Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Low magnetic permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

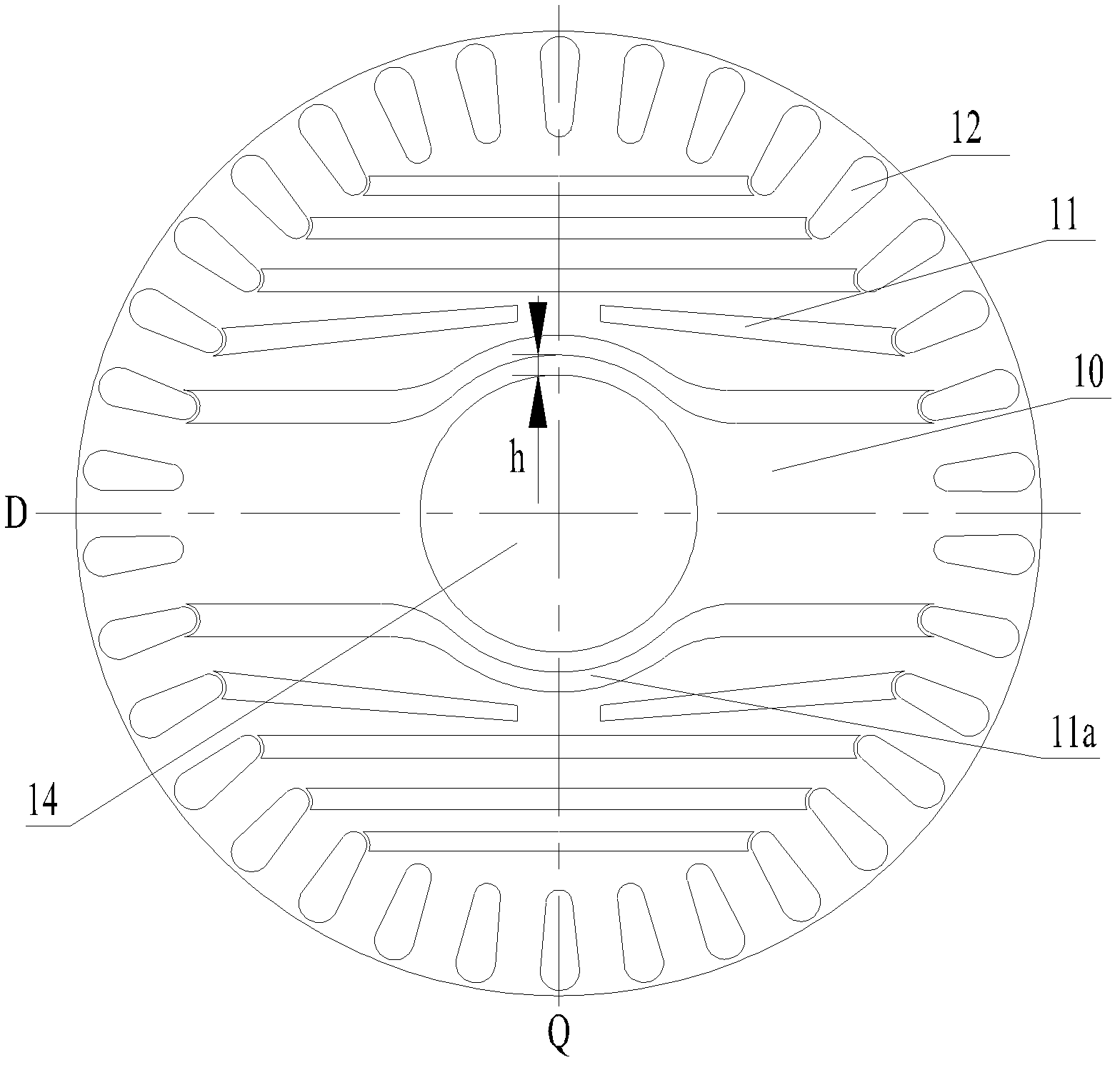

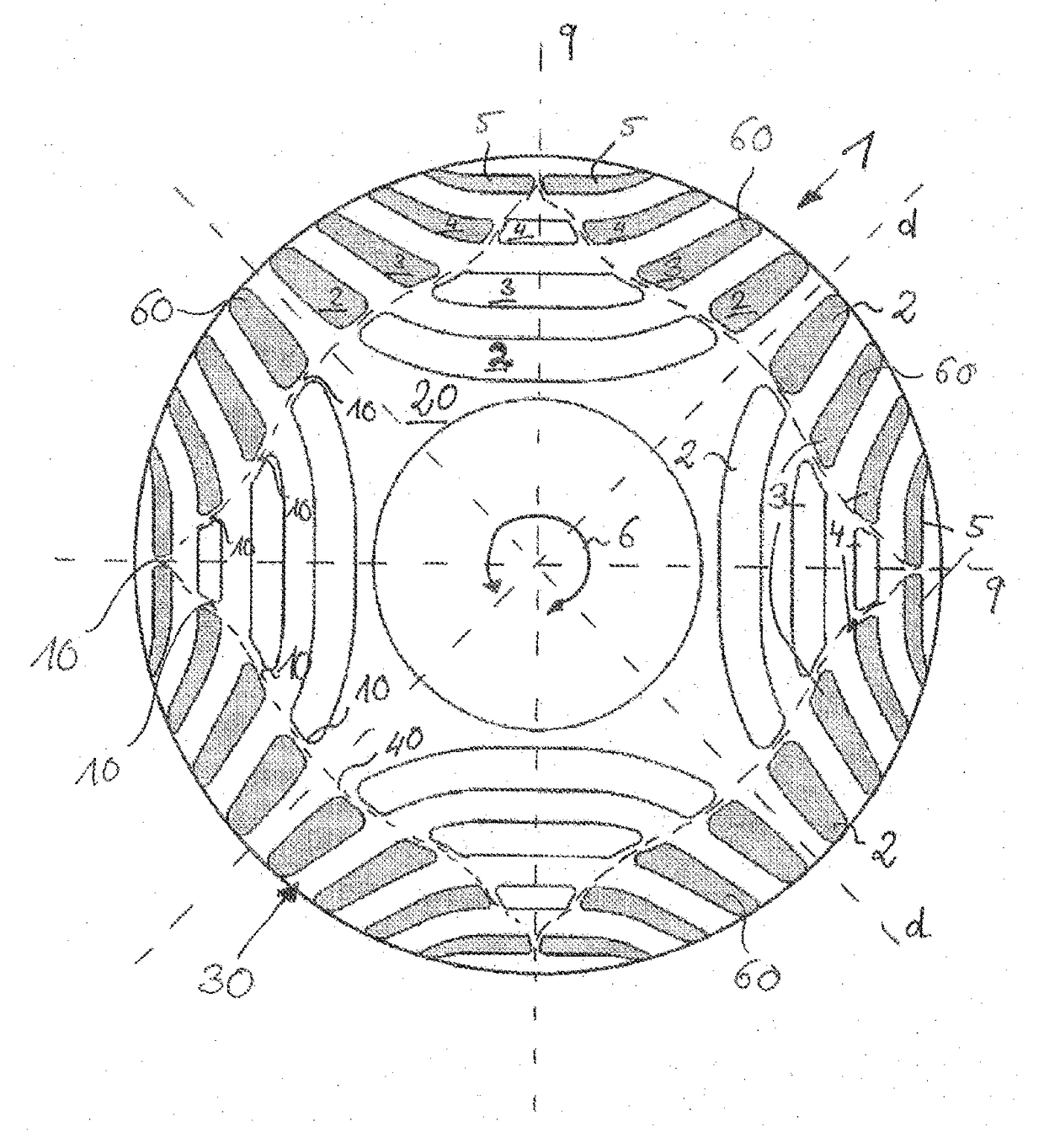

Self-starting synchronous reluctance motor and rotor thereof

ActiveCN103208894ARaise the saliency ratioImprove efficiencySynchronous machinesAsynchronous induction motorsSynchronous reluctance motorInductance

The invention provides a self-starting synchronous reluctance motor and a rotor thereof. The rotor of the self-starting synchronous reluctance motor comprises an iron core and squirrel-cage grooves, wherein magnetic flux separation grooves are arranged on the iron core, and the squirrel-cage slots are distributed along the periphery of the iron core. In the cross section of the rotor, the center line of the cross sections of the squirrel-cage slots deviates from the center circle of the iron core. The self-starting synchronous reluctance motor comprises a stator and the rotor of the self-starting synchronous reluctance motor. According to the self-starting synchronous reluctance motor and the rotor, the center line of the cross sections of the squirrel-cage grooves is led to deviate from the center circle of the iron core by adjusting the angle of the squirrel-cage grooves arranged on the rotor, magnetic permeability in the direction of the D axis is improved, magnetic permeability in the direction of the Q axis is reduced, inductance Ld in the direction of the D axis is increased and inductance Lq in the direction of the Q axis is reduced, namely salient pole ratio (Ld / Lq) of the motor is improved, and further motor efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

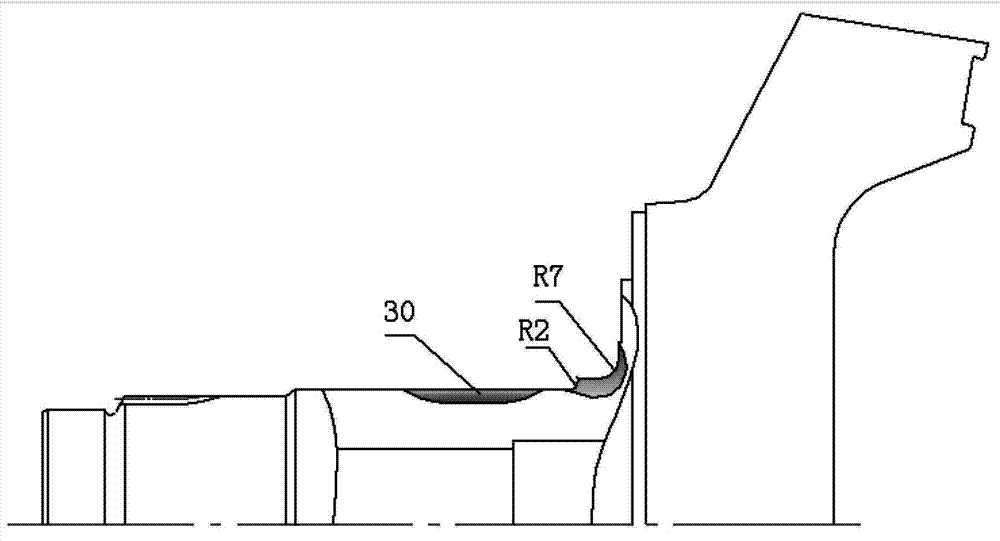

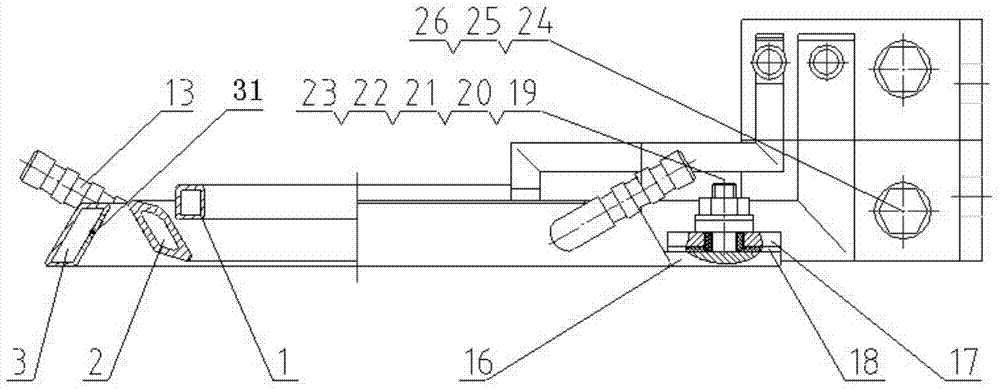

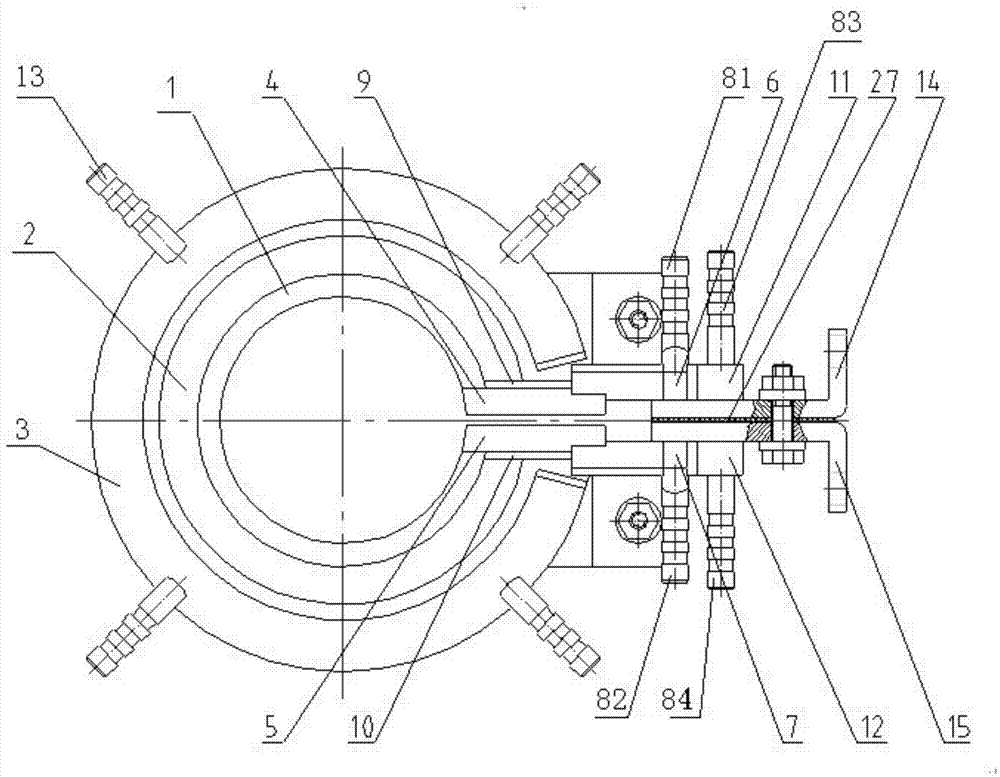

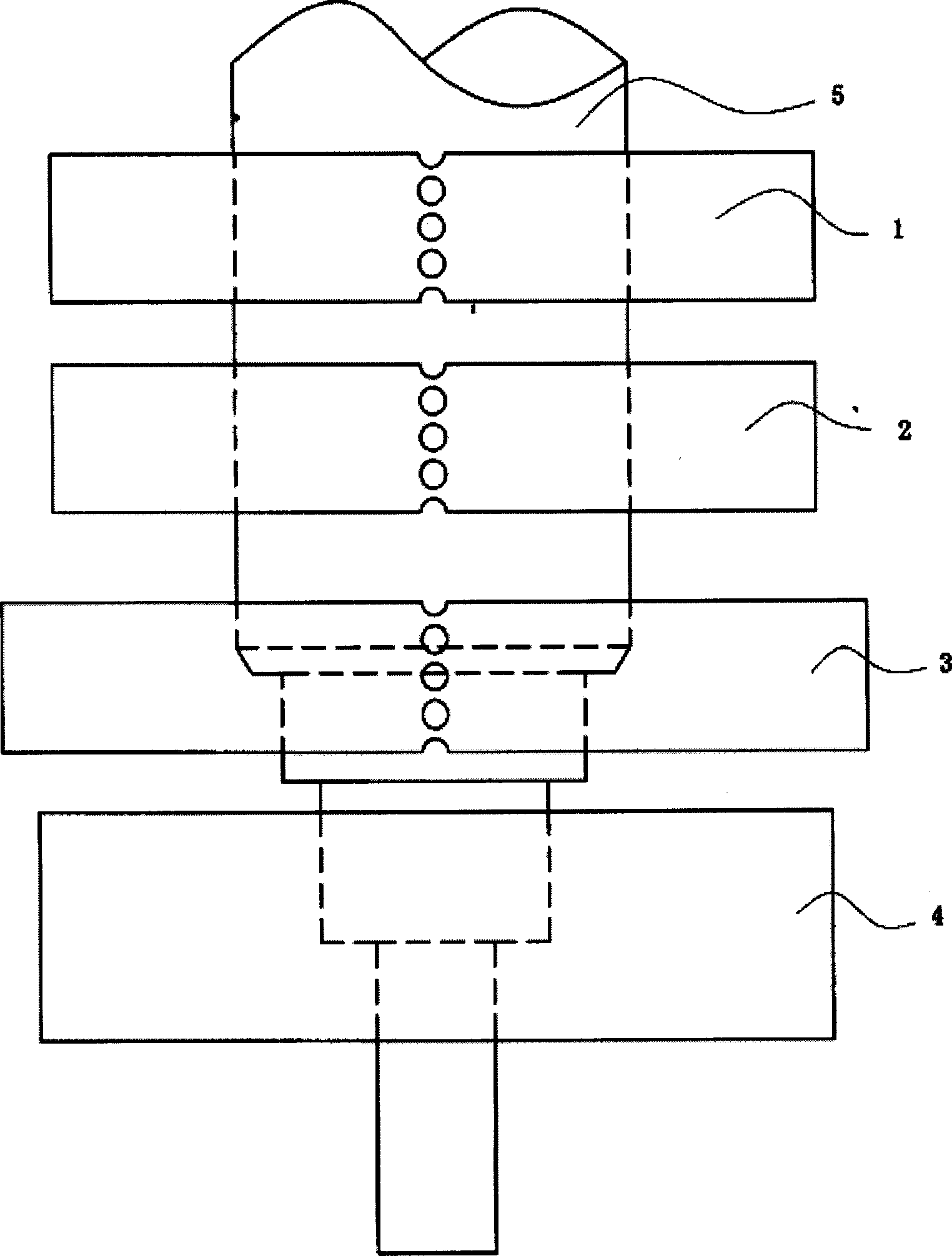

Quenching inductor for double steps of steering joint and quenching method for steering joint

ActiveCN103589846AAvoid safety accidentsContinuous distributionFurnace typesIncreasing energy efficiencyAcute angleInductor

The invention relates to a quenching inductor for double steps of a steering joint and a quenching method for the steering joint. The section of the lower part of an inner circumferential part of a second annular effective heating ring of the quenching inductor is of an acute angle shape; a first annular effective heating ring is positioned above the acute angle shape; two ends of the first annular effective heating ring and two ends of the second annular effective heating ring are assembled and welded with water pipe connectors through cooling water pipes to respectively form a first conductive loop and a second conductive loop; a circular water spraying ring is positioned on one side of the periphery of the second annular effective heating ring; a water spraying hole is formed in the inner circumferential surface of the circular water spraying ring. The quenching inductor can heat the double steps of the steering joint section by section through the two effective heating rings and cool the double steps of the steering joint through the circular water spraying ring and is high in heating efficiency and high in cooling capacity, and an effective hardening layer is distributed uniformly and continuously.

