Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Less odor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

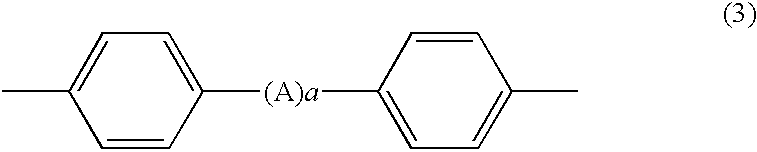

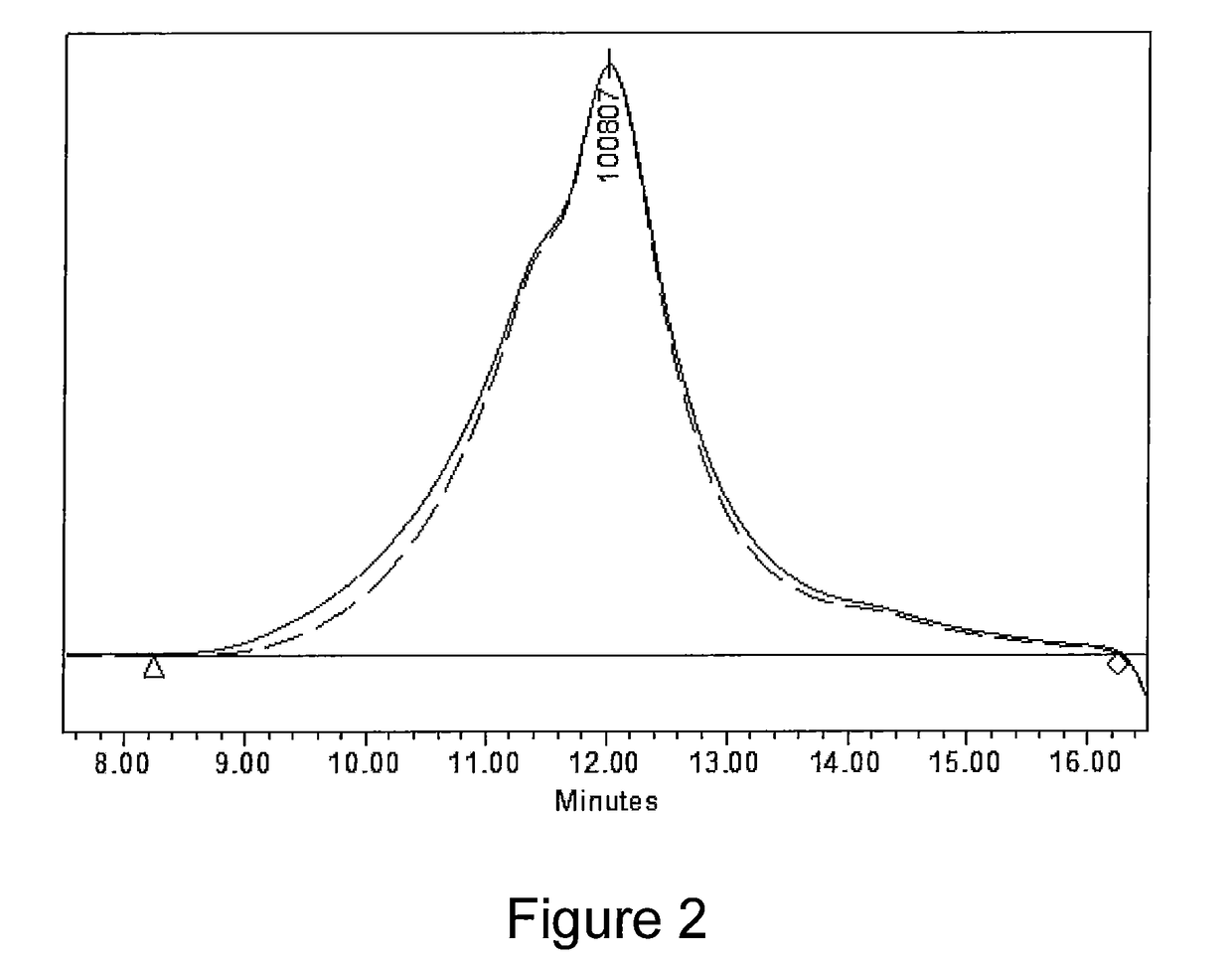

Block copolymer, composition thereof, and film made thereof

InactiveUS6841261B2Favorable spontaneous shrinkage resistanceLow temperature shrinkabilitySynthetic resin layered productsDomestic articlesDynamic viscoelasticityAromatic hydrocarbon

It is to provide a block copolymer and its copolymer composition which provides a heat shrinkable (multilayer) film with less spontaneous shrinkage while maintaining favorable low temperature shrinkability, and a heat shrinkable (multilayer) film containing the block copolymer. By using a block copolymer comprising a vinyl aromatic hydrocarbon and a conjugated diene characterized in that the relation of the loss tangent value obtained by dynamic viscoelasticity measurement with the temperature satisfies specific conditions, or a composition containing the copolymer composition as an essential component, a heat shrinkable (multilayer) film with less spontaneous shrinkability and less odor while maintaining favorable low temperature shrinkability can be obtained.

Owner:DENKA CO LTD

Organic peracid polymer composition and process for producing the same

ActiveUS8110603B2Not easily decomposedLess odorBiocideInorganic phosphorous active ingredientsOrganic acidSolubility

It is intended to provide an organic peracid polymer composition which is stable, odorless and has sufficient water solubility and is suitably used as a bactericide, a bleaching agent and a cleaning agent. By mixing and dissolving an organic acid polymer, hydrogen peroxide and an inorganic acid and maintaining the mixture for a period ranging from 1 hour to 1 month at a temperature ranging from 10 to 80° C., the organic peracid polymer-containing composition containing an organic peracid polymer (2 to 50% by weight) and, in some cases, the hydrogen peroxide (2 to 50% by weight) and the inorganic acid (0.1 to 10% by weight) is obtained.

Owner:MITSUBISHI GAS CHEM CO INC

Tire puncture sealant

A tire puncture sealant including a urethane emulsion, an acrylic emulsion or a polyolefin emulsion, and an antifreezing agent has a comparatively low viscosity and an excellent storage stability while showing sealing properties equivalent to those of a conventional tire puncture sealant. A tire puncture sealant including a synthetic resin emulsion and an antifreezing agent, and having a hydrogen ion exponent of 5.5 to 8.5 has a less pungent odor and hardly causes corrosion of steel cord. A tire puncture sealant including a chloroprene emulsion and an antifreezing agent and having a hydrogen ion exponent of less than 9.0 has a comparatively low viscosity and a less odor while showing sealing properties equivalent to those of a conventional tire puncture sealant.

