Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Low dehydration temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Former hot blast and latter vacuum microwave combining drying process of producing crisp fruit and vegetable grains

InactiveCN1672531AReduce drying loadReduced moisture removal requirementsFruits/vegetable preservation by dehydrationWater contentFood processing

The present invention is former hot blast and latter vacuum microwave combining drying process of producing fruit and vegetable grains, and belongs to the field of fruit and vegetable food processing technology. The drying process includes the steps of: washing fruit and vegetable material, dicing, scalding to killing enzyme, cooling in flow water, draining, optional fast freezing and defrosting, soaking with seasoning, draining, pre-dewatering with hot blast to obtain semi-finished product with water content of 40-60 %, and final vacuum microwave drying to obtain product with water content of 2-5 %. The said process has the nutritious components and color well maintained, crisp product, short production period, low cost, high product quality and other features.

Owner:JIANGNAN UNIV

Intermediate wave infrared and radio frequency combined drying method suitable for dehydration of large-scale seasoning edible mushrooms

ActiveCN102986838AHeating up fastLittle impact on qualityFruits/vegetable preservation by dehydrationNutritionDrying time

The invention relates to an intermediate wave infrared and radio frequency combined drying method suitable for dehydration of large-scale seasoning edible mushrooms, and belongs to the field of edible mushroom foodstuff processing technology. The method comprises the steps of pre-treating the edible mushrooms (carefully chosen, cleaning, sorting and sharding, blanching for enzyme deactivation at a temperature of 90-100 DEG C), cooling in a seasoning liquid, immersing and draining, pre-dehydrating with the intermediate wave infrared at a temperature of 60-70 DEG C with a wind speed of 1-3 m / s and a radiation distance of 10-18 cm to make moisture content reduced to 30%-60%; then performing radio frequency drying to make the moisture content of the edible mushroom reduced to 8%, wherein plate distance is 20.5 cm; frequency is 27 MHz; power is 6 KW; a material temperature is 50-60 DEG C; and material plates can be arranged in three layers. Problems of difficulty for removing the moisture in a later stage of the intermediate wave infrared drying by employing the intermediate wave infrared and radio frequency combined drying method, because the radio frequency has strong penetrability. The materials during the radio frequency drying process can be placed in a plurality of layers, so that nutrition and shapes of the product can be retained to a large extent; at the same time, drying time is shortened significantly; drying energy consumption is lowered; and cost is reduced.

Owner:JIANGNAN UNIV

Water soluble polyurethane associative thickener, and inverse polymerization method and use thereof

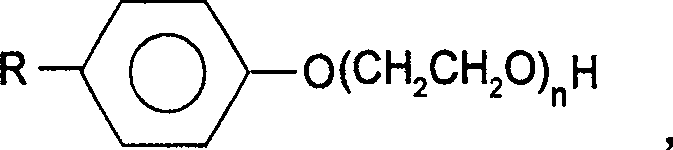

ActiveCN102101909AGood lookingExtended opening hoursCosmetic preparationsTransportation and packagingPolyethylene glycolHydrolysis

The invention discloses a water soluble polyurethane associative thickener, and an inverse polymerization method and use thereof. The method comprises: dehydrating polyethylene glycol by using an organic solvent with a boiling point below 110 DEG C; adding diisocyanate in the protection of an inert gas to perform a reaction; adding fatty alcohol of which the chain is 8 to 22 carbon atoms long as a capping agent for further reaction; adding polyol containing at least three hydroxys as a chain extender to perform an reaction till there are no free isocyanate groups; and adding water, and removing the organic solvent by an azeotropic process to obtain the water soluble polyurethane associative thickener which is white, transparent and sticky fluid. The dehydration temperature of water soluble associative polyurethane is low, so the side reactions are inhibited effectively; and reaction is performed in the organic solvent and catalyst is not required, so cost is reduced and the hydrolysis side reaction of the product due to the catalyst is avoided. Because the polyol is used as a chain extender, the thickener of the invention has a branch structure and high thickening performance.

Owner:GUANGZHOU SHINE POLYMER TECH

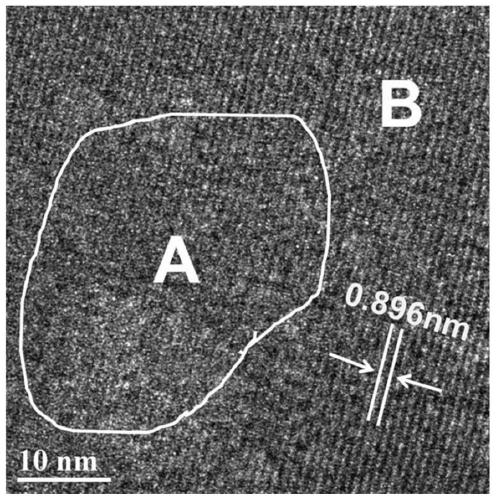

Flaky iron phosphate, and preparation method and application thereof

ActiveCN110357057AModerate particle size distributionEasy to processPhosphorus compoundsPhosphoric acidSlurry

The invention discloses flaky iron phosphate, and a preparation method and application thereof. The microscopic morphology of the flaky iron phosphate is a primary particle in a sheet shape with a thickness of 10 to 50 nm, a length of 100 nm to 3 [mu]m and a width of 100 nm to 3 [mu]m. The preparation method comprises the following steps of: weighing a ferrous ion solution and adding phosphoric acid and a crystal modifier; weighing a phosphorus salt solution and adding an oxidizing agent; carrying out mixing to obtain a mixed solution C, controlling the pH value of the mixed solution C to be 1.5-2.2, and carrying out a reaction to obtain pale yellow iron phosphate slurry; converting the iron phosphate slurry into white or pink-white iron phosphate slurry containing crystal forms under theconditions of stirring and heating, reducing a stirring speed by 20%-50% after the completion of the conversion, and carrying out ageing and heat preservation; performing solid-liquid separation, andcollecting a solid portion to obtain a crystalline iron phosphate precipitate; and washing the precipitate and then performing calcination to obtain the flaky iron phosphate. The iron phosphate of theinvention can be used for preparing lithium iron phosphate with high compaction density.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

Preparation method and application of silver-free powdery solid solution anti-bacterial agent

InactiveCN104206420APrevent crystallizationModerate melting propertiesBiocideAntifouling/underwater paintsSolid solutionAnti bacterial

The invention discloses a preparation method and application of a silver-free powdery solid solution anti-bacterial agent. The silver-free powdery solid solution anti-bacterial agent is prepared by adding a zinc salt or a copper salt and an oxide or a hydroxide to water, and performing a stirring process, a separating process, a cleaning process and a grinding process. The preparation method is simple and low in cost. The silver-free powdery solid solution anti-bacterial agent is wide in applications, is high-temperature-resistant, is safe and is good in anti-bacterial effect.

