Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Low filtration accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

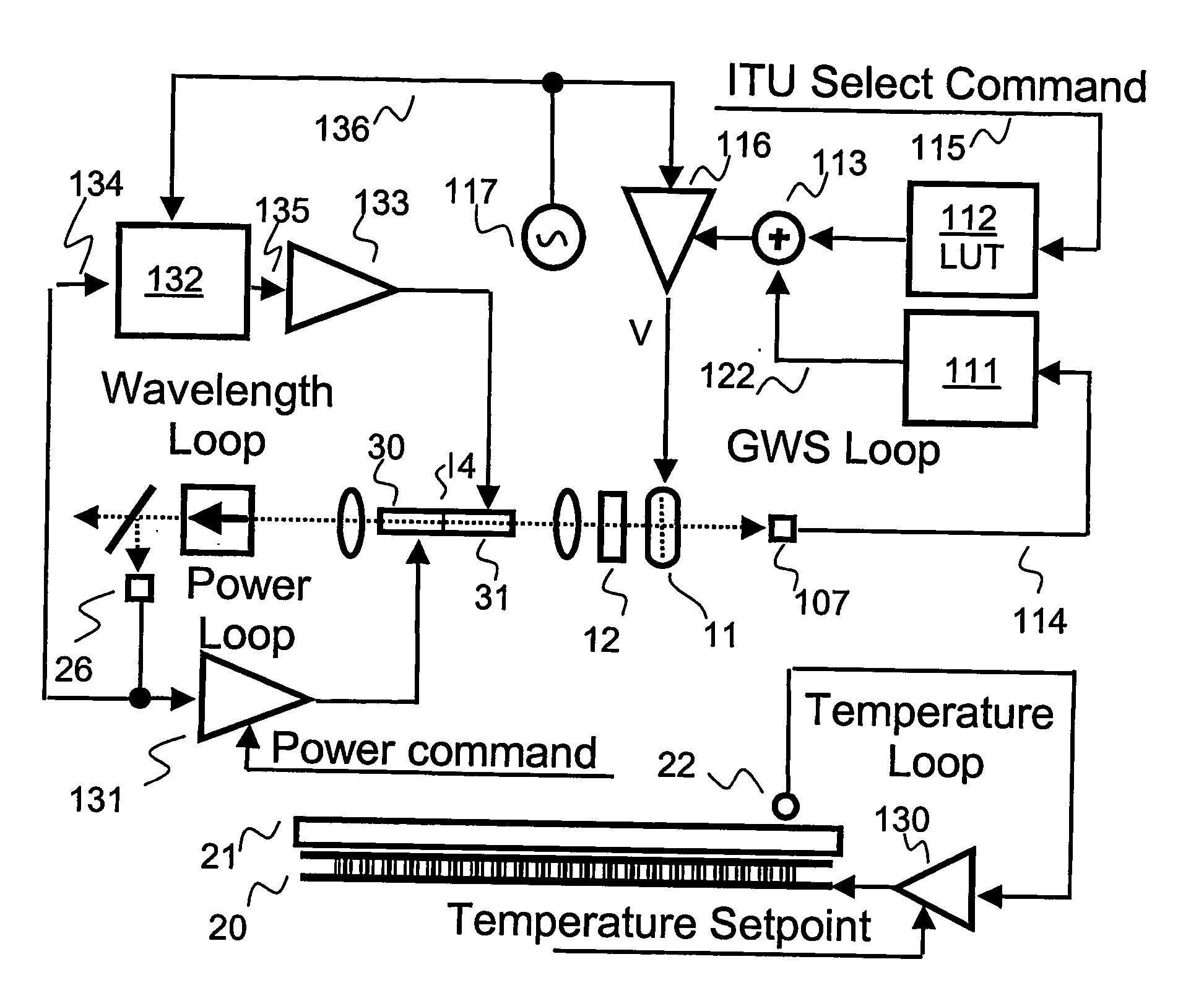

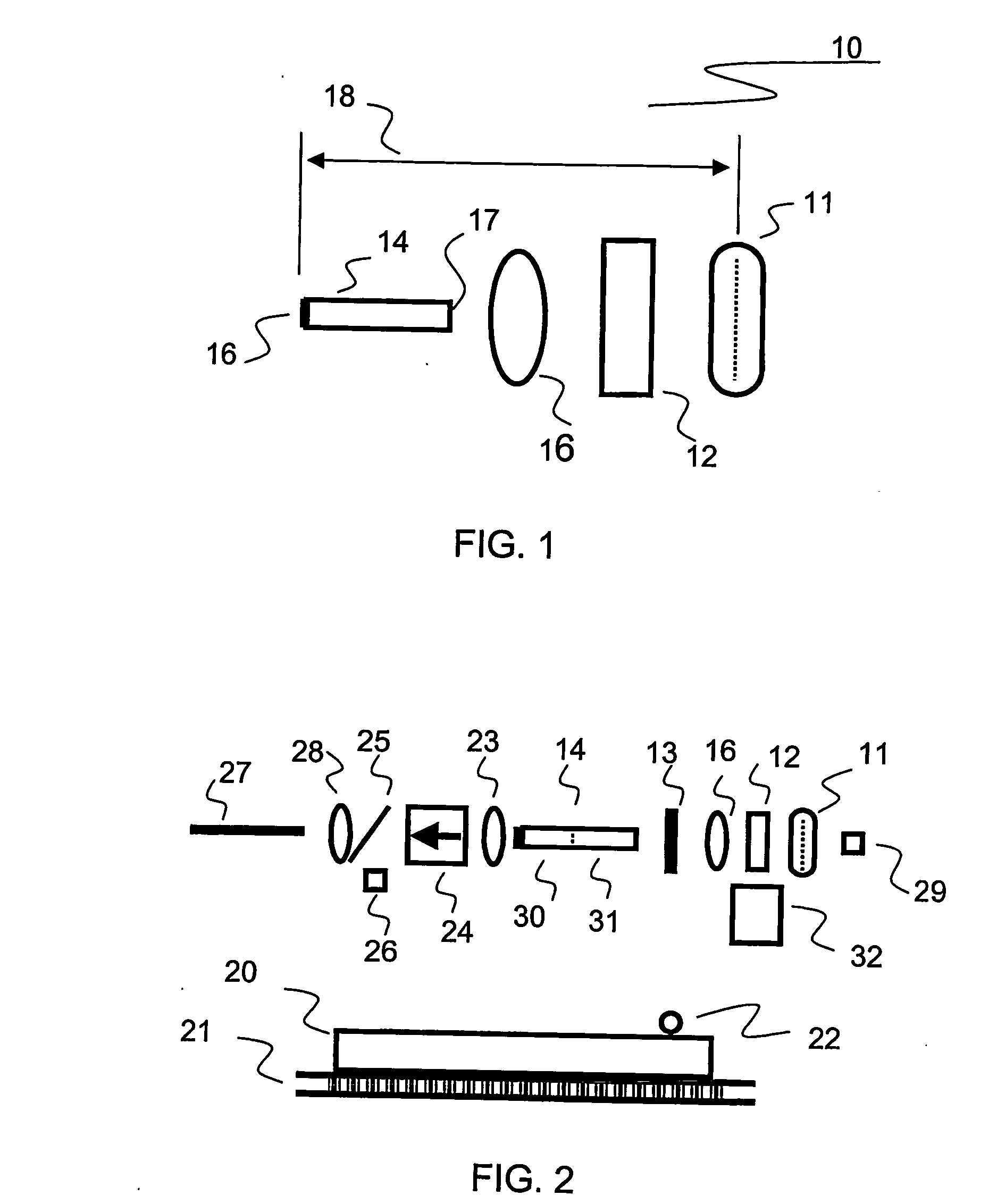

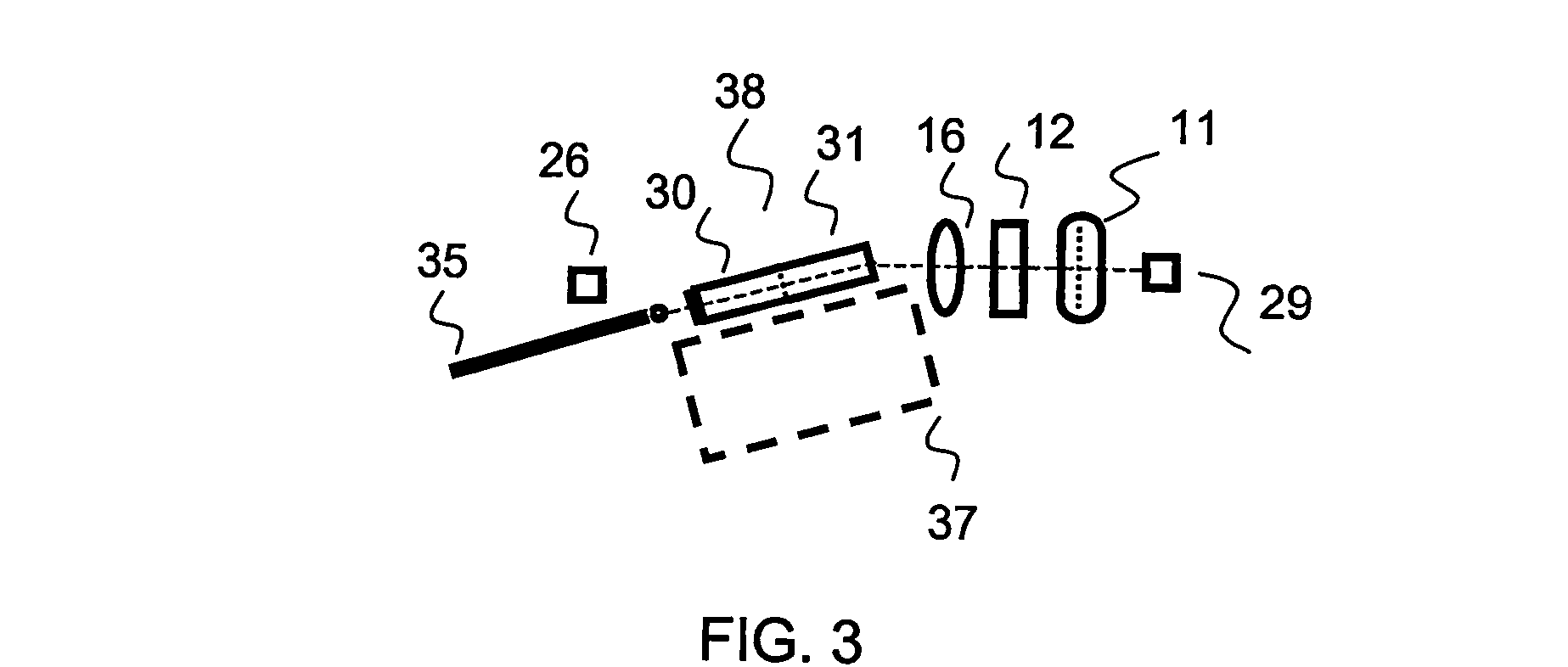

External Cavity Tunable Laser and Control

InactiveUS20060193354A1Avoid lasing instabilityEffect on its overall performanceLaser optical resonator constructionOptical resonator shape and constructionGratingPhase shifted

An optical lasing device, comprising (i) a lasing medium disposed in a lasing cavity, (ii) an etalon disposed within the lasing cavity, and (iii) an electrically tuned filter device, such as a grating waveguide structure device. The lasing device also comprises a detector for determining the lasing power of the lasing device, and a controllable phase shift capability, and the device is preferably locked to a maximum of the lasing power by adjusting the phase, thereby achieving locking to a wavelength predetermined by the etalon, aligned to an ITU grid wavelength. Adjusting the phase shift to achieve the maximum of the lasing power is preferably performed using a closed loop system. Furthermore, adjusting of the phase shift to achieve a maximum of the lasing power is preferably also operative to wave lock the lasing device to a peak wavelength of the etalon.

Owner:ROSENBLATT YEHUDA

Preparation method of porous film

ActiveCN106000123AControl pore structureHigh porosityMembranesSemi-permeable membranesChemical reactionAdditive ingredient

The invention discloses a preparation method of a porous film. The preparation method comprises the following steps: (1) acquiring a porous support body; (2) preparing a thick size containing raw material powder, a binder, a dispersant and a pore forming agent; (3) loading the size onto the porous support body, and drying to make a film billet; (4) sintering the film billet to make a porous film precursor; (5) removing the pore forming agent from the precursor to obtain a porous film with the thickness of 5-3,000 [mu]m, the average aperture of 0.05-100 [mu]m and the porosity of 40-90%. The preparation method has the following advantages: firstly, no chemical reaction occurs between the pore forming agent and the raw material powder, so that the ingredients of the porous film cannot be damaged; secondly, the pore forming agent is excellent in thermal stability and always occupies a certain space (place) in the sintering process; after sintering, the pore forming agent is removed, holes or pores are generated in situ; therefore, the whole technological process is simple, the hole structure of the porous film is easy to control, and the porosity is remarkably improved.

Owner:CHENGDU INTERMENT TECH

Porous film and preparation method thereof

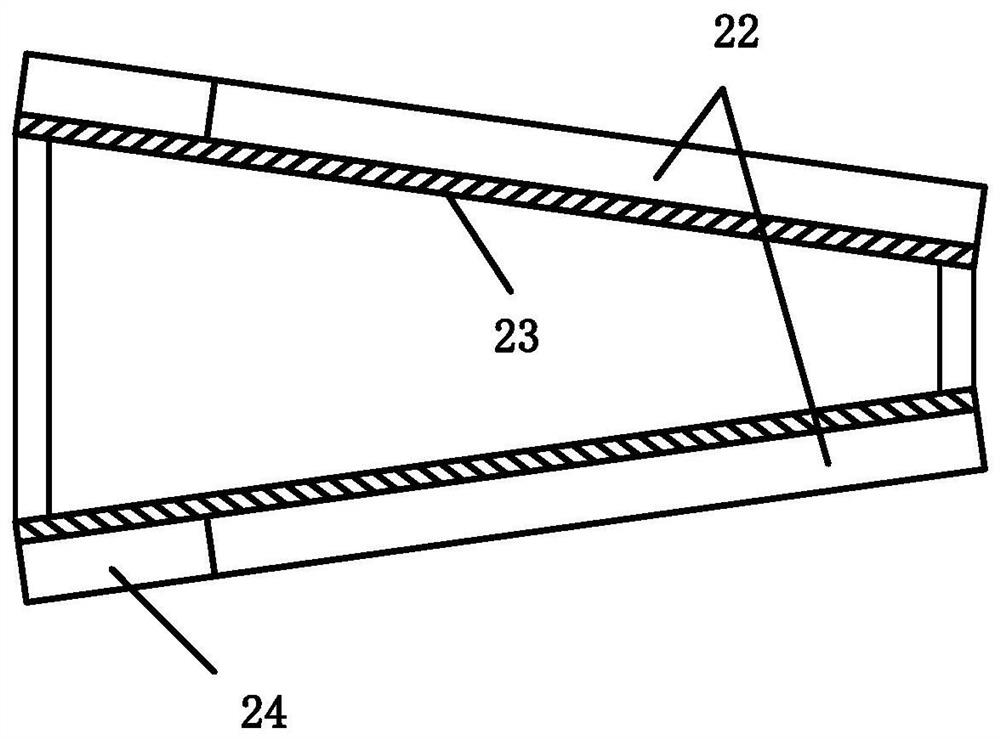

ActiveCN105854633AImprove uniformityLow filtration accuracySemi-permeable membranesMembranesSlurryMetal

The invention discloses a porous film which comprises a filtering layer and a porous support, wherein the filtering layer is composed of dendritic metal substance powder and / or metal substance oxide powder. A preparation method for the porous film comprises the following steps: 1) acquiring the raw material powder and the porous support, wherein the raw material powder is the dendritic metal substance powder and / or the metal substance oxide powder; 2) preparing slurry; 3) loading the slurry on the surface of the porous support, drying and preparing into a film blank; 4) sintering the film blank and cooling, thereby acquiring the porous film. Firstly, the dendritic metal substance powder is stacked and formed into the pores of the porous film, the complex hole-forming process is avoided and the porosity is high and is easy to control; the filtering layer composed of the dendritic metal substance powder and / or the metal substance oxide powder is stable in physico-chemical property, long in service life and free from mutual reaction; the complex phase-forming process is avoided; the component of the porous film is easy to control.

Owner:CHENGDU INTERMENT TECH

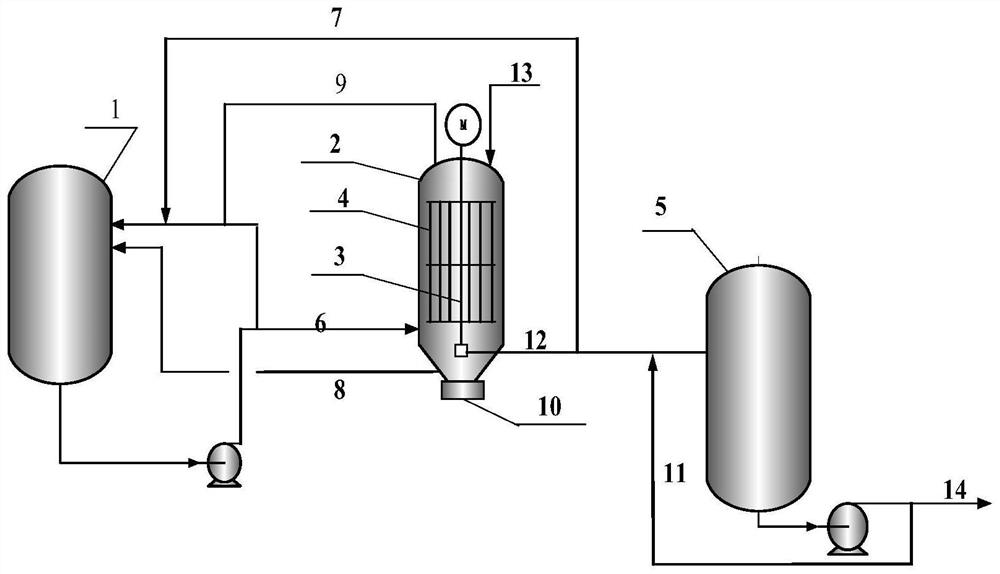

Extraction method of lincomycin

ActiveCN103724380AHigh strengthExtended service lifeSugar derivativesSugar derivatives preparationChemical oxygen demandUltrafiltration

The invention provides an extraction method of lincomycin. The extraction method mainly comprises the following steps: adjusting acidity of fermentation liquor, filtering by using a ceramic ultrafiltration membrane, then adjusting alkalinity, then filtering by using a ceramic ultrafiltration membrane again, then carrying out primary sec-octyl alcohol extraction and hydrochloric acid back-extraction, adjusting alkalinity of the primary back extraction liquor and then filtering by using a ceramic ultrafiltration membrane again; carrying out secondary sec-octyl alcohol extraction and hydrochloric acid back-extraction and adding acetone to the secondary back extraction liquor to carry out evaporative crystallization. According to the extraction method provided by the invention, the yield of the lincomycin is high, the color grade of the lincomycin can be improved, and the B component content in the lincomycin is reduced. According to the extraction method of the lincomycin, the feed liquid quality of other extraction technologies can be improved by a membrane treatment process, the integral extraction efficiency is further improved, the residual volume of sec-octyl in raffinate in the extraction procedure is reduced, the product quality is improved, and meanwhile, the COD (Chemical Oxygen Demand) in produced wastewater is reduced. The extraction method has certain economic benefit and environmental benefit.

