Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Low bleeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ionic-type foam concrete foaming agent and preparation method thereof

The invention discloses an ionic-type foam concrete foaming agent and a preparation method thereof, belonging to the technical field of building chemical materials. The ionic-type foam concrete foaming agent is prepared from the following components in parts by weight: 1.5-3 parts of polydimethyldiallylammonium chloride, 0.4-1.2 parts of zwitterionic surfactant, 5-10 parts of anionic surfactant, 0.2-1 part of thickening agent and 70-80 parts of water. The ionic-type foam concrete foaming agent prepared by the method has the advantages that the raw materials are easy and convenient to obtain, the cost is relatively low, the foam stability is high, and the quality guarantee period of the foaming agent is long.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

Fiber-reinforced polymer modified crack resistant mortar

InactiveCN1594194ALow bleedingHigh viscositySolid waste managementPolymer modifiedStabilizing Agents

The invention provides a fiber-reinforced polymer modified crack resistant mortar, which is prepared by coating resilient water-proof maintenance liquid onto a mortar layer comprising cement, sand, inorganic ore powder, alkali resistant fiber, volume stabilizing agent, polymer modifier, the maintenance liquid penetrates into the capillary openings of the mortar layer, thus forming new crack resisting layer.

Owner:奥捷科技股份有限公司

Environment-friendly compound concrete foaming agent and preparation method thereof

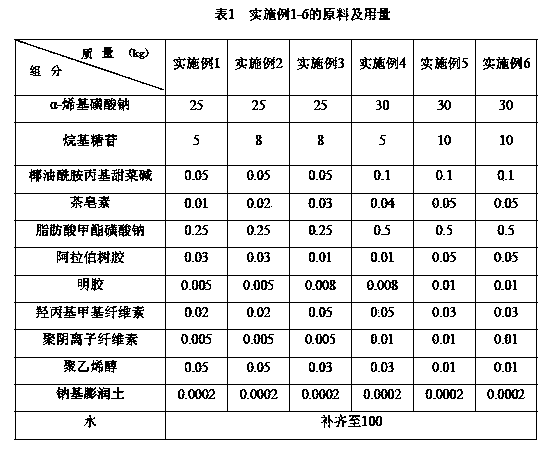

The invention discloses an environment-friendly compound concrete foaming agent and a preparation method thereof. The environment-friendly compound concrete foaming agent comprises the following components: sodium alpha-olefin sulfonate, alkyl glycoside, methyl ester sulfonate, cocamidopropyl betaine, tea saponin, arabic gum, hydroxypropyl methyl cellulose, gelatin, polyanionic cellulose, polyvinyl alcohol and sodium bentonite. The environment-friendly compound concrete foaming agent disclosed by the invention is alkalescent, achieves the pH value of 7-9, has the advantages of high foaming power, large foam expansion, fine uniform and tough foam, durability, stability, long foam stabilizing time, small bleeding amount, small deposition amount, good hard water resistance and suitability for water with various rigidities.

Owner:深圳市中天元实业有限公司

High efficiency concrete composite admixture

InactiveCN103588415ALate strengthDelay the initial setting and final setting time of concrete without affecting the later strengthSuperplasticizerWater reducer

The invention discloses a high efficiency concrete composite admixture, which comprises the following components: by weight, 5%-20% of triethanolamine, 10%-15% of sodium lignin sulfonate, 2% - 3% of a naphthalene-series high efficiency water reducer, 1% - 2% of bone glue, 5% - 15% of tartaric acid, 2% - 3% of rosin, 3% - 5% of sodium dodecyl benzene sulfonate, and the balance of water. The high efficiency concrete composite admixture has the advantages of simple process and excellent performances.

Owner:JIANGSU BAIRUIJI NEW MATERIAL

Phosphogypsum flame retardant foaming agent

The invention discloses a phosphogypsum flame retardant foaming agent. The technical scheme is characterized in that the phosphogypsum flame retardant foaming agent is composed of phosphogypsum, high-viscosity attapulgite clay powder, active attapulgite clay, sodium bicarbonate, sodium alkyl benzene sulfonate, sodium polyacrylate, sodium pyrophosphate, ammonium polyphosphate and zinc borate which are dehydrated; and all the ingredients of the phosphogypsum flame retardant foaming agent are stirred, ground and packaged to obtain a finished product of the phosphogypsum flame retardant foaming agent. After water is added into the phosphogypsum flame retardant foaming agent and the mixture is stirred at a high speed, a great amount of gases are rapidly released, and thus, porous foam sludge is formed; the foam slurry is directly used for extinguishing a fire after being sprayed by using a high-pressure water gun; the foam slurry is stably covered on the surface layer of a combustible material to form a foam slurry film which can be used for rapidly isolating the contact of the combustible material and the air and preventing the combustible material from continuing combusting, and thus, the aims of flame retarding and fire extinguishing are achieved; and the phosphogypsum flame retardant foaming agent is suitable for producing flame retarding and fire extinguishing products, light boards, light walls and silencing and noise reducing products.

Owner:李兴乐

Powdery talcum foaming agent

InactiveCN103265318AShort demoulding timeImprove stabilityCeramicwarePolymer scienceSodium phosphates

The invention discloses a powdery talcum foaming agent. The foaming agent comprises acidified talcum, high-viscosity attapulgite clay powder, active attapulgite clay, sodium dodecyl sulfate, sodium percarbonate, sodium polyacrylate, sodium pyrophosphate and sodium poly[(naphthaleneformaldehyde)sulfonate]. The finished product of the powdery talcum foaming agent is produced by stirring ingredients of the powdery talcum foaming agent, milling the ingredients into powder and packaging the powder. The powdery talcum foaming agent has the advantages that the powdery talcum foaming agent has strong foaming capacity, high foam expansion and high foam yield in unit volume, has good foam outer membrane tenacity and is not easy to break, has good foam stability, can not be defoamed for a long time, is exquisite in foam, is uniform in sizes of holes generated in media and has low bleeding quantity and good compatibility of used media. The products produced by using the powdery talcum foaming agent not only can effectively control noise pollution but also have the functions of preserving heat and purifying air. The powdery talcum foaming agent is suitable for producing lightweight boards, lightweight walls and noise reducing products.