Owner:ANHUI WANXING IND LTD

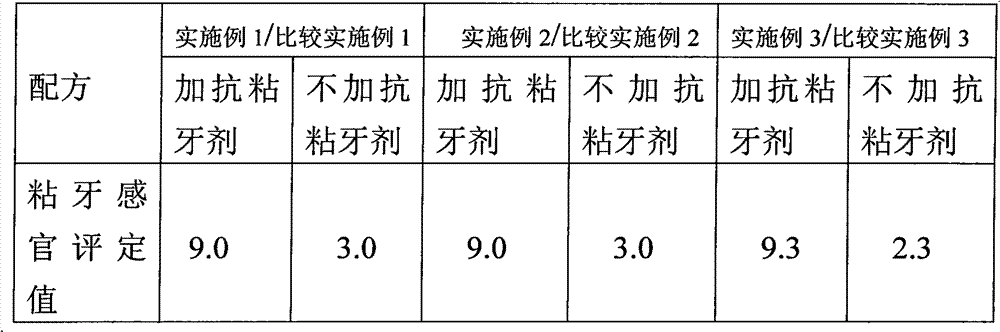

Solid honey candy and preparation method thereof

InactiveCN102058004AChange the curing characteristicsImprove product valueConfectionerySweetmeatsSucroseMicrowave

The invention relates to a solid honey candy and a preparation method thereof. The solid honey candy comprises the following components in percentage by weight: 100 percent of liquid pure honey, 3 to 6 percent of edible solid gum and 0.7 to 3 percent of teeth stick-resisting agent, wherein the edible solid gum is selected from arabic gum, konjac gum and pectin, and the teeth stick-resisting agentis selected from lecithin, sucrose fatty acid ester and water-soluble glycerol monostearate. The preparation method of the solid honey candy comprises the following steps of: weighing the components in a weight ratio, dissolving the edible solid gum and the teeth stick-resisting agent in hot water, adding the solution into the liquid pure honey, dehydrating the obtained mixed liquid by a vacuum microwave heating method to ensure that water content is below 3 percent, performing cast molding at the temperature of between 60 and 70 DEG C, cooling and demolding to obtain the solid honey candy. The honey content of the solid honey candy is above 90 percent; the color, aroma, taste and nutrients of the original liquid honey are basically not changed; a solid shape can be kept at room temperature; and the edible teeth stick-resisting agent is added into the formula, so that the solid honey candy is not sticky to teeth and has good mouthfeel during chewing. The preparation method is easy.

Owner:JIANGNAN UNIV

Foam combination flooding produced liquid demulsifier and preparation method thereof

ActiveCN102925204AEffective demulsificationEffective treatment of demulsificationDewatering/demulsification with chemical meansDemulsifierPotassium hydroxide

The invention discloses a foam flooding produced liquid demulsifier which is a non-ionic polyether demulsifier and is characterized in that the demulsifier is prepared by three steps: phenolic resin serving as an initiator firstly reacts with epoxypropane in the presence of an alkaline compound serving as a catalyst to obtain a propoxylated polyether compound; the propoxylated polyether compound performs addition reaction with ethylene oxide under the effect of an alkaline catalyst to form an intermediate; and the intermediate reacts with epoxypropane, wherein in the reaction formula of each step, the alkaline compound is sodium hydroxide, potassium hydroxide or sodium ethoxide; in the three steps of reaction for preparing the demulsifier, the mass ratio of the phenolic resin to alkaline compound to epoxypropane in the first step of reaction is (20-30):(0.05-0.15):(50-90); the mass ratio of the propoxylated polyether compound to alkaline compound to ethylene oxide in the second step of reaction is (20-35):(0.1-0.45):(70-160); and the mass ratio of the intermediate to alkaline compound to epoxypropane in the third step of reaction is (20-30):(0.05-0.15):(50-90).

Owner:CHINA PETROLEUM & CHEM CORP +2

Graphene oxide aerogel thermochemical heat storage composite material and preparation method thereof

ActiveCN109929518AOvercome uneven distribution of hydrated inorganic saltsSolve reunionHeat-exchange elementsSelf-assemblyHigh energy

The invention relates to a graphene oxide aerogel thermochemical heat storage composite material and a preparation method thereof. The method comprises the following steps: 1) ultrasonically strippinga graphite oxide aqueous solution to obtain a graphene oxide aqueous solution; 2) uniformly mixing the graphene oxide aqueous solution with MgCl2.6H2O, and carrying out hydrothermal crosslinking self-assembly to obtain MgCl2.6H2O-graphene oxide hydrogel compound; and 3) carrying out vacuum drying treatment on the MgCl2.6H2O-graphene oxide hydrogel compound to obtain the graphene oxide aerogel thermochemical heat storage composite material. Compared with the prior art, graphene oxide aerogel is used as a carrier; a large specific surface area is provided for MgCl2.6H2O crystallization, so thatthe problem that hydrated inorganic salt is easy to agglomerate can be effectively solved, and the MgCl2.6H2O-graphene oxide hydrogel compound has the advantages of high energy storage density, adjustable reaction temperature, good dispersity and the like. The composite material has a huge application space in the field of medium and low temperature thermochemical heat storage.

Owner:TONGJI UNIV

Method for preparing anhydrous boron oxide

ActiveCN103523793AMeet the process requirementsHigh purityBoron-oxygen compoundsCrucibleRoom temperature

The invention discloses a method for preparing anhydrous boron oxide. The method comprises the following steps: (1) carrying out vacuum dehydration treatment of boric acid to obtain boron oxide; (2) placing boron oxide in a crucible, heating to 400-500 DEG C, and then keeping for 30 min; (3) carrying out microwave heating dehydration treatment of boron oxide with the dehydration time of 10-40 min; and (4) under a normal temperature and normal pressure condition with the water content of less than 1 ppm, cooling to the room temperature to obtain anhydrous boron oxide. The method has the advantages of simple production process and low production cost, and the obtained product has the water content of below 150 ppm and the purity of up to 99.999%.

Owner:清远先导材料有限公司

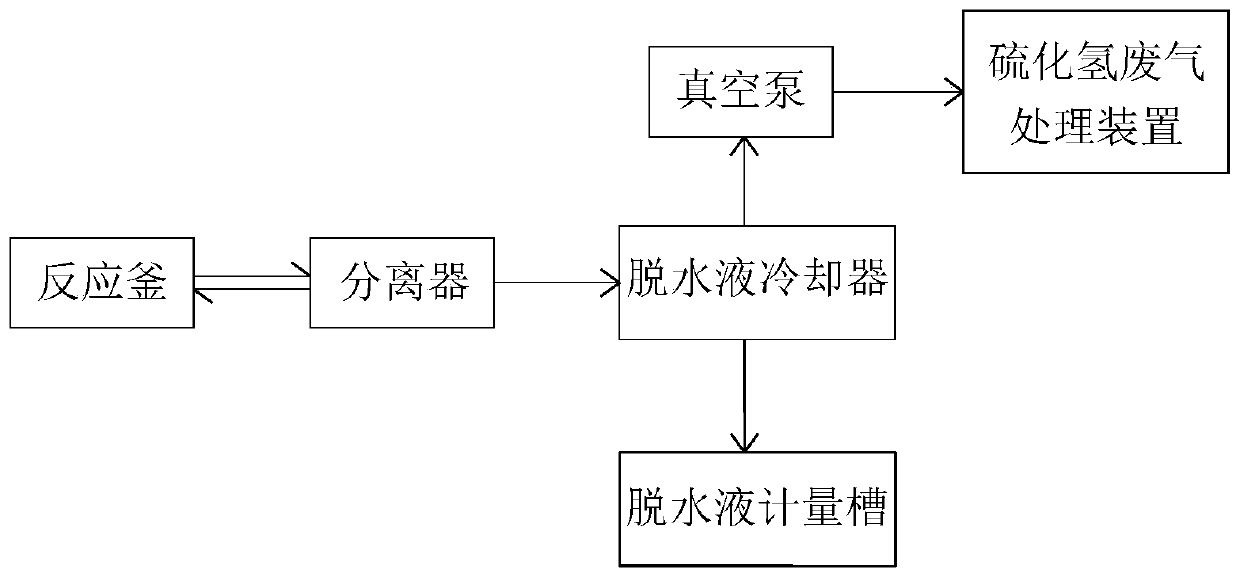

Method for dehydrating sodium sulfide polyhydrate in polyphenylene sulfide production

The invention relates to the technical field of sodium sulfide dehydration, particularly to a method for dehydrating sodium sulfide polyhydrate in polyphenylene sulfide production. The specific schemeis that the method comprises: adding sodium sulfide polyhydrate, NMP, an auxiliary agent and sodium hydroxide into a reaction kettle, and heating and dehydrating the materials in the reaction kettle;making the mixed steam generated by the dehydrating enter a separator, separating, returning the separated liquid returns to the reaction kettle, and carrying out condensation recovery and waste gastreatment on the separated gas; and adding molten p-dichlorobenzene into the reaction kettle, and carrying out a step-by-step heating reaction on the mixed solution in the reaction kettle to finally obtain the polyphenylene sulfide product. In the prior art, the existing PPS production is high in dehydration temperature, performs two-section evaporation dehydration by requiring steam and other energy sources, is instable, and does not have the fixed dehydration time, and the process control is instable during dehydration to cause a large amount of liquid carrying so as to cause the high NMP content in the dehydrated water. According to the invention, the problem in the prior art is solved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

