Self-insulation system foam concrete and preparation method thereof

A technology of foam concrete and self-insulation system, which is applied in the field of building materials, can solve the problems of reducing strength, low strength of foam concrete, and reducing the mechanical properties of foam concrete, and achieve the effect of improving the stability of foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

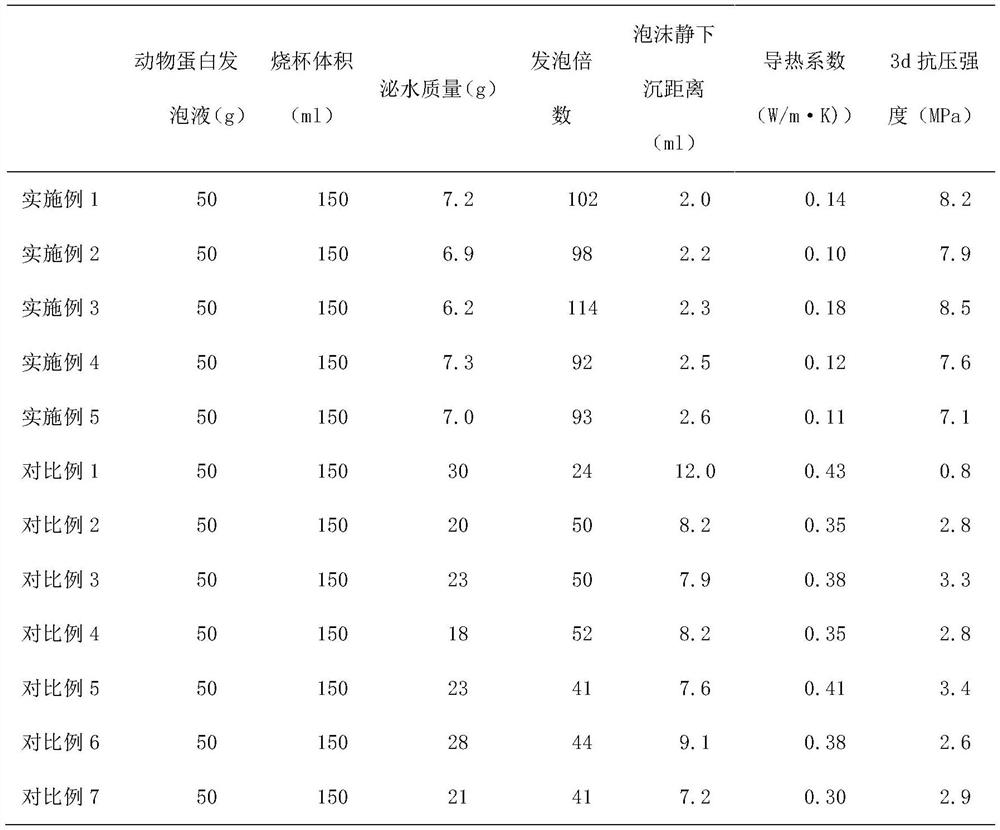

Examples

Embodiment 1

[0027] A foam concrete, in parts by weight, made of the following raw materials: 30 parts of sulphoaluminate cement, 30 parts of animal protein foaming agent, 8 parts of sodium α-olefin sulfonate, 8 parts of sodium lauryl sulfate Parts, 8 parts of sodium dodecylbenzenesulfonate.

Embodiment 2

[0029] A kind of foam concrete, in parts by weight, made of the following raw materials: 25 parts of sulfoaluminate cement, 25 parts of animal protein foaming agent, 7 parts of sodium α-alkenyl sulfonate, 7 parts of sodium lauryl sulfate Parts, 7 parts of sodium dodecylbenzenesulfonate.

Embodiment 3

[0031] A kind of foam concrete, in parts by weight, made of the following raw materials: 40 parts of sulphoaluminate cement, 40 parts of animal protein foaming agent, 12 parts of sodium α-alkenyl sulfonate, 12 parts of sodium lauryl sulfate Parts, 12 parts of sodium dodecylbenzenesulfonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com