Environment-friendly compound concrete foaming agent and preparation method thereof

An environment-friendly concrete technology, which is applied in the field of building materials, can solve problems such as difficulty in meeting market demand and poor performance, and achieve improved strength and waterproof performance, improved foaming power and foam stability, and fine, uniform and tough foam. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

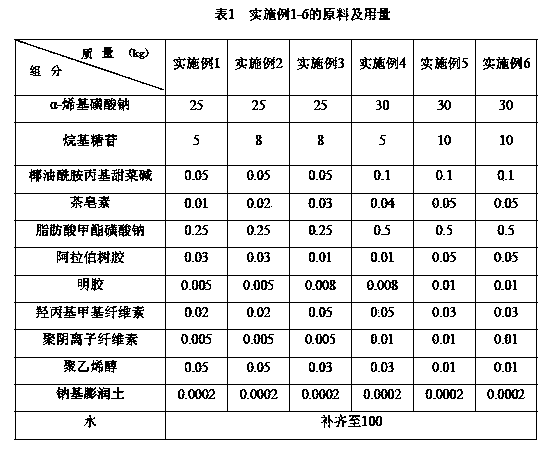

[0013] The raw materials and dosage of the blowing agent are shown in Table 1. The preparation process is as follows: add 25 kg of sodium α-alkenyl sulfonate, 5 kg of alkyl glycoside, 0.01 kg of tea saponin, 0.05 kg of cocamidopropyl betaine and 0.25 kg of fatty acid methyl ester sulfonic acid into the reaction kettle in sequence, Keep the temperature at 40~60°C, control the pH value at 7~9, and mix well; then add 0.03kg of gum arabic, 0.005kg of gelatin, and mix evenly; then add 0.02kg of hydroxypropyl methylcellulose to the reaction kettle, poly Anionic cellulose PAC-HV 0.005kg, mix evenly; then add polyvinyl alcohol 0.05kg to the kettle, mix evenly; finally add sodium bentonite 0.0002kg, and make up the water to 100kg, mix evenly, to the required concentration, The obtained slurry can be used as a liquid high-efficiency compound foaming agent. Or the mixed slurry is spray-dried in a high tower to remove water to less than 5% to make a powdery high-efficiency compound foami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com