Owner:JIANGSU JIUWU HITECH

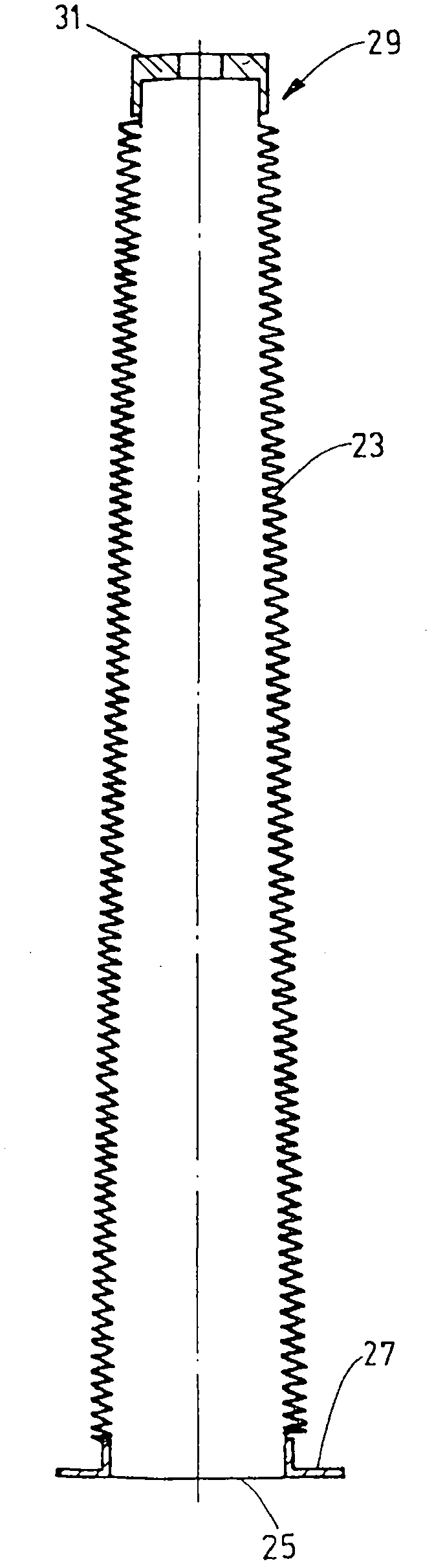

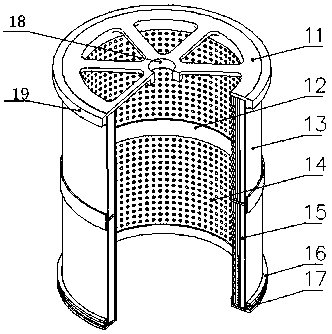

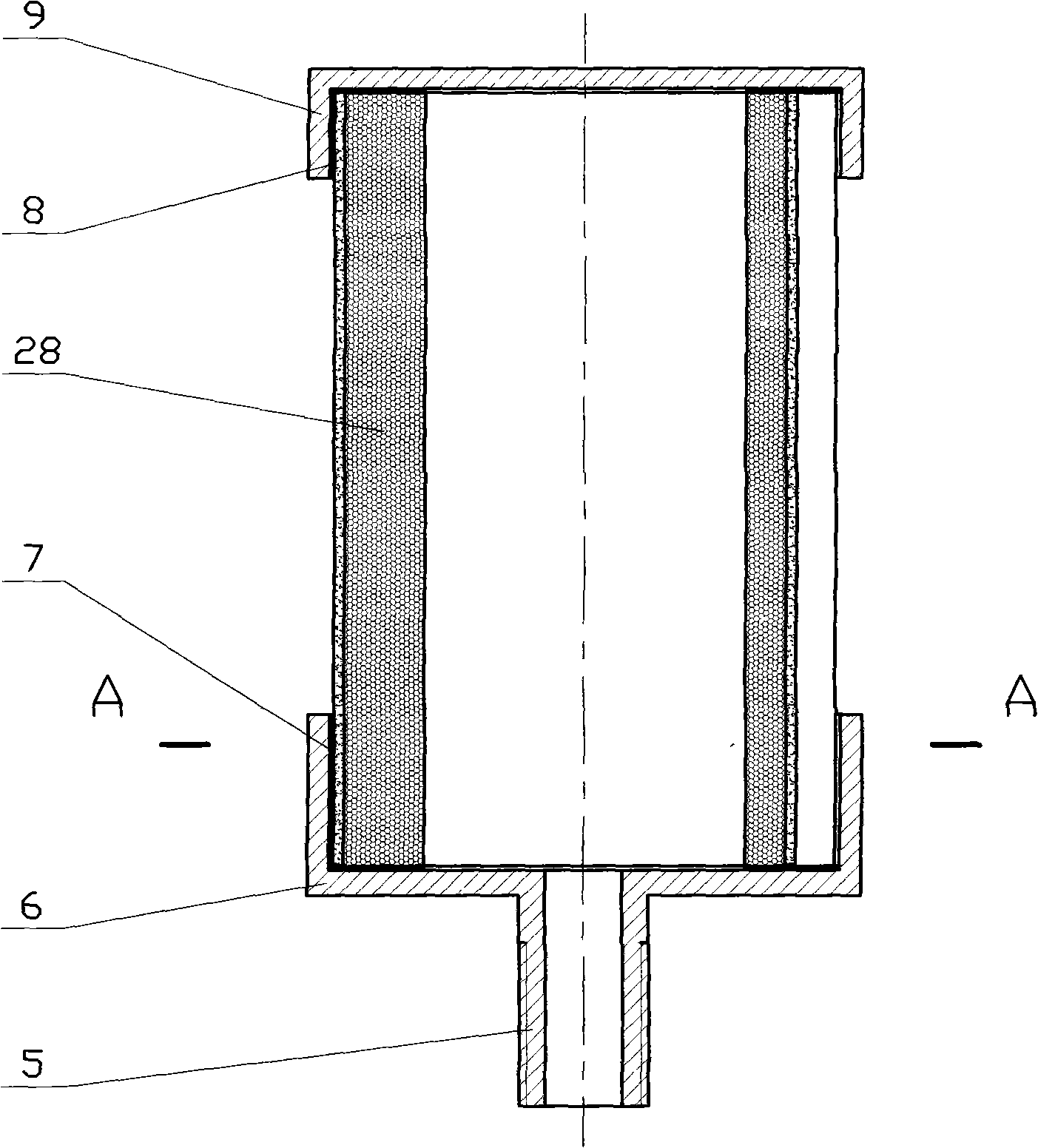

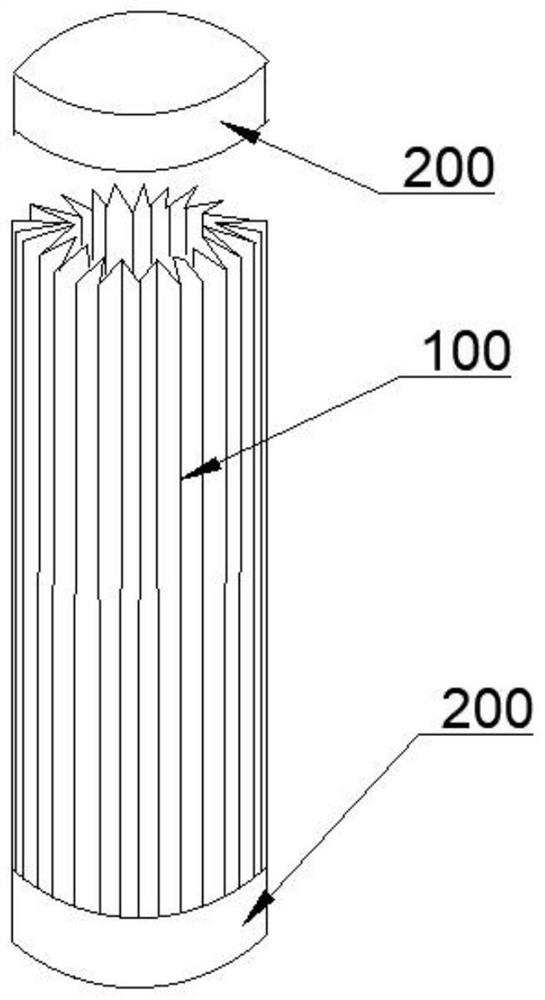

Filter device

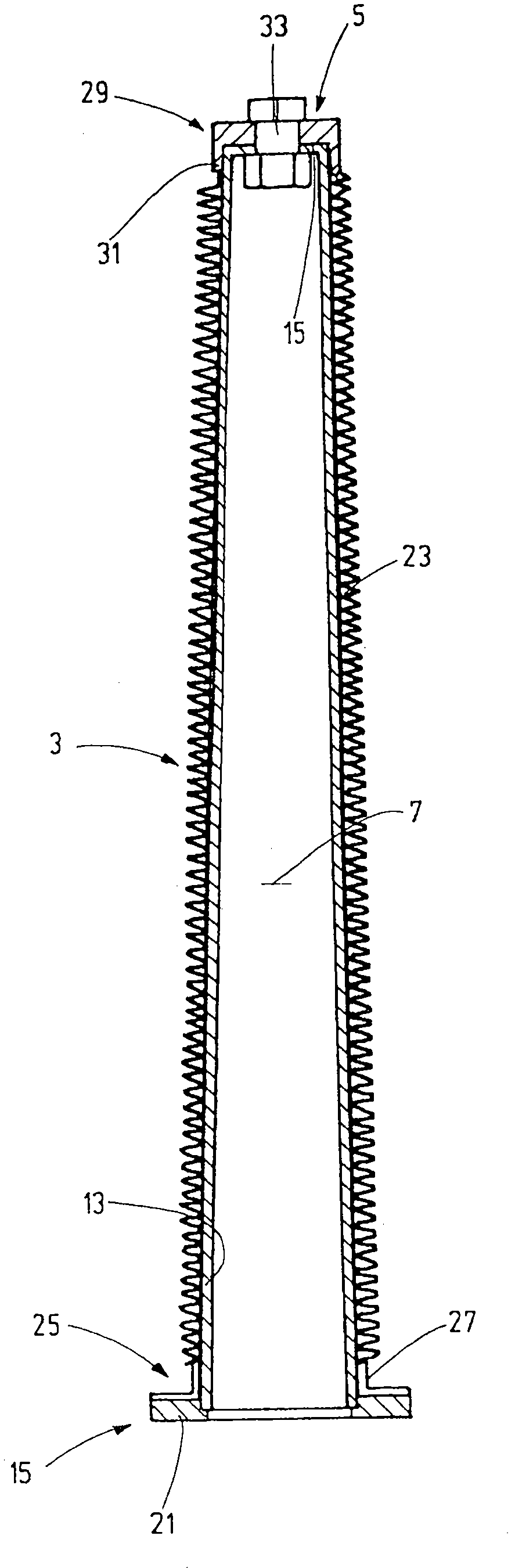

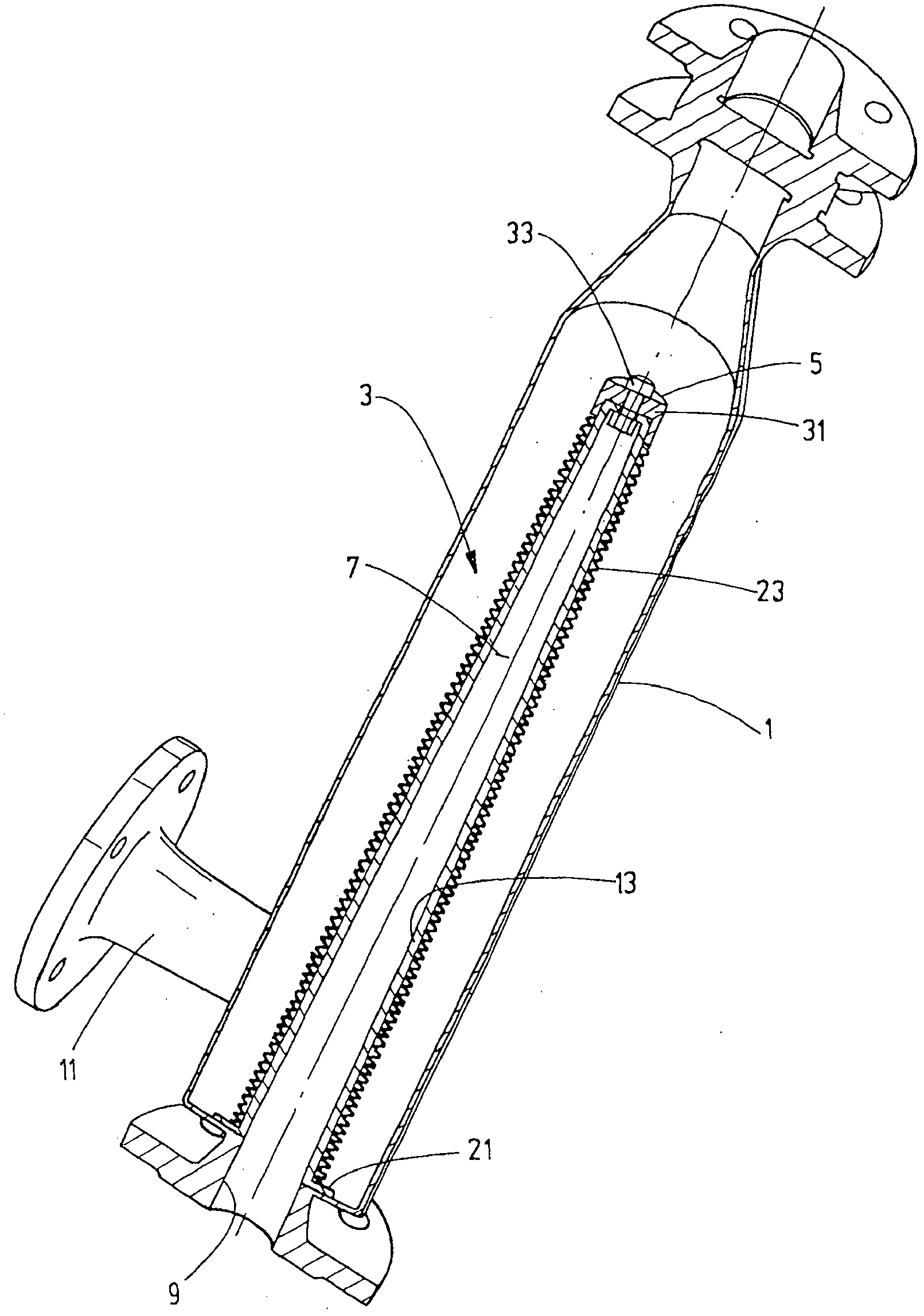

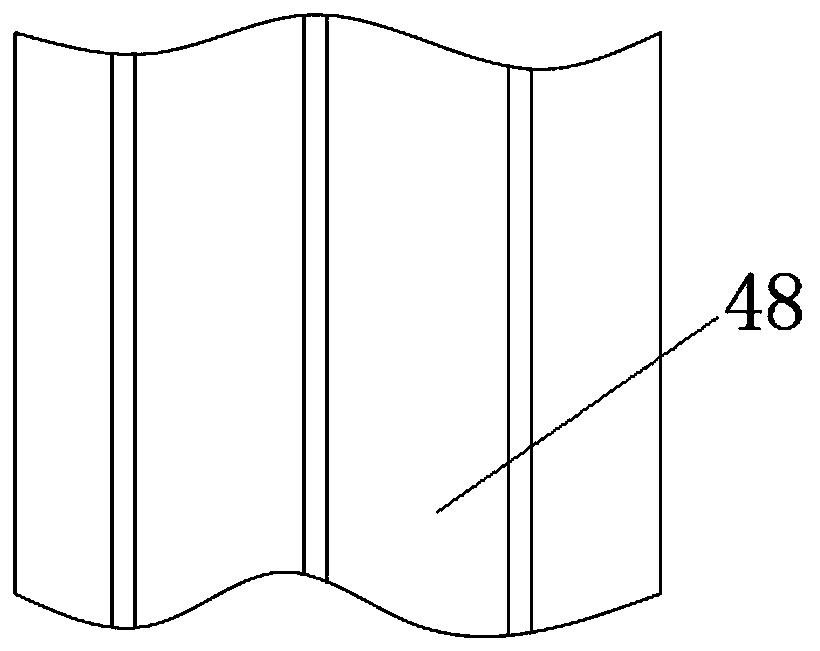

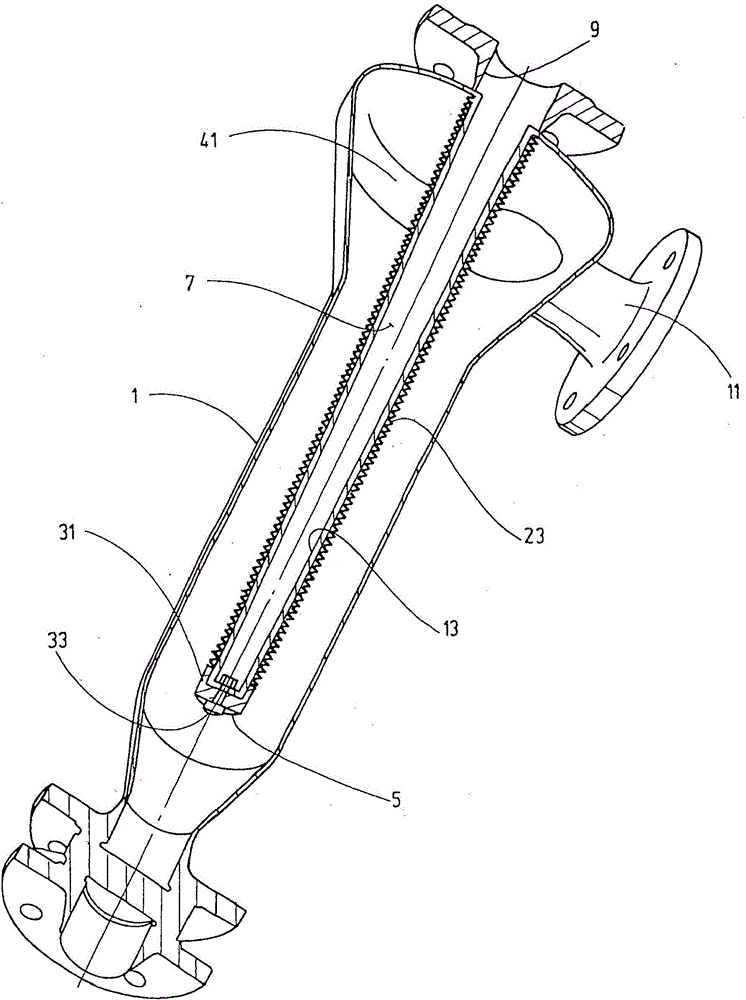

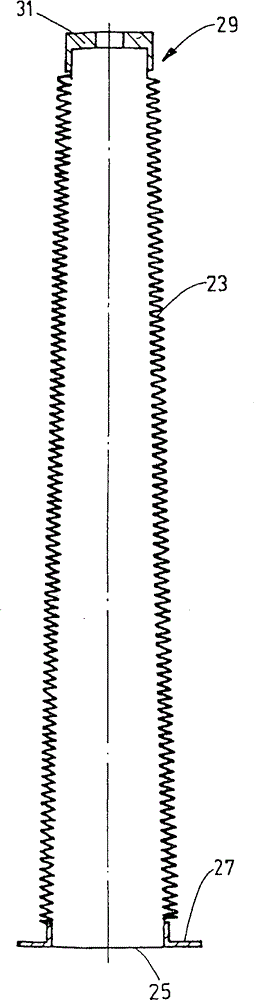

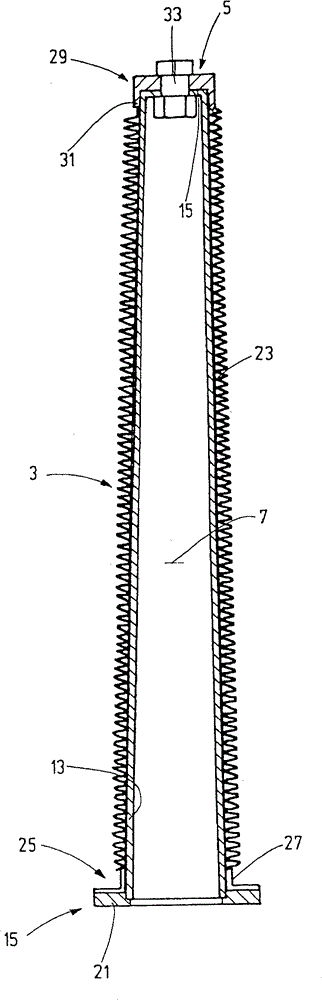

InactiveCN102665850ALow costComfortable and simple replacement processMembrane filtersStationary filtering element filtersEngineeringFilter element

The invention relates to a filter device, in particular for fluids such as hydraulic oil, lubricating media, processing, surface or sea water, having at least one filter element (3) that has at least one effective filter surface (23), which is suitable for removing contaminants from a media flow crossing the filter surface, wherein an effective filter surface is designed as a flexible filter sock (23) that can be pulled onto a support body (13) of the filter element (3). The invention is characterized in that the filter sock (23), while enlarging the effective filter surface thereof, is designed to be longer in the axial direction of the filter element (3) such that the effective filter surface lies in folds upon pulling the filter sock (23) over the support body (13).

Owner:HYDAC PROCESS TECH

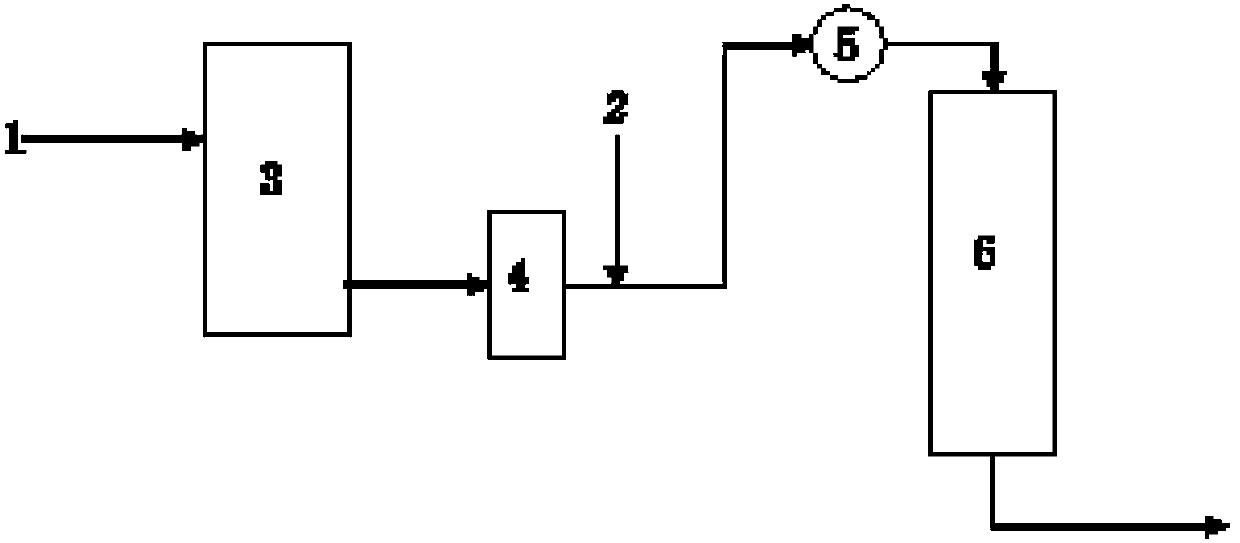

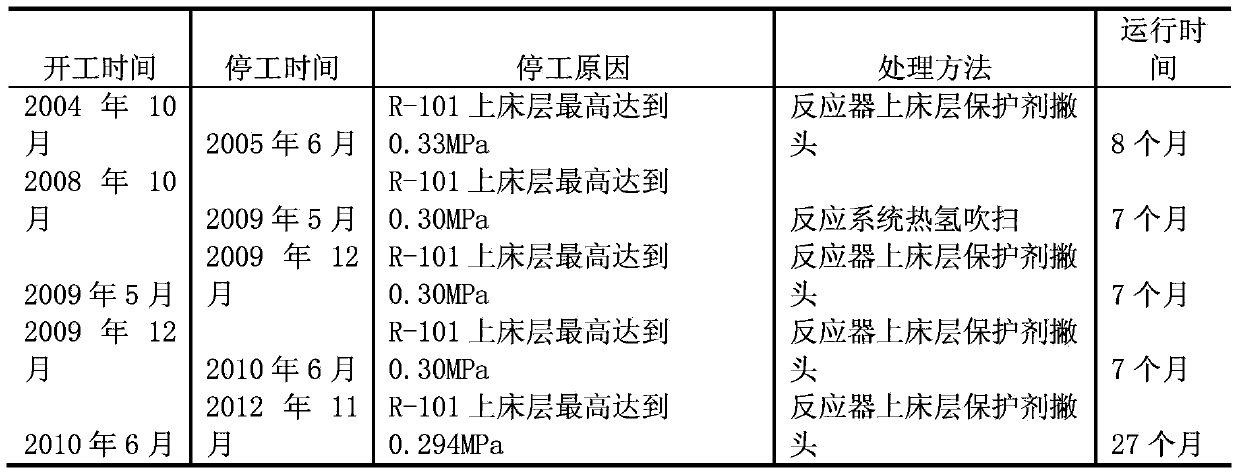

Method for prolonging operation cycle of coker gasoline hydrogenation unit

InactiveCN104212486AReduce the occurrence of polymerization reactionsReduce pump operationTreatment with hydrotreatment processesNitrogen gasAlkene

The invention relates to a method for prolonging the operation cycle of a coker gasoline hydrogenation unit; and the method is as follows: (1) before coker gasoline enters into a coker gasoline hydrogenation reactor from a coking device, the coker gasoline first enters into a dehydration buffer tank sealed by nitrogen, water carried in the raw material is removed, the nitrogen sealing pressure is controlled in 0.7MPa; the dwell time is controlled in 4-8 hours; (2) and then the coker gasoline first enters into an automatic backwash filter, the filtration precision control is controlled in 15 to 20 mu m; (3) before the coker gasoline enters into a hydrogen mixing raw material for hydrogen mixing with a refined product heat exchanger, a polymerization resistant dispersant is injected, so that before the coker gasoline enters into the reactor, olefin polymerization reaction does not occur or occurs in a small amount; the agent injection ratio is controlled in 40ppm-50ppm; the method can effectively reduce the rise velocity of reactor bed pressure drop and reaction system pressure drop, and can effectively prolong the operation cycle of the unit.

