Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Meet different product needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

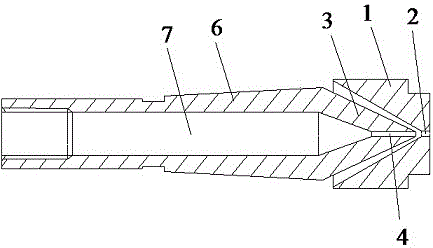

Optical fiber temperature/humidity sensor inductive layer and preparation method and application thereof

InactiveCN101776493ASimple processEasy to operateCladded optical fibrePhase-affecting property measurementsEngineeringMoisture sensor

The invention provides a preparation method of an optical fiber temperature / humidity sensor inductive layer, which comprises the following steps of: forming an optical fiber sensing segment with smaller outside diameter on an optical fiber, forming a rail at the periphery of the optical fiber sensing segment which is positioned in the rail, filling a liquid material in the rail, forming a layer of liquid film, wrapping the optical fiber sensing segment in the liquid film and coating an inductive layer on the outer surface of the optical fiber sensing segment. The optical fiber temperature / humidity sensor inductive layer manufactured by utilizing the preparation method of the optical fiber temperature / humidity sensor inductive layer is applied to producing an optical fiber temperature / humidity sensor. The invention has the advantages of simple process, easy operation, low manufacturing cost and good applicability.

Owner:SOUTH CHINA UNIV OF TECH

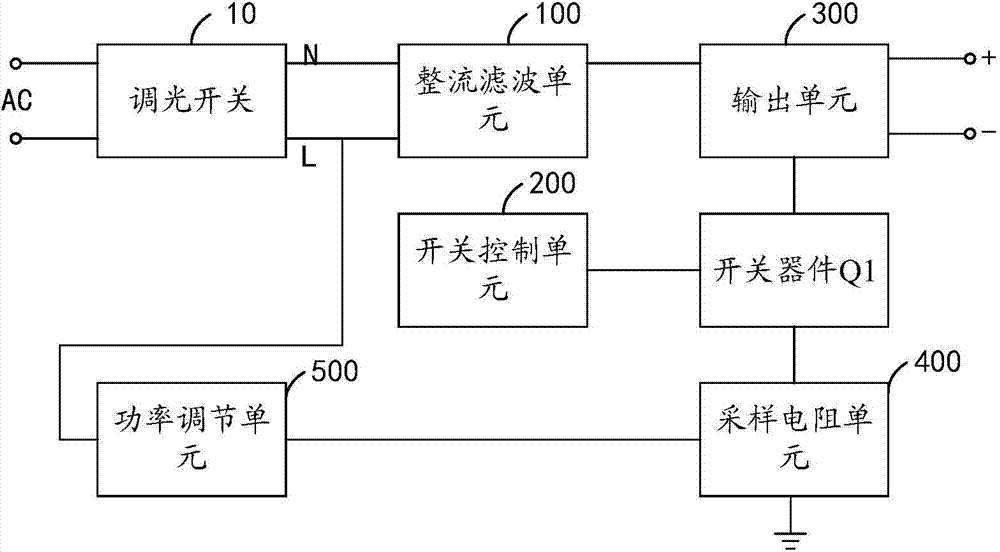

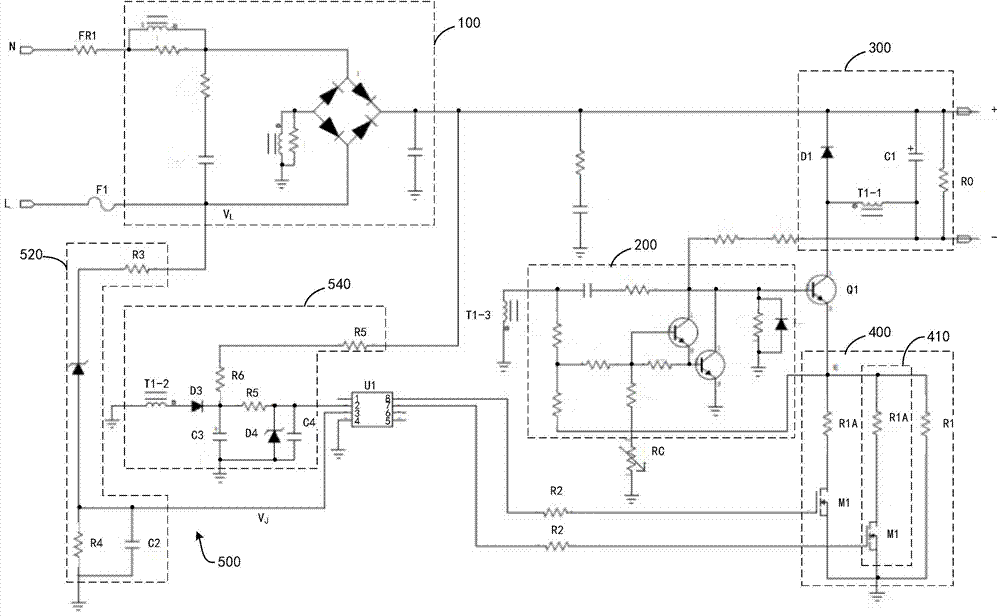

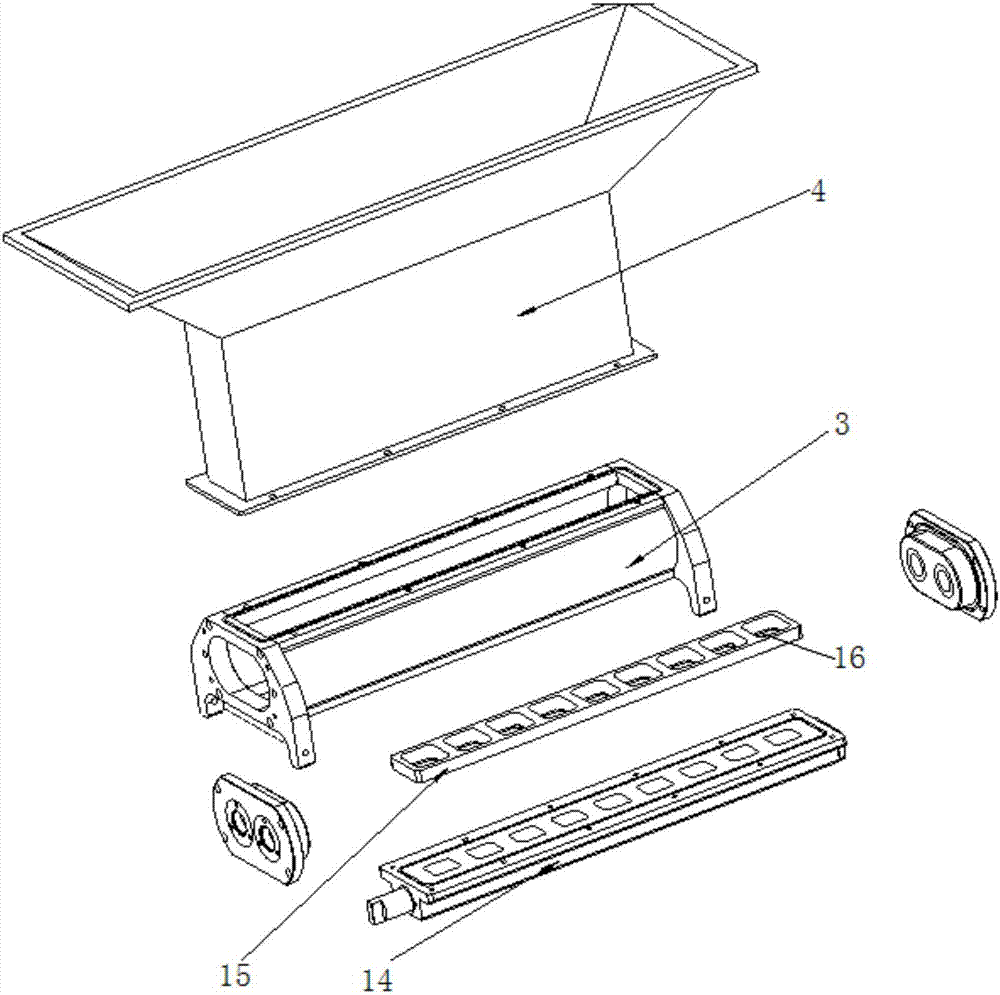

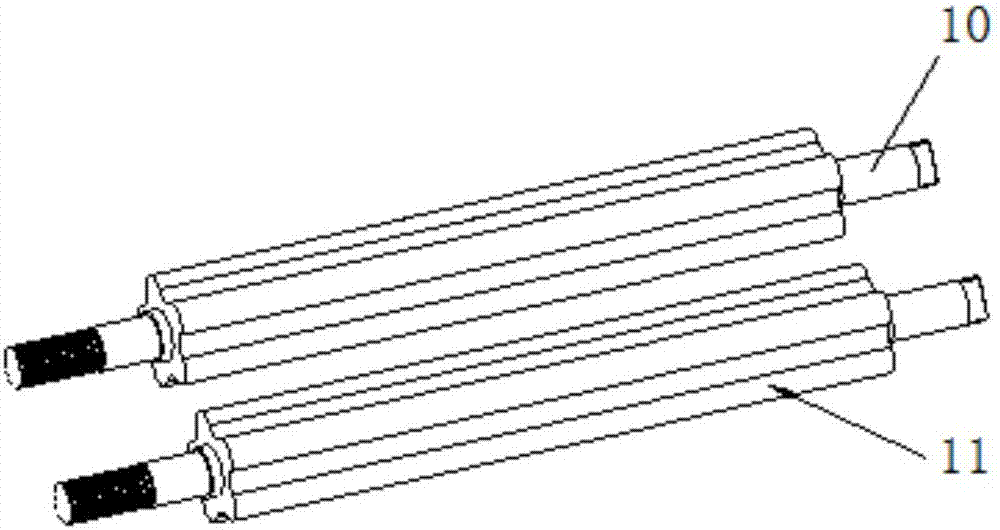

LED dimming circuit and LED lamp

ActiveCN104853476AEasy to useMeet different product needsElectric light circuit arrangementWave formEngineering

The invention provides an LED lamp including an LED dimming circuit connected with a dimming switch. The LED dimming circuit includes a rectification filtering unit, a switch device, a switch control unit, an output unit, a sampling resistor unit and a power adjusting unit. The power adjusting unit collects wave forms of the output voltage at the output terminal of the dimming switch. When the wave forms are normal sine waves, output power of the output unit is adjusted according to on-off frequency of the output voltage meeting requirements. When the wave forms are chopping sine waves, the output power of the output unit is adjusted to be the maximum. According to the invention, by detecting the wave forms of the current flowing through the adjusting switch and judging the type of the adjusting switch according to features of different influence on current of a common switch and a silicon controlled adjusting switch, different control strategies are used for controlling the output power of the control circuit, so that the compatibility between stepless dimming and segmentation dimming is achieved.