Owner:CHINA FIRST AUTOMOBILE

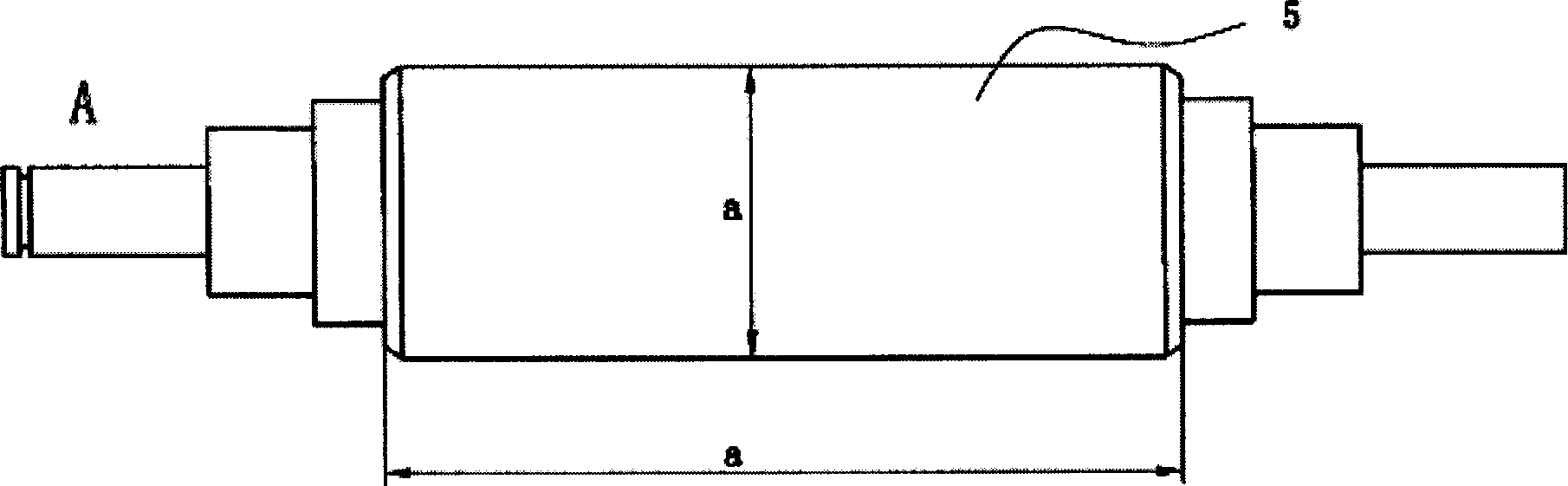

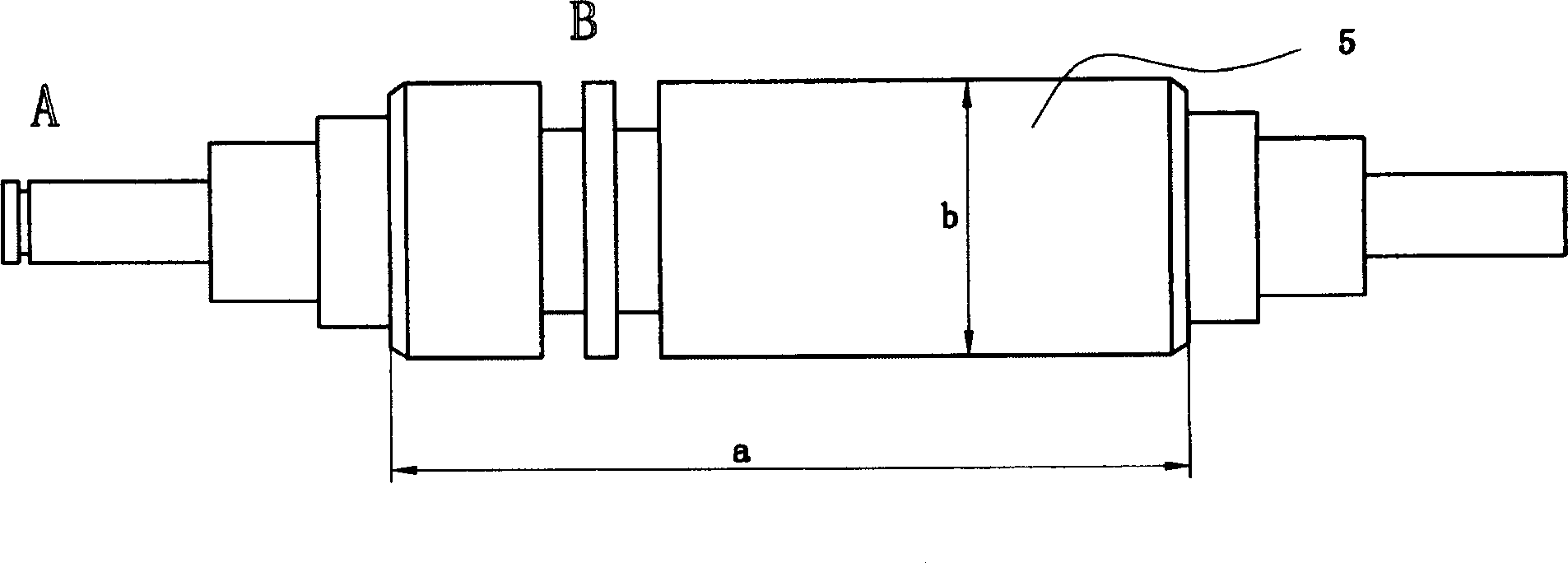

Method for making quench hardening layer of cold roll barrel

ActiveCN1840714AQuality improvementAdd depthIncreasing energy efficiencyProduction rateIntermediate frequency

The related processing method for quench-hardening layer of roller body comprises: processing roller with steel, letting roller body cross in turn the first and second LF sensors and MF sensor for induction electric heating, and spraying water for cool to obtain the target layer with depth more than 50mm. This invention can improve wear and yield, reduces energy consumption, and brings great economic benefits.