Owner:YOKOHAMA RUBBER CO LTD

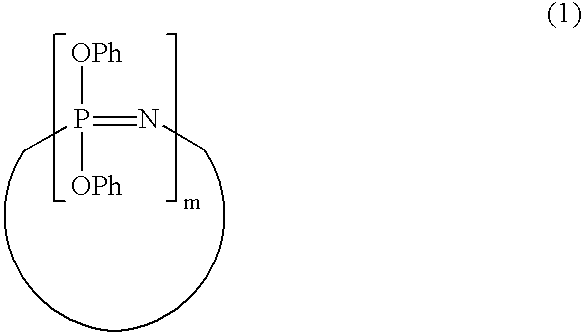

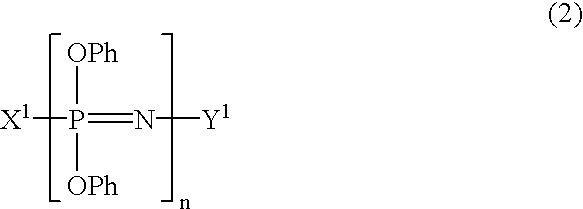

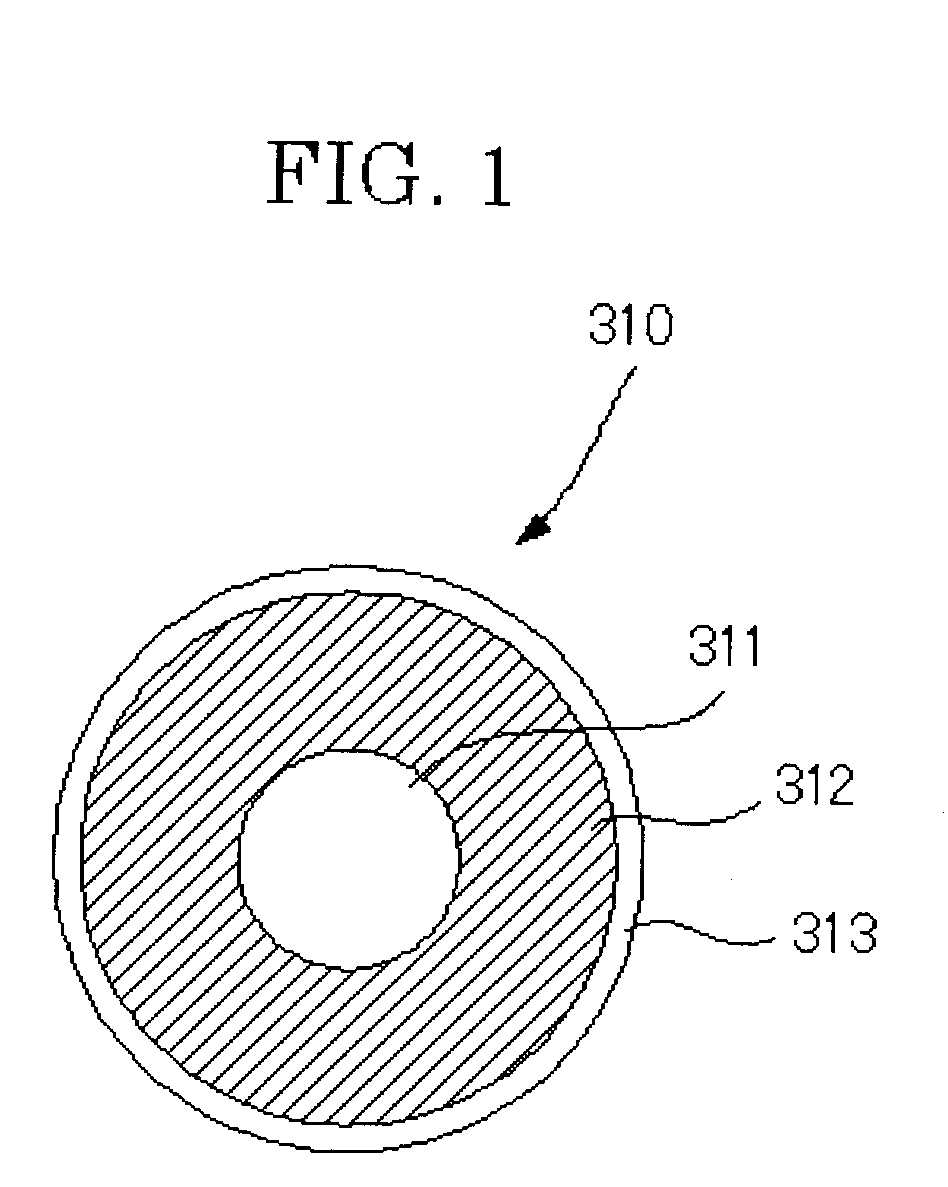

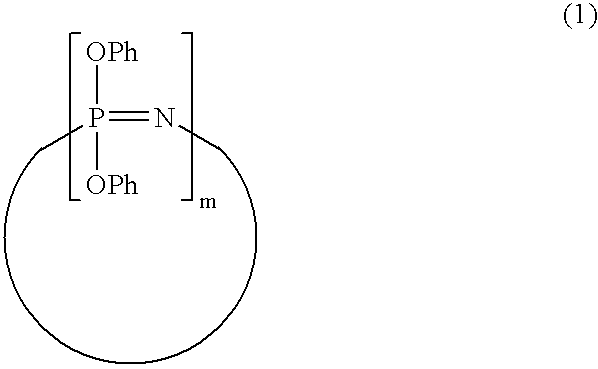

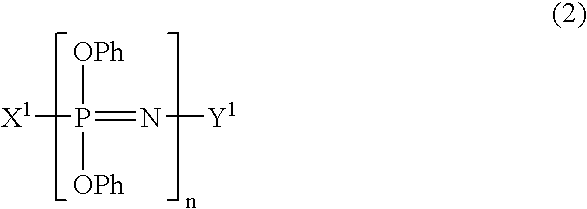

Process for producing phenoxyphosphazene compound, flame- retardant resin composition, and flame-retardant resin molding

InactiveUS20030040643A1Quality improvementIncrease resistanceGroup 5/15 element organic compoundsAlkanePolymer science

The phenoxyphosphazene compound of the present invention is prepared by treating a phenoxyphosphazene compound with (a) at least one adsorbent selected from activated carbon, silica gel, activated alumina, activated clay, synthetic zeolite and macromolecular adsorbents, (b) at least one reagent selected from metal hydrides, hydrazine, hypochlorites, thiosulfates, dialkyl sulfuric acids, ortho esters, diazoalkanes, lactones, alkanesultones, epoxy compounds and hydrogen peroxide or (c) both the adsorbent and reagent. Incorporation of the phenoxyphosphazene compound prepared by the process of the invention into a synthetic resin achives the following advantages: the synthetic resin can be prevented from discoloration; when the resultant resin composition is stored for a long time, the properties of the synthetic resin, such as heat resistance, weatherability, resistance to discoloration and chemical resistance are not deteriorated; and the resin composition gives a resin composition molded article excellent in properties such as flame retardancy, thermal stability, and moldability.

Owner:OTSUKA CHEM CO LTD

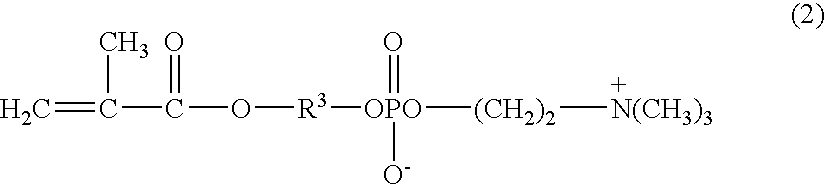

Photopolymerizable inkjet ink, ink cartridge, and inkjet recording device

To provide a photopolymerizable inkjet ink including: diethylene glycol dimethacrylate; caprolactone-modified dipentaerythritol hexaacrylate; and a photopolymerization initiator represented by the following general formula (1):where X1 is represented by the following general formula (1-1), and X2 is represented by the following general formula (1-2):where R1 to R4 are each independently a C1-C6 alkyl group, and R1 and R2 may be linked to form a ring, and R3 and R4 may be linked to form a ring; Z1 and Z2 is —NR5R6 or OR7; R5 and R6 are each independently a C1-C6 alkyl group, and R5 and R6 may be linked to form a ring; and R7 is a hydrogen atom, a methyl group, or a trimethylsilyl group.

Owner:RICOH KK

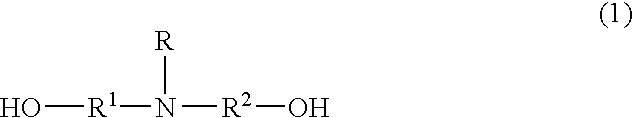

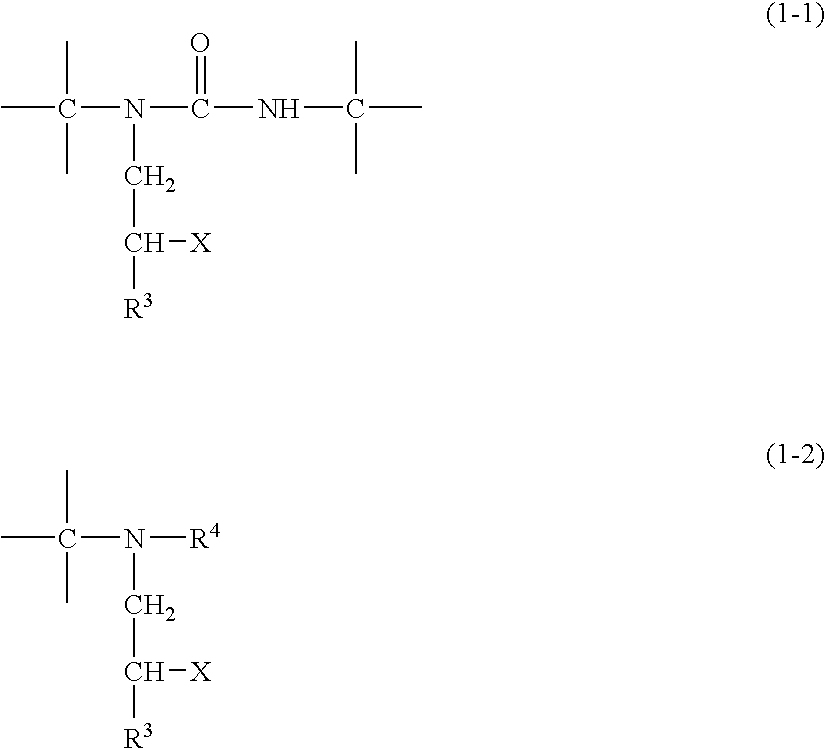

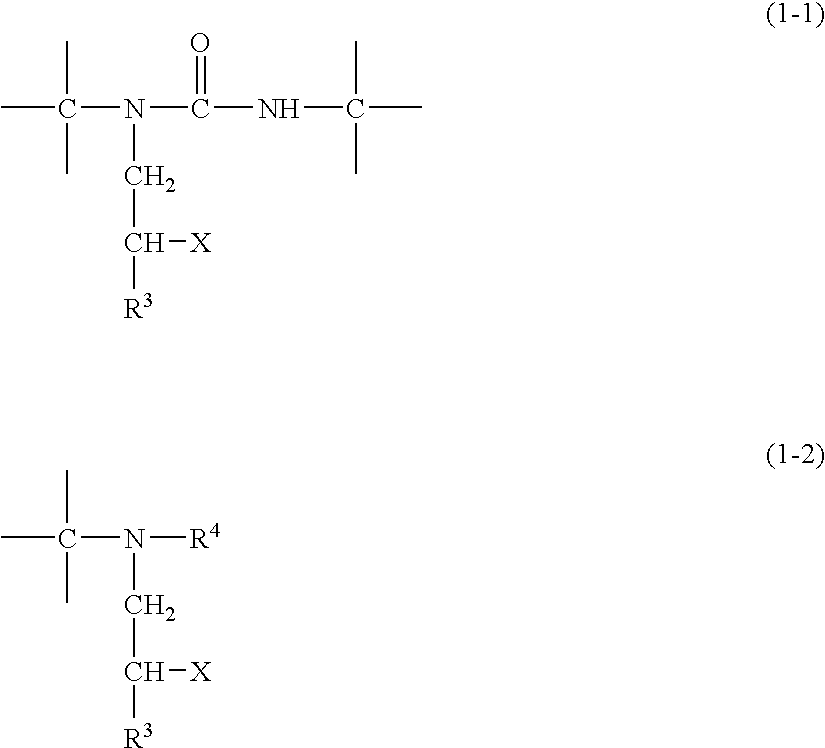

Michael addition type urethane urea resin, production process therefor, adhesive, production process therefor, coating agent for forming ink receiving layer and recording material

This invention provides a Michael addition type urethane urea made from starting materials including a polyol (a), a polyisocyanate (b), a polyamine (c) and an unsaturated compound (d), and comprising a bonded portion represented by the following formula (1-1) or (1-2): (where R<3 >represents a monovalent organic group, X represents a hydrogen atom or an alkyl group having 1 to 3 carbon atoms and R<4 >represents a hydrogen atom or a monovalent organic group).

