Animal charcoal for efficiently fixing heavy metals and preparation method and application thereof

A technology of animal charcoal and heavy metals, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the complex process of roasting or carbonization, and the meat, tissue or glue of animals is not well utilized, and there is no Advantages and other issues, to achieve the effect of reducing potential contamination risk, preventing the spread of bacteria and viruses, and good fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

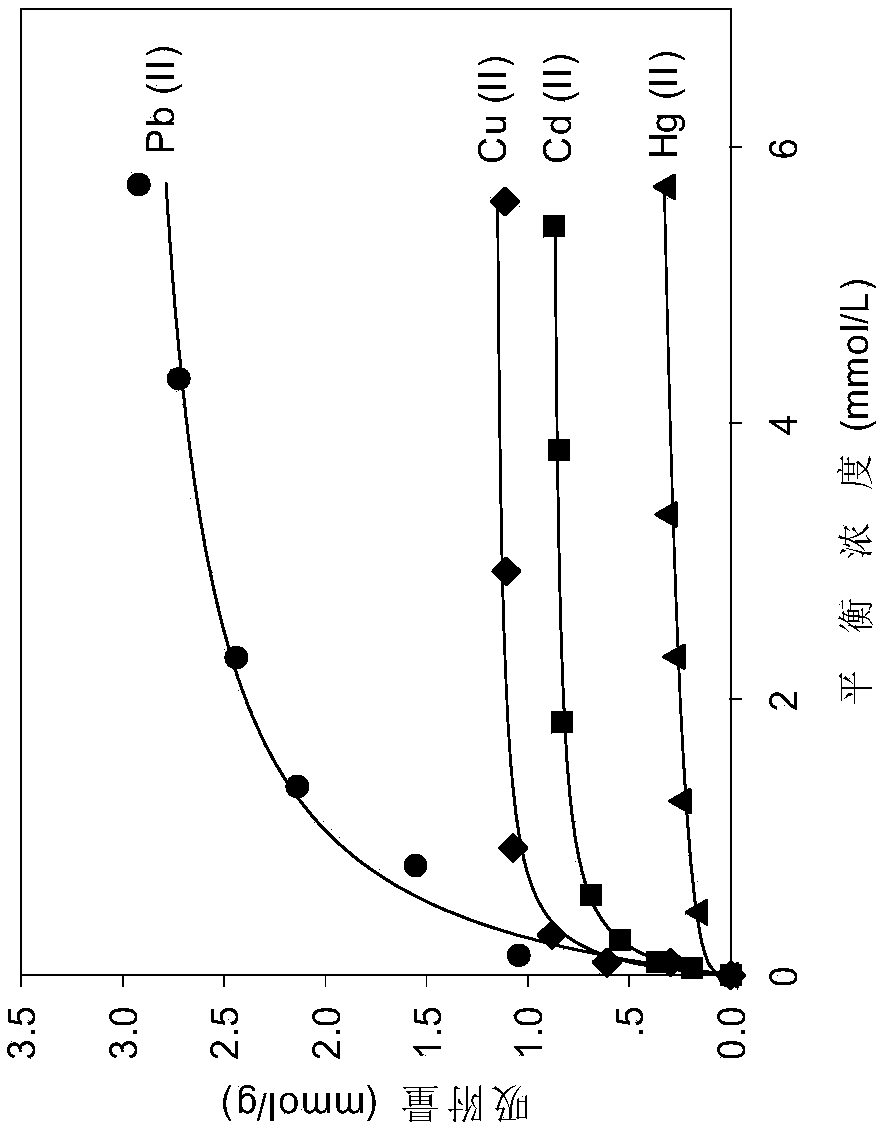

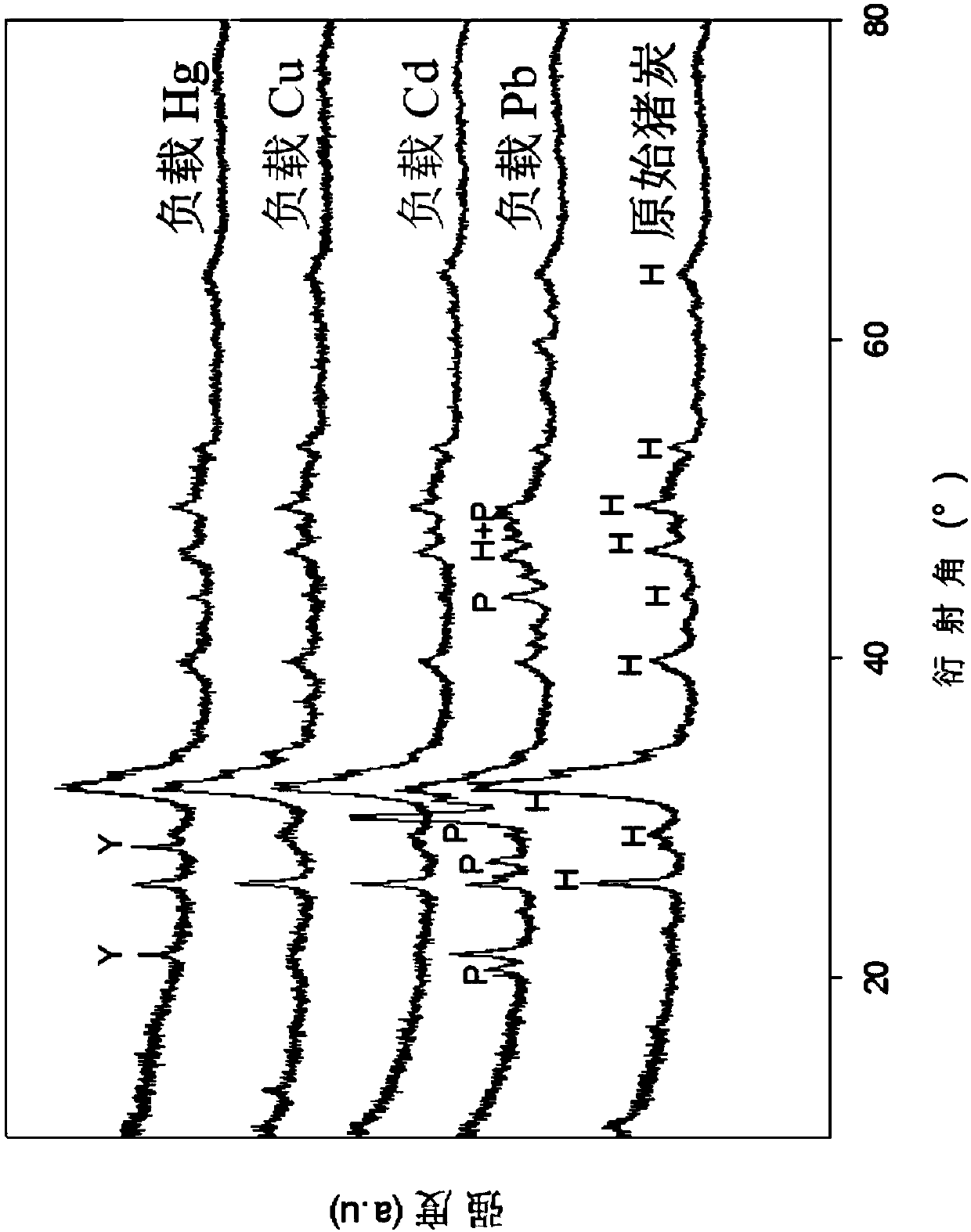

[0042] Immobilization of Pb(II), Cd(II), Cu(II) and Hg(II) by porcine charcoal

[0043] The whole frozen pig carcass was placed in a pyrolysis furnace for anoxic pyrolysis, and the pyrolysis temperature was kept higher than 450° C. and the pyrolysis time was 6 hours to obtain pig charcoal.

