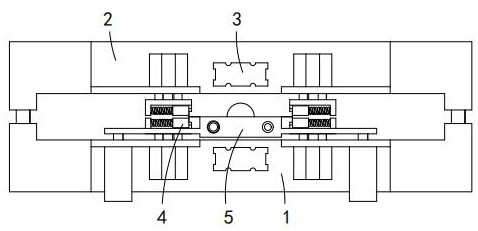

Power insulator forming machining equipment and machining technology

ActiveCN113370436ALow input costMeet the needs of molding processingDomestic articlesSilicone rubber insulatorsMachining process

The invention relates to the technical field of insulator production and manufacturing, in particular to power insulator forming machining equipment and machining technology. The equipment comprises a lower mold base and an upper mold base, the lower mold base and the upper mold base are each provided with a combined mold device, and the two combined mold devices are arranged in the vertical direction in a mirror opposite manner. A lower mold frame and an upper mold frame are each provided with two mold set aligning mechanisms in the horizontal direction in a mirror symmetry manner. Two demolding mechanisms are arranged on the lower mold frame in a mirror symmetry manner in the horizontal direction. In the equipment, a modular combined forming structure is adopted, a new module can be formed through module recombination to realize forming machining of silicone rubber insulators with different length specifications, the forming machining requirements of the silicone rubber insulators with the same type and different specifications are met, a large quantity of corresponding forming mold equipment does not need to be produced, and therefore the problem of high investment cost of forming equipment in the prior art is greatly reduced.