Owner:SHENZHEN JBT SMART LIGHTING

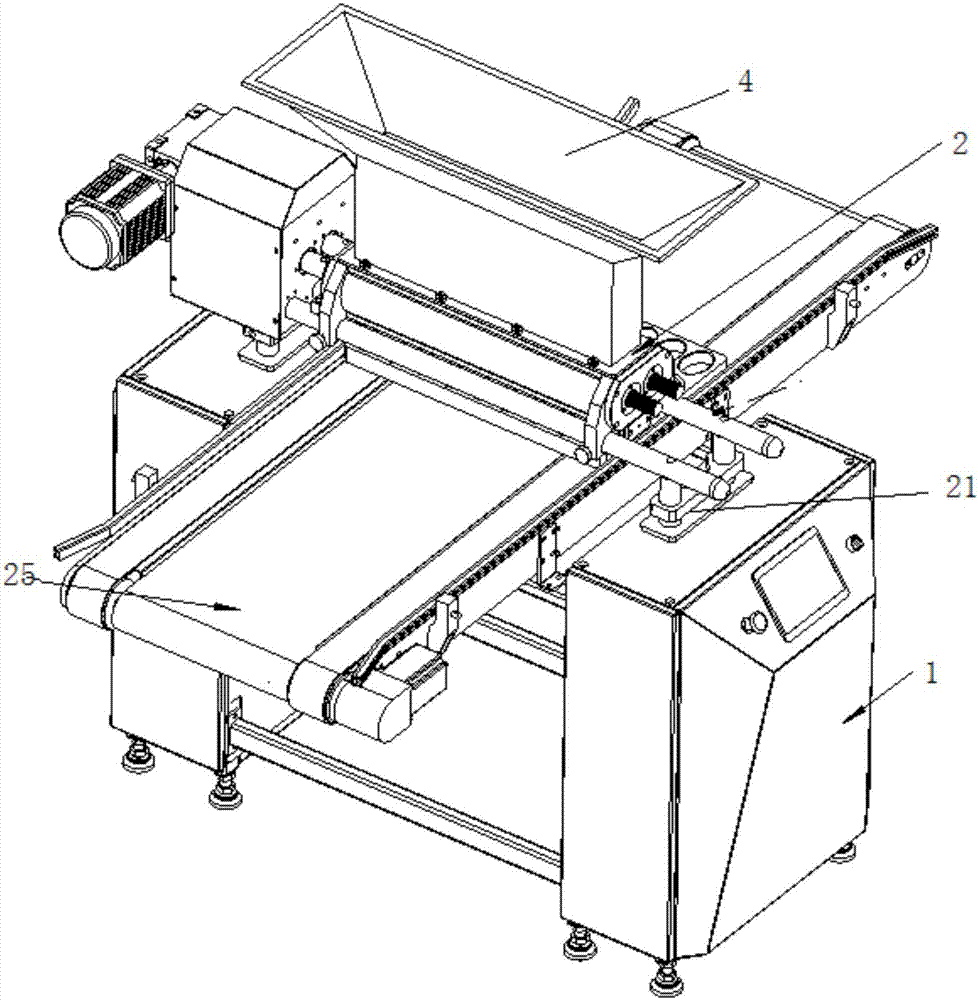

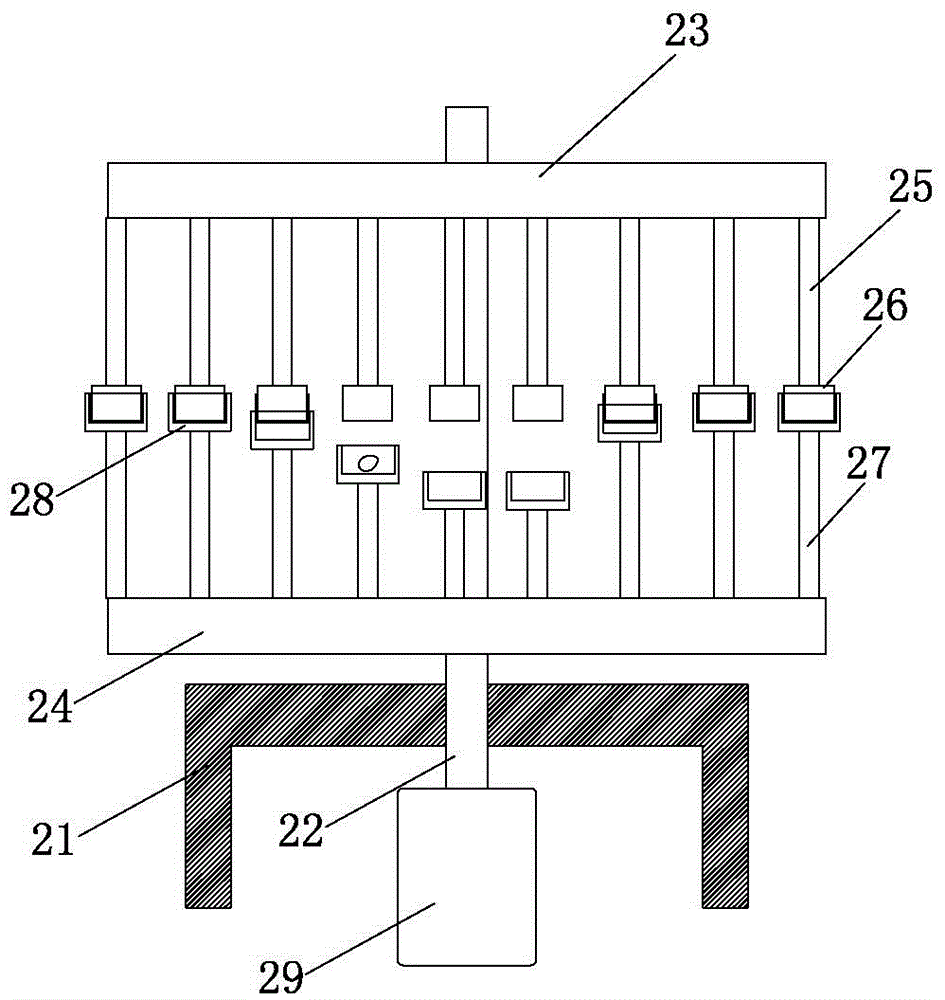

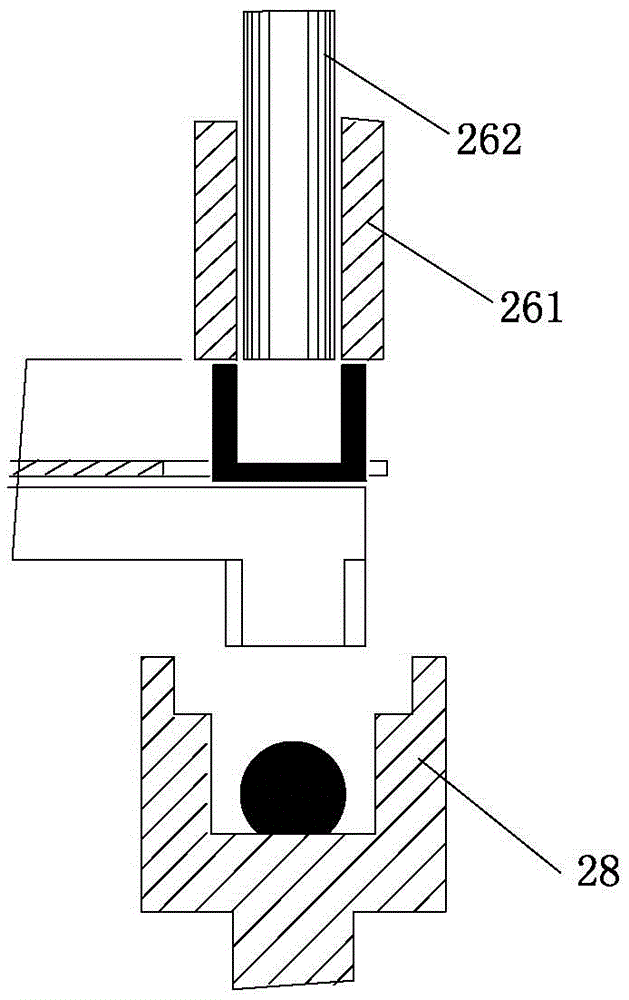

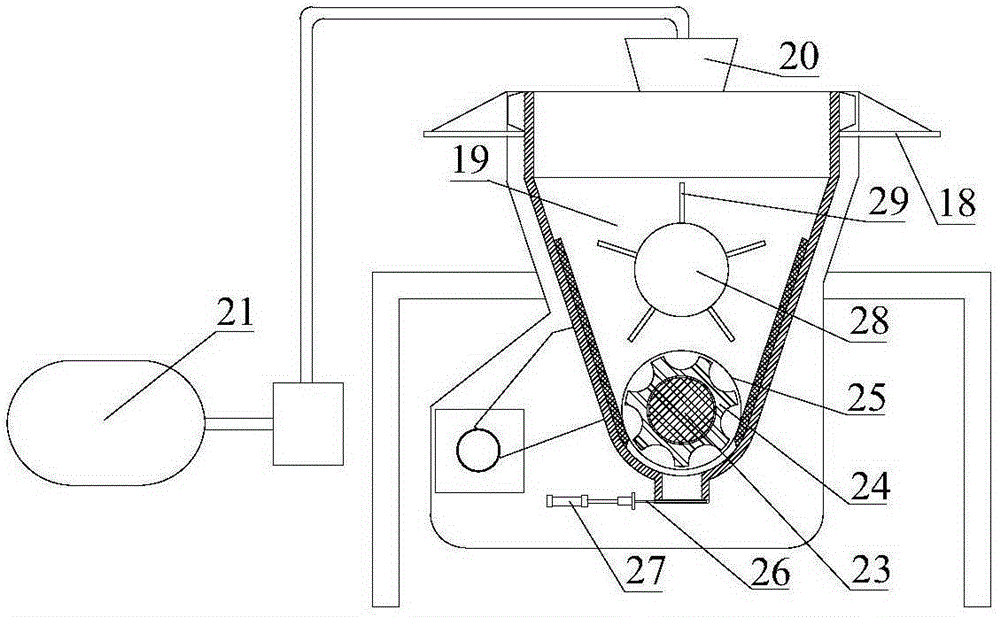

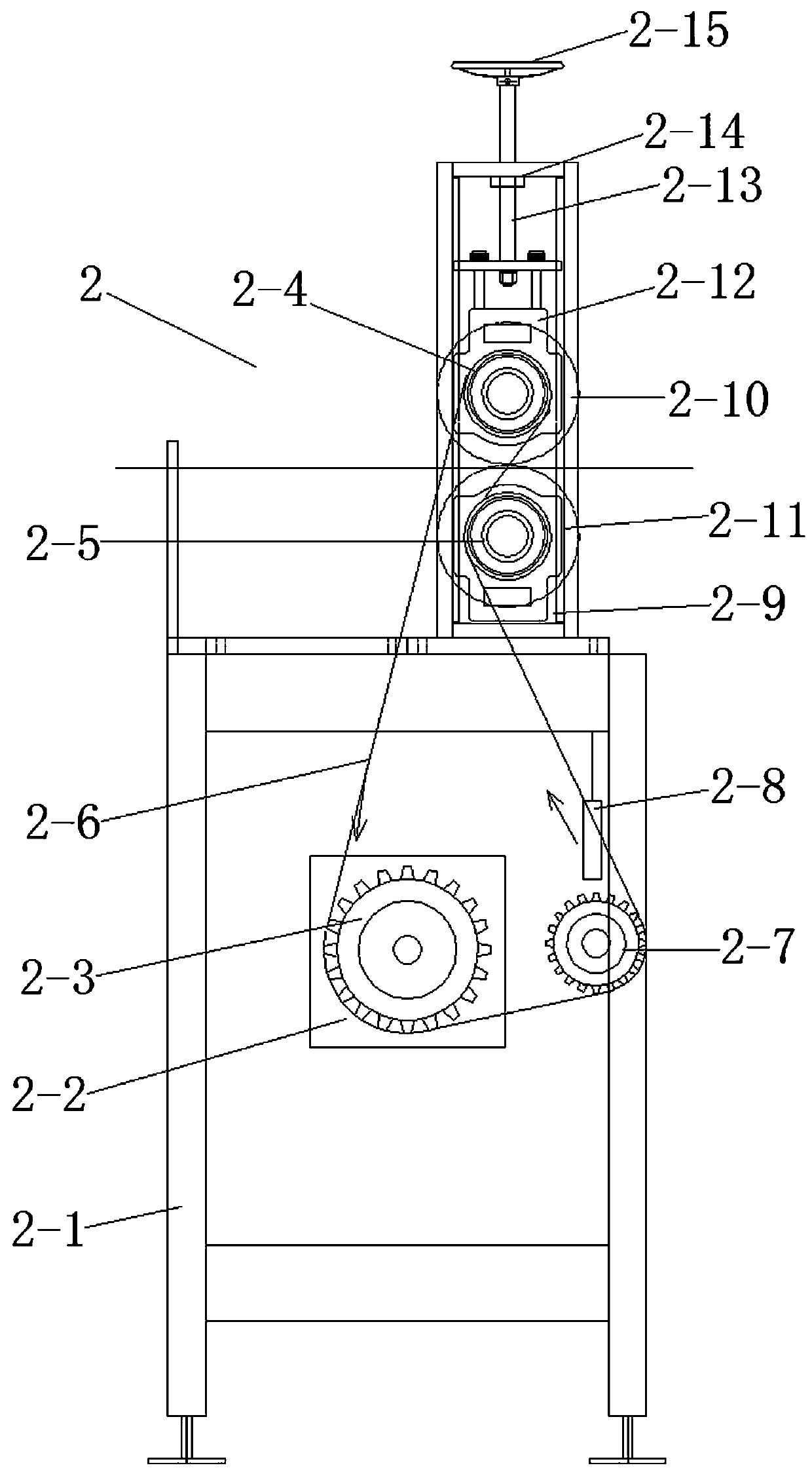

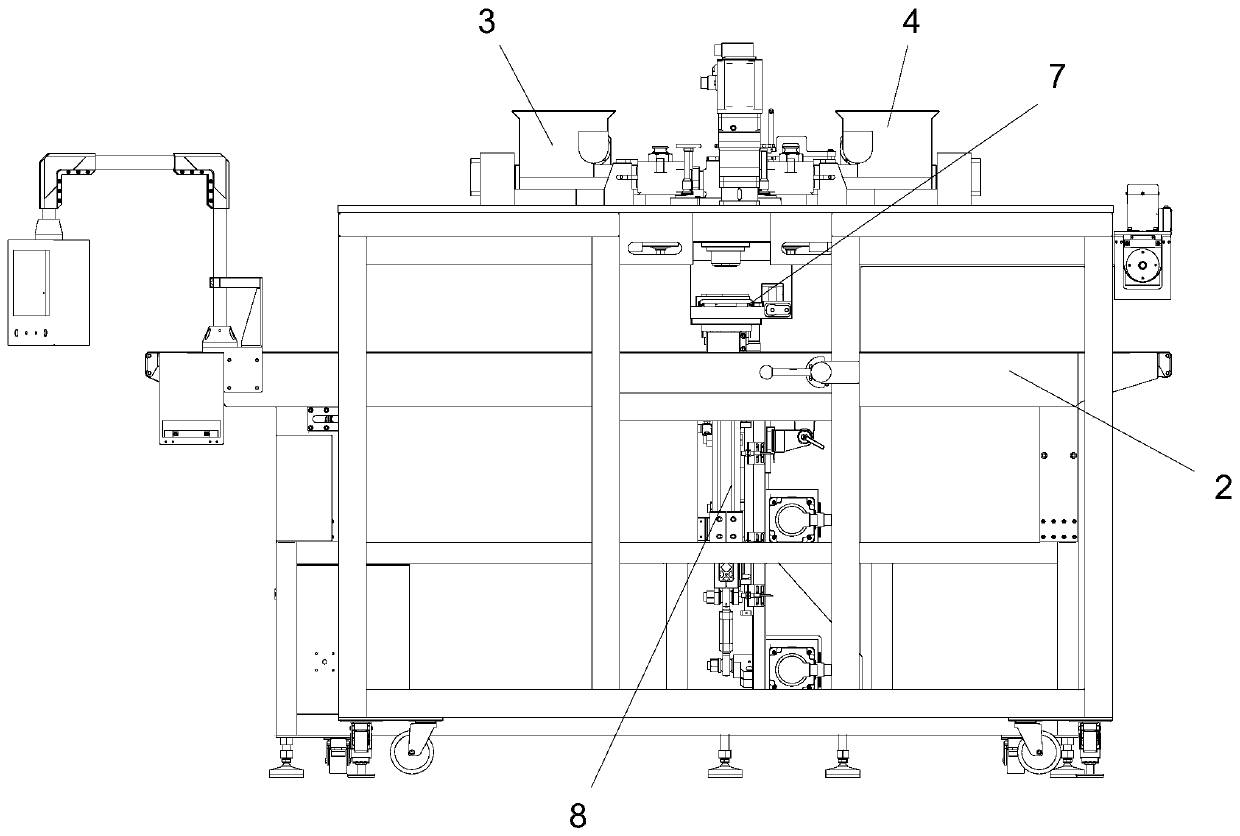

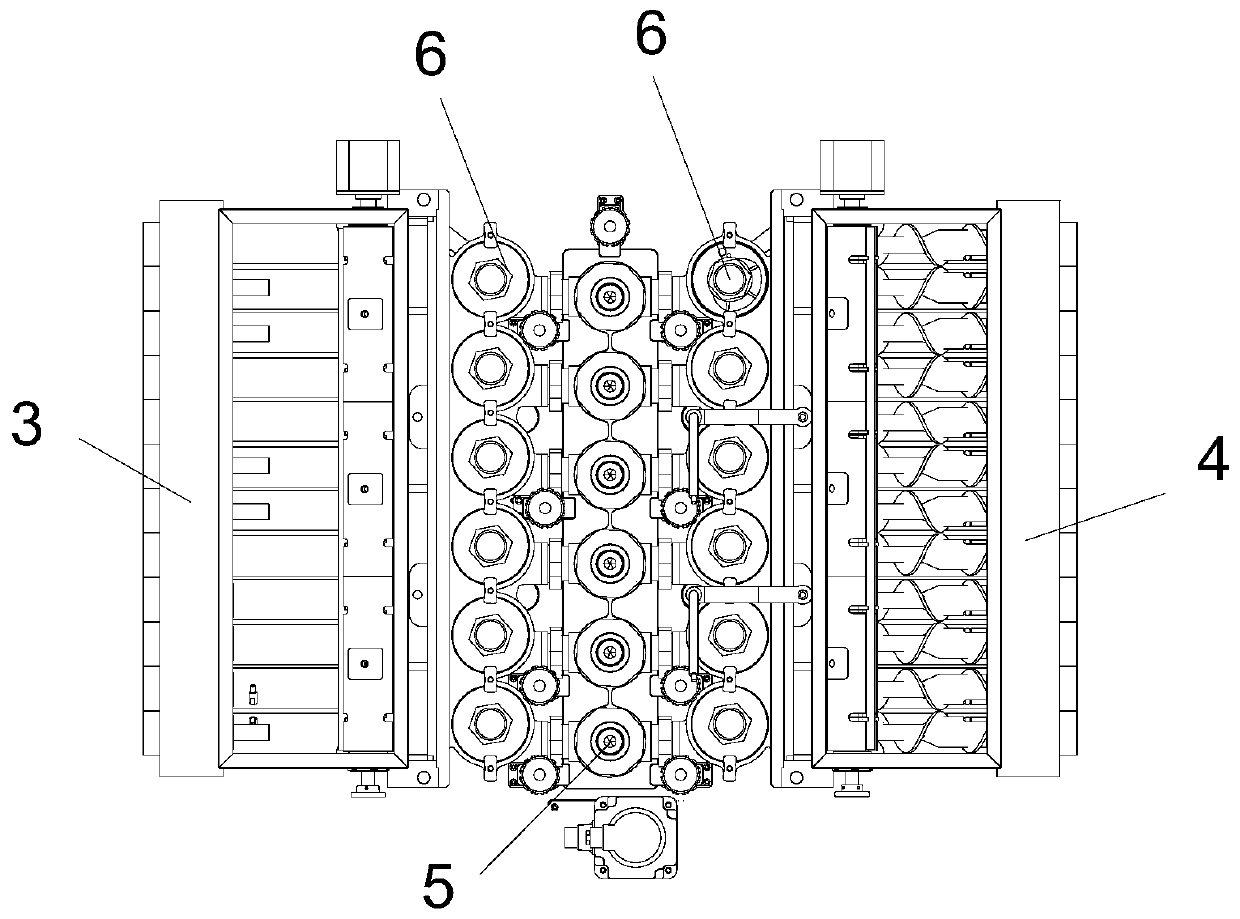

Grouting machine

ActiveCN106879659AUniform discharge scaleGood cutting effectDough dividingBaking plantsEngineeringManufacturing line

The invention discloses a grouting machine, which comprises a rack, wherein the rack is provided with a liftable pump body mechanism; the pump body mechanism comprises a pump body; the top of the pump body is provided with a hopper communicating with a feeding inlet in the pump body; a feed roller mechanism for conveying slurry is rotationally arranged in the pump body; a material closing base is arranged at the bottom of the pump body; a material cavity is arranged in the material closing base; a feeding hole and a discharge hole are formed in the top and the bottom of the material closing base separately; a material closing shaft is rotationally arranged in the material cavity; and material guide openings corresponding to the feeding hole and the discharge hole are formed in the material closing shaft. The grouting machine can be connected with a cake production line for use, can be used as a single machine, and is high in production efficiency and high in yield. Two structures are adopted by the material closing base and can be exchanged to meet different product requirements. Slurry dripping or trailing is avoided. A cake material is completely separated from a feed gate through material returning, material cutting and fast raising during material extrusion, no residue is formed and the slurry dripping or trailing can be avoided.

Owner:ANHUI ZHONGLE FOOD MACHINERY

Process system for producing exquisite sand by adopting machine-made sand vertical mill

PendingCN110732383AAchieve multi-functionalityLow fines contentSievingScreeningProcess systemsProcess engineering

The invention discloses a process system for producing exquisite sand by adopting a machine-made sand vertical mill. The process system comprises a raw material cabin, the machine-made sand vertical mill, a combined powder concentrator, a vibrating screen, a cyclone and a circulating fan, wherein the raw material cabin, the machine-made sand vertical mill and the combined powder concentrator are sequentially connected; a bottom discharging opening of the combined powder concentrator is connected with the vibrating screen; the vibrating screen returns oversize products to the machine-made sandvertical mill; the air outlet of the combined powder concentrator is connected with the cyclone; the air outlet of the cyclone is connected with the circulating fan; a plurality of layers of screens with different pore diameters are arranged on the vibrating screen; a pre-screening device is arranged between the machine-made sand vertical mill and the combined powder concentrator; the process system further comprises a machine-made sand blending system for blending sand out of the combined powder concentrator and the vibrating screen; and the machine-made sand blending system comprises a weighing device, a mixing device, a conveying device and a storing device. The process system can realize high-quality machine-made sand production, can produce the machine-made sand meeting any fineness modulus requirement, meets different product demands and realizes multiple functions of a production system.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

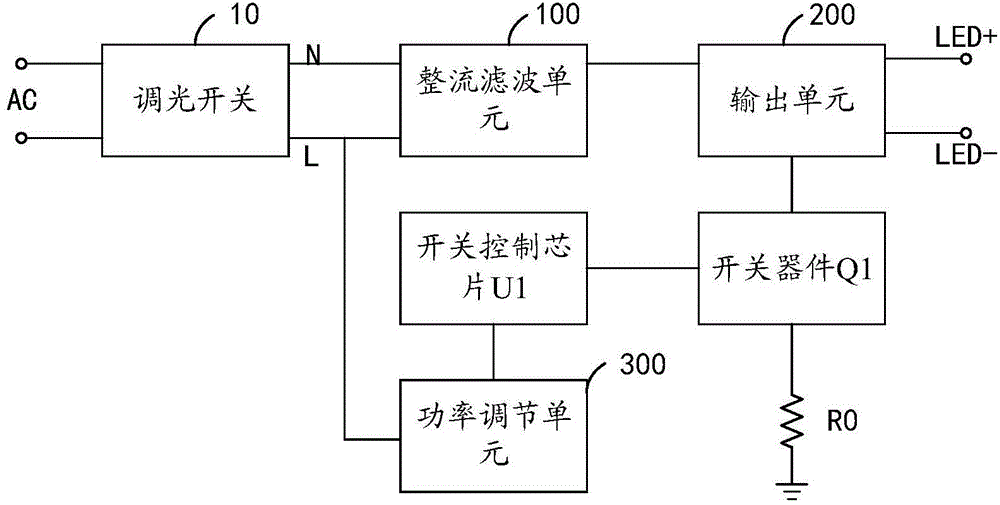

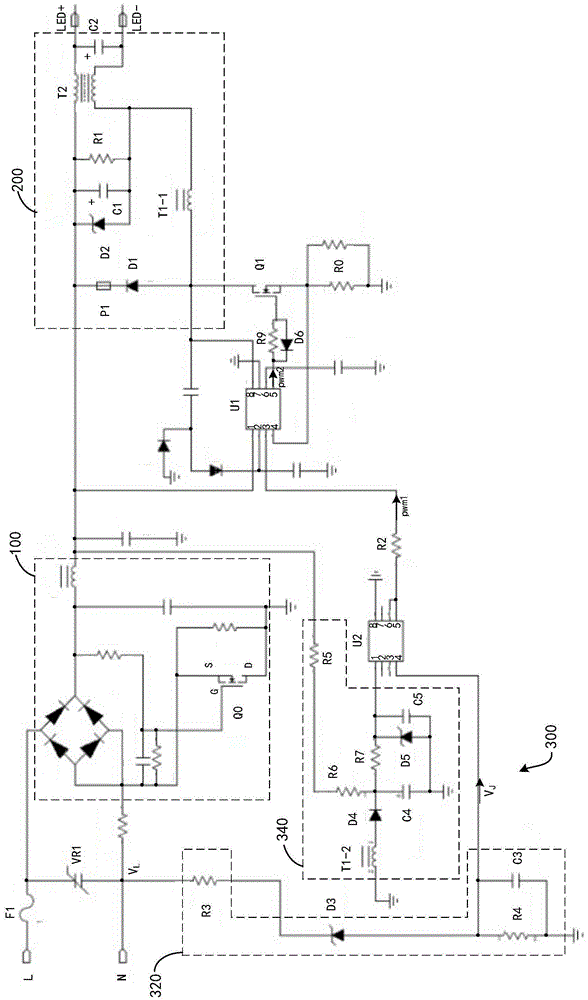

LED dimming circuit and LED lamp

ActiveCN104661408AEasy to useMeet different product needsElectric light circuit arrangementEnergy saving control techniquesPower flowLED lamp

The invention provides an LED lamp. The LED lamp comprises an LED dimming circuit connected with a diming switch, wherein the LED dimming circuit comprises a rectifying and filtering unit, a switch device, a switch control chip, an output unit, a sampling resistor and a power regulating unit; the power regulating unit is used for collecting waveform of output voltage of the output end of the diming switch; when the waveform is a normal sine wave, the output power of the output unit is regulated according to switching on and off frequency of the output voltage with accordance with the condition; when the waveform is a chopped sine wave, the output power of the output unit is regulated to be maximum. The LED dimming circuit is used for detecting the current waveform which passes through regulation switches and judging the type of the regulation switches according to the characteristics of different influences of ordinary switches and silicon-controlled regulation switches on the current, thereby controlling output power of the circuit by using different control strategies and implementing compatibility of stepless dimming and segmental dimming.

Owner:SHENZHEN JBT SMART LIGHTING

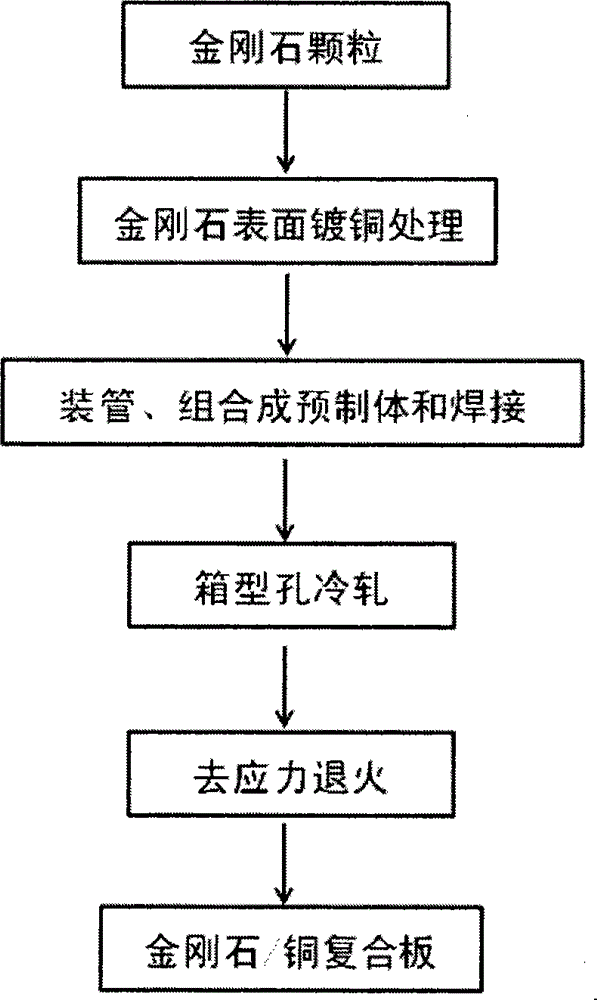

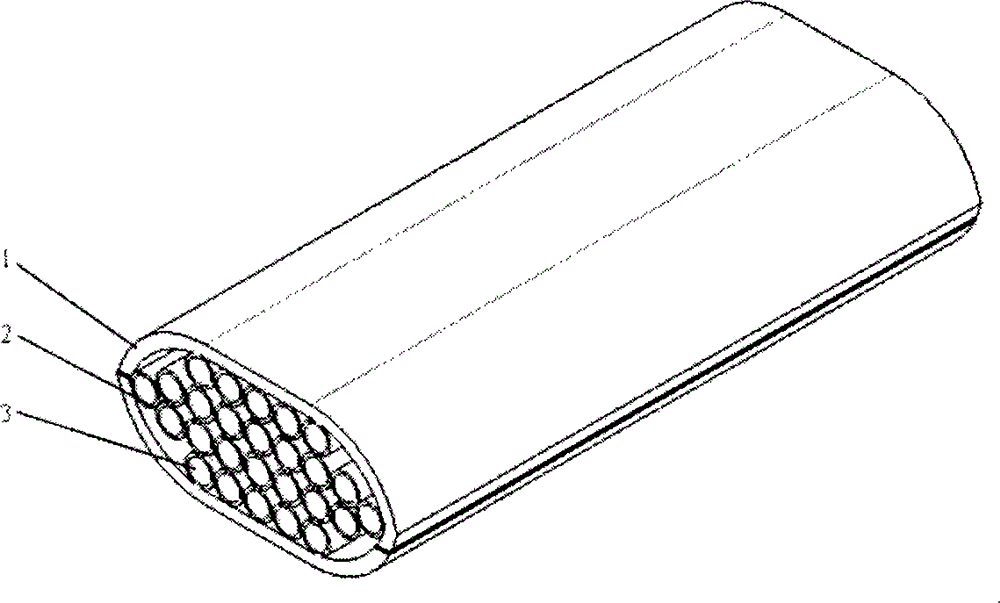

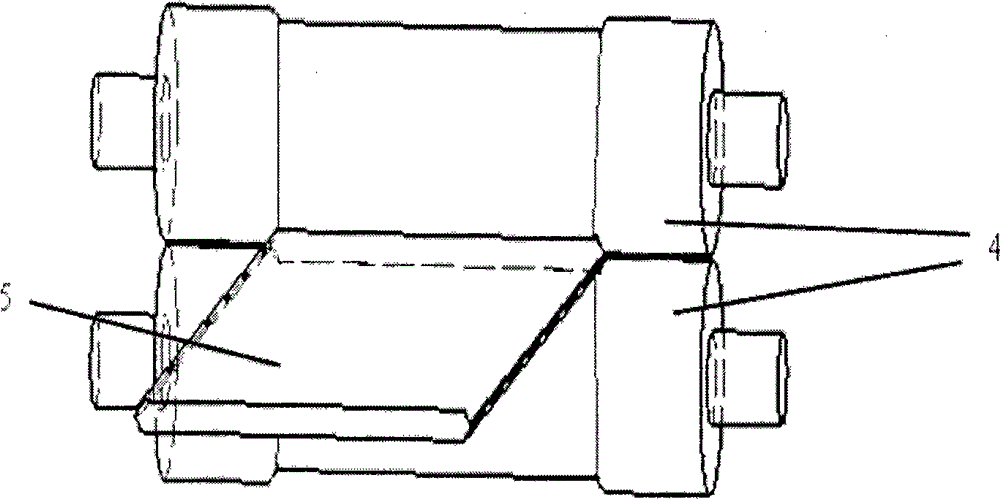

Boxy hole rolling method for large-sized high-thermal-conductivity diamond/copper composite board

InactiveCN104308465AOvercome difficult processing and forming problemsSolve processing problemsMetal rolling arrangementsCopper platingComposite plate

The invention discloses a boxy hole rolling method for a large-sized high-thermal-conductivity diamond / copper composite board. The method particularly comprises the following steps: uniformly placing diamond particles with copper-coated surfaces into thin-walled copper tubes with the external diameter of 2.5-3.5 mm; stacking the copper tubes into a bundle between an upper layer of copper sheets and a lower layer of copper sheets and welding the side edges of the two layers of copper sheets into a precast body; subjecting the prepared preform to multi-pass boxy hole cold rolling, and performing stress relieving at the temperature of 260-400 DEG C after each pass of rolling. Owing to the hardness difference between diamond and pure copper, in the rolling process, the diamond particles enter the copper matrix in an embedded manner. The boxy-hole pass rolling method has the advantages of uniform deformation, large deflection, capability of mass production and the like, and facilitates improvement on the production efficiency and reduction of the manufacturing cost. In the prepared diamond / copper composite board, the volume fraction of the diamond particles is 55-65%, and the thermal conductivity can reach more than 400W / (m.K). Therefore, a wide application prospect is achieved in the electronic encapsulation field.