Owner:BAOSTEEL ROLL SCI & TECH

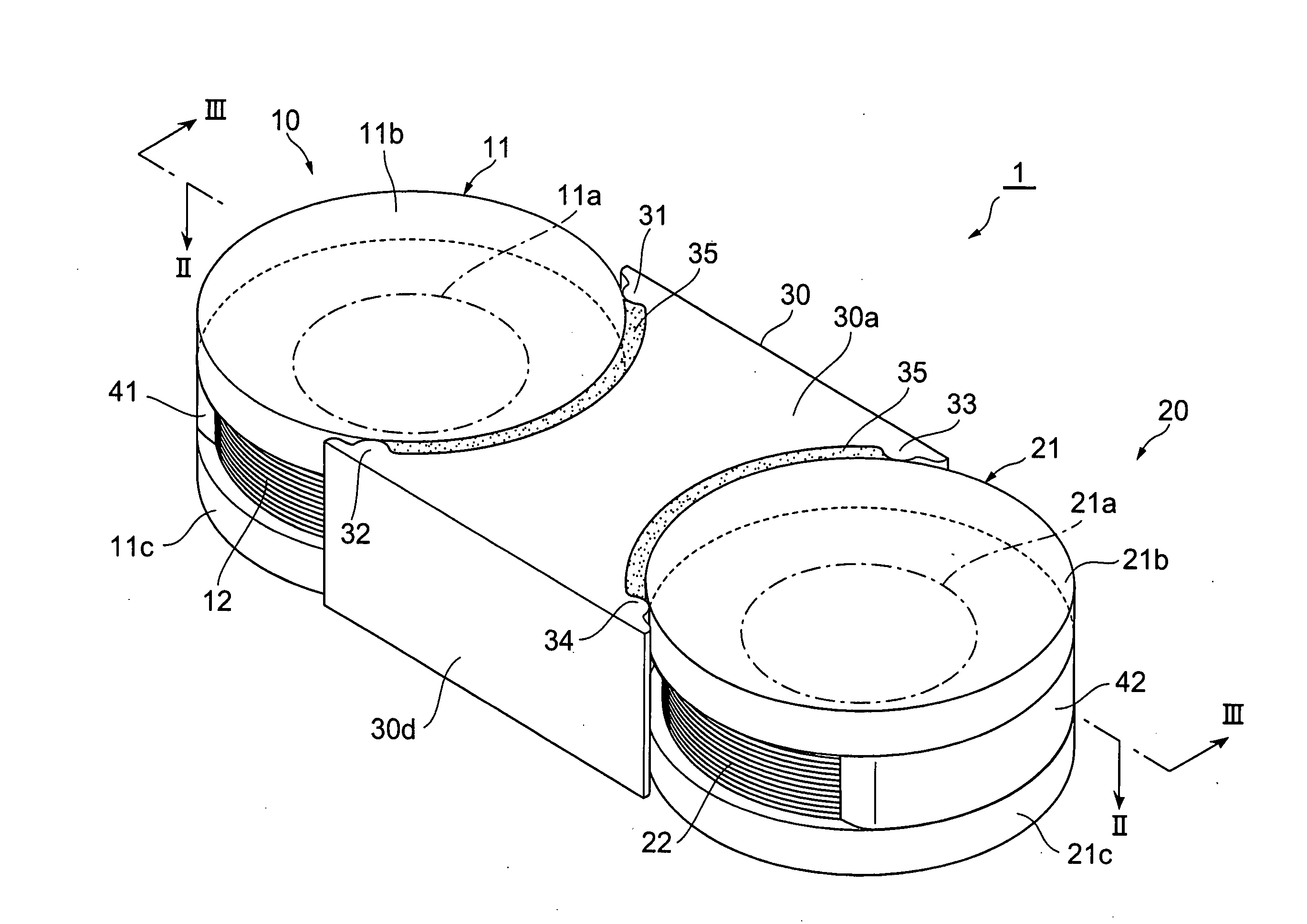

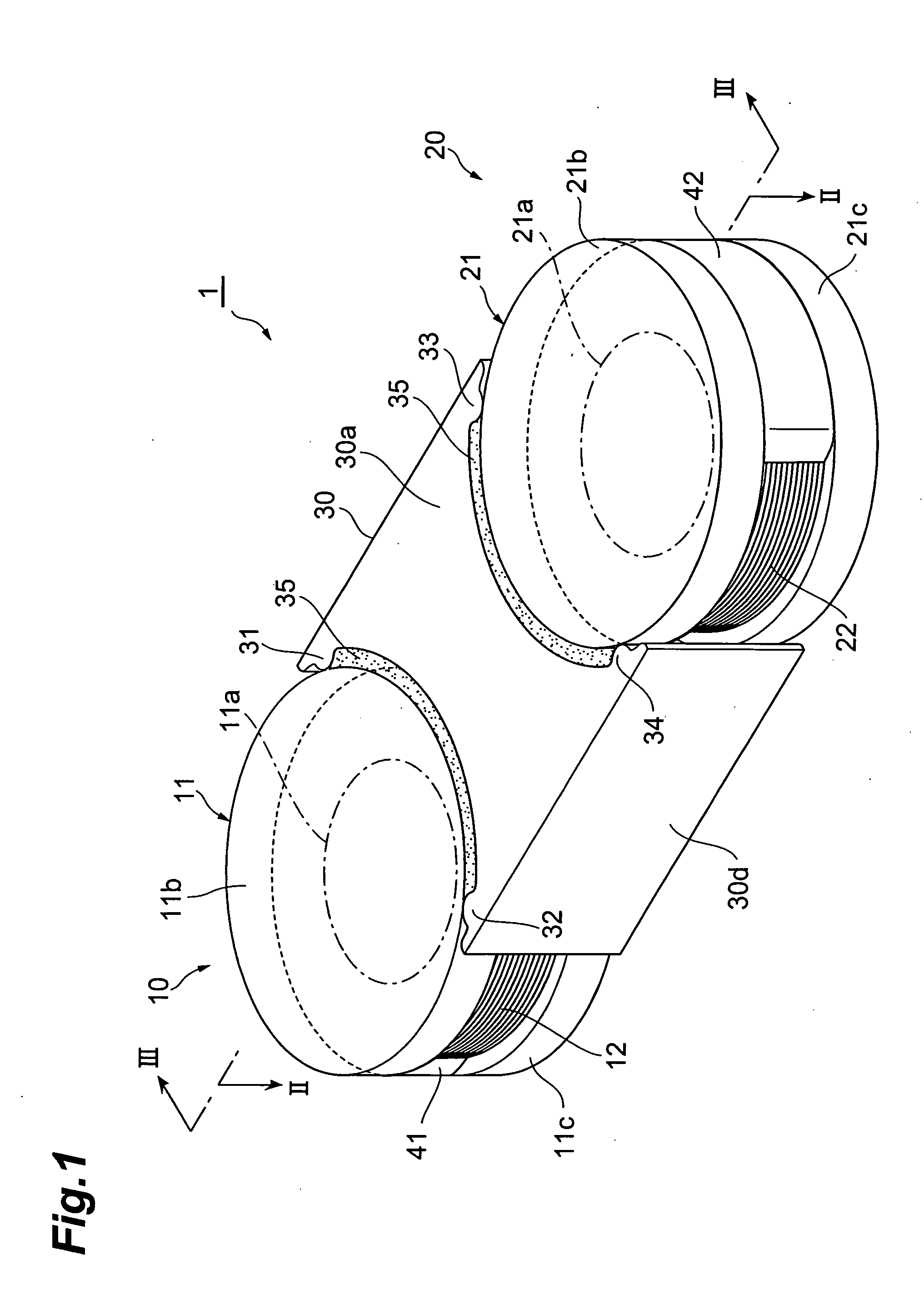

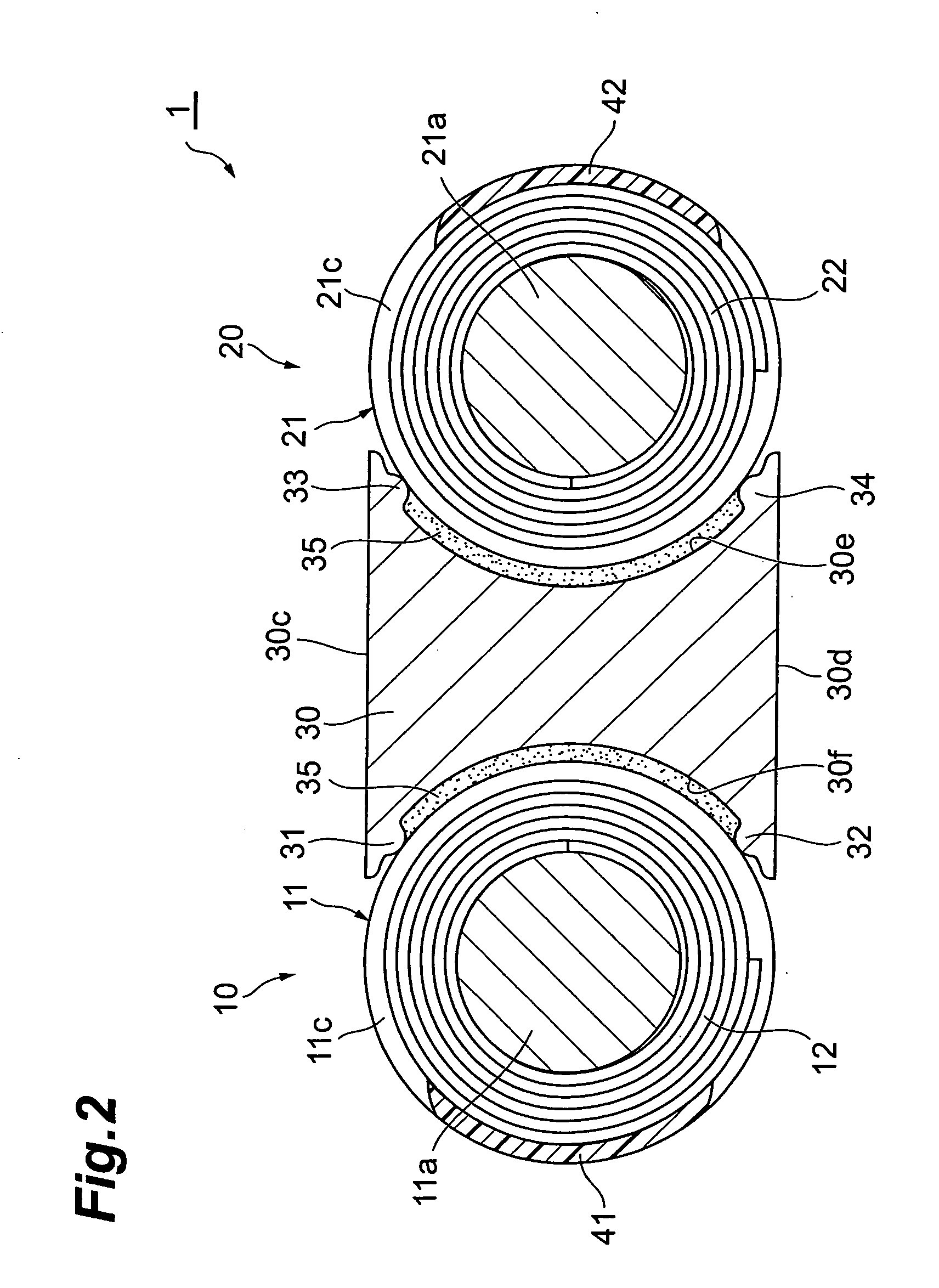

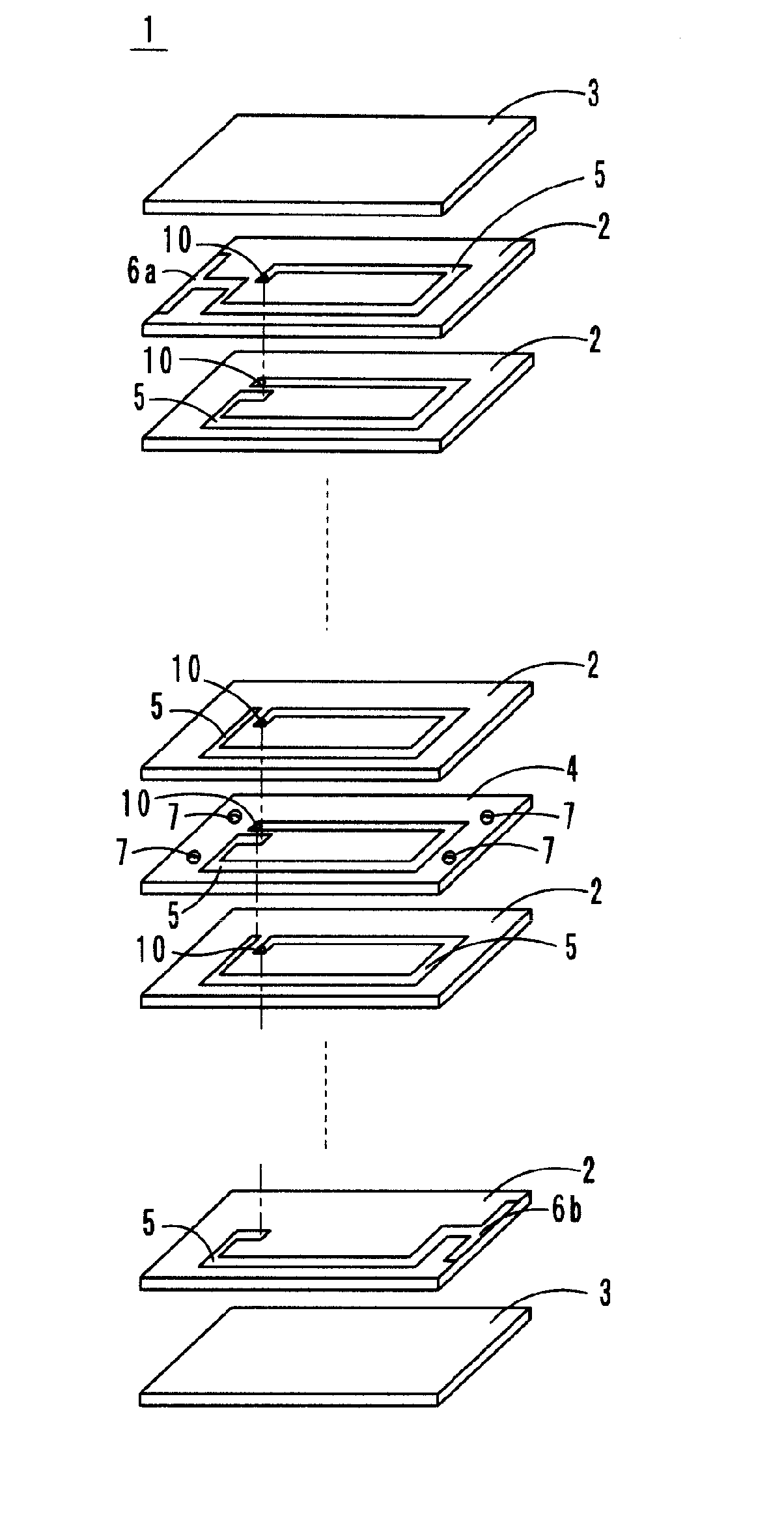

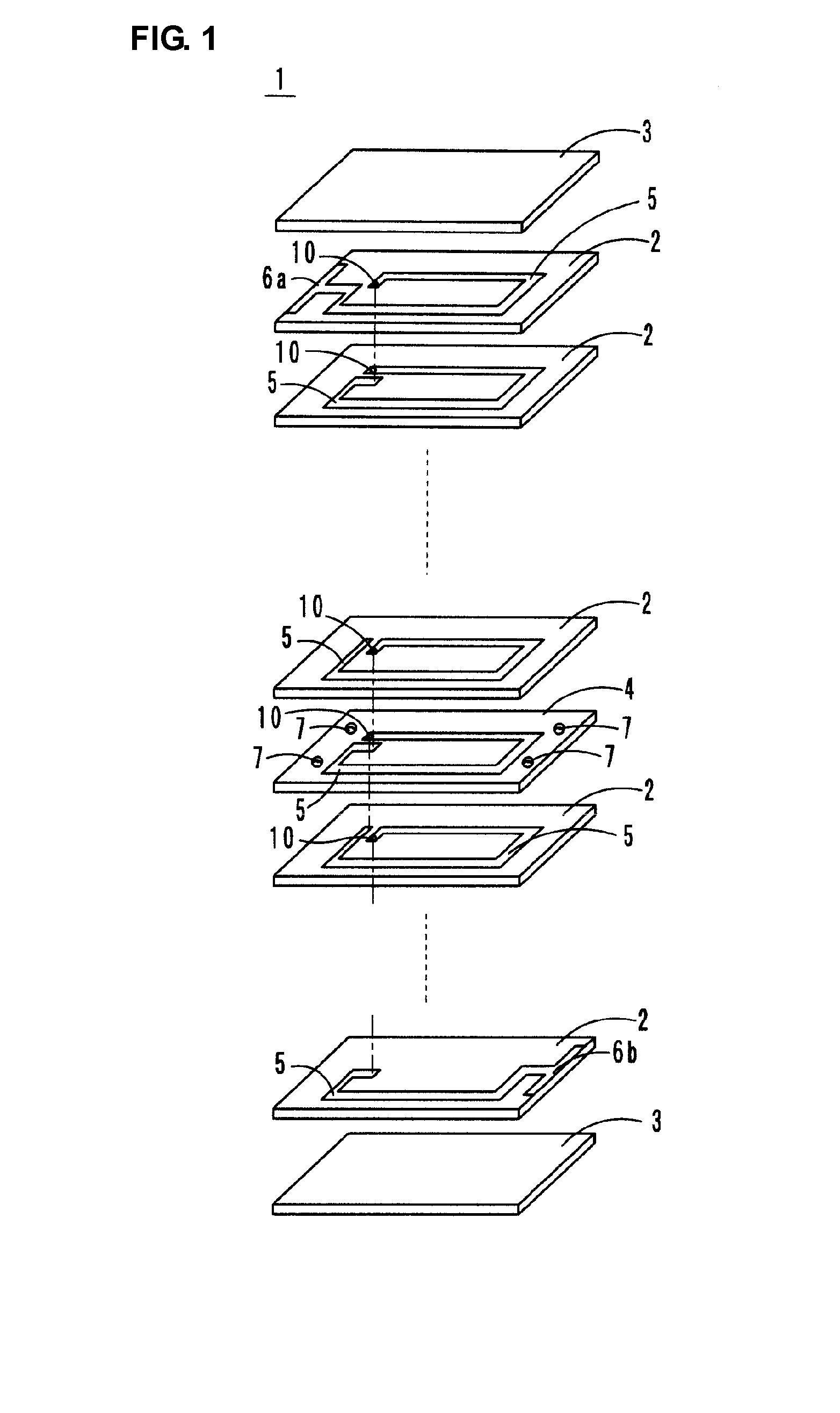

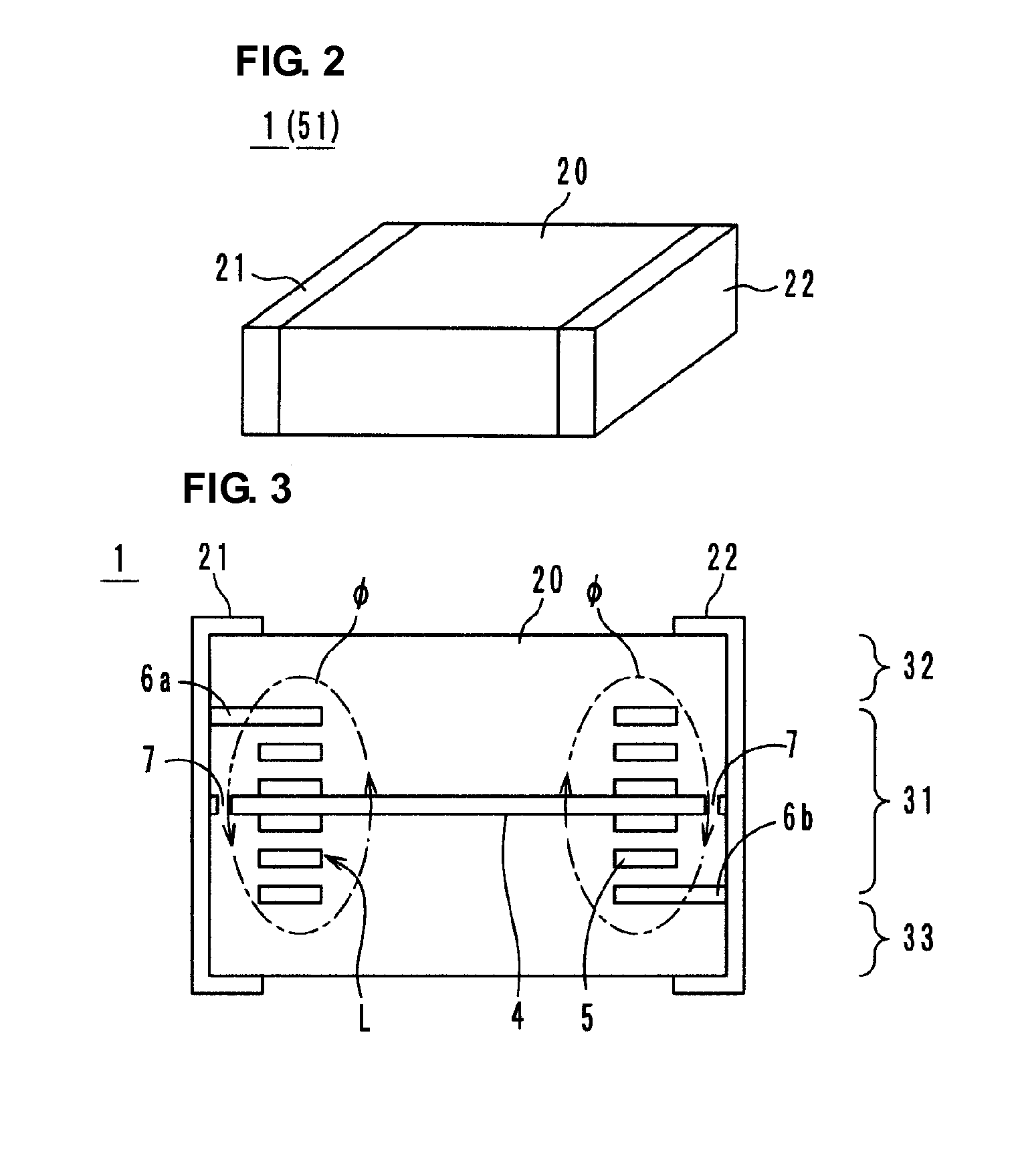

Coil component

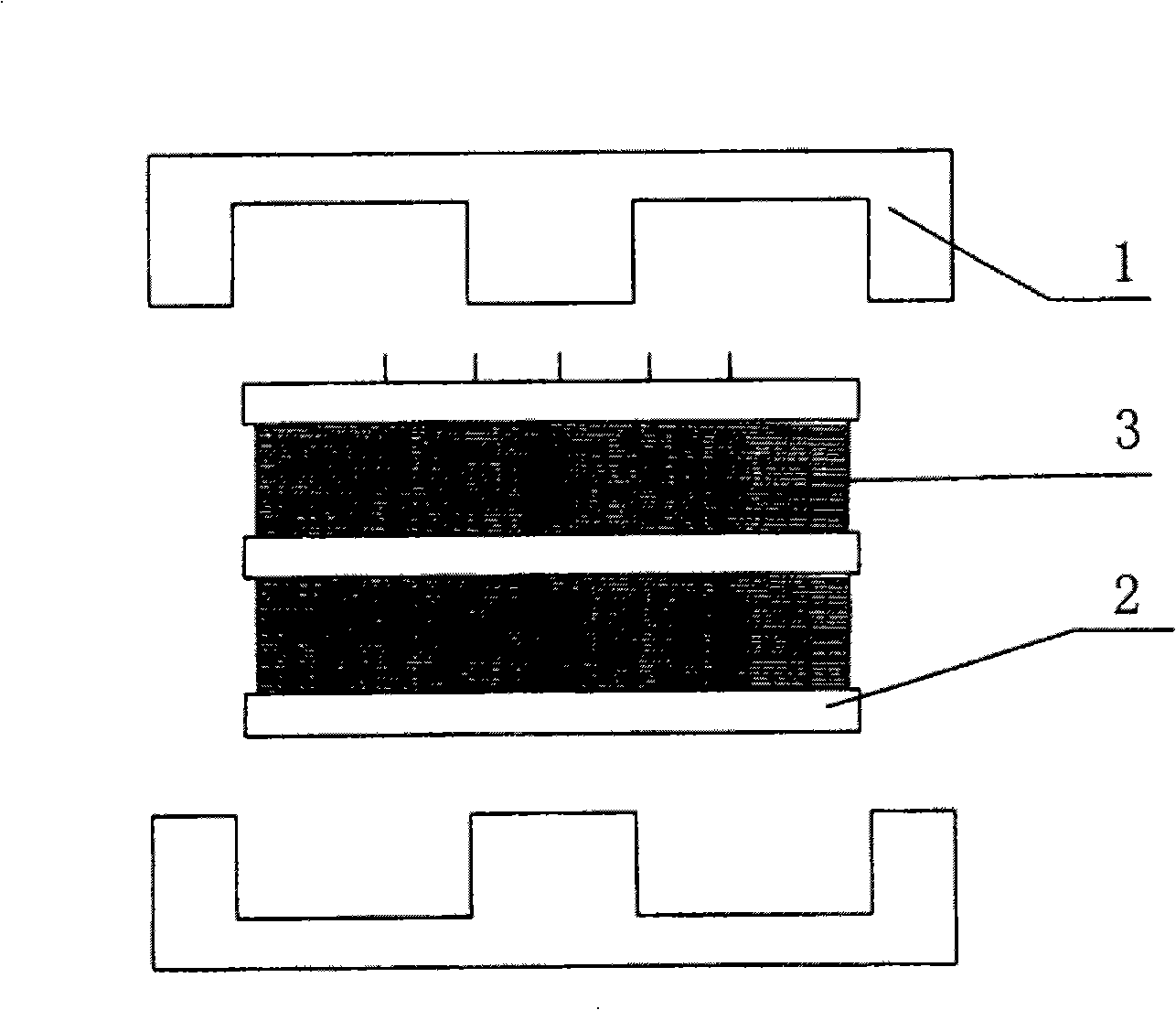

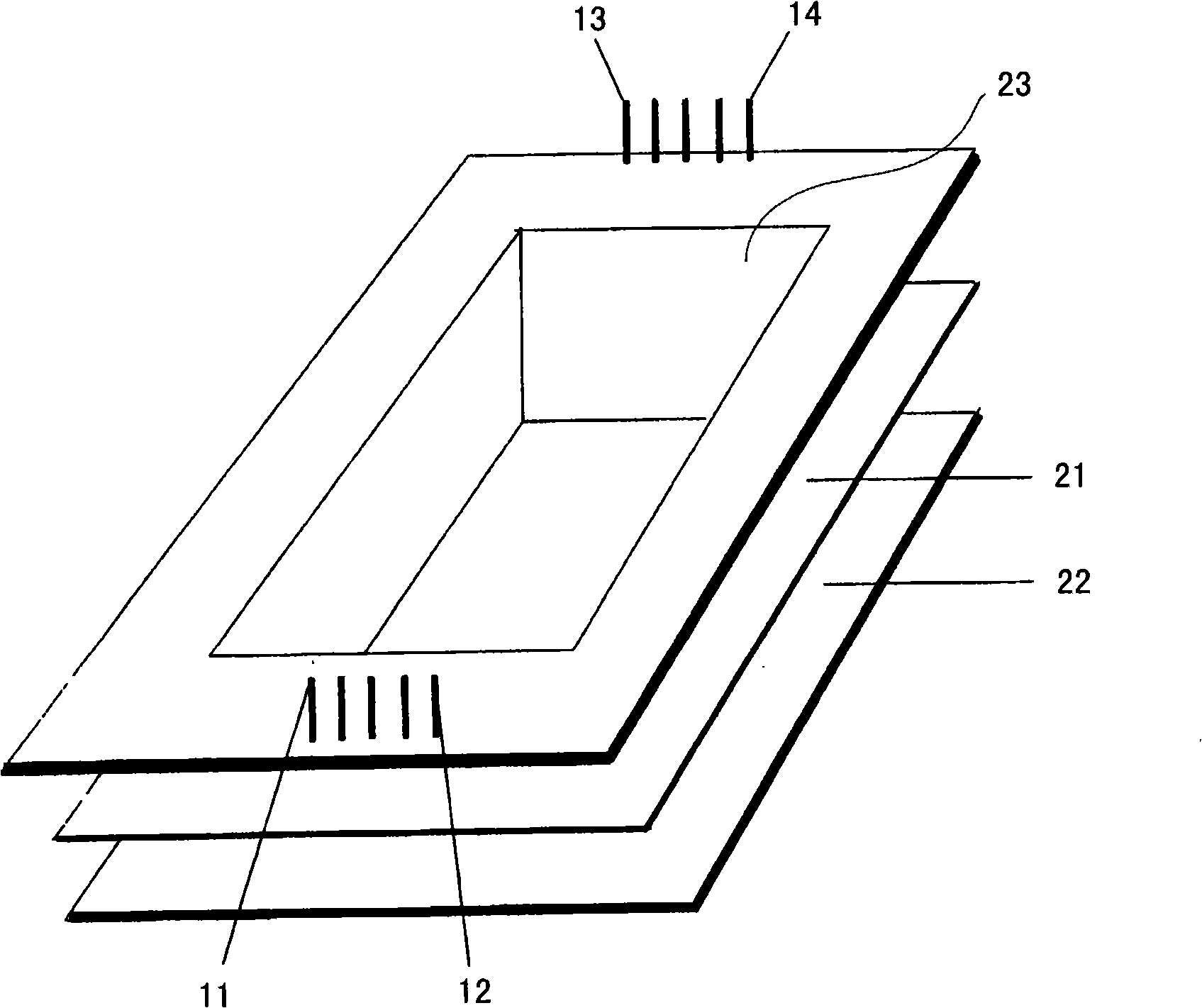

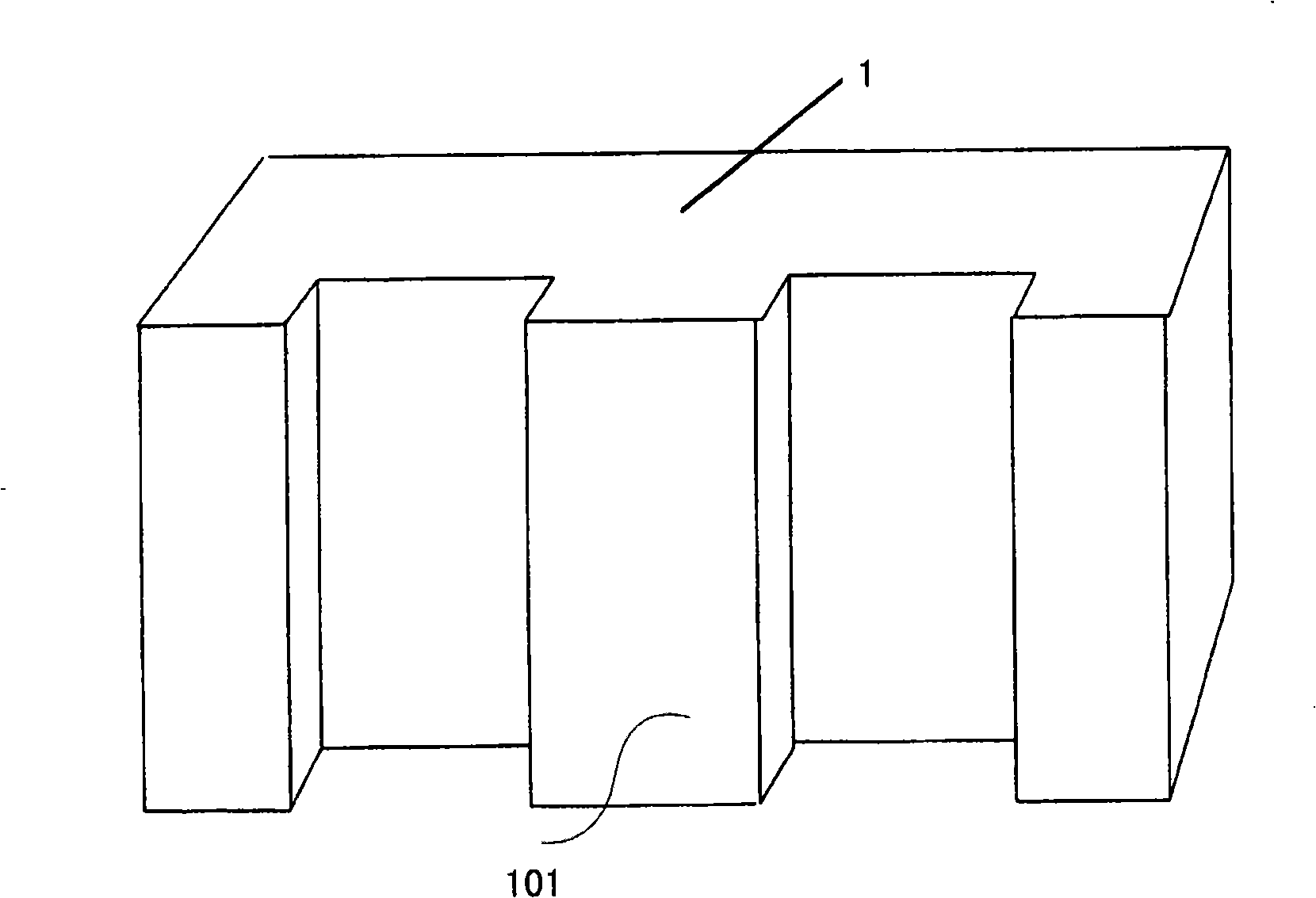

ActiveUS20080179445A1Reduce crosstalkImprove shielding effectTransformers/inductances coils/windings/connectionsFilament handlingEngineeringConductor Coil

A coil component has a first coil part and a second coil part, a middle member, and a shield member. Each of the first and second coil parts includes a drum core and a winding. The middle member is located between the first and second coil parts arranged in a state in which axes of winding drums in the respective first and second coil parts are parallel to each other. The shield member is formed at least in part of an outside surface of the winding in each of the first and second coil parts and is a resin containing a magnetic material powder. The magnetic permeability of the middle member is lower than that of the core and the shield member.

Owner:TDK CORPARATION

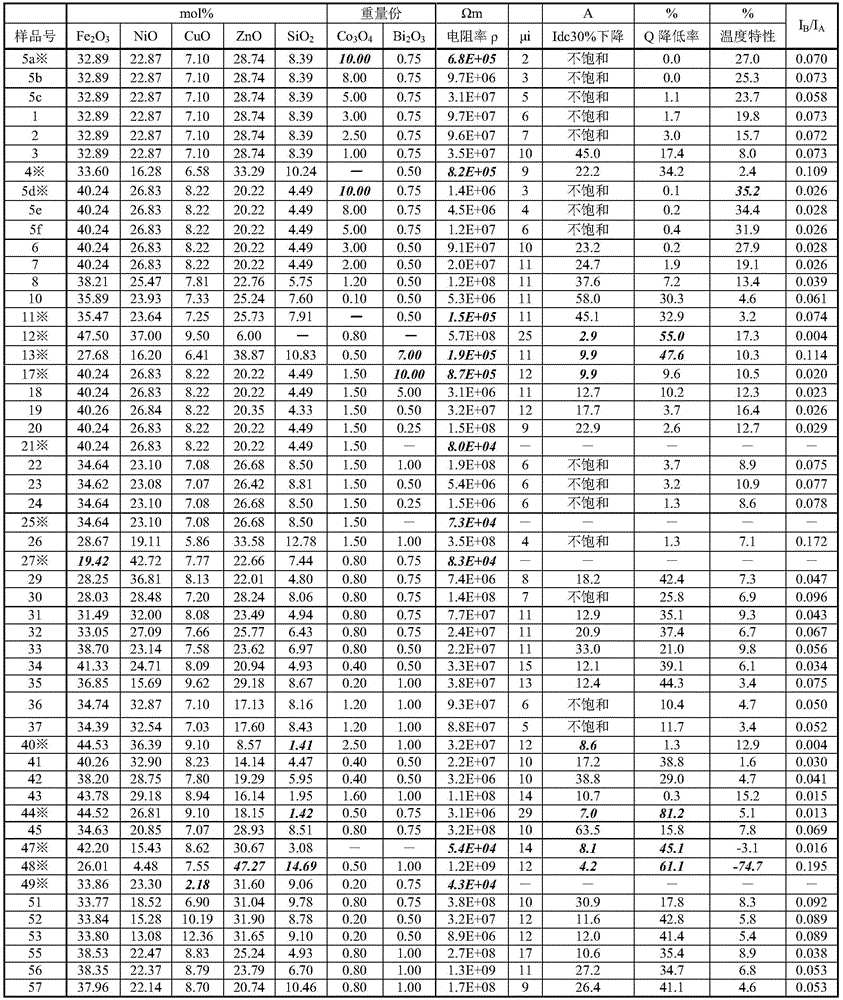

Ferrite composition and electronic component

ActiveCN106045492AMiniaturizationLow magnetic permeabilityInorganic material magnetismTransformers/inductances detailsMetallurgyElectronic component

The invention relates to a ferrite composition and an electronic component, a main component including 23.0 to 47.0 mole% of Fe compound in terms of Fe2O3, 3.0 to 16.0 mole% of Cu compound in terms of CuO, 4.0 to 39.0 mole% of Zn compound in terms of ZnO, 1.5 to 13.0 mole% of Si compound in terms of SiO2, and a residue of Ni compound; and a subcomponent including, with respect to 100 parts by weight of the main component, 0.1 to 8.0 parts by weight of Co compound in terms of Co3O4 and 0.25 to 5.00 parts by weight of Bi compound in terms of Bi2O3.