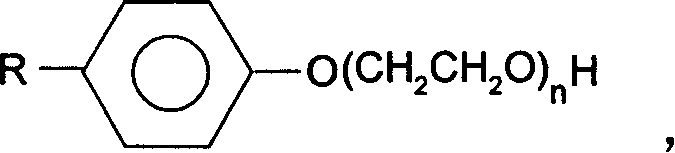

Efficient super-heavy oil demulsifier and preparation method thereof

InactiveCN106190229APromote demulsificationFast dehydrationDewatering/demulsification with chemical meansEpoxyPhosphate

The invention discloses an efficient super-heavy oil demulsifier and a preparation method thereof. The efficient super-heavy oil demulsifier comprises, by weight, 14-19 parts of C10-16-alkyl alcohol ethoxylate propoxylate, 12-17 parts of tetraethylenepentamine polypropylene oxide polyoxyethylene ether, 7-13 parts of nonoxynol-10 phosphate, 5-10 parts of emulsifier OP-4, 6-12 parts of ethylene oxide-epoxy propane segmented copolymer, 4-8 parts of sorbeth hexalaurate, 3-6 parts of ammonium polyacryloyldimethyl taurate, 5-9 parts of sodium lauryl diphenyl ether disulfonate and 4-7 parts of N-propyl-perfluorooctane sulfonamide potassium glutamate. The raw materials such as C10-16-alkyl alcohol ethoxylate propoxylate, tetraethylenepentamine polypropylene oxide polyoxyethylene ether and ethylene oxide-epoxy propane segmented copolymer are added in the demulsifier, so that the demulsifier has the advantages of good demulsifying performance, high dehydration rate, low dehydration temperature and the like, and is wide in application range and promising market prospect.

Owner:安徽炎胜新材料科技有限公司

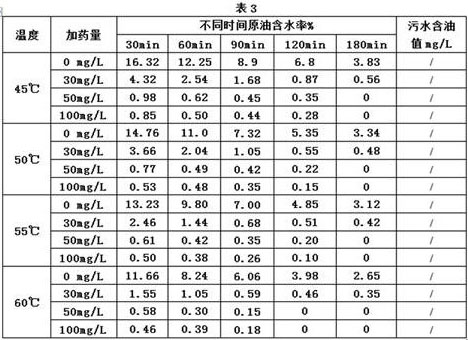

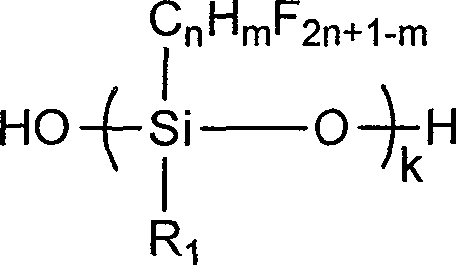

Fluorine-silicon contd. linkage polyether demulsification agent and its prepn. method

InactiveCN1831092AReduce dosageLow dehydration temperatureHydrocarbon oil dewatering/demulsificationToluene diisocyanateOxygen

This invention relates to fluorin contain silicon interlinkage polyether emulsion breaker and its preparation method. The breaker made up by hydroxy compounds contains fluorosilicic (A)and one kind of alcohol, acid, hydroxybenzene, amine that contains active hydrogen or active hydroxy group or resin contains hydroxybenzene and oxygen ethylene agent and oxygen propylene agent, they conglomerate block polyether (B). There conglomeration is act under function of interlinkage agent (E) toluene disocynate or multi alkylene polyisocyanate or diphenyl methane-4,4- diisocyanate. The agent material components and their weight percentage content as following fluorosilicic 1-15%, (B) 70-98%, (E) interlinkage agent 1-15%. Comparing to existing technique, the dosage is few, desiccation temperature is low, desiccation velocity is fast, oil contain ratio of emerged water is low, it is a high efficiency and quick crude oil demulsifying agent.

Owner:SHANGHAI UNIV OF ENG SCI

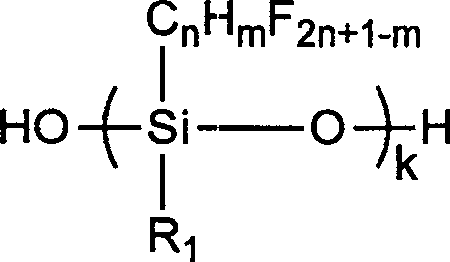

Fluorine-contd. linkage polyether demulsification agent and its prepn. method

InactiveCN1831093AReduce dosageLow dehydration temperatureHydrocarbon oil dewatering/demulsificationToluene diisocyanateOxygen

This invention relates to fluorin interlinkage polyether demulsifying agent and its preparation method. The demulsifying agent made up by alcohol or acid with fluorin or alcohol, acid, hydroxybenzene, amine that contains active hydrogen or active hydroxy group or resin contains hydroxybenzene and oxygen ethylene agent and oxygen propylene agent, they conglomerate block polyether (B). There conglomeration is act under function of interlinkage agent (E) toluene disocynate or multi alkylene polyisocyanate or diphenyl methane-4,4- diisocyanate. The agent material components and their weight percentage content as following (A) 1-45%, (B) 40-97%, (E) interlinkage agent 2-15%. Comparing to existing technique, the dosage is few, desiccation temperature is low, desiccation velocity is fast, oil contain ratio of emerged water is low, it is a high efficiency and quick crude oil demulsifying agent.

Owner:SHANGHAI UNIV OF ENG SCI

Antibiotic zymocyte dreg curing dehydrating method

InactiveCN106925593ANo secondary fermentationSolve storage problemsSolid waste disposalSolid fuelsResource utilizationRoom temperature

The invention provides an antibiotic zymocyte dreg curing dehydrating method. The method comprises the steps that antibiotic zymocyte dregs and a curing dehydrating agent are mixed for a curing reaction, and moisture in the antibiotic zymocyte dregs is removed; and the curing dehydrating agent is any or a combination of at least two inorganic substances and / or organic substances which can form hydrates, absorb moisture or react with water. Zymocyte dreg solid mixtures generated through the curing reaction can be subjected to resource utilization or incineration disposal directly or after dehydration. Through the method, the rapid dehydrating temperature and complete dehydrating temperature of the zymocyte dregs can be lowered by 10-90%, the problems that antibiotic zymocyte dregs are difficult to store and transport at the room temperature, prone to secondary fermentation and pollution and high in cost in treatment processes such as dehydration are solved, and a new method is provided for low-cost resource utilization and harmless treatment of the antibiotic wet zymocyte dregs.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