Owner:UNIV OF SCI & TECH BEIJING

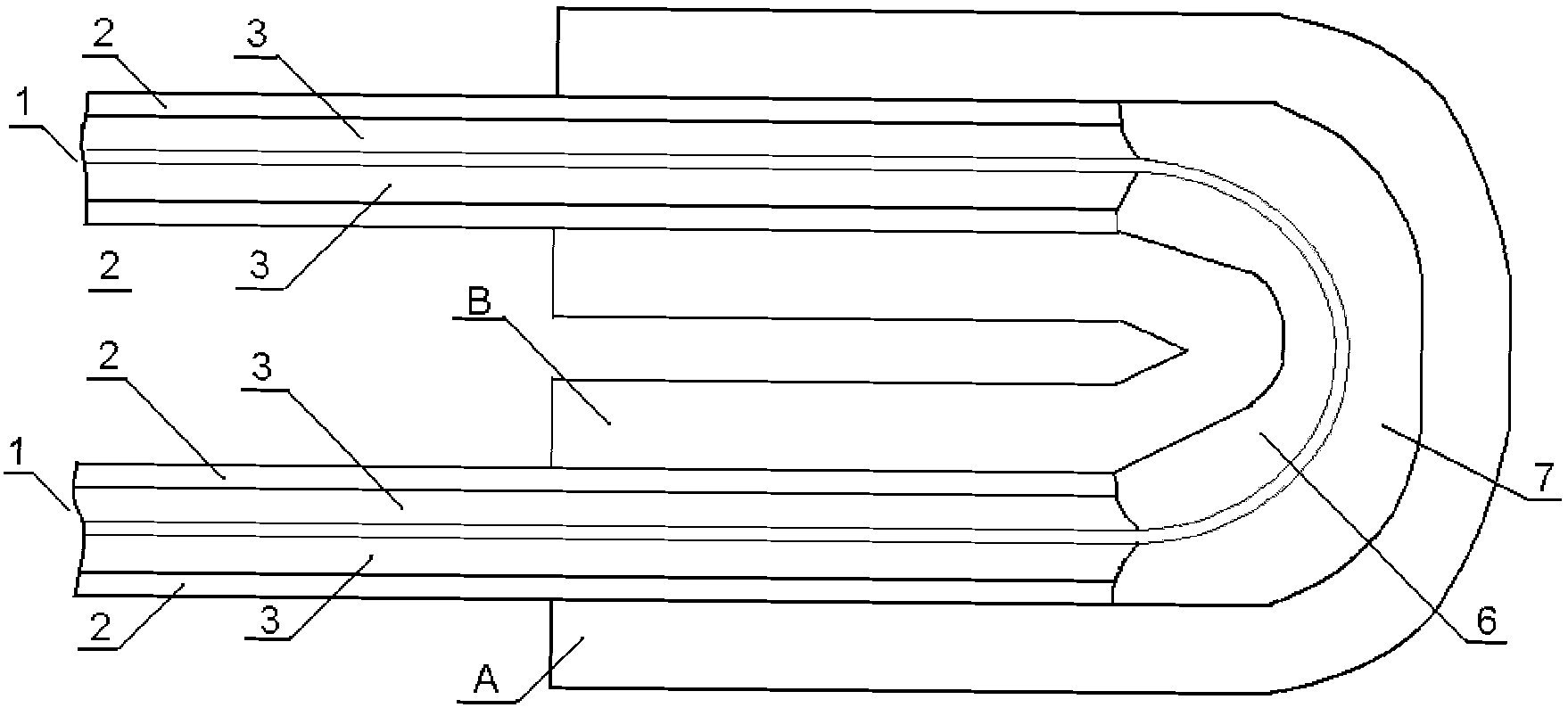

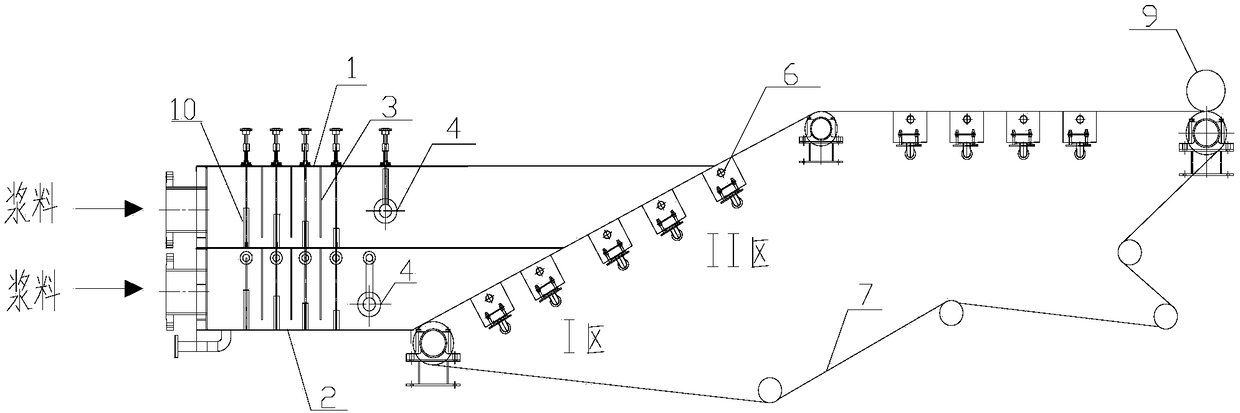

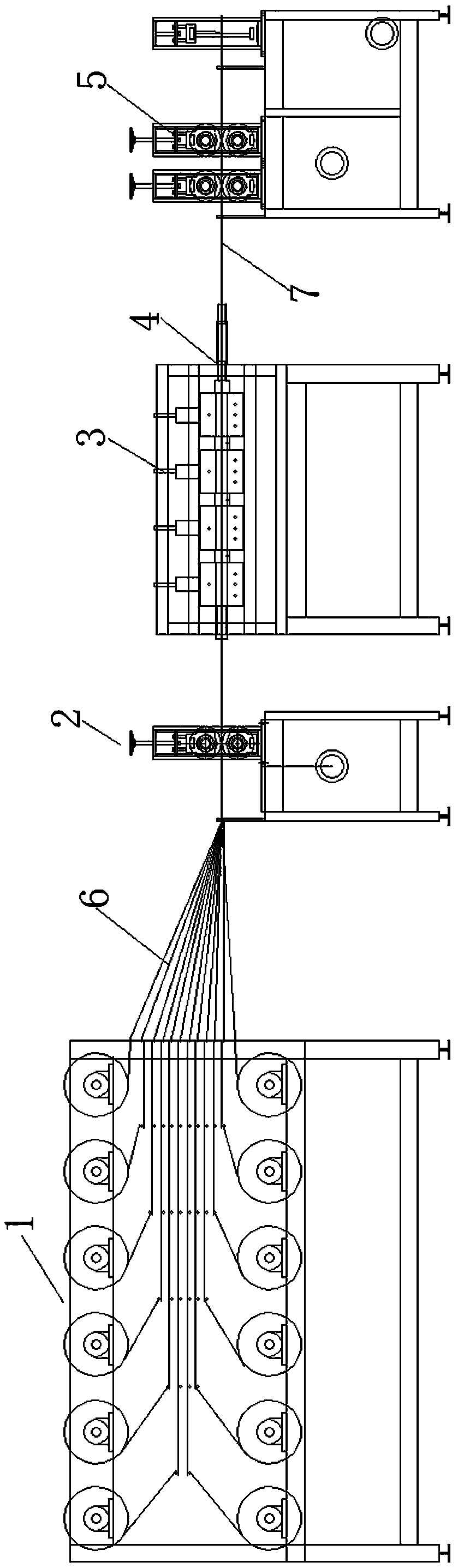

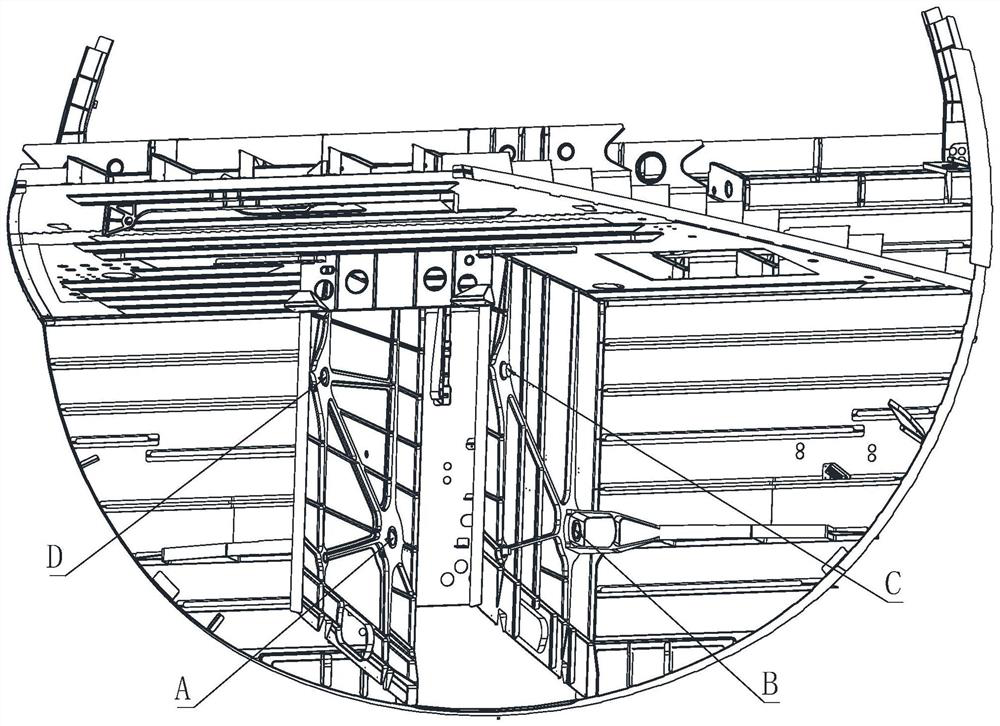

Open type single-net double-flow slurry inclined net forming machine

The invention discloses an open type single-net double-flow slurry inclined net forming machine. The forming machine comprises two flow slurry boxes, a forming net wound in a ring shape on a pluralityof driving rolls, vacuum suction boxes and homogenizing rolls. A plurality of partition plates are arranged inside the two flow slurry boxes and divided into an upper partition plate group and a lower partition plate group, the upper partition plate group includes a plurality of upper partition plates which have the same height and are arranged at equal distances, the upper ends and two sides ofthe upper partition plates are in sealed and fixed connection with top plates and two side plates of the flow slurry boxes, and gaps are formed between the lower ends of the upper partition plates andbottom plates of the flow slurry boxes; the lower partition plate group includes a plurality of lower partition plates which are arranged at equal distances and have progressively decreased height inthe flow direction of slurry, the lower ends and two sides of the lower partition plates are in sealed and fixed connection with the bottom plates and the two side plates of the flow slurry boxes, and gaps are formed between the upper ends of the lower partition plates and the top plates of the flow slurry boxes; the upper partition plates and the lower partition plates are arranged at intervals.The designed homogenizing rolls meet the characteristics of the slurry, the adjustment is convenient, and the slurry can be evenly spread to the net. Meanwhile, the vacuumizing pressure of a wet absorbing box is independently and accurately controlled to ensure uniform dehydration.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

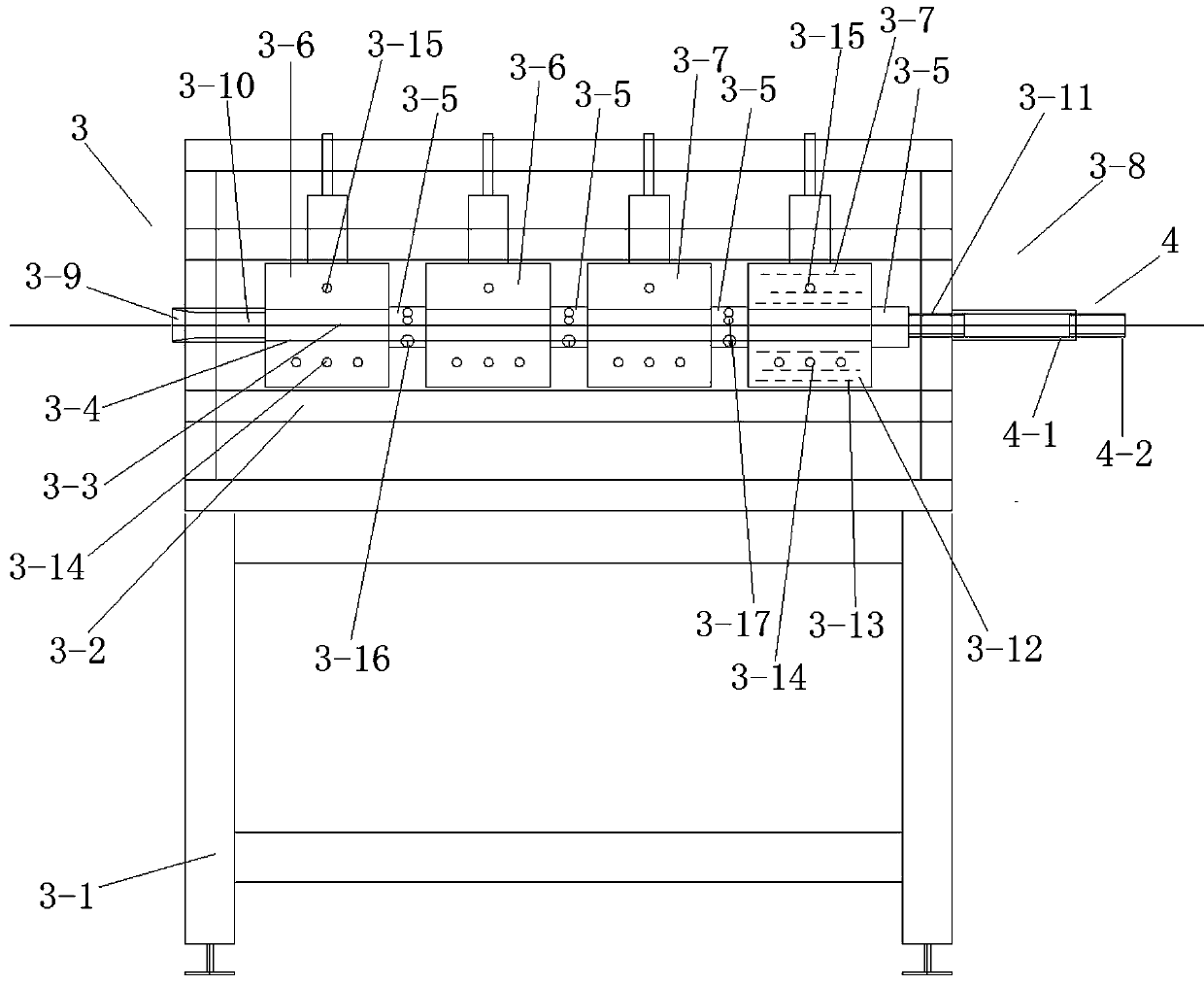

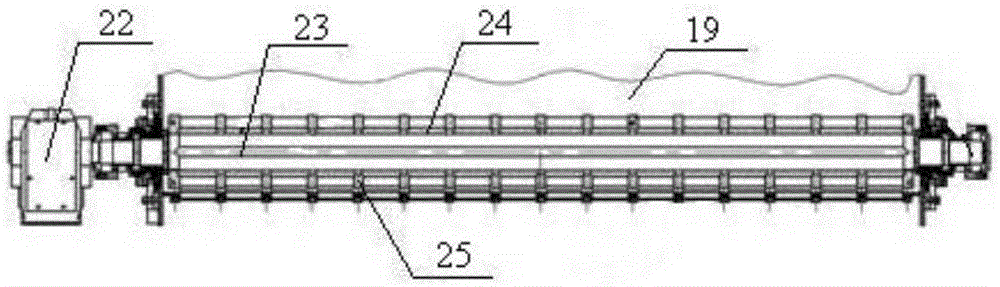

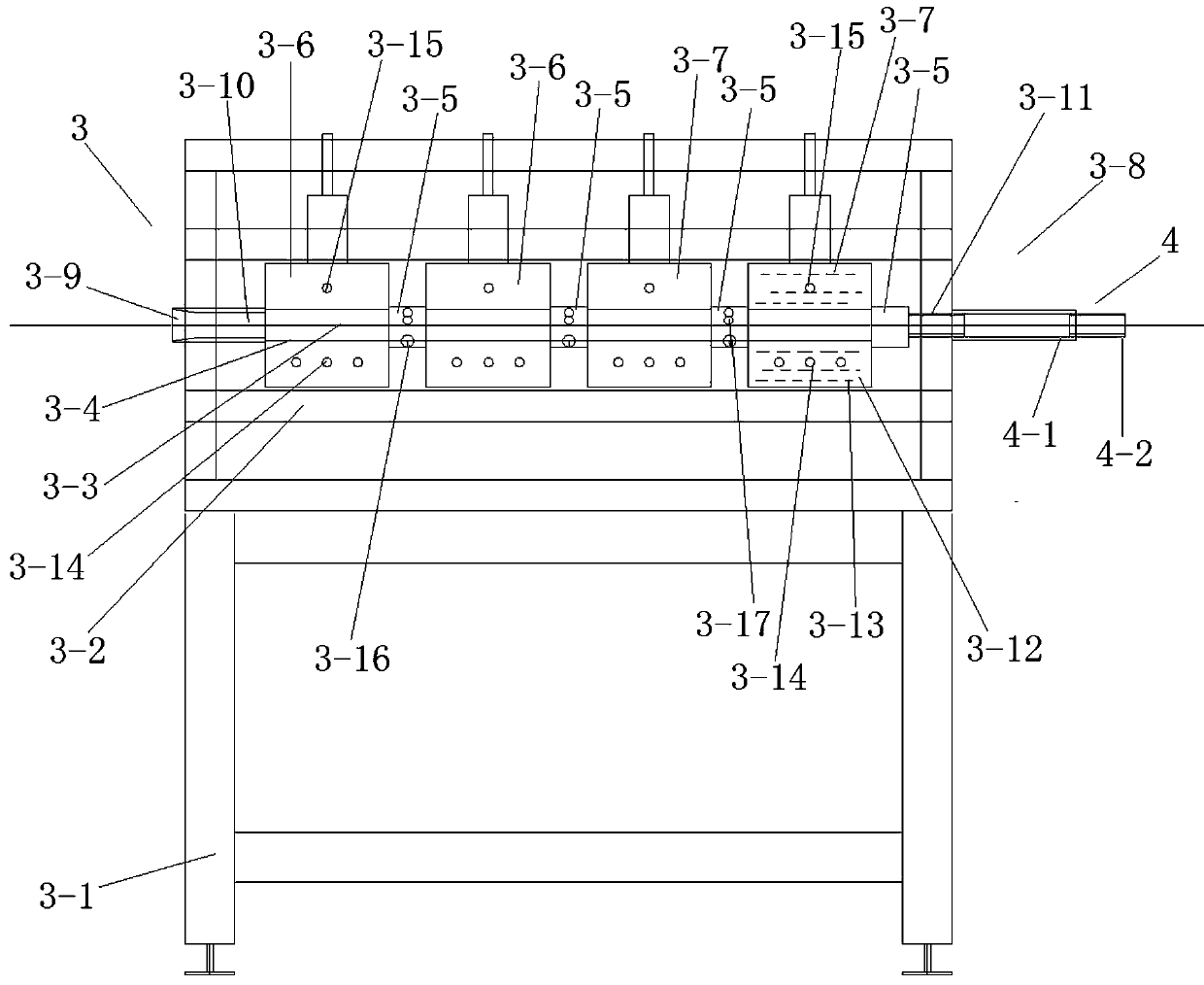

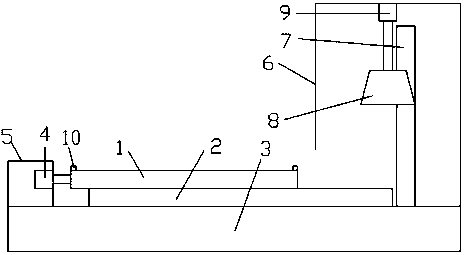

Glue-free fiber bar heat setting machine for glue-free fiber bar production line

The invention relates to a glue-free fiber bar heat setting machine for a glue-free fiber bar production line. The machine is matched with the glue-free fiber bar production line, and is suitable forglue-free fiber bar processing production. The machine comprises a heat setting machine frame, a fiber bundle channel, a fiber bundle channel tube, a plurality of fiber bundle temperature equalizing zones, a plurality of temperature control preheating zones, a plurality of temperature control heating zones and a fiber bundle solidifying forming zone; and a machine box body is arranged at the upperpart of the heat setting machine frame, the plurality of temperature control heating zones are arranged in the machine box body, the plurality of temperature control preheating zones are arranged atthe front parts of the temperature control heating zones, one fiber bundle temperature equalizing zone is arranged between every two adjacent temperature control preheating zones, one fiber bundle temperature equalizing zone is arranged between every two adjacent temperature control heating zones, a fiber bundle inlet temperature equalizing zone is arranged at a fiber bundle inlet, and the fibersolidifying forming zone is arranged at the front end of the heat setting machine. The design is reasonable, the production process is simple, the production cost is greatly saved, glue and solvents are not needed to be added in the production process, and the environment-friendly and energy-saving effects are achieved.