Owner:如皋市樊川贸易有限公司

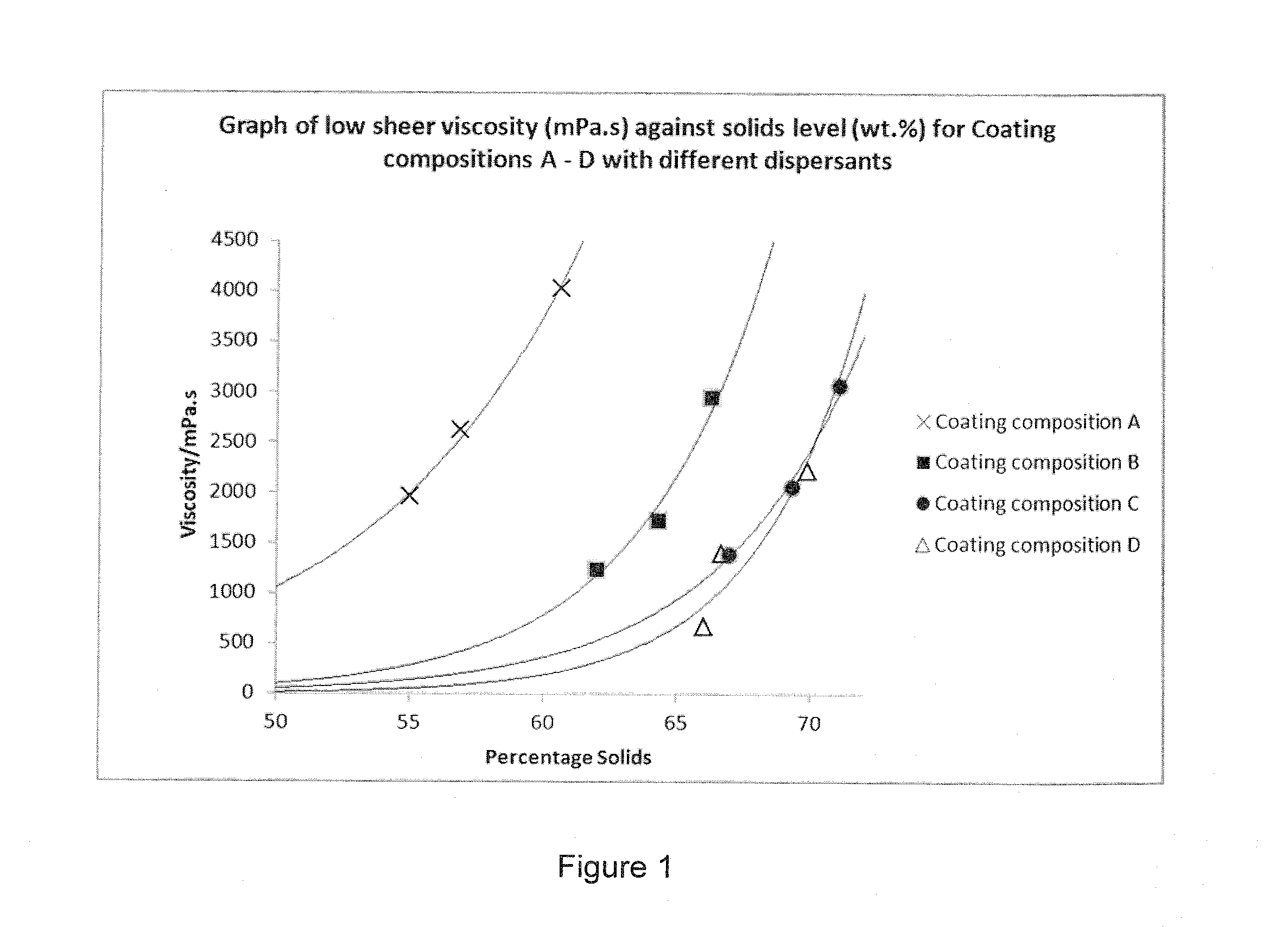

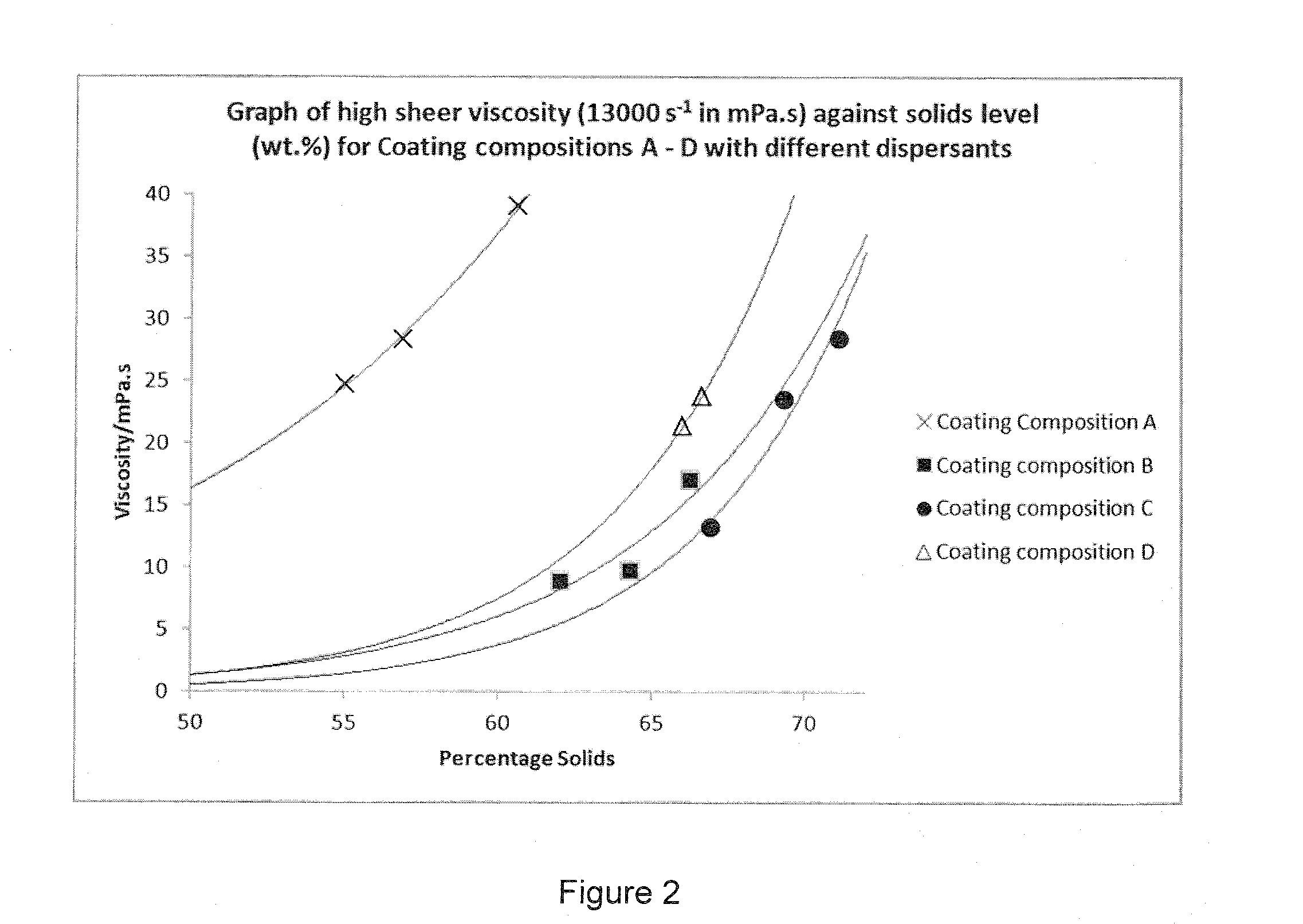

Pigment compositions

InactiveUS20150030869A1Minimal and no runnability issueImprove printing qualityCoatings with pigmentsDuplicating/marking methodsNon ionicParticulate material

Owner:IMERTECH SAS

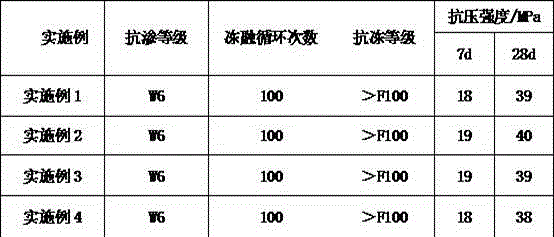

Method for producing concrete channel prefabricated part from mineral slag

InactiveCN106007593AImprove anti-seepage effectImprove flexibilitySolid waste managementAluminateSlag

The invention relates to a method for producing a concrete channel prefabricated part from mineral slag. The method is characterized in that the concrete channel prefabricated part is prepared from the following raw materials in parts by weight: 60-70 parts of fine and coarse aggregate, 10-20 parts of 42.5 sulfoaluminate cement, 5-10 parts of fly ash, 5-10 parts of slag micropowder, 1-3 parts of early-strength admixture, 1-3 parts of high efficiency water reducing agent and 0.1-0.5 part of defoaming agent. The high efficiency water reducing agent is a calcium lignosulphonate water reducing agent. The concrete channel prefabricated part has the advantages of low cost, excellent properties, stable quality, excellent compression strength, excellent compression strength, excellent freeze resistance and excellent water impermeability. The method aims to further enhance the standard construction of irrigation projects, comprehensively enhance the construction level and management and protection level of agricultural hydraulic engineering in China, increase the utilization ratio of irrigation water and implement high-efficiency utilization of water resources.

Owner:象州县科学技术局

Powdery kieselguhr foamer

InactiveCN103265307AReduce surface tensionShort demoulding timeCeramicwareSodium phosphatesPyrophosphate

The invention discloses a powdery kieselguhr foamer, wherein the essential of the technical scheme is as follows: the powdery kieselguhr foamer is composed of dried kieselguhr, high-viscosity attapulgite clay powder, sodium dodecyl sulphate, sodium percarbonate, sodium polyacrylate, sodium pyrophosphate and sodium naphthaldehyde sulfonate. The powdery kieselguhr foamer finished product is obtained by stirring, grinding and packaging the ingredients of the powdery kieselguhr foamer. The powdery kieselguhr foamer has the advantages of being strong in foaming capacity, high in foaming times, high in foam production amount per unit volume, good in the toughness of foam outer membranes with low possibility of breaking, good in foam stability, unable to defoam for a long time, fine in foam, uniform in the size of the holes generated in a medium, low in bleeding amount, good in the compatibility of the used medium, and the like. The products produced by virtue of the powdery kieselguhr foamer are capable of effectively controlling noise pollution, and have the functions of insulating heat and purifying air; and the powdery kieselguhr foamer is suitable for producing light-weight boards, light-weight wall bodies as well as silencing and noise-reducing products.

Owner:邹五华

Kaolin flame-retardant foaming agent

ActiveCN103265200AImprove stabilityHigh foaming ratioFireproof paintsActivated attapulgiteSodium bicarbonate

The invention discloses a kaolin flame-retardant foaming agent. The technical scheme has the following key points: the kaolin flame-retardant foaming agent comprises dried kaolin, activated attapulgite, sodium hydrogen carbonate, sodium alkyl benzene sulfonate, sodium polyacrylate, sodium pyrophosphate, ammonium polyphosphate and zinc borate. The finished product of the kaolin flame-retardant foaming agent is prepared by stirring, grinding and packaging the ingredients. Water is added into the kaolin flame-retardant foaming agent, and a great deal of gas is rapidly released after the water solution is stirred at high speed, so that porous foam slurry can be formed; the foam slurry is jetted by a high-pressure water gun so as to be directly used for putting out a fire; the foam slurry is stably covered on the surface layer of combustible material so as to form a foam slurry film; and the foam slurry film can rapidly isolate the contact between the combustible material and the air, and the combustible material is prevented from continuously burning, so that the aims of inflaming retarding and extinguishing a fire can be achieved. The kaolin flame-retardant foaming agent is suitable for producing light weight boards, light weight walls and noise reduction products which have the inflaming retarding and fire extinguishing functions.

Owner:安徽优盾信息科技有限公司

Technology for producing slag micro powder and application of slag micro powder in cement production

The invention discloses a technology for producing slag micro powder and application of the slag micro powder in cement production. The cement comprises the following raw materials in part by weight: 25 to 30 parts of slag micro powder, 45 to 55 parts of clinker, 3 to 8 parts of desulfurized gypsum, 5 to 10 parts of coal gangue, and 5 to 10 parts of fly ash. The technology is low in investment and quick in response, a large quantity of blast furnace slag can be digested, and the produced cement product has excellent performance. When the slag micro powder is applied to common cement concrete, the consumption of the cement can be reduced, and the cost of the concrete is reduced.