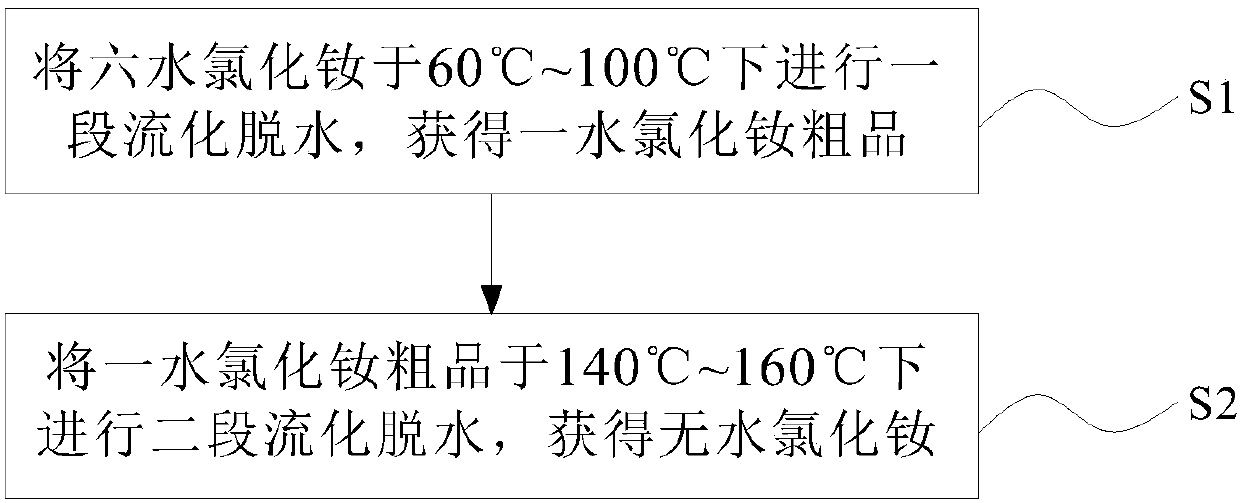

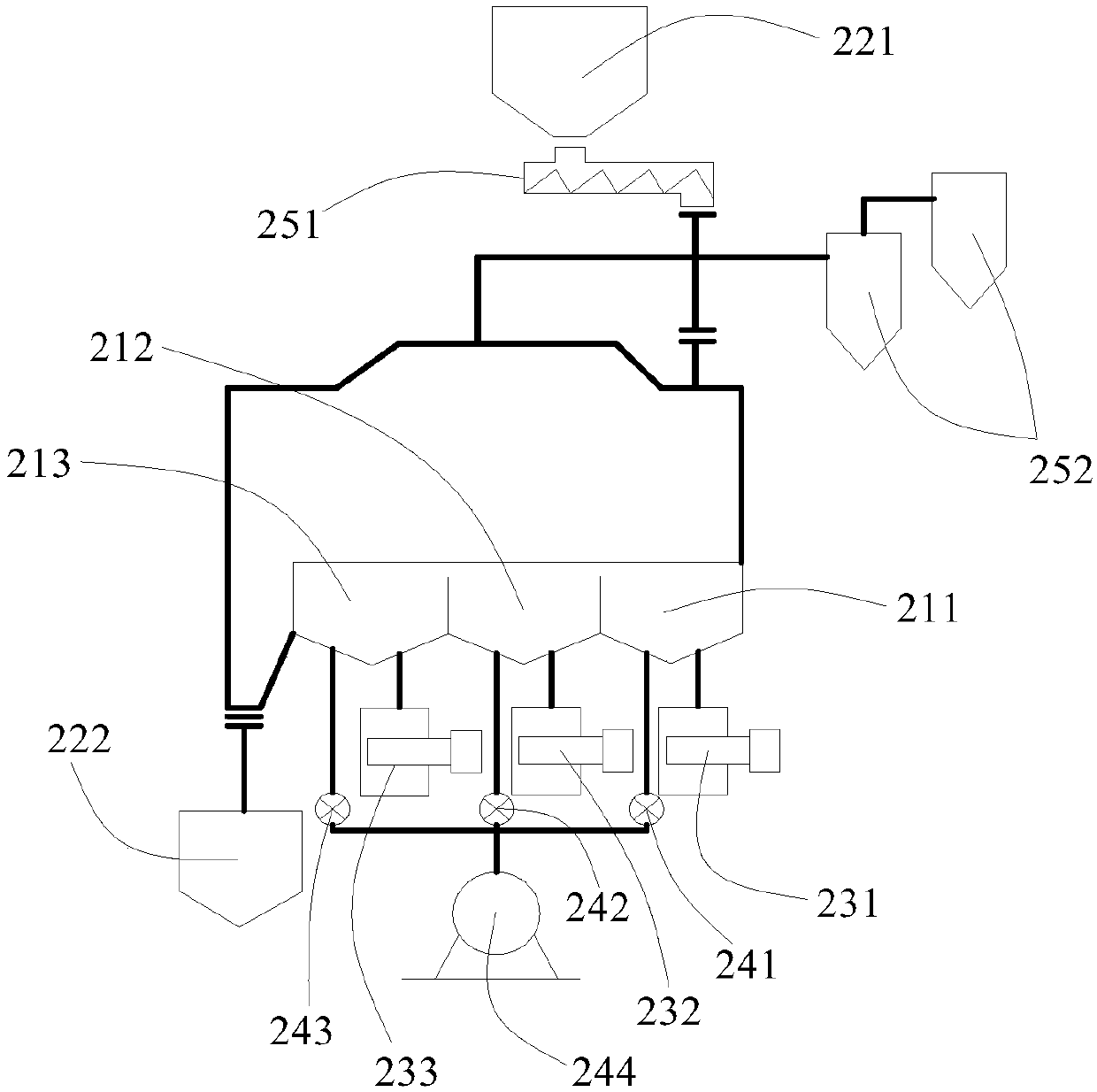

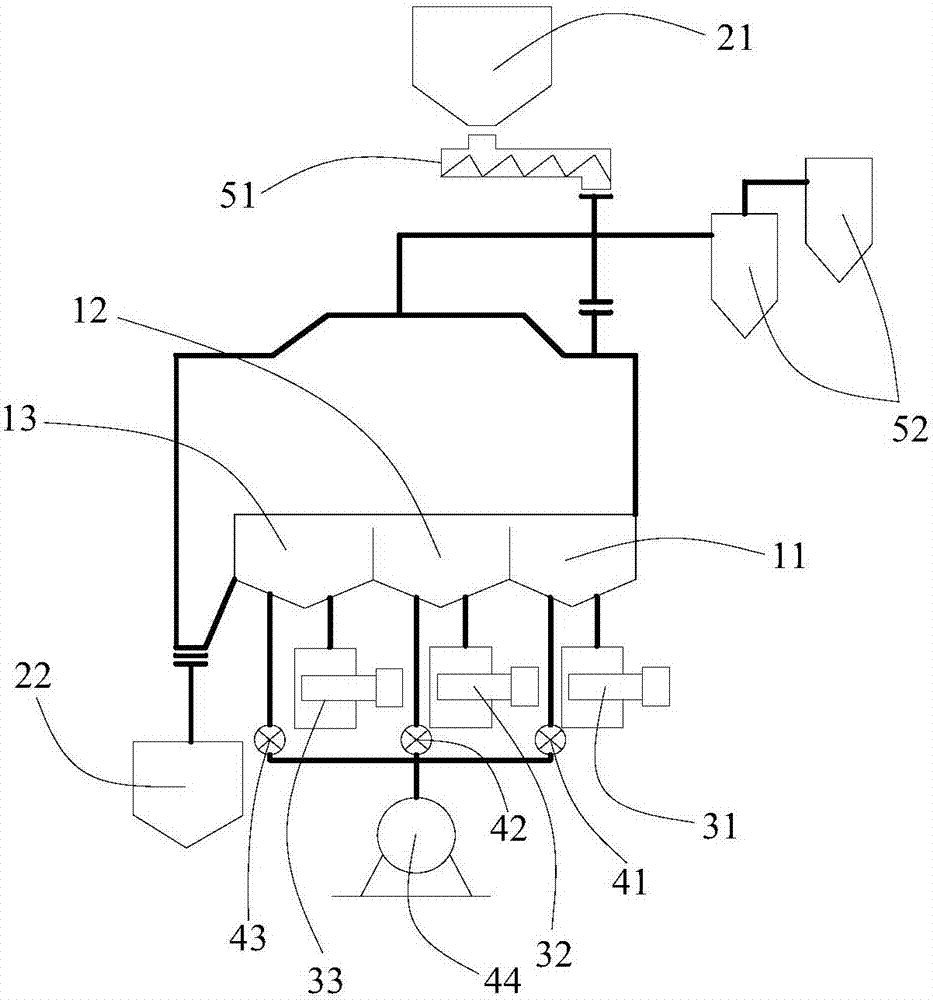

Preparation method of absolute neodymium chloride

InactiveCN107601544AInhibition of hydrolysisReduce pollutionRare earth metal compoundsCalcium Chloride HexahydrateNeodymium chloride

