Conductive polypropylene composite material and preparation method thereof

A technology of composite materials and polypropylene, which is applied in the field of conductive polypropylene composite materials and its preparation, can solve problems such as high cost, poor processing performance and mechanical properties, and increased melt viscosity, so as to achieve low prices, improve processing performance, and promote scattered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

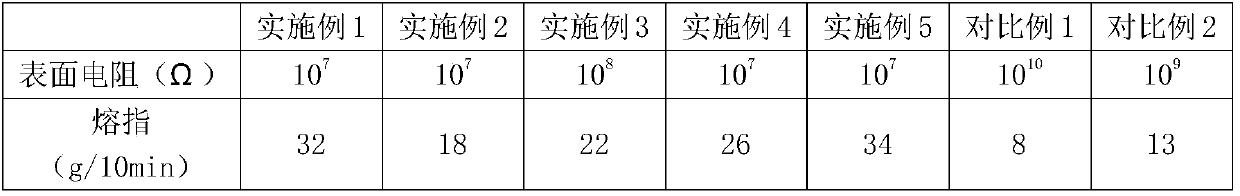

Examples

Embodiment 1

[0024] After mixing 3 parts by mass of 1-allyl-3-methyl-imidazolium chloride salt and 15 parts of conductive carbon black according to a certain mass ratio, they were ground and mixed at room temperature.

[0025] The conductive carbon black prepared above, 81 parts of homopolypropylene with a melt index of 60g / 10min, and 1 part of hindered phenolic heat stabilizer were weighed according to the mass ratio and mixed evenly, passed through a twin-screw extruder, through mixing, Conductive polypropylene composite material can be obtained by extrusion, drawing and pelletizing.

Embodiment 2

[0027] After mixing 4 parts by mass of 1-allyl-3-methyl-imidazolium chloride salt and 18 parts of conductive carbon black according to a certain mass ratio, they were ground and mixed at room temperature.

[0028] The conductive carbon black prepared above was mixed with 76.5 parts of copolymerized polypropylene having a melt index of 40g / 10min and 1.5 parts of heat stabilizer according to the mass ratio, and then mixed evenly, passed through a twin-screw extruder, through mixing, extrusion, drawing The conductive polypropylene composite material can be obtained by stripping and pelletizing.

Embodiment 3

[0030] After mixing 3.5 parts by mass of 1-allyl-3-methyl-imidazolium chloride salt and 20 parts of conductive carbon black according to a certain mass ratio, they were ground and mixed at room temperature.

[0031] The conductive carbon black prepared above was mixed with 75.7 parts of homopolypropylene with a melt index of 80g / 10min, and 0.8 parts of hindered phenolic heat stabilizer according to the mass ratio, and mixed evenly, passed through a twin-screw extruder, through mixing, Conductive polypropylene composite material can be obtained by extrusion, drawing and pelletizing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com