Owner:HENAN HAIHUANG CEMENT

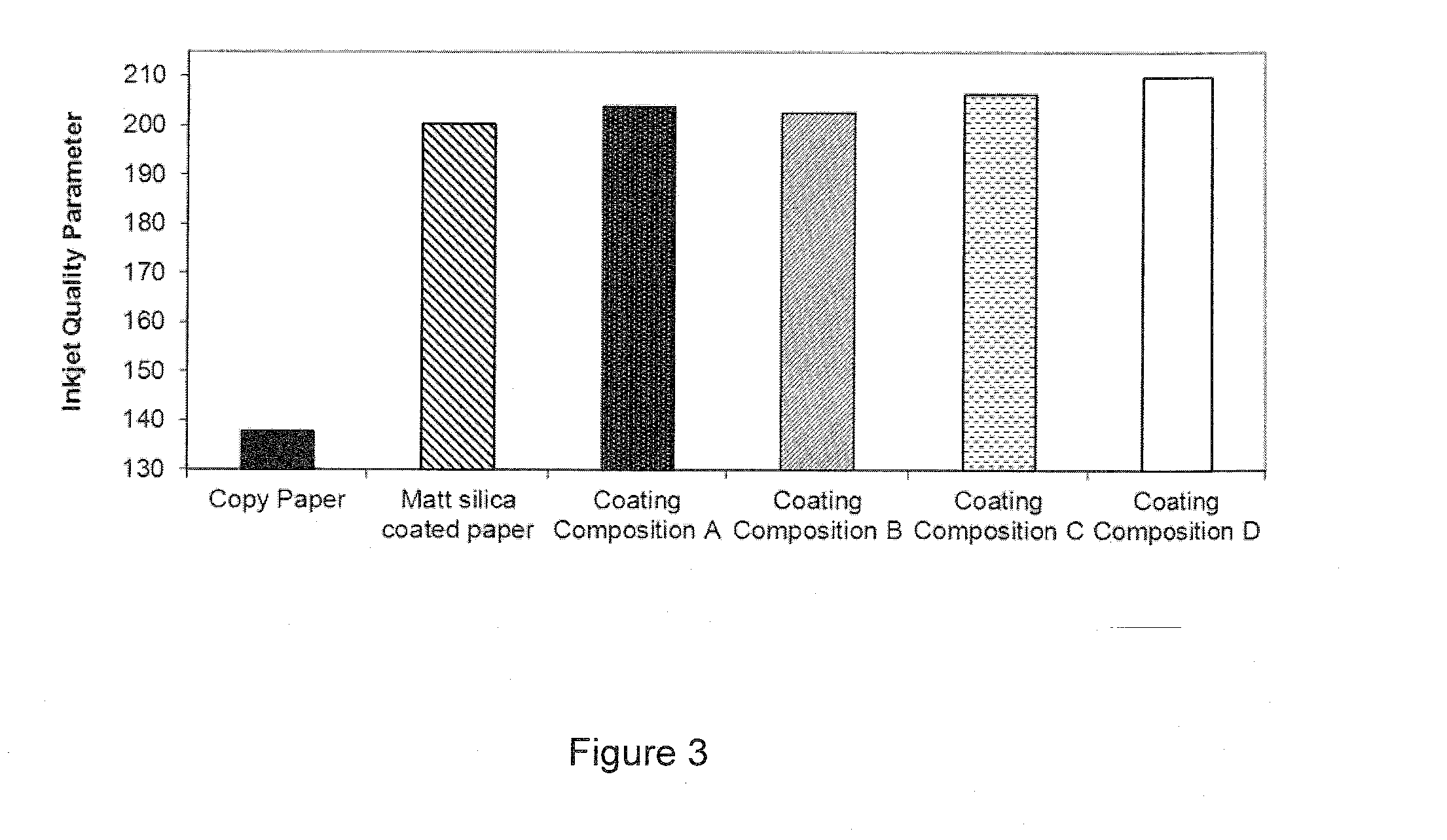

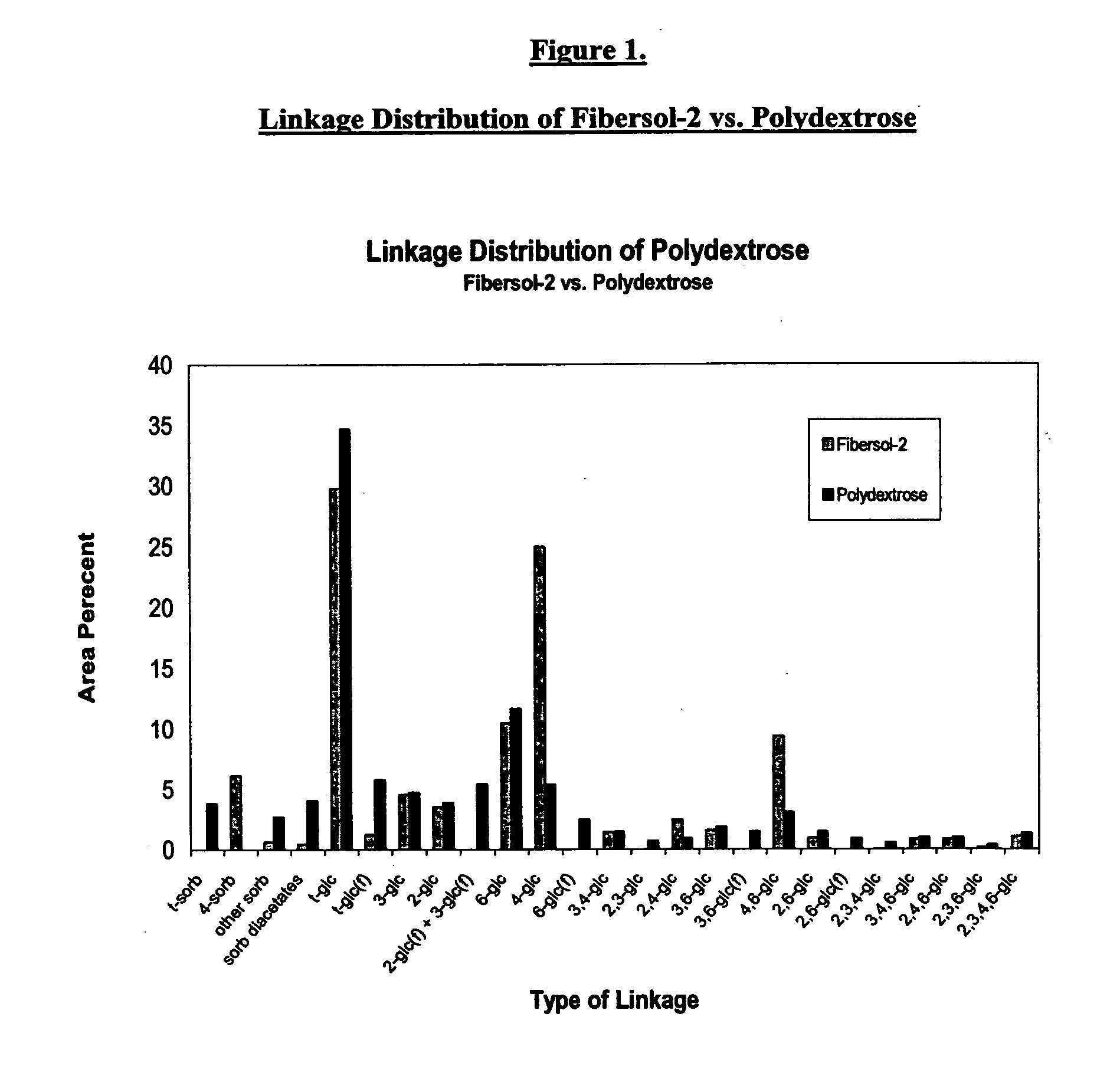

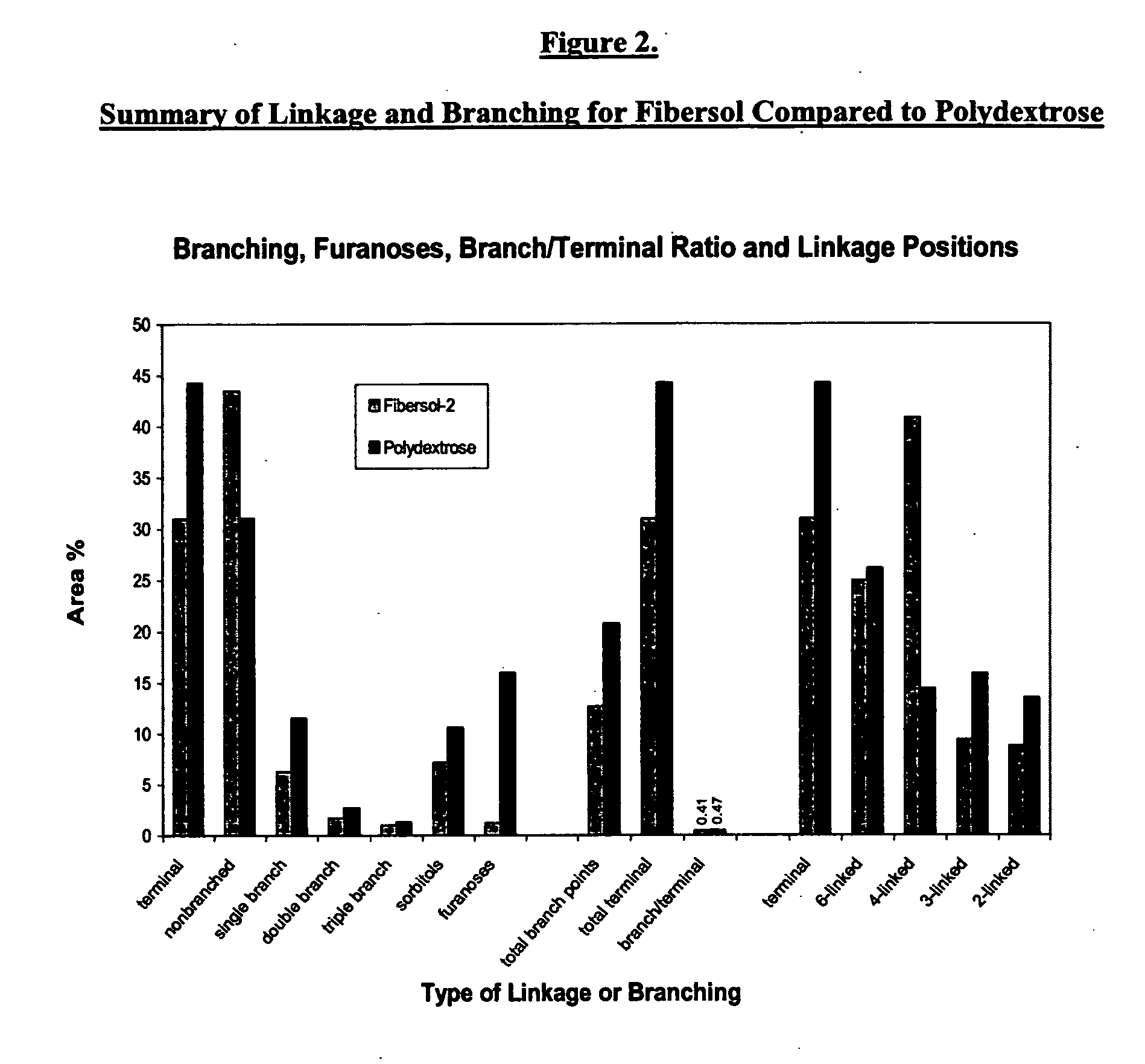

Print receptive topcoat for ink jet printing media

InactiveUS20060263550A1Good printabilityGood colorDextran coatingsThermographyPrinting inkPolyvinyl alcohol

An ink jet media ink receptive topcoat composition of a number of constituent components including a binder comprised of polydextrose and / or indigestible polysaccharide or combination thereof, wherein a topcoat derived from the coating composition is printable with either pigment or dye composition ink jet printing inks. The invention also relates to ink jet media with a base support layer and a media coating composition, or ink receptive topcoat which includes a polydextrose and / or indigestible dextrin binder wherein the topcoat is printable with liquid ink jet inks. The invention results in improved print quality, significantly improved print color (Chroma) development, and a lower cost coating when compared to like media employing a coating containing polyvinyl alcohol or polyvinylpyrrolidone as a binder.

Owner:AS DE DANSKE SUKKERFABRIKKER

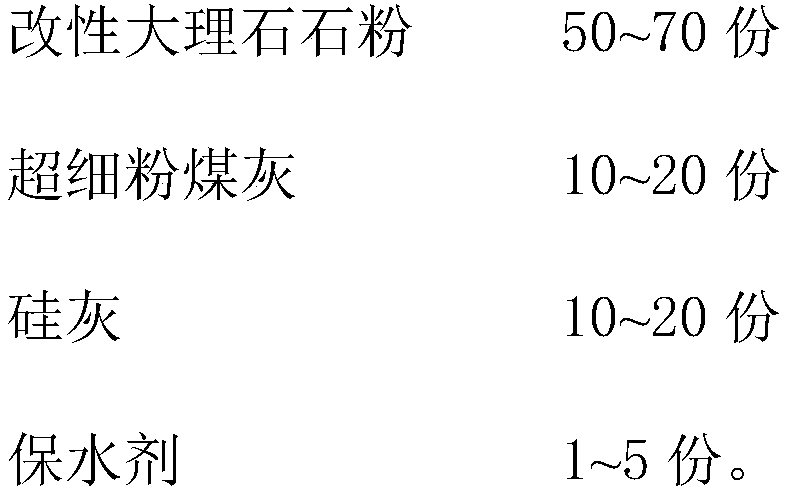

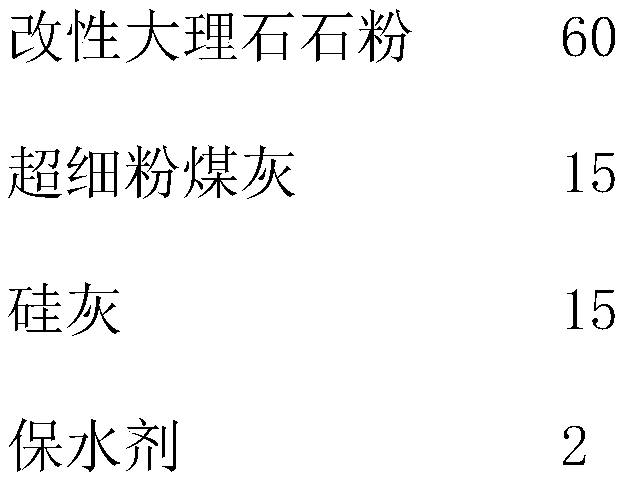

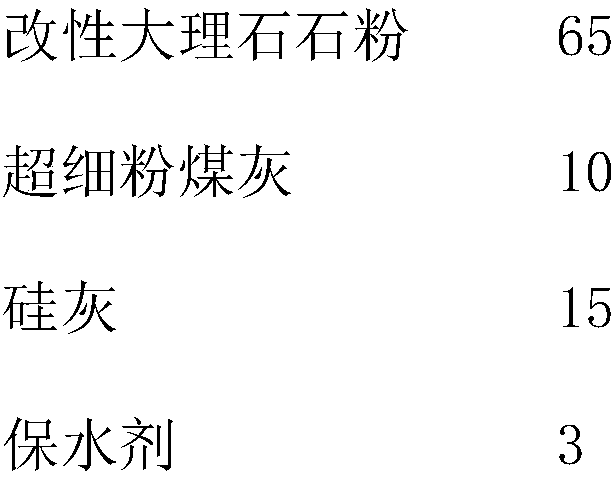

Bleeding-reduced-type concrete admixture by using marble powder as major and preparation method thereof

The invention relates to the field of building materials and in particular to a bleeding-reduced-type concrete admixture by using marble powder as a major and a preparation method thereof. The bleeding-reduced-type concrete admixture comprises the following components in parts by weight: 50-70 parts of modified marble powder, 10-20 parts of superfine coal ash, 10-20 parts of silica fume, and 1-5 parts of a water-retaining agent. The preparation method thereof comprises the following steps: simultaneously adding the water-retaining agent and the silica fume to a blender and stirring for 10-20 minutes, and adding the superfine coal ash, stirring for 10-20 minutes, finally adding the modified marble powder, and stirring for 20-30 minutes, after uniformly mixing, preparing the bleeding-reduced-type concrete admixture. The bleeding-reduced-type concrete admixture is capable of, through introducing the modified marble powder, the superfine coal ash and the silica fume and optimizing the concrete admixture, improving a concrete flow rate, improving pumping performance, improving concrete homogeneity through introducing the water-retaining agent, and reducing the concrete bleeding, and canbe extensively used for construction of pump concrete, and middle and low grade concrete.

Owner:FUJIAN KZJ NEW MATERIALS CO LTD

Unfired sludge foaming acoustical board

InactiveCN103806567AIncrease moisture contentHarm reductionMouldsNoise reduction constructionPublic placeFoaming agent

The invention discloses an unfired sludge foaming acoustical board. According to the technical scheme, the unfired sludge foaming acoustical board is characterized in that a built-in frame is horizontally placed on a mold, after short steel pipes in the built-in frame are inserted into stand columns, sludge cement foaming agent is poured on the periphery of the built-in frame, the built-in frame is totally inlaid in the sludge cement foaming agent, maintenance is performed according to a conventional cement product maintenance method, and packaging is performed to form an unfired sludge foaming acoustical board finished product; the sludge cement foaming agent is prepared from a sludge mixture, high-viscosity attapulgite clay powder, cement and other raw materials; the sludge cement foaming agent and the built-in frame form an integrated whole after the sludge cement foaming agent is cured, and thus the overall strength, the bending resistance and the actual using effect of the unfired sludge foaming acoustical board are improved. The unfired sludge foaming acoustical board not only can be used for effectively controlling noise pollution but also has the functions of heat preservation and air purification and is suitable for being mounted in facilities such as expressways, viaducts, urban light rails, subways, public places and the like.

