Filter device

A filter device and filter surface technology, applied in the direction of filtration separation, membrane filter, fixed filter element filter, etc., can solve the problems of high manufacturing cost and operation cost, expensive structure, complicated system, etc., and achieve low-cost manufacturing, Low structural outlay, comfortable and simple replacement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

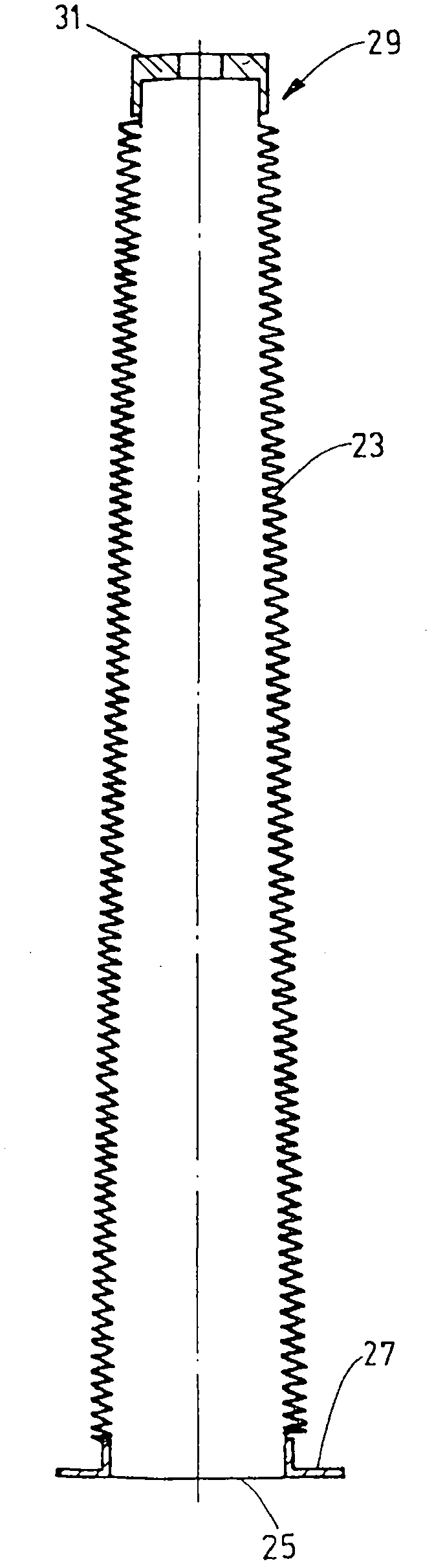

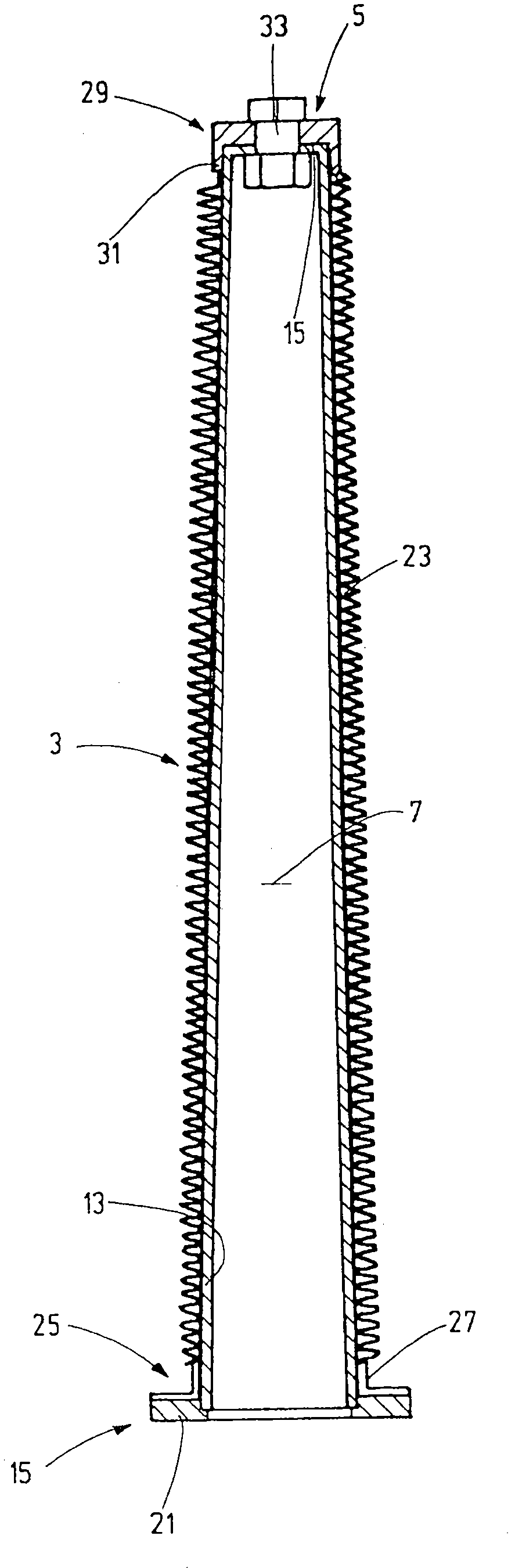

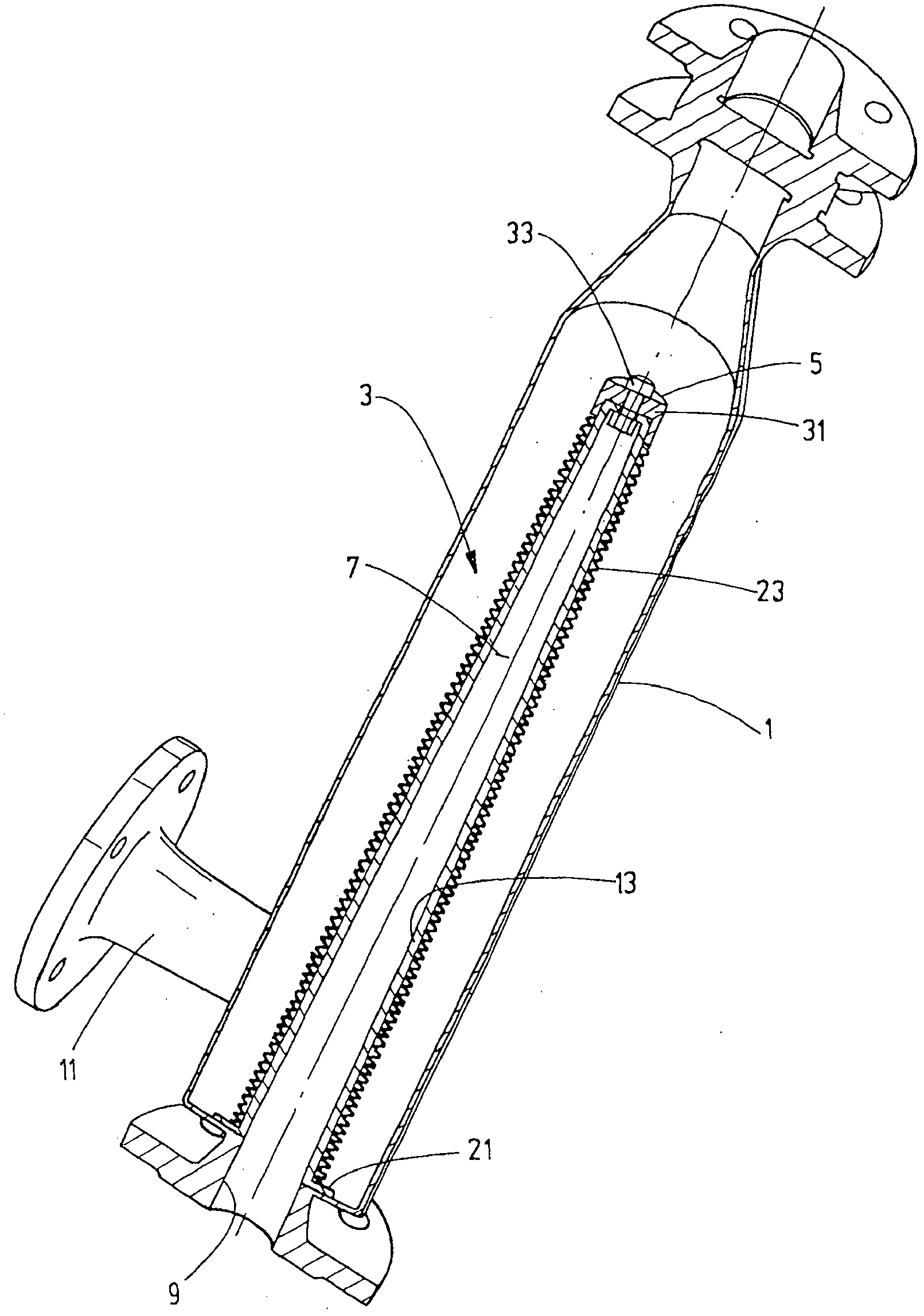

[0027] First of all, with the help of Figures 1 to 5 The example of the filtering device illustrates the present invention, wherein, in Figure 4 In the filter housing designated by 1 is arranged a filter element designated as a whole by 3 which is designed in the type of a so-called filter candle stick and forms two filter stages in operation. In this example, the filter element 3 has a shape that tapers slightly conically towards the closed end 5 . However, the invention can also be implemented as a cylindrically shaped filter element. as in Figure 4 , the filter element 3 is arranged in the housing 1 in such a way that the inner filter cavity 7 adjoins the housing bore 9 which is arranged at one axial end of the filter housing 1 And an inflow hole is formed during the filtering operation. The lateral housing connection 11 forms an outlet for the cleaned medium during filtering operation. Further details of the embodiment to be explained here of the filter element 3 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com