Owner:PETROCHINA CO LTD

Wound filter element and application thereof

InactiveCN102100987AGood chemical resistanceGood resistance to steam and heatGravity filtersYarnFiltration

The invention discloses a wound filter element and application thereof. The wound filter element comprises a porous aggregate and a rough yarn wound on the porous aggregate, wherein the rough yarn contains polyphenylene sulfide fibre, has a coefficient of twist of 180-280, has excellent bulkiness and better filtering property, and can not be excessively drafted during the winding. The wound filter element disclosed by the invention has the characteristics of small pressure loss, high filtering accuracy, and excellent steaming resistance and chemical properties, and can be applied to the field of filtration of various kinds of high-temperature liquids.

Owner:TORAY IND INC

A kind of extraction method of lincomycin

ActiveCN103724380BHigh strengthExtended service lifeSugar derivativesSugar derivatives preparationBiotechnologyChemical oxygen demand

The invention provides an extraction method of lincomycin. The extraction method mainly comprises the following steps: adjusting acidity of fermentation liquor, filtering by using a ceramic ultrafiltration membrane, then adjusting alkalinity, then filtering by using a ceramic ultrafiltration membrane again, then carrying out primary sec-octyl alcohol extraction and hydrochloric acid back-extraction, adjusting alkalinity of the primary back extraction liquor and then filtering by using a ceramic ultrafiltration membrane again; carrying out secondary sec-octyl alcohol extraction and hydrochloric acid back-extraction and adding acetone to the secondary back extraction liquor to carry out evaporative crystallization. According to the extraction method provided by the invention, the yield of the lincomycin is high, the color grade of the lincomycin can be improved, and the B component content in the lincomycin is reduced. According to the extraction method of the lincomycin, the feed liquid quality of other extraction technologies can be improved by a membrane treatment process, the integral extraction efficiency is further improved, the residual volume of sec-octyl in raffinate in the extraction procedure is reduced, the product quality is improved, and meanwhile, the COD (Chemical Oxygen Demand) in produced wastewater is reduced. The extraction method has certain economic benefit and environmental benefit.