Owner:无锡盛烨特邦新材料科技有限公司

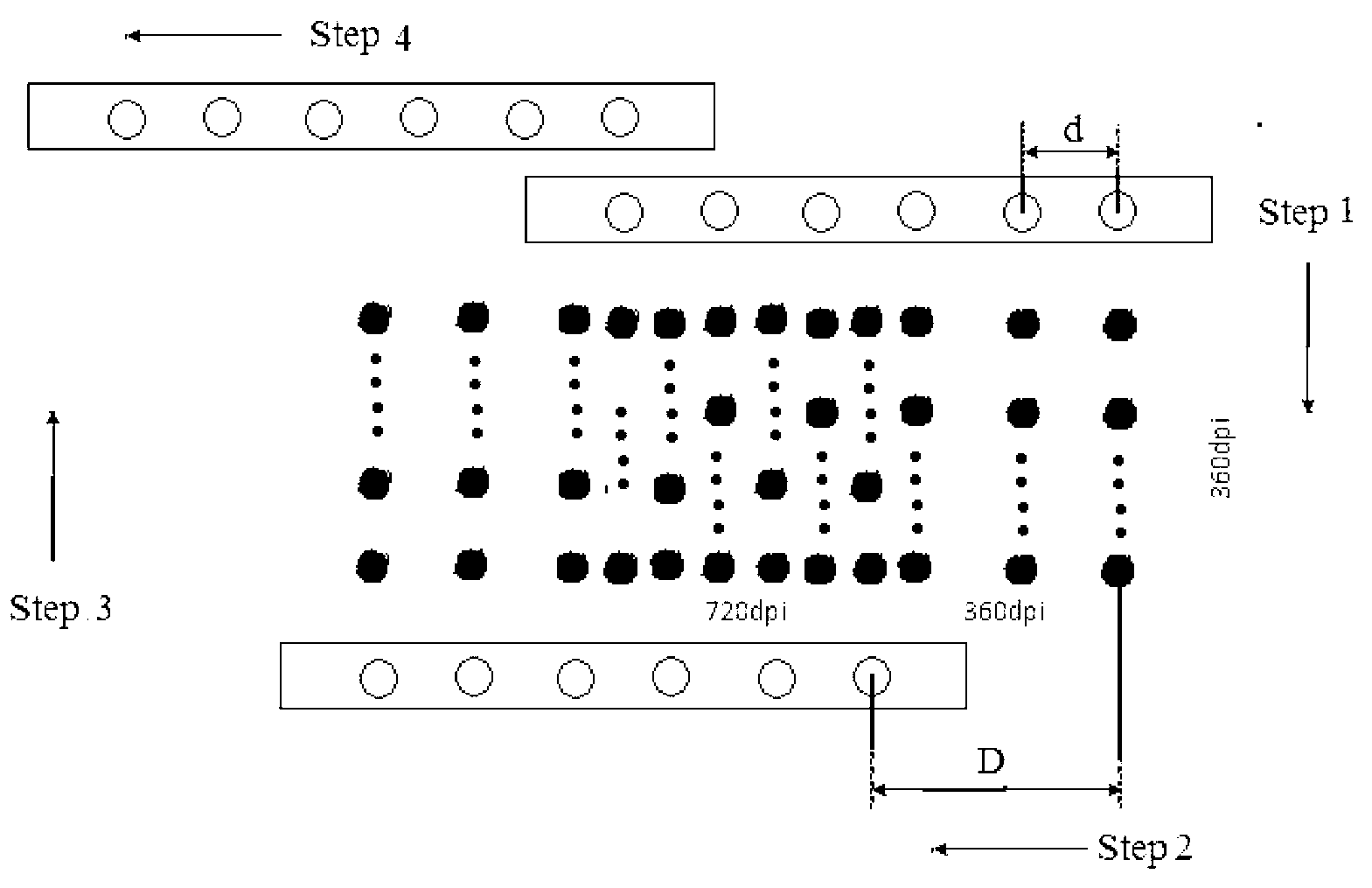

Printed circuit board jet printing motion scanning method

InactiveCN102837520AHigh-resolutionConsistent print qualityDuplicating/marking methodsImage resolutionPrinted circuit board

Relating to the technical field of printed circuit board jet printing, the invention provides a printed circuit board jet printing motion scanning method, which adopts an insertion point type uniform stepping mode. The technical scheme does not add any cost or extra jet printing process on the basis of current printed circuit board jet printing equipment. In other words, under the premise of ensuring both the cost and the efficiency, by means of simple parameter adjustment, an obvious disconnection problem caused by clogging of a part of nozzles can be effectively avoided. At the same time, the resolution of a jet printing pattern can be improved manyfold according to needs conveniently. The method has a simple principle, is easy to popularize, and can obtain smooth graphics with consistent jet printing quality.

Owner:江苏汉印机电科技股份有限公司

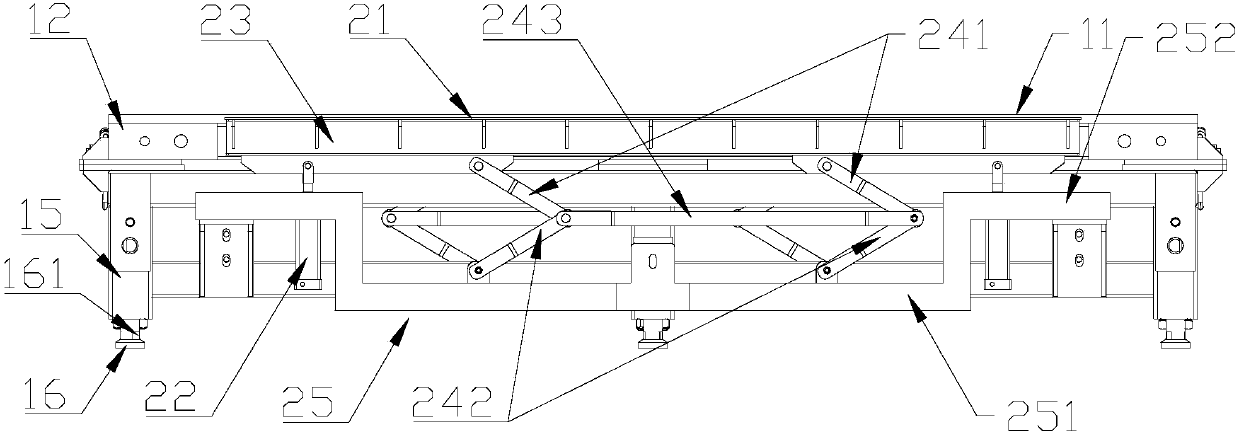

Integrated maintenance and detection platform of side wall framework

PendingCN107695961AImprove versatilitySave spaceMeasurement devicesWork benchesStructural engineeringMechanical engineering

Owner:天津中车唐车轨道车辆有限公司

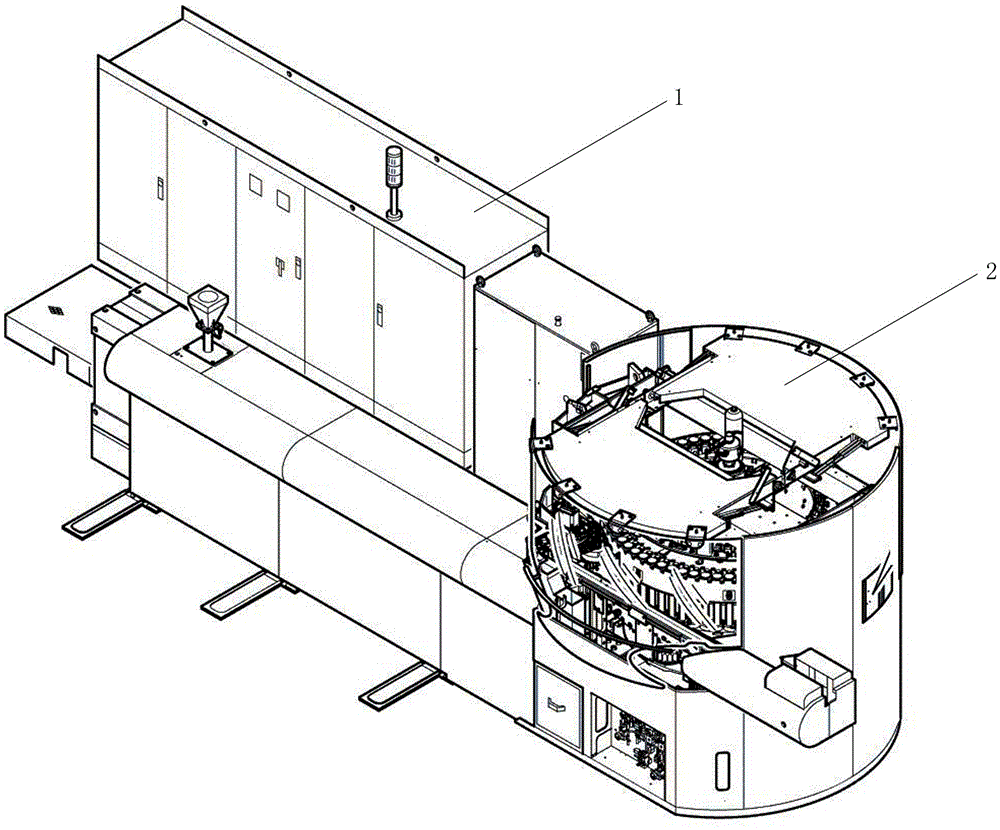

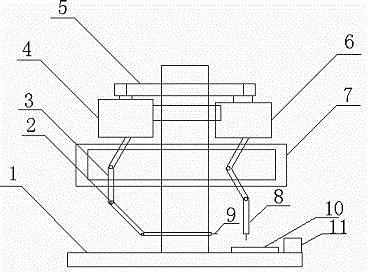

A magic color bottle cap compression molding equipment

ActiveCN105128303BReduce production processHigh degree of automationDomestic articlesCompression moldingEngineering

The present invention relates to the technical field of compression-molding equipment, in particular to compression-molding equipment for magic color bottle caps, which includes a machine base, and is characterized in that: the machine base is provided with an extruding rotating device, a feeding device, a rotating scraping device and at least Two extruding screw mechanisms, the at least two extruding screw mechanisms extrude molten plastics of different colors to the feeding device to meet, and the rotating scraping device scrapes the molten plastic from the feeding device and sends it into the extrusion Extrusion molding in the rotating device, the machine base is also equipped with a discharge mechanism for unloading the molded products; this bottle cap compression molding equipment has the following advantages: 1. It greatly reduces the existing production process of color caps; 2. The entire production process of this equipment does not require manual intervention, the degree of automation is high, and the production efficiency is significantly improved, thereby reducing labor costs; 3. It is easier to form and the product yield is high; 4. It provides personalized expressions for products to meet different products. different needs.

Owner:DONG GUAN JIN FU IND CO LTD

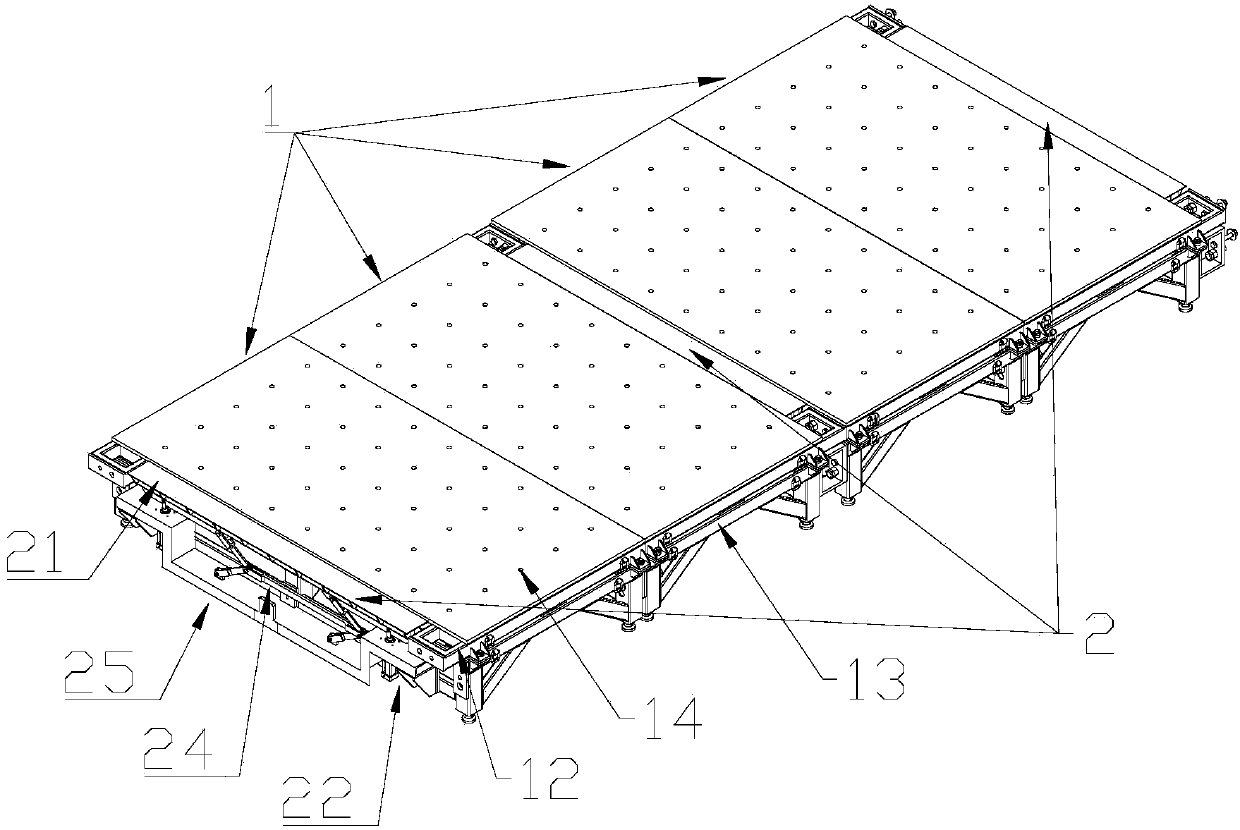

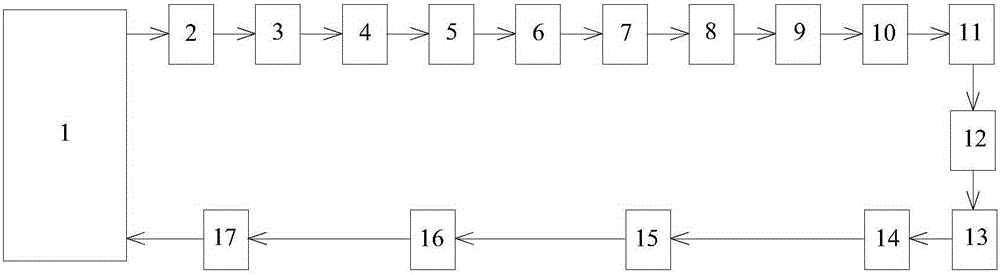

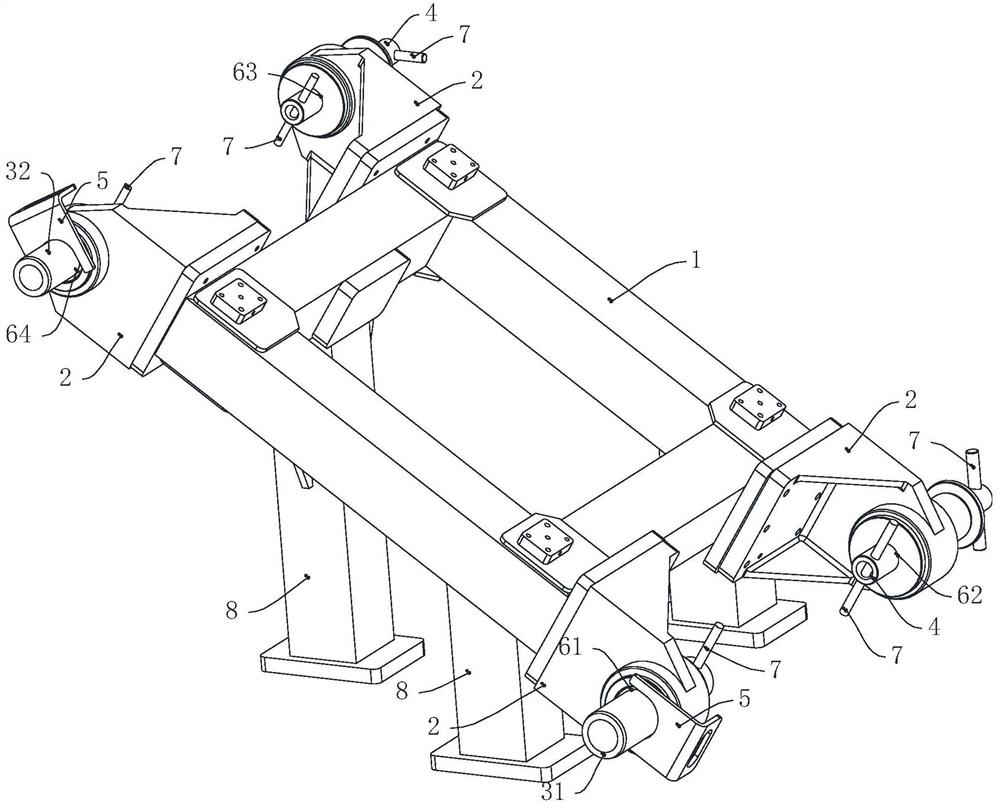

Production systems for concrete elements

ActiveCN104057537BReduce labor intensitySimple structureDischarging arrangementCeramic shaping plantsPre treatmentWaste management

A concrete member production system comprises a formwork table conveying device, formwork table pre-treatment equipment, a first spreader, a second spreader, post-spreading treatment equipment, a maintenance storehouse and an edge-on bottom formwork removal device, wherein a formwork removal station, a formwork pre-treatment station, a first spreading station and a vibro-compacting station are sequentially arranged on the formwork table conveying device and at the exit of the maintenance storehouse; a post-spreading treatment station, a second spreading station and an insulation board placing station are sequentially arranged on the formwork table conveying device and at the entrance of the maintenance storehouse; the edge-on bottom formwork removal device, the formwork table pre-treatment equipment, the first spreader, a formwork vibrating device, the second spreader and the post-spreading treatment equipment are correspondingly arranged on the formwork removal station, the formwork pre-treatment station, the first spreading station, the vibro-compacting station, the second spreading station and the post-spreading treatment station respectively to form a circulating production system. The concrete member production system is operated mechanically, achieves continuous production, saves time and labor and improves the working efficiency.