The invention discloses a preparation method of absolute neodymium chloride. The method comprises the following steps: S1) performing primary fluidization and dehydration on neodymium chloride hexahydrate at the temperature of 60-100 DEG C to obtain a neodymium chloride monohydrate crude product; and S2) performing secondary fluidization and dehydration on the neodymium chloride monohydrate crudeproduct at the temperature of 140-160 DEG C to obtain absolute neodymium chloride; wherein, the step of secondary fluidization and dehydration is carried out under hydrogen chloride gas atmosphere. According to the preparation method of absolute neodymium chloride, the neodymium chloride hexahydrate is subjected to segment fluidization and dehydration, hydrogen chloride protective gas atmosphere is provided, the hydrolysis of an intermediate product neodymium chloride monohydrate in a dehydration process to absolute neodymium chloride is effectively inhibited, product purity is greatly increased, the dehydration temperature in the preparation method of the absolute neodymium chloride is low, the preparation cost is low, and the dehydration effect is good.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Fluorine- contained linkage polyether demulsification agent and preparing method thereof

InactiveCN100480360CReduce dosageLow dehydration temperatureHydrocarbon oil dewatering/demulsificationOxygenMethane

This invention relates to fluorin interlinkage polyether demulsifying agent and its preparation method. The demulsifying agent made up by alcohol or acid with fluorin or alcohol, acid, hydroxybenzene, amine that contains active hydrogen or active hydroxy group or resin contains hydroxybenzene and oxygen ethylene agent and oxygen propylene agent, they conglomerate block polyether (B). There conglomeration is act under function of interlinkage agent (E) toluene disocynate or multi alkylene polyisocyanate or diphenyl methane-4,4- diisocyanate. The agent material components and their weight percentage content as following (A) 1-45%, (B) 40-97%, (E) interlinkage agent 2-15%. Comparing to existing technique, the dosage is few, desiccation temperature is low, desiccation velocity is fast, oil contain ratio of emerged water is low, it is a high efficiency and quick crude oil demulsifying agent.

Owner:SHANGHAI UNIV OF ENG SCI

Preparation method of anhydrous lanthanum chloride

InactiveCN107500334AInhibition of hydrolysisReduce pollutionRare earth metal chloridesChlorideLanthanum

The invention discloses a preparation method of anhydrous lanthanum chloride. The preparation method comprises the following steps: S1, carrying out first-section fluidization dehydration on lanthanum chloride heptahydrate at 60 DEG C to 100 DEG C to obtain a lanthanum chloride trihydrate crude product; S2, carrying out second-section fluidization dehydration on the lanthanum chloride trihydrate crude product at 120 DEG C to 130 DEG C to obtain a lanthanum chloride monohydrate crude product; S3, carrying out third-section fluidization dehydration on the lanthanum chloride monohydrate crude product at 140 DEG C to 160 DEG C to obtain the anhydrous lanthanum chloride, wherein the three sections of fluidization dehydration are carried out in a hydrogen chloride gas atmosphere. According to the preparation method of the anhydrous lanthanum chloride, disclosed by the invention, the lanthanum chloride heptahydrate is subjected to sectioned fluidization dehydration and a hydrogen chloride protection gas atmosphere is provided, so that a hydrolysis effect in a process of dehydrating an intermediate product lanthanum chloride monohydrate into the anhydrous lanthanum chloride is effectively inhibited and the purity of a product is greatly improved; the preparation method of the anhydrous lanthanum chloride has the advantages of low dehydration temperature, low preparation cost and good dehydration effect.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Preparation method of anhydrous boron oxide

InactiveCN106904626ALow dehydration temperatureReduce energy consumptionBoron oxidesWater contentChemistry

The invention discloses a method for preparing anhydrous boron oxide. The steps are as follows: (1) boric acid is subjected to vacuum dehydration treatment to obtain boron oxide; (2) boron oxide is placed in a crucible and heated to 400-500°C Keep it for 30 minutes; (3) Dehydrate the boron oxide by microwave heating, the dehydration time is 10-40 minutes; (4) Cool to room temperature under normal temperature and pressure conditions with a water content of less than 1ppm to obtain anhydrous boron oxide. The production process of the invention is simple, the production cost is low, the water content of the obtained product is below 150ppm, and the purity is as high as 99.999%.

Owner:雅安百图高新材料股份有限公司

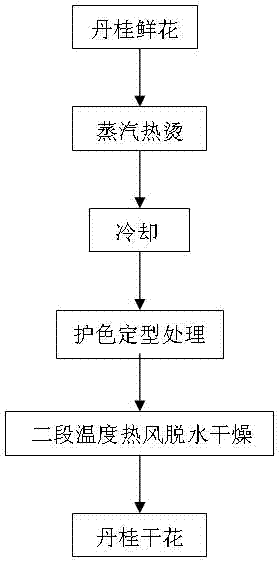

Orange osmanthus dried flowers and color-protecting shaping process thereof

The invention discloses orange osmanthus dried flowers and a color-protecting shaping process thereof. According to the process, orange osmanthus fresh flowers are used as raw materials, and orange osmanthus dried flower products can be obtained through steam blanching, cooling and color-protecting shaping treatment and then two-stage temperature hot air dewatering and drying. The orange osmanthus dried flowers produced through the process are good in color, fragrance and taste, high in nutritive value, free from safety risks caused by sulphur fuming color protection in a traditional process, high in safety, capable of greatly improving commodity value and economic value added of the orange osmanthus dried flowers and reducing environment pollution, and have great significance in industrialization application of quality products of the orange osmanthus dried flowers.

Owner:FUJIAN AGRI & FORESTRY UNIV

Iron phosphate precursor as well as preparation method and application thereof

InactiveCN113247876ASmall specific surface areaHigh tap densityCell electrodesSecondary cellsO-Phosphoric AcidPhosphate

The invention belongs to the field of lithium ion battery materials, and discloses an iron phosphate precursor and a preparation method and application thereof. The microstructure of the iron phosphate precursor is spherical, the particle size D50 is 10-20 [mu] m, the specific surface area is 1-3 m < 2 > / g, and the tap density is 1-1.5 g / cm < 3 >. According to the method, ferric iron is selected as an iron source, then phosphoric acid is added into a ferric iron solution, and the morphology and the particle size distribution of primary particles of ferric phosphate are controlled by controlling the pH and the reaction temperature. The initial pH of the system is very low by adding phosphoric acid into ferric iron salt. Then, the reaction temperature is controlled to be 70-100 DEG C. Spherical dense primary particles can be formed and stacked, iron phosphate dehydrate with low specific surface area and no internal gap can be obtained after the primary particles are dried, and the tap density of the iron phosphate dehydrate is high and can reach 1-1.5 / cm < 3 >.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