Owner:许庆华

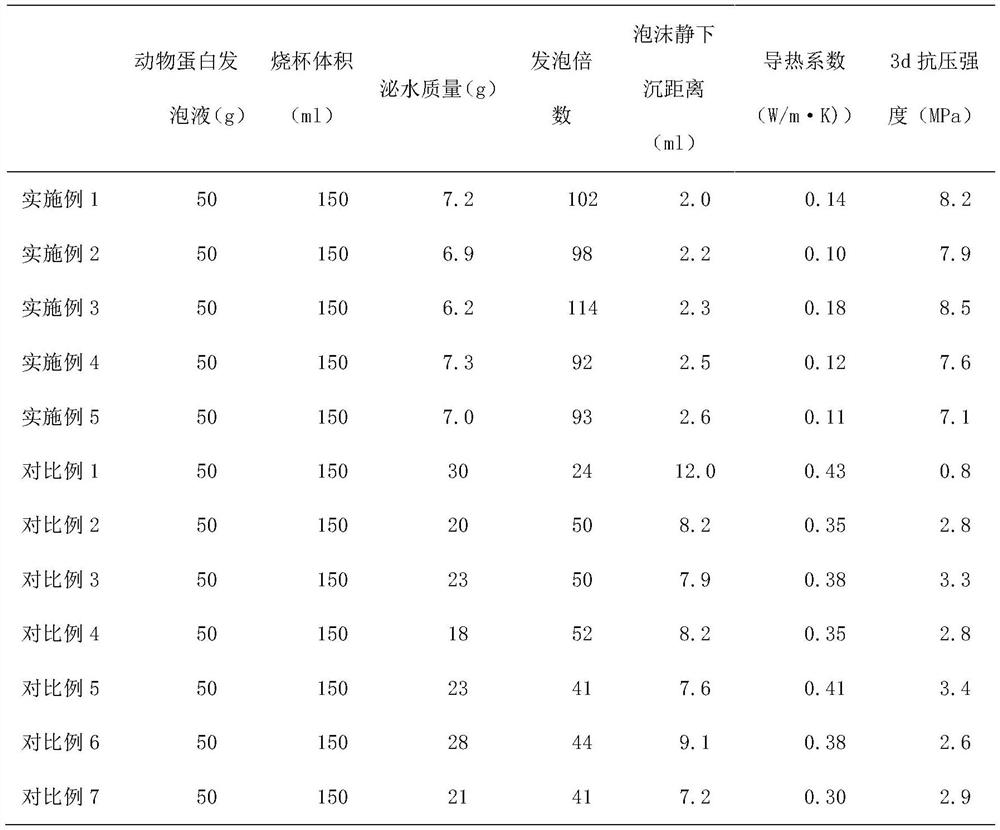

Preparation method of stable-type odor-free low-density foam concrete foamer

The invention relates to a preparation method of a stable-type odor-free low-density foam concrete foamer and belongs to the technical field of concrete foamers. The method includes the steps of: dissolving active components in humic acid by a NaOH solution, filtering the solution to remove impurities and dropwise adding hydrochloric acid to remove macro-molecular substances and modify water soluble small-molecular active components; by means of microorganisms in earthworm feces, fermenting active sludge in a secondary sedimentation tank to achieve deodorization; and enzymolysing the microorganisms and animal and plant proteins by means of protease, and compounding the enzymolyzed substances with the modified humic acid extract and sodium dodecyl benzene sulfonate to obtain the stable odor-free low-density foam concrete foamer. By means of octadecyl trimethyl ammonium chloride, hydrophobicity and lipophobicity of the small-molecular substances in the humic acid can be equilibrated, and through compounding with the protein in the active sludge and the sodium dodecyl benzene sulfonate, the problems of poor stability and low foaming times in a conventional concrete foamer are solved effectively. By means of the deodorization function of the earthworm feces, a problem of intensive stink of the foamer is solved.

Owner:福建科胜加固材料有限公司

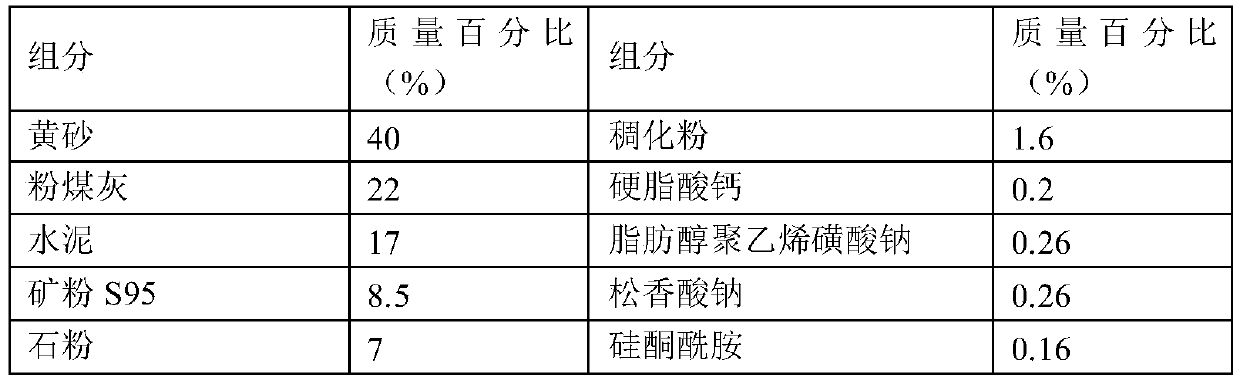

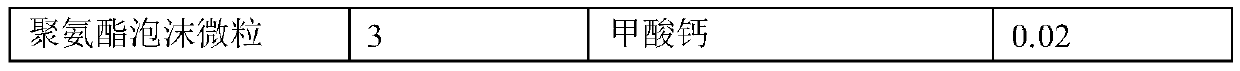

Cement mortar dry powder

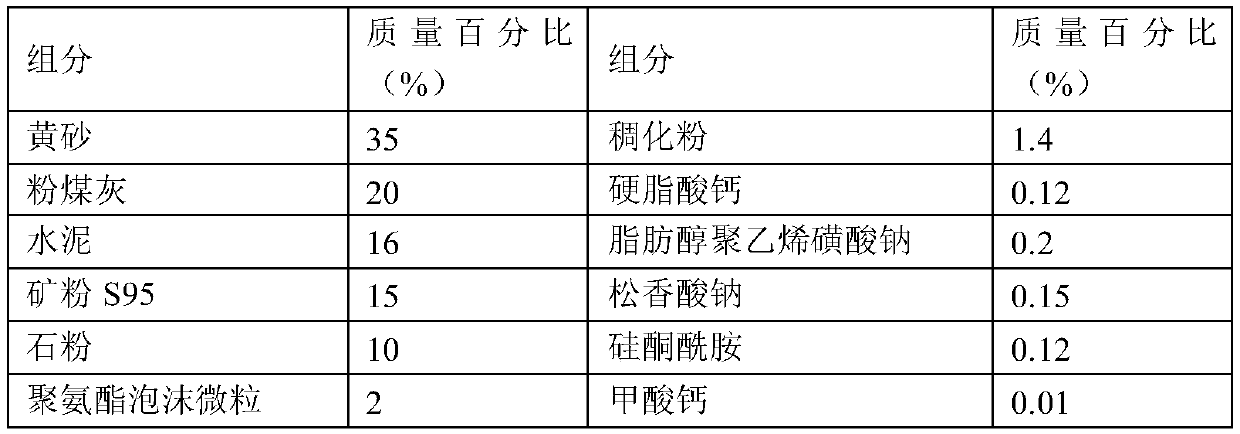

The invention relates to cement mortar dry powder which comprises the following components in percentage by mass: 35-45% of yellow sand, 20-25% of fly ash, 15-20% of cement, 5-15% of mineral powder, 5-10% of stone powder, 2-4% of polyurethane foam particles, 1-2% of a thickening powder, 0.1-0.3% of a waterproof agent, 0.2-0.3% of fatty alcohol polyvinyl sodium sulfonate, 0.15-0.25% of sodium abietate, 0.1-0.2% of silicone amide and 0.01-0.02% of calcium formate. The thickening powder comprises the following components in parts by weight: 380-420 kg / t of bentonite, 30-45 kg / t of rubber powder,20-30 kg / t of hydroxypropyl methylcellulose, 15-20 kg / t of sodium polyacrylate and 2-5 kg / t of a water reducer. The cement mortar dry powder has the effect of improving the physical property of cementmortar mixing.

Owner:宁波新广亿建材有限公司

Powdery basalt foaming agent

The invention discloses a powdery basalt foaming agent. The foaming agent comprises porous basalt, high-viscosity attapulgite clay powder, active attapulgite clay, sodium dodecyl sulfate, sodium percarbonate, sodium polyacrylate, sodium pyrophosphate and sodium poly[(naphthaleneformaldehyde)sulfonate]. The finished product of the powdery basalt foaming agent is produced by stirring ingredients of the powdery basalt foaming agent, milling the ingredients into powder and packaging the powder. The powdery basalt foaming agent has the advantages that the powdery basalt foaming agent has strong foaming capacity, high foam expansion and high foam yield in unit volume, has good foam outer membrane tenacity and is not easy to break, has good foam stability, can not be defoamed for a long time, is exquisite in foam, is uniform in sizes of holes generated in media and has low bleeding quantity and good compatibility of used media. The products produced by using the powdery basalt foaming agent not only can effectively control noise pollution but also have the functions of preserving heat and purifying air. The powdery basalt foaming agent is suitable for producing lightweight boards, lightweight walls and noise reducing products.

Owner:李兴乐

Unburned zeolite foam sound-absorbing board

InactiveCN103556746AHigh strengthImprove bending resistanceNoise reduction constructionSound proofingThermal insulationMaterials science

The invention discloses an unburned zeolite foam sound-absorbing board. The technical scheme is characterized in that an internal frame is flatly placed on a mould, after short steel tubes in the internal frame are inserted into columns, a zeolite cement foaming agent is poured on the periphery of the internal frame, the internal frame is totally inlaid in the inside of the zeolite cement foaming agent, curing is carried out according to a conventional cement product curing method, and packaging is performed to form an unburned zeolite foam sound-absorbing board finished product. The zeolite cement foaming agent is composed of raw material such as zeolite, high-viscosity attapulgite clay powder and cement. The zeolite cement foaming agent is integrated with the internal frame into a whole after curing, so that integral strength, bending resistance capacity and actual use effect of the unburned zeolite foam sound-absorbing board are improved. The unburned zeolite foam sound-absorbing board can not only effectively control noise pollution but also has functions in thermal insulation and air purification; besides, the unburned zeolite foam sound-absorbing board is suitable for being mounted in facilities such as highways, viaducts, urban light rails, subways and public places.

Owner:张连重

Self-insulation system foam concrete and preparation method thereof

The invention discloses self-insulation system foam concrete. The self-insulation system foam concrete is prepared from the following raw materials in parts by weight: 20-40 parts of sulphoaluminate cement, 20-40 parts of an animal protein foaming agent, 6-15 parts of sodium alpha-olefin sulfonate, 6-15 parts of lauryl sodium sulfate and 6-15 parts of sodium dodecyl benzene sulfonate. The preparation method comprises the following steps: diluting the animal protein foaming agent, mixing slurry with prepared foam, and then conducting pouring and curing. By adding the ionic animal protein modifier, the stability of the foam is enhanced, porosity is improved, and the thermal insulation property of the foam concrete is improved. The foam concrete is prepared from the sulphoaluminate cement, CO2 emission is reduced, energy is saved, and environment friendliness is achieved; meanwhile, a prepared foam concrete test block is high in porosity; and collapse of the foam in the foam concrete during pouring and curing can be reduced by means of the fast setting property of the sulphoaluminate cement, the heat preservation and heat insulation performance of the foam concrete is good, compressive strength is high, and the application prospect of the foam concrete is wide.