Owner:HEBEI XUELONG MACHINERY MFG

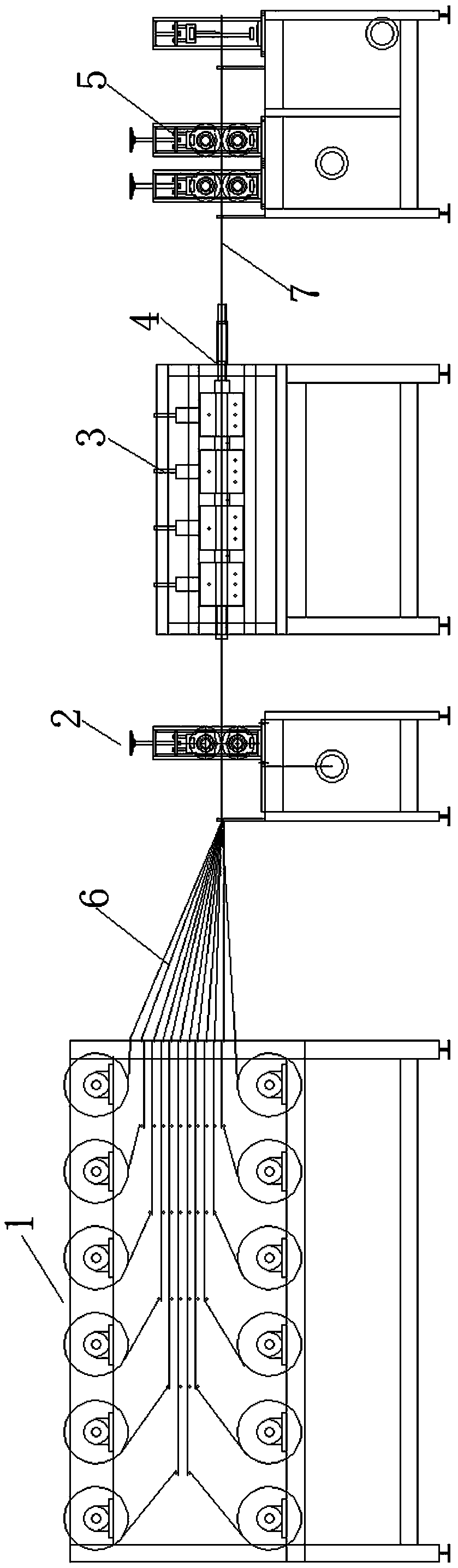

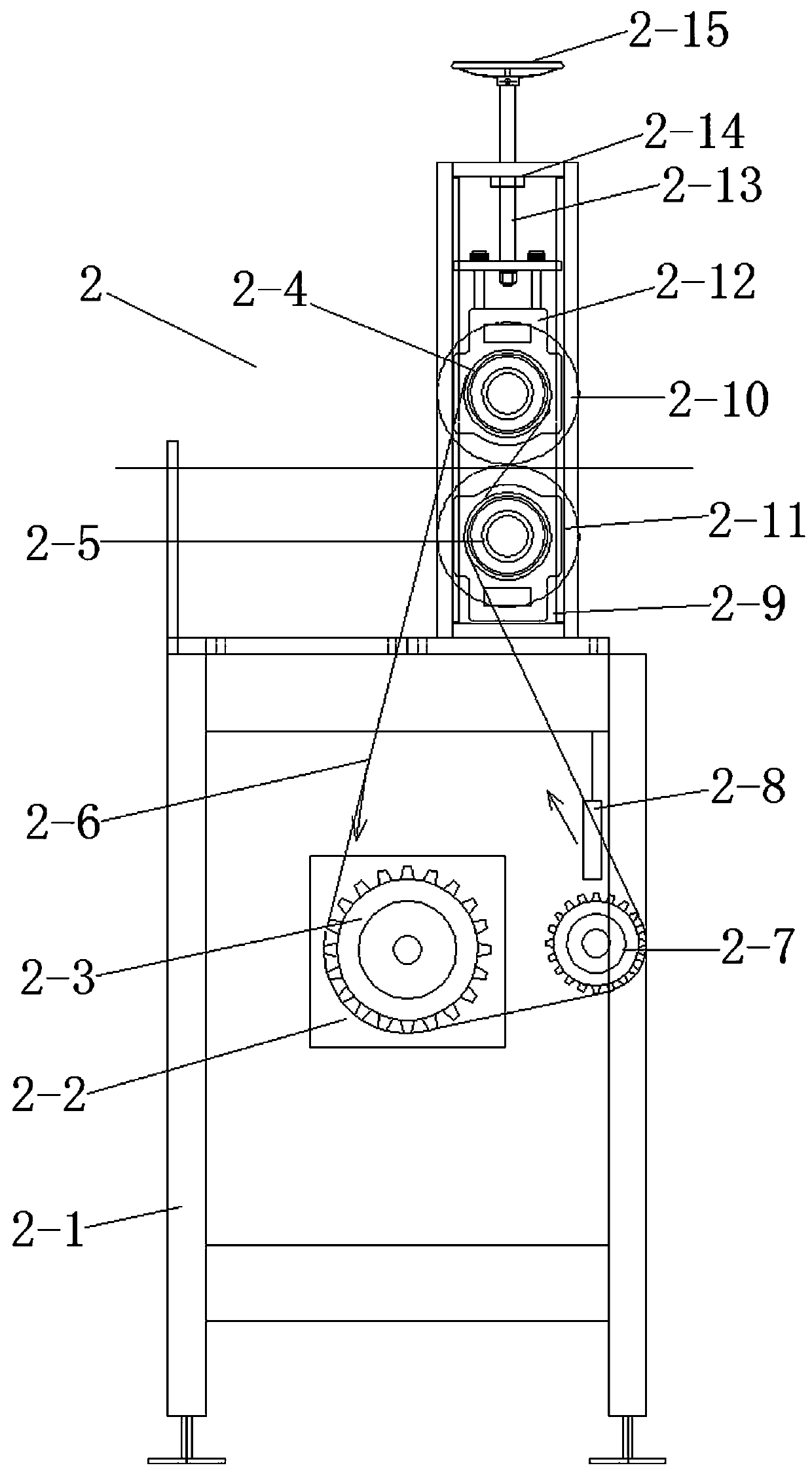

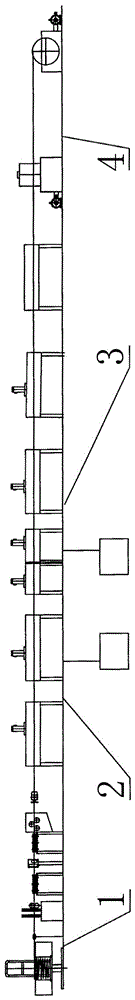

Glue-free fiber bar production line

The invention relates to a glue-free fiber bar production line. The glue-free fiber bar production line is suitable for glue-free fiber bar processing production. The glue-free fiber bar production line involves a glue-free fiber bundle constant-tension unwinding device, a glue-free fiber bundle traction device, a glue-free fiber bar heat setting machine, a glue-free fiber bar traction cutting-offmachine and an accurate curing forming combined mold; the glue-free fiber bundle traction device is arranged at the front part of the glue-free fiber constant-tension unwinding device, the front partof the glue-free fiber bundle traction device is provided with the glue-free fiber bar heat setting machine, the glue-free fiber bar traction cutting-off machine is arranged at the front part of theglue-free fiber bar heat setting machine, and the accurate curing forming combined mold is arranged at a glue-free fiber bar output end which is arranged at the front part of the glue-free fiber bar heat setting machine. The glue-free fiber bar production line is reasonable in design and simple in production process; and the production cost is greatly saved, glue and solvent are not needed to be added in the production process, no volatile pollutants are generated, the environment-friendly and energy-saving effects are achieved, the production environment is greatly improved, and no pollutionor harm is caused to production personnel.

Owner:WUXI SHENGYE TEBANG NEW MATERIALS TECH CO LTD

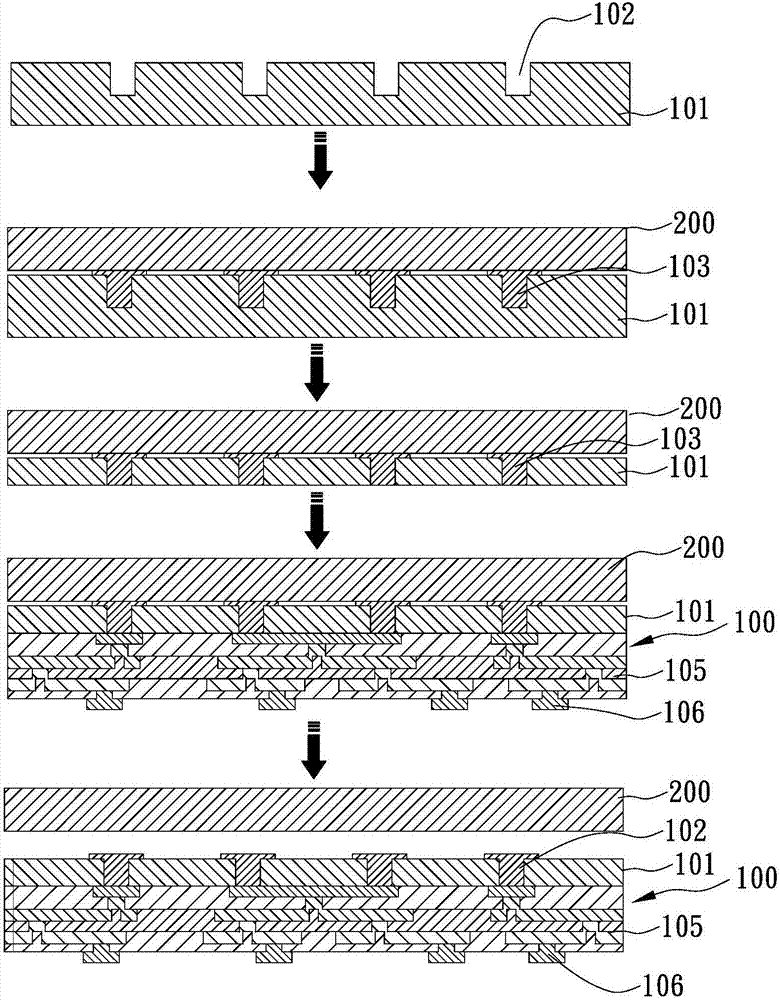

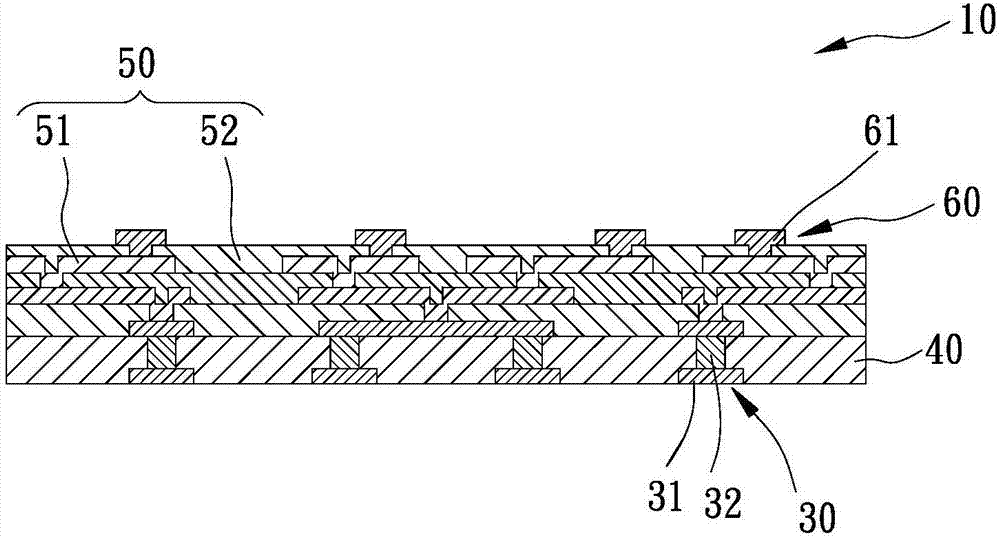

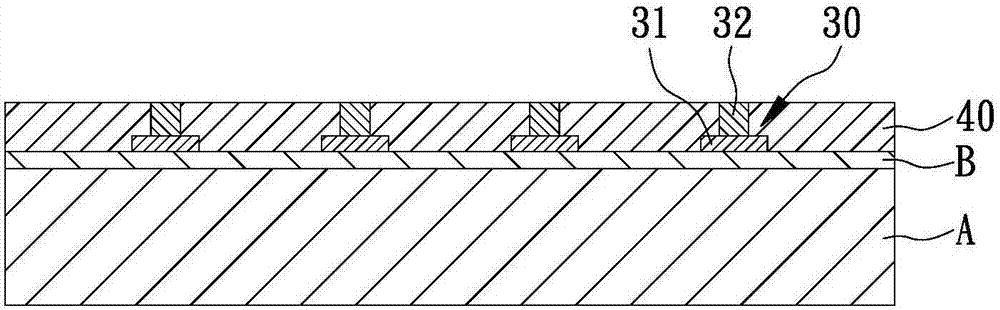

Non-substrate medium layer, and semiconductor device using same

InactiveCN107359142AIncrease production speedIncrease the number ofSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceOrganic layer

The invention provides a non-substrate medium layer, and a semiconductor device using same, and especially, relates to a non-substrate medium layer which is free from using substrates, such as a prefabricated wafer, glass or organic layers. In the non-substrate medium layer, a plurality of conductive pathways, which connecting an upper and a lower surfaces, are formed in an insulation separation layer formed by deposition, coating and the like technologies in a solidifying manner. At least one wire rearrangement layer is arranged on one side surface of the insulation separation layer. The wire rearrangement layers are respectively provided with a dielectric layer and a plurality of wire patterns. In addition, a plurality of electrode pathways, which are electrically connected to a part of the wire patterns, are formed on the most-outer wire rearrangement layer on the insulation separation layer. By such way, thickness of the insulation separation layer is effectively controlled, and the conductive pathways are more accurate and micronized, numbers and density of pins thereon are greatly increased, and the medium layer is reduced in thickness and is more suitable for heating, compressing processes in later treatment. The non-substrate medium layer is effectively increased in production speed and qualification rate, and can satisfy demands in the following packaging processes.

Owner:李志雄

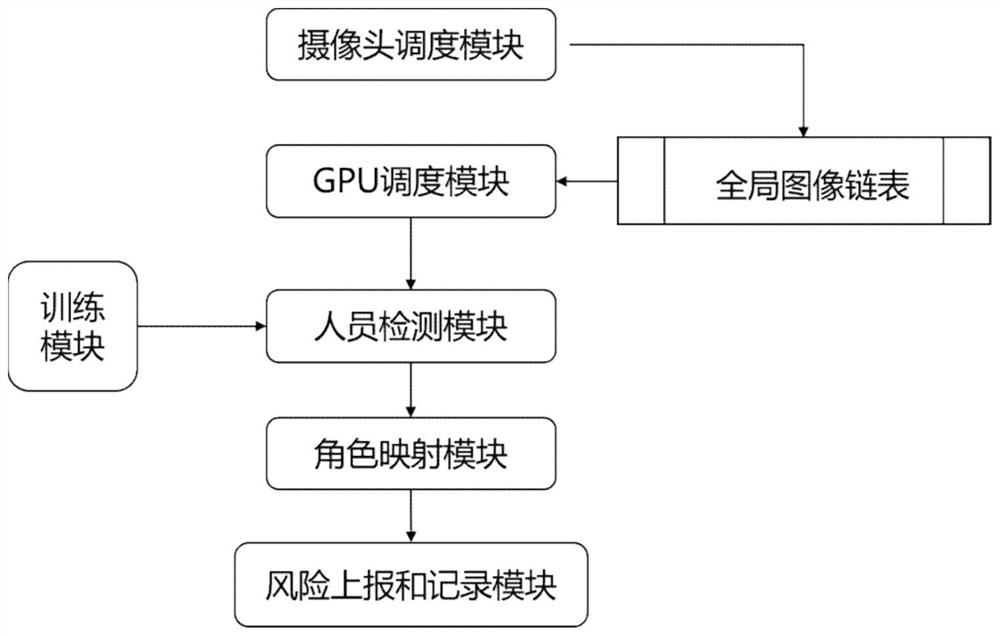

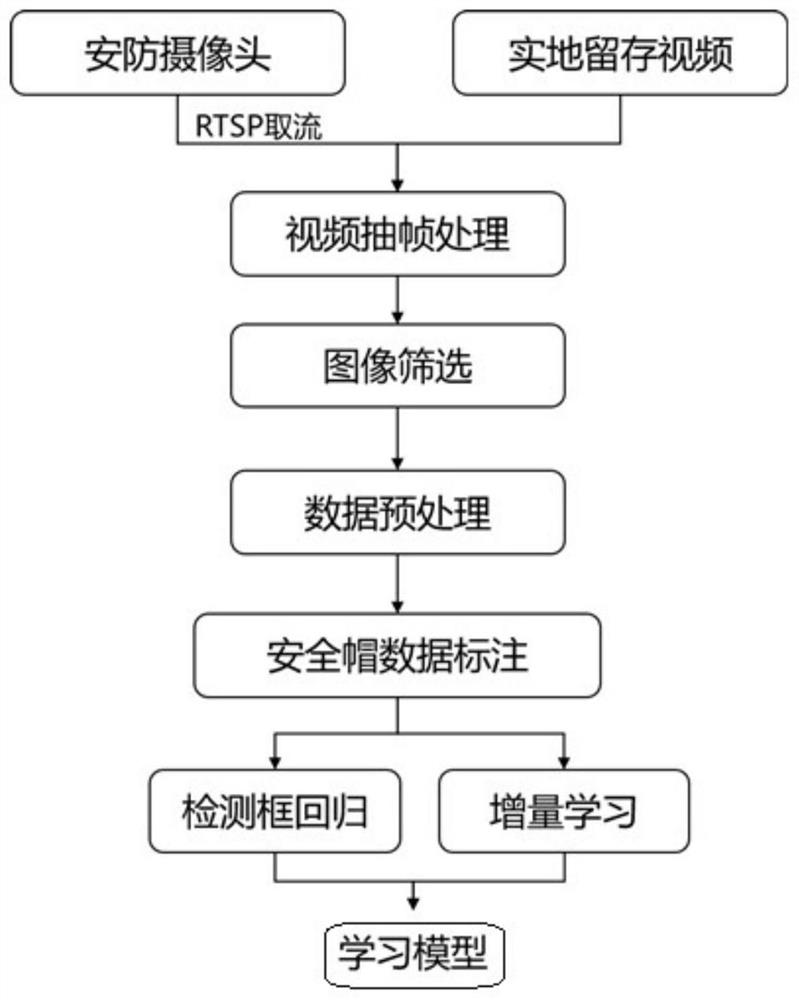

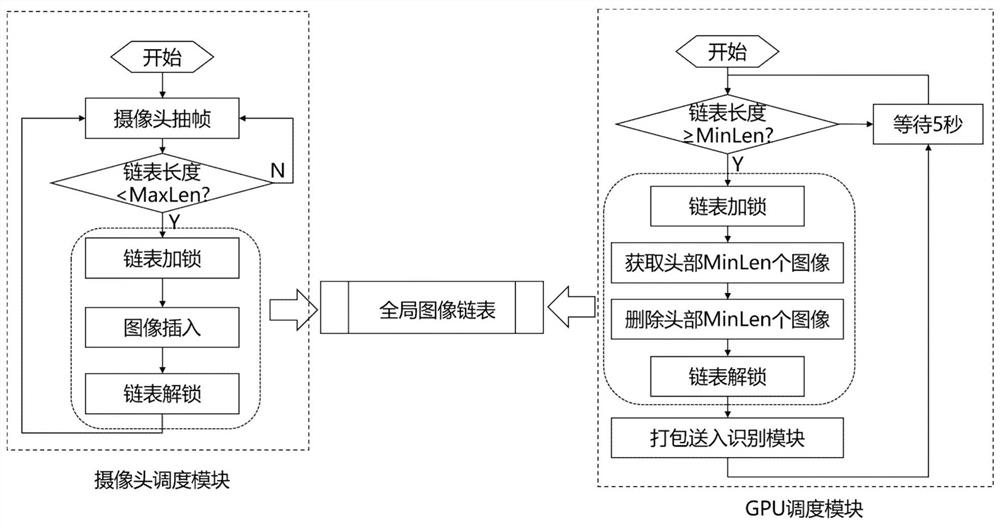

Safety helmet identification incremental learning and role determination method based on deep learning

PendingCN113963436AIncrease flexibilityImprove acceleration performanceCharacter and pattern recognitionEarly warning systemData set

The invention discloses a safety helmet identification incremental learning and role judgment method based on deep learning, and the method comprises the steps: carrying out the stream extraction operation of a camera through an RTSP, and carrying out the frame skipping processing of a collected video; recording batch information of the training data added into the data set, and performing fine adjustment on the network after new training data is added to realize incremental learning; determining learning rules according to batches, and avoiding catastrophic forgetting; and detecting and identifying safety helmets with different colors in the video and the situation of not wearing the safety helmets, and determining personnel roles of personnel wearing the safety helmets through the colors of the safety helmets while judging the unsafe behavior of not wearing the safety helmets. According to the invention, a target detection technology and a safety mechanism of a factory are combined, a risk detection early warning system is completed, a lot of manpower and material resources are saved, a safety protection mechanism of the factory is improved, a factory management system is perfected, and life health and safety of personnel are maintained.

Owner:SHANDONG UNIV +1

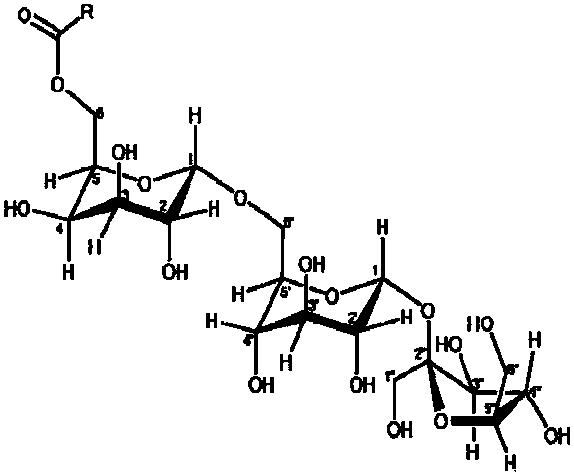

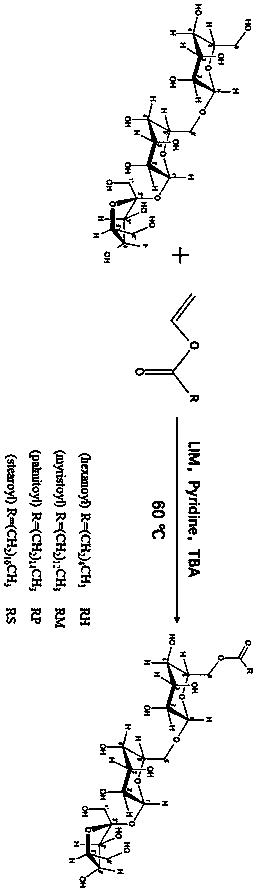

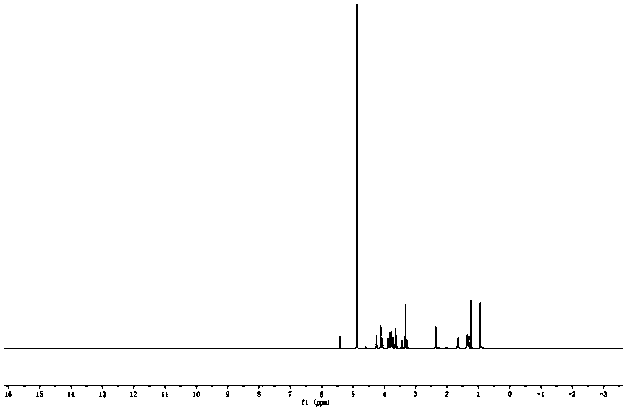

6-O-acyl raffinose monoester and synthesis method thereof

InactiveCN110272926ACan't ignore the health effectPrecise constructionEsterified saccharide compoundsSugar derivativesFoaming agentSynthesis methods

The invention provides a 6-O-acyl raffinose monoester and a synthesis method thereof. On the basis of designing a novel structural model of a raffinose monoester, four kinds of 6-O-acyl raffinose monoesters with different carbon chain lengths are successfully synthesized for the first time. In the synthesis method, reactants with fatty chains of different lengths are selected, through enzymatic reaction, the structure of a glycosyl ester can be accurately formed a reaction site can be controlled, and the molecular weight and structure of the glycosyl ester are changed by continuously forming new fatty chains; and then, the 6-O-acyl raffinose monoester with the required molecular weight and structure is obtained by rapid chromatography elution separation. According to the 6-O-acyl raffinose monoester and the synthesis method thereof, products of different properties are obtained to meet different product requirements, and the synthesis method has simple steps, convenient to operate, significantly shortened in time consumption and environment-friendly; the produced raffinose glycosyl ester has good performance and can be used as an excellent foaming agent and emulsifier; and the monoester output is high and the cost is low, and the 6-O-acyl raffinose monoester is suitable for large-scale industrial production.