Owner:新沂市向荣电子有限公司

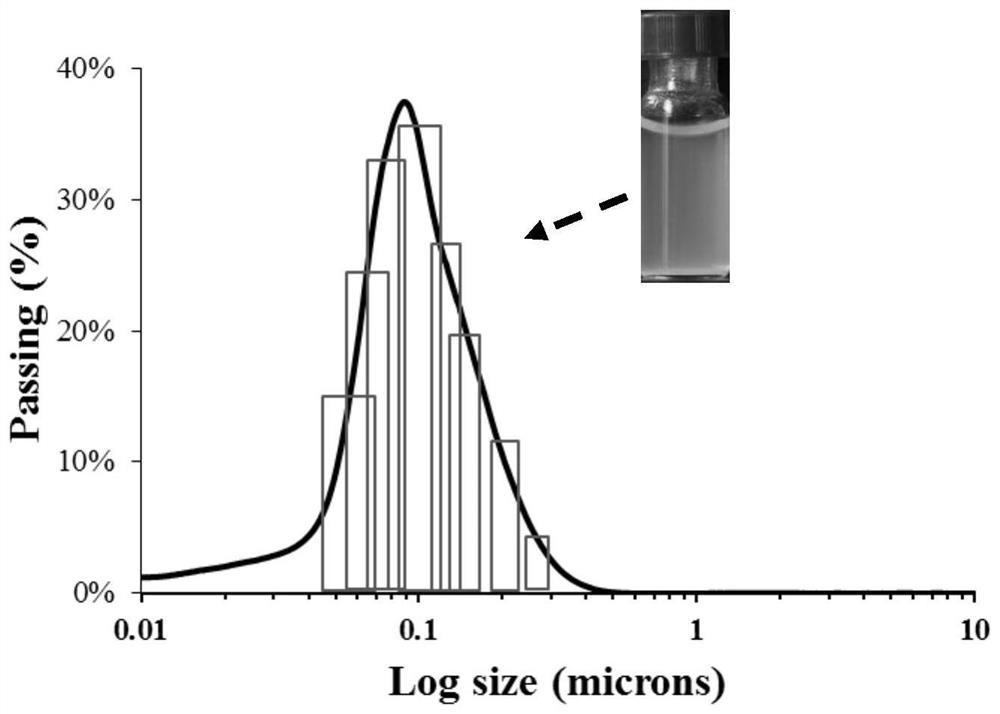

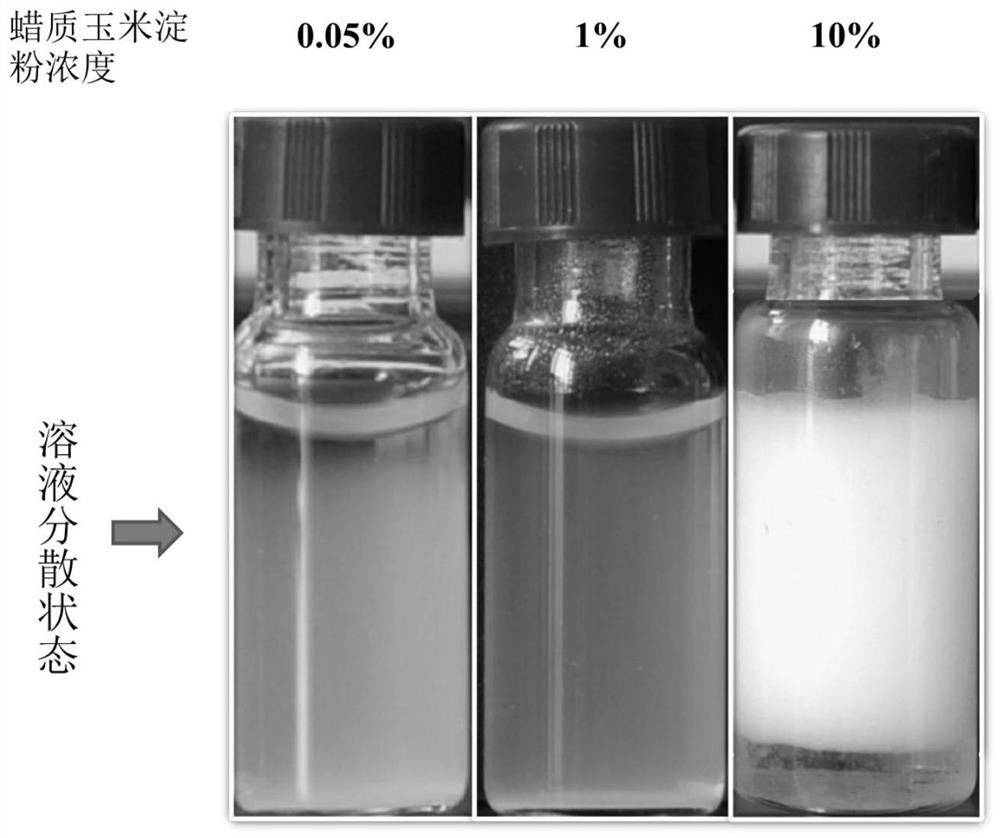

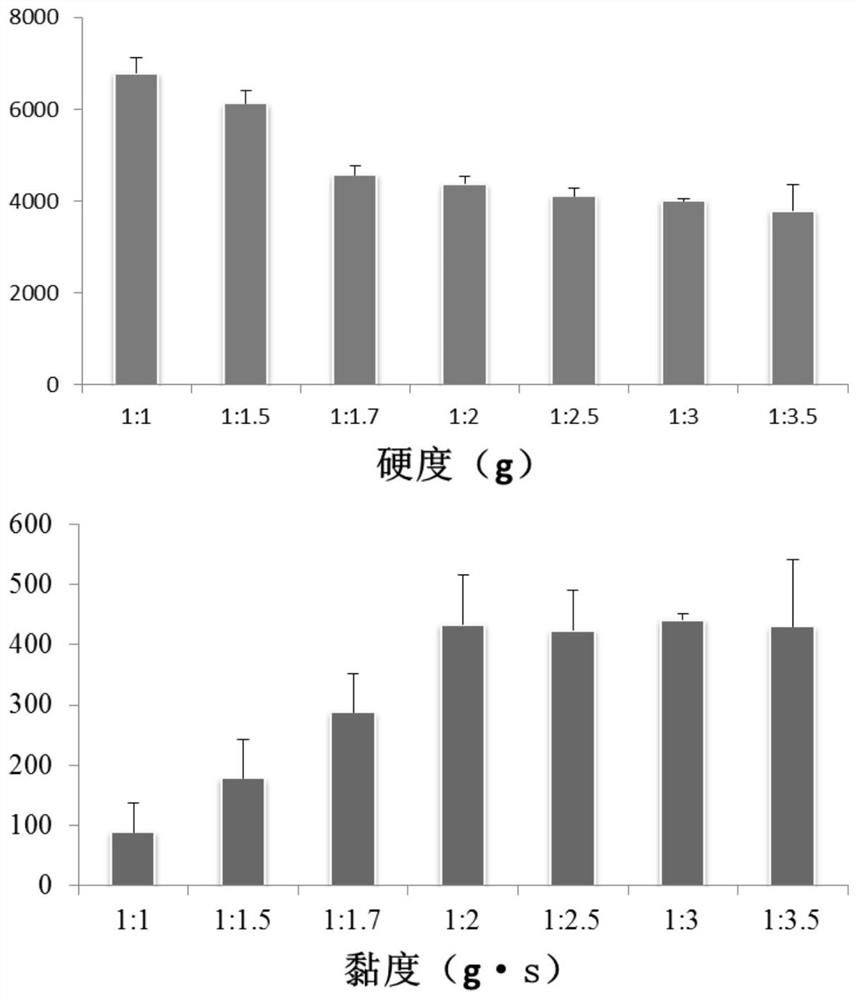

A processing method using indica rice as a raw material for making rice dumplings and sushi with low GI value

ActiveCN108323684BSoft tasteSticky tasteUltra high pressure food processesFood ultrasonic treatmentBiotechnologyDigestion

The invention relates to the field of food processing, in particular to a processing method of using indica rice as a raw material for making zongzi and sushi with low GI value, comprising the following process steps: soaking indica rice in water and performing ultrasonic treatment; preparing nano-scale waxy starch Colloid; the indica rice after ultrasonic treatment is mixed with the above-mentioned nano-scale starch colloid; the above-mentioned indica rice is directly used as a raw material for producing rice dumplings and sushi with low GI value. The taste of the indica rice obtained by the method of the invention is soft, sticky and easy to chew, and the digestion rate and GI value are significantly lower than that of boiled glutinous rice and sushi.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

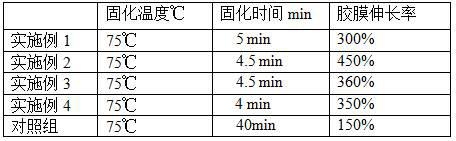

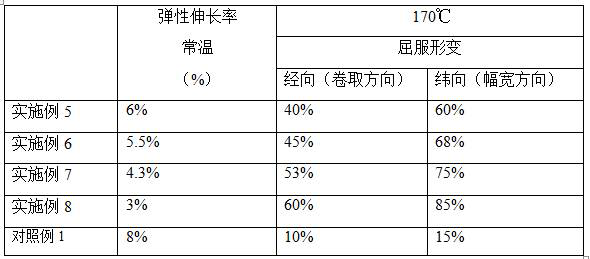

Thermoplastic electrostatic flocking fabric as well as preparation method and application thereof

ActiveCN112921672ALow curing temperatureHigh elongationConstructions elementsCoatingsEpoxyThermoplastic

The invention discloses thermoplastic electrostatic flocking fabric as well as a preparation method and application thereof. The electrostatic flocking fabric is composed of a surface layer, a middle layer and a bottom layer, wherein the surface layer is fiber fluff, the middle layer is a glue curing layer, and the bottom layer is base cloth; the glue curing layer is electrostatic flocking glue and is composed of a mixed monomer, an emulsifier, an initiator, a cross-linking agent and water, and the mixed monomer comprises methyl methacrylate, dibutyl maleate, butyl acrylate, ethyl acrylate and epoxy resin. The electrostatic flocking glue is low in curing temperature, and is high in elongation and softness of glue film, and when the electrostatic flocking glue is applied to preparation of the thermoplastic electrostatic flocking fabric, a formed composite structure is stable, yield deformation can be improved, and the forming requirement is met after mechanical foaming; the electrostatic flocking fabric is stable in size at normal temperature, has the elastic elongation of 5-8%, can generate plastic deformation, which is uniform and free of tearing and cracking phenomena, at a thermal state (150-170 DEG C), and can be applied to a new material required by an embedded automobile carpet foot pad.