Owner:JIANGSU JIUWU HITECH

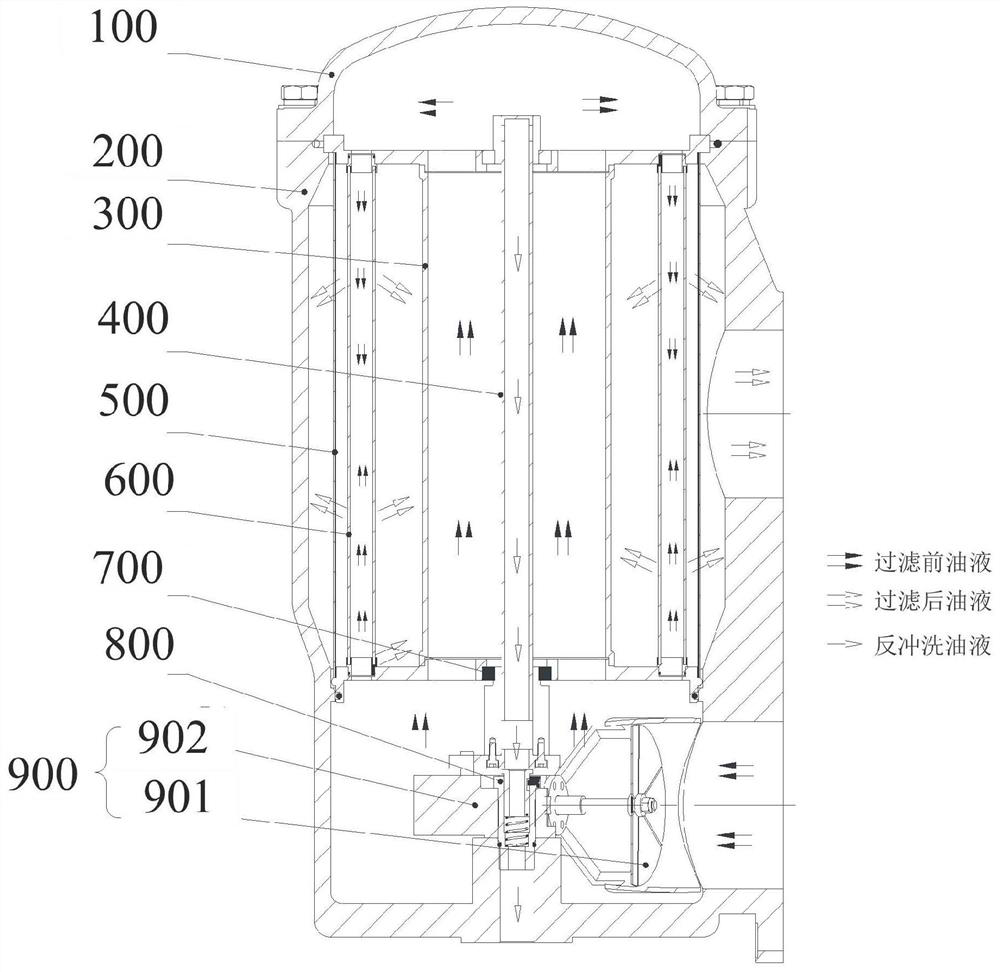

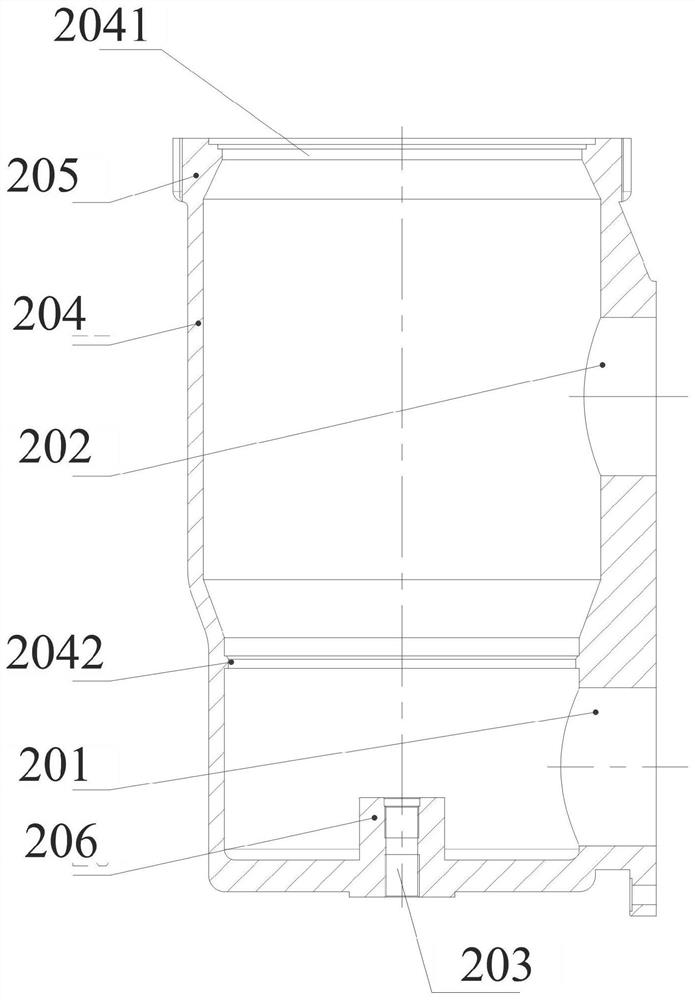

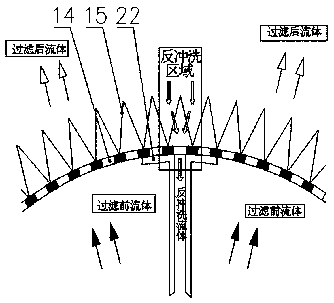

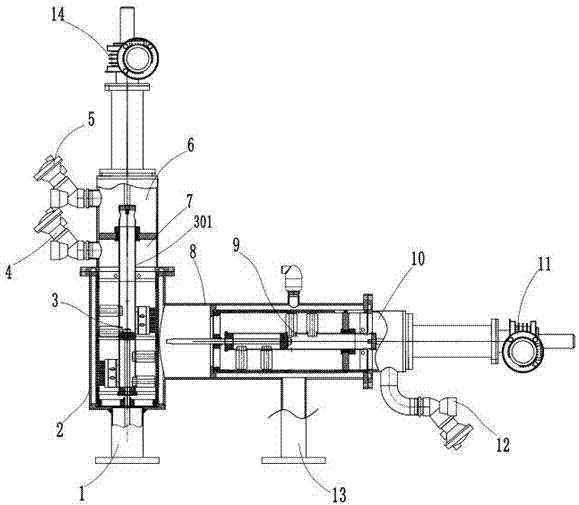

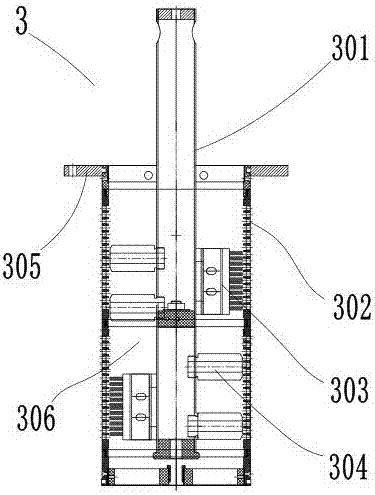

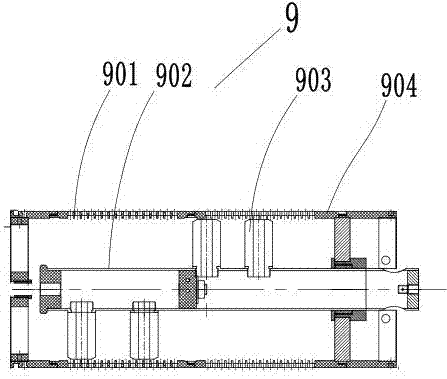

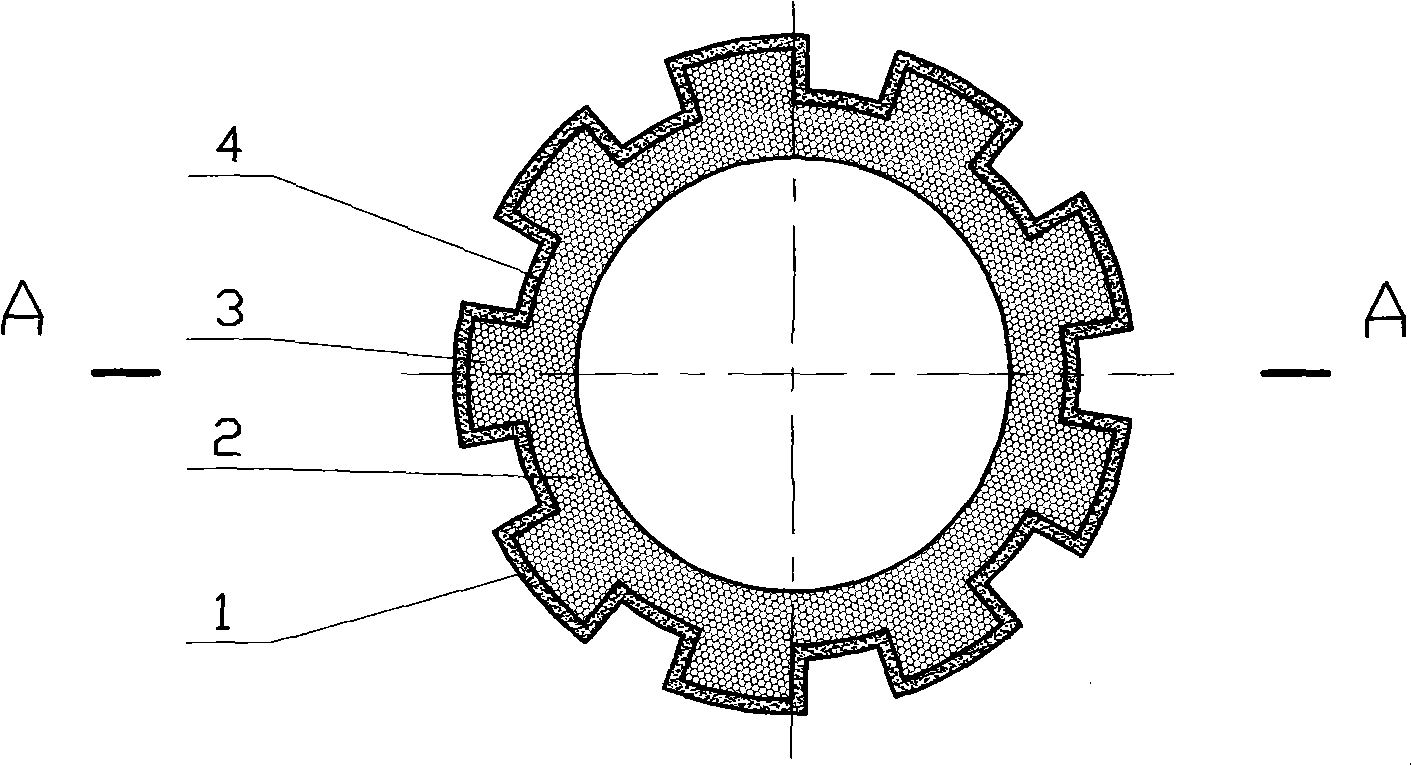

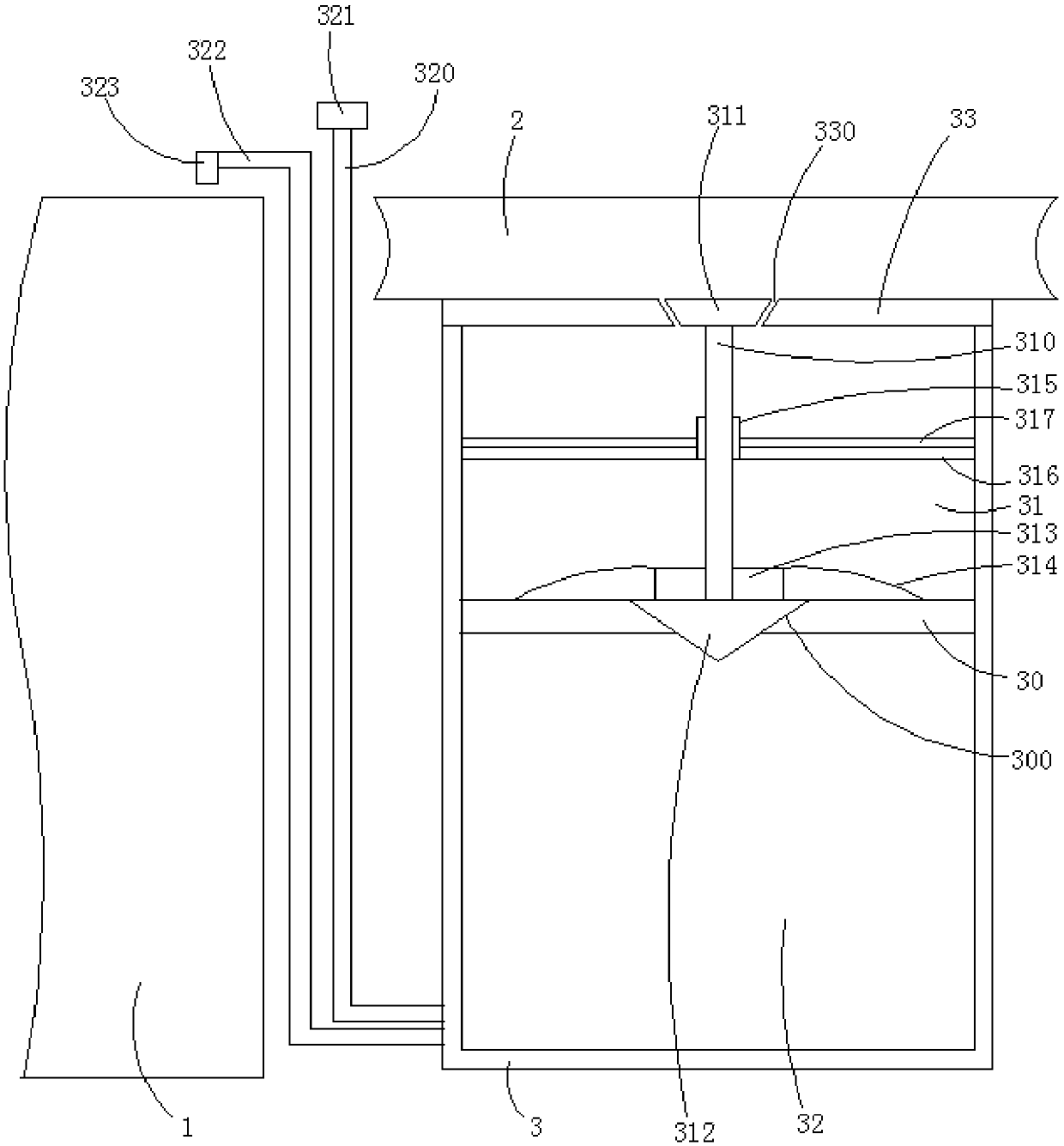

Self-operated bidirectional time-staggered backwashing self-cleaning filter and filtering backwashing method thereof

PendingCN111841109ACompact structureSolve the problem of incomplete cleaningStationary filtering element filtersSewageControl theory

The invention relates to a self-operated bidirectional time-staggered backwashing self-cleaning filter and a filtering backwashing method thereof. The filter comprises a tank body in which a circulating cavity is formed; a driving speed reducing mechanism is arranged at the bottom of the circulating cavity and corresponds to the oil inlet in position, and power for oil to enter drives the drivingspeed reducing mechanism to rotate; a fixing assembly is fixed in the circulating cavity, and two circles of filter element mounting holes which are arranged in a staggered manner and are correspondingly arranged up and down are formed in the top and the bottom of the fixing assembly; two circles of filtering elements are sequentially connected in the radial direction of the fixing assembly from inside to outside; the output end of the driving speed reducing mechanism drives the end part of a sewage suction assembly, the sewage suction assembly rotates in the fixing assembly, and two ends of the sewage suction assembly are respectively connected with suction nozzles which synchronously run with the sewage suction assembly and are communicated or blocked with the inner-ring or outer-ring filter element mounting hole; while the filtering elements are used for filtering, the two filtering elements are always communicated with the top suction nozzle and the bottom suction nozzle, and two-way time-staggered backwashing is formed under the action of external pressure difference.

Owner:中国船舶集团有限公司第七零七研究所九江分部 +1

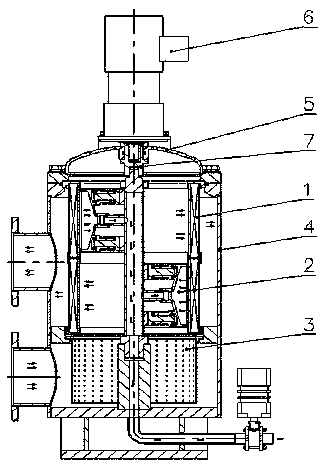

Filtering device with self-cleaning function

PendingCN108926889AReduce self-cleaning flowUniform flowStationary filtering element filtersPre filteringDISC assembly

The invention relates to a filtering device with a self-cleaning function. The filtering device comprises a tank body, an upper cover assembly is arranged at the upper end of the tank body, a self-cleaning filter element is arranged in the tank body, a suction disc assembly is arranged in the self-cleaning filter element, a pre-filter element is arranged at the lower end of the self-cleaning filter element, the upper end of the suction disc assembly is fixedly connected to a geared motor mounted on the upper end of the upper cover assembly via a connecting shaft, the tank body comprises a cylinder body disposed at the upper end of a mounting seat, an end cover is disposed at the upper end of the cylinder body, the side wall of the cylinder body is provided with an oil inlet and an oil outlet, the oil inlet is located at the lower side of the oil outlet, a position, located between the oil inlet and the oil outlet, on the inner side wall of the cylinder body is provided with a separation plate used for separating and fixing the self-cleaning filter element and the pre-filter element, the center position at the bottom end in the cylinder body is provided with a fixed seat, and the lower end of the fixed seat is connected with a discharge valve arranged outside the cylinder body via a discharge pipe. The filtering device of the invention solves the problem that an existing self-cleaning filter in a lubricating oil system requires a more self-cleaning flow rate and the pressure fluctuation of subsequent equipment is large due to an uneven flow of a self-cleaning liquid.

Owner:中国船舶重工集团公司第七0七研究所九江分部 +1

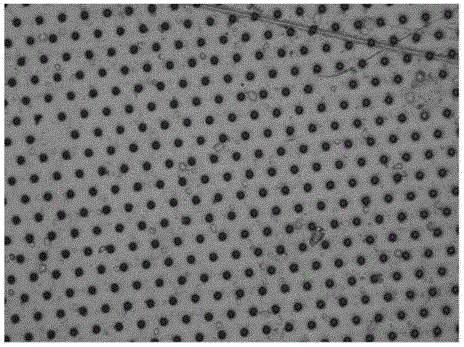

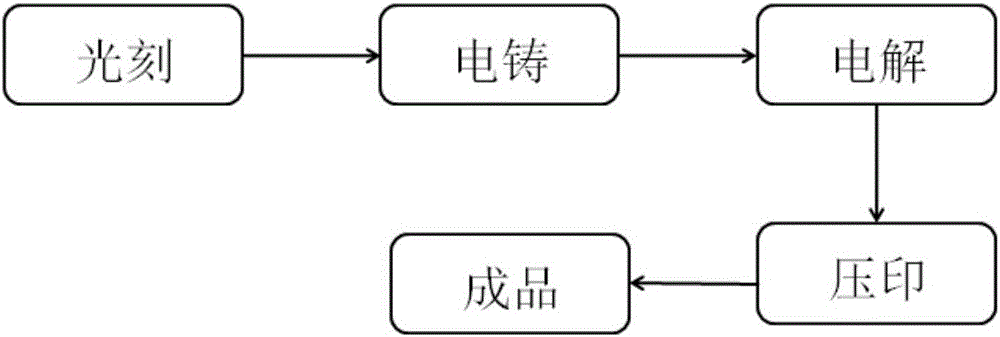

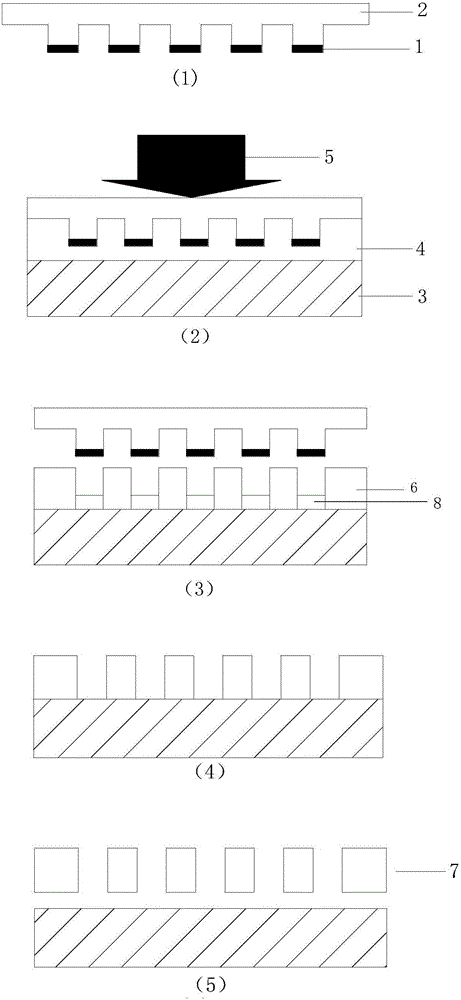

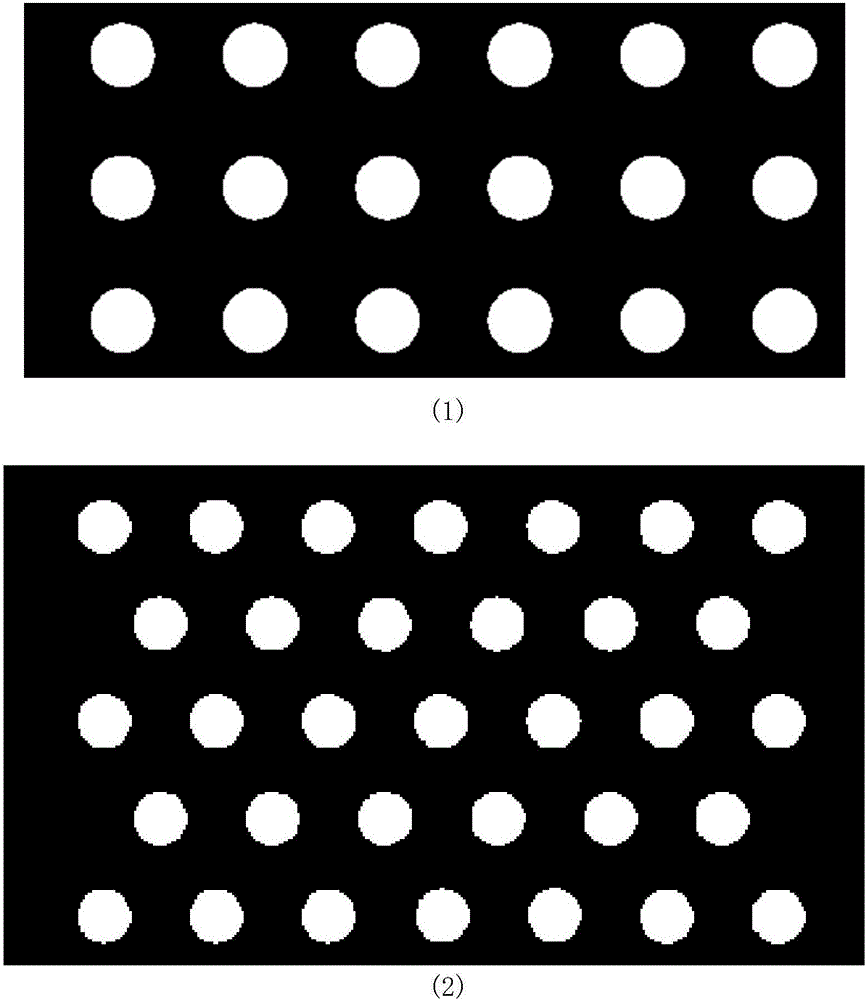

Hot-piercing manufacturing method of micro-via array biological chip

InactiveCN106000489APore size variesLow filtration accuracyBiological particle analysisLaboratory glasswaresHot stampingHigh density