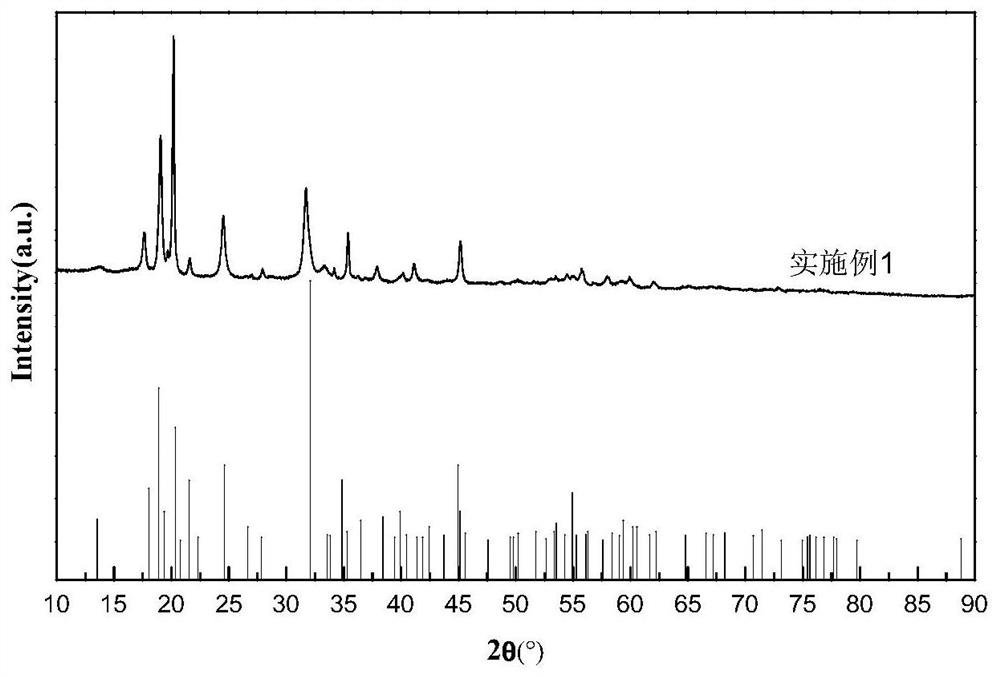

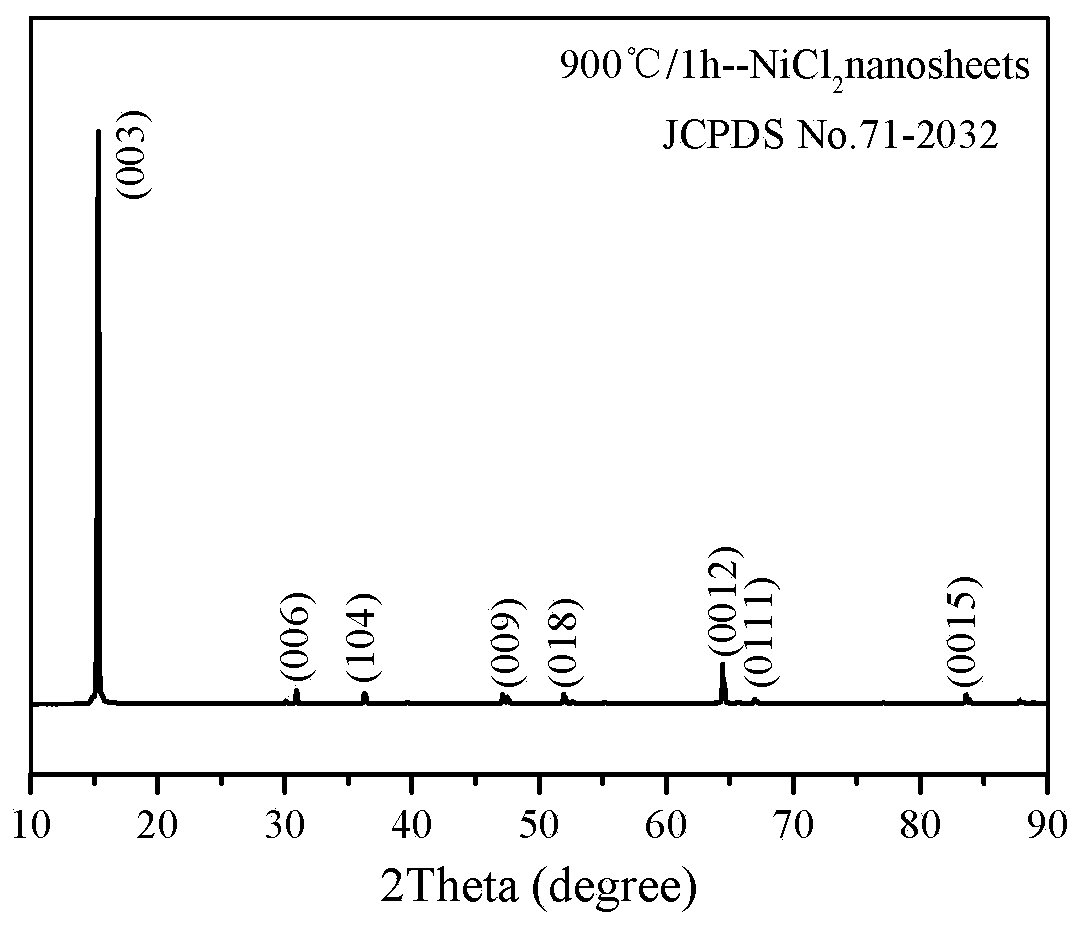

An ultrathin single crystal nicl 2 Nanosheet and its preparation method and application

ActiveCN109537053BHigh yieldQuality improvementPolycrystalline material growthFrom chemically reactive gasesElectrical batterySodium-ion battery

The invention relates to an ultrathin monocrystalline NiCl2 nanosheet and a preparation method and application thereof. The nanosheet has the thickness of 2-20 nm and has the preferred orientation of(003) crystal face. The preparation method comprises the following steps: firstly placing nickel chloride hexahydrate into a tubular furnace, and dehydrating under the protection of inert gas; and then placing the pretreated powder into a clean and dry tubular furnace, and sublimating under the protection of inert gas to obtain the ultrathin monocrystalline NiCl2 nanosheet. The designed and prepared product is applied to at least one of the following materials: a cathode material of a thermal battery, a supercapacitor, a lithium ion battery, a sodium-ion battery and a magnetic material.

Owner:HUNAN UNIV

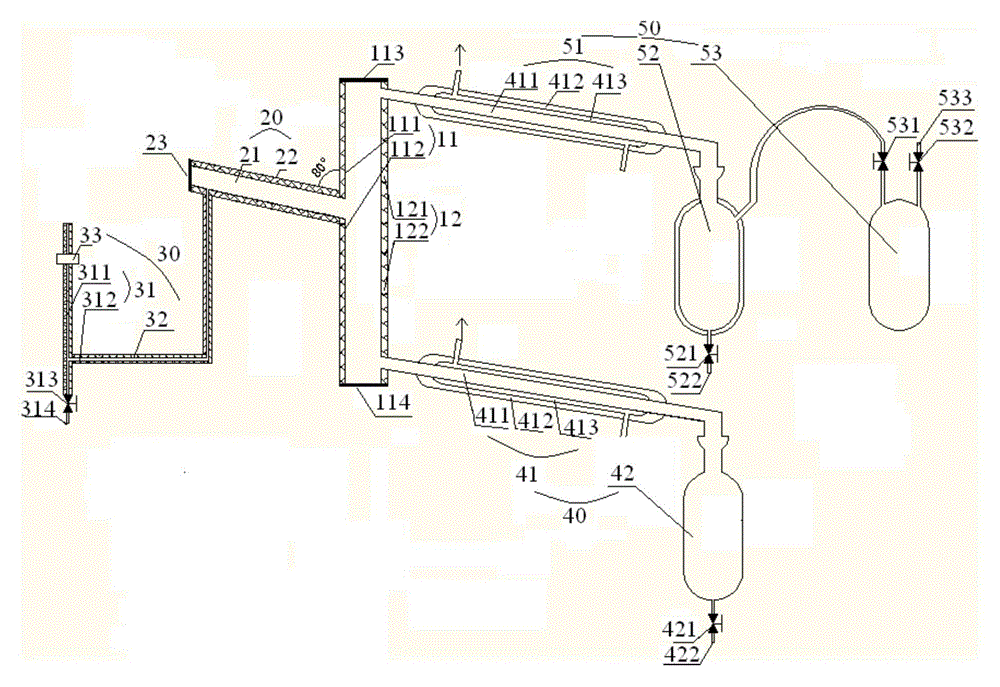

Crude oil continuous distillation and dehydration method

ActiveCN105623706AContinuous and rapid dehydrationLarge amount of processingHydrocarbon dewateringGas phaseWater storage tank