Owner:TOYO INK SC HOLD CO LTD

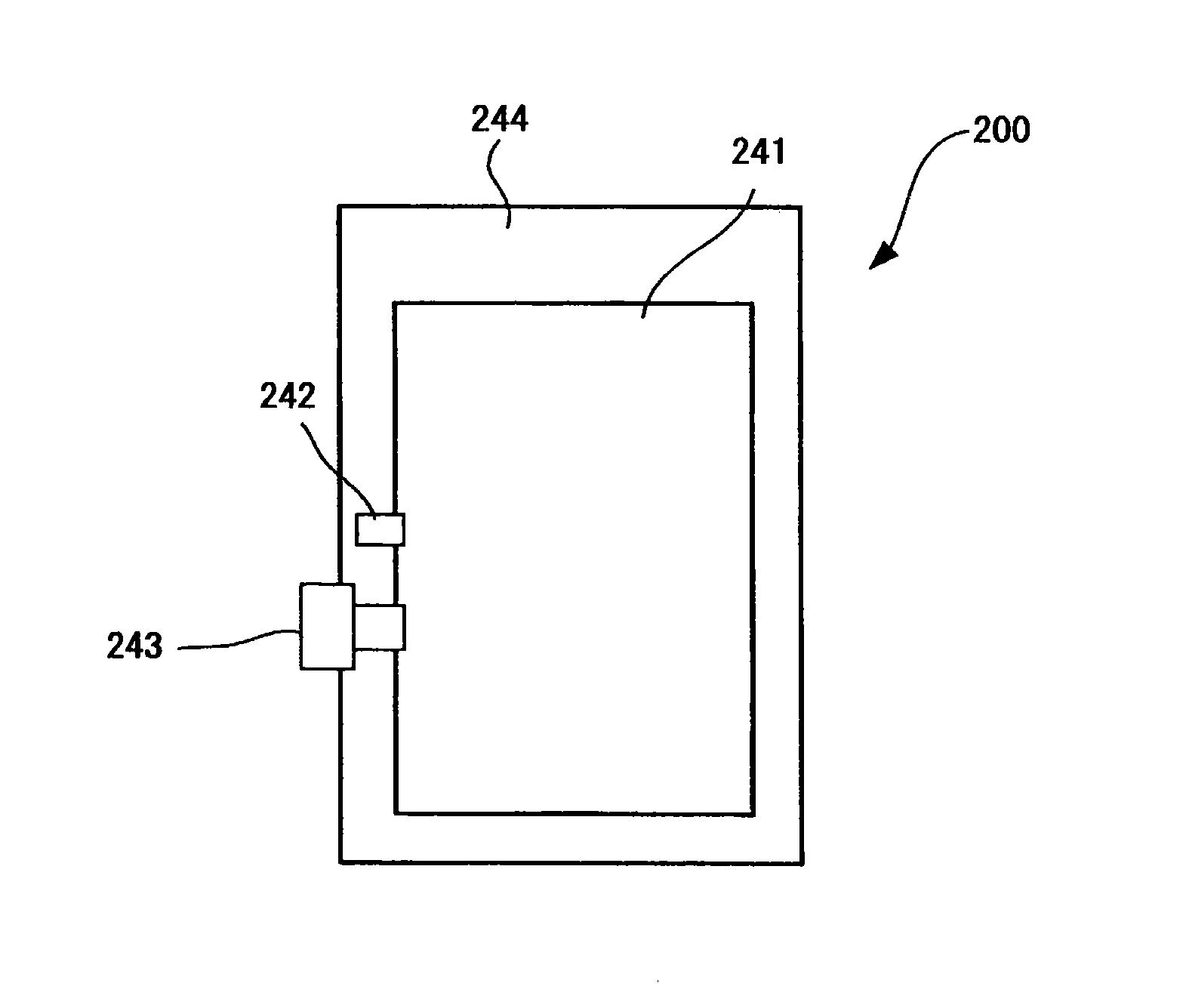

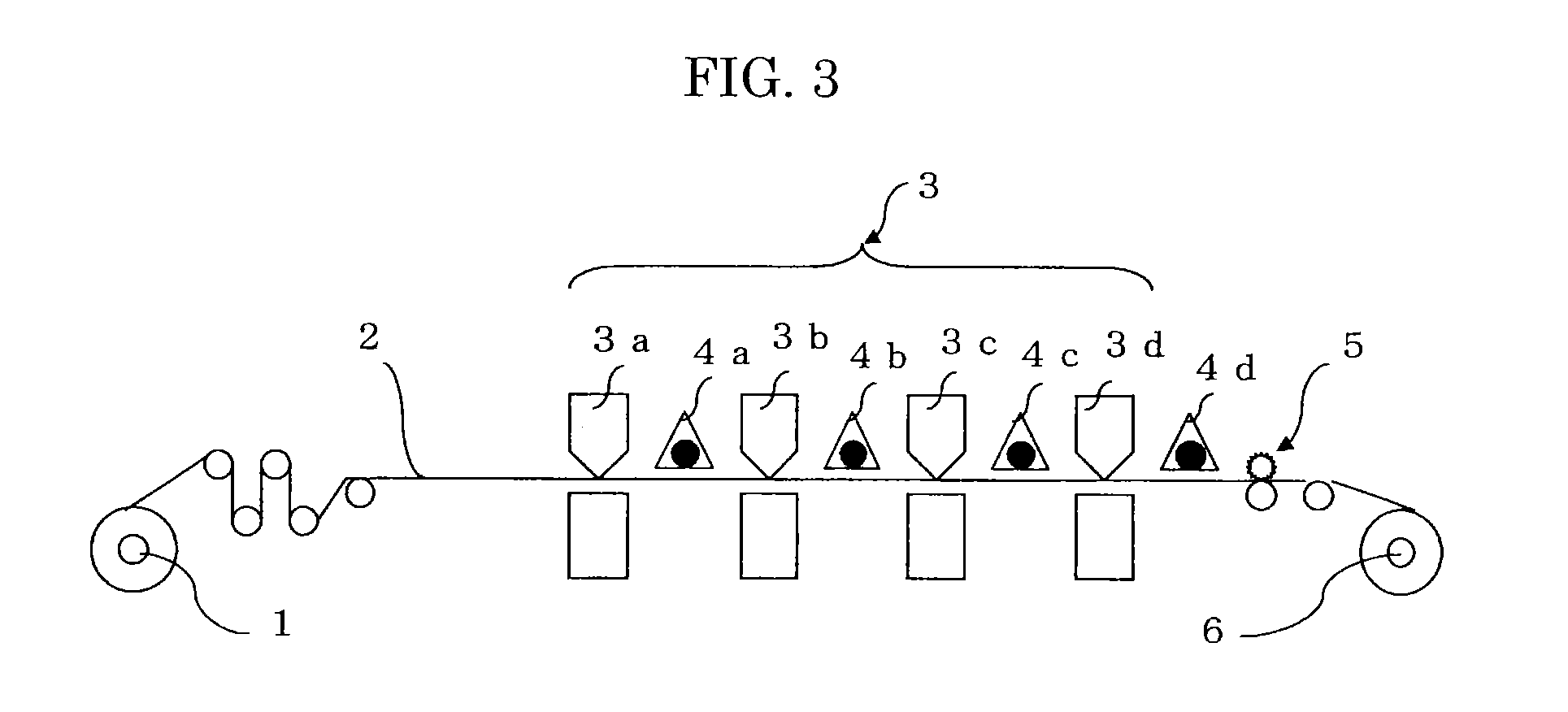

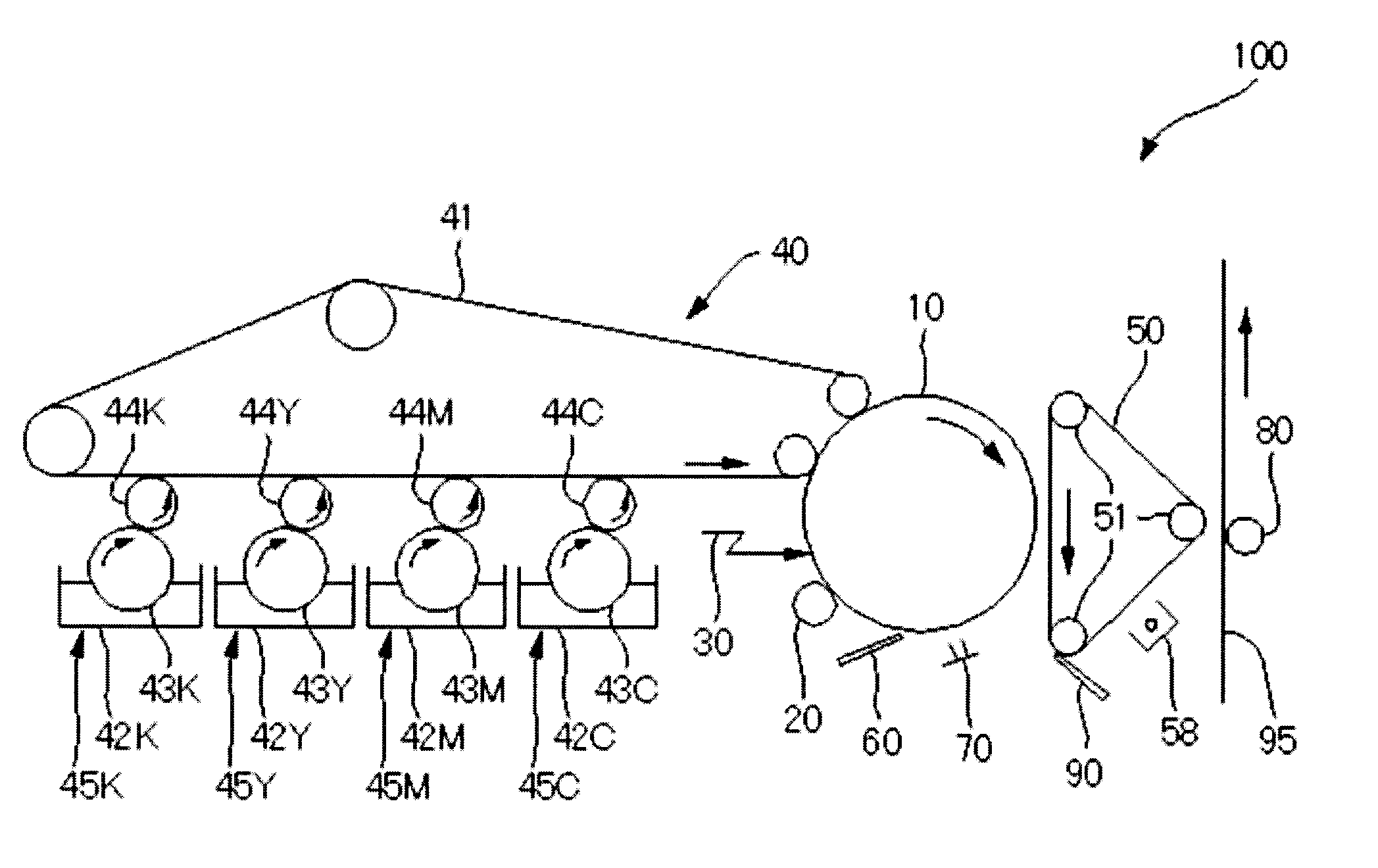

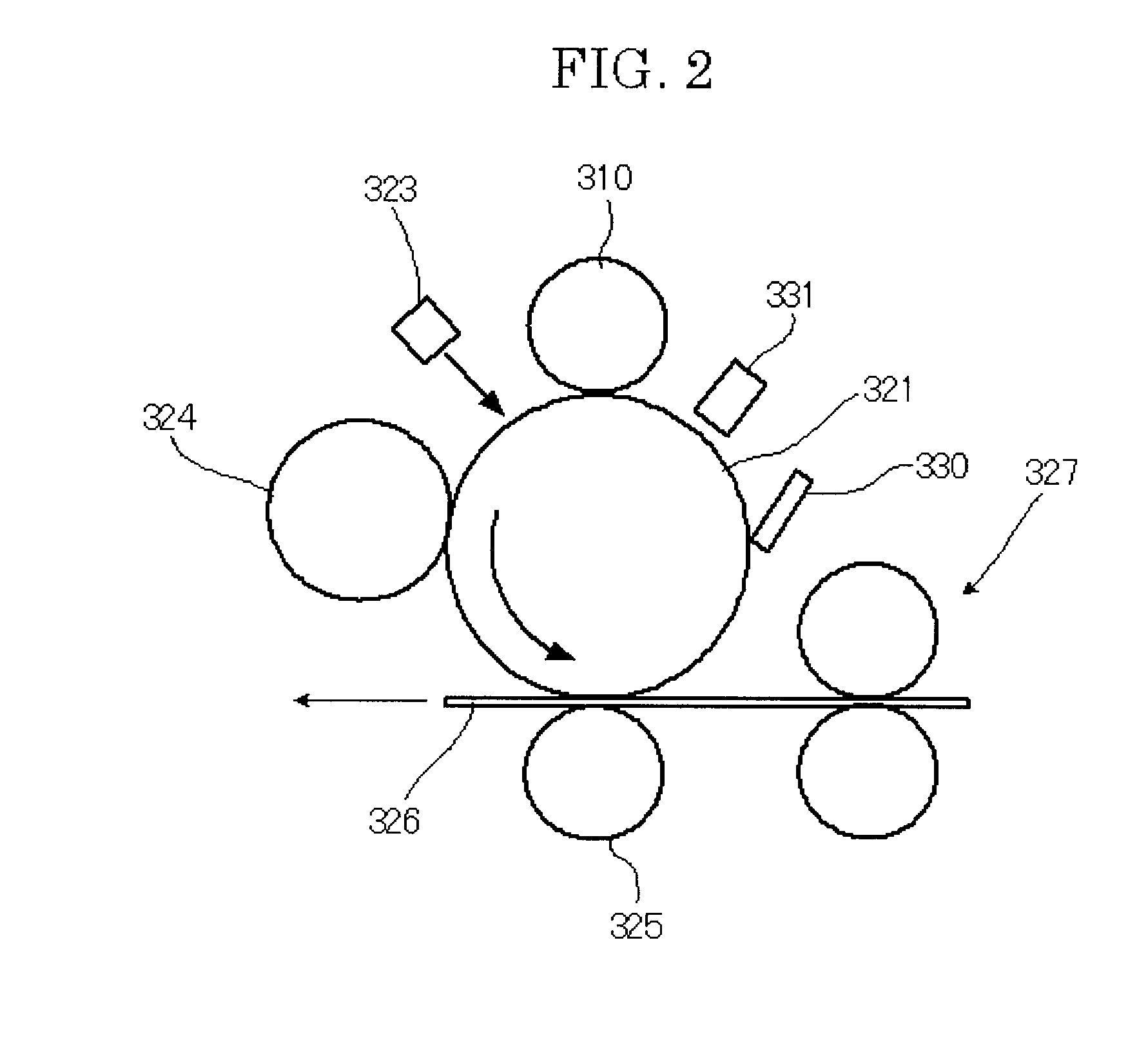

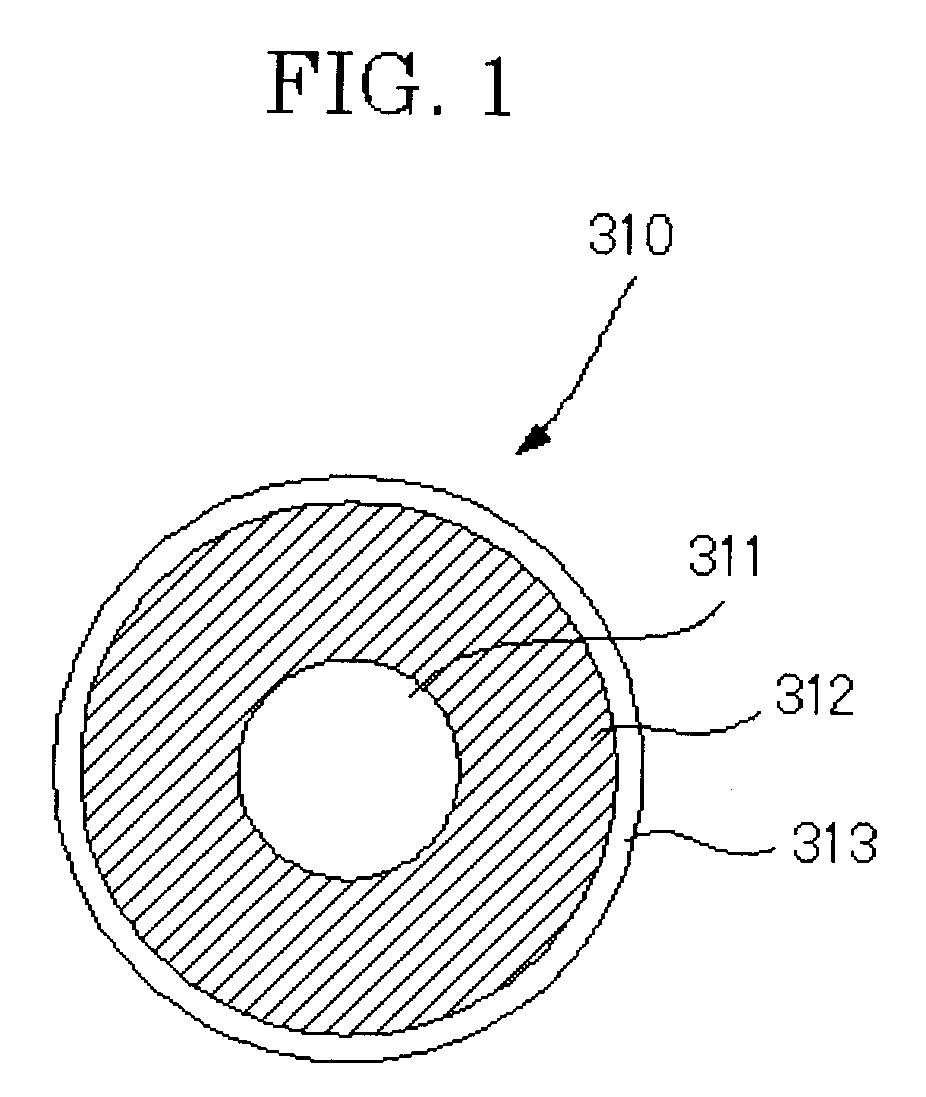

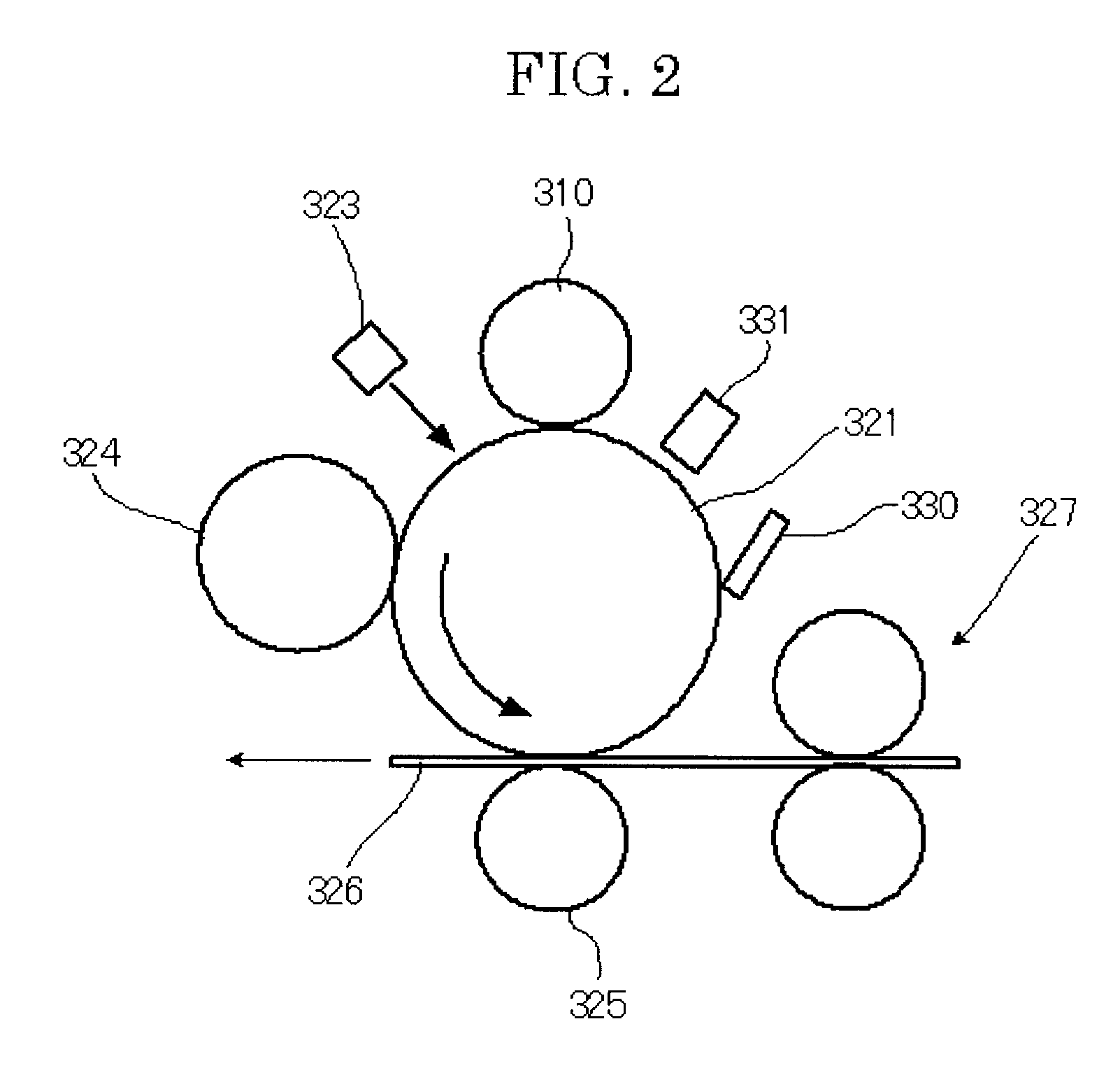

Image forming apparatus, image forming method, and process cartridge

ActiveUS20080318143A1Less odorQuality improvementDevelopersElectrographic process apparatusChemistryRosin

An image forming apparatus including a charging unit, an exposing unit, a developing unit, a transferring unit, and a fixing unit. A toner containing a colorant and a binder resin which contains a polyester resin (A) and a polyester resin (B) having a softening point 10° C. or more higher than that of the polyester resin (A); the polyester resin (A) is a (meth)acrylic acid-modified rosin derived resin having a polyester unit obtained by polycondensation of an alcohol component, which contains 65 mol % or more of 1,2-propanediol in a dihydric alcohol component, and a carboxylic acid component containing a (meth)acrylic acid-modified rosin; the polyester resin (B) is a purified rosin derived resin having a polyester unit obtained by polycondenstation of an alcohol component, which contains a total of 70 mol % or more of 1,2-propanediol and 1,3-propanediol in a dihydric alcohol component, and a carboxylic acid component containing purified rosin.

Owner:RICOH KK

Process for producing phenoxyphosphazene compound, flame-retardant resin composition, and flame-retardant resin molding

InactiveUS6946578B2Reduce molecular weightChange hueGroup 3/13 element organic compoundsPhosphorus organic compoundsHypochloriteHydrazine compound

An improved phenoxyphosphazene compound is produced by treating a phenoxyphosphazene compound with (a) at least one adsorbent selected from activated carbon, silica gel, activated alumina, activated clay, synthetic zeolite and macromolecular adsorbents, (b) at least one reagent selected from metal hydrides, hydrazine, hypochlorites, thiosulfates, dialkyl sulfuric acids, ortho esters, diazoalkanes, lactones, alkanesultones, epoxy compounds and hydrogen peroxide, or (c) both the adsorbent and reagent, thereby reducing the acid value of said phosphazene compound to lower than 0.025 mgKOH / g.

