Inverter welding machine power transformer nanocrystalline iron core and preparation method thereof

A technology of power transformer and inverter welding machine, which is applied in the direction of inductance/transformer/magnet manufacturing, transformer/inductor magnetic core, circuit, etc., which can solve the problems of poor power supply efficiency and power operation safety and stability, transformer temperature rise, iron core Solve the problems of high residual magnetism, achieve the effect of improving batch processing consistency, good strip toughness, low loss and magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method for preparing a low-remanence and low-loss nanocrystalline iron core of the present invention will be further explained in detail below in conjunction with the accompanying drawings and examples.

[0024] According to the method of the present invention, the nanocrystalline iron core with low remanence and low loss is prepared, which specifically includes the following steps:

[0025] (1) According to the method of the present invention, an iron-based nanocrystalline strip with a thickness of 24 μm and a lamination coefficient greater than 78% is prepared, wherein the nozzle gap during the preparation process is 0.25-0.3 mm, the distance between the roller nozzles is 0.1-0.5 mm, and the liquid level The height is 0.7-0.9m, and the cooling roll speed is 20-25m / s.

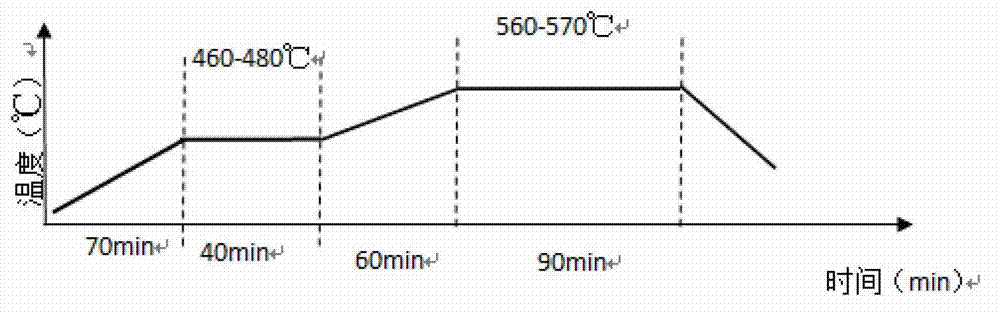

[0026] (2) Wind the above strip into a nanocrystalline iron core, and adopt the following heat treatment process system: under the condition of applying a magnetic field and a magnetic field current...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| stacking factor | aaaaa | aaaaa |

| stacking factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com