Self cleaning precise filter and filtering method

A precision filter and self-cleaning technology, which is applied in chemical instruments and methods, fixed filter elements, filter separation, etc., can solve problems such as filter blockage, improve filtration efficiency, reduce floor space and equipment production raw materials The effect of reducing loss and reducing the occurrence of filter clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

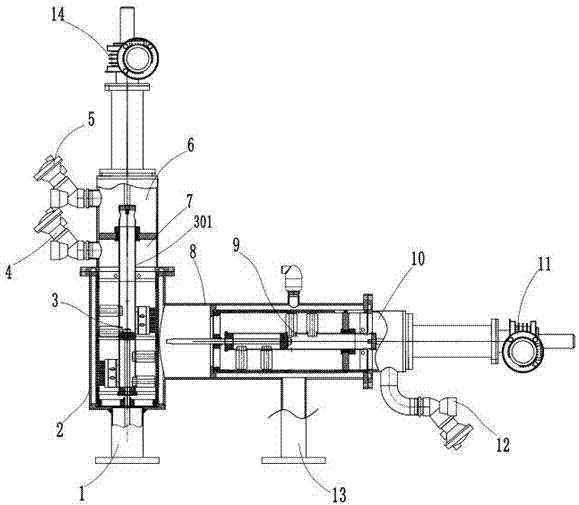

[0042] Such as Figure 1 to Figure 3 As shown, the self-cleaning precision filter of this embodiment includes a primary filter mechanism 3, and the primary filter mechanism 3 is provided with a primary sewage discharge chamber 7 and a secondary sewage discharge chamber 6 that are independent of each other, and the primary sewage discharge chamber 7 It communicates with the primary filter cavity 306 of the primary filter mechanism 3, and the secondary sewage discharge cavity 6 is provided with a primary sewage suction mechanism connected with the primary filter cavity 306, and the primary sewage discharge cavity 7 and the secondary sewage discharge cavity 6 are respectively provided with Sewage outlet.

[0043] Further, the primary sewage discharge chamber 7 of this embodiment is arranged above the primary filter chamber 306 . The primary sewage discharge cavity is set above the filter cavity, and the suspended solids in the sewage can be automatically accumulated in the prima...

Embodiment 2

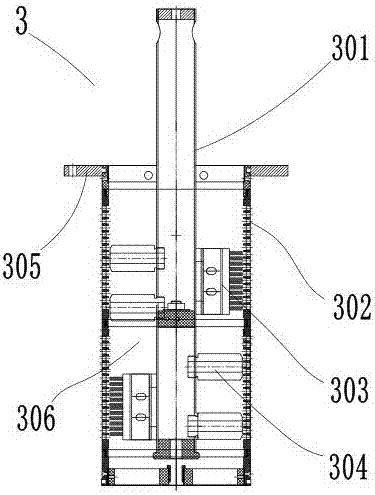

[0048] Such as Figure 1 to Figure 3 As shown, according to the self-cleaning precision filter described in Embodiment 1, the primary filter mechanism 3 of this embodiment includes a primary filter housing 2 and a primary filter screen cylinder 302, and also includes a primary filter that extends into the primary filter screen cylinder 302. The sewage suction pipe shaft 301 is provided with a scraping strip brush 303 for cleaning the filter screen on the primary filter sewage suction pipe shaft 301 .

[0049] After the liquid to be filtered enters the primary filter mechanism, primary filtration is carried out in the primary filter cartridge, and a driving device is arranged on the shaft of the primary filter sewage suction pipe. When the filter screen is blocked by impurities or suspended matter, the primary filter sewage suction pipe is driven by the driving device The shaft rotates to drive the scraping strip brush to scrape off the suspended matter or large particles of im...

Embodiment 3

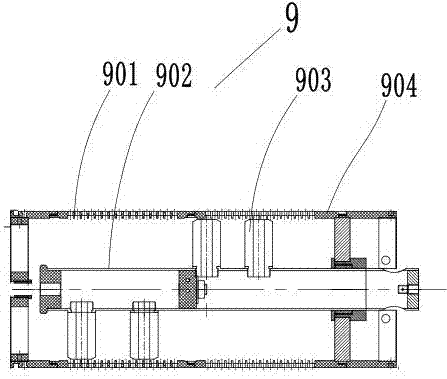

[0052] Such as Figure 1 to Figure 3 As shown, according to the self-cleaning precision filter described in embodiment 1 or embodiment 2, it also includes a secondary filter mechanism 9 connected in series with the primary filter mechanism 3, and the filtration precision of the primary filter mechanism 3 is equal to that of the secondary filter mechanism 9. The secondary filter mechanism 9 includes a secondary filter screen cylinder 901 arranged in the secondary filter housing 8, and a secondary dirt suction mechanism corresponding to the secondary filter screen cylinder 901, and also includes a The secondary filter chamber 904 of the sewage mechanism communicates with the secondary sewage discharge chamber 10 , and the secondary sewage discharge chamber 10 is provided with a secondary sewage discharge valve 12 .

[0053] The filter of this embodiment is provided with a primary filter mechanism and a secondary filter mechanism connected in series to reduce floor space and equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com