Owner:JINAN UNIVERSITY

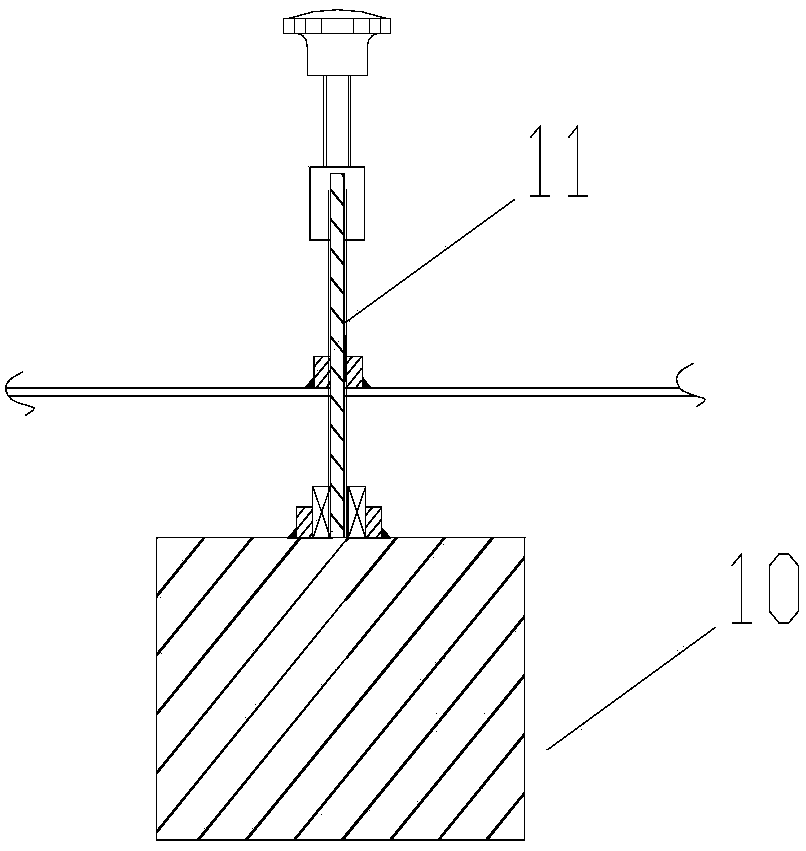

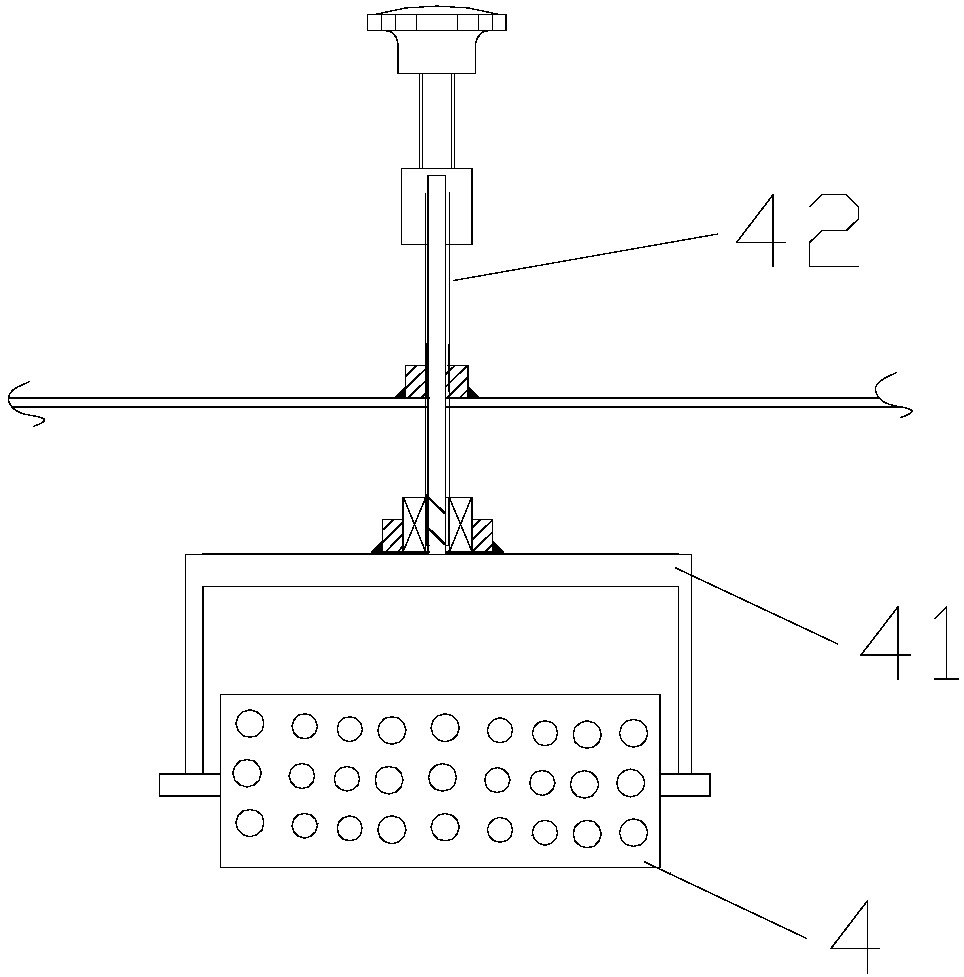

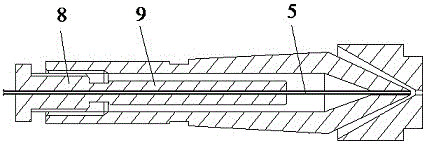

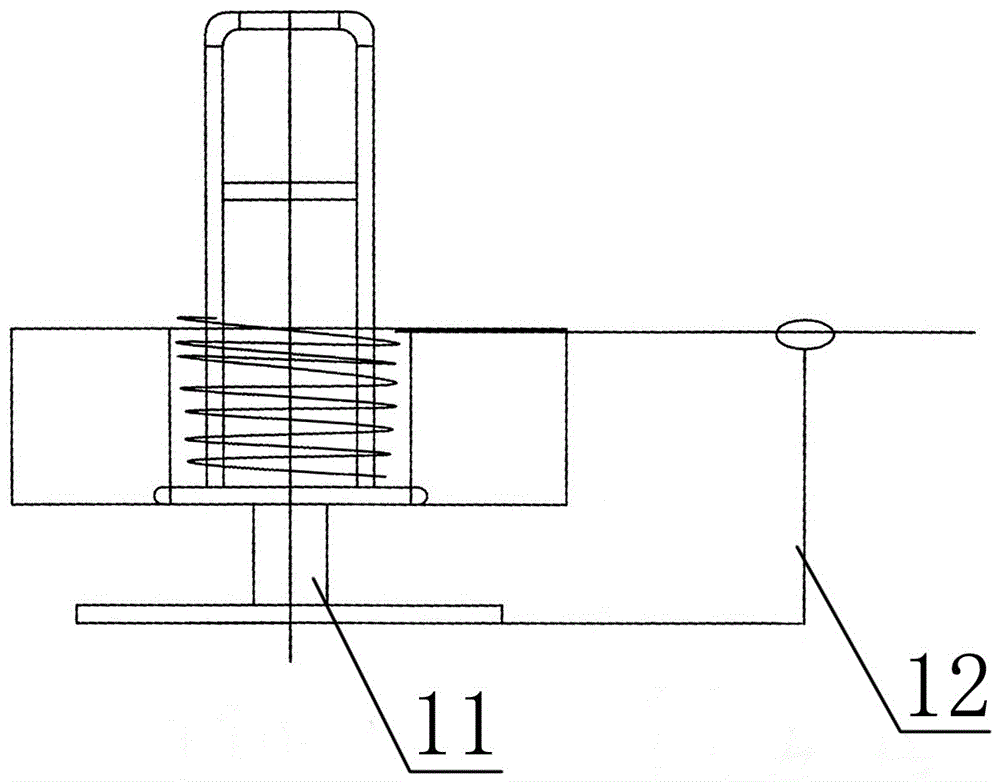

Adjustable tightly packaged optical fiber extrusion molding mold

The invention discloses an adjustable tightly packaged optical fiber extrusion molding mold. The mold comprises a mold sleeve and a mold core, wherein the mold sleeve is provided with a extrusion molding hole; the mold core comprises a mold core mouth part; the mold core mouth part is provided with a center lead-in hole; the center lead-in hole is provided with an adjustable fiber-guiding needle tube capable of moving forwards and backwards along the axial direction of the center lead-in hole; the outer wall of the adjustable fiber-guiding needle tube is matched with the inner wall of the center lead-in hole; the length of the fiber-guiding needle tube extending out of the center lead-in hole is adjusted, so that the type of the extrusion molding mold is changed. According to the adjustable tightly packaged optical fiber extrusion molding mold and by means of the above mentioned mode, the structure is simple and reasonable; the adjustable fiber-guiding needle tube is arranged in the mold core, and the relative positions of the needle tube and the core sleeve are adjusted, thus the extrusion mode of the extrusion molding mold is changed, and different product requirements are met; and the mold is convenient to adjust, easy to machine, reliable in performance and stable in size.

Owner:江苏盈科通信科技有限公司

Breathable and moisture-permeable coating, coated fabric and preparation method of coated fabric

InactiveCN109763348AImprove waterproof performanceImprove cold resistanceTextiles and paperSodium bicarbonateThermal insulation

The invention discloses a breathable and moisture-permeable coating. The breathable and moisture-permeable coating is prepared from 70-80 parts of polyurethane, 30-40 parts of polyvinyl chloride, 10-14 parts of polytetrafluoroethylene, 7-9 parts of a super absorbent polymer and 0.5-0.7 parts of wood pulp. Coated fabric comprises a base fabric and the breathable and moisture-permeable coating bonded to the base fabric; the base fabric is nylon fabric with the thread count of 100-136*80-96 count / 10 cm; the thickness of the breathable and moisture-permeable coating is 0.1-0.5 mm. A preparation method of the coated fabric comprises the steps as follows: weaving nylon fabric; making the nylon fabric into large rolls; stacking the large rolls in a sodium bicarbonate environment; spreading and cleaning the large rolls; performing dyeing and hot tentering finish; mixing and stirring the breathable and moisture-permeable coating and water uniformly; spraying the mixture onto a plane; leaving the mixture to stand for solidification; bonding the breathable and moisture-permeable coating to the surface of the nylon fabric. The breathable and moisture-permeable coating has water-repellent property, moisture permeability, windproof property, thermal insulation, flexibility and high structural strength, and breathability, moisture permeability and waterproof property can be adjusted as required.

Owner:苏州蓝纳青医用材料科技有限公司

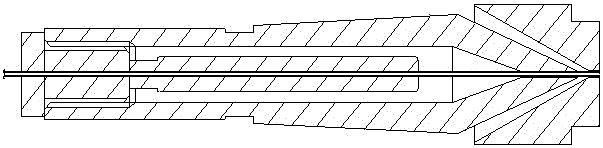

Preparation method of ultra-fine wollastonite with high length-diameter ratio

ActiveCN111943217AAchieve rapid growthGrowth priorityAlkaline-earth metal silicatesCalcium silicateSilicic acid

The invention provides a preparation method of ultra-fine wollastonite with a high length-diameter ratio, and relates to the technical field of wollastonite preparation. According to the invention, ultrafine acicular wollastonite is used as a matrix, a mixed silicon source (water glass and tetraethoxysilane) and a calcium source calcium hydroxide turbid liquid are used as reaction raw materials, asurfactant is used as a crystal form inducer, and new calcium silicate is constructed in the one-dimensional direction of the ultrafine acicular wollastonite through a hydrothermal method to increasethe length-diameter ratio of raw wollastonite so as to obtain the superfine wollastonite with high length-diameter ratio, wherein the length-diameter ratio of the superfine wollastonite ranges from 12 to 18, and in combination with treatment with a coupling agent, the superfine wollastonite powder with the high length-diameter ratio can be effectively prevented from being agglomerated, the dispersity of the superfine wollastonite powder with the high length-diameter ratio in downstream application is improved, and the compatibility of the superfine wollastonite powder with matrix resin is improved, so that the comprehensive performance of a product is improved.

Owner:JIANGXI GUANGYUAN CHEM

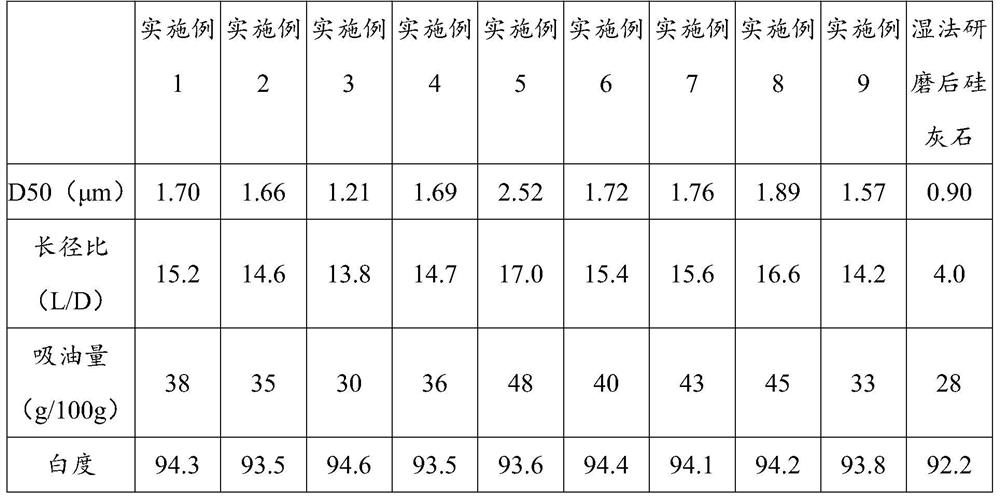

Multi-head stuffing-wrapping machine

PendingCN110037068AHighly integratedImprove processing efficiencyDough shaping and cutting apparatusDough processingHigh volume manufacturingEngineering

The invention discloses a multi-head stuffing-wrapping machine, and belongs to the field of stuffing-wrapping machines. The multi-head stuffing-wrapping machine comprises a machine body, a conveyor line, a wrapper hopper, a stuffing hopper, material feeders, wrapper-stuffing reclosing die heads, and a cutter head; the wrapper hopper communicates with wrapper tubes of the wrapper-stuffing reclosingdie heads through one of the material feeders; the stuffing hopper communicates with stuffing tubes of the wrapper-stuffing reclosing die heads through one of the material feeders; the material feeders comprise a plurality of material discharging ports; the number of the wrapper-stuffing reclosing die heads is multiple; the cutter head is a multi-head cutter head; and the multi-head cutter head is arranged under the wrapper-stuffing reclosing die heads so as to cut off material columns discharged from the wrapper-stuffing reclosing die heads. The multi-head stuffing-wrapping machine is capable of simultaneously forming plural material columns, thereby greatly improving production efficiency so as to meet needs of mass production and processing; moreover, the multi-head stuffing-wrapping machine is also capable of making products more regularized, as well as ensuring more hygienic processes.

