Graphene-modified heat-conducting and insulating nylon 6 material and preparation method thereof

A graphene modification, heat conduction and insulation technology, which is applied in the field of nylon composite materials, can solve problems such as limited use, and achieve the effects of promoting dispersion, improving thermal conductivity, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

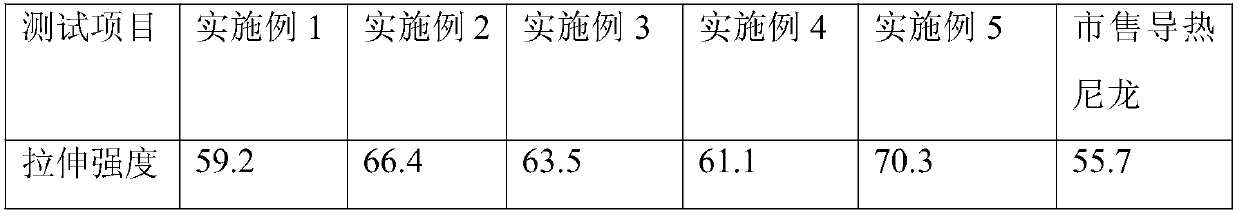

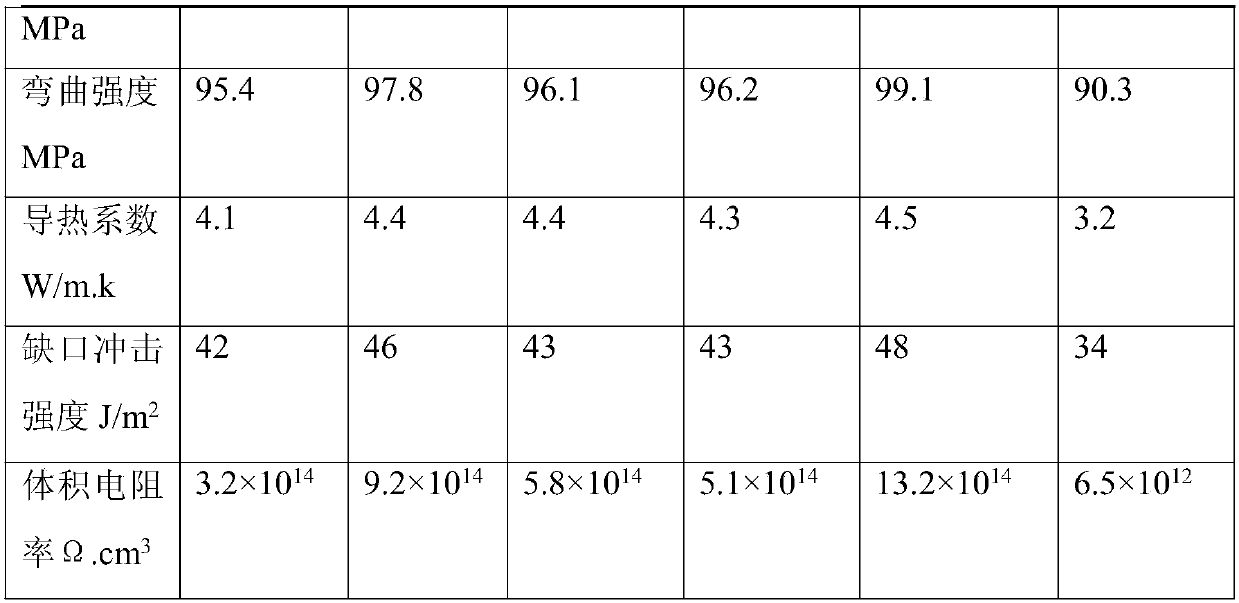

Examples

preparation example Construction

[0032] A preparation method of a graphene-modified thermally conductive insulating nylon material, comprising the following steps:

[0033] 1) Take various raw materials according to the above-mentioned formula,

[0034] 2) Dry the high-flow nylon resin at a temperature of 70°C-80°C for 1-2 hours, and then mix it with all other raw materials evenly;

[0035] 3) The mixed raw materials are placed in the lower hopper of the extruder, melted, extruded and granulated by a twin-screw extruder to obtain a graphene-modified thermally conductive and insulating nylon material.

[0036] Further, the process parameters of the above-mentioned twin-screw extruder melt extrusion granulation are: the temperature of the first zone is 190-195°C, the temperature of the second zone is 225-230°C, the temperature of the third zone is 230-235°C, and the temperature of the fourth zone is 225-230°C , the temperature of the fifth zone is 220-225°C, the temperature of the sixth zone is 205-210°C, the ...

Embodiment 1

[0038] A graphene-modified thermally conductive and insulating nylon 6 material comprising the following mass fractions:

[0039] High flow nylon 75.5%; glass fiber 5%; basalt fiber powder 1%; sulfonated graphene 5%; nano molybdenum powder 1%; aluminum nitride 10%; nano cellulose 0.5%; lead nitrate 1%; antioxidant Agent 0.5%; lubricant 0.5%.

[0040] The thermally conductive and insulating nylon 6 material was prepared according to the above method.

Embodiment 2

[0042] A graphene-modified thermally conductive and insulating nylon material comprising the following mass fractions:

[0043] High fluidity nylon 48.5%; glass fiber 12%; basalt fiber powder 4%; sulfonated graphene 9%; nano molybdenum powder 3%; tungsten tetraboride 15%; Oxygen 0.5%; lubricant 1.0%.

[0044] Prepare the thermally conductive and insulating nylon material according to the above method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com