Owner:HUBEI UNIV OF TECH

Fibre-reinforced anti-crack mortar dry powder

The invention provides a fiber mortar dried powder material for strengthening the anti-crack, which comprises functionality the materials of cement, sand, silicon aluminum hollow spheroid, alkali proof fiber, mineral contraction inhibitor, cement hydration regulation agent, modifier and so on. Wherein, the cement hydration regulation agent comprises cement hydration slow hardening components and molding moisture and negative setup components. The mortar dried powder material for strengthening the anti-crack is able to be used through adding water to solve the problem of inaccurate calculation and material wasting of the traditional method owing to the preparation of the material in the scene. The prepared mortar solves the problem of crack owing to the stress of the ordinary mortar. The invention has the advantages of molding moisture, slow hardening, waterproof and easy construction, which is mainly used as the anti-crack mortar for the construction of heat preservation and heat insulation wall and also other construction walls.

Owner:武汉科华高新材料发展有限公司

Building waste prefabricated part and preparation method thereof

InactiveCN108373304AReduce manufacturing costImprove mechanical propertiesSolid waste managementSocial benefitsSuperplasticizer

The invention provides a building waste prefabricated part and a preparation method thereof. The building waste prefabricated part is prepared from the following raw materials of 50 to 80% of buildingwaste, 1 to 5% of domestic garbage, 5 to 15% of cement, 5 to 9.6% of water, 0.5 to 4% of fly ash, 1 to 3% of high-efficiency water reduction agent, 0.1 to 0.5% of defoaming agent, and 0.5 to 1% of silicon ash. The building waste prefabricated part can be used for replacing the concrete prefabricated parts to provide building materials of ground tiles, cutting blocks or curbs and the like with high strength; the building waste can be treated in a harmless way at low cost, and the good economic benefit and social benefit are realized.

Owner:贵州隆盛源建材有限公司

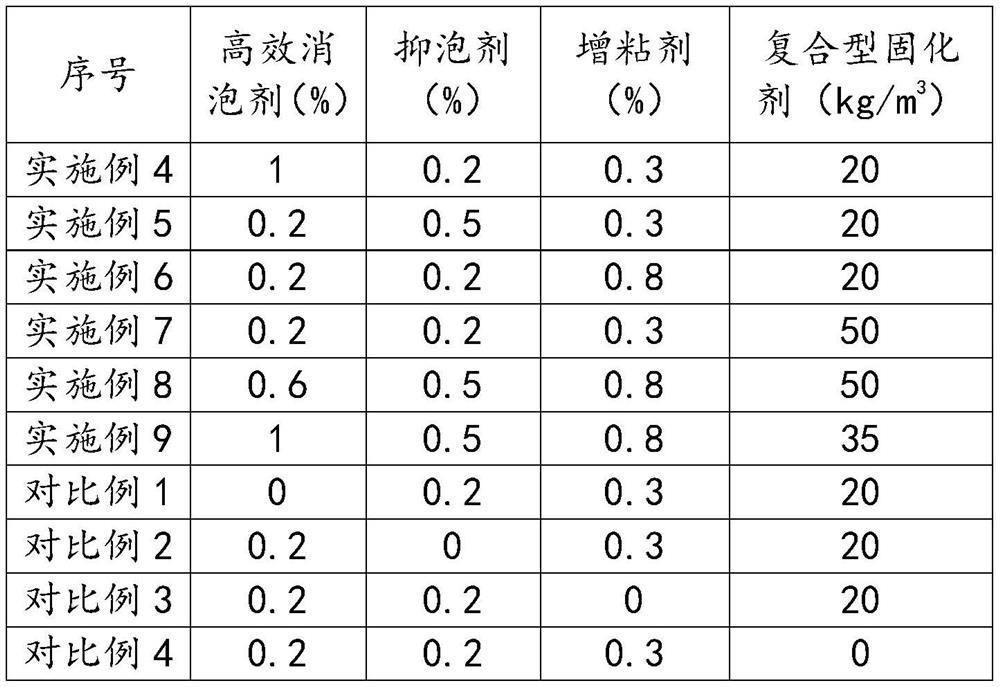

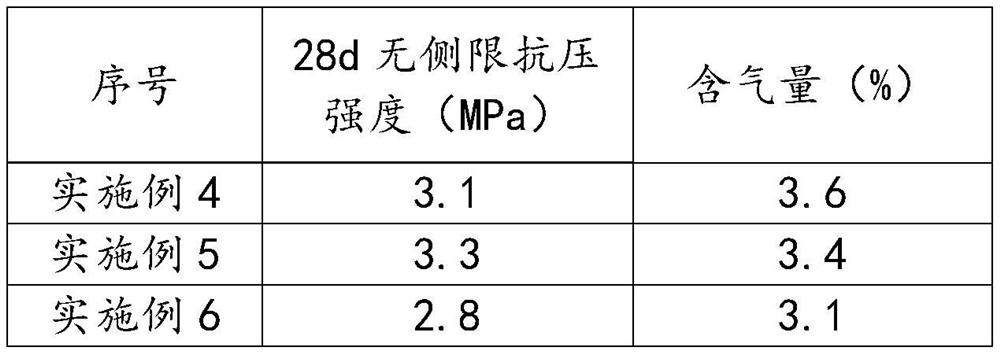

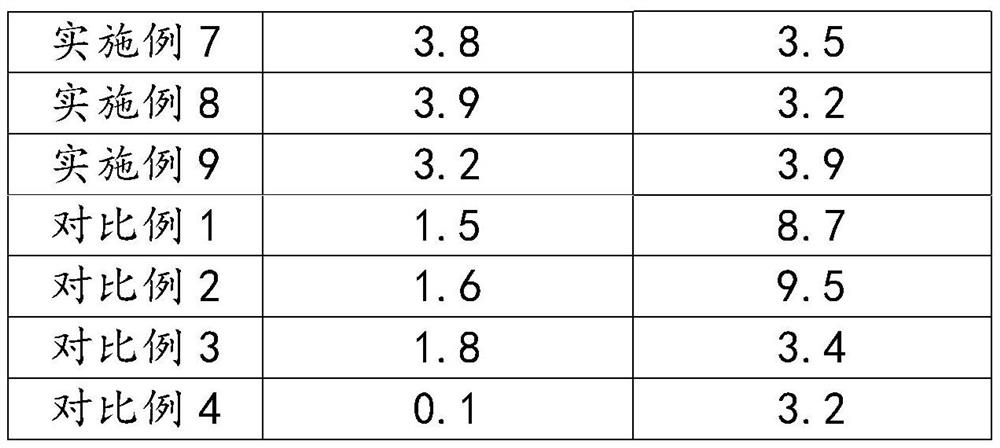

Method for preparing roadbed material by curing hard rock shield muck

The invention provides a method for preparing a roadbed material by curing hard rock shield muck, which particularly comprises the following steps: during shield construction, adding an efficient defoaming agent solution into the shield muck at the front end of a screw conveyor, and uniformly mixing by virtue of a screw conveying process, then respectively spraying a foam inhibitor solution and a tackifier solution into the shield muck at a muck outlet of the spiral conveyor, uniformly mixing by utilizing a belt conveying process, then adding a compound curing agent into the shield muck at the tail end of the belt conveyor, and finally uniformly stirring by utilizing forced stirring equipment arranged in a muck trolley to prepare the roadbed material. A common muck truck is adopted to be transported to the site, and then roadbed construction can be conducted. According to the method, the hard rock shield muck which is high in water content, flowing and rich in foaming agent is prepared into the roadbed material of which the performance and environmental protection both meet the standard requirements by adopting a chemical curing mode and adopting the technical means of foam elimination, bubble inhibition, system tackifying and the like, so that high-value resource utilization of the shield muck is realized.

Owner:中铁十局集团有限公司 +1

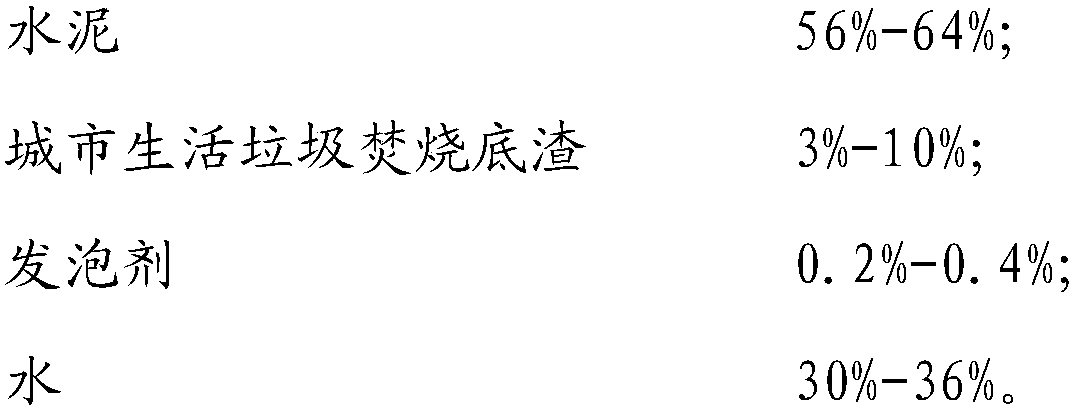

Lightweight water permeable material for bridgehead back backfill and preparation method thereof