Owner:SHANDONG HUACHENG HIGH TECH ADHESIVE

Carton forming die

PendingCN114789581AMeet molding needsEnvelopes/bags making machineryBags/boxes manufactureCartonEngineering

The invention discloses a carton forming mold, and belongs to the technical field of forming molds, the carton forming mold comprises a base and a forming mold body on the base, the base comprises a fixing seat and a rotating disc installed on the fixing seat, the forming mold body comprises a bottom plate and a forming plate arranged on the bottom plate and perpendicular to the bottom plate, and the forming plate comprises a plurality of forming grooves formed in the length direction of the bottom plate; the plurality of forming transverse plates are arranged along the width direction of the bottom plate and are perpendicular to the bottom plate, the plurality of forming longitudinal plates are arranged along the width direction of the bottom plate and are perpendicular to the bottom plate, and the middle parts of the forming transverse plates and the middle parts of the forming longitudinal plates form a carton accommodating cavity. According to the forming mold of the carton, the forming transverse plates are arranged to be of a telescopic structure in the length and height directions of the bottom plate, the forming longitudinal plates are arranged to be of a telescopic structure in the width and height directions of the bottom plate, the forming mold can be adjusted according to the size of the carton, the forming requirements of different cartons are met, and the application range is wide.

Owner:全安达冷链包装科技(深圳)有限公司

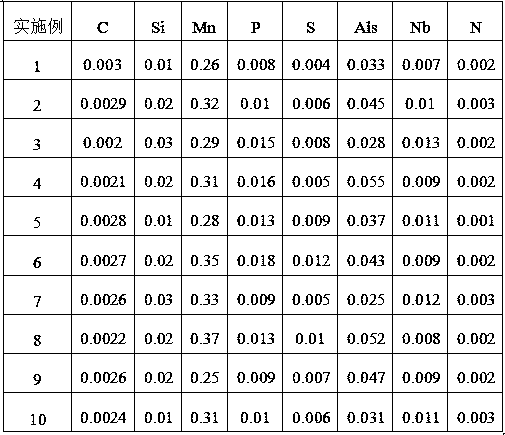

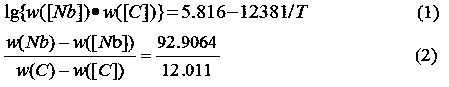

140 MPa grade cold rolled ultra-low carbon steel with high bake hardening characteristic and production method

The invention relates to 140 MPa grade cold rolled ultra-low carbon steel with a high bake hardening characteristic. The steel comprises the following components in percent by weight: 0.002-0.003% ofC, less than or equal to 0.3% of Si, 0.25-0.35% of Mn, 0.008-0.018% of P, less than or equal to 0.012% of S, 0.025-0.055% of Als, less than or equal to 0.003% of N, 0.007-0.013% of Nb and the balanceFe and inevitable impurities. A production method of the 140 MPa grade cold rolled ultra-low carbon steel with the high bake hardening characteristic comprises the steps of steelmaking, hot rolling, pickle-rolling and continuous annealing. In the annealing step, the soaking temperature is 840-850 DEG C and the insulation time is 75-94 s. The 140 MPa grade cold rolled ultra-low carbon steel produced by the production method has a relatively good forming ability at normal temperature and has a stable high bake hardening value greater than 50 Mpa, not only meets a forming demand of a part, but also meets a rigidity demand of the formed part, and shows a good comprehensive property.

Owner:HANDAN IRON & STEEL GROUP +1

Special device for manufacturing composite material molded arc mold release film

The invention relates to the technical field of mold release film manufacturing, and in particular relates to a special device for manufacturing a composite material molded arc mold release film. Compared with the prior art, the special device for manufacturing the composite material molded arc mold release film comprises a feeding frame and an up-down welding mold which is engaged with the feeding frame, wherein the up-down welding mold comprises an upper mold and a lower mold; uniformly distributed welding contact cutters are arranged on the upper mold and the lower mold; the welding contact cutters on the upper mold and the lower mold are contacted in a matching manner; the outer end of each welding contact cutter is circular arc-shaped; and straight line type films can be asymmetrically staggered and extruded, so that the straight line type films can form an arc structure so as to meet the molding requirement of various arc-shaped pipes. The special device has the advantages of being simple in structure, high in production efficiency, relatively smooth in surface, uniform in air bag thickness, good in air impermeability and the like.