Owner:OTSUKA CHEM CO LTD

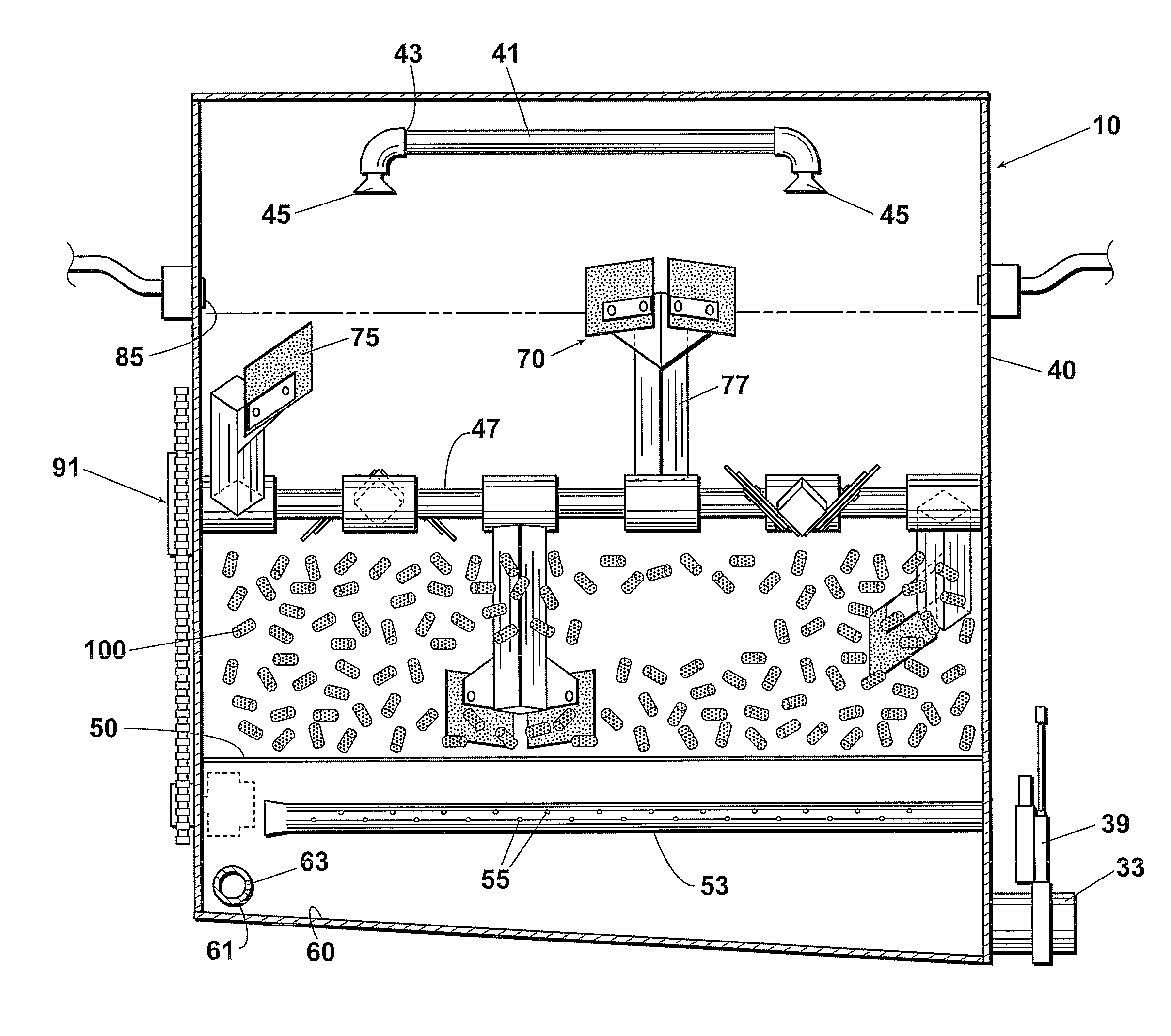

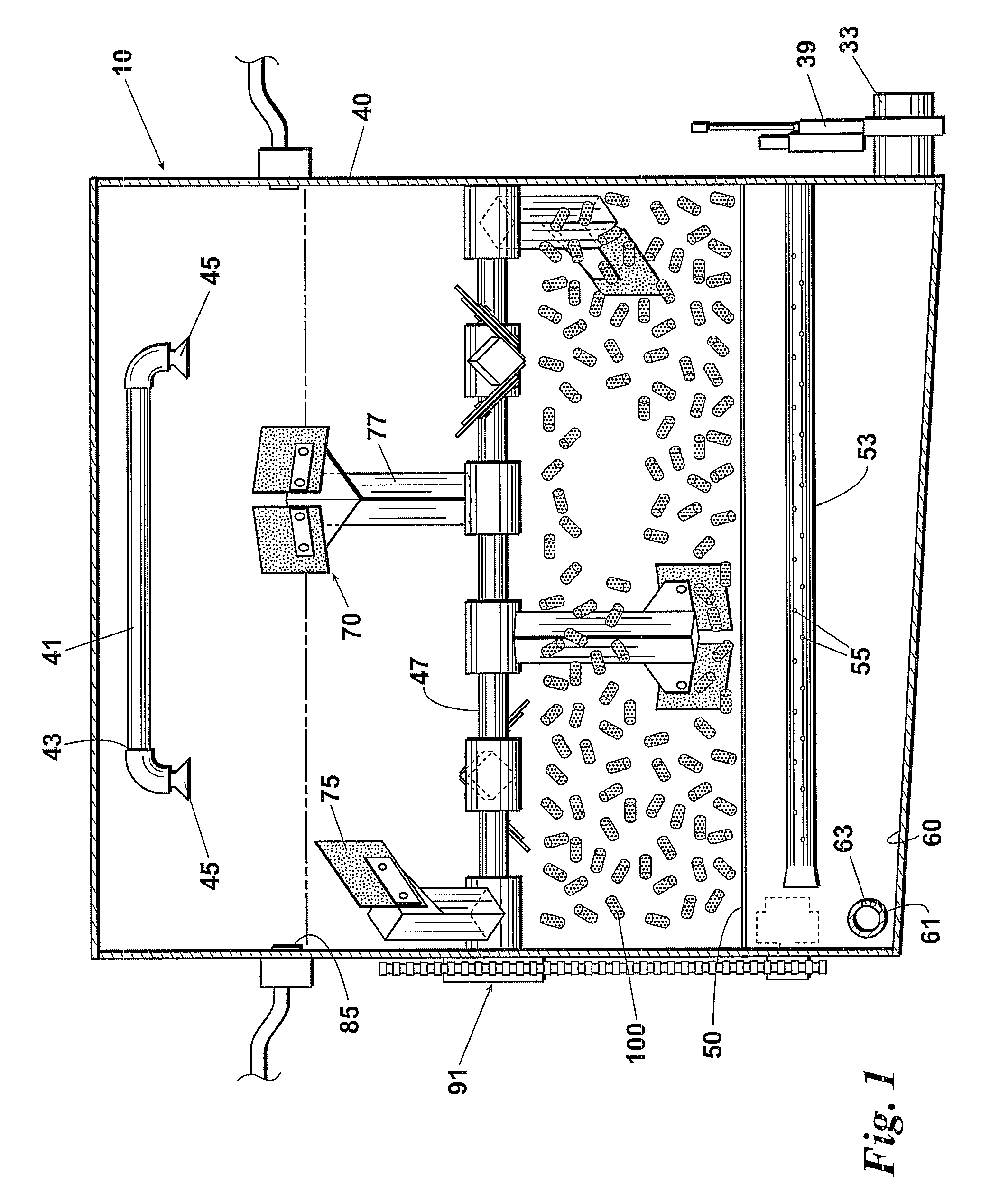

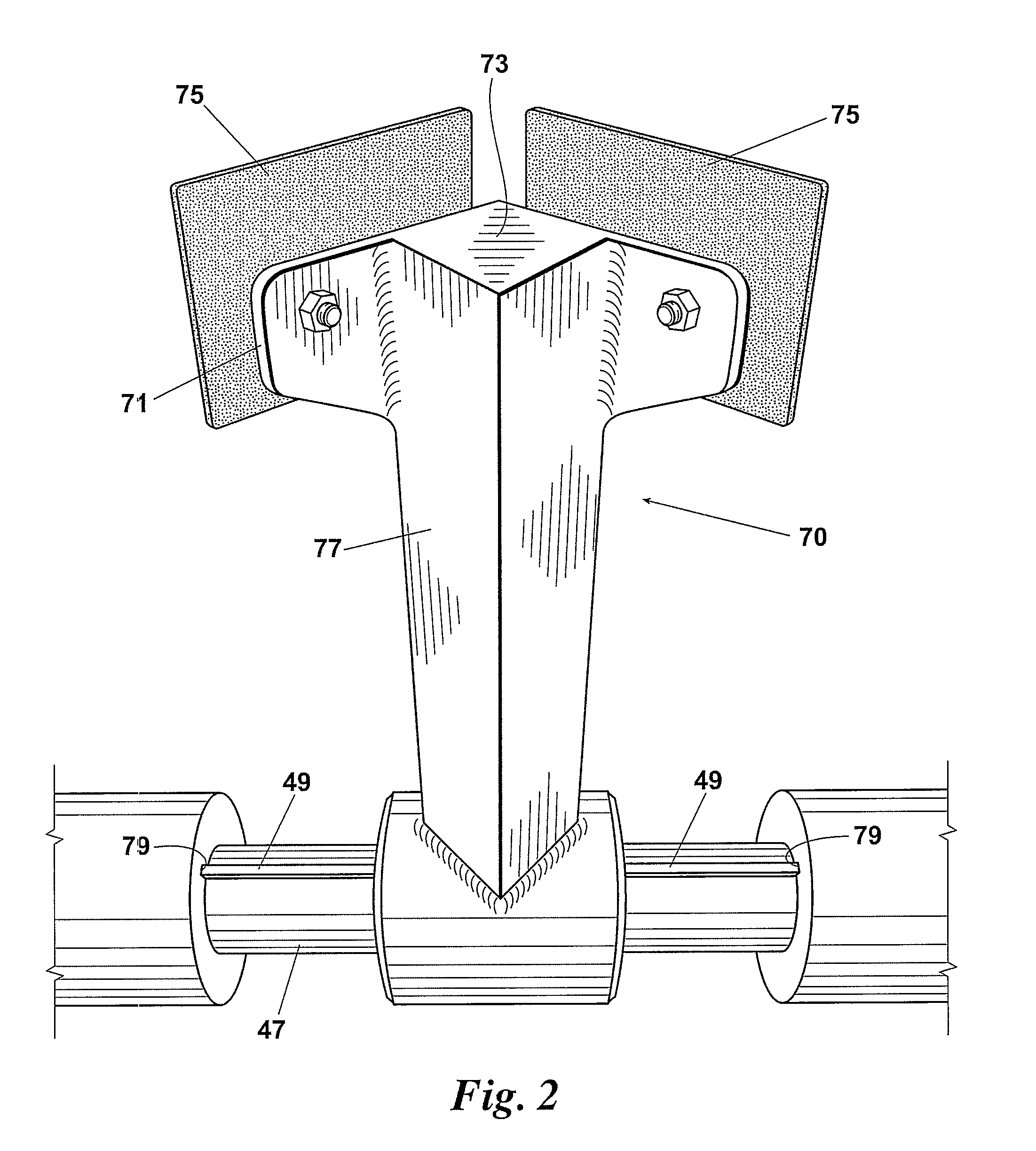

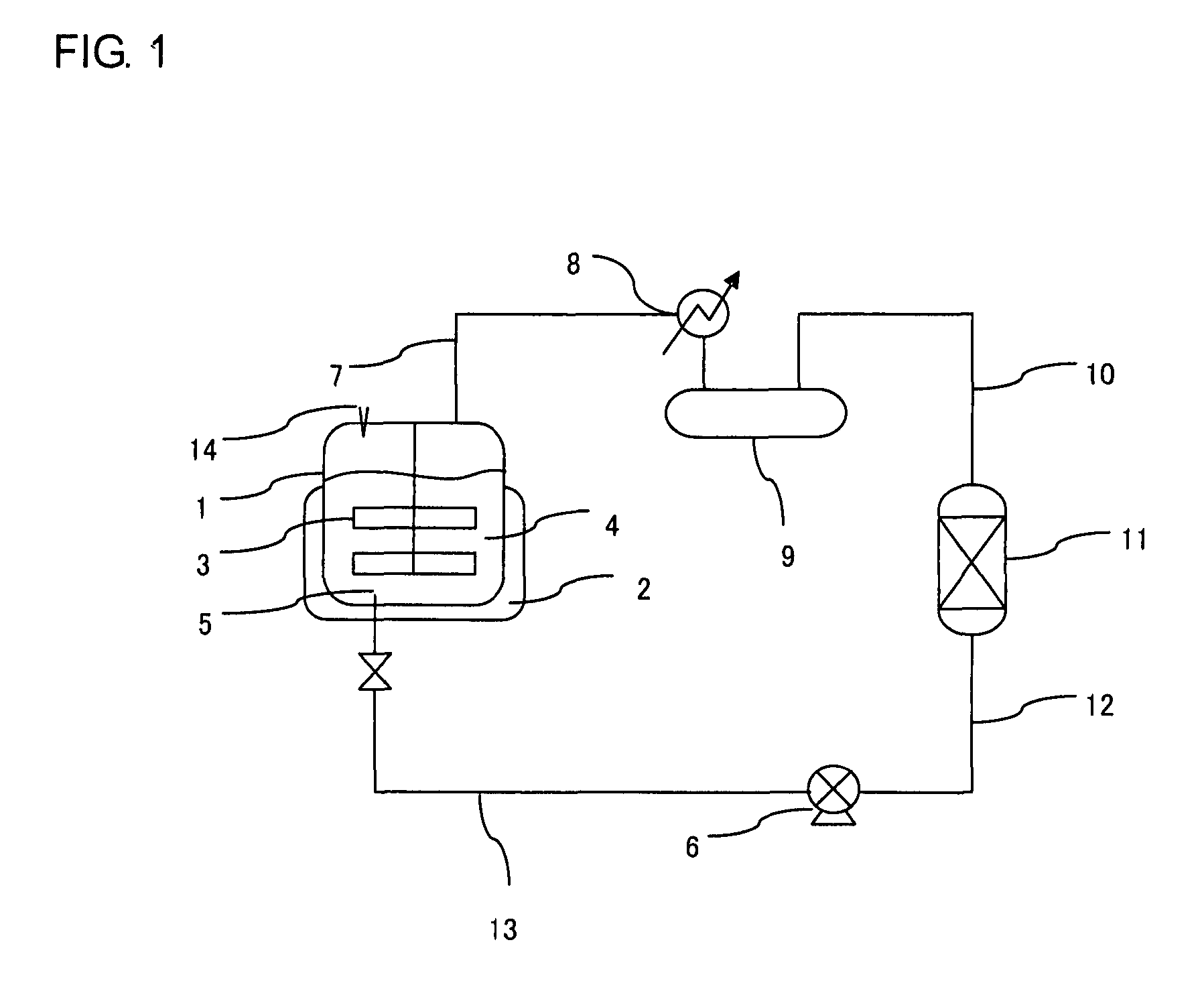

Bio-Reactor System and Method for Composting Food Waste

InactiveUS20120252107A1Low costEfficient and effective and reliableBioreactor/fermenter combinationsBio-organic fraction processingMicroorganismReactor system

A bio-reactor made according to this invention uses low temperature aerobic composting to decompose bio-compostable material. The reactor includes mixing paddles with wiper blades which aerate and agitate a set of plastic resin biochips which house microorganisms and cause the chips to come into contact with bio-compostable material. A water pipe located toward the upper portion of the bio-reactor delivers fresh or recycled water (or some mix of the two) and the bio-reactor cycles between a water cycle and a non-water cycle. Agitation also cycles on and off. Perforated bottom screens limit the size of the composted material exiting the bio-reactor. The wiper blades, which may be brushes, continually wipe the bottom screens and work to prevent blockage and build-up of debris within the bio-reactor.

