Industrial filter cloth, and production method and use thereof

A production method and filter cloth technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems such as surface hairiness, low strength of nonwoven fabrics, large average pore size, etc., and achieve high interception accuracy and low production cost The effect of low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

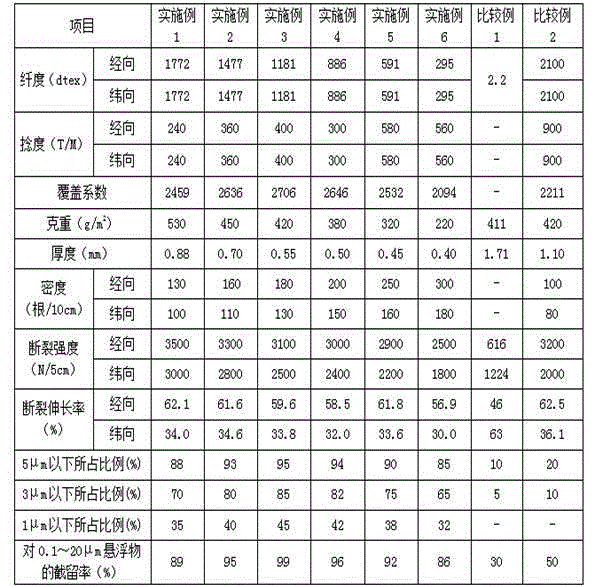

[0031] Using polyphenylene sulfide yarns with warp and weft deniers of 1772 dtex and twist of 240T / M to weave on a heavy arrow shaft loom to produce a plain weave fabric with a warp yarn density of 130 yarns / 10cm and a weft yarn density of 100 yarns / 10cm , and then the above-mentioned plain weave fabric is refined at a temperature of 90°C and a speed of 30m / min, then cylinder-dried at a temperature of 150°C, and finally dried at a temperature of 190°C, a pressure of 5MPa, and a speed of 5m / min. The PPS woven fabric was calendered to obtain a filter cloth with a coverage factor of 2459. The measured porosity of the filter cloth accounted for 88% of the pores with a pore diameter below 5 μm. The physical properties of the industrial filter cloth of the present invention are shown in Table 1.

Embodiment 2

[0033] The polyphenylene sulfide yarns with warp and weft yarn deniers of 1477dtex and twist of 360T / M are woven on a projectile loom to obtain a plain weave fabric with a warp density of 160 / 10cm and a weft density of 110 / 10cm. Refining the above-mentioned plain weave fabric at a temperature of 95°C and a speed of 40m / min, then performing cylinder drying at a temperature of 130°C, and finally drying the dried fabric at a temperature of 200°C, a pressure of 6MPa, and a speed of 6m / min The PPS woven fabric was calendered to obtain a filter cloth with a coverage factor of 2636, and the measured porosity of the filter cloth accounted for 93% of the pores with a diameter below 5 μm. The physical properties of the industrial filter cloth of the present invention are shown in Table 1.

Embodiment 3

[0035] The polyphenylene sulfide yarn with a warp and weft density of 1181dtex and a twist of 400T / M is used for weaving on a heavy arrow shaft loom to obtain a plain weave fabric with a warp density of 180 / 10cm and a weft density of 130 / 10cm , then the above-mentioned plain weave fabric is refined at a temperature of 98°C and a speed of 40m / min, then cylinder-dried at a temperature of 140°C, and finally dried at a temperature of 210°C, a pressure of 4MPa, and a speed of 5m / min. The final PPS woven fabric was calendered to obtain a filter cloth with a coverage factor of 2706. The porosity of the filter cloth was measured to account for 95% of the pores with a pore diameter below 5 μm. The physical properties of the industrial filter cloth of the present invention are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com