Owner:TDK CORPARATION

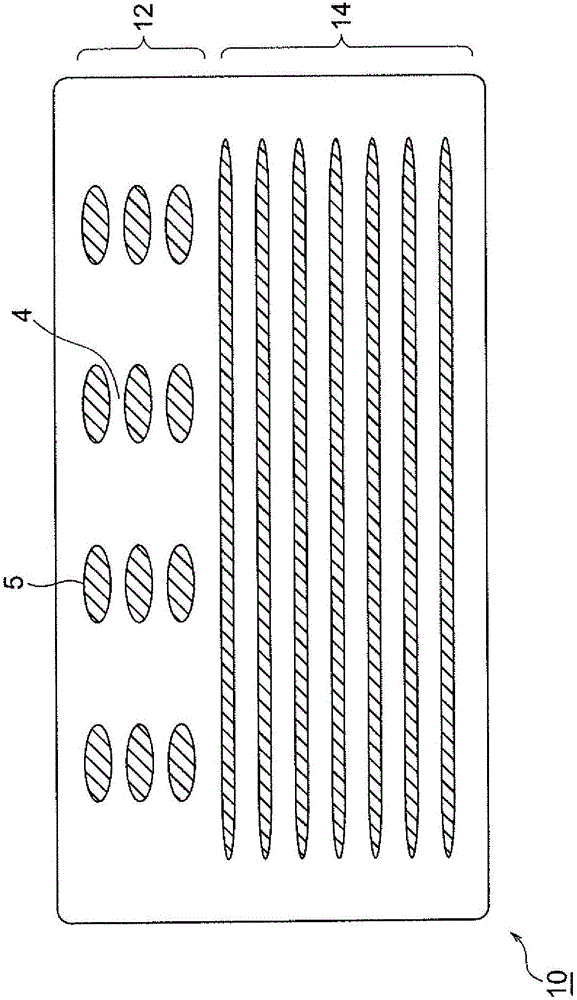

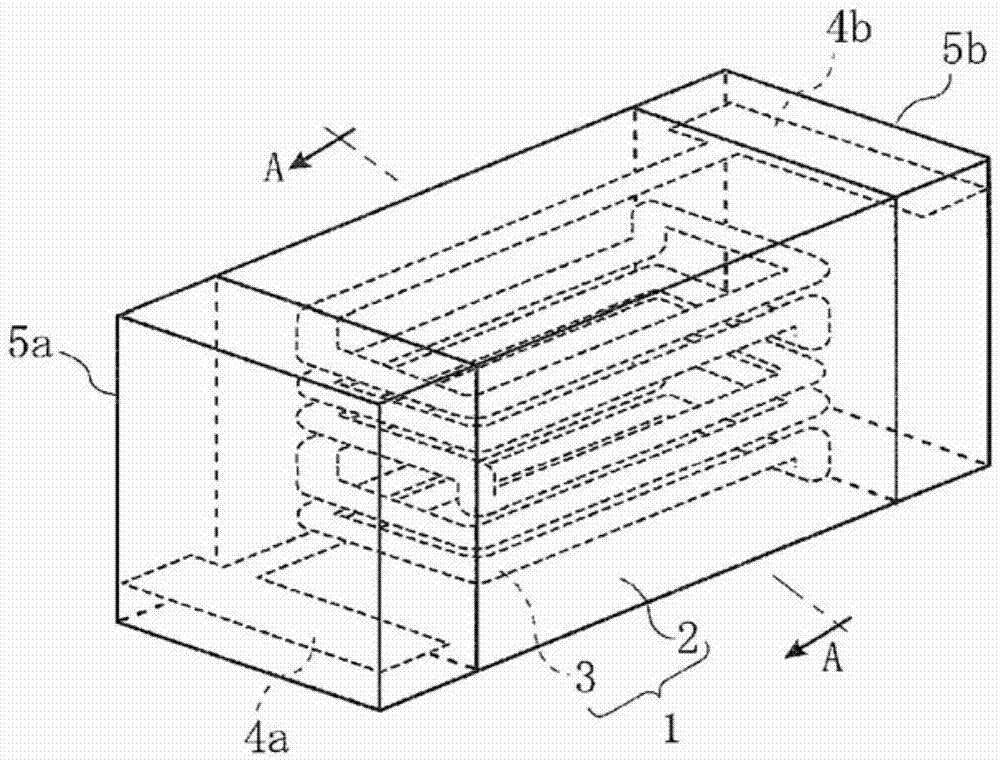

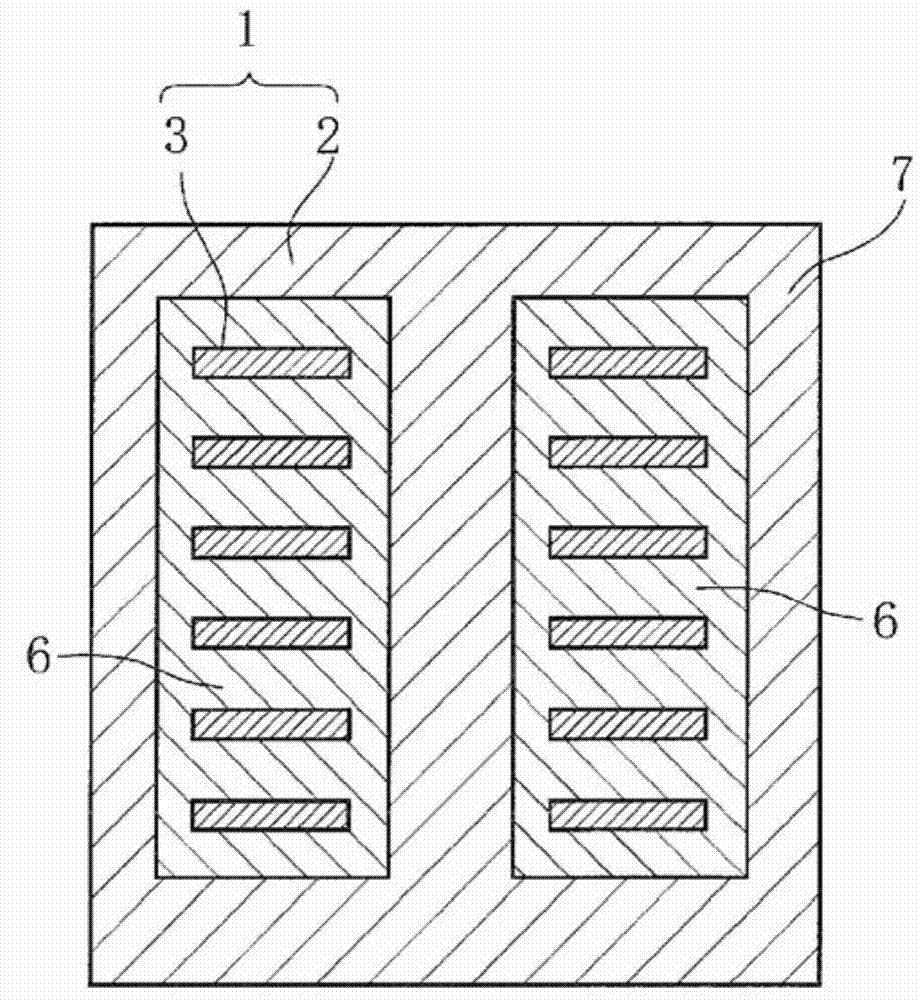

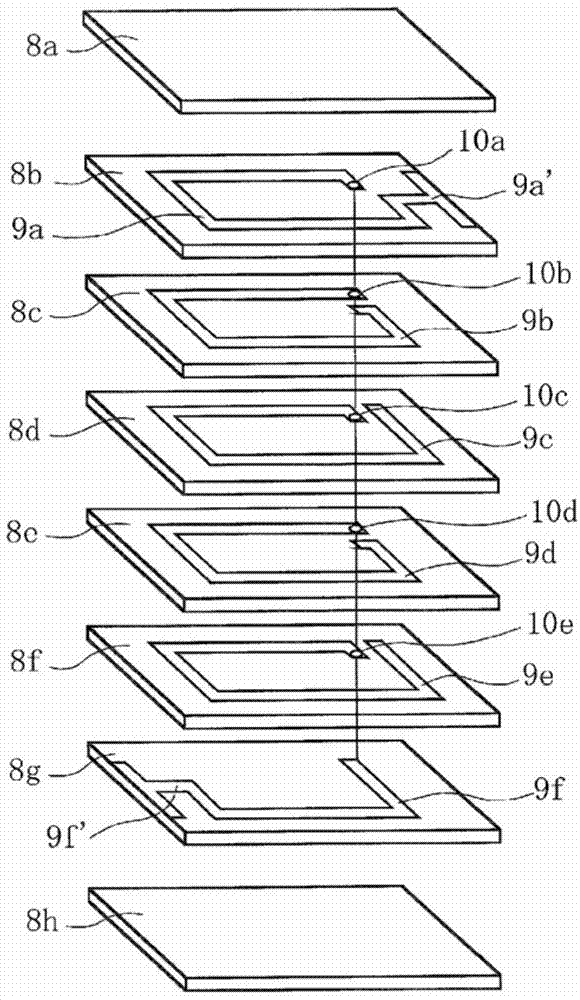

Multilayer coil component and method of manufacturing the same

InactiveUS20080218301A1Efficient preparationLow magnetic permeabilityTransformers/inductances casingsInductances/transformers/magnets manufactureElectrical conductorMetallurgy

A multilayer coil component includes a coil formed by stacking first ceramic sheets in which coil conductor patterns are provided and a second ceramic sheet having a lower magnetic permeability than the first ceramic sheets, the coil conductor patterns being connected to each other. The second ceramic sheet is disposed between the first ceramic sheets. In a main surface of the second ceramic sheet, holes or recesses are provided. The first ceramic sheets adjacent to the second ceramic sheet are in contact with inner peripheral surfaces of the holes.

Owner:MURATA MFG CO LTD

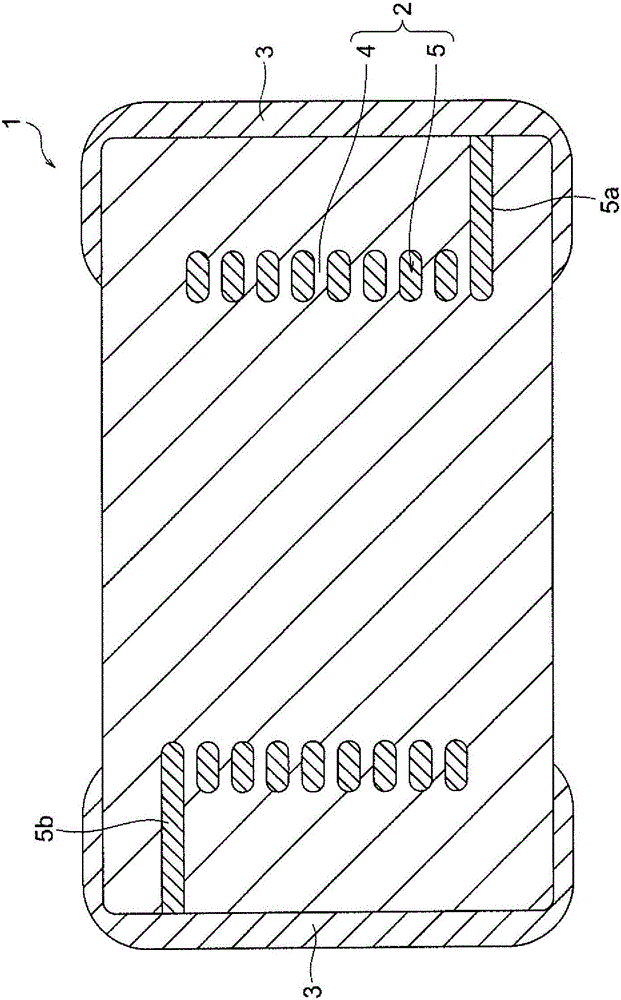

Multilayer coil part

ActiveCN103597558AInhibit growthReduced sinterabilityTransformers/inductances coils/windings/connectionsInorganic material magnetismElectrical conductorSize ratio

This multilayer coil part has a magnetic body section (2) that is made of an Ni-Zn system ferrite material and a Cu-based coil conductor (3) that has been wound into a coil shape. The coil conductor (3) is buried inside the magnetic body section (2) to form a part element body (1). The part element body (1) is divided into a first region (6) that is located close to the coil conductor (3) and a second region (7) that comprises the region other than the first region (6). The grain size ratio (D1 / D2) between the average crystal grain size (D1) of the magnetic body section (2) in the first region (6) and the average crystal grain size (D2) of the magnetic body section (2) in the second region (7) is equal to or lower than 0.85. The molar quantity of CuO content in the ferrite material is set to 6 mol% or less, and the ferrite material is baked in a reductive atmosphere with the oxygen partial pressure being equal to or lower than the Cu-Cu2O equilibrium oxygen partial pressure. Thus, a multilayer coil part that exhibits not only little fluctuation of inductance and excellent thermal shock resistance when subjected to a thermal shock or an external stress but also excellent direct-current superposition characteristics can be obtained without requiring any complicated step.