The invention provides a hot-piercing manufacturing method of a micro-via array biological chip. The hot-piercing manufacturing method comprises the following steps: photoetching, thus obtaining a photoresist pattern; plating a metal layer on the photoresist pattern by using a chemical deposition method; electroforming and demolding, thus obtaining an original die blank; electrolyzing, thus obtaining a die; piercing a high molecular material through the die by using a hot stamping method, cooling and demolding, thus obtaining the micro-via array biological chip. According to the hot-piercing manufacturing method provided by the invention, the hot stamping method is adopted, devices can be easily obtained, and the requirements on an implementation environment are low; meanwhile, both the pore diameter periodicity and the size uniformity are good, and the detection accuracy is high; through the methods of die manufacturing and hot-piercing copying, controllable manufacturing of the micro-via array biological chip made from the high molecular material is realized, the machining steps are greatly simplified, the machining efficiency is high, the technological cost and the material cost are lower, and the hot-piercing manufacturing method is beneficial for manufacturing a high-density pore array, so that the detection efficiency is further increased, and the hot-piercing manufacturing method is very suitable for large-scale industrial production.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

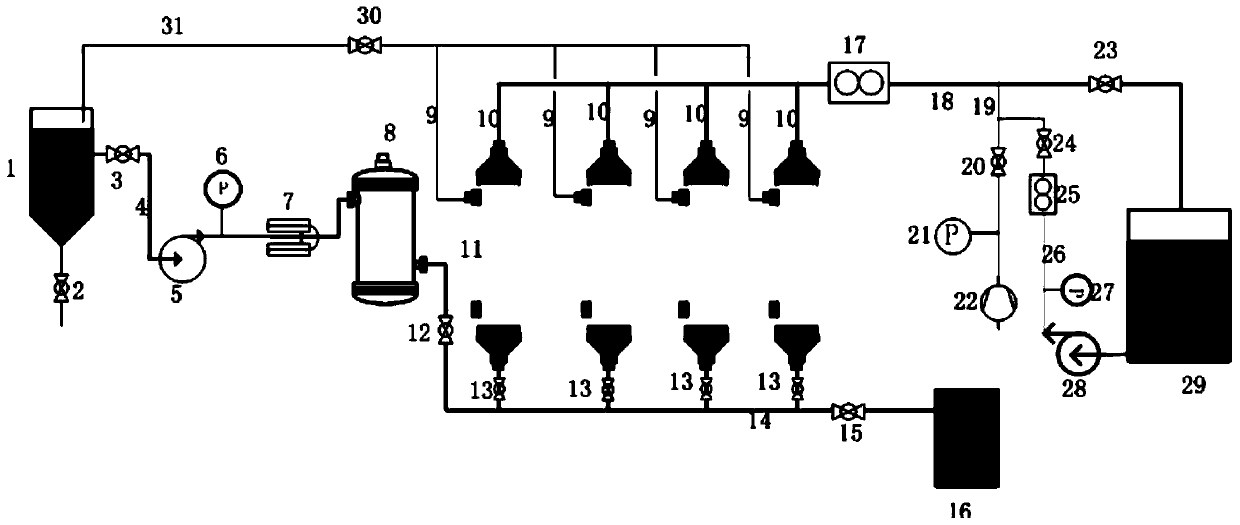

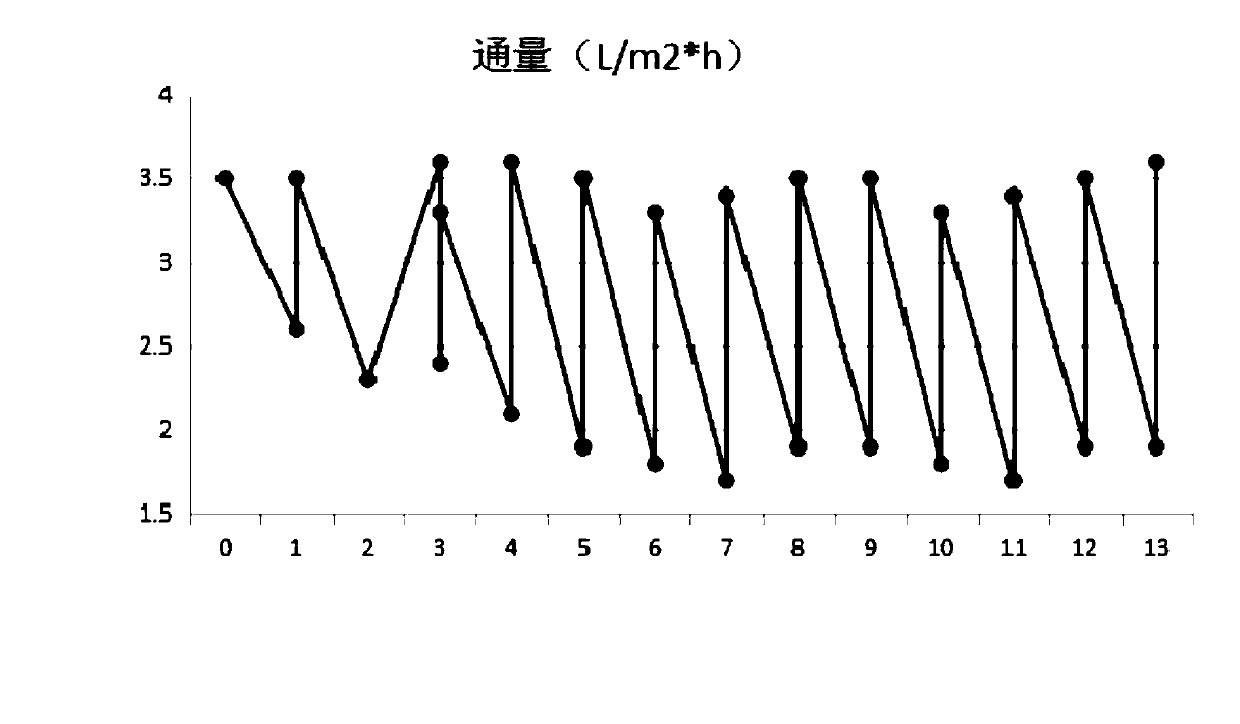

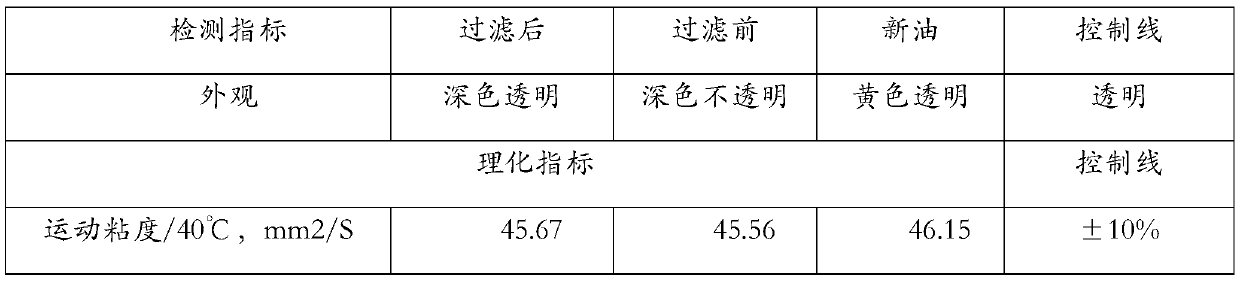

Oil product purification membrane filtration system and use process thereof

PendingCN111495025AHigh interception precisionSmall footprintSemi-permeable membranesFiltration circuitsFiltrationFilter system

The invention belongs to the technical field of petrochemical engineering and environmental protection, and particularly relates to an oil product purification membrane filtration system and a use process thereof. The system comprises a primary sedimentation tank, a coarse filtration device, an oil product purification membrane assembly unit and an oil production tank which are sequentially communicated, the oil product purification membrane assembly unit comprises a plurality of oleophylic and hydrophobic membrane assemblies which are connected in parallel; each oleophylic and hydrophobic membrane assembly comprises an oil inlet, an oil outlet and a thick oil outlet; the oil inlets are respectively communicated with the coarse filtration device and a backwashing liquid collecting device;and the oil production tank is respectively communicated with a gas path cleaning unit, an oil path cleaning unit and the oil production tank. The technology aims at solving the problems that an existing filter element is low in filtering precision and large in pore diameter, and an oil product cannot meet the equipment use standard after one-time filtering; the membrane filtration system and process are high in filtration precision, and dehydration and impurity removal are completed at a time at normal temperature. The system is short in process, low in energy consumption, high in automationdegree, small in occupied area and easy to popularize in the industry.

Owner:天津新启缘环境材料科技有限公司

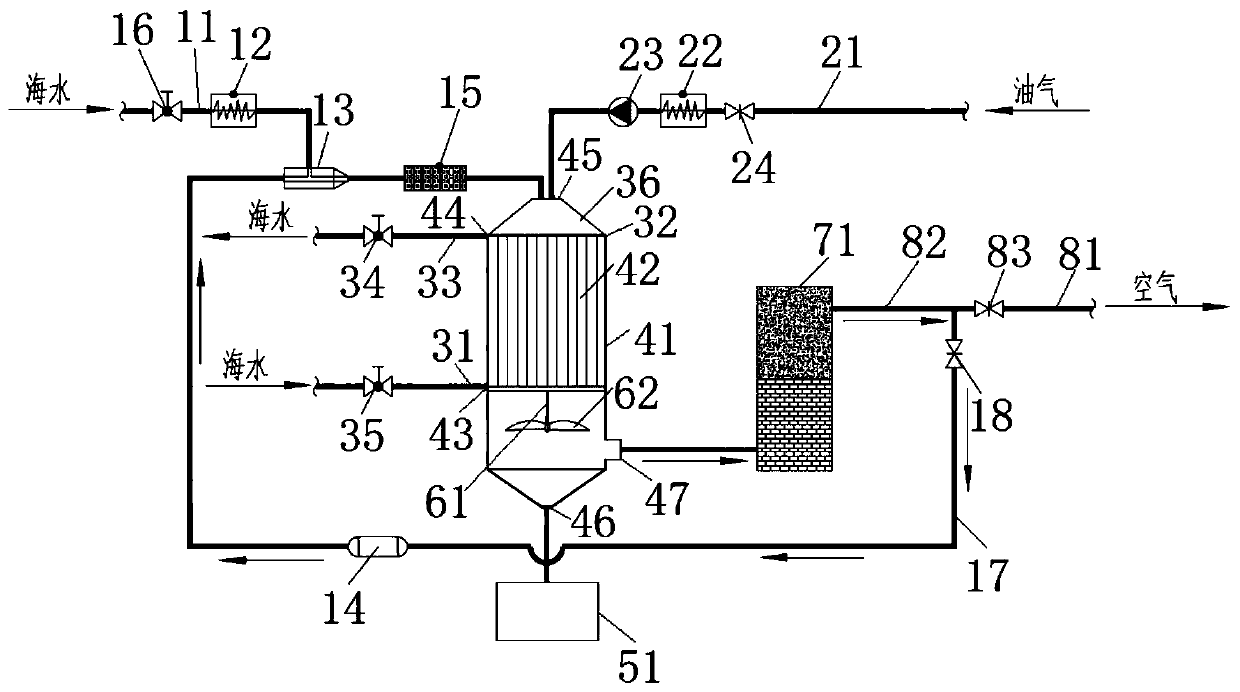

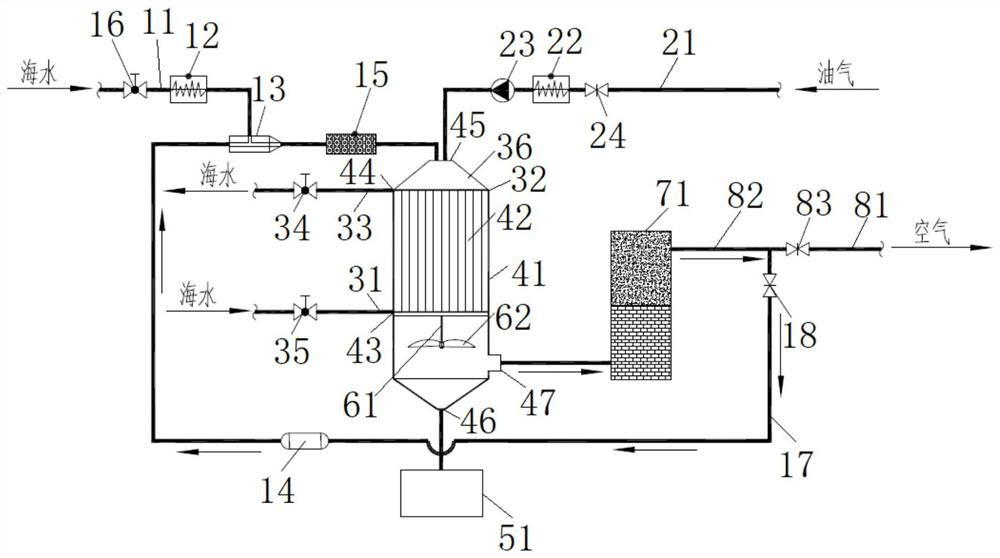

Oil-gas purification device and method for deep sea confined space

ActiveCN110420526AImprove purification efficiencyExtend your lifeCombination devicesAuxillary pretreatmentImpellerFuel tank

The invention discloses an oil-gas purification device for deep sea confined space. The oil-gas purification device comprises a condensation nucleus generating device, an oil-gas pumping device, an oil-gas condensation device, a centrifugal separation device, an oil collecting tank and a filtering purification device, wherein the condensation nucleus generating device comprises a first water inletpipe, a first heater, an atomizer, an air compressor and a dryer; the oil-gas pumping device comprises an oil inlet pipe, a second heater and a fan; the oil-gas condensation device includes a secondwater inlet pipe, a tubular condenser and a water outlet pipe; the oil collecting tank is arranged under a shell body; the centrifugal separation device includes a driving motor and a centrifugal impeller; and the inlets of the filtering purification device are connected with the outlets on the side wall of the shell body, and the outlets of the filtering purification device are correspondingly connected with air outlet pipes and the inlets of the air compressor. According to the oil-gas purification device for the deep sea confined space, the oil-gas purification efficiency can be improved, the air quality of the deep sea confined space is better improved, energy is saved, noise is reduced, the service life of a system is prolonged, and the use cost of the system is lowered.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Self cleaning precise filter and filtering method

PendingCN107982981AReduce congestionImprove filtration efficiencyFiltration circuitsStationary filtering element filtersSewagePollution

The invention discloses a precise filtering technology. A self cleaning precise filter comprises a primary filtering mechanism, a primary pollution discharging cavity and a secondary pollution discharging cavity, wherein the primary pollution discharging cavity and the secondary pollution discharging cavity are in mutually independent arrangement on the primary filtering mechanism; the primary pollution discharging cavity communicates with a filtering cavity of the primary filtering mechanism; a pollution suction mechanism communicating with the filtering cavity is arranged in the secondary pollution discharging cavity; a pollution discharging outlet is respectively formed in each of the primary pollution discharging cavity and the secondary pollution discharging cavity. The self cleaningprecise filter is provided with two mutually independent pollution discharging cavities on the filtering mechanism, so that most suspension matters and other particle impurities in sewage can be sequentially removed; the occurrence of filtering screen filtering conditions is greatly reduced; the filtering efficiency is improved; the self cleaning precise filter is applicable to the condition of existence of a great number of suspension matters or high filtering precision requirements.

Owner:成都飞创环保设备有限公司

High precision high flow rate micropore ceramic tube

The invention provides a high-precision low-flux micro-porous ceramic pipe which is made of two materials with obviously different filtration precision; the water inlet surface of the micro-porous ceramic pipe is provided with a thin filter layer which is made of the material with high filtration precision and other parts thereof are made of materials with extremely low filtration precision. The high-precision large-flux micro-porous ceramic pipe of the invention is mainly used for filtrating drinking water and also for filtrating similar sanitary liquid. Compared with the prior art, the high-precision low-flux micro-porous ceramic pipe has the advantages of thin filtering layer and small water filtration resistance, improves the flux of the filtration water without reducing the filtration precision, thus leading the filter equipments to be designed to have small volume and low cost.

Owner:黄瑞中

Garden water circulation using system and method

ActiveCN109653290ARelieve pressureReduce volumeSewerage structuresGeneral water supply conservationWater storageWater discharge

The invention relates to a garden water circulation using system. The garden water circulation using system comprises a water collecting tank and multiple water discharging channels, and further comprises a sub-collecting tank. The sub-collecting tank comprises a tank body buried in the underground. The tank body is internally provided with a separating plate. The upper part of the tank body is provided with an opening, and the edge of the opening is provided with a cover plate. The middle of the cover plate is provided with a through hole. The middle of the separating plate is provided with awater inlet hole. A connecting rod is installed in a filtering area. The upper end of the connecting rod is provided with a sealing plate, and the lower end of the connecting rod is provided with a reverse cone-shaped stopper. The lower end of the connecting rod is sheathed with an annular floating cylinder. A filter screen is further installed in the filtering area. The upper end of the filter screen is fixedly connected with the surface of the circumferential side of the floating cylinder, and the lower end is fixedly connected with separating plate. A height of the upper surface of the cover plate is aligned to the bottom of the water discharging channels in a covering state. While the side surface of the reverse cone-shaped stopper contacts with the inner wall of the water inlet hole,the sealing plate is positioned in the through hole and a gap exists between the sealing plate and the through hole. Safety is good, water circulation utilization is more convenient through distributed water storage, a pressure of the water discharging channels is reduced, so a volume of the water discharging channels can be reduced, and overflowing probability of the water discharging channels is reduced.