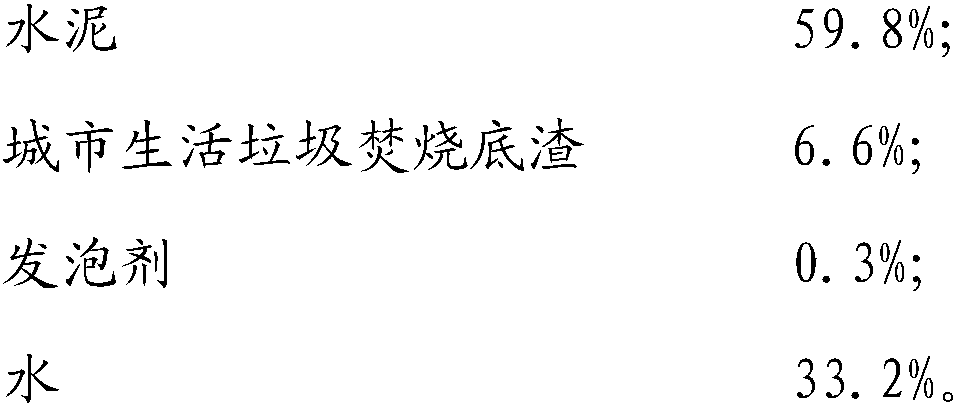

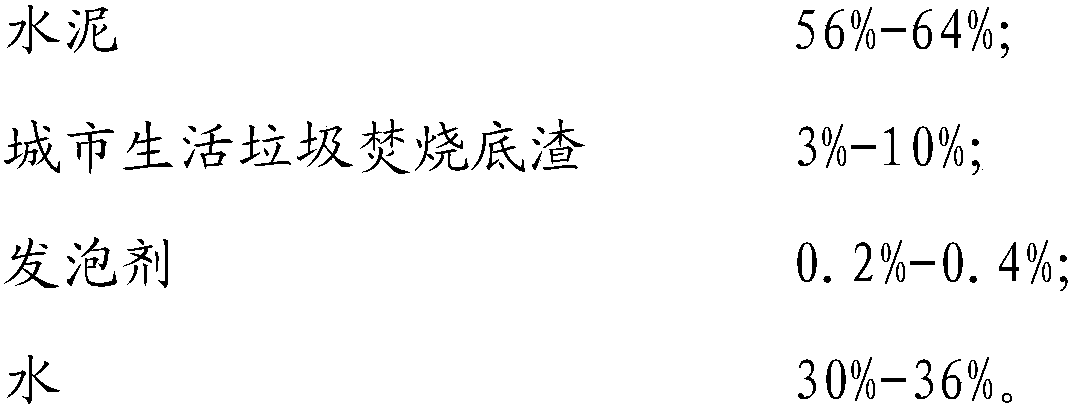

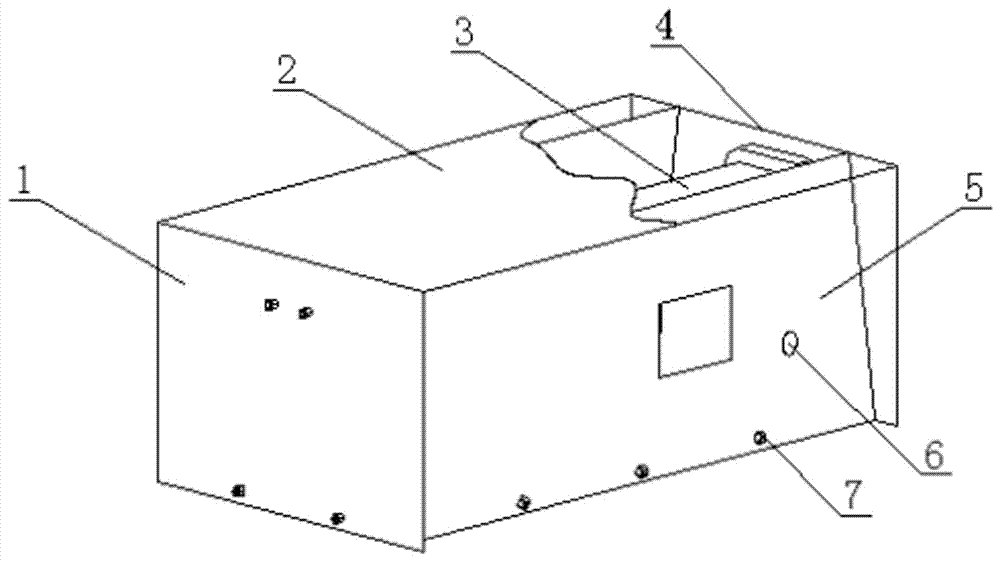

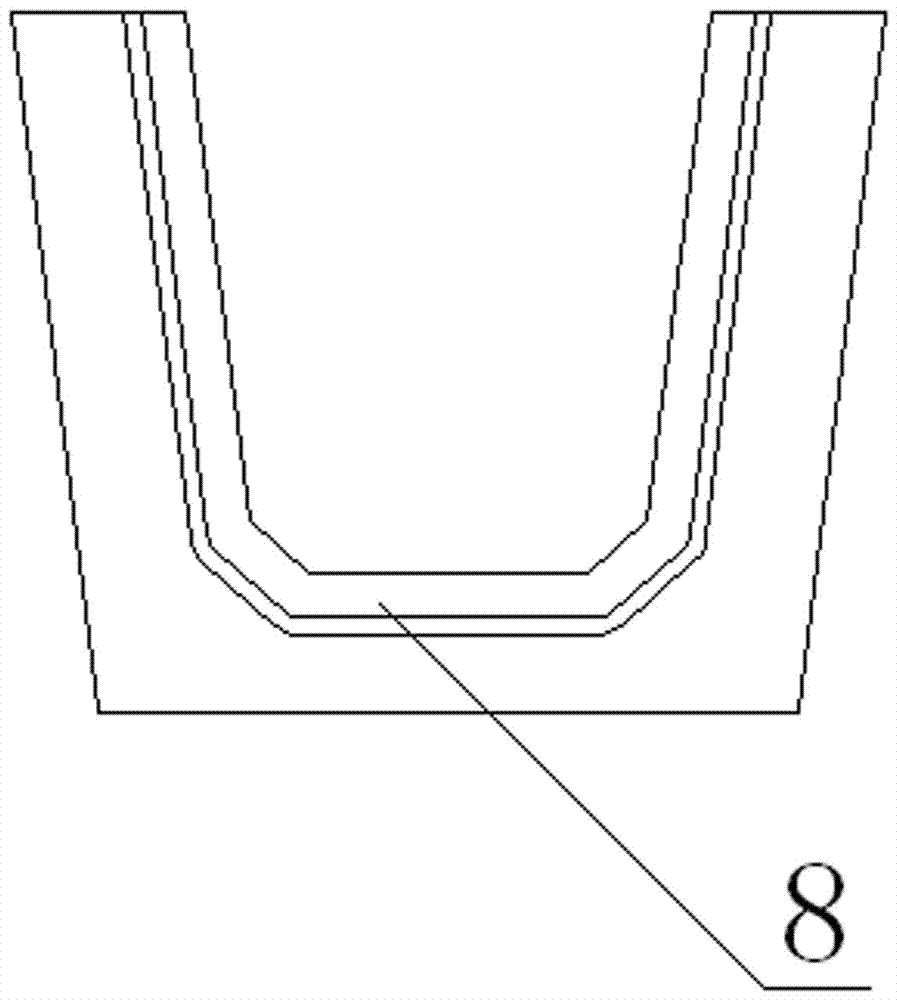

The invention relates to a lightweight water permeable material for bridgehead back backfill and a preparation method thereof. The lightweight water permeable material comprises the following components in percentage by weight: 56-64 percent of cement, 3-10 percent of municipal domestic waste incineration bottom slag, 0.2-0.4 percent of a foaming agent and 30-36 percent of water. The lightweight water permeable material for bridgehead back backfill, provided by the invention, is lightweight, can greatly reduce the self weight of foundation soil, is more suitable in liquidity, can meet the self-flow requirements for backfilled materials during construction, is good in water resistance, can keep the integrity of an original structure intact in a flowing water environment, meets the strengthrequirements, does not shrink and is good in durability.

Owner:WUHAN MUNICIPAL ENG DESIGN & RES INST

Reinforced type plastering mortar

The invention belongs to the technical field of building materials, and provides a reinforced type plastering mortar. The reinforced type plastering mortar is prepared from the following raw materials in parts by weight: 20 to 25 parts of silicate cement, 1 to 5 parts of superfine calcium carbonate, 50 to 65 parts of quartz sand, 5 to 8 parts of wollastonite powder, 1 to 2 parts of foamed polytetrafluoroethylene, 0.01 to 0.03 part of glycol ether, 0.1 to 0.2 part of dispersant, 0.02 to 0.05 part of synergist and 0.1 to 0.15 part of film-forming base material. The reinforced type plastering mortar has the beneficial effects and characteristics that the heat preservation and heat insulation properties are good, the anti-seepage and anti-cracking properties are good, the adhering strength is high, the wind pressure-resistant property is realized, the freezing and melting-resistant property is realized, and the like.

