Grouting machine

A grouting machine and frame technology, which is applied in dough cutting machines, baking workshops, baking, etc., can solve problems such as easy slag, uneven grouting, and damage to product quality, and achieve uniform output scale , good cutting effect and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

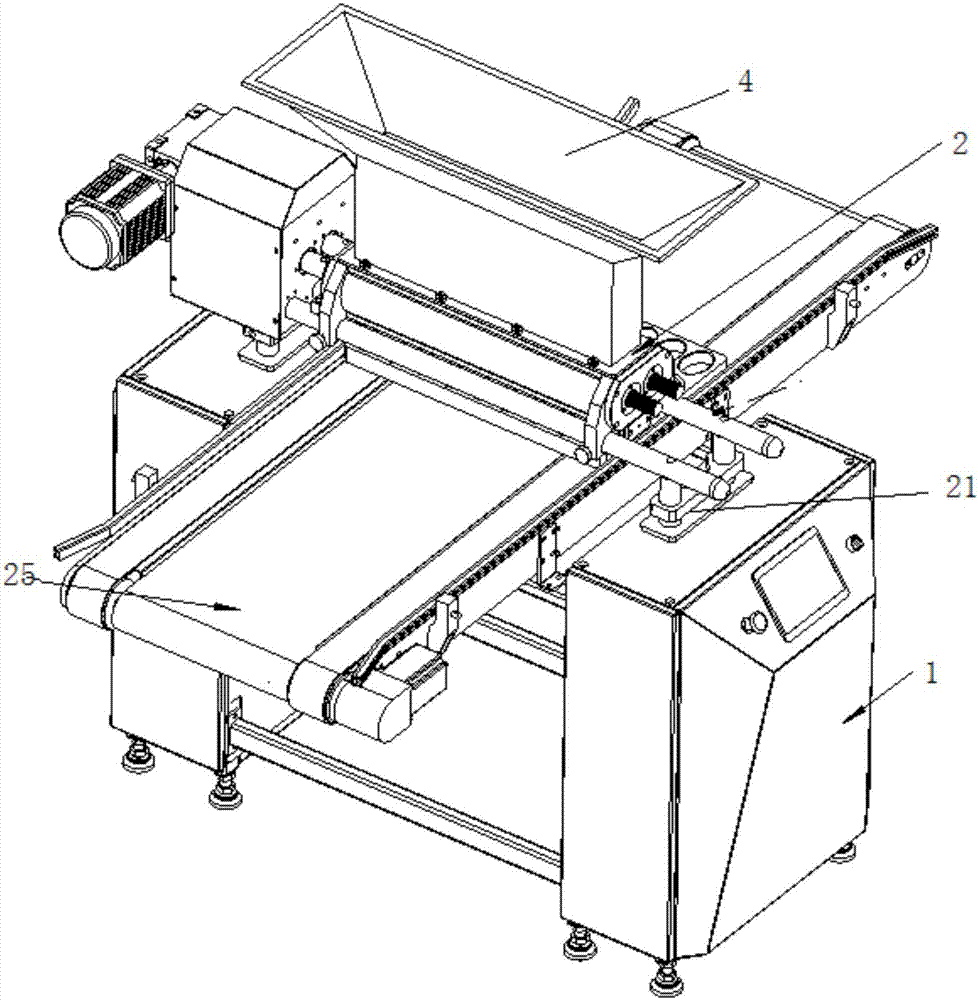

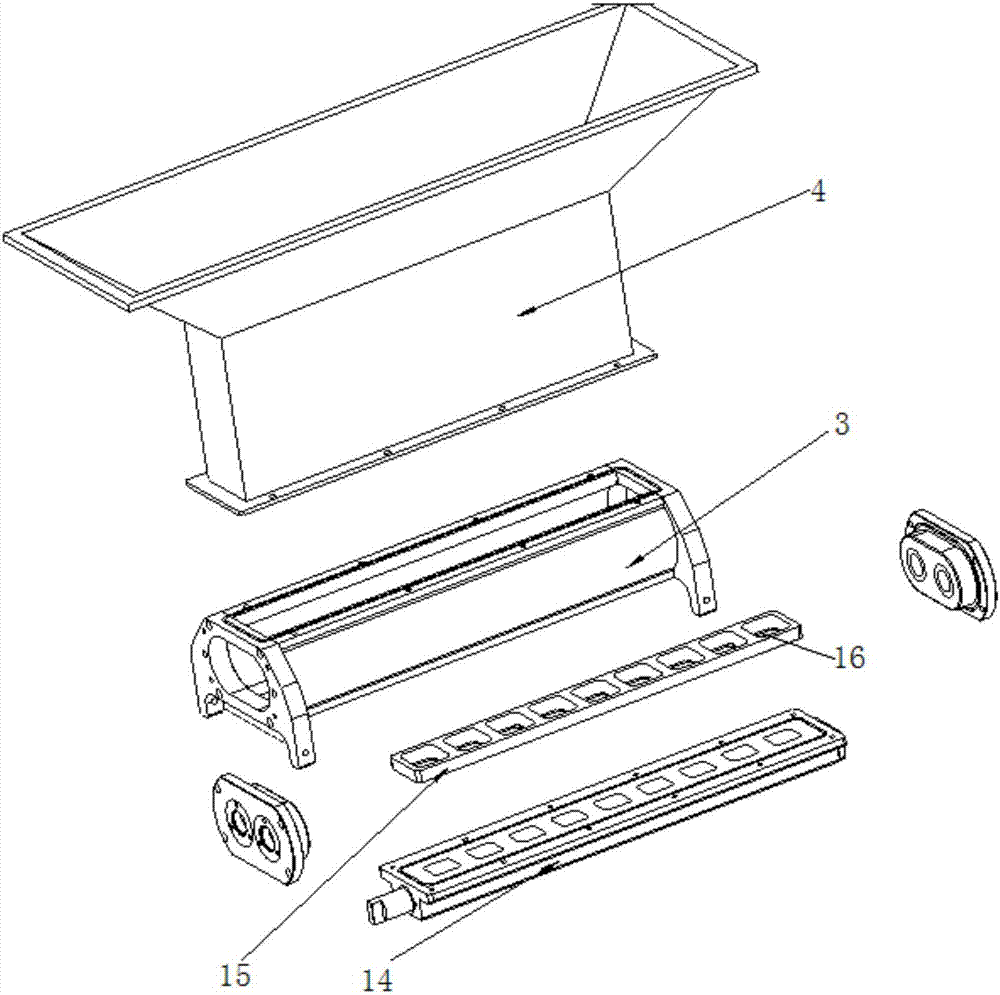

[0052] See attached picture.

[0053] A grouting machine, comprising a frame 1, on which a liftable pump body mechanism 2 is installed; the pump body mechanism 2 includes a pump body 3, and the top of the pump body is equipped with a The hopper 4 of the pump body is installed with a material roller mechanism for transferring slurry, and