The invention discloses a crude oil continuous distillation and dehydration method. The dehydration method includes that water-containing crude oil is continuously introduced into a feeding and conveying pipeline of a feeding and conveying assembly of an crude oil continuous distillation and dehydration device, then enters a pre-heating pipeline in a pre-heating assembly, is pre-heated, next enters a shell body of a shell body assembly and is distilled; water and light oil in the crude oil are discharged from a gas phase outlet at the upper part of the shell body, are condensed by a distillation gas recovery assembly and then enter a light oil and water storage tank, wherein the water is discharged from the bottom of the light oil and water storage tank, and gas hydrocarbons are discharged from the upper part of the light oil and water storage tank and then enter a gas hydrocarbon recovery tank; heavy oil in the crude oil is discharged from a liquid phase outlet at the lower part of the shell body, is condensed by a heavy oil recovery assembly and then enters a heavy oil recovery tank. A to-be-dehydrated material (such as the crude oil) is subjected to pre-heating treatment on the pre-heating pipeline, and then the to-be-dehydrated material after heating treatment is distilled in the shell body assembly and is subjected to gas-liquid separation at the same time to achieve dehydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of magnesium nitrate and magnesium nitrate based multi-element molten salt

InactiveCN110054206ALow dehydration temperatureShorten the timeMagnesium nitratesHeat-exchange elementsDecompositionMolten salt

The invention discloses a preparation method of magnesium nitrate and magnesium nitrate based multi-element molten salt. The method includes the steps: placing an open container containing magnesium nitrate hexahydrate or multi-element molten salt mixture with the magnesium nitrate hexahydrate into a heating device for vacuum heating dehydration; placing dehydrated products into an anhydrous oxygen-free glove box and crushing the dehydrated products to obtain the magnesium nitrate or magnesium nitrate based multi-element molten salt. According to the preparation method, the content of alkali magnesium nitrate in the magnesium nitrate and magnesium nitrate based multi-element molten salt can be effectively decreased, high-purity magnesium nitrate or magnesium nitrate based multi-element molten salt can be acquired at lower temperature within a shorter time, and the acquired magnesium nitrate or magnesium nitrate based multi-element molten salt has higher decomposition temperature.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Dry lily and color protection and shaping technology of dry lily

InactiveCN108094509AAvoid damageReduce the temperatureFood thermal treatmentFruits/vegetable preservation by heatingNutritive valuesLilium

The invention discloses a dry lily and a color protection and shaping technology of the dry lily. According to the technology, the dry lily product is prepared by taking a fresh lily as a raw material, and performing steam blanching, cooling, color protection and shaping treatment, and two-stage temperature hot air dewatering and drying. The dry lily produced by the technology is good in color, aroma and taste and has a higher nutritive value; potential safety hazards caused by sulphitation color protection in the traditional technology are broken through; the safety is high; a commodity valueand an economic additional value of the dry lily are increased; the environmental pollution is reduced; and the technology has great significance for industrial implementation of choicest products ofthe dry lily.

Owner:NINGBO YUANHONG BIOTECH

Foam combination flooding produced liquid demulsifier and preparation method thereof

ActiveCN102925204BEffective demulsificationEffective treatment of demulsificationDewatering/demulsification with chemical meansDemulsifierPotassium hydroxide

The invention discloses a foam flooding produced liquid demulsifier which is a non-ionic polyether demulsifier and is characterized in that the demulsifier is prepared by three steps: phenolic resin serving as an initiator firstly reacts with epoxypropane in the presence of an alkaline compound serving as a catalyst to obtain a propoxylated polyether compound; the propoxylated polyether compound performs addition reaction with ethylene oxide under the effect of an alkaline catalyst to form an intermediate; and the intermediate reacts with epoxypropane, wherein in the reaction formula of each step, the alkaline compound is sodium hydroxide, potassium hydroxide or sodium ethoxide; in the three steps of reaction for preparing the demulsifier, the mass ratio of the phenolic resin to alkaline compound to epoxypropane in the first step of reaction is (20-30):(0.05-0.15):(50-90); the mass ratio of the propoxylated polyether compound to alkaline compound to ethylene oxide in the second step of reaction is (20-35):(0.1-0.45):(70-160); and the mass ratio of the intermediate to alkaline compound to epoxypropane in the third step of reaction is (20-30):(0.05-0.15):(50-90).

Owner:CHINA PETROLEUM & CHEM CORP +2

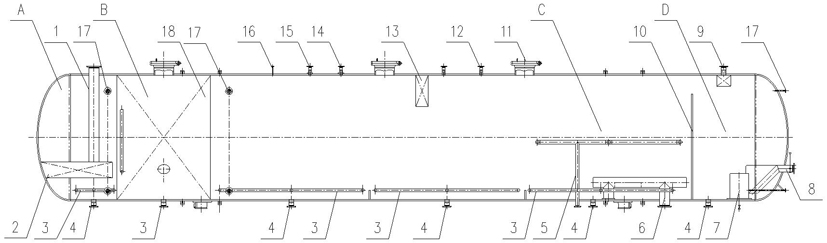

Low-interfacial-tension efficient oil-gas-water separation method and device

PendingCN112337138AImprove development efficiencyLow dehydration temperatureNon-miscible liquid separationProduced waterOil field

The invention relates to the technical field of oil-gas-water separation of petroleum and natural gas, in particular to a low-interfacial-tension efficient oil-gas-water separation method and device.According to the method, a gas-liquid mixture produced by an oil well enters a washing chamber and is pre-separated by a liquid distribution device, gas is discharged from a gas collection bag at thetop of an oil chamber, water-containing crude oil enters a coalescence chamber and flows through a hydrophilic filler, low interfacial tension is formed under the synergistic effect of a demulsifier,then the water-containing crude oil undergoes round hole rectification and parallel rectification and then enters a separation chamber for oil-water separation, separated upper-layer crude oil entersan oil chamber, produced water is discharged, an emulsion is collected and then discharged, and purified crude oil is discharged through an oil outlet. The device comprises the washing chamber, the coalescence chamber, the separation chamber and the oil chamber. According to the invention, low interfacial tension is formed through the synergistic effect of demulsification, physical coalescence, rectification and the like, so a dehydration temperature can be effectively reduced, dehydration time is shortened, separation efficiency is improved, and meanwhile the beneficial effects that an equipment size is reduced, engineering investment is reduced, operation energy consumption is reduced and oilfield development benefits are improved are achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

Microbe emulsion breaker

InactiveCN1186425CReduce interfacial tensionLow dehydration temperatureHydrocarbon oil dewatering/demulsificationDemulsifierInorganic salts

The microbial emulsion breaker is composed of (wt%) 10-25% of microbe, 25-50% of chemical demulsifier, 0.1-5% of inorganic salt and 25-50% of water. The utilization of said invented product can greatly reduce oil and water interfacial tension, and has the advantages of quick dewatering speed, lower dewatering temp. and low oil content in discharged sewage.