Owner:新昌县永佳耐火材料厂

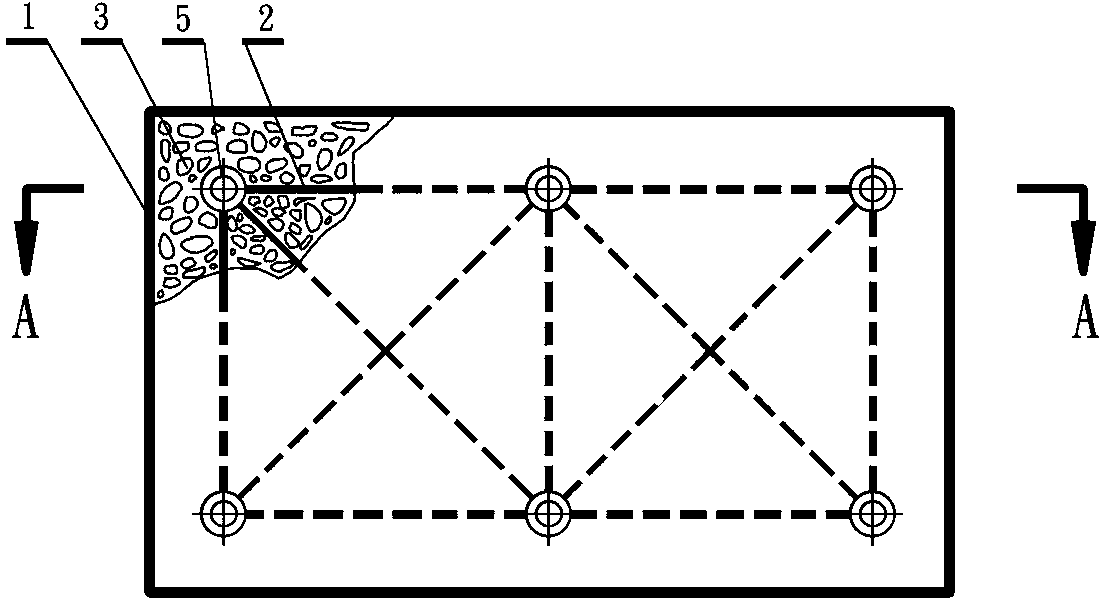

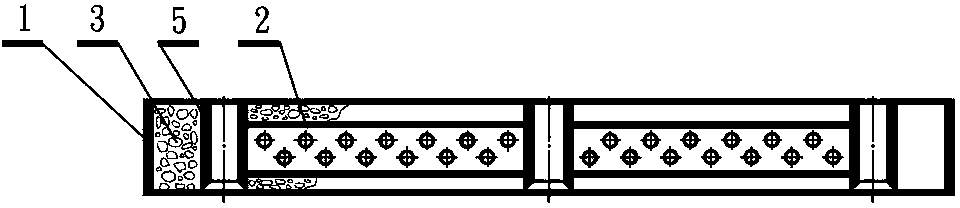

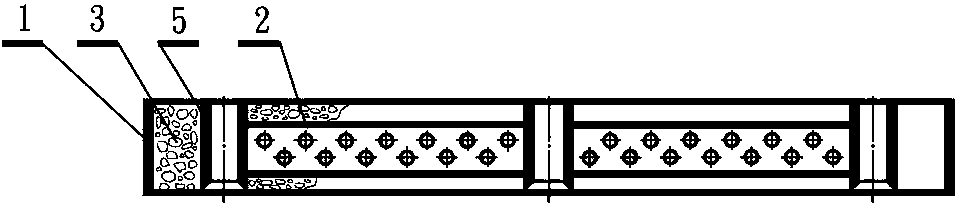

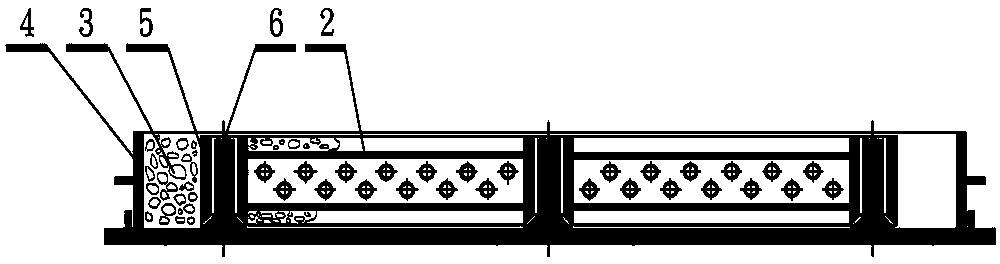

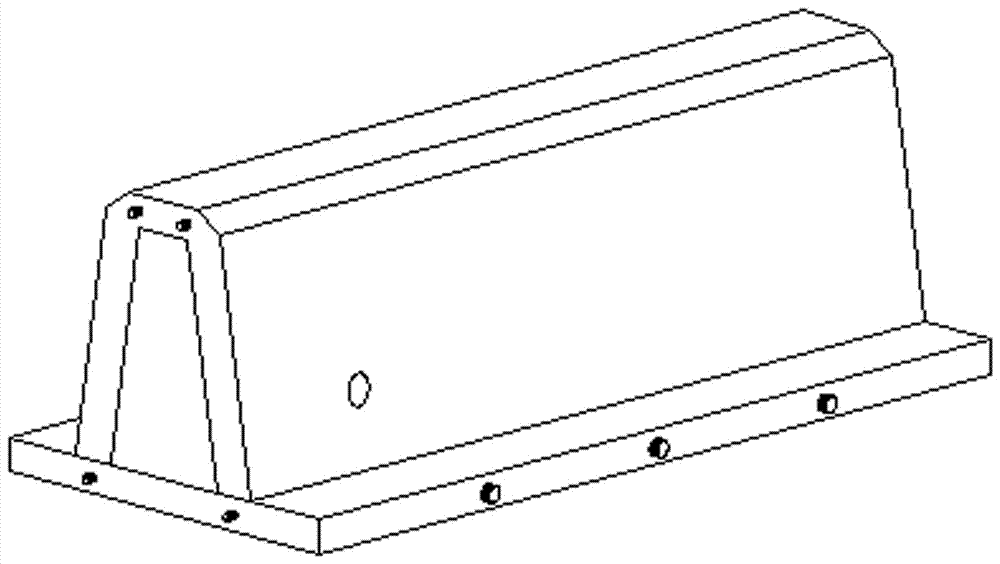

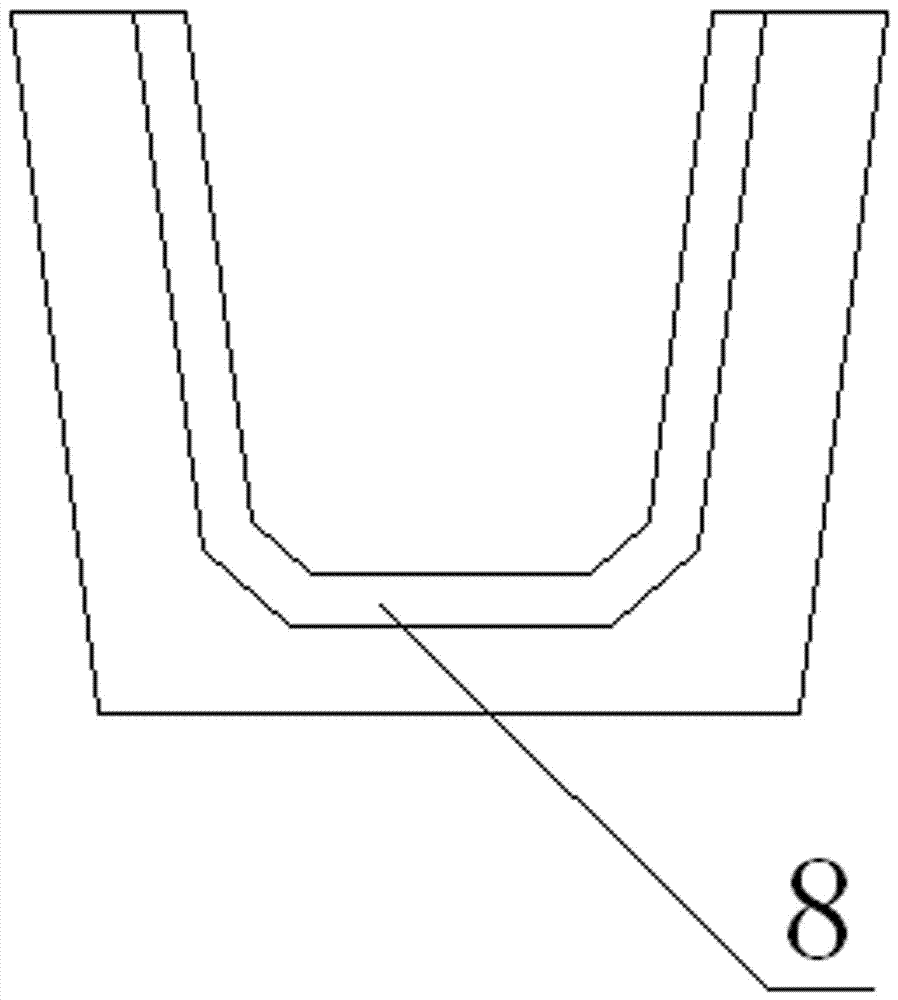

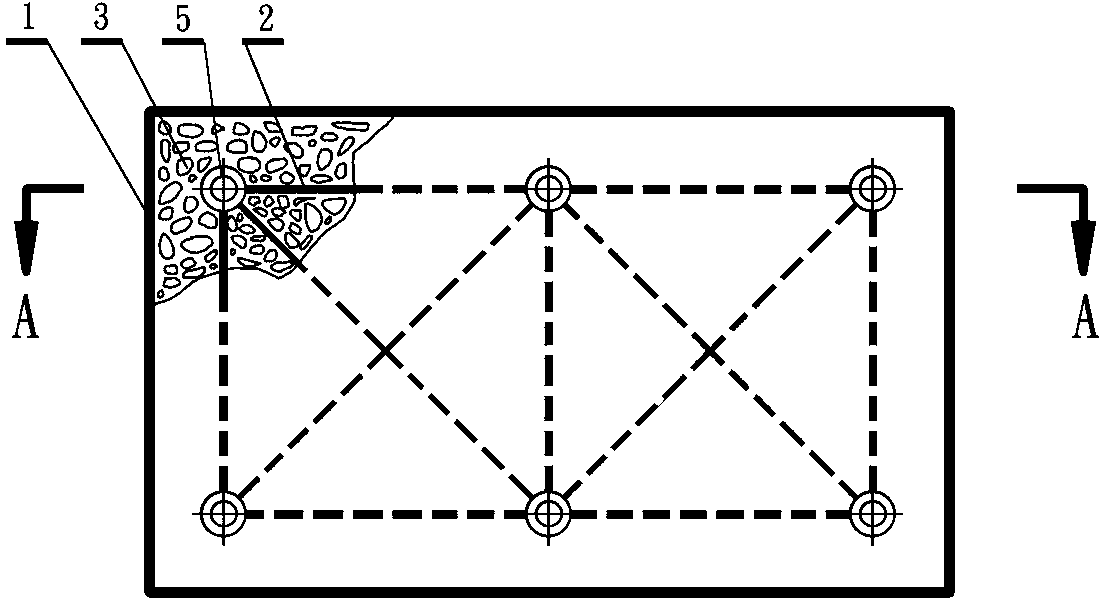

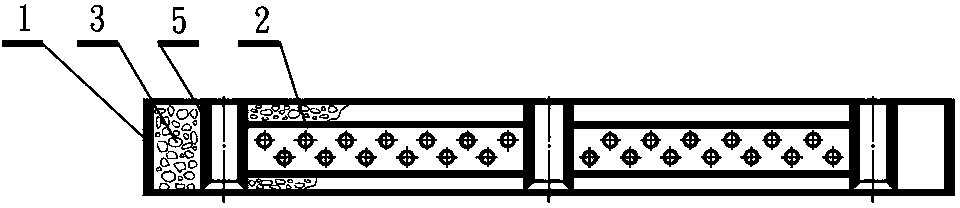

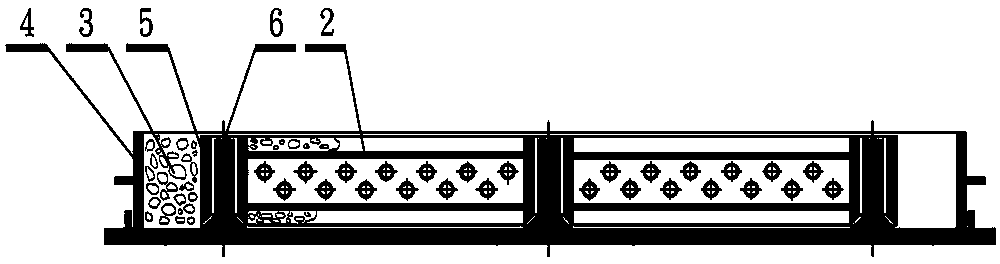

Production method of canal groove side penetration prefabricated part

PendingCN107471404AHighlight substantiveSignificant progressMouldsClimate change adaptationRebarPlastic film

The invention discloses a production method of a canal groove side penetration prefabricated part. The production method comprises the steps that (1) a required mold with the same shape of a canal prefabricated part is manufactured, the mold is placed upside down, and concrete is poured from the bottom; (2) the inner side of the mold is uniformly smeared with demolding oil or a plastic film is put on the inner side of the mold; (3) a manufactured rebar skeleton is arranged in the pouring mold in a sleeving manner, and a concrete protection layer is adjusted; (4) concrete required by pouring is manufactured on site, concrete is poured into the mold, is uniformly flattened to the two ends, and is vibrated for 1 min to 3 min through a vibrator, the upper surface of the mold is finished, and a mold cover plate is closed; and (5) the canal prefabricated parts subjected to concrete pouring are maintained on site, side molds are disassembled after the time.temperature of maintenance is larger than 500 h.DEG C, an inner mold is disassembled after the time.temperature of watering maintenance is larger than 1500 h.DEG C, after mold disassembly, the prefabricated parts are stacked concentratedly, and the prefabricated parts are discharged and utilized after the time.temperature of maintenance is 2000 h.DEG C or above. The production method has the characteristic that construction efficiency can be greatly improved.

Owner:潘春光

A kind of environment-friendly composite concrete foaming agent and preparation method thereof

The invention discloses an environment-friendly compound concrete foaming agent and a preparation method thereof. The environment-friendly compound concrete foaming agent comprises the following components: sodium alpha-olefin sulfonate, alkyl glycoside, methyl ester sulfonate, cocamidopropyl betaine, tea saponin, arabic gum, hydroxypropyl methyl cellulose, gelatin, polyanionic cellulose, polyvinyl alcohol and sodium bentonite. The environment-friendly compound concrete foaming agent disclosed by the invention is alkalescent, achieves the pH value of 7-9, has the advantages of high foaming power, large foam expansion, fine uniform and tough foam, durability, stability, long foam stabilizing time, small bleeding amount, small deposition amount, good hard water resistance and suitability for water with various rigidities.

