Oil product purification membrane filtration system and use process thereof

A filtration system and purification membrane technology, applied in filtration loop, filtration separation, membrane technology and other directions, can solve the problems of high disposal cost, low operation efficiency, poor oil quality, etc. low impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

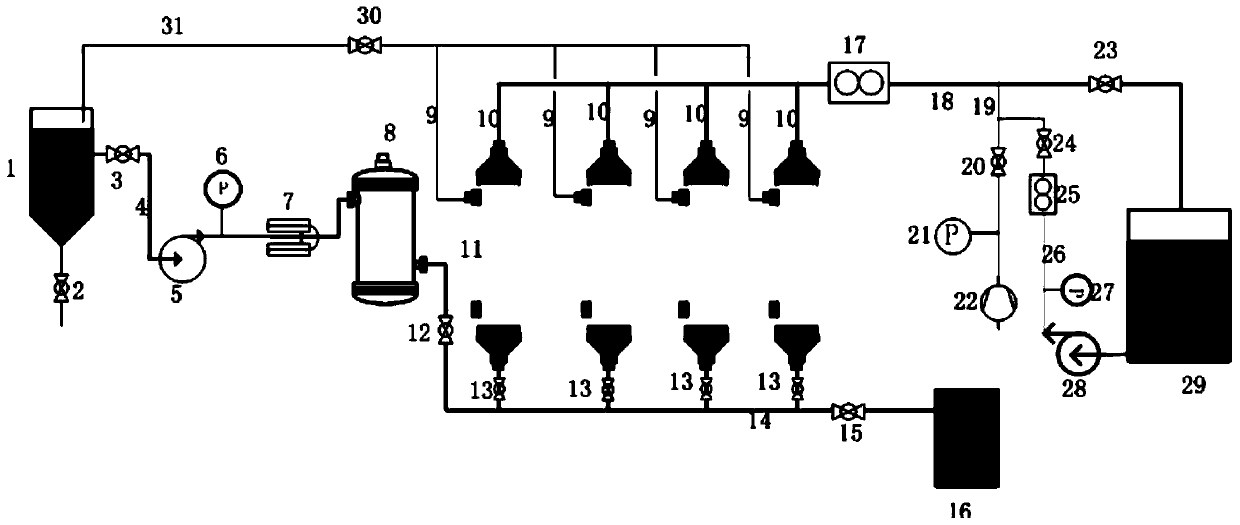

Method used

Image

Examples

specific Embodiment 1

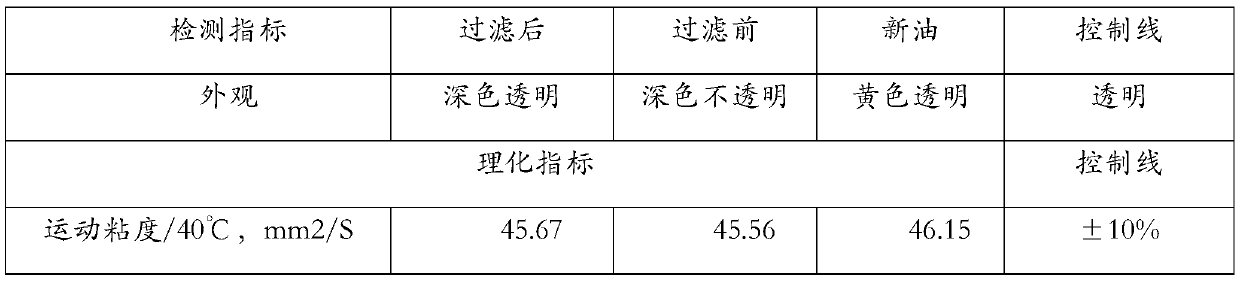

[0044] Specific embodiment 1: An air switch factory of Tianjin State Grid: processing capacity: 3 tons; Table 1 is the performance comparison of new oil, filtrate and polluted lubricating oil.