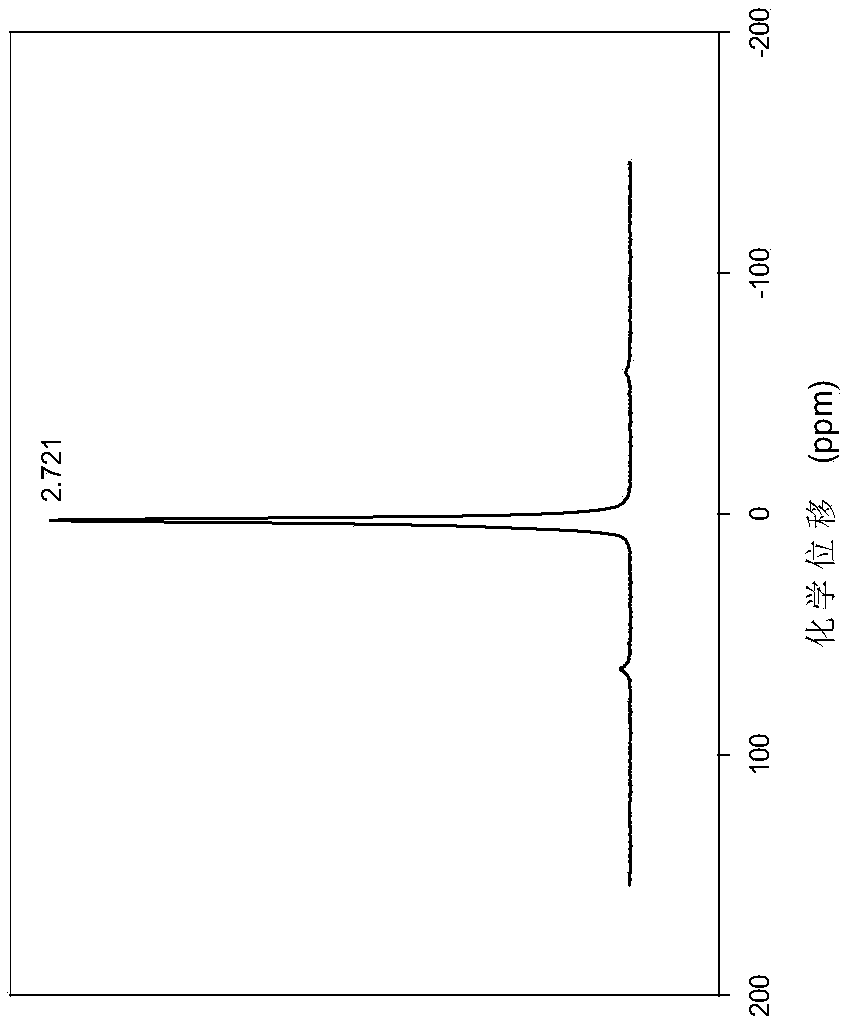

[0044] The basic physical and chemical properties of pig charcoal are shown in Table 1. The results of solid phosphorus NMR showed that phosphorus in pig charcoal mainly existed in the form of calcium hydroxyphosphate. See figure 1 .

[0045] Table 1: Physical and chemical properties of pig charcoal

[0046]

[0047] Accurately weigh 100mg pig charcoal in a 50mL conical flask, add 20mL 0-10mmol / L heavy metal solution (10mmol / L NaNO 3 As the background solution), adjust the pH of the solution to 5.5. Shake the shaker at a rate of 180 rpm for 24 hours at 25 °C. After standing, take the supernatant, pass through a 0.22 μm filter membrane, measure the concentration of heavy metals, and ...

Embodiment 2

[0053] Immobilization of Pb(II), Cd(II), Cu(II) and Hg(II) by bovine charcoal

[0054] The whole frozen whole cow carcass is placed in a pyrolysis furnace for anoxic pyrolysis, the pyrolysis temperature is kept greater than 450° C., and the pyrolysis time is 6 hours to obtain cattle charcoal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com