Owner:SHANGHAI YUCHENG MACHINERY

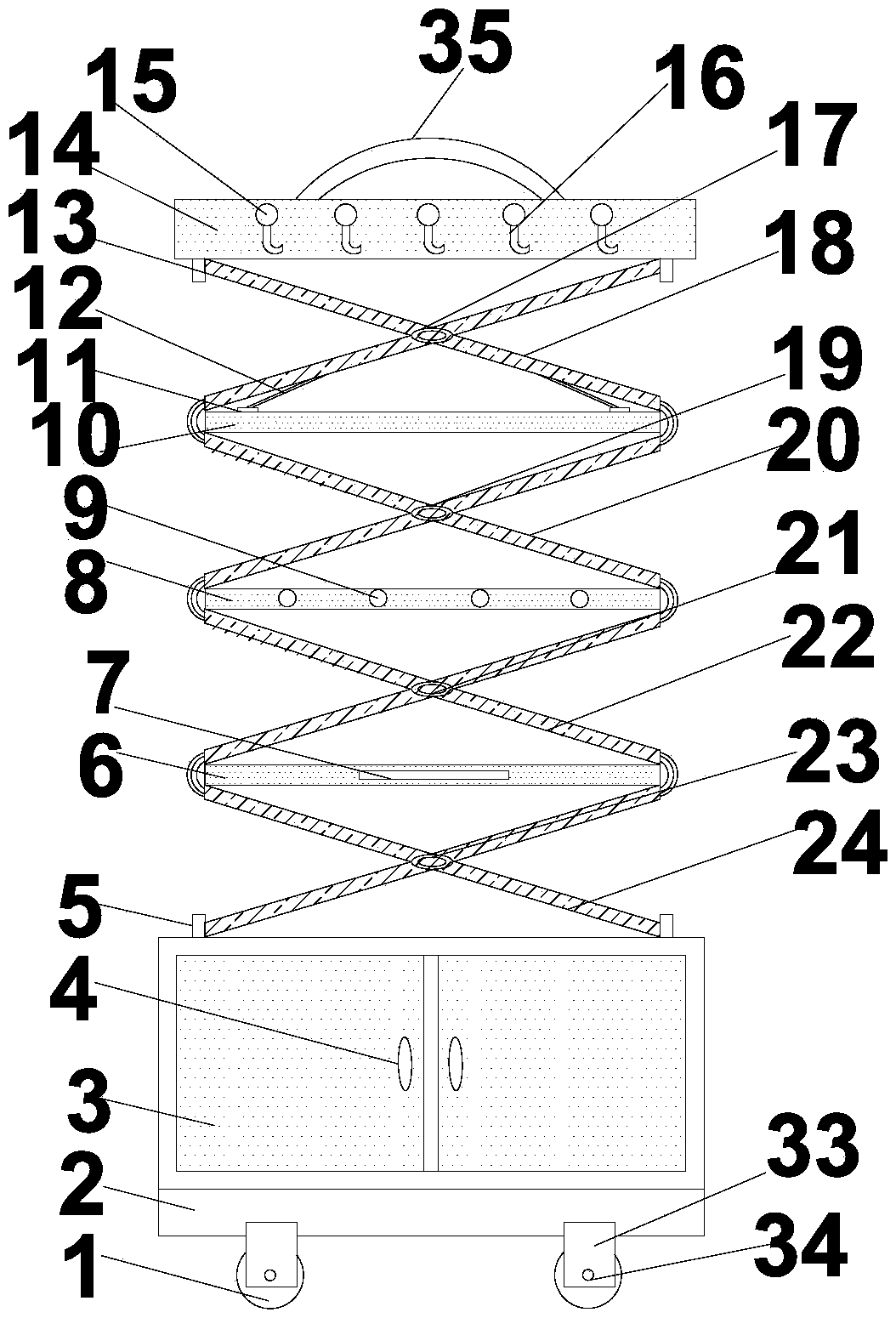

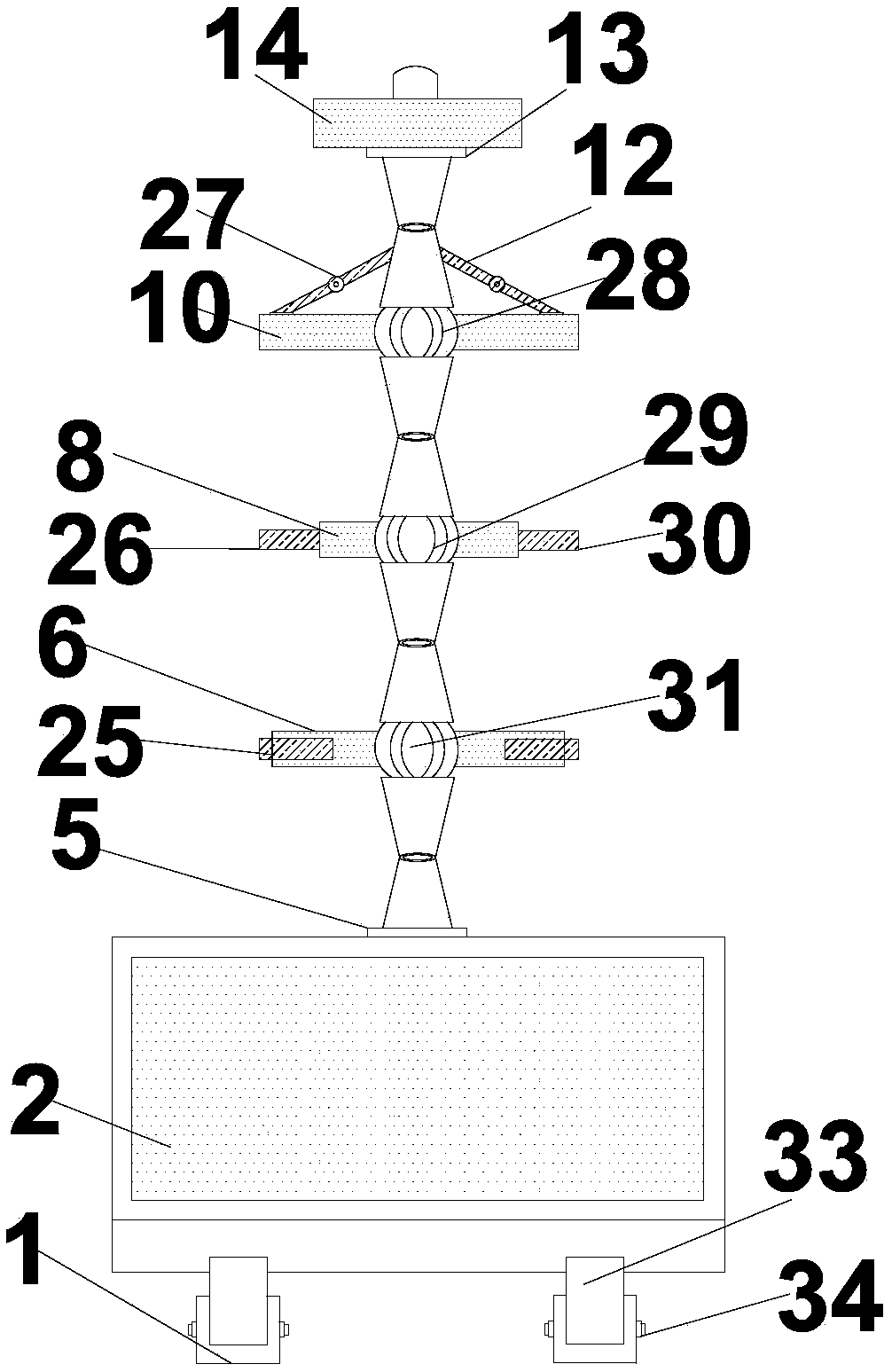

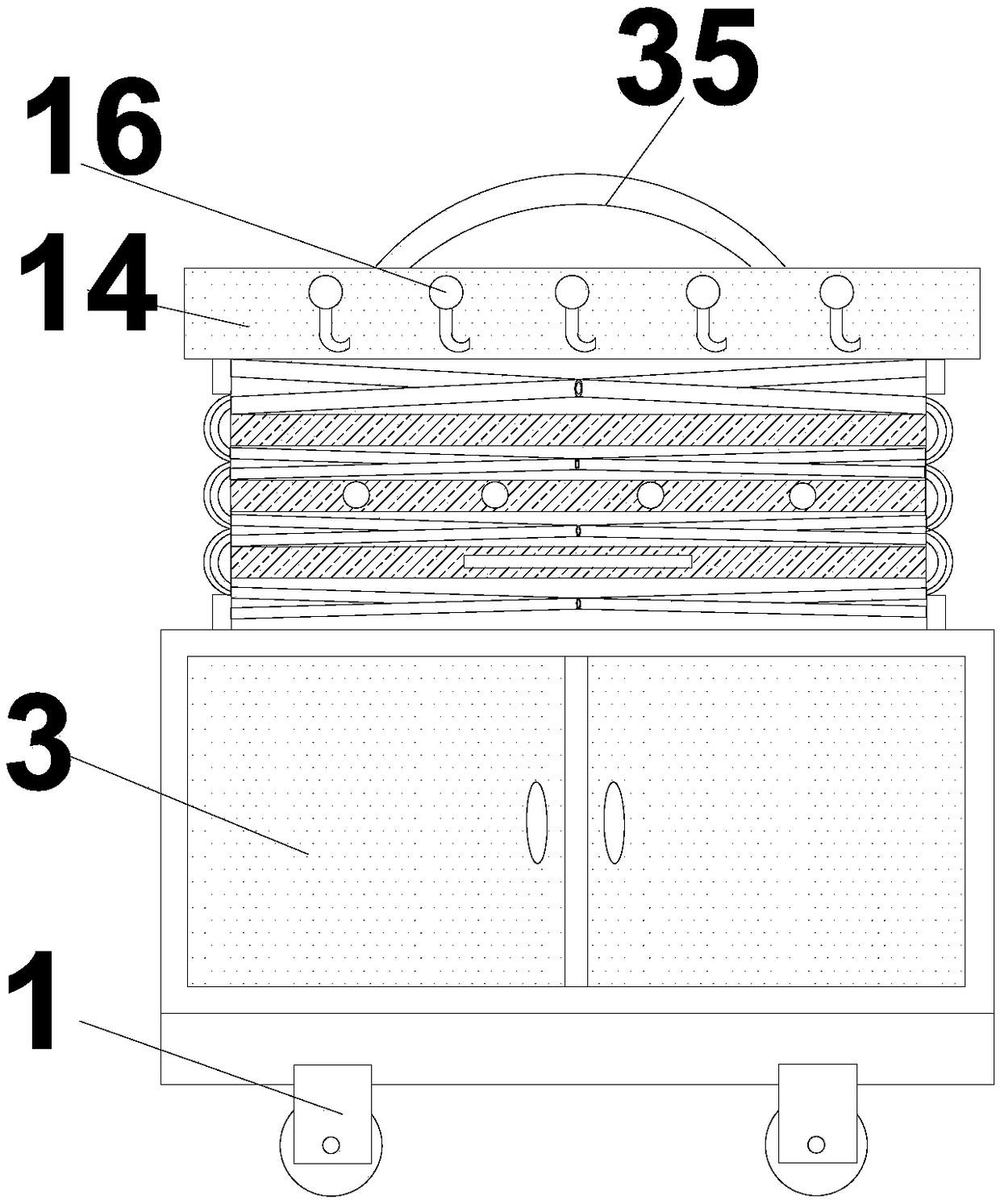

Sales exhibition rack for automotive components

The invention discloses a sales exhibition rack for automotive components. The sales exhibition rack for automotive components comprises a cabinet, a first holding rack, a second folding rack, a thirdfolding rack and a fourth folding rack. First, a folding handle is pulled up to a vertical state from a device body, articles needed to be exhibited and sold are orderly placed on a third placing plate, then a hanging rod is taken away from a second placing plate, the articles are placed on the second placing plate, and different articles different from those on a third placing plate can be placed, so that the articles are classified. The articles of other types are placed on the first placing plate, a door body of the cabinet is opened through the handle, and goods are supplemented anytime conveniently by means of the cabinet, thereby bringing great convenience to sales staff and saving a lot of time. Finally, the exhibition rack is placed in a proper position through rollers, so that the integral stability is ensured well to meet different demands for commodities. Common commodities are placed on the rack, so that the sales exhibition rack is convenient and rapid to use and very high in practicality.

Owner:广州市欧之星商贸有限公司

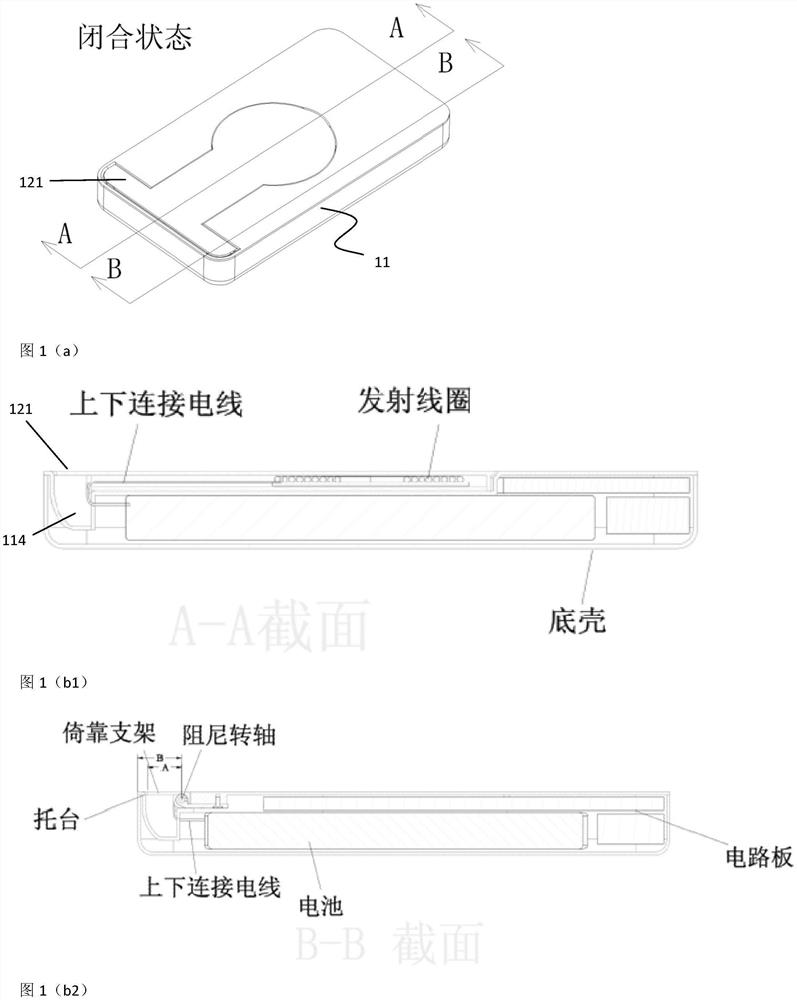

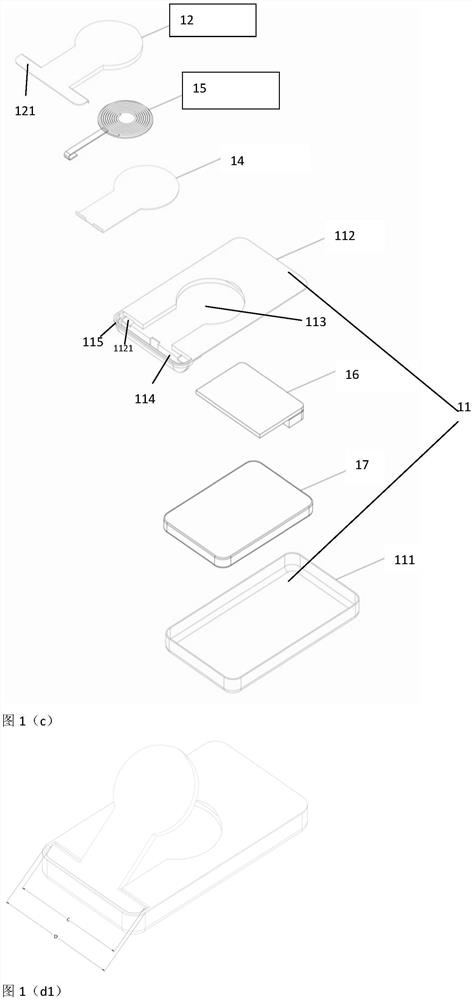

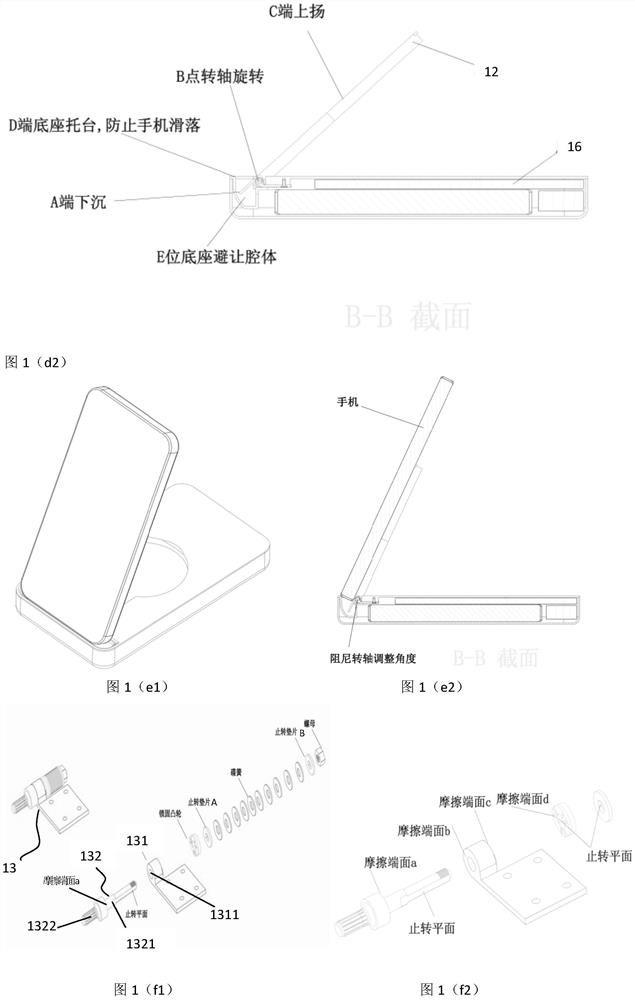

Supporting device for portable electronic equipment and wireless charging supporting device

PendingCN113137545AEasy to carryMeet different product needsBatteries circuit arrangementsElectric powerControl theoryMechanical engineering

The invention discloses a supporting device for portable electronic equipment. The supporting device for the portable electronic equipment comprises a supporting main body mechanism and a rotary connecting mechanism, wherein the rotary connecting mechanism is rotationally connected with the supporting main body mechanism through a torsion rotating shaft mechanism, so that the rotary connecting mechanism can stay in a range of 0 to 90 degrees when rotating around the supporting main body mechanism; the supporting main body mechanism is at least provided with a rotary motion space capable of accommodating the front end part of the rotary connecting mechanism to rotate around the supporting main body mechanism in a range of 0 to 90 degrees; and the rotary motion space and the rotary connecting mechanism form a supporting platform for supporting the electronic equipment. The torsion rotating shaft mechanism adopts a damping rotating shaft mechanism, and the damping rotating shaft mechanism is used for enabling the rotary connecting mechanism to stay when rotating around the supporting main body mechanism within the range of 0 to 90 degrees; or the torsion rotating shaft mechanism adopts a semi-automatic opening and closing rotating shaft mechanism and is used for enabling the rotary connecting mechanism to stay at a set angle.

Owner:黄芬芬

Porous electrode carbon as well as preparation method and application thereof

PendingCN114477171AReduce manufacturing costMeet different product needsCarbon compoundsHybrid capacitor electrodesPtru catalystCresol

The invention provides a preparation method of porous nano electrode carbon, which comprises the following steps: A) mixing m-cresol and formaldehyde in water, adding an alkali catalyst, transferring into a constant temperature box, and culturing an intermediate to obtain a wet intermediate; b) immersing the wet intermediate in a polyether solution, carrying out water replacement, and drying to obtain a dry intermediate; c) carbonizing the dry intermediate in a nitrogen atmosphere to obtain carbonized electrode carbon; and D) activating the carbonized electrode carbon in a CO2 atmosphere to obtain the porous nano electrode carbon. On the basis of a sol-gel method, m-cresol, p-cresol and a formaldehyde solution are used as precursors, NaOH is used as a catalyst to prepare an intermediate, then the intermediate and a polyether solution are subjected to water replacement, and then the porous nano electrode carbon is prepared through carbonization and activation. The preparation method disclosed by the invention is simple, low in cost and capable of realizing industrial batch production. The invention also provides a preparation method and application of the porous nano electrode carbon.

Owner:YUYUE HOME TEXTILE

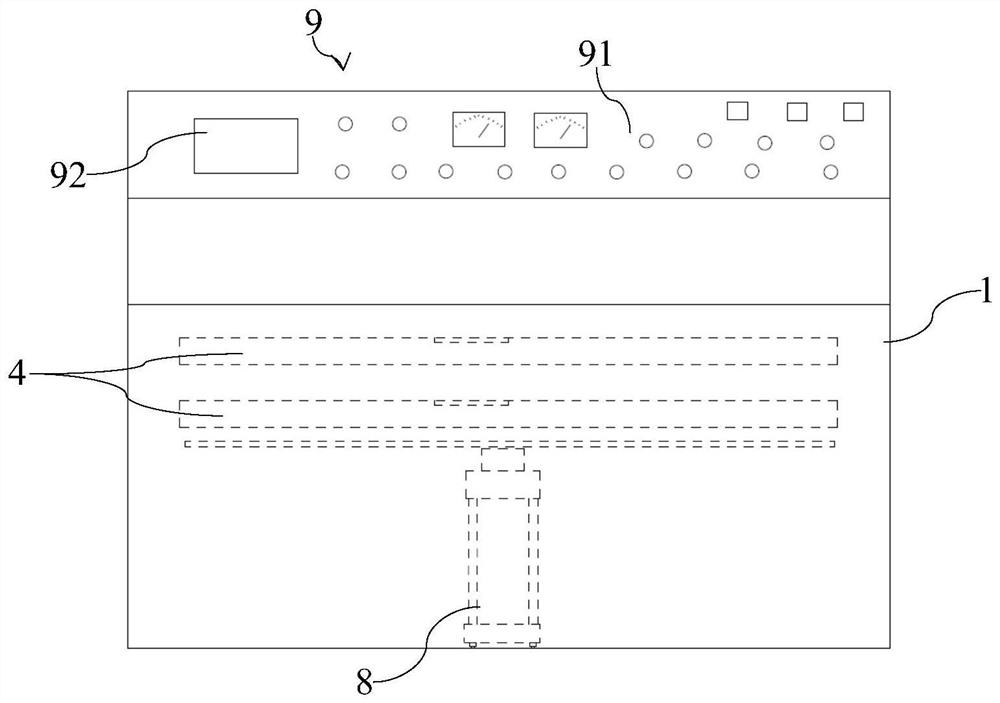

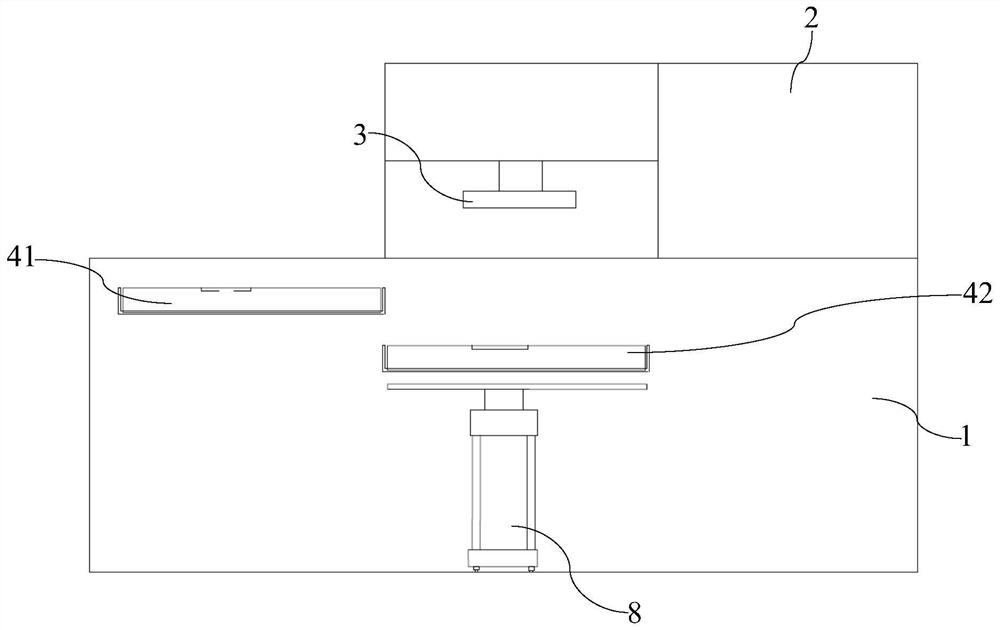

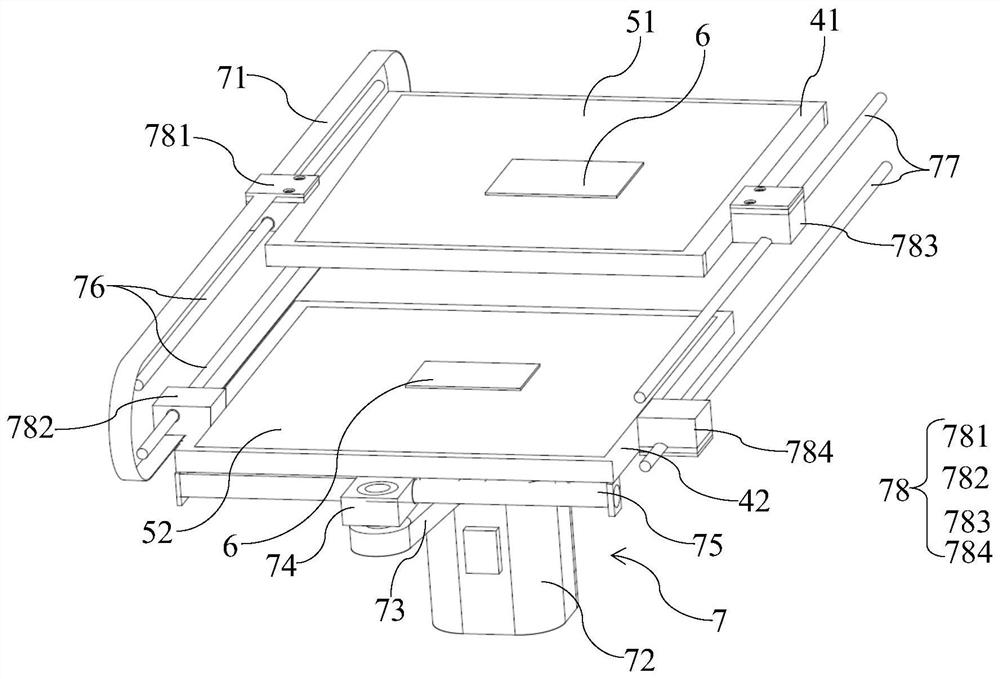

Automatic carpet high-frequency welding machine

InactiveCN111823600AImprove welding efficiencyMeet different product needsElectrical connectionWorkbench

The invention discloses an automatic carpet high-frequency welding machine. The automatic carpet high-frequency welding machine comprises a machine base, a high frequency generator, at least two sliding tables, a driving mechanism and a jacking mechanism, wherein the high frequency generator is installed on the machine base and provided with a positive terminal and a negative terminal, and the negative terminal is electrically connected with a welding plate; the sliding tables are sequentially stacked on the machine base from top to bottom and located bellow the welding plate, working tables are arranged on the sliding tables, and welding die heads are installed on the working tables and electrically connected with the positive terminal of the high frequency generator; the driving mechanism can drive the sliding tables to sequentially slide back and forth in the horizontal direction; and the jacking mechanism is installed at the bottom of the machine base and located at the bottoms ofthe working tables, and can drive the working tables of the sliding tables sliding over the jacking mechanism to move upwards to make the welding die heads close to the welding plate. In the automaticcarpet high-frequency welding machine, the multiple working tables are arranged, at the time when one worktable is used for welding, the welding die heads can be installed on the other working tables, and thus the welding efficiency of the product is improved.