[0045] Table 1

[0046]

[0047]

[0048] It can be seen from Table 1 that the physical and chemical properties of the samples before and after filtration are all within the normal range compared with the new oil. The cleanliness of the sample after membrane filtration is significantly improved, especially the number of small particles (intermittent size particles) that have a greater impact on the hydraulic system is significantly reduced. And it is much better than the new oil sample, which can significantly reduce the wear rate of parts. The additive content remained constant after filtration, indicating that the filtration did not affect the additive.

specific Embodiment 2

[0049] Specific example 2: a waste oil factory in Dongli District, Tianjin: equipment processing capacity: 1 ton / day; treatment oil product: waste cleaning oil, table 2 shows the comparison of feed liquid performance indicators before and after membrane filtration

[0050] Table 2

[0051]

[0052]

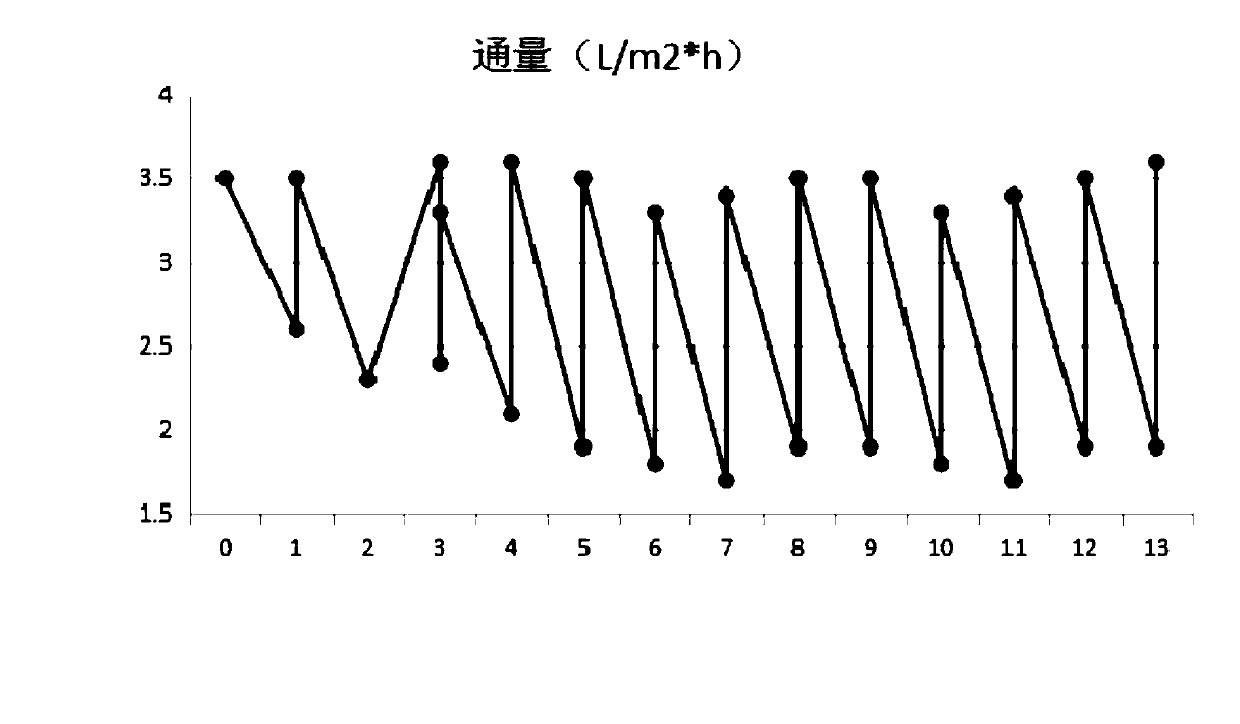

[0053] Table 2 shows that the oil purification membrane system is very effective in filtering waste oil. After membrane filtration, the particle size and moisture are significantly reduced, the particle size is increased to NAS6 level, and the moisture is reduced from 1100ppm to below 100ppm. figure 2 The diagram of the change of membrane flux is shown; the membrane filtration system is cleaned once a day by gas backwashing. After cleaning, the membrane flux has a good recovery effect and basically returns to the initial flux.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com