Owner:MURATA MFG CO LTD

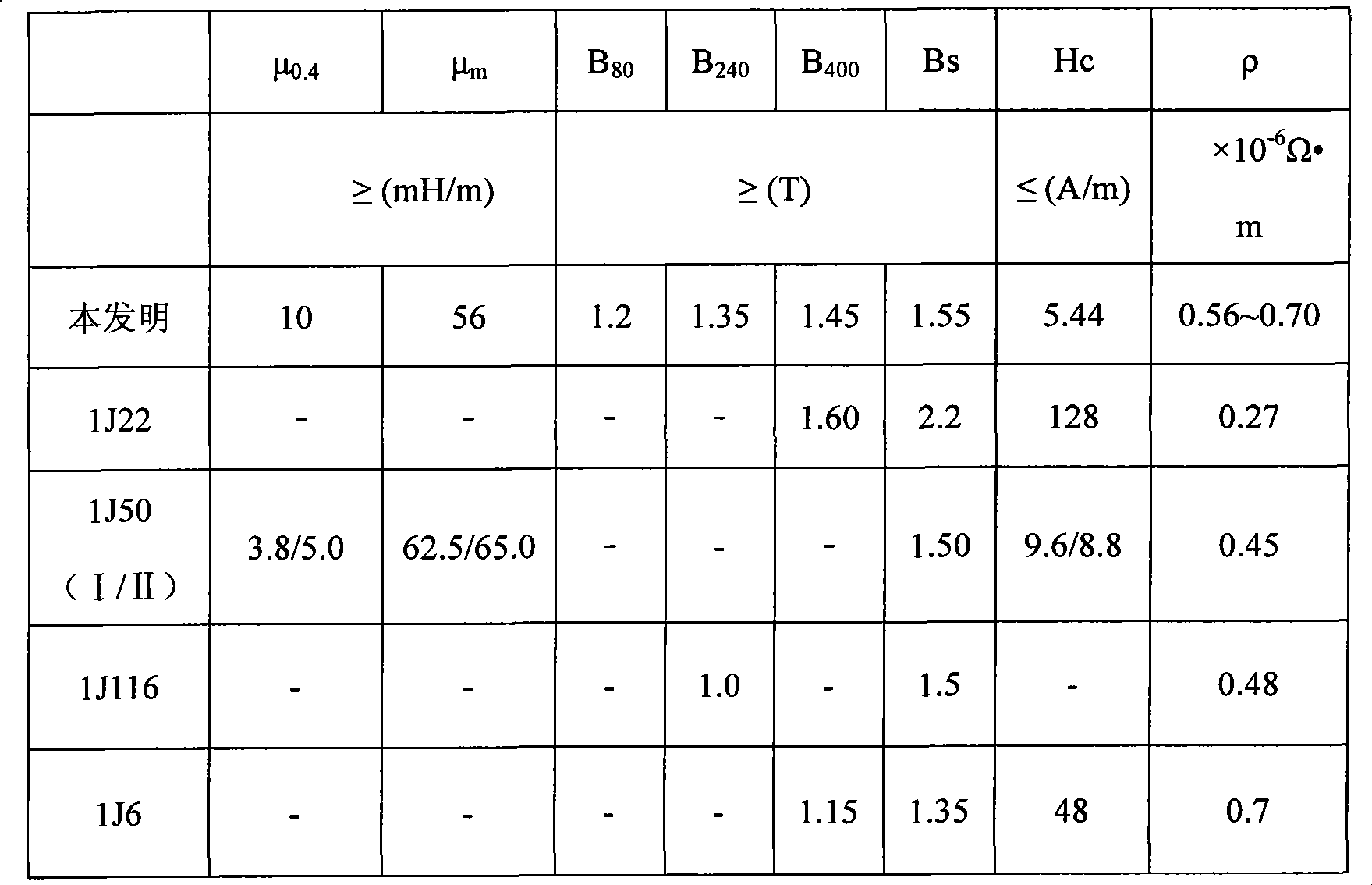

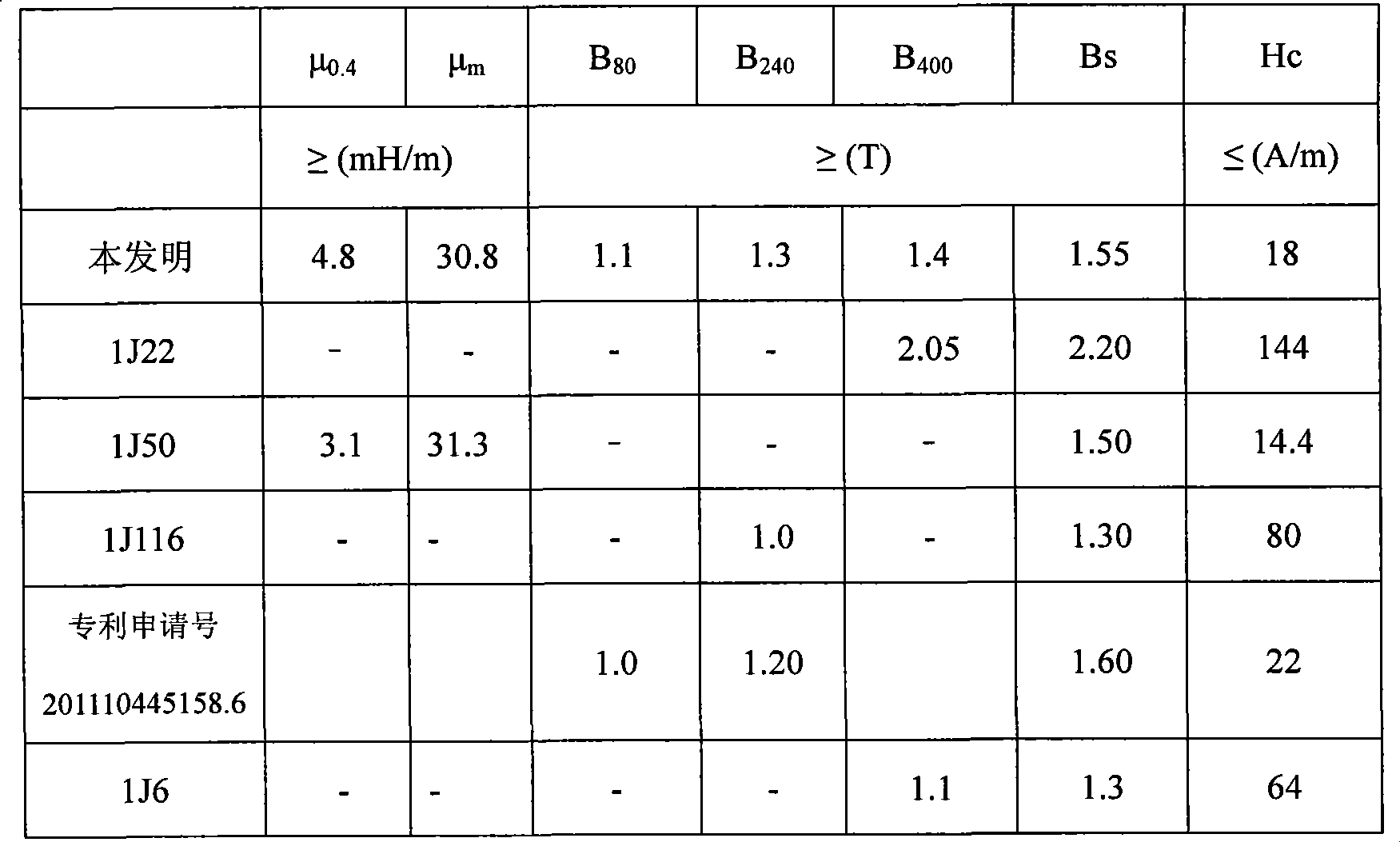

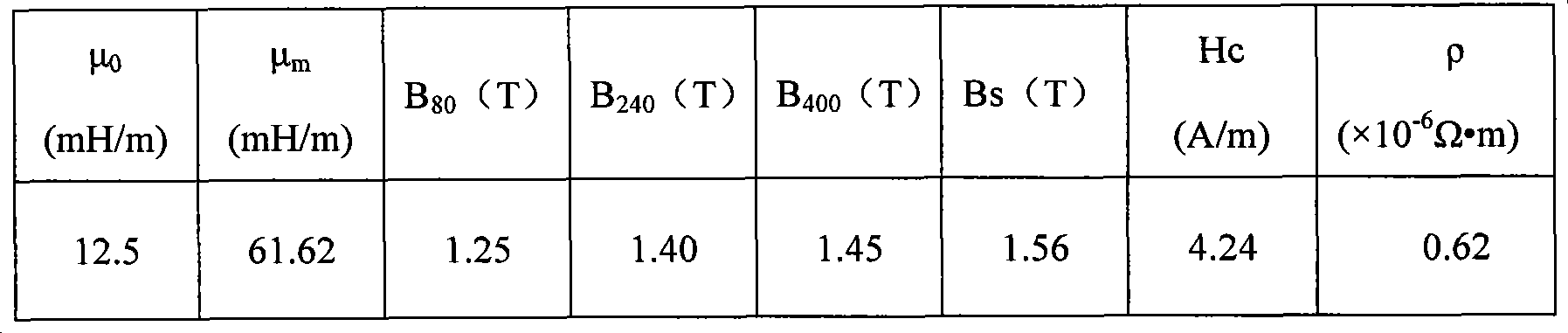

Anti-corrosion FeNiCo magnetically soft alloy with high magnetic induction intensity

The invention includes a FeNiCo magnetically soft alloy and a production method thereof, wherein the FeNiCo magnetically soft alloy has high magnetic induction intensity, high magnetic permeability, low coercive force, high stability and good corrosion resistance in a low magnetic field. The FeNiCo magnetically soft alloy comprises the following components by mass percent: not more than 0.02 percent of C, 0.2-0.80 percent of Si, not more than 0.50 percent of Mn, 29.00-35.00 percent of Ni, 25.00-32.00 percent of Co, not more than 5.00 percent of Mo, not more than 0.50 percent of Cu, 0.01-0.55 percent of microelements including 0.001-0.05 percent of rare earth elements, and the balance of Fe and inevitable impurities. The FeNiCo magnetically soft alloy is processed and manufactured by adopting the methods of vacuum melting, forging, hot rolling and cold rolling, and after heat treatment, the FeNiCo magnetically soft alloy has the characteristics of high magnetic induction intensity, high magnetic permeability, low coercive force, high stability and good corrosion resistance in a low magnetic field, and can be manufactured into the transducer, the filter, the electromagnetic valve, the transformer and the like in the field of aviation, aerospace, navigation, electron, electric power and the like.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

Sputtering target for magnetic recording film and method for manufacturing such sputtering target

InactiveCN101835920AHigh densityGrowth inhibitionVacuum evaporation coatingSputtering coatingOptoelectronicsVolumetric Mass Density

Provided is a sputtering target for a magnetic recording film, by which film formation efficiency and film characteristics can be improved by suppressing growth of crystal grains, reducing magnetic permeability and increasing density. A method for manufacturing such sputtering target is also provided. The sputtering target is composed of a matrix phase, which includes Co and Pt, and a metal oxide phase. The sputtering target has a magnetic permeability of 6-15 and a relative density of 90% or more.

Owner:MITSUI MINING & SMELTING CO LTD

Fe-Co based target material and method for producing the same

InactiveUS20080038145A1High densityLow magnetic permeabilityVacuum evaporation coatingSputtering coatingPowder mixtureMetallurgy

There is disclosed a method for producing a Fe—Co based target material for forming a soft magnetic thin-film. This method comprises the steps of: preparing a first raw-material powder having an Fe:Co weight ratio ranging from 8:2 to 7:3 and a second raw-material powder having an Fe—Co weight ratio ranging from 2:8 to 0:10; mixing the first raw-material powder and the second raw-material powder together to obtain a powder mixture having an Fe:Co weight ratio ranging from 8:2 to 2:8; and applying a pressure of not less than 100 MPa to the powder mixture at a temperature ranging from 1073 to 1473 K for consolidation. At least one additional element selected from the group consisting of Nb, Zr, Ta and Hf is added to either one or both of the first and second raw-material powders in a total amount of 3 to 15 atom % with respect to the total amount of the powder mixture. The Fe—Co based target material thus produced has a high density, while having a magnetic permeability lower than the conventional one.

Owner:SANYO SPECIAL STEEL COMPANY

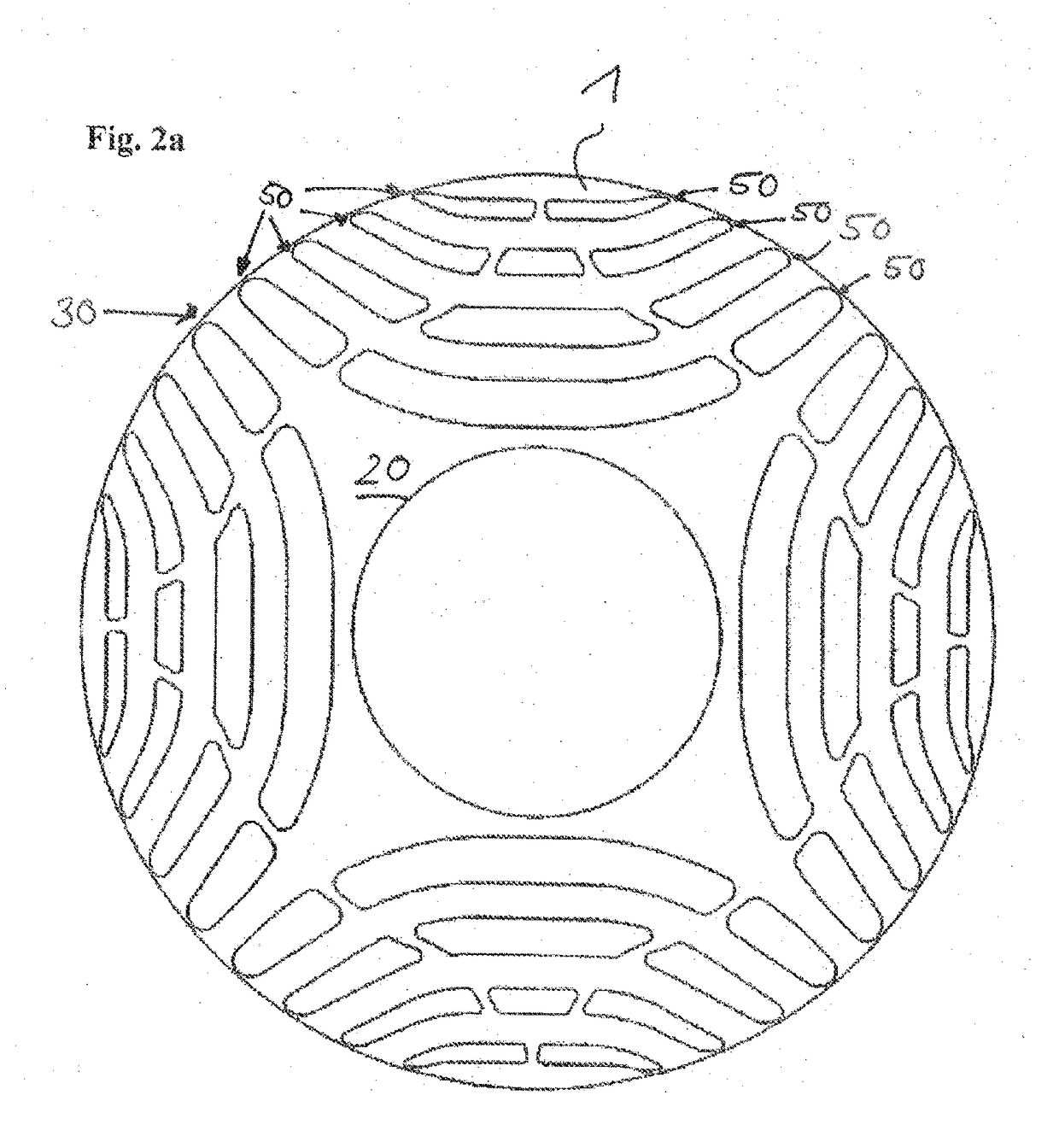

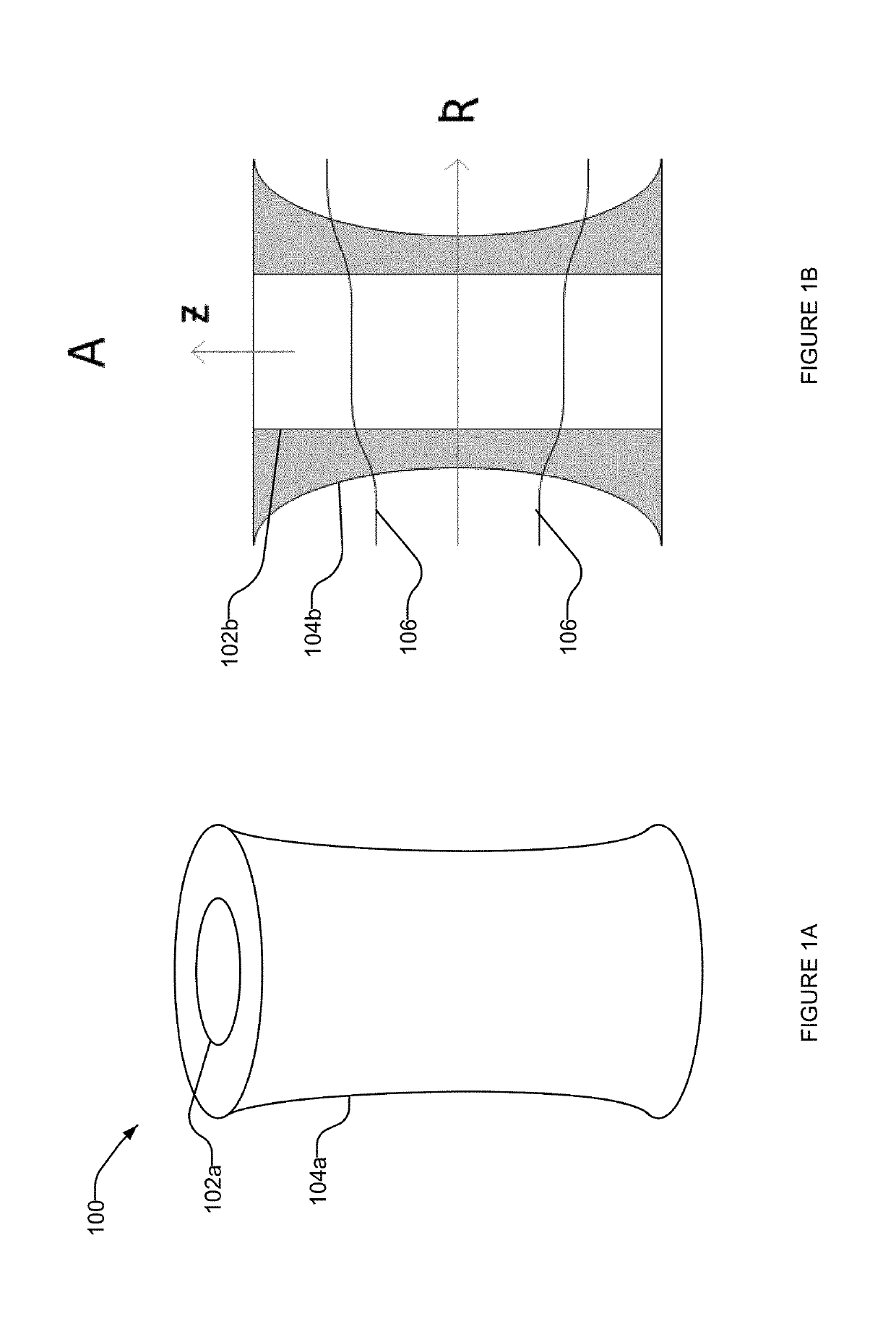

Rotor, Reluctance Machine and Method for Manufacturing the Rotor

ActiveUS20170237307A1Improve stabilityImprove the immunityMagnetic circuit rotating partsSynchronous motorsFilling materialsMechanical engineering

A rotor for a reluctance machine and a method of producing a rotor for a reluctance machine is provided. The rotor is formed as a soft magnetic element which is cylindrical in shape. The soft magnetic element has recesses for forming flux barriers, one or more flux barriers being at least partially filled with a filler material, and the filler material of said flux barriers extending up to the rotor periphery and forming part of the rotor periphery.

Owner:KSB AG

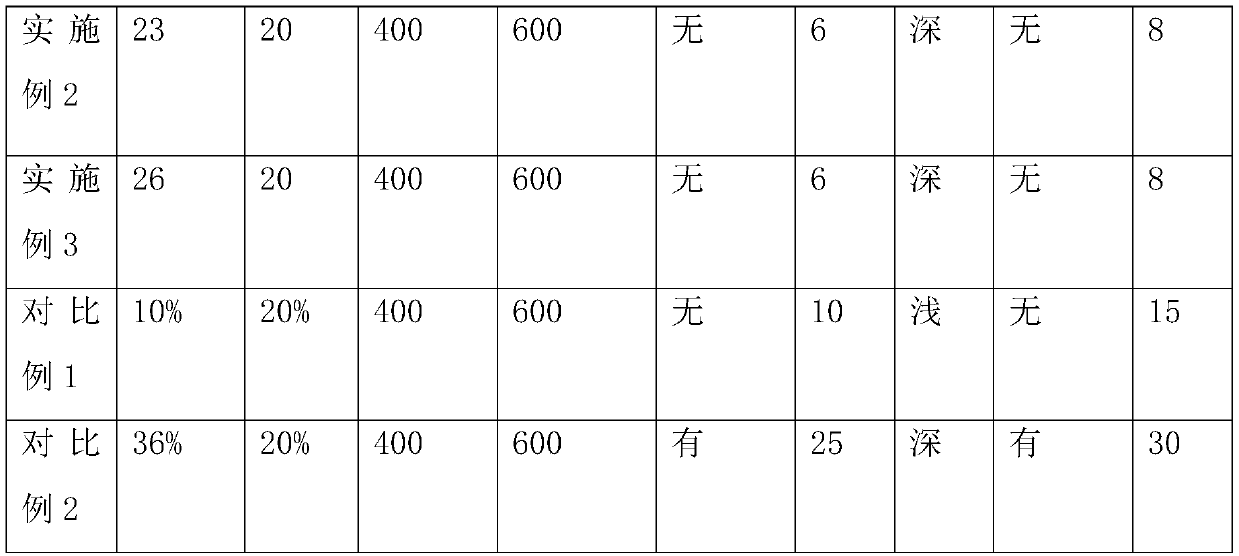

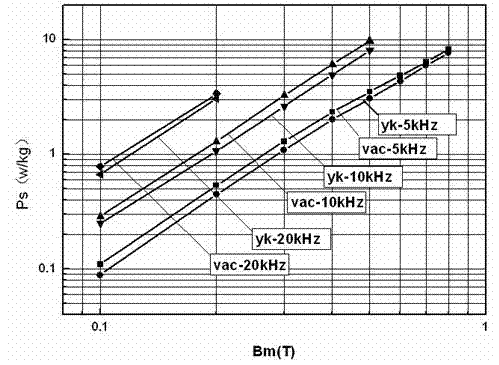

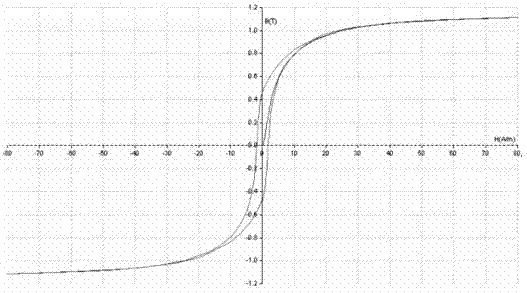

Inverter welding machine power transformer nanocrystalline iron core and preparation method thereof

InactiveCN103117154ALow remanence at high frequencyReduce lossFurnace typesTransformers/inductances magnetic coresTransformerEngineering

The invention belongs to the technical field of magnetic cores of transformers, relates to a preparation method of a nanocrystalline iron core, and in particular to an inverter welding machine power transformer nanocrystalline iron core and a preparation method of the inverter welding machine power transformer nanocrystalline iron core. The steps of rapid hardening method tape preparation, winding the iron core and heat treatment are adopted to prepare the inverter welding machine power transformer nanocrystalline iron core, and the nanocrystalline iron core is made of iron-based nanocrystalline strip material with thickness of 24+ / -2 micrometers. Compared with an iron core made of iron-based nanocrystalline strip material with thickness of 30 micrometers in the prior art, through different heat treatment technics, the temperature of the heat treatment, the soaking time and the magnetic field current process are adjusted, so that an iron-based nanocrystalline iron core with lower remancence, lower loss and lower magnetic permeability under high frequency is obtained, and meanwhile the temperature rising of the iron core transformer is reduced, the operational stability of power efficiency is improved, and the design requirements that high frequency, miniaturization and more safety of the inverter welding machine power transformer are met.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