Owner:深圳市木雅园林股份有限公司

Solid-liquid separation method for Fischer-Tropsch synthetic wax

InactiveCN111991898AReduce lossIncrease lossLiquid hydrocarbon mixture productionFiltration separationWaxSlag

The invention relates to the field of Fischer-Tropsch synthesis wax filtration, and discloses a solid-liquid separation method for Fischer-Tropsch synthetic wax. The method comprises the steps of: (1)feeding raw material wax obtained by Fischer-Tropsch synthesis into a filter, and carrying out solid-liquid separation to obtain qualified wax with an iron content of not more than 10ppm; and (2) when the pressure difference between the inlet pressure and the outlet pressure of the filter reaches 0.6MPa or above, stopping feeding of the raw material wax, and conducting slag removal on the filter.The slag removal process comprises the steps of (2-1) emptying the raw material wax in the filter; (2-2) introducing inert gas into the emptied filter for back flushing; and (2-3) introducing the qualified wax into the filter for washing. The steps (1) and (2) are repeated, and the content of iron in the raw material wax is 10-1000ppm. The method is low in operation cost and good in filtering effect.

Owner:CHINA ENERGY GRP NINGXIA COAL IND CO LTD

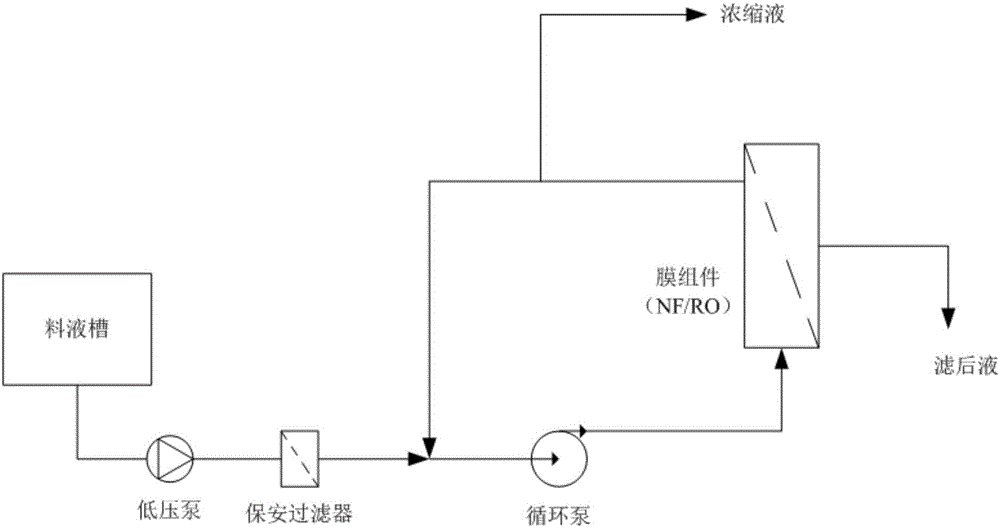

Concentration technology for producing lithium salt by sulfuric acid method

InactiveCN106006684AIncrease lithium ion contentImprove purityLithium carbonates/bicarbonatesLithium sulfates/sulfitesLithium sulphateEvaporation

The invention relates to a concentration process for the production of lithium salt by sulfuric acid method, which is used for concentration of lithium sulfate solution before the lithium sinking step, comprising the following steps: membrane concentration: using a concentration membrane with a pore size of 0.1-1nm to concentrate the lithium sulfate solution Membrane concentration is carried out to obtain lithium sulfate concentrate and permeate. The invention intercepts the lithium ions in the lithium sulfate solution through the concentration membrane, separates excess water, increases the total lithium ion content of the lithium sulfate solution, and achieves the purpose of concentration, and the separated permeate has a higher purity, It can continue to be recycled and applied to the leaching and extraction process of lithium sulfate solution; compared with the evaporation concentration in the prior art, the membrane concentration process adopted in the present invention has the advantages of low energy consumption, low production cost, high concentration efficiency, small processing difficulty, and environmental protection. The advantage of less pollution.

Owner:SICHUAN SIDANENG ENVIRONMENTAL PROTECTION TECH CO LTD

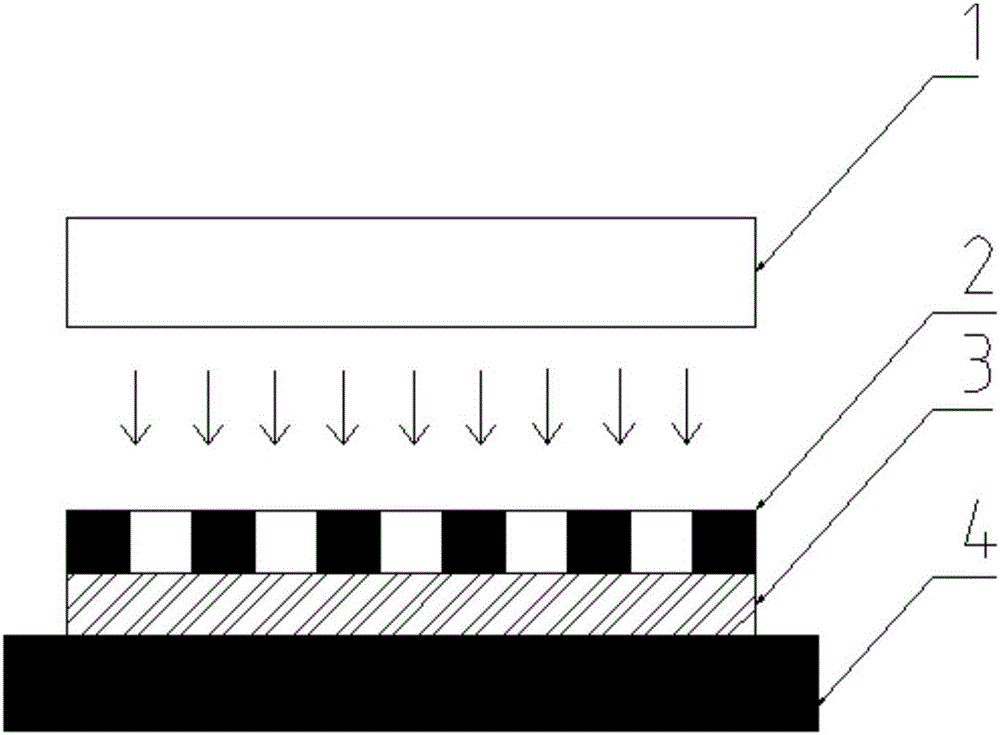

Ultraviolet imprint lithography fabricating method of micro-hole array cancer cell detecting chip

InactiveCN106115609AEasy to getPore size variesDecorative surface effectsPhotomechanical exposure apparatusMicro nanoCancer cell

The invention provides an ultraviolet imprint lithography fabricating method of micro-hole array cancer cell detecting chips and belongs to the micro-nano processing. The method adopts the technology of ultraviolet imprint lithography and fabricates micro-hole arrays on a polymer film material. The idea of the method lies in that a metal concealing layer is plated on a protruding part of a transparent moulage as a light shielding film; light shielding processing is performed in the case of ultraviolet imprint lithography so that the protruding part of the transparent moulage is not cured when other parts of the transparent moulage are cured into a hole wall structure; and a detecting chip is obtained after demolding and adhesive residue cleaning. With application of the chip, normal cells can be filtered out while cancerous cells in larger size can be blocked; and further, mature pathological analysis means in the prior art can be further utilized to discriminate cancer cells and types of cancer cells. Cancer detecting chips can be fabricated in batches with low cost by means of the method, providing an effective way to detection of early cancer.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