the bottom of the pump body is equipped with a material seat 5; a material cavity is provided in the material closing seat 5, and the top and bottom of the material closing seat 5 are respectively equipped with inlet and outlet. Mouth 6,7, the relevant material shaft 8 that is installed in the material cavity is rotated, and the material guide port 9 corresponding to the position of the inlet and outlet is provided on the material closing shaft 8.

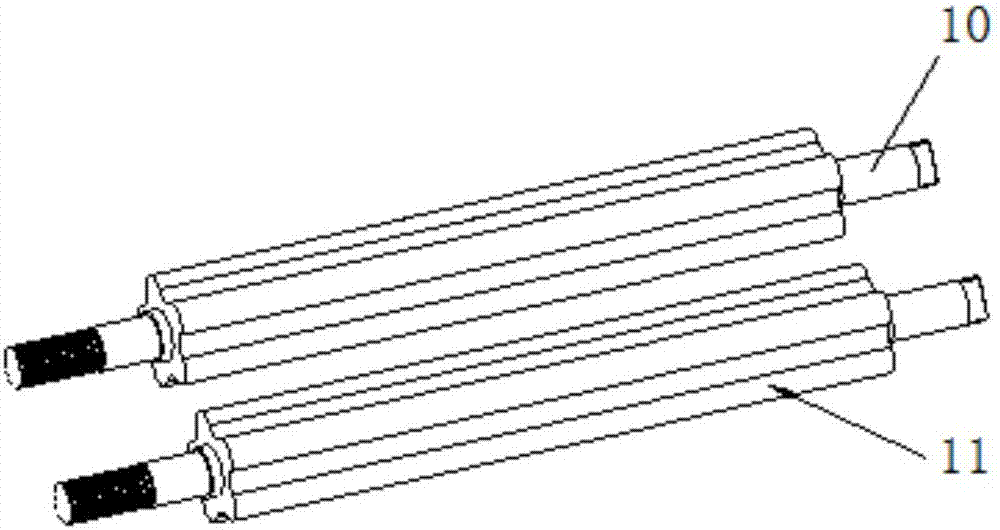

[0054] The material roller mechanism includes a group of material roller shafts 10 that turn in opposite directions. The material roller shafts 10 are respectively fixed with arc-shaped pentagonal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com