Owner:GUANGZHOU JINSHANG GIKEN CAR ARTICLES CO LTD

Precision detection tool and detection method for intersection hole in side wall of nose landing gear

ActiveCN113532245ASimple structureEasy to operateWeight reductionMechanical measuring arrangementsAirplaneLanding gear

The invention discloses a nose landing gear side wall intersection point hole precision detection tool and detection method, relates to the field of aircraft assembly and manufacturing, and aims to solve the problems by providing a nose landing gear side wall intersection point hole precision detection tool and detection method. According to the technical scheme, the nose landing gear side wall intersection hole precision detection tool comprises a framework, connector supports, positioning pins, inspection pins of various diameter specifications and gaskets of different thickness specifications, the connector supports are arranged at the four corners of the framework respectively, and the four connector supports are each provided with a pin hole, namely, a first pin hole, a second pin hole, a third pin hole and a fourth pin hole; wherein the first pin hole is provided with a first positioning pin, the second pin hole and the third pin hole are respectively provided with inspection pins, the fourth pin hole is provided with a second positioning pin and an inspection pin, the positioning pins are used for forming detection base points, and the inspection pins are of various specifications and are used for detection. The detection tool and detection method are used for detecting the coaxiality, the location degree and the left and right crotch size of the main intersection point of the nose landing gear and the intersection point of the front supporting rod after product assembly.

Owner:AVIC CHENGFEI COMML AIRCRAFT COMPANY

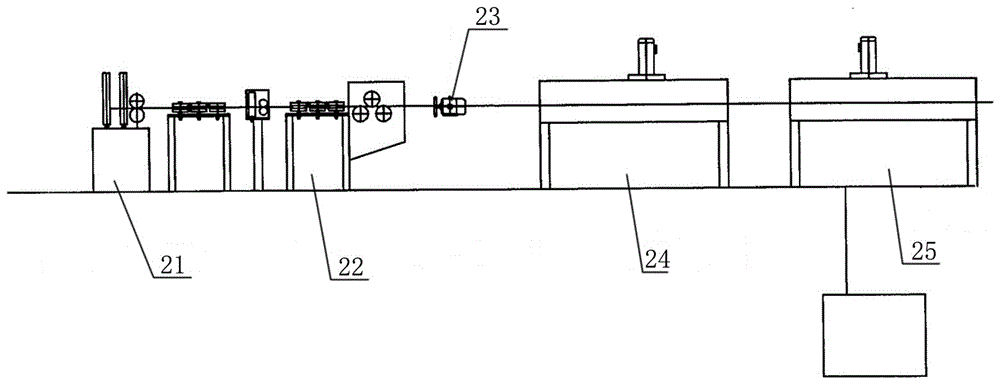

An online double phosphating method for steel wire and its continuous production equipment

ActiveCN105951155BReduce pollutionIncrease multi-purpose usePhosphatisationMetallic material coating processesOne passProduction line

The invention provides an online double phosphating method for steel wires and continuous production equipment for the method. According to the method, a wire drawing machine is adopted to serve as a power source; the steel wires drawn by a pay-off device pass through shucking wheels which are mutually perpendicular, and then a steel brush is adopted to remove residual oxide scales on the surfaces of the steel wires; the steel wires are pickled and activated by phosphoric acid, then enter a medium and low temperature phosphating slot for prephosphating, and subsequently enters an electrolytic phosphating slot for phosphating; and the continuous production equipment consists of the pay-off device, a shucking and pickling device, a double phosphating device and a wire drawing and paying-off device. Compared with an original method for removing the oxide scale by pickling, a mechanical scale removing method adopted by the invention has the advantage that the pollution to the environment is greatly reduced; meanwhile, the invention adopts the double phosphating method, thereby reducing the amount of phosphated residues, shortening phosphating time, changing components and thickness of a phosphating film structure, meeting the demands of multiple products, improving multiple functions of a production line and greatly improving the utilization rate of equipment; and by adopting the wire drawing machine to take up, one-pass drawing is reduced, so that the production cost is further reduced.

Owner:中钢集团郑州金属制品研究院股份有限公司

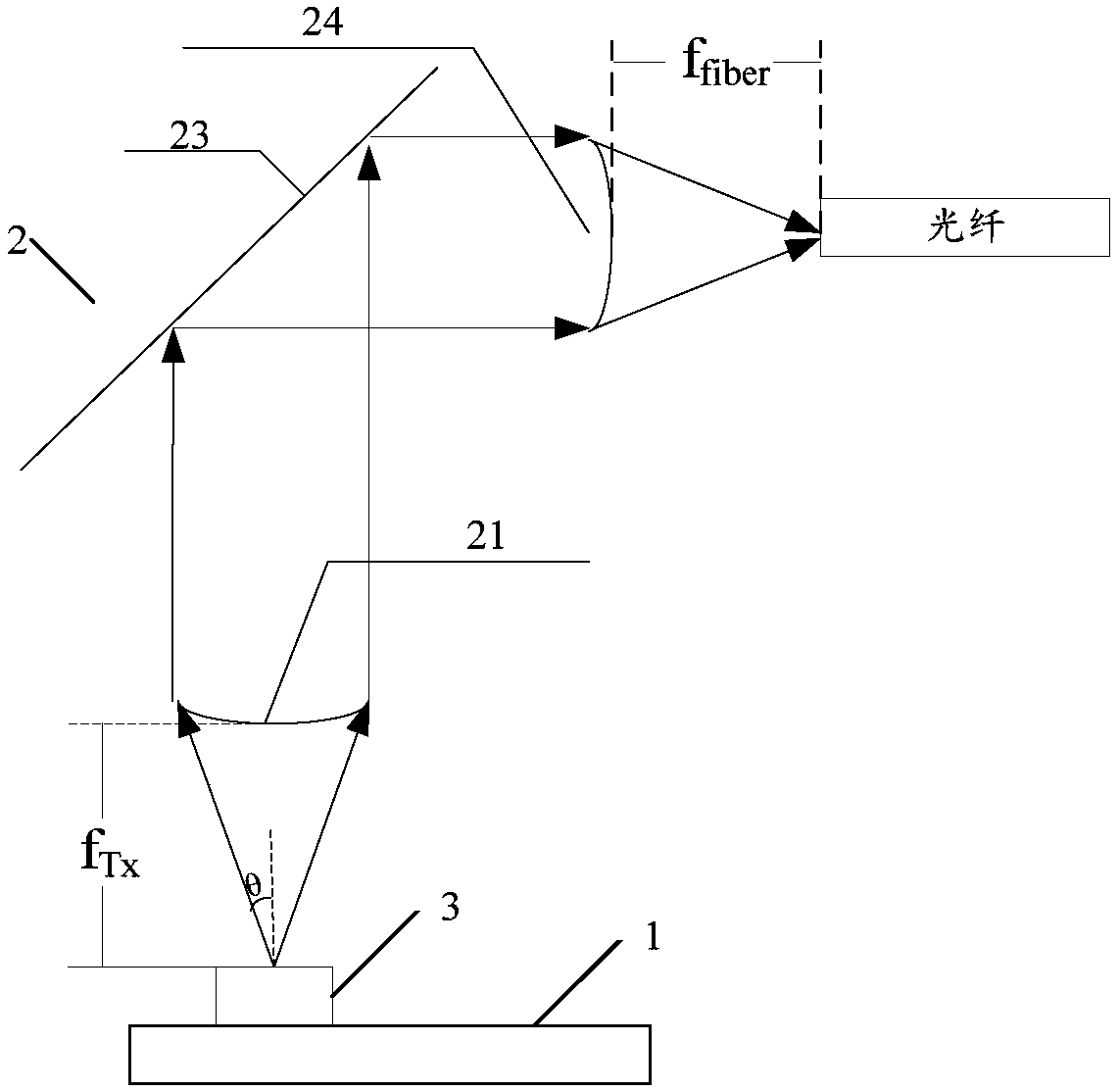

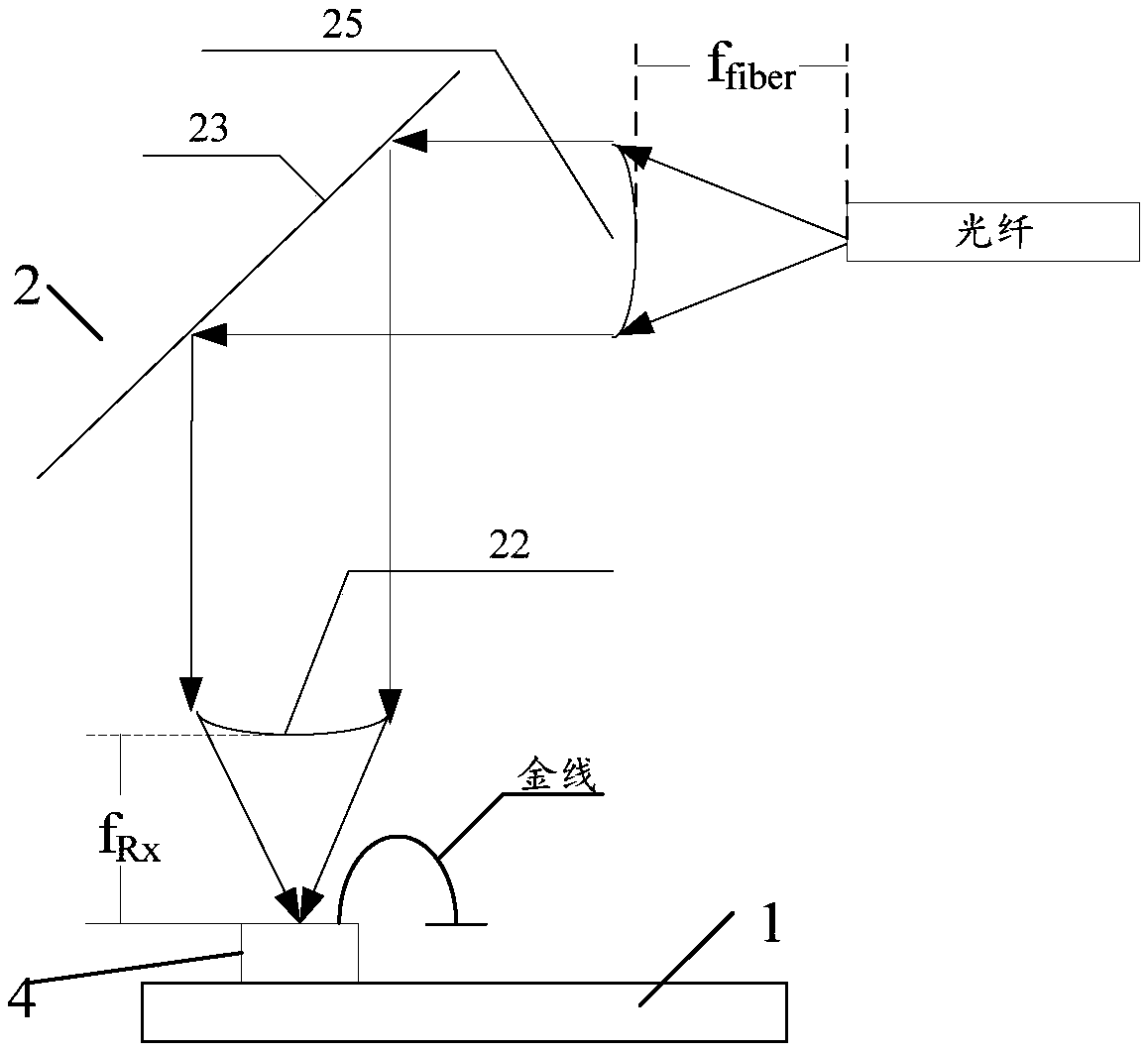

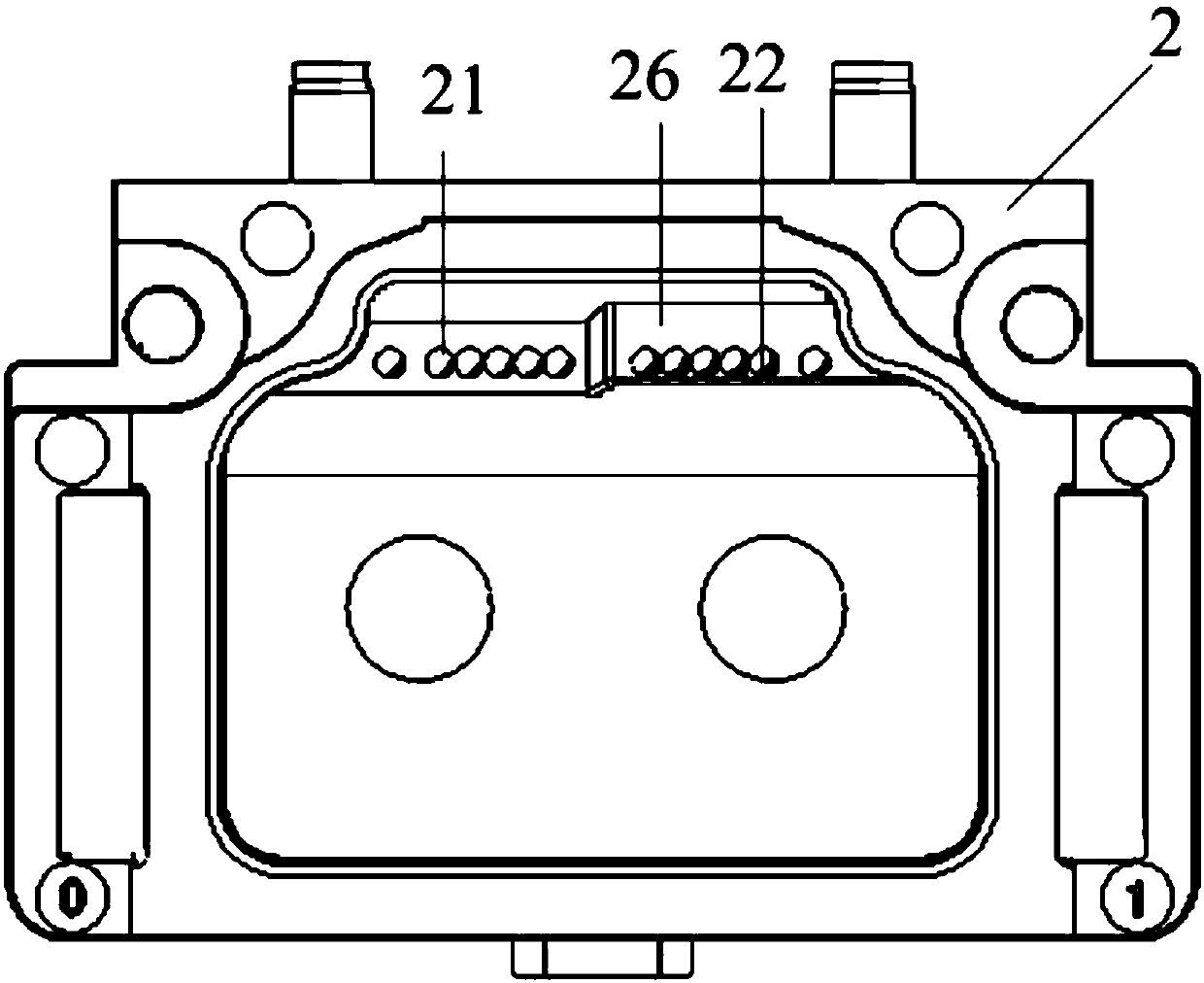

an optical module

The invention discloses an optical module, which belongs to the communication field. The optical module includes: a circuit board, a lens assembly, a laser chip, and a photodetection chip. The laser chip and the photodetection chip are respectively mounted on the surface of the circuit board; the lens assembly is covered by the laser Above the chip and the light detection chip; the lens assembly has a transmitting lens, a receiving lens, a reflective surface, a first fiber optic lens and a second fiber optic lens; the transmitting lens and the receiving lens have different focal lengths; the The first optical fiber lens has the same focal length as the second optical fiber lens; the emitting lens emits the light emitted by the laser chip to the first optical fiber lens through the reflecting surface; the light from the second optical fiber lens passes through The reflective surface is then directed to the light detection chip through the receiving lens. The invention can meet the demands of different products.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

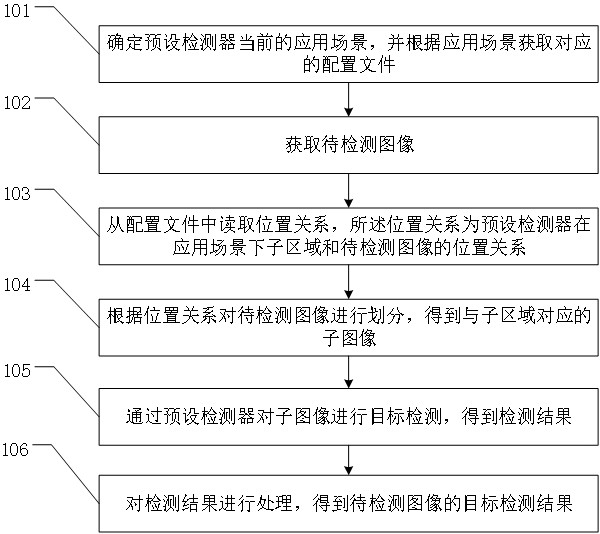

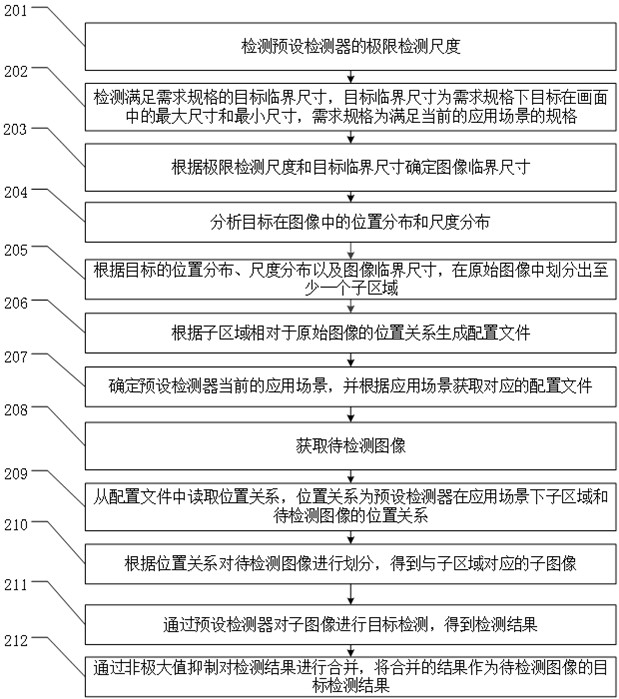

Image target detection method, device and camera equipment

ActiveCN113936199BMeet expected specificationsMeet different product needsBiometric pattern recognitionRadiologyComputer vision

The application discloses an image target detection method, device and imaging equipment, which are used to improve the existing detectors so that they can flexibly adapt to different detection ranges and meet different product requirements. The method of the present application includes: determining the current application scene of the preset detector, and obtaining the corresponding configuration file according to the application scene; obtaining the image to be detected; reading the positional relationship from the configuration file, and the positional relationship is the Presetting the positional relationship between the detector sub-region and the image to be detected in the application scene; dividing the image to be detected according to the positional relationship to obtain a sub-image corresponding to the sub-region; through the preset It is assumed that the detector performs target detection on the sub-image to obtain a detection result; the detection result is processed to obtain the target detection result of the image to be detected.

Owner:珠海视熙科技有限公司

Factory test device for solar product

PendingCN110726721AImprove test efficiencyImprove test stabilityPreparing sample for investigationMaterial analysis by optical meansThermodynamicsMechanical engineering

The invention discloses a factory test device for a solar product. The factory test device comprises a product carrier, a first slide rail, a base, a first driving part, a cover body, a second slide rail, a halogen tungsten lamp, a second driving part, a heat dissipation part and a control part, wherein the product carrier is aranged on the first slide rail, the first slide rail is aranged on thebase, the first driving part is connected with the product carrier, the cover body is aranged on the base, the first slide rail extends into the cover body, the second slide rail is aranged in the cover body, the halogen tungsten lamp is aranged on the second slide rail, the second driving part is connected with the halogen tungsten lamp, the heat dissipation part is located on a side wall of thecover body, and the control part is separately connected with the first driving part and the second driving part. Through the above manner, the factory test device can improve the test efficiency ofoperating staff and improve the test stability, and can simulate light intensity changes to perform multiple types of test adjustment, satisfy different product requirements, and protect the skin of the staff from damage of ultraviolet rays.

Owner:FLEXTRONICS ELECTRONICS TECH SUZHOU

Multi-shaft tapping machine

InactiveCN105750666AShorten the timeImprove work efficiencyThread cutting machinesOther manufacturing equipments/toolsDrive shaftEngineering

The invention discloses a multi-shaft tapping machine comprising a motor, a pedestal and tapping mechanisms; a work table on the pedestal is connected with the pedestal; the tapping mechanisms comprise a first tapping mechanism and a second tapping mechanism; the first and second tapping mechanism are connected on a support; the support can effectively keep the first and second tapping mechanisms to be stable; the first tapping mechanism comprises a connecting rod and a first tapping shaft; the second tapping mechanism comprises a connecting rod, a transmission shaft, and a second tapping shaft; the multi-shaft tapping machine can simultaneously process various tapping holes on various surfaces, thus saving multi-clamping processing time, greatly improving work efficiency, preventing miss-processing quality troubles, fast adjusting works according to different product structures, and satisfying different product needs.

Owner:泰州市海陵区固泰标准件厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com