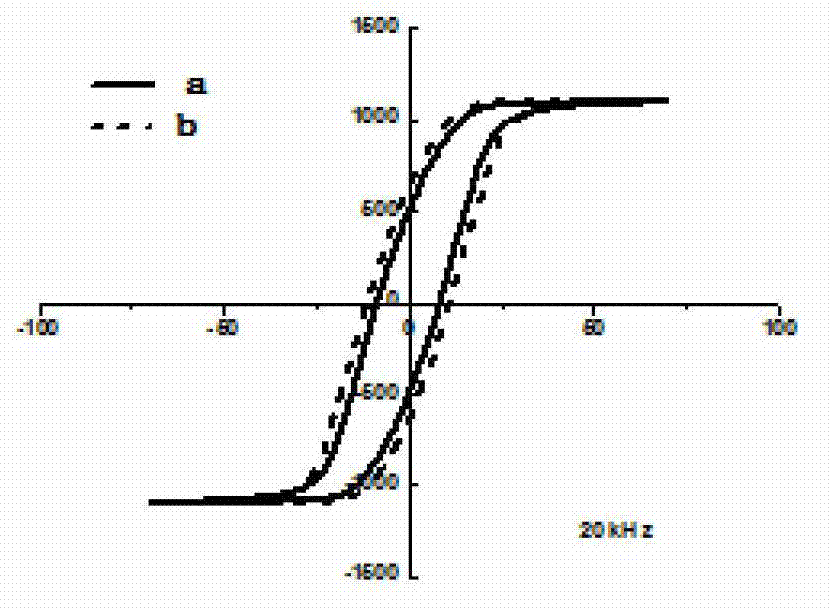

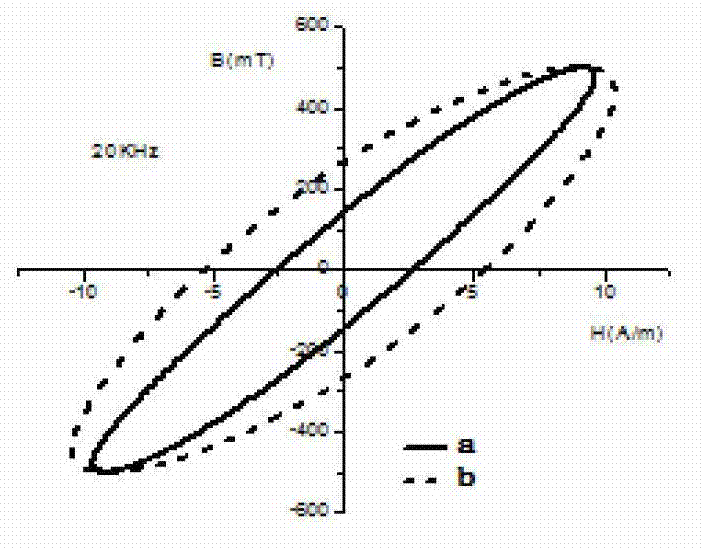

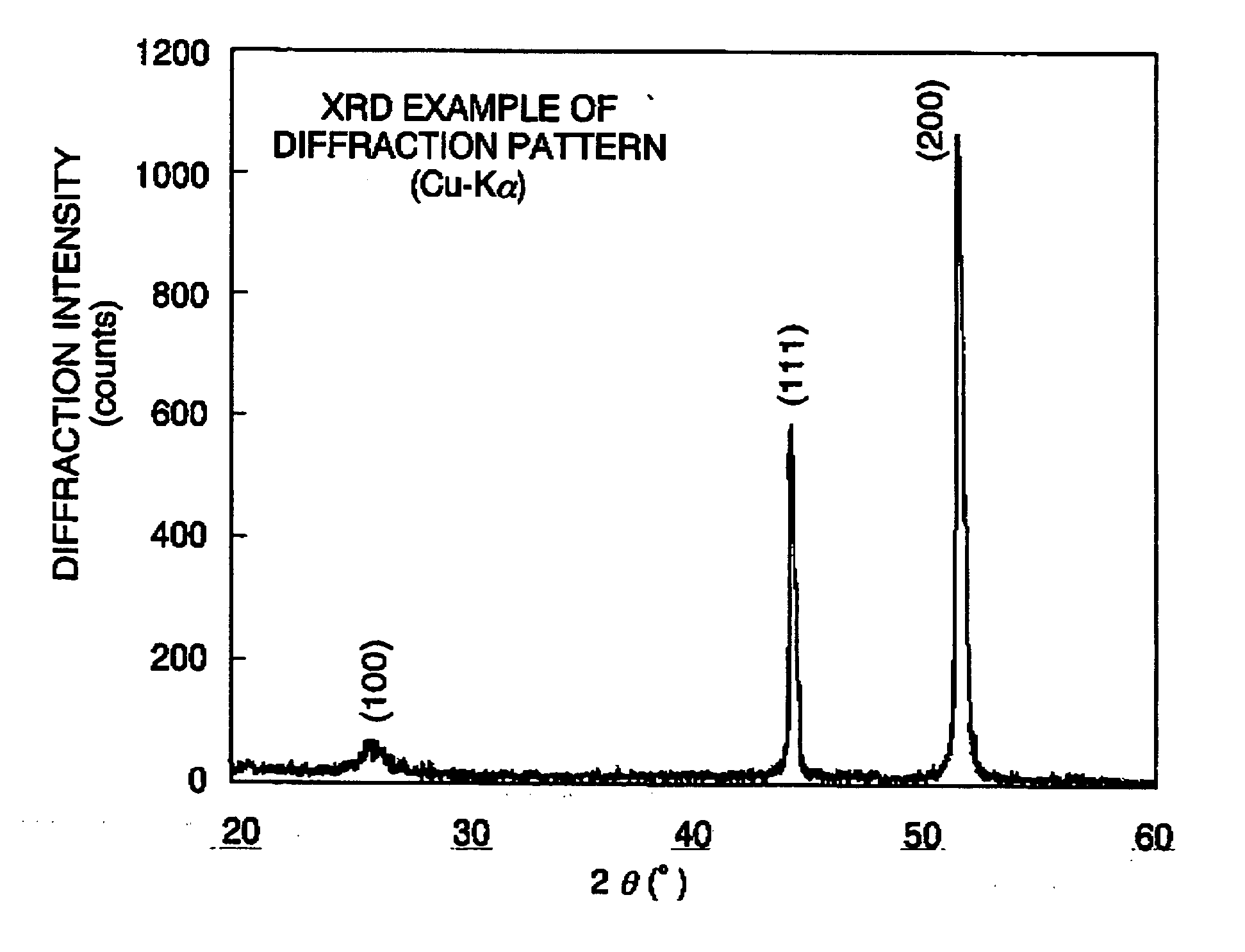

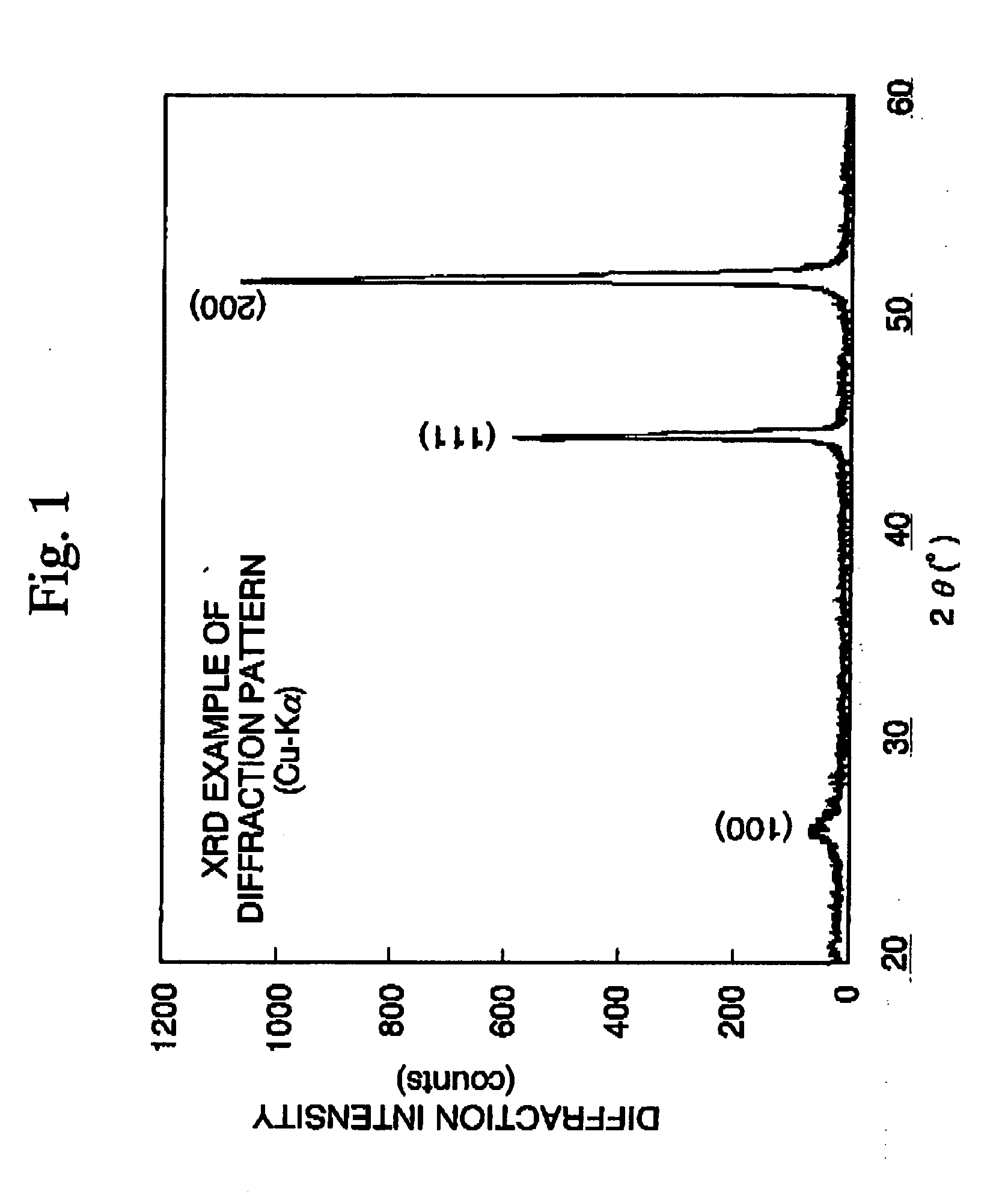

Fe-ni soft magnetic flaky powder and magnetic composite material containing soft magnetic powder

InactiveUS20070131311A1High viscosityLow magnetic permeabilityMetal-working apparatusInorganic material magnetismX-rayUltimate tensile strength

The invention provides an Fe—Ni—Mo soft magnetic flaky powder having a component composition of, in percent by mass, Ni: 60 to 90%, Mo: 0.05 to 1.95%, and the balance of Fe and unavoidable impurities, and a flat surface of an average particle size of 30 to 150 μm, and an aspect ratio (average particle size / average thickess) of 5 to 500; and having a peak intensity ratio I200 / I111 within a range between 0.43 and 10, where I200 is the peak height of the face index (200) and I111 is the peak height of the face index (111), in an X-ray diffraction pattern measured in such a manner that the plane including the X-ray incident direction and the diffraction direction is perpendicular to the flat surface of the soft magnetic flaky powder, and the angle between the incident direction and the flat surface is equal to the angle between the diffraction direction and the flat surface. Furthermore, the invention provides a soft magnetic flaky powder with oxide layer wherein an oxide layer of a thickness of 50 to 1000 Å is formed on the surface of this soft magnetic flaky powder.

Owner:MITSUBISHI MATERIALS CORP +1

Flat coil, fabrication method thereof and flat coil wireless charger

InactiveCN105896682AReduce permeabilityLow magnetic permeabilityBatteries circuit arrangementsTransformers/inductances coils/windings/connectionsElectromagnetic interferenceUltimate tensile strength

The invention relates to a flat coil. The flat coil is a single-layer coil formed by winding a single self-adhered enameled wire form inside to outside, two wiring ends are led out of the single-layer coil, one side of the single-layer coil is in fixed contact with a magnetic shielding plate, the induction intensity of the flat coil is utilized to the greatest extent, the loss is relatively low, particularly, the flat coil is relatively high in environmental adaptability and stable is performance, and the normal operation of an electromagnetic interference device is prevented. The invention also provides a fabrication method of the flat coil and a flat coil wireless charger employing the flat coil.

Owner:WUXI JINGLEI ELECTRONICS

Pressure gel forming method for multi-winding current transformer

ActiveCN104299766AReduce labor intensityIncrease productivityTransformersInductances/transformers/magnets manufactureInjection pressureContraction rate

The invention discloses a pressure gel forming method for a multi-winding current transformer, and belongs to the technical field of electric manufacturing and electric equipment. According to the method, the traditional method that multiple windings are shielded respectively in a device correcting process is improved, the windings are combined and wrapped as a whole, and exhaust dead corners generated in the pouring process of the multi-winding current transformer are effectively avoided. In a transformer die preparation process, temperatures of different parts of a die are set, so that it is guaranteed that the curing process of gel materials which are injected firstly and the curing process of gel materials which are injected later basically keep consistent, and cracks generated due to an inconsistent curing contraction rate in the transformer are avoided. In the pressure gel forming process, viscosity of mixed materials is large, a certain period of time is needed when gas is exhausted from the inside of a product, and accordingly a staged material injection method is adopted. Besides, staged pressure maintaining can effectively avoid the situation that iron core magnetic permeability is reduced because of excessively large material injection pressure and accordingly error tests are not qualified, and therefore product quality and the pass percent are guaranteed.

Owner:STATE GRID CORP OF CHINA +1

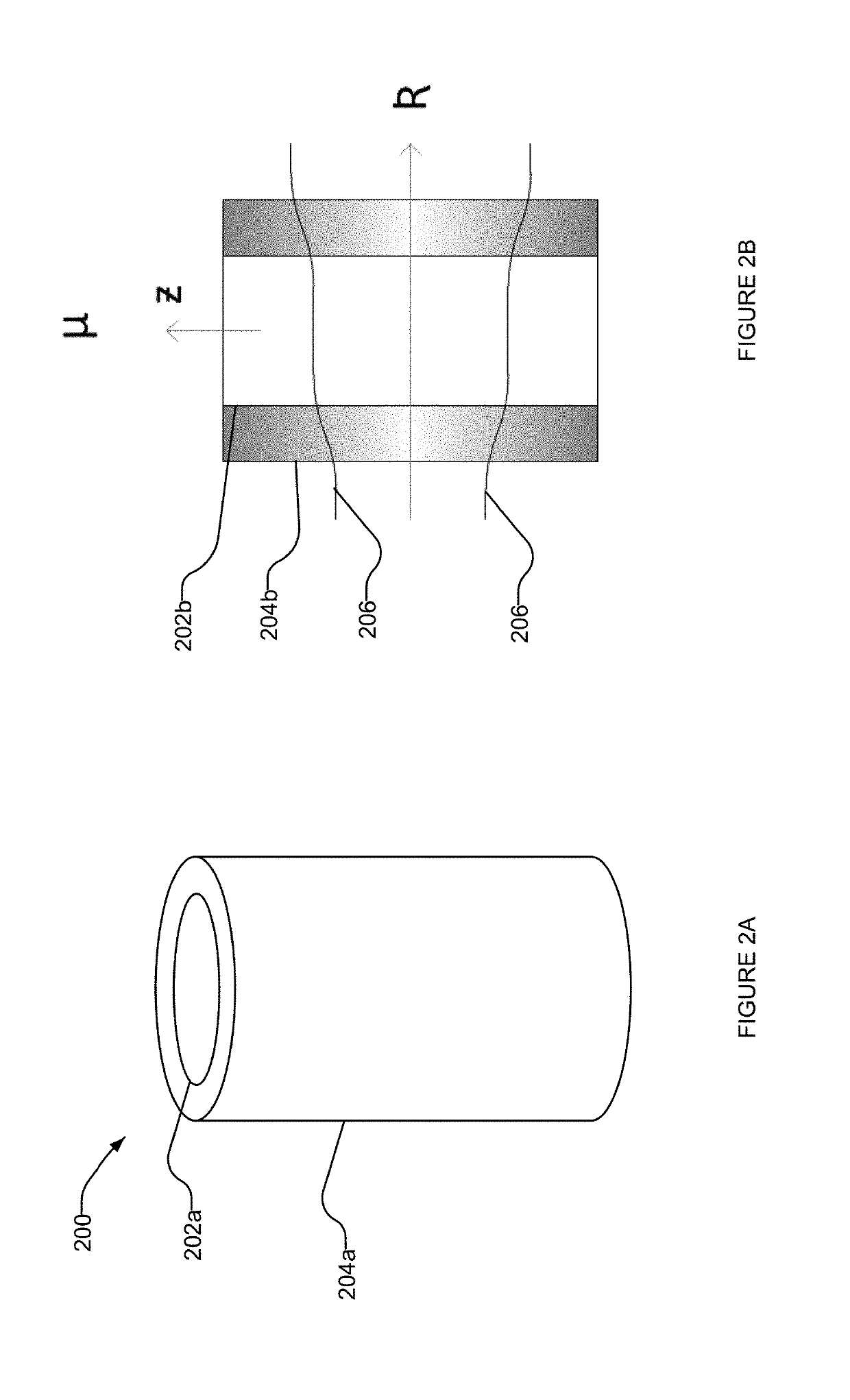

Rotor and Reluctance Machine

ActiveUS20170222505A1Small massOptimal degree of efficacyMagnetic circuit rotating partsSynchronous motorsFilling materialsPhysics

A rotor for a reluctance machine is provided. The rotor includes a soft magnetic element which is cylindrical in shape. The soft magnetic element has recesses forming flux barriers. At least part of the recesses are filled with an electrically conducting and magnetically non-conducting filler material such that a starting cage is formed in a peripheral region of the rotor. The ratio of the surface of the filled region of the flux barriers to the surface of the region of the unfilled flux barriers is at least 0.2 for at least one rotor cycle.

Owner:KSB AG

Method for manufacturing austenite stainless steel thin strip for electronic product shell

InactiveCN102383060AImprove performanceGuaranteed expected performance indicatorsReduction ratePerformance index

The invention discloses a method for manufacturing an austenite stainless steel thin strip for an electronic product shell. Due to an alloy design of austenite stainless steel, elements generate a synergistic effect; on the basis of a large number of experiments, process parameters of smelting, hot rolling and cold rolling are optimized; proper temperature and a proper reduction rate of a smelting and B adding process, the hot rolling, the cold rolling and annealing are controlled; the optimization of the parameters in the manufacturing method is favorable for guaranteeing that the stainless steel thin strip reaches an estimated performance index, namely the hardness is greater than 280 Hv; the level of impurities is lower, namely (A+B+C+D ) is less than or equal to 2.0; needle holes and concave troughs are prevented after polishing, so the smoothness of a mirror surface is realized, and the magnetic inductivity is less than 0.6 Gs / Oe; therefore, the manufacturing method meets a requirement of an electronic element, particularly the higher and higher requirement in the field of communication devices, such as a mobile phone shell and the like.

Owner:YONGXIN PRECISION MATERIAL WUXI

High-strength wear-resistant corrosion-resistant antimagnetic stainless steel

InactiveCN103602918AImprove overall mechanical propertiesLow magnetic permeabilitySS - Stainless steelAlloy

The invention discloses high-strength wear-resistant corrosion-resistant antimagnetic stainless steel belonging to the field of alloy materials. The stainless steel comprises the following components in percentage by weight: 0.25-0.35% of C, 0.7-1.00% of Si, 0.50-1.50% of Mn, 17.00-19.00% of Cr, 11.00-13.00% of Ni, 2.00-2.50% of Mo, 0.45-0.55% of V, 0.13-0.18% of Ti, 0.10-0.15% of Nb, 0.13-0.18% of RE and 61.59-67.74% of Fe. The stainless steel disclosed by the invention is new non-magnetic steel which is non-magnetic and resistant to marine corrosion and has high strength and hardness.

Owner:LESHAN LIDUN CAST STEEL

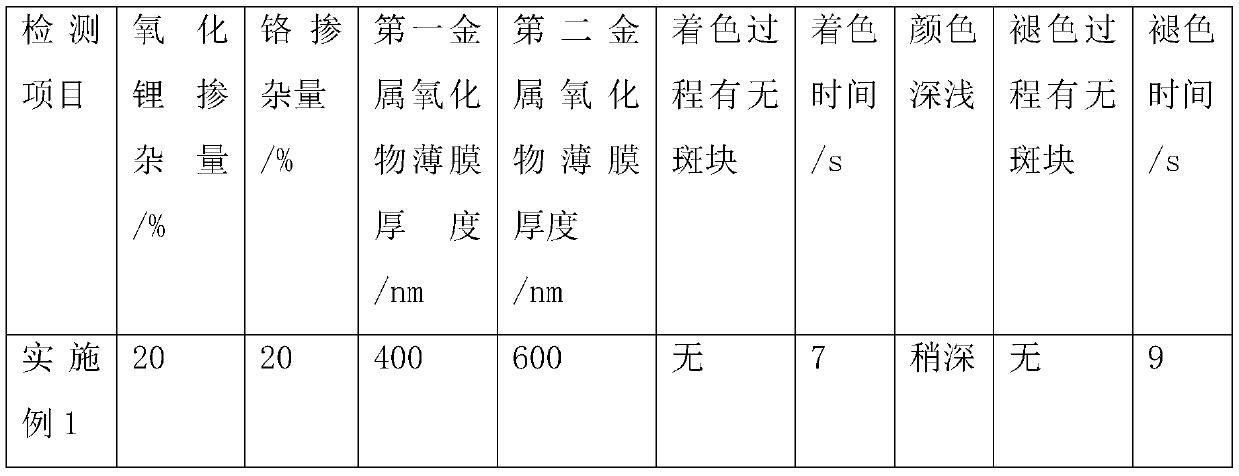

Metal target used for electrochromic glass and preparation method and application method thereof

ActiveCN109825805ALow magnetic permeabilityDoes not affect light transmittanceVacuum evaporation coatingSputtering coatingLithium oxideNiobium

The invention discloses a metal target used for electrochromic glass and a preparation method and application method thereof. The metal target used for the electrochromic glass comprises a first metaltarget and a second metal target. The first metal target is one of metal tungsten, molybdenum, niobium or titanium. The second metal target includes nickel, chrome and lithium oxide, wherein the massratio of the nickel to the chrome to lithium oxide is 1:(0.05-0.3):(0.2-0.26). The preparation method of the metal target includes the preparation method of the first metal target and the preparationmethod of the second metal target; the preparation method of the first metal target includes the step that the target is made of one of the metal tungsten, the molybdenum, the niobium or the titaniumin a hot-pressing or canning hot isostatic pressing manner; and the preparation method of the second metal target includes the steps that the nickel, the chrome and the lithium oxide are mixed, sufficiently stirred for 22 h to 26 h and manufactured into the target in a hot-pressing or canning hot isostatic pressing manner. The metal target used for the electrochromic glass has the beneficial effects of being short in film forming time, high in production efficiency, low in target manufacture difficulty and suitable for mass production.