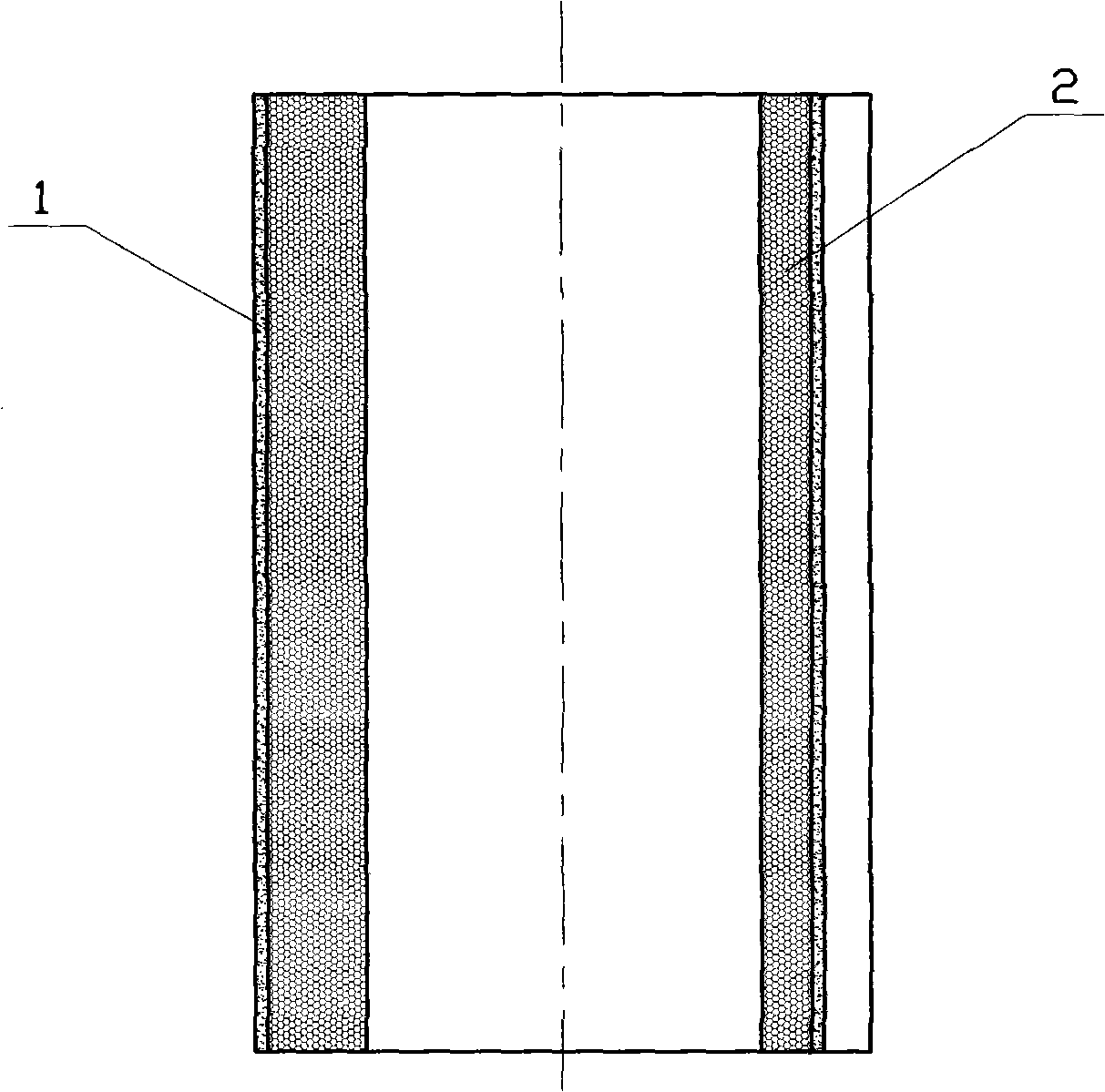

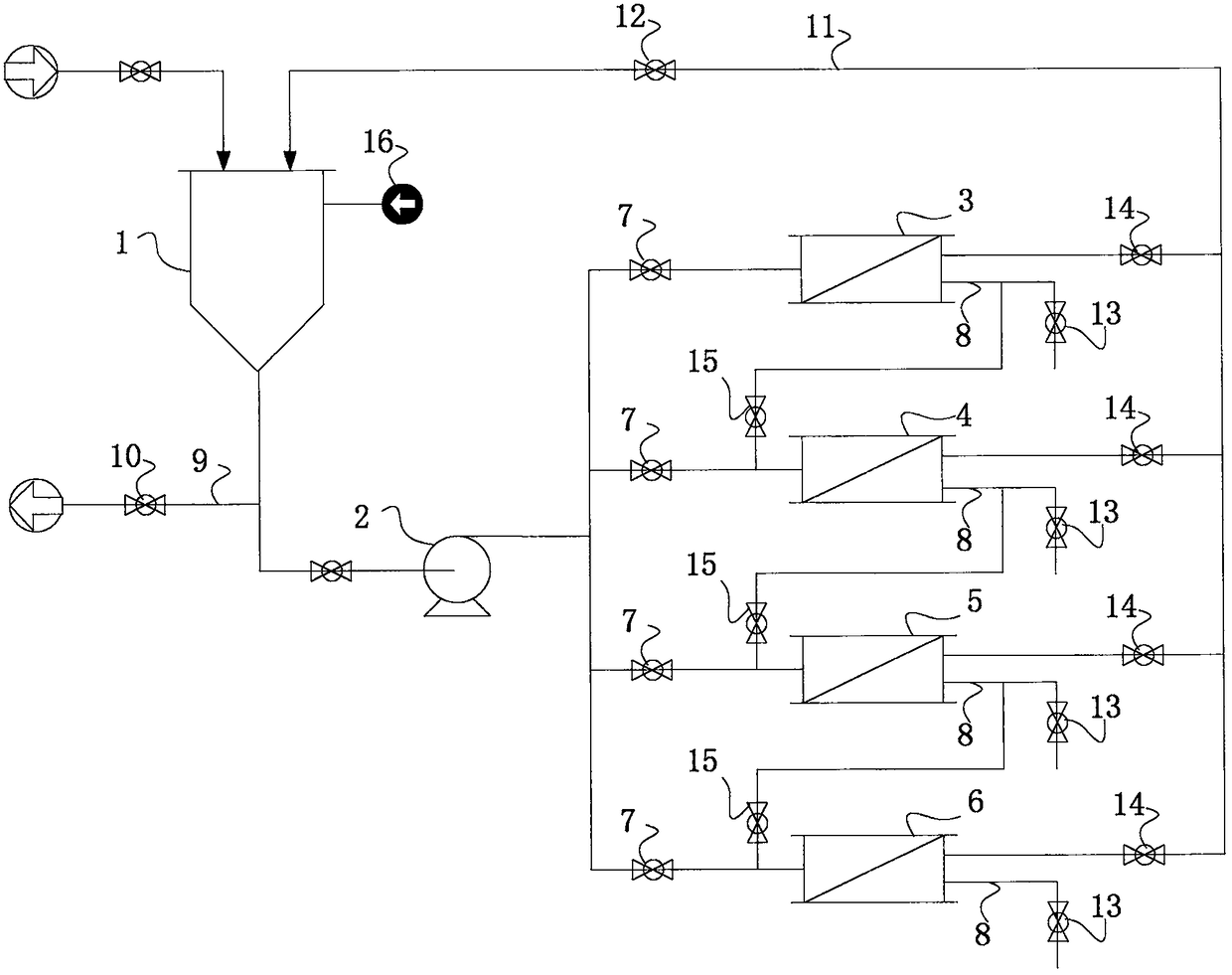

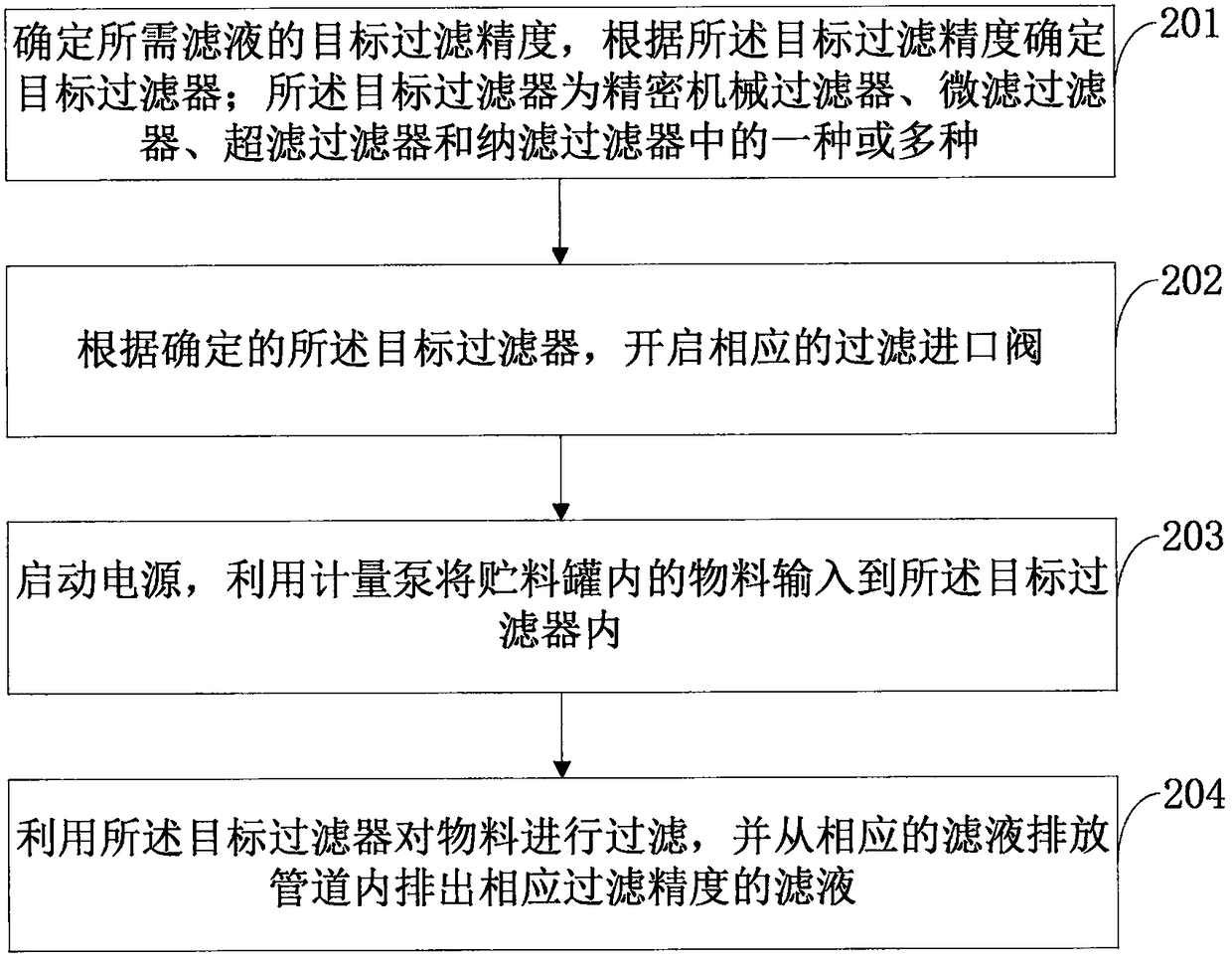

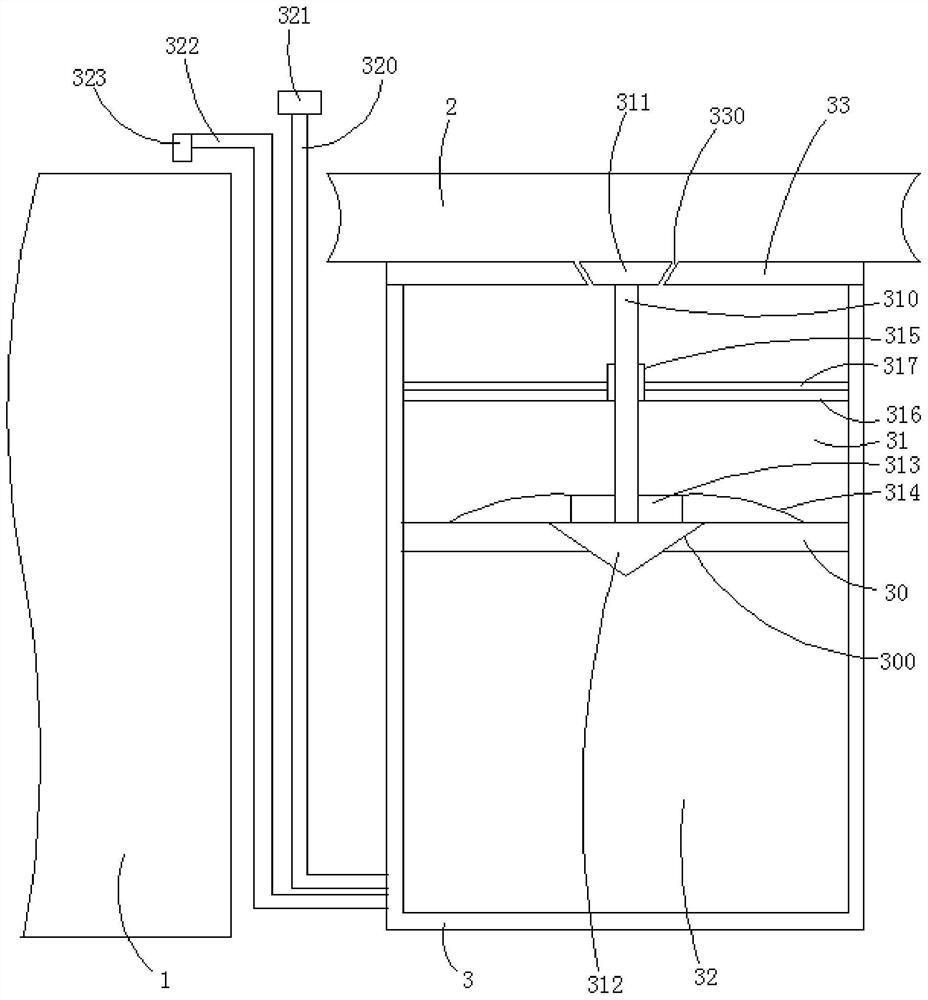

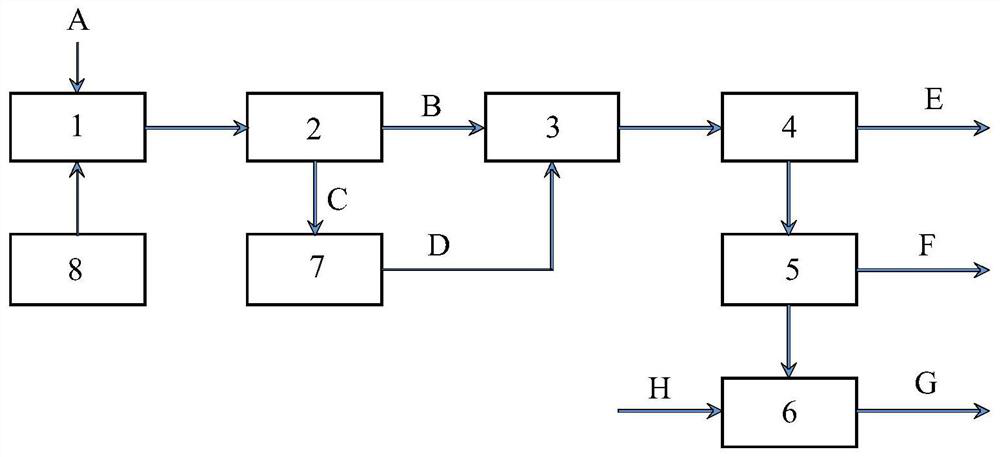

Integrated membrane separation and filtration method and device

PendingCN108097049ALow filtration accuracyImprove filtering effectUltrafiltrationReverse osmosisLiquid productFiltration

The invention relates to an integrated membrane separation and filtration method and device. The device includes: a power supply, a storage tank, a metering pump, a precision mechanical filter, a microfiltration filter, an ultrafiltration filter and a nanofiltration filter. Specifically, the power supply is connected to the metering pump; a discharge port of the storage tank is communicated with the inlet of the metering pump through a pipeline; the outlet of the metering pump is communicated with the inlets of the precision mechanical filter, the microfiltration filter, the ultrafiltration filter and the nanofiltration filter respectively through a pipeline, and the pipelines between the metering pump and the precision mechanical filter, the microfiltration filter, the ultrafiltration filter and the nanofiltration filter are respectively equipped with a filtration inlet valve; the precision mechanical filter, the microfiltration filter, the ultrafiltration filter and the nanofiltration filter are all equipped with a filtrate discharge pipeline; and the filtration precision of the precision mechanical filter, the microfiltration filter, the ultrafiltration filter and the nanofiltration filter decreases successively. The technical scheme adopted by the invention can realize acquisition of a plurality of liquid products of different filtration precision on the same equipment.

Owner:SHANXI QINGZE ENVIRONMENTAL SCI & TECH

Preparation method of porous film

ActiveCN106000123BControl pore structureHigh porositySemi-permeable membranesMembranesChemical reactionPore diameter

The invention discloses a preparation method of a porous film. The preparation method comprises the following steps: (1) acquiring a porous support body; (2) preparing a thick size containing raw material powder, a binder, a dispersant and a pore forming agent; (3) loading the size onto the porous support body, and drying to make a film billet; (4) sintering the film billet to make a porous film precursor; (5) removing the pore forming agent from the precursor to obtain a porous film with the thickness of 5-3,000 [mu]m, the average aperture of 0.05-100 [mu]m and the porosity of 40-90%. The preparation method has the following advantages: firstly, no chemical reaction occurs between the pore forming agent and the raw material powder, so that the ingredients of the porous film cannot be damaged; secondly, the pore forming agent is excellent in thermal stability and always occupies a certain space (place) in the sintering process; after sintering, the pore forming agent is removed, holes or pores are generated in situ; therefore, the whole technological process is simple, the hole structure of the porous film is easy to control, and the porosity is remarkably improved.

Owner:CHENGDU INTERMENT TECH

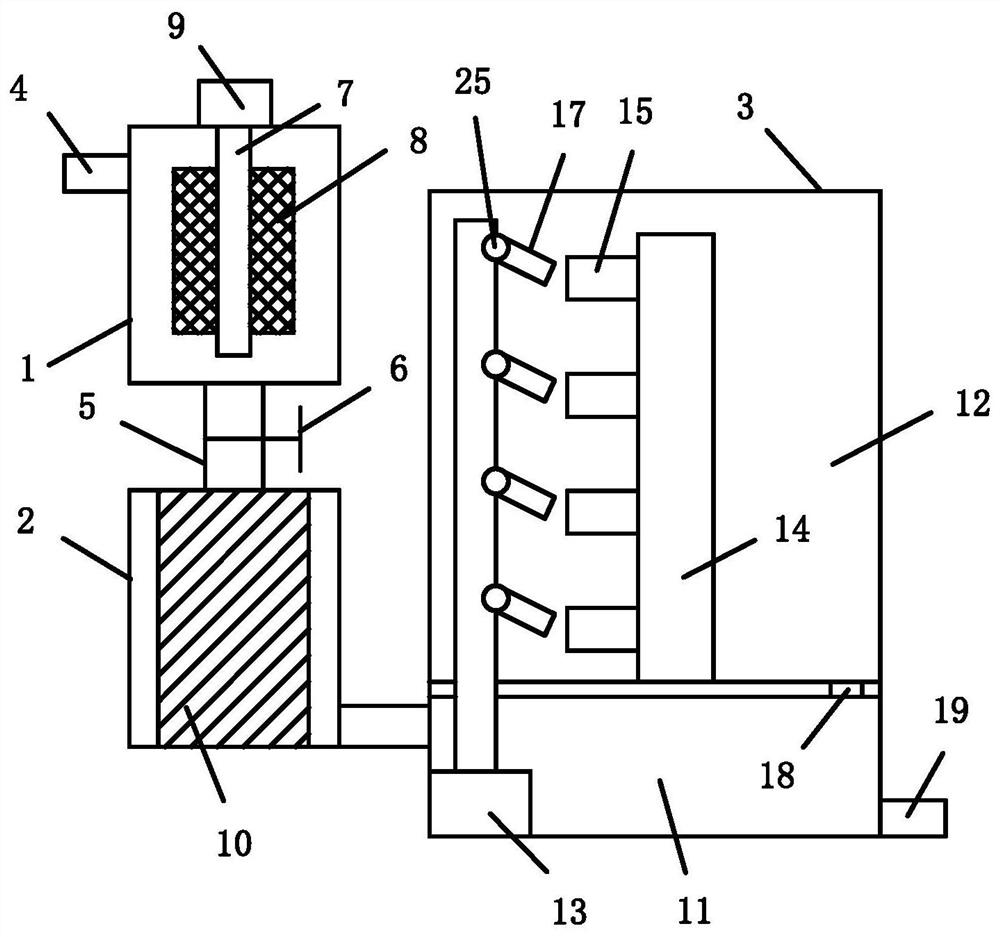

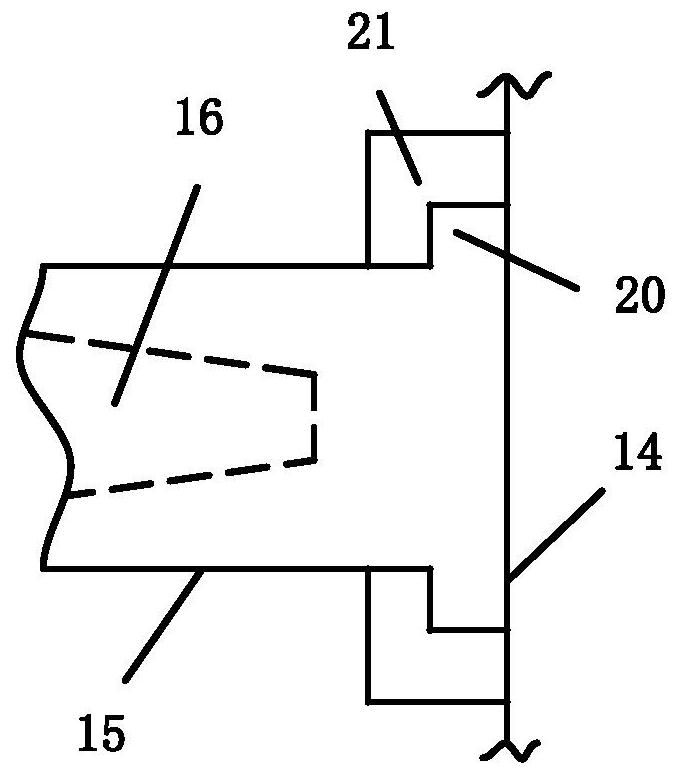

Collecting and filtering device for microorganisms in water sample

PendingCN112795467AIncrease usageEfficient collection and filtrationApparatus sterilizationBiological material testing proceduresElectric machineryRotational axis

The invention discloses a collecting and filtering device for microorganisms in a water sample. The collecting and filtering device comprises a primary filtering cylinder, a fine filtering cylinder and a collecting and filtering cylinder which are sequentially connected in series. The primary filtering cylinder is connected with a water inlet pipe, the bottom of the primary filtering cylinder is connected to the top of the fine filtering cylinder through a connecting pipe, and a switch valve is mounted on the connecting pipe; a rotating shaft is mounted in the primary filtering cylinder, a plurality of metal wire meshes are mounted on the rotating shaft, the rotating shaft is connected with a motor, and a PP cotton filter element is mounted in the fine filtering cylinder; a water storage tank and a filter tank are arranged in the collecting and filtering cylinder, the water storage tank is connected with the fine filtering cylinder, a submersible pump is mounted in the water storage tank, a mounting rack is fixed in the filter tank, a plurality of mutually parallel slots are connected to the mounting rack, filter discs are inserted into the slots, nozzles in one-to-one correspondence with the slots are connected to the mounting rack, and a back-flow hole communicated with the water storage tank is formed in the bottom of the filter tank. The defects in the prior art can be overcome, and the service life of the filter disc is prolonged while the microorganism collection and enrichment efficiency is guaranteed.

Owner:史欢欢 +2

Wound filter element and application thereof

InactiveCN102100987BGood chemical resistanceGood resistance to steam and heatGravity filtersYarnFiltration

The invention discloses a wound filter element and application thereof. The wound filter element comprises a porous aggregate and a rough yarn wound on the porous aggregate, wherein the rough yarn contains polyphenylene sulfide fibre, has a coefficient of twist of 180-280, has excellent bulkiness and better filtering property, and can not be excessively drafted during the winding. The wound filter element disclosed by the invention has the characteristics of small pressure loss, high filtering accuracy, and excellent steaming resistance and chemical properties, and can be applied to the field of filtration of various kinds of high-temperature liquids.

Owner:TORAY IND INC

Filter device

InactiveCN102665850BLow efficiencyImprove efficiencyMembrane filtersStationary filtering element filtersEngineeringFilter element

The invention relates to a filter device, in particular for fluids such as hydraulic oil, lubricating media, processing, surface or sea water, having at least one filter element (3) that has at least one effective filter surface (23), which is suitable for removing contaminants from a media flow crossing the filter surface, wherein an effective filter surface is designed as a flexible filter sock (23) that can be pulled onto a support body (13) of the filter element (3). The invention is characterized in that the filter sock (23), while enlarging the effective filter surface thereof, is designed to be longer in the axial direction of the filter element (3) such that the effective filter surface lies in folds upon pulling the filter sock (23) over the support body (13).