Owner:TOTALLY GREEN

Preparation of fatty acids in solid form

ActiveUS8203013B2Promote digestionLess odorOrganic compound preparationFatty-oils/fats refiningGlycerolAqueous solubility

A method for making a fatty acid mineral salt is disclosed where liquid oils containing fatty acids are hydrolyzed using a base solution. A buffering agent is added to the hydrolyzed solution to maintain pH between 8.0 and 11.0 followed by a water soluble metal salt solution which causes a metathesis reaction with the hydrolyzed solution, forming a precipitates of fatty acid metal salts which are glycerin-free. The precipitates are filtered, washed and subsequently dried. The produced fatty acid metal salt is easier for the human body to digest than omega-3 fatty acid in oil form and also is less prone to oxidation and emitting of unpleasant odor.

Owner:J H BIOTECH

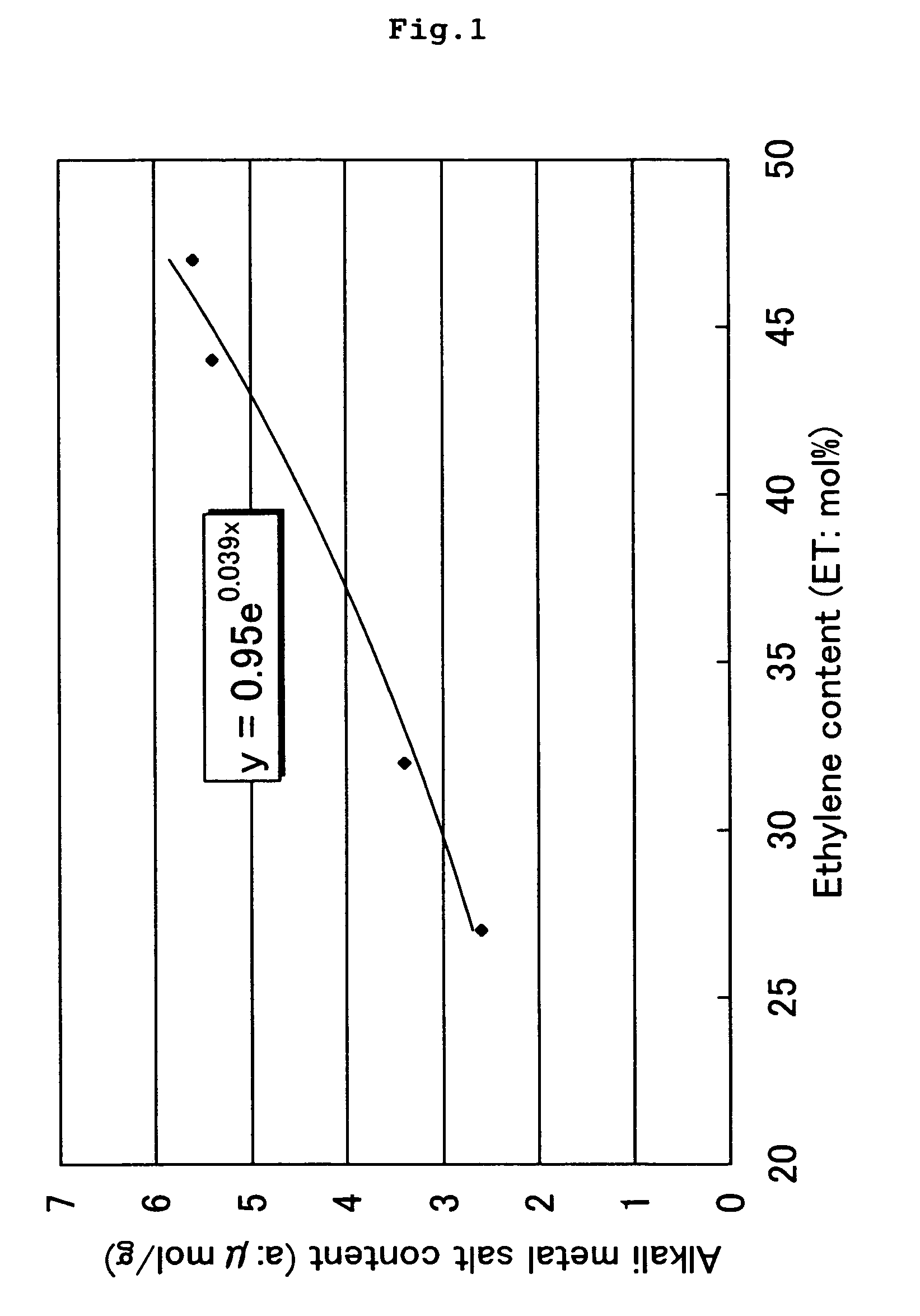

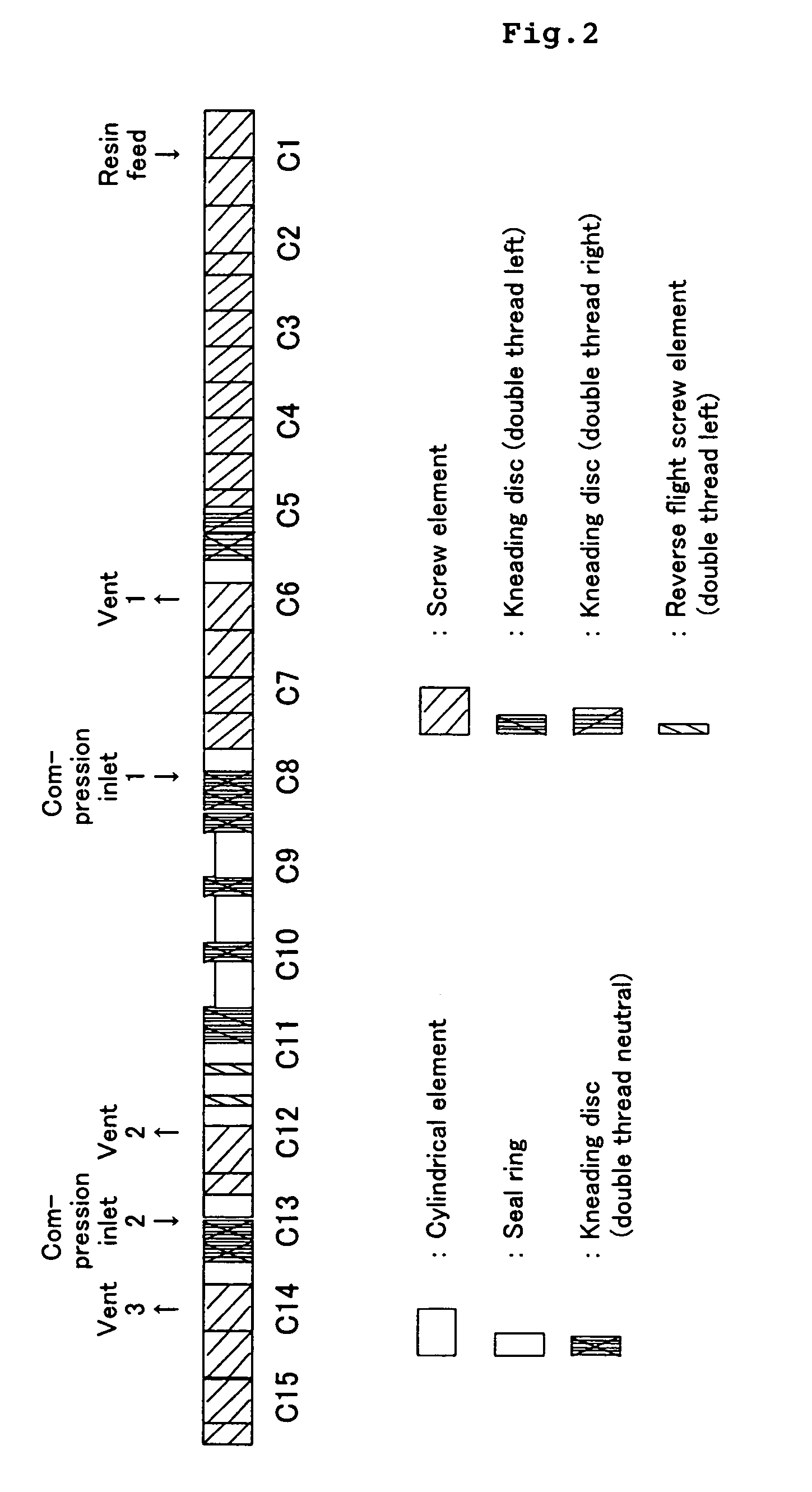

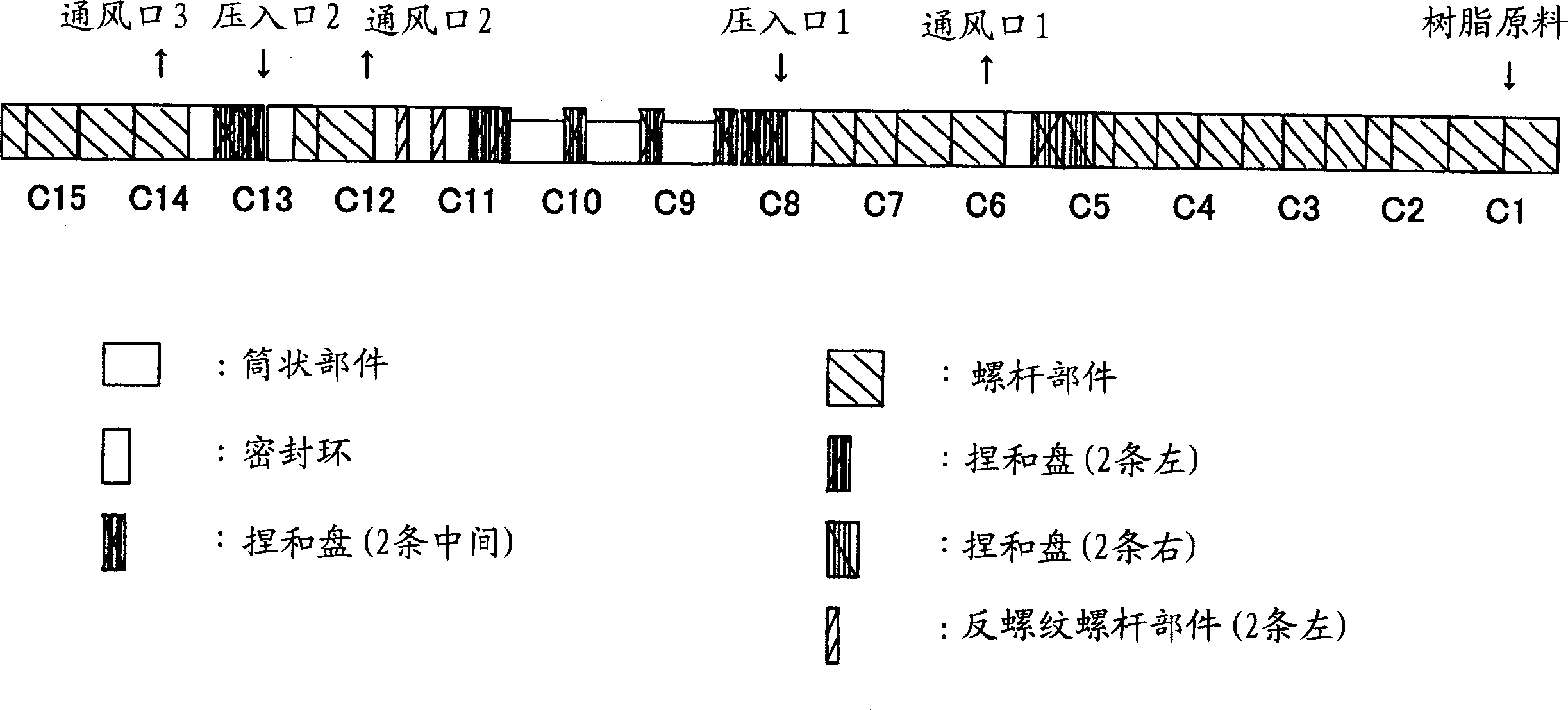

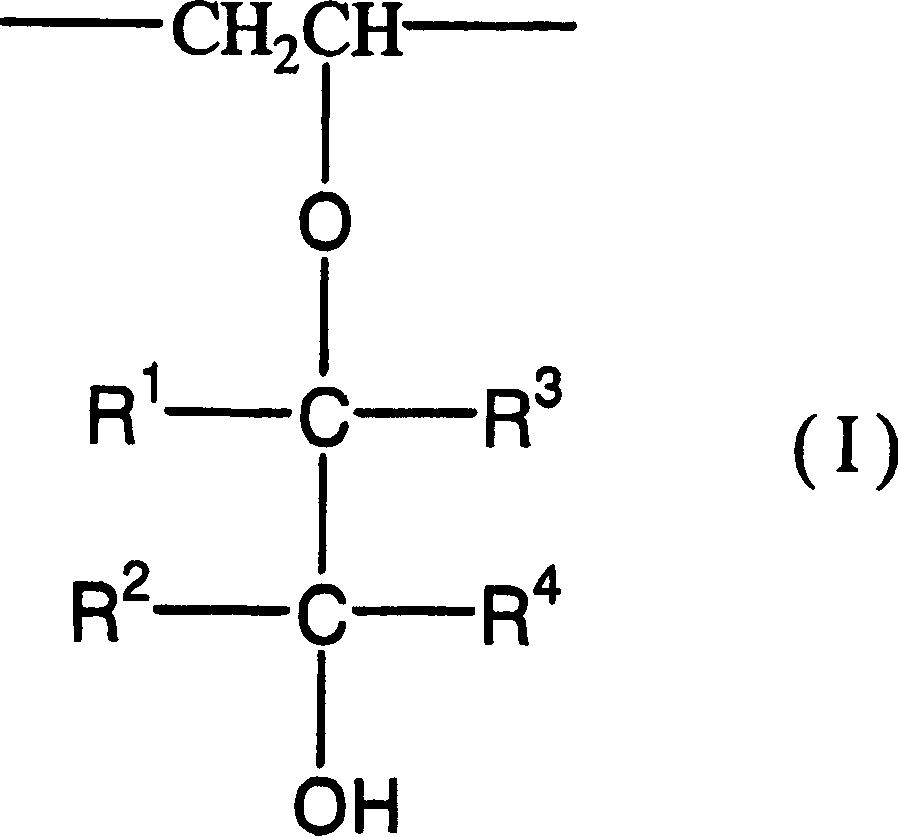

Resin composition and method for producing the same

ActiveUS7473735B2Improved melt stabilityImprove workabilityRecord information storageMagnetic recordingAcetic acidCarboxylic acid

The present invention provides a resin composition which comprises EVOH and a thermoplastic resin other than EVOH and which generates less odor and therefore is suitable for food packaging applications. The invention also provides an environmentally friendly method for producing a resin composition, without releasing any carboxylic acid such as acetic acid to the peripheral environment. A resin composition containing less carboxylate group is obtained by contacting an ethylene-vinyl alcohol copolymer resin with an aqueous solution containing both carbon dioxide gas and at least one additive selected from the group consisting of an alkali metal salt (A) and a boron compound (B) and then melt kneading with a thermoplastic resin (G) other than EVOH.

Owner:KURARAY CO LTD

Block copolymer, its composition and film made of it