Owner:上海博译金属有限公司

Composite electromagnetic pulse solidification structure treatment device and method for casting of ultralumin

ActiveCN106424567AReduce warm-up costsWarm up evenlyFoundry mouldsFoundry coresElectromagnetic pulseWater cooling

The invention discloses a composite electromagnetic pulse solidification structure treatment device and method for casting of ultralumin. The treatment device comprises a metal mold, a side electromagnetic pulse device and a top electromagnetic pulse device, wherein an inner chamber of the metal mold is used for storing a melt; the sidewall of the metal mold comprises an outer layer and an inner layer; a water cooling cavity is formed between the outer layer and the inner layer; a cooling water inlet is formed in the bottom part of the water cooling cavity, and a cooling water outlet is formed in the top part of the water cooling cavity; the side electromagnetic pulse device is arranged at the outer wall of the metal mold; the top electromagnetic pulse device is positioned right above the inner chamber of the metal mold. According to the composite electromagnetic pulse solidification structure treatment device for casting of the ultralumin, electromagnetic energy can enter the melt to the maximum, so that the metal mold can be uniformly preheated, and the core structure of an ultra-thick casting can be uniformly thinned through the electromagnetic energy while the solidification supercooling degree of a casting blank is improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

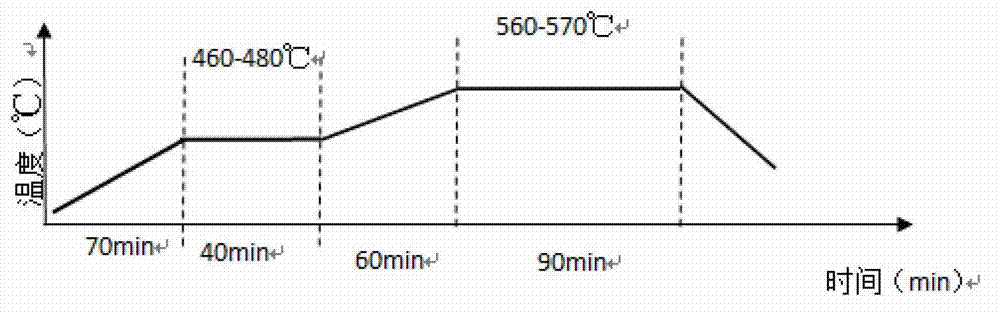

Manufacturing method of nanocrystalline magnetic core for high-frequency electrostatic dust collection power transformer

InactiveCN104200982AThe production process is simpleLow costTransformers/inductances magnetic coresInductances/transformers/magnets manufactureMagnetic coreMicrometer

The invention discloses a manufacturing method of a nanocrystalline magnetic core for a high-frequency electrostatic dust collection power transformer. The manufacturing method sequentially comprises the following steps that an iron-based nanocrystalline band is adopted to be wound into the rectangular nanocrystalline magnetic core, the thickness of the iron-based nanocrystalline band is smaller than 25 micrometers, the width of the iron-based nanocrystalline band is 40 mm to 60 mm, and the lamination factor is larger than or equal to 70 percent; two stages of heat preservation heat treatment of magnetic-field-free annealing and inert gas shielding are carried out on the rectangular nanocrystalline magnetic core, the temperature of the first stage is 450 DEG C to 480 DEG C, heat preservation is carried out for 60 min to 90 min, the temperature of the second stage is 520 DEG C to 550 DEG C, and heat preservation is carried out for 60 min to 90 min; natural cooling is carried out; epoxy resin immersion treatment is carried out on the cooled rectangular nanocrystalline magnetic core in a vacuum impregnation mode, and the vacuum degree is 0.6 Mpa to 0.8 Mpa; the rectangular nanocrystalline magnetic core immersed in epoxy resin is cured through a three-stage heat preservation method, the temperature of the first stage is 80 DEG C, heat preservation is carried out for 60 min to 90 min, the temperature of the second stage is 120 DEG C, heat preservation is carried out for 120 min, the temperature of the third stage is 150 DEG C to 160 DEG C, and heat preservation is carried out for 120 min; natural cooling is carried out.

