Hot-piercing manufacturing method of micro-via array biological chip

A technology of biochip and manufacturing method, which is applied in the direction of bioparticle analysis, chemical instruments and methods, and laboratory containers, etc., which can solve the problem of poor accuracy and speed of cancer cell morphology, inability to identify white blood cells, and greater influence on operators and other issues, to achieve the effect of low environmental requirements, controllable operation, low production process and raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

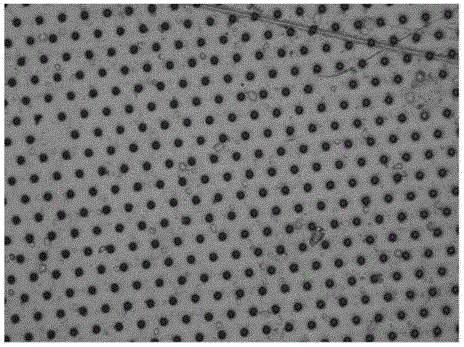

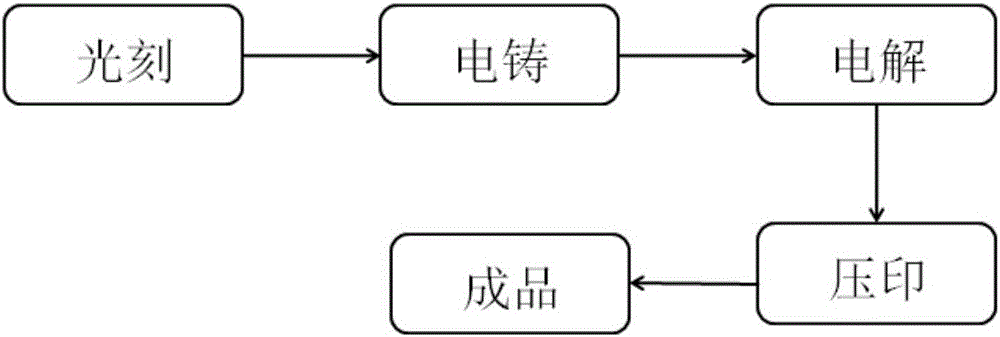

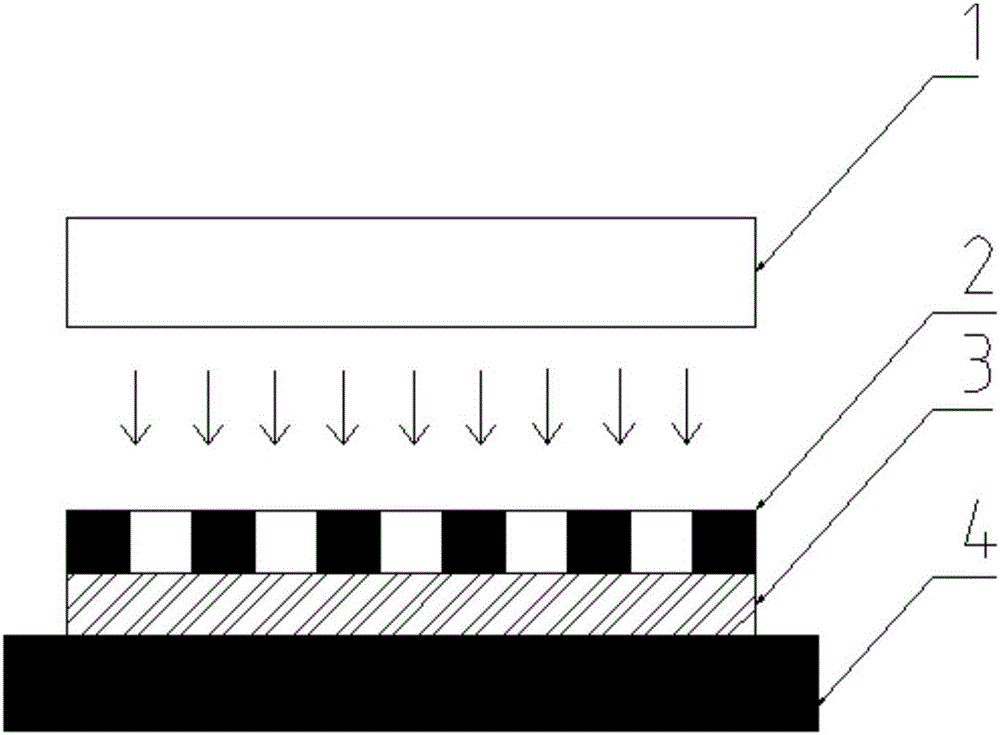

[0036] (1) The schematic diagram of the photolithography process is as follows: figure 2 As shown, the photoresist 3 is spin-coated on the quartz substrate 4, the photoresist 3 is AZ4562, the thickness of the glue is 30um, and it is baked on a hot plate at 100 degrees for 10min, and the mask plate 2 is placed on the photoresist, and the mask plate 2 The graphic is an array of microporous graphics, the micropores are circular, the pore diameter is 4um, and the ratio of the pore diameter to the gap size between the pores is 1:4. Then, it is exposed under a 365nm ultraviolet light source 1 by a contact exposure method, the exposure dose is 100mJ / cm, and it is developed for 40s, that is, the mask pattern is copied into a photoresist pattern 5 . The schematic diagram of the structure after photolithography development is as follows: image 3 shown.

[0037] (2) Configure silver ammonia solution and reducing agent solution required for chemical immersion silver. The configuratio...

Embodiment 2

[0041] (1) The schematic diagram of the photolithography process is as follows: figure 2 As shown, the photoresist 3 is spin-coated on the quartz substrate 4, the photoresist 3 is AZ50XT, the thickness of the glue is 20um, it is baked on a hot plate at 100 degrees for 10min, and the mask plate 2 is placed on the photoresist, and the mask plate 2 The pattern is an array of microporous graphics, the micropores are regular hexagons, the pore diameter is 10um, and the ratio of the pore diameter to the gap size between the pores is 1:10. Then, it is exposed under a 365nm ultraviolet light source 1 by a contact exposure method, the exposure dose is 100mJ / cm, and it is developed for 40s, that is, the mask pattern is copied into a photoresist pattern 5 . The schematic diagram of the structure after photolithography development is as follows: image 3 shown.

[0042] (2) Configure silver ammonia solution and reducing agent solution required for chemical immersion silver. The config...

Embodiment 3

[0046] (1) The schematic diagram of the photolithography process is as follows: figure 2 As shown, the photoresist 3 is spin-coated on the quartz substrate 4, the photoresist 3 is AZ50XT, the thickness of the glue is 30um, it is baked on the hot plate at 100 degrees for 10min, and the mask plate 2 is placed on the photoresist, and the mask plate 2 The graphic is an array of microporous graphics, the micropores are square, the pore diameter is 15um, and the ratio of the pore diameter to the gap size between the pores is 1:3. Then, it is exposed under a 365nm ultraviolet light source 1 by a contact exposure method, the exposure dose is 100mJ / cm, and it is developed for 40s, that is, the mask pattern is copied into a photoresist pattern 5 . The schematic diagram of the structure after photolithography development is as follows: image 3 shown.

[0047] (2) Configure silver ammonia solution and reducing agent solution required for chemical immersion silver. The configuration m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com