Owner:深圳市中天元实业有限公司

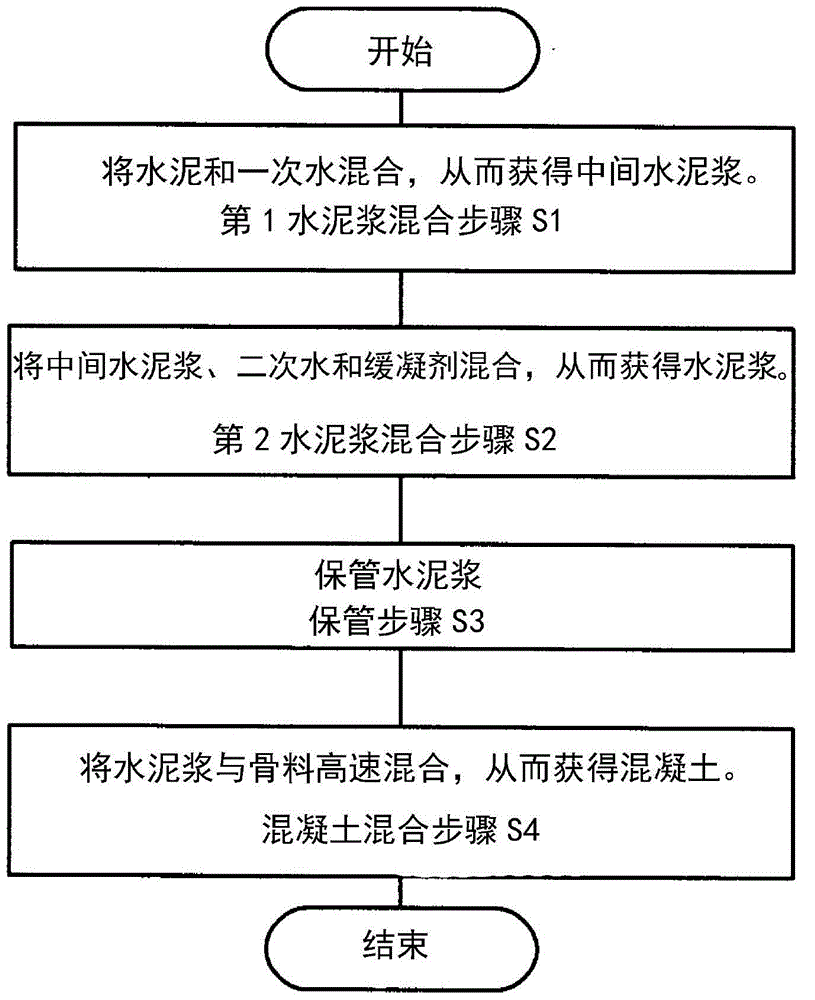

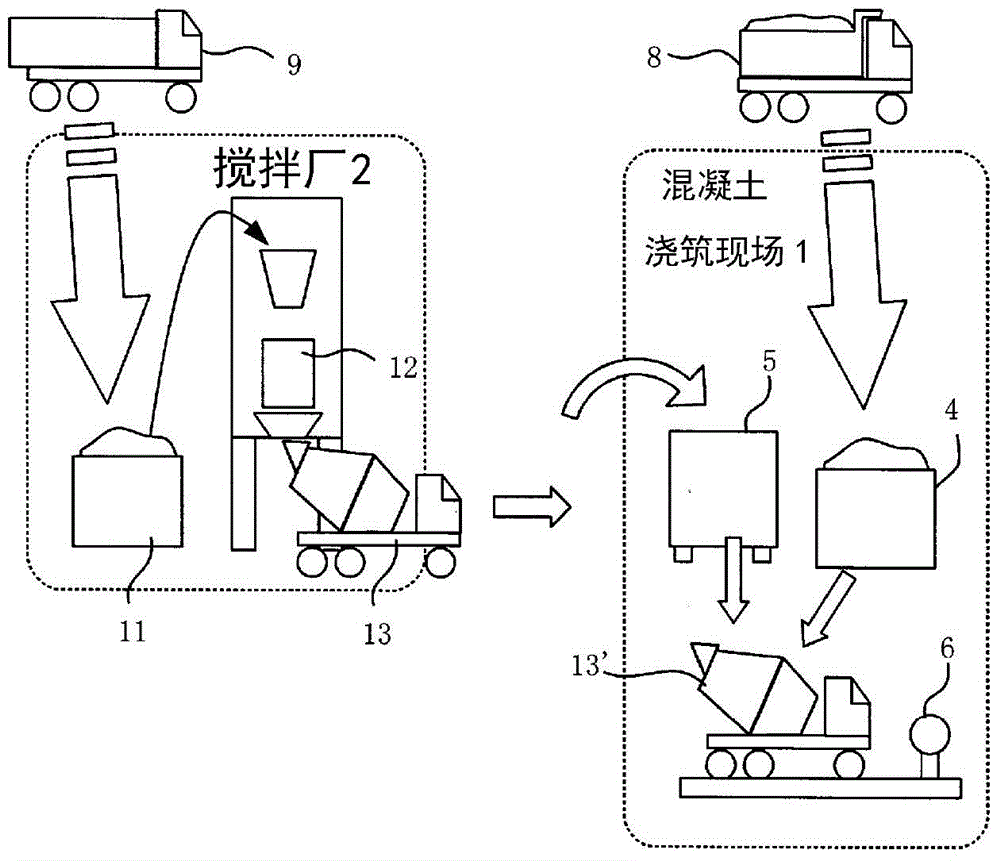

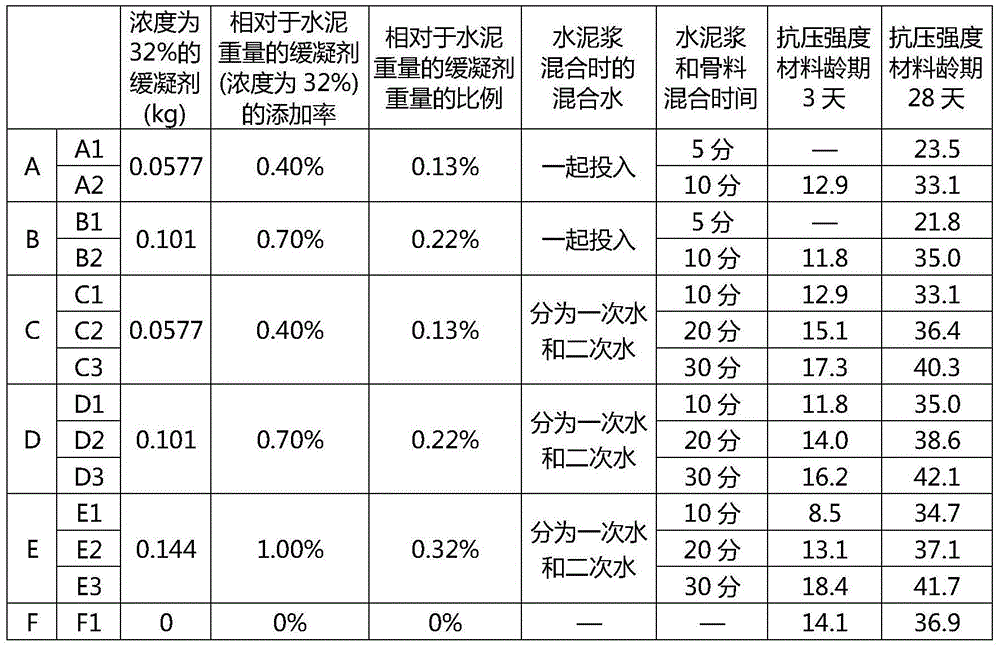

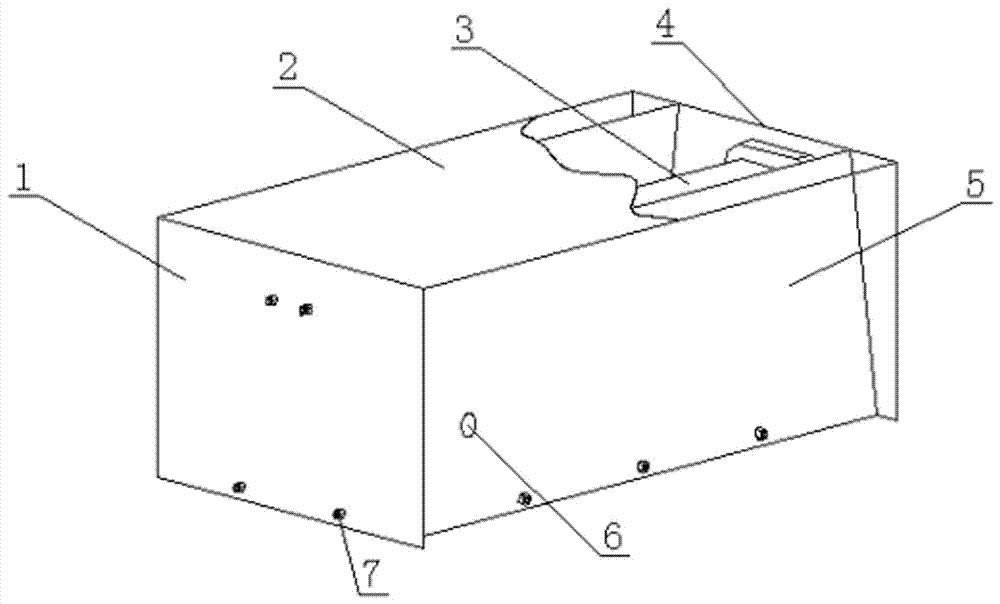

Production method for concrete

ActiveCN104470692APrevent hardeningRelease coagulation delayTransportation and packagingMixersCement pasteConstruction aggregate

To provide a low-cost production method for concrete in which setting and hardening are appropriately controlled and there is a high degree of freedom in production and handling. This concrete production method is configured from a cement paste mixing step and a concrete mixing step. In the cement paste mixing step, cement, mixing water, and a retardant are mixed together to obtain a cement paste. As a result, setting and hardening of the cement paste are inhibited, and it is possible to store the cement paste for a predetermined length of time. In the concrete mixing step, an aggregate is mixed into the cement paste in order to obtain concrete. This mixing cancels the setting retardation effect of the retardant.

Owner:AIZAWA CONCRETE CORP

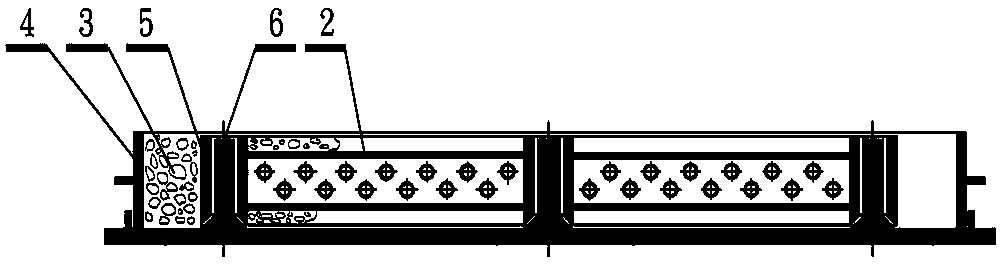

Production method of water channel groove prefabricated members

PendingCN107443548AImprove construction efficiencyShorten the construction period of the projectMouldsPlastic filmRebar

The invention discloses a production method of water channel groove prefabricated members. The production method comprises the following steps that (1) a pouring die needed by the water channel prefabricated members in same shapes is manufactured, the die is inversely placed, and the bottom of the die is upward; (2) the inner side of the die is evenly coated with mold oil, or a plastic thin film is paved on the inner side of the die; (3) a manufactured reinforcement cage is arranged in the pouring die in a sleeved manner, and a concrete protection layer is adjusted well; (4) concrete needed by pouring is manufactured on site, wherein the concrete is poured in from the middle of the bottom of the die and is evenly spread to the two ends, a tamping device is used for vibrating for 1 minute to 3 minutes, then the upper surface of a groove opening of the die is troweled, and a die cover plate is closed; and (5) the water channel prefabricated members obtained after concrete pouring are maintained on site, during maintenance, edge dies can be detached after the time.temperature is larger than 500 h.DEG C, during watering maintenance, an inner die can be detached after the time.temperature is larger than 1500 h.DEG C, the prefabticated members are stacked in a concentrated manner after the inner die is detached, and during maintenance, factory leaving for use can be achieved after the time.temperature is larger than 2000 h.DEG C. The production method has the beneficial effect that the construction efficiency can be greatly improved.

Owner:潘春光

Unfired kaolin foamed acoustic panel

ActiveCN103526852AHigh strengthImprove bending resistanceSound proofingCeramicwareFoaming agentPublic place

The invention discloses an unfired kaolin foamed acoustic panel. According to the technical scheme, a built-in frame is flatly arranged on a mould, kaolin cement foaming agents are poured on the periphery of the built-in frame after short steel tubes in the built-in frame are inserted into stand columns, the built-in frame is completely embedded inside the kaolin cement foaming agents, maintenance is carried out according to a regular maintenance method of cement products, and an unfired kaolin foamed acoustic panel finished product is packed; the kaolin cement foaming agents are formed by dried kaolin, active attapulgite clay, cement and other raw materials; the kaolin cement foaming agents and the built-in frame form a whole after solidification, and thus the overall strength, the counter bending capability and the actual using effects of the unfired kaolin foamed acoustic panel are improved. The unfired kaolin foamed acoustic panel can effectively control noise pollution and further has the functions of heat preservation and air purification. The unfired kaolin foamed acoustic panel is suitable for being mounted on facilities such as expressways, viaducts, urban light rails, metros and public places.

Owner:HEQU WANLIAN ENERGY SAVING MATERIALS

Manufacturing method for ultrafine powder enhanced composite board

The invention provides a manufacturing method for ultrafine powder enhanced composite board. The manufacturing method is characterized in that a board having the characteristics similar to natural stone materials and elegant texture is prepared by mixing tree waste raw materials such as construction wastes, slag ultrafine powder and fly ash, a proper amount of magnesia, and a trace amount of boric oxide, water and cement. Since the slag ultrafine powder is obtained by grinding blast-furnace slag and has high specific surface area and high fineness, the slag ultrafine powder can be modified to be a potential self-gelating material. In an alkaline condition, activity can be fully played, so that a plurality of performances of concrete and cement are greatly improved and increased. The manufacturing method is an environment-friendly technology, and has wide sources of materials and low cost. The composite board has good use performance, low toxicity, moisture resistance, corrosion resistance and no pollution, integrates the advantages of ceramic and glass ceramics, has the advantages of no radiation, pollution resistance and corrosion resistance, and has relatively good processability.

Owner:SHENZHEN KENAILE NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com