Owner:BEIJING YEKE MAGNETIC MATERIAL

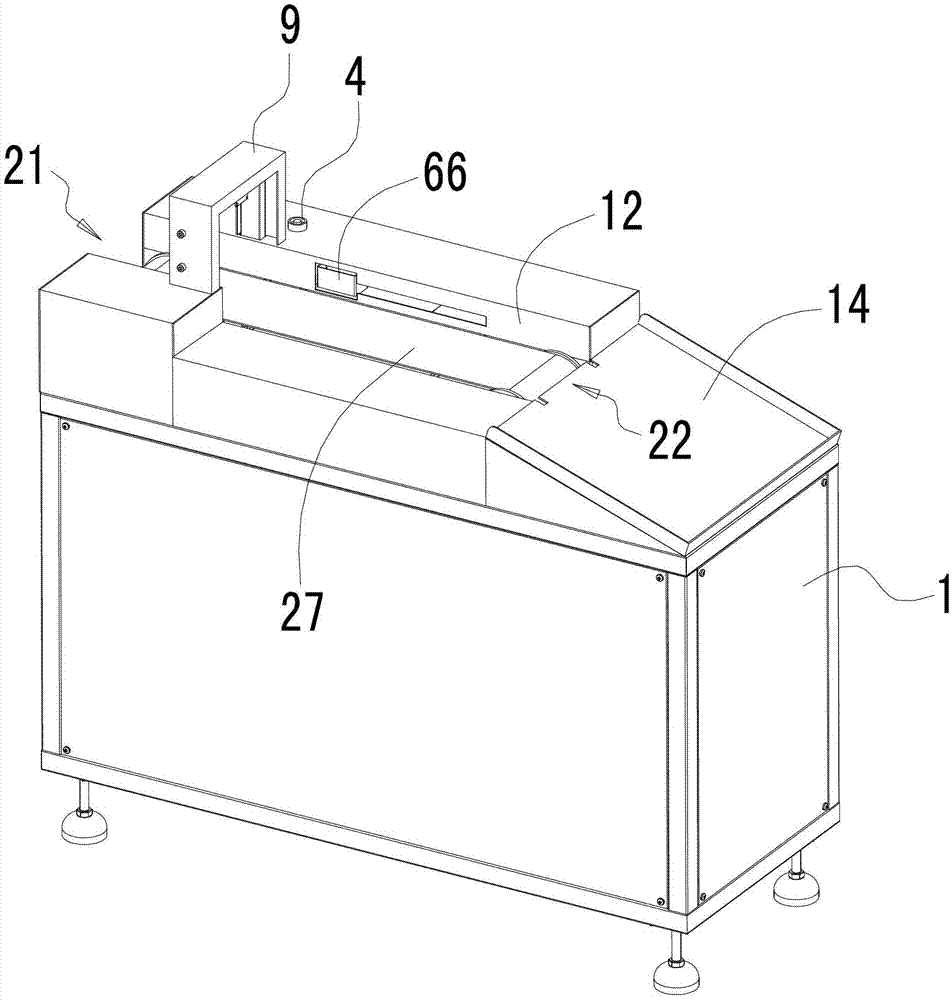

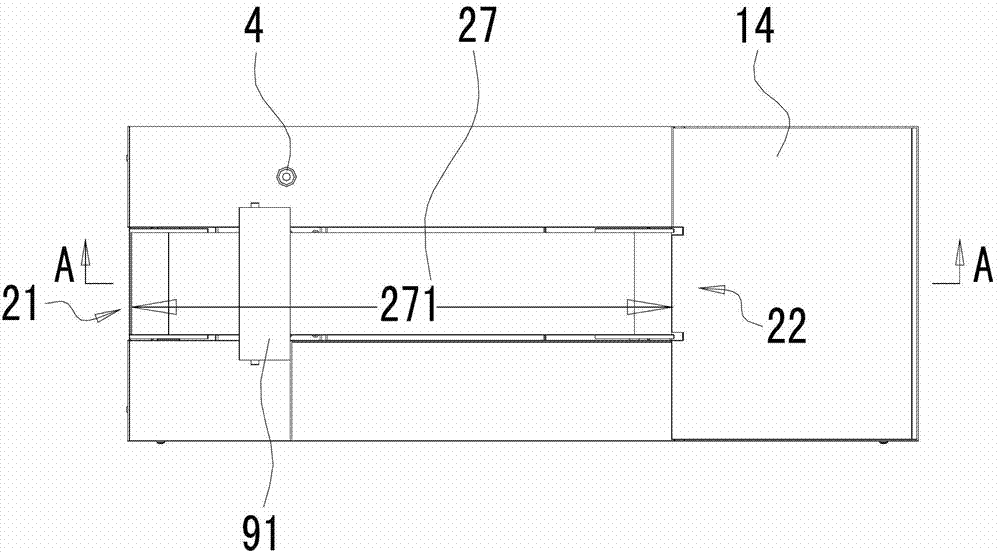

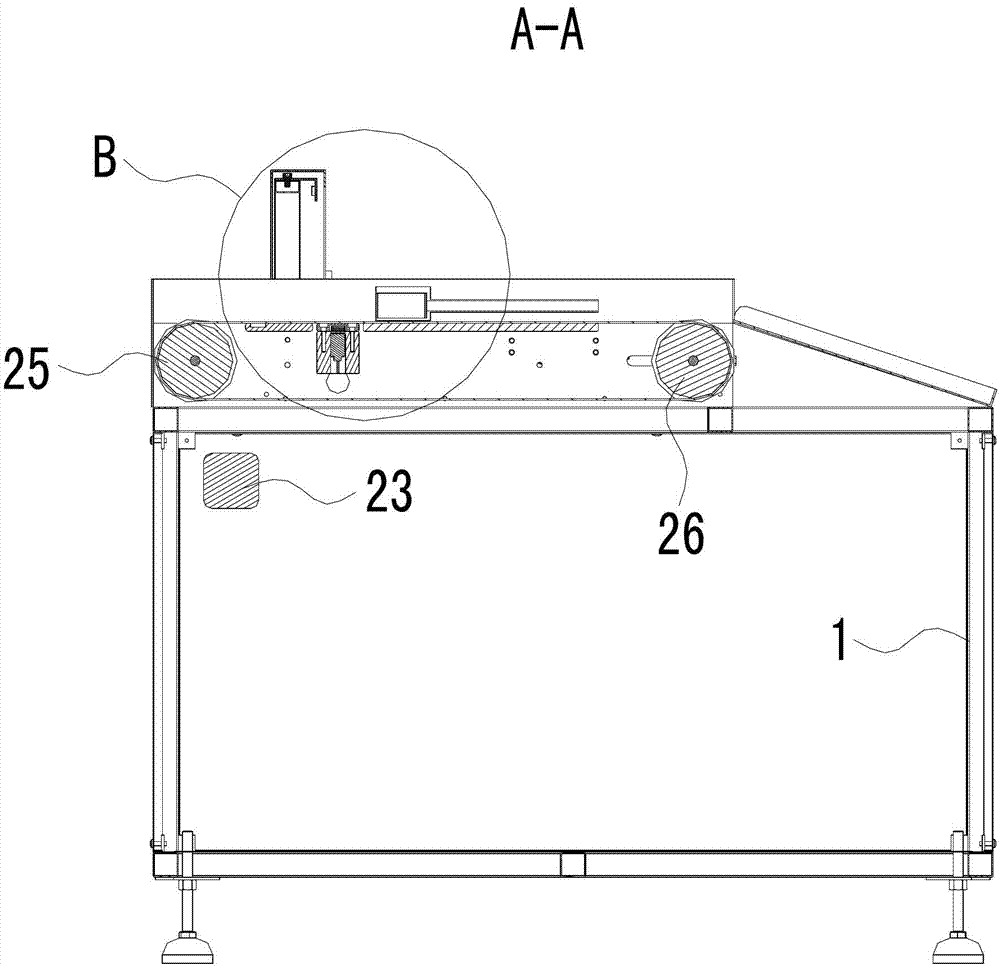

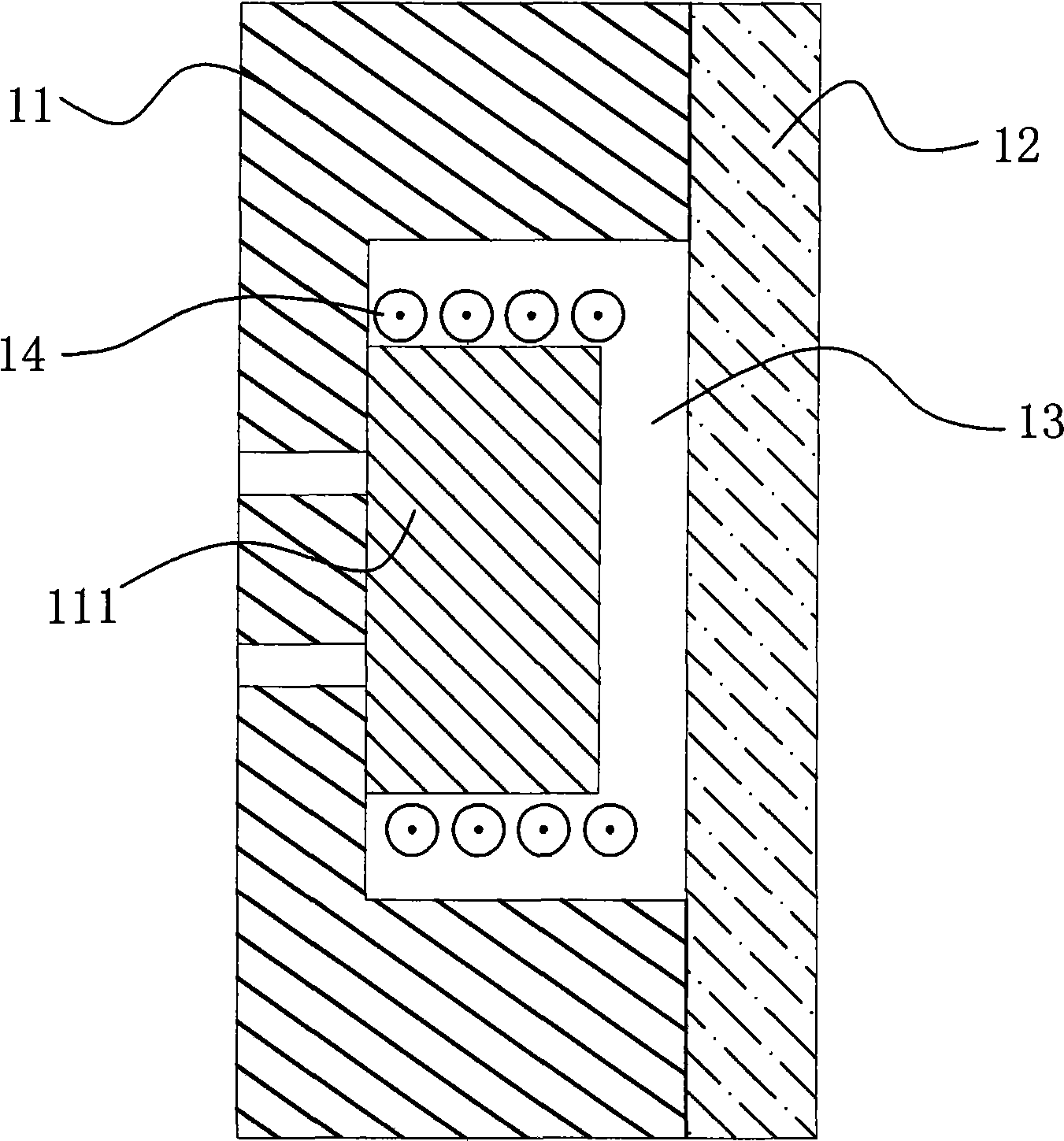

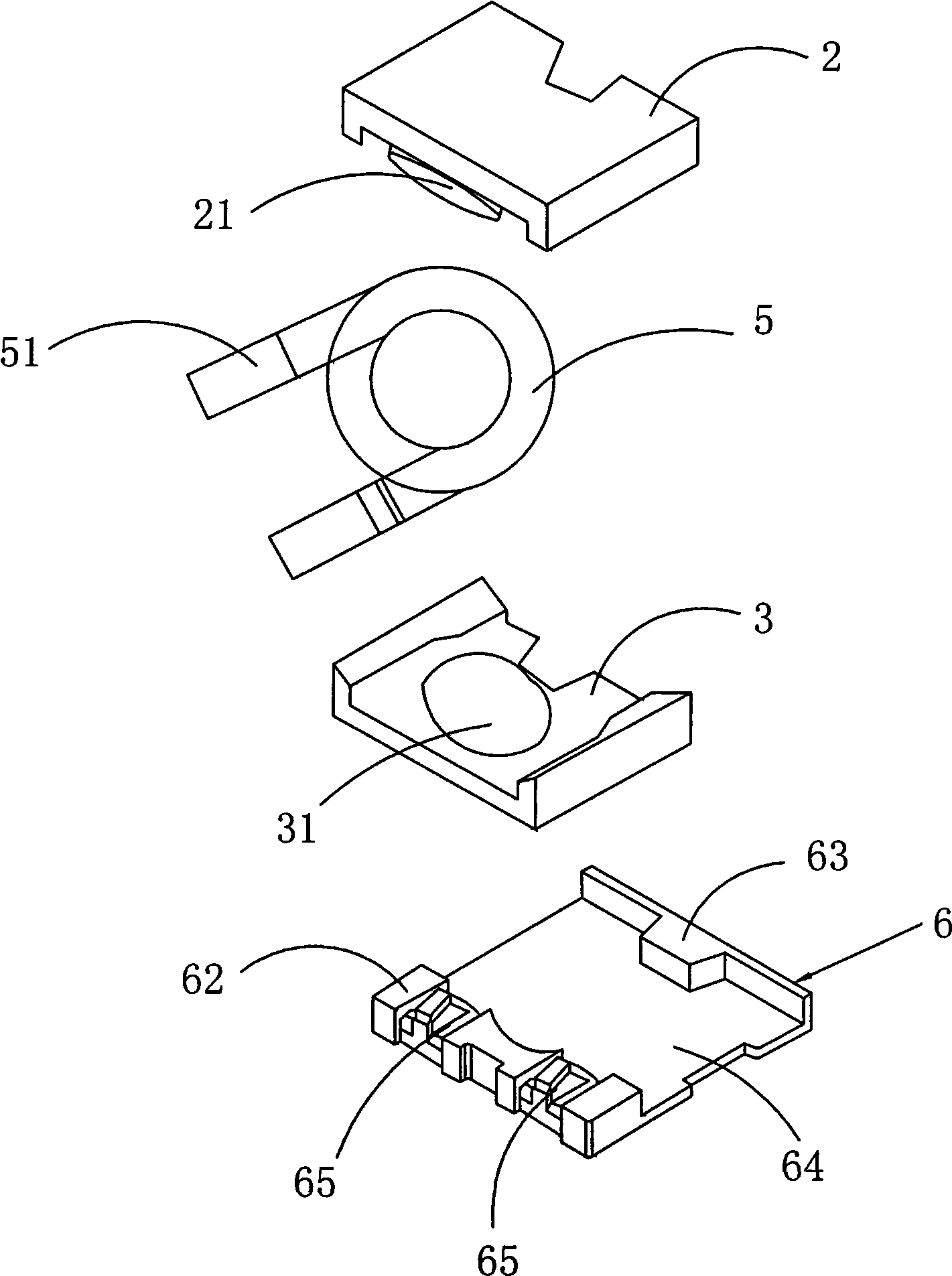

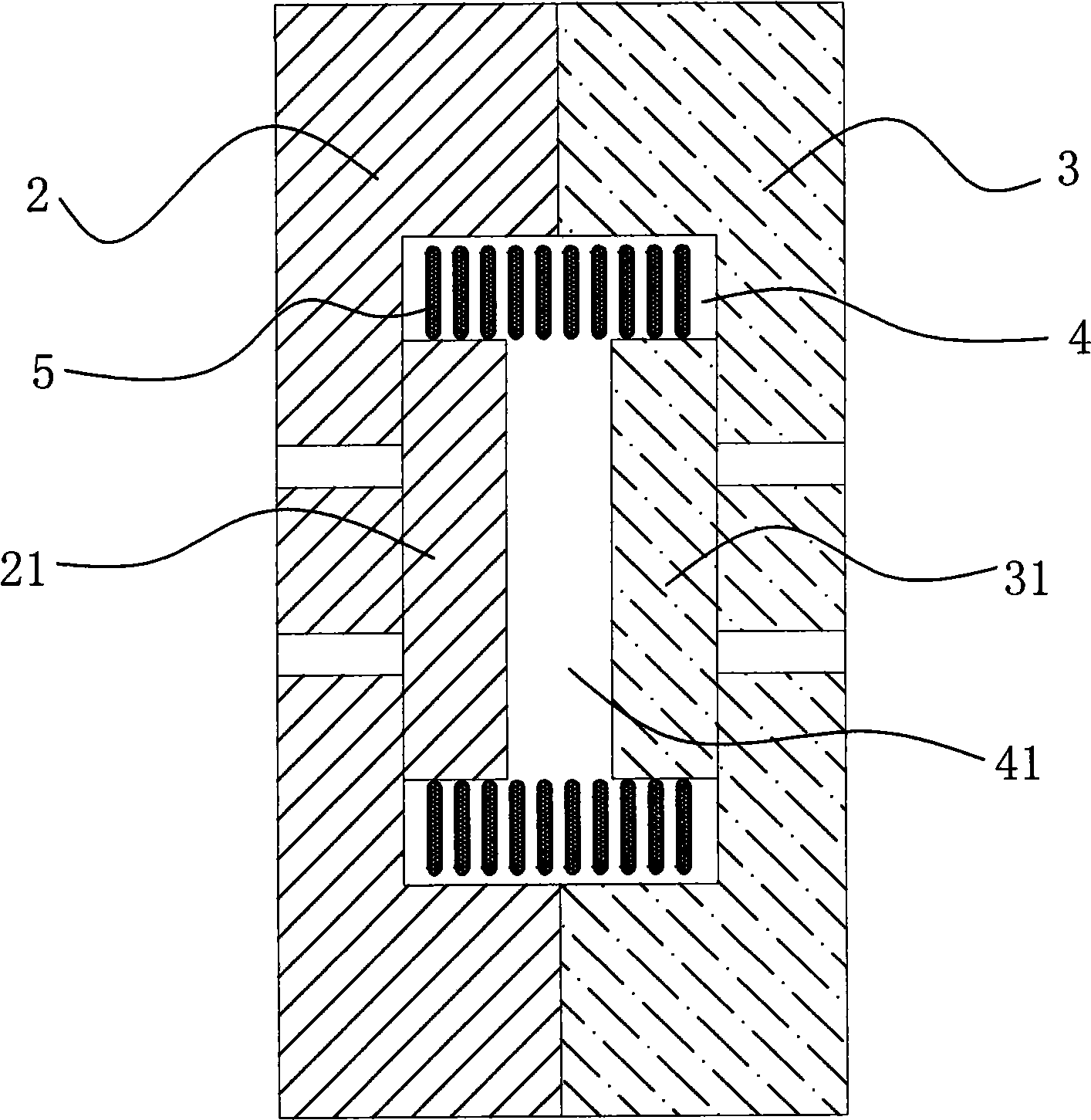

Detection machine for detecting whether packaged food contains deoxidizing agent or not and detection method thereof

ActiveCN103171799ASimple structureEasy to manufacturePackaging automatic controlEmbedded systemTimer

The invention relates to a detection machine for detecting whether packaged food contains deoxidizing agent or not and a detection method thereof. The detection machine comprises a machine frame and a conveying device which is installed on the machine frame. A material sensor, a deoxidizing agent sensor and a cleaning mechanism are arranged on the machine frame. When the material sensor detects that when the packaged food to be detected passes, a trigger signal is sent to a timing switch controller which is arranged on the machine frame, a timer of the timing switch controller is triggered to begin timing, and the timer presets timing value T. When the deoxidizing agent sensor detects the packaged food containing the deoxidizing agent, a reset signal is sent to the timing switch controller. The cleaning mechanism is used for popping packaged food without the deoxidizing agent out of the conveying device, and power-on action or power-off waiting of the cleaning mechanism is controlled by the timing switch controller. Automation detection is adopted by the detection machine, so that the detection machine is high in efficiency, low in labor intensity, simple in structure and low in manufacturing cost and saves cost. The detection method is accurate and reliable, easy to achieve and high in efficiency.

Owner:ZHONGSHAN AOSI FINE MACHINERY TECH

Austenite stainless steel thin strip for electronic product shell

The invention discloses an austenite stainless steel thin strip for an electronic product shell. The austenite stainless steel comprises the following components by weight percent: 0.06-0.08% of C, 14.5-16.5% of Cr, 11.0-13.0% of Ni, 1.4-1.8% of Mn, 0.3-1.0% of Si, 0.5-0.8% of Mo, 0.3-0.6% of Nb, 0.001-0.005% of B, 0.010-0.060% of Al, 0.05-0.20% of N, no more than 0.03% of P, no more than 0.005% of S, no more than 0.0050% of O and the balance of Fe and inevitable impurities. The Ni-bal% range of the stainless steel is 0.5-1.5 and Ni-bal% is calculated according to the following formula: Ni-bal% = Ni% + 30(C% + N% + B%) + 0.5Mn%-1.5(Cr% + 1.5Si% + Mo% + 0.5Nb%) + 8.5%.

Owner:YONGXIN PRECISION MATERIAL WUXI

Coil component

ActiveUS20160064136A1Low magnetic permeabilityImprove wettabilityTransformers/inductances casingsTransformers/inductances coils/windings/connectionsAlloyOxygen

A coil component is constituted by a composite magnetic material containing alloy grains whose oxygen atom concentration in their surfaces is 50 percent or less, and resin, and also by a coil. The coil component using the composite magnetic material does not require high pressure when formed.

Owner:TAIYO YUDEN KK

Inducer

InactiveCN101499361AImprove abilitiesLow magnetic permeabilityTransformers/inductances magnetic coresInductances/transformers/magnets manufactureForce linesInductor

The invention provides an inductor, including a first magnetic core and a second magnetic core; the first magnetic core is connected with the second magnetic core, forming a cavity. In the cavity, the first magnetic core is provided with a first magnetic pillar; the second magnetic core is also correspondingly provided with a second magnetic pillar which is coaxial with the first magnetic pillar; a certain gap is arranged between the end surfaces of the first magnetic pillar and the second magnetic pillar; and a coil is wound on the first magnetic pillar, the gap and the second magnetic pillar. A certain gap is arranged between the first magnetic pillar and the second magnetic pillar. By winding the coil on the two magnetic pillars, after being electrified, the magnetic force lines are centralized around the coil. As the current-carrying coil does not have magnetic pillars at the gap part, the generated magnetic induction lines are dispersed in the whole space; and compared with the prior art in which the coil is wound on the whole magnetic pillar, the technical proposal improves the saturation resistance capacity of the inductor and reduces the permeability.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

Casting method of high-strength high-hardness anti-marine-corrosion non-magnetic steel

InactiveCN103600041AMeet the use requirementsImprove mechanical propertiesFurnace temperatureFerroniobium

The invention discloses a casting method of high-strength high-hardness anti-marine-corrosion non-magnetic steel and belongs to the field of alloy materials. The method includes the steps of heating to melt raw iron in a smelter which is a medium-frequency induction furnace, at the melting temperature of 1450 DEG C-1550 DEG C, sequentially adding nickel, ferrochromium, ferrovanadium and ferroniobium into the smelter after full melting, controlling the content ratio of the element components to be satisfactory, melting down, performing deoxidation, dehydrogenation and denitrification when the furnace temperature reaches 1550 DEG C-1580 DEG C, pressuring deoxidant deep in the smelter, adding ferrotitanium, covering the surface of melt with covering agent to isolate external air, and adding rare-earth ferrosilicon into a ladle. The casting method is applied to novel non-magnetic steel which is non-magnetic, resistant to marine corrosion, and high in strength and hardness.

Owner:LESHAN LIDUN CAST STEEL

An electronic transformer

InactiveCN101266872AReduce instabilityLow magnetic permeabilityTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerEngineering

The invention discloses a electronic transformer, characterized in that the electronic transformer comprises: a coil winding rack, above or below which through holes are provided, and a plurality of pins are provided at a bottom face of the coil winding rack; two E type iron cores whose middle posts are respectively inserted into the upper and lower through holes of the coil winding rack; a winding, which is wound on the coil winding rack, and connected with an external circuit respectively through the pins. The invention replaces the traditional U type magnet iron by the E type iron core and saves structure of a steel clamp, which not only reduces cost, but also greatly lessens the magnetic conductivity.

Owner:SHANGHAI CHARLES ELECTRONICS

Systems and methods for magnetic shielding for a superconducting computing system

ActiveUS20190182995A1Improve permeabilityLow magnetic permeabilityQuantum computersShielding materialsMagnetic fluxComputing systems

A magnetic shielding system that includes a shield that is non-uniform in the axial direction and a shield cap that is non-uniform in the radial direction. Each shield in the system may have a magnetic permeability, thickness, and / or radius that varies in the axial direction to create low-reluctance paths that redirect flux away from a sample towards the ends of the shield. Each shield cap in the system may have a magnetic permeability and / or thickness that varies in the radial direction to create low-reluctance paths that redirect flux away from the sample towards shield walls. An inner shielding layer formed from a material of low permeability and moderate-to-high coercivity may be implemented as the innermost layer of a magnetic shielding system.

Owner:D-WAVE SYSTEMS

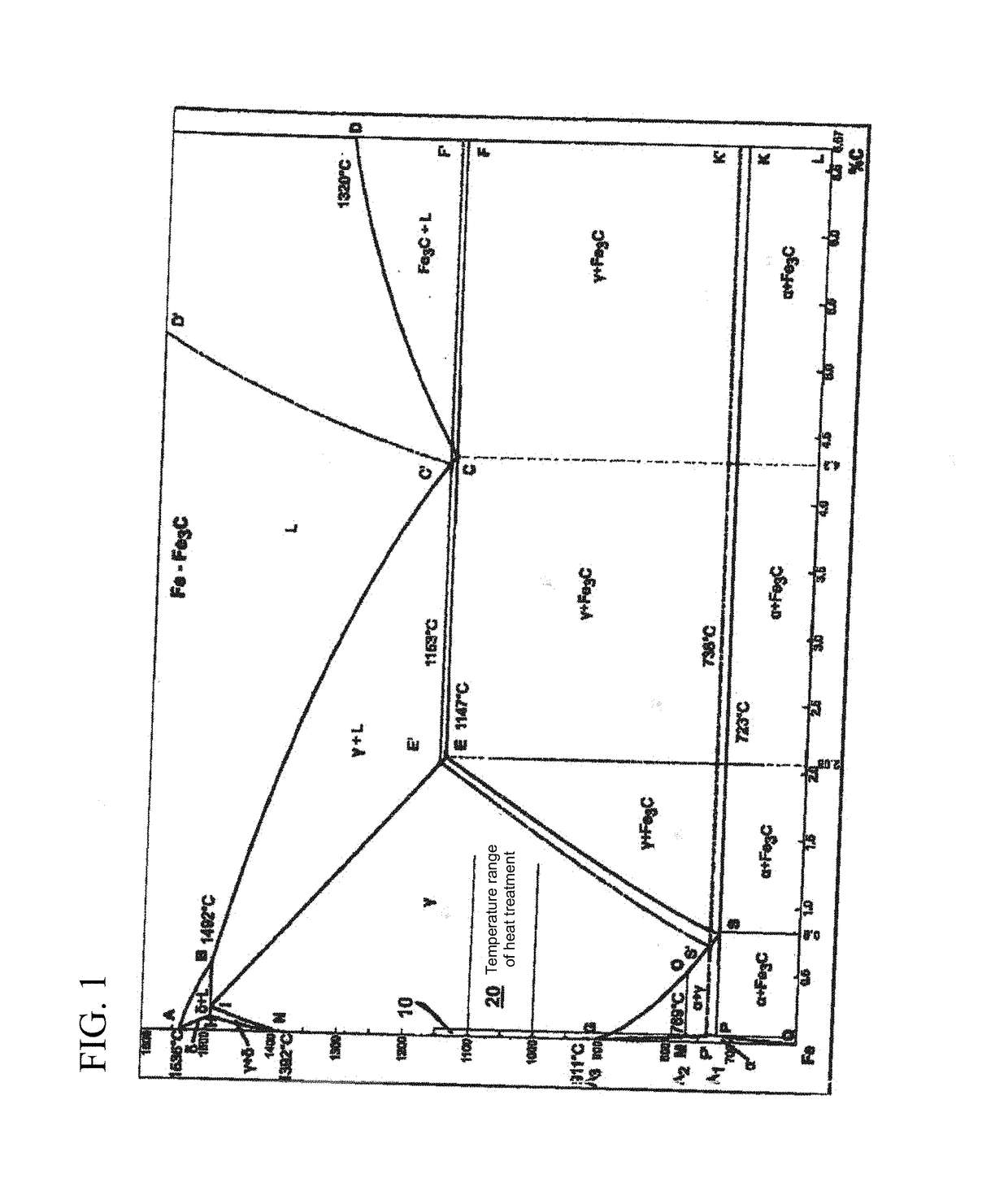

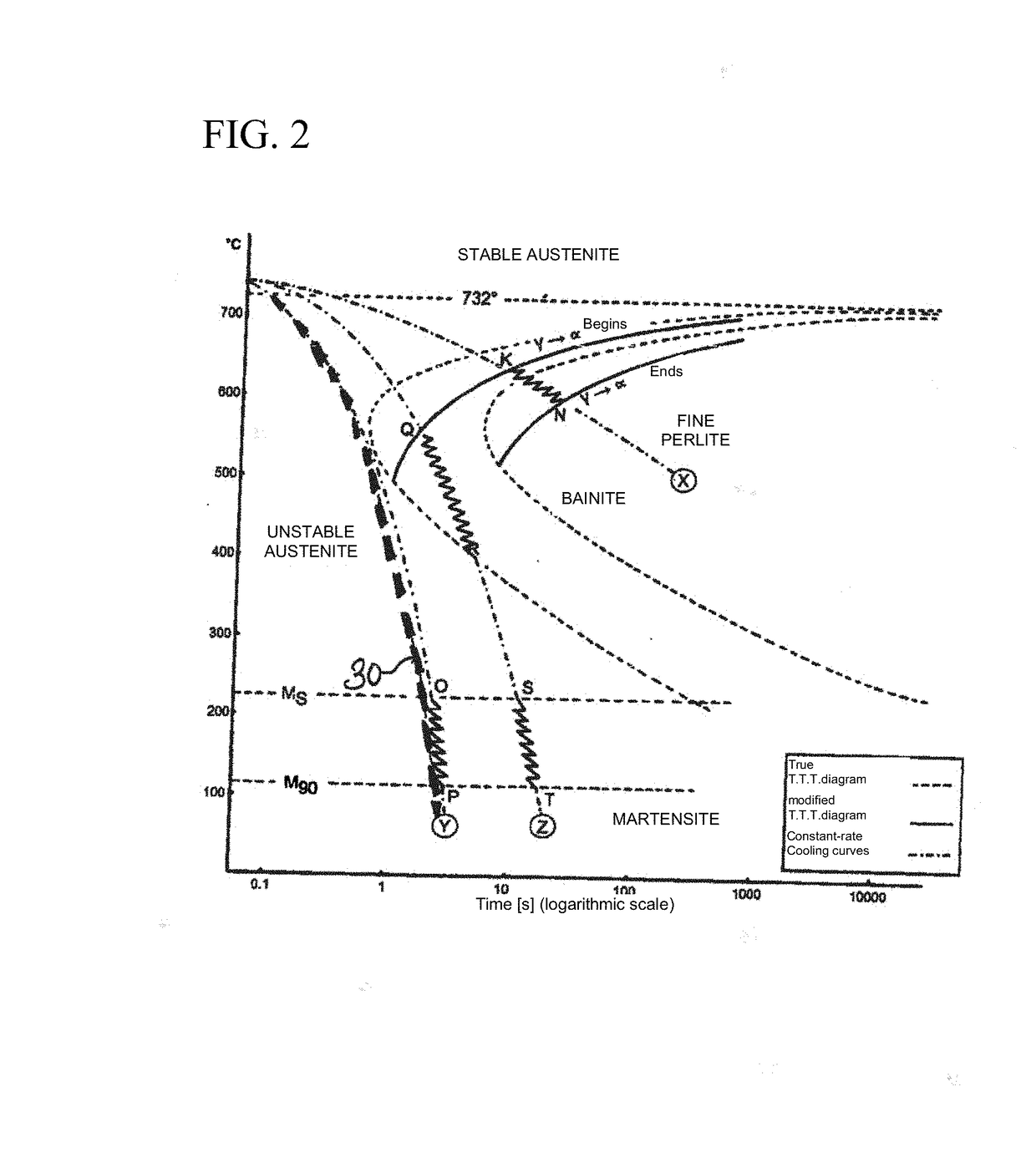

Heat treatment method for high-strength high-hardness marine-corrosion-resistant non-magnetic steel

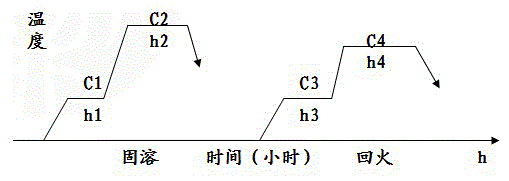

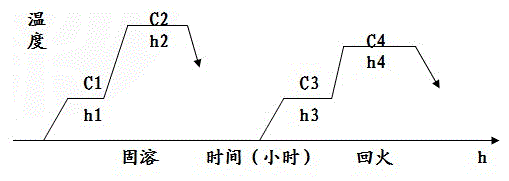

InactiveCN103602795AMeet the use requirementsImprove mechanical propertiesSolution treatmentMachining

The invention discloses a heat treatment method for high-strength high-hardness marine-corrosion-resistant non-magnetic steel, belonging to the field of alloy materials. The heat treatment method comprises the following steps: (1) feeding smelted corrosion-resistant antimagnetic steel of which the temperature is no more than 500 DEG C into a heat treatment furnace; (2) heating to 600-650 DEG C at a heating rate of 80-100 DEG C / h, and keeping the constant temperature for 2-3 hours; and (3) heating to 1050-1080 DEG C at a heating rate of 80-100 DEG C / h, and keeping the constant temperature for 5-6 hours; and performing solution treatment, performing welding combination, machining, and performing stabilizing heat treatment, wherein the treatment process is specifically as follows: (1) heating to 600-630 DEG C at a heating rate of 100-120 DEG C / h, and keeping the constant temperature for 2-3 hours; and (2) heating to 820-850 DEG C at a heating rate of 100-120 DEG C / h, keeping the constant temperature for 6-8 hours, and cooling to room temperature in the furnace, thus finishing the process. The heat treatment method disclosed by the invention is used for new non-magnetic steel which is non-magnetic and resistant to marine corrosion and has high strength and hardness.

Owner:LESHAN LIDUN CAST STEEL

Method of manufacturing a rotor and electric machine

ActiveUS20180062487A1Good magnetic performanceEffective interferenceMagnetic circuit rotating partsFurnace typesElectric machineProcess region

The invention relates to a method of manufacturing a rotor for an electric machine, wherein the rotor is composed of at least one electric sheet wherein at least one electric sheet is thermally treated regionally to directly modify its magnetic permeability in the treated region.

Owner:RWTH AACHEN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com