Owner:厦门新旺新材料科技有限公司

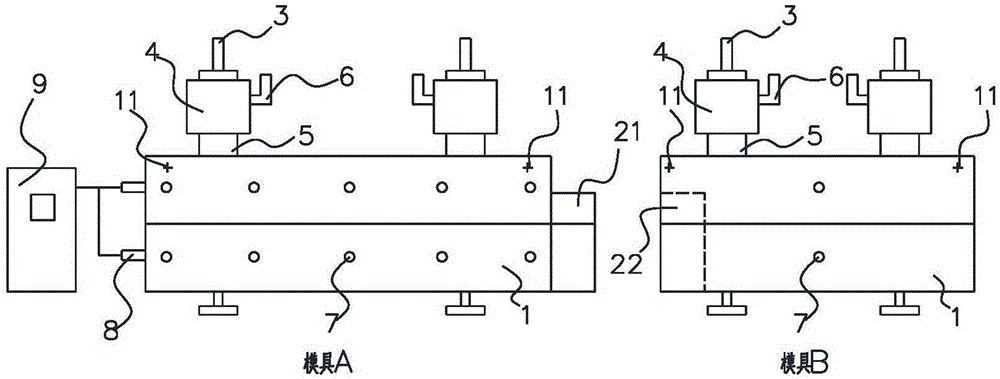

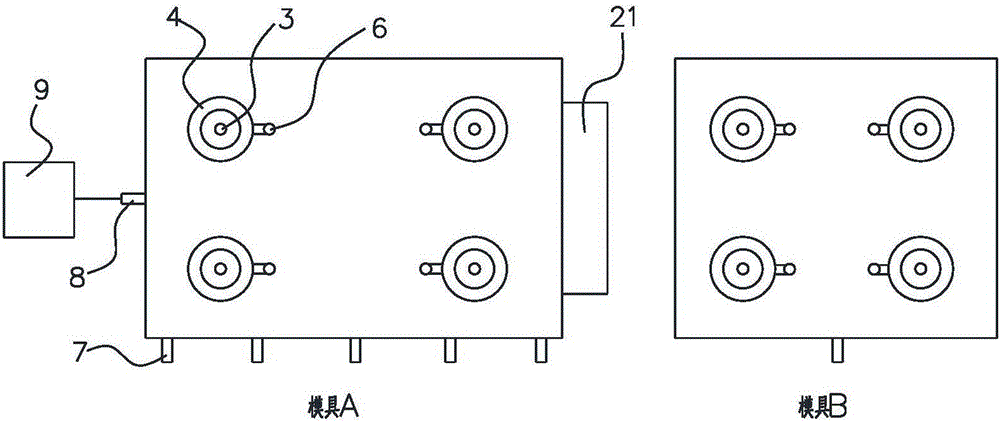

Composite forming mold with self-provided pressure source and heat source and mold unit

The invention discloses a composite forming mold with a self-provided pressure source and heat source, and a mold unit. The composite forming mold with the self-provided pressure source and heat source comprises a mold body, the pressure source and the heat source, and the pressure source is connected with the mold body by a conductive connection device. The conductive connection device penetrates the upper and lower surfaces of the mold body, and the heat source is connected with the mold body through the heat pipe. The composite forming mold has the advantages that the independent pressing equipment and the heating equipment are no longer needed, the operation of the equipment is simple, the production efficiency is high and the production cost is significantly reduced; the molding demand of the composite parts of different sizes can be satisfied, and particularly the molding needs of ultra-large composite parts can be met.

Owner:北京鸿鹄雄狮技术开发有限公司

Hair curler

ActiveCN105193061AMeet molding needsSimple structureCurling-ironsCurling-tongsEngineeringMoving parts

Owner:ZHEJIANG MEISEN ELECTRICAL APPLIANCE

Processing technology of arc-shaped spring

ActiveCN102501009BSmall thermal relaxation rateLarge momentary torqueFurnace typesHeat treatment furnacesStress reliefMaterials science

The invention relates to a processing technology of a large-radian arc-shaped spring. The processing technology is characterized by comprising the following procedures of: spring coiling: primary stress relief annealing; spring grinding; spring bending into an arc-shaped spring; secondary stress relief annealing; shot blasting; hot-strong pressing; sorting; angular rigidity and torque test; fatigue life test; and surface antirust treatment. According to the forming technology of the arc-shaped spring provided by the invention, the arc-shaped spring with the free angle of being more than 45 degrees can be effectively formed, the thermal relaxation rate of the spring is less than 2%, the instantaneous torque is large, the fatigue life is 1 million times, and the technical problems of low finished product rate and incapability for normal use of the large-radian arc-shaped spring in the prior art are solved.

Owner:HANGZHOU FUCHUN SPRING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com