Method for prolonging operation cycle of coker gasoline hydrogenation unit

A technology for coking gasoline and operating cycle, which is used in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc. It can solve the problems of extending the operating cycle, slowing down the growth rate of pressure drop in the reaction system, etc., so as to prolong the operating cycle and reduce the polymerization reaction. The effect of occurrence and reduction of downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

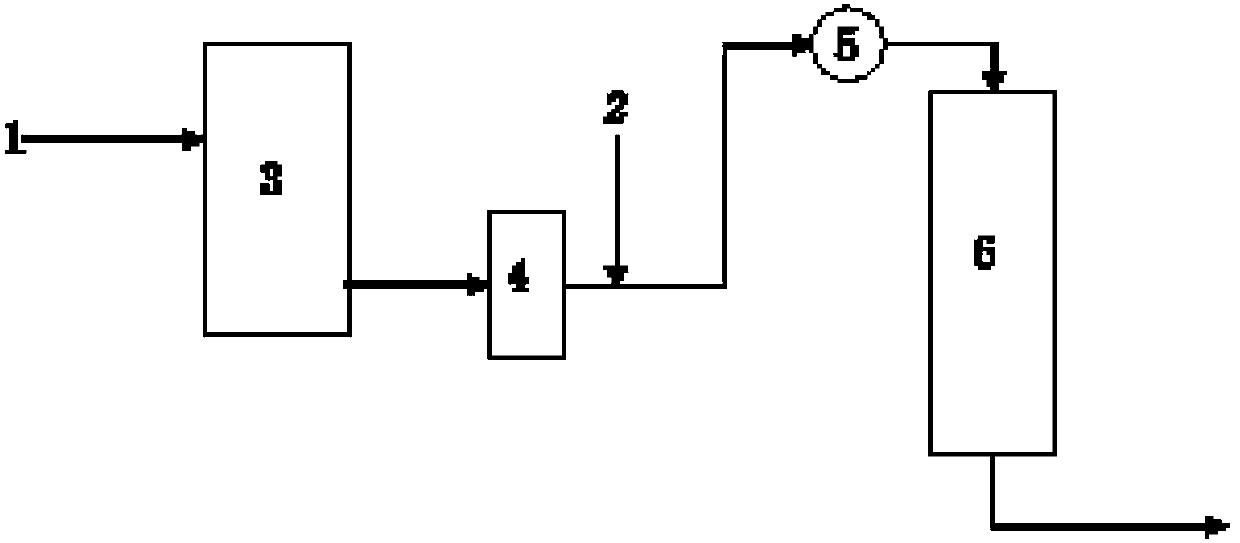

[0015] A kind of method prolonging the operation cycle of coker gasoline hydrogenation unit described in the present invention:

[0016] (1) Before the coker gasoline 1 enters the coker gasoline hydrogenation reactor from the coking unit, it first enters the nitrogen-sealed dehydration buffer tank 3 to remove the water carried in the raw material; the nitrogen-sealed pressure is controlled at 0.7 MPa; the residence time is controlled at 4 - between 8 hours;

[0017] (2) Then enter the automatic backwash filter 4, and the filtration accuracy is controlled at 15-20μm;

[0018] (3) Inject the polymerization inhibitor dispersant 2 before the coker gasoline enters the hydrogen mixing raw material and refined product heat exchanger 5, so that the olefin polymerization reaction does not occur or a small amount occurs before the coker gasoline enters the reactor 6; the injection ratio is controlled at 40ppm-50ppm.

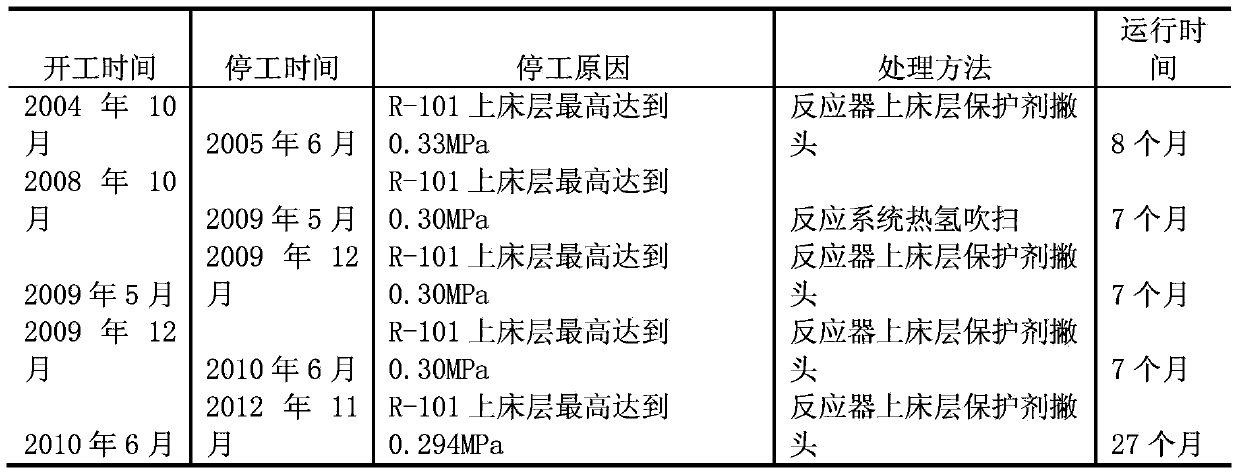

[0019] Effects of using this invention on coker gasoline hydrogenat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com