Owner:唐山冀油瑞丰化工有限公司 +1

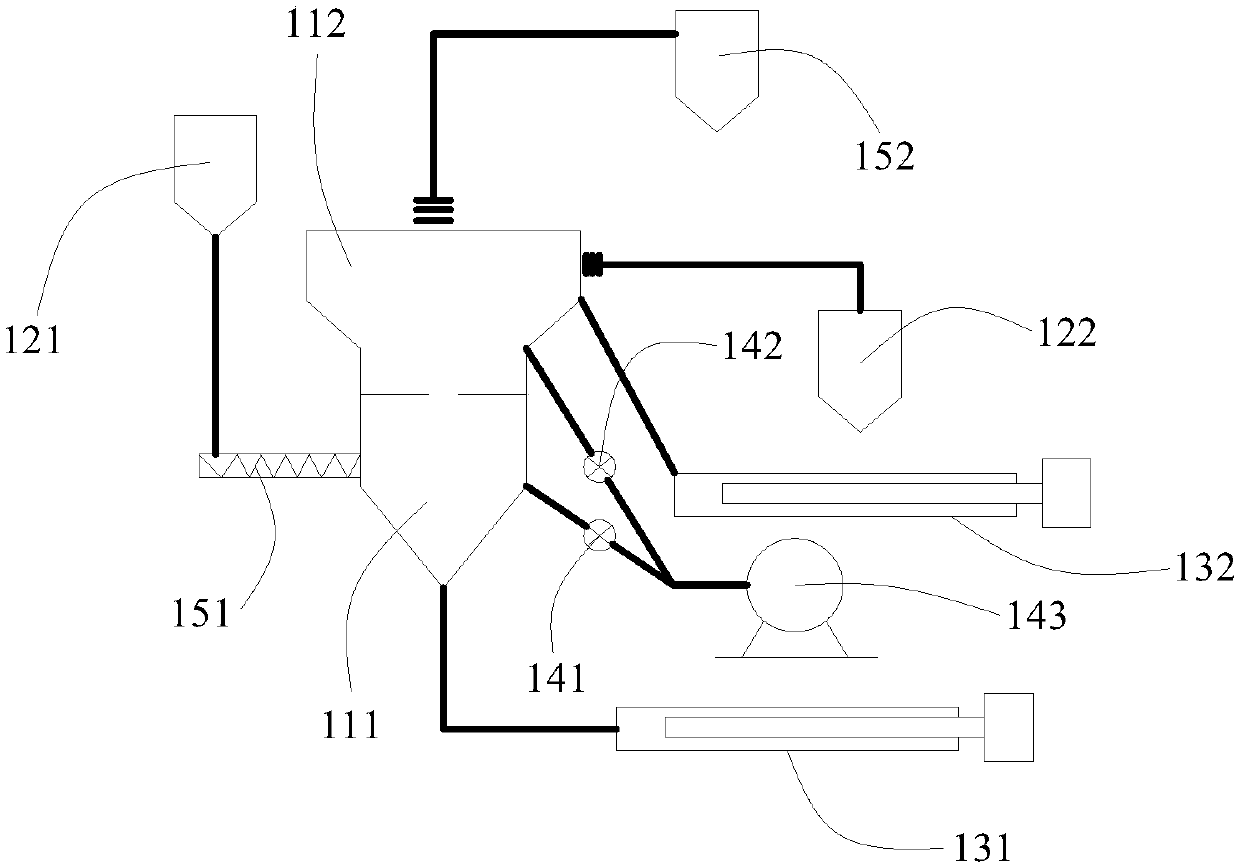

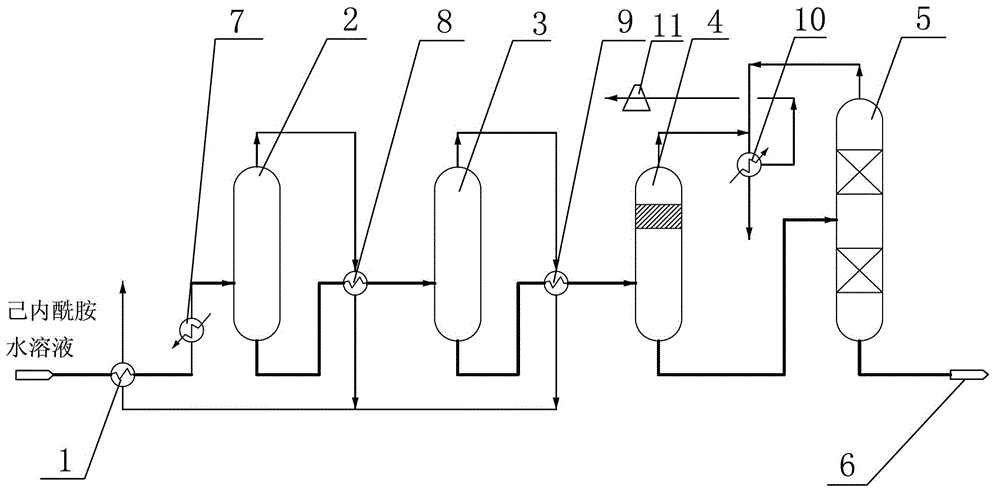

A production system and method for caprolactam dehydration

ActiveCN102989185BReduce consumptionReduce thermal decompositionLactams separation/purificationEvaporator accessoriesEvaporationEngineering

The invention discloses a production system of dehydrated caprolactam and a method thereof. The system is characterized by comprising a first-efficiency heat exchanger, a first-efficiency evaporator, a second-efficiency heat exchanger, a second-efficiency evaporator, a third-efficiency heat exchanger and a third-efficiency evaporator which are sequentially connected and then connected with a rectifying tower. The production method comprises the following steps of: pre-heating the materials and then sending the materials to the first-efficiency evaporator for evaporation under the conditions of a temperature of 115-125 DEG C and a pressure range from 0.2 to 0.35MPaG; heating the materials and sending the materials to the second-efficiency evaporator for evaporation under the conditions of a temperature of 105-110 DEG C and a pressure range from 0.05 to 0.1MPaG; heating the materials and sending the materials to the third-efficiency evaporator for evaporation under the conditions of a temperature of 85-95 DEG C and a pressure range from 0.05 to 0.08MPaG; and sending the materials to the rectifying tower for rectification under the conditions of a temperature of 90 DEG C and a pressure range from 0.05 to 0.08MPaG, wherein the dehydrated caprolactam with less than 0.001% of water is obtained at the bottom of the rectifying tower. The invention has the advantages that multiple effective and gradient utilization of steam is realized through rational control of pressure and temperature, a large amount of cold and heat are saved, and the thermal decomposition of the caprolactam is reduced at a lower operating temperature.

Owner:SEDIN NINGBO ENG

Fluorine-silicon contained linkage polyether demulsification agent and preparing method thereof

InactiveCN100480359CReduce dosageLow dehydration temperatureHydrocarbon oil dewatering/demulsificationToluene diisocyanateOxygen

This invention relates to fluorin contain silicon interlinkage polyether emulsion breaker and its preparation method. The breaker made up by hydroxy compounds contains fluorosilicic (A)and one kind of alcohol, acid, hydroxybenzene, amine that contains active hydrogen or active hydroxy group or resin contains hydroxybenzene and oxygen ethylene agent and oxygen propylene agent, they conglomerate block polyether (B). There conglomeration is act under function of interlinkage agent (E) toluene disocynate or multi alkylene polyisocyanate or diphenyl methane-4,4- diisocyanate. The agent material components and their weight percentage content as following fluorosilicic 1-15%, (B) 70-98%, (E) interlinkage agent 1-15%. Comparing to existing technique, the dosage is few, desiccation temperature is low, desiccation velocity is fast, oil contain ratio of emerged water is low, it is a high efficiency and quick crude oil demulsifying agent.

Owner:SHANGHAI UNIV OF ENG SCI

Solid honey candy and preparation method thereof

InactiveCN102058004BChange the curing characteristicsImprove product valueConfectionerySweetmeatsSucroseRoom temperature

The invention relates to a solid honey candy and a preparation method thereof. The solid honey candy comprises the following components in percentage by weight: 100 percent of liquid pure honey, 3 to 6 percent of edible solid gum and 0.7 to 3 percent of teeth stick-resisting agent, wherein the edible solid gum is selected from arabic gum, konjac gum and pectin, and the teeth stick-resisting agentis selected from lecithin, sucrose fatty acid ester and water-soluble glycerol monostearate. The preparation method of the solid honey candy comprises the following steps of: weighing the components in a weight ratio, dissolving the edible solid gum and the teeth stick-resisting agent in hot water, adding the solution into the liquid pure honey, dehydrating the obtained mixed liquid by a vacuum microwave heating method to ensure that water content is below 3 percent, performing cast molding at the temperature of between 60 and 70 DEG C, cooling and demolding to obtain the solid honey candy. The honey content of the solid honey candy is above 90 percent; the color, aroma, taste and nutrients of the original liquid honey are basically not changed; a solid shape can be kept at room temperature; and the edible teeth stick-resisting agent is added into the formula, so that the solid honey candy is not sticky to teeth and has good mouthfeel during chewing. The preparation method is easy.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com