Owner:HYDAC PROCESS TECH

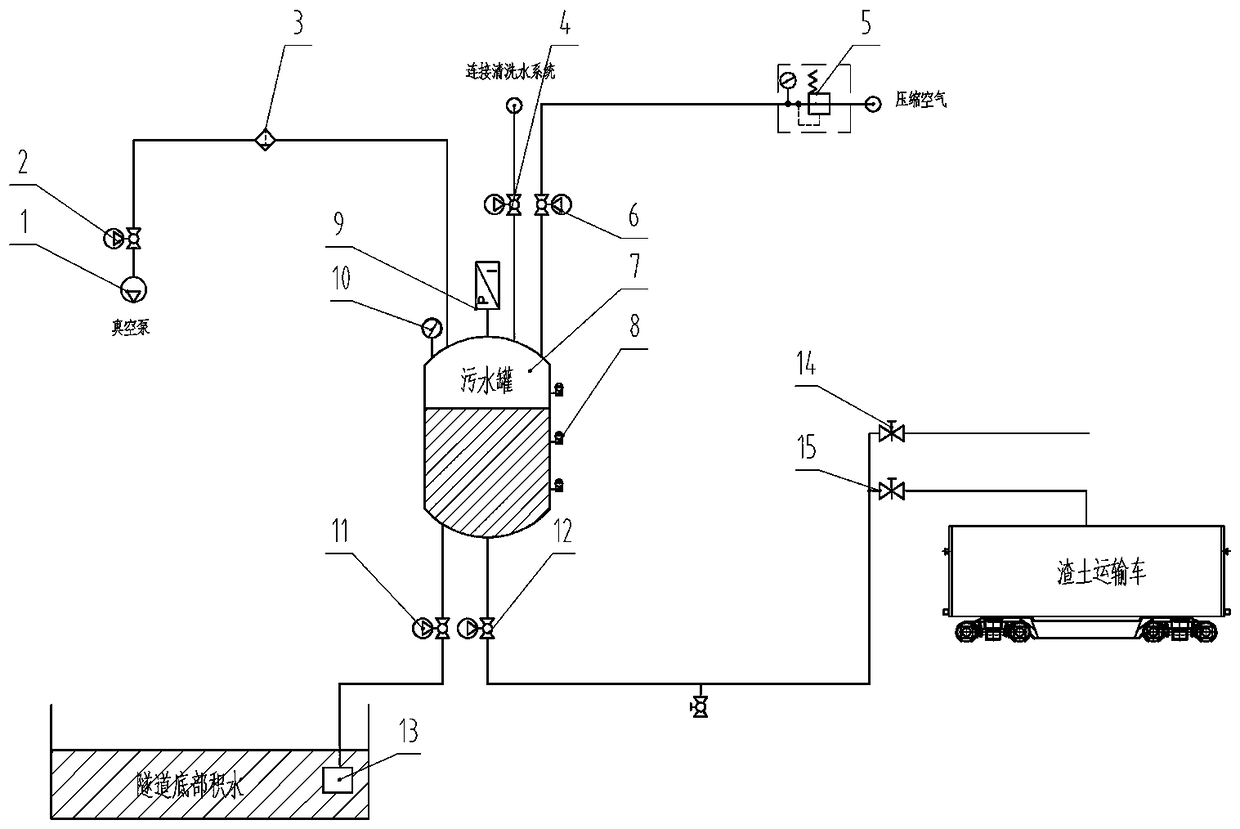

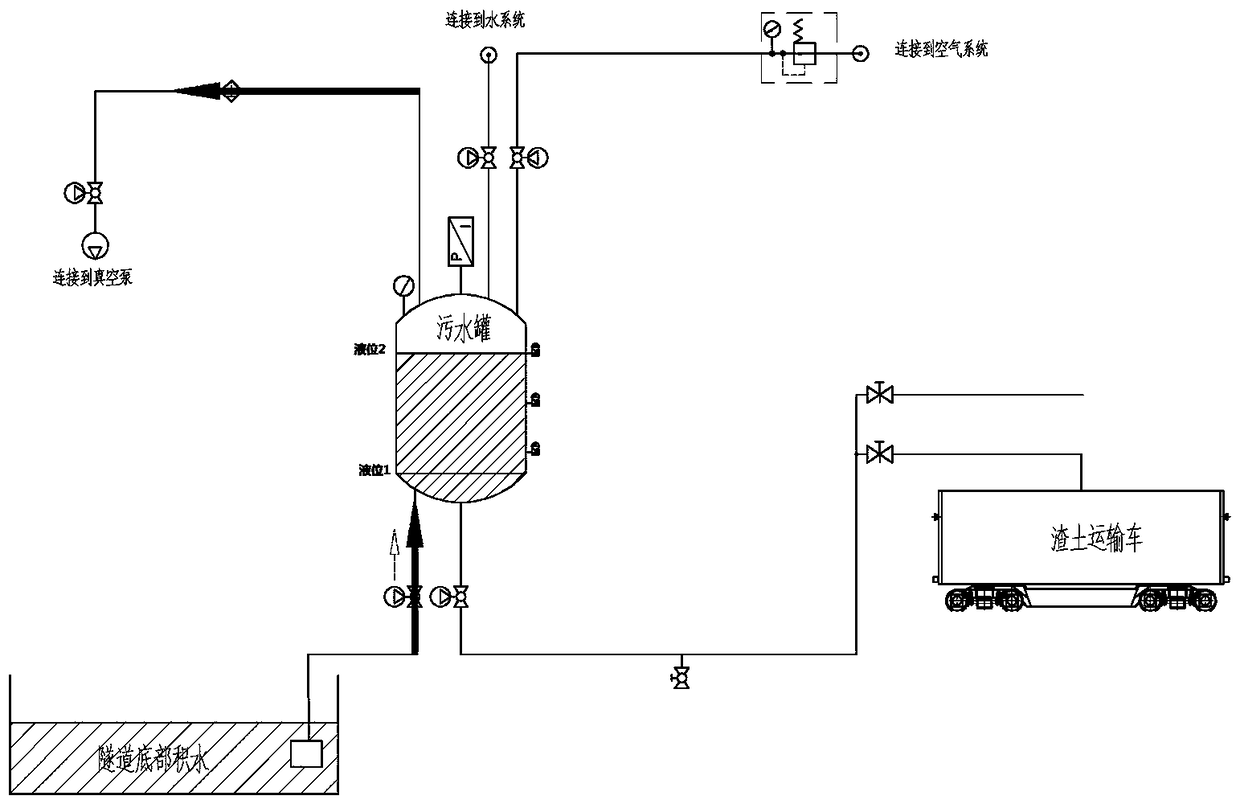

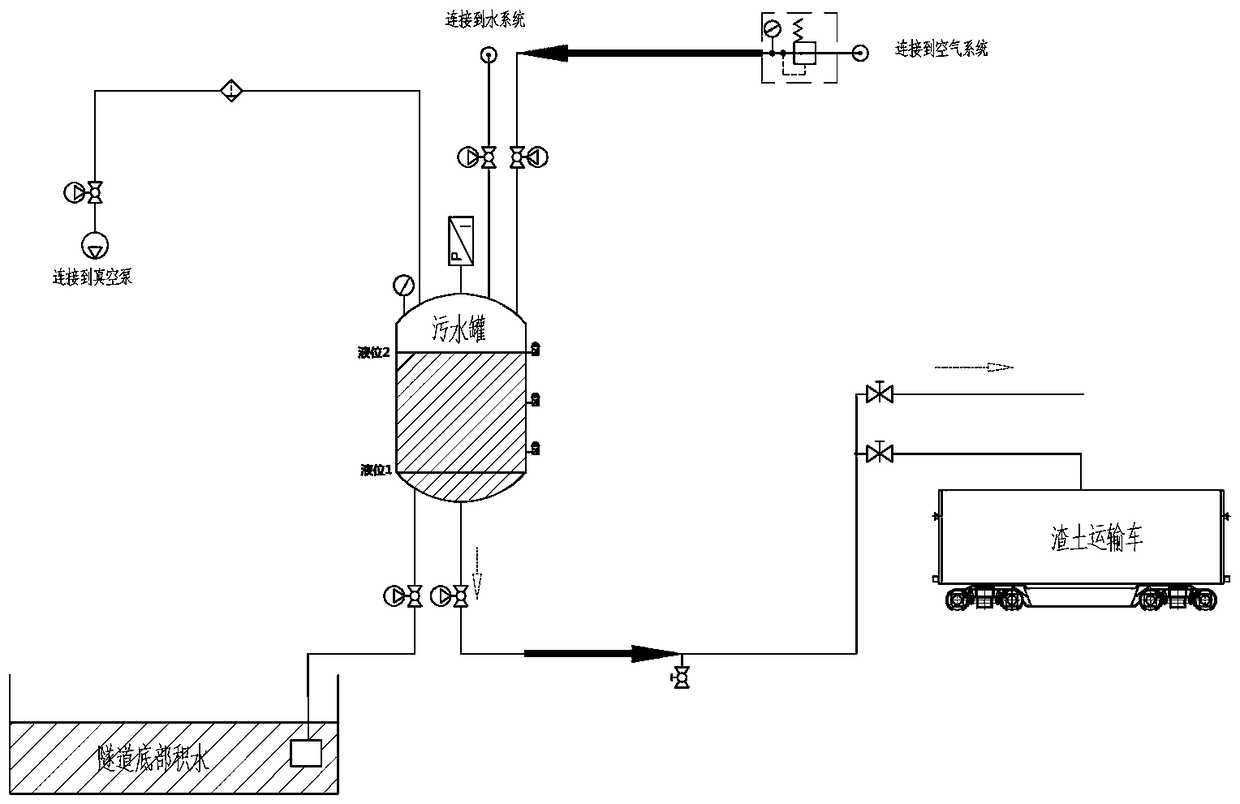

Tunnel vacuum sewage discharge system and sewage discharge method

PendingCN108589879AImprove dirt absorption capacityReduce lossSewage drainingSewer pipelinesControl systemControl valves

The invention relates to the technical field of engineering construction, in particular to a tunnel vacuum sewage discharge system and a sewage discharge method. The system comprises a suction mechanism and a sewage discharge mechanism, the sewage discharge mechanism comprises a sewage discharge tank and a pressure regulating pipeline, a vacuum port is formed in a sewage tank, and a sewage inlet and a sewage discharge port are formed in the bottom of the sewage discharge tank; the suction mechanism comprises a sewage filtering device disposed at a water accumulated position of a tunnel and a vacuum pump connected to the vacuum port through the vacuum pipeline, the sewage filtering device is communicated with the sewage inlet through a sewage treatment pipeline, a vacuum regulating valve isarranged on the vacuum pipeline, and a sewage control valve is arranged on the sewage treatment pipeline; the sewage discharge port is connected to a muck transport vehicle or an external sewage discharge pipeline through the sewage discharge pipeline, and the sewage discharge pipeline is provided with the sewage discharge valve. The system has novel and reasonable design and strong sewage absorption ability, automatically discharges sewage under the participation of a control system, reduces the loss of consumable parts, achieves rapid sewage discharge, and improves construction efficiency.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

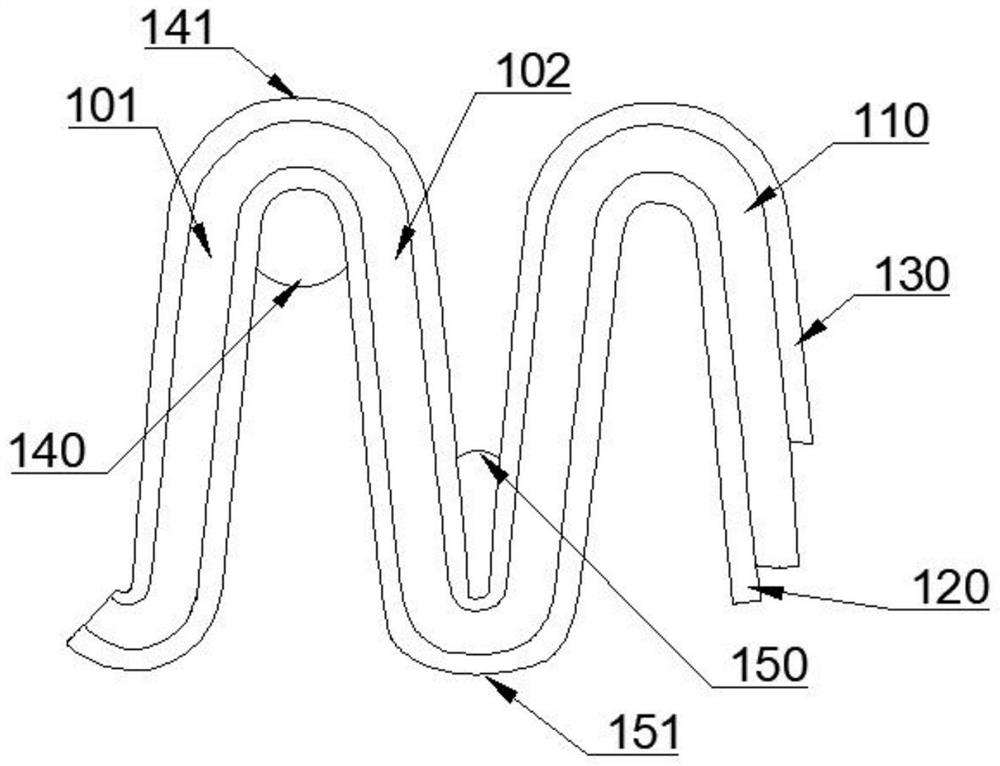

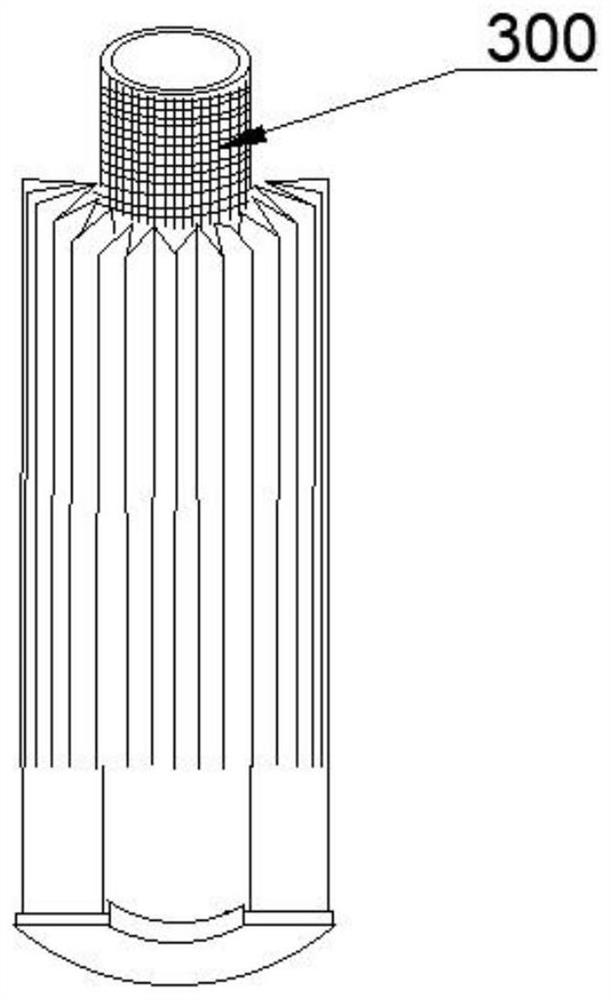

Folding natural gas filter element

PendingCN114733282AHigh filtration precisionFiltration accuracy high to lowDispersed particle filtrationLayered productsMechanical engineeringMechanics

The folding type natural gas filter element is provided with a first axis, and the filter element comprises a plurality of folding units which are distributed around the first axis and are integrally formed; the folding unit comprises a first filtering layer; the second filter layer is formed on the first filter layer and is relatively close to the first axis side; the third filter layer is formed on the first filter layer and is relatively far away from the first axis side; in a non-filtering state, the second filtering layer and the third filtering layer can maintain that a first included angle with an opening facing the first axis is formed on one side, relatively close to the first axis, in each folding unit; a second included angle with an opening far away from the first axis is formed between every two adjacent folding units; in a filtering state, the second filtering layer and the third filtering layer can maintain the first included angle within a first preset range, and can maintain the second included angle within a second preset range. The folding type natural gas filter element has the advantages of being high in structural strength, not prone to deformation and capable of preventing non-uniform flow of the filter element due to natural gas extrusion.

Owner:廊坊坤合过滤器材有限公司

A garden water recycling system and method

ActiveCN109653290BRelieve pressureReduce volumeSewerage structuresGeneral water supply conservationWater storageEnvironmental engineering

The invention relates to a garden water recycling system, which includes a collection tank and a plurality of drainage ditches; it also includes a sub-collection tank; the sub-collection tank includes a tank body buried in the ground, and a partition is arranged in the tank body; the upper part of the tank body is open, and the edge of the opening is provided with a Cover plate; the middle part of the cover plate is provided with a through hole; the middle part of the partition is provided with a water inlet hole; An annular buoy; a filter screen is also provided in the filter area; the upper end of the filter screen is fixedly connected to the peripheral surface of the buoy, and the lower end is fixedly connected to the partition; the height of the upper surface of the cover plate is flush with the bottom of the drainage ditch when it is closed; When the side surface of the tapered plug is attached to the inner wall of the water inlet hole, the sealing plate is located in the through hole and there is a gap with the through hole; the safety is good, and the distributed water storage makes water recycling more convenient, reduces the pressure of the drainage ditch, and makes the drainage ditch Volume can be reduced while reducing the chance of gutter overflow.

Owner:深圳市木雅园林股份有限公司

Method for treating polymethoxydialkyl ether production wastewater

ActiveCN111978152ALow filtration accuracyLow costWater contaminantsTreatment involving filtrationFlocculationDistillation

The invention discloses a method for treating polymethoxydialkyl ether production wastewater. The method comprises the following steps: step 1, putting the polymethoxydialkyl ether production wastewater in a flocculation reactor, and adding a flocculant for flocculation reaction; step 2, leaving a material after the flocculation reaction to stand for separation to obtain a supernatant and a precipitate; step 3, carrying out filter-pressing treatment on the precipitate, and mixing an obtained supernatant with the supernatant obtained in the step 2 for filtration; step 4, enabling a clear liquid obtained after filtration in the step 2 to enter an alcohol distillation recovery tower for rectification separation, obtaining an alcohol product from the top of the alcohol distillation recovery tower, and obtain an aldehyde aqueous solution from the bottom of the tower; enabling the aldehyde aqueous solution to enter the aldehyde distillation recovery tower for distillation separation, and obtaining a concentrated aldehyde solution from the top of the aldehyde rectification recovery tower; and step 5, obtaining wastewater from the bottom of the aldehyde rectification recovery tower, and adding inorganic alkali for saccharification reaction treatment. The method can effectively treat suspended solids in the wastewater, recover alcohol and aldehydes, and reduce raw material consumption.

Owner:SICHUAN DAXING ENERGY +2

A device and method for purifying oil and gas in a deep-sea confined space

ActiveCN110420526BImprove purification efficiencyExtend your lifeCombination devicesAuxillary pretreatmentImpellerFiltration

The invention discloses an oil gas purification device used in a deep-sea confined space, which comprises a condensation nucleation generating device, an oil and gas suction device, an oil gas condensing device, a centrifugal separation device, an oil collection tank and a filtering and purification device. The condensation nucleation generating device includes a first Water pipe, first heater, atomizer, air compressor and dryer; oil and gas suction device includes oil and gas inlet pipe, second heater and fan; oil and gas condensing device includes second water inlet pipe, shell and tube condenser and outlet water pipe; the oil collection tank is arranged under the housing; the centrifugal separation device includes a driving motor and a centrifugal impeller; the inlet of the filtering and purifying device is connected to the outlet on the side wall of the housing, and the outlets of the filtering and purifying device are respectively connected to Air pipe and air compressor inlet. The invention can improve the oil and gas purification efficiency, better improve the air quality in the deep-sea confined space, save energy, reduce noise, increase the service life of the system, and reduce the use cost of the system.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Porous film and its preparation method

ActiveCN105854633BImprove uniformityLow filtration accuracyMembranesSemi-permeable membranesSlurryMetal

The invention discloses a porous film which comprises a filtering layer and a porous support, wherein the filtering layer is composed of dendritic metal substance powder and / or metal substance oxide powder. A preparation method for the porous film comprises the following steps: 1) acquiring the raw material powder and the porous support, wherein the raw material powder is the dendritic metal substance powder and / or the metal substance oxide powder; 2) preparing slurry; 3) loading the slurry on the surface of the porous support, drying and preparing into a film blank; 4) sintering the film blank and cooling, thereby acquiring the porous film. Firstly, the dendritic metal substance powder is stacked and formed into the pores of the porous film, the complex hole-forming process is avoided and the porosity is high and is easy to control; the filtering layer composed of the dendritic metal substance powder and / or the metal substance oxide powder is stable in physico-chemical property, long in service life and free from mutual reaction; the complex phase-forming process is avoided; the component of the porous film is easy to control.

Owner:CHENGDU INTERMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com