InactiveUS20050089702A1Increase resistanceImprove shrinkabilitySynthetic resin layered productsDomestic articlesPolymer scienceDynamic viscoelasticity

It is to provide a block copolymer and its copolymer composition which provides a heat shrinkable (multilayer) film with less spontaneous shrinkage while maintaining favorable low temperature shrinkability, and a heat shrinkable (multilayer) film containing the block copolymer. By using a block copolymer comprising a vinyl aromatic hydrocarbon and a conjugated diene characterized in that the relation of the loss tangent value obtained by dynamic viscoelasticity measurement with the temperature satisfies specific conditions, or a composition containing the copolymer composition as an essential component, a heat shrinkable (multilayer) film with less spontaneous shrinkability and less odor while maintaining favorable low temperature shrinkability can be obtained.

Owner:DENKA CO LTD

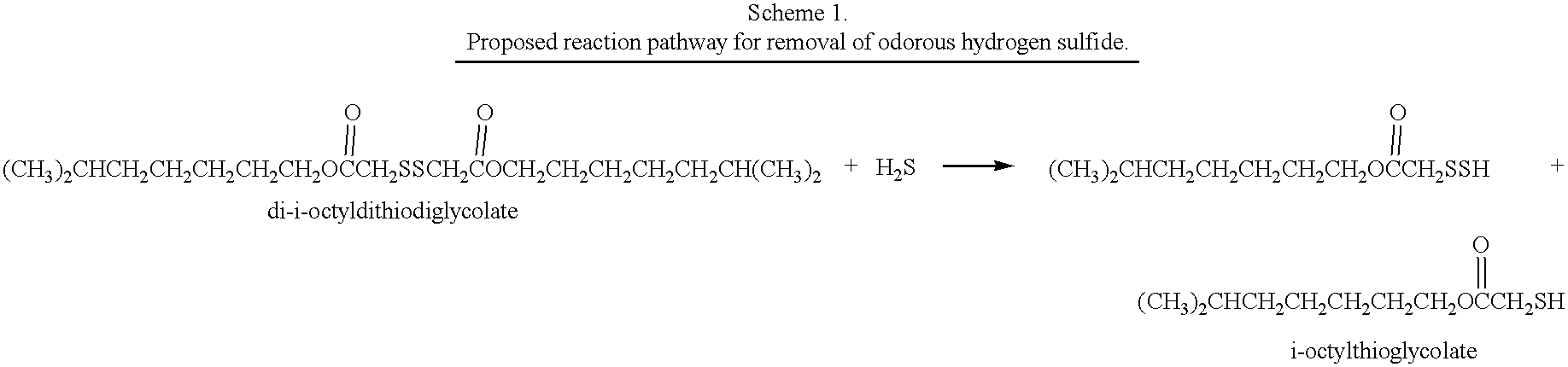

Low odor permanent waving compositions containing a disulfide

This invention provides compositions and methods for reducing odors associated with permanent hair waving by contacting the hair with a disulfide before, during, or after application of a sulfur-based reducing agent.

Owner:CLAIROL

Preparation of fatty acids in solid form

ActiveUS20100179347A1Improve oxidation stabilityPromote digestionOrganic compound preparationFatty-oils/fats refiningGlycerolWater soluble

A method for making a fatty acid mineral salt is disclosed where liquid oils containing fatty acids are hydrolyzed using a base solution. A buffering agent is added to the hydrolyzed solution to maintain pH between 8.0 and 11.0 followed by a water soluble metal salt solution which causes a metathesis reaction with the hydrolyzed solution, forming a precipitates of fatty acid metal salts which are glycerin-free. The precipitates are filtered, washed and subsequently dried. The produced fatty acid metal salt is easier for the human body to digest than omega-3 fatty acid in oil form and also is less prone to oxidation and emitting of unpleasant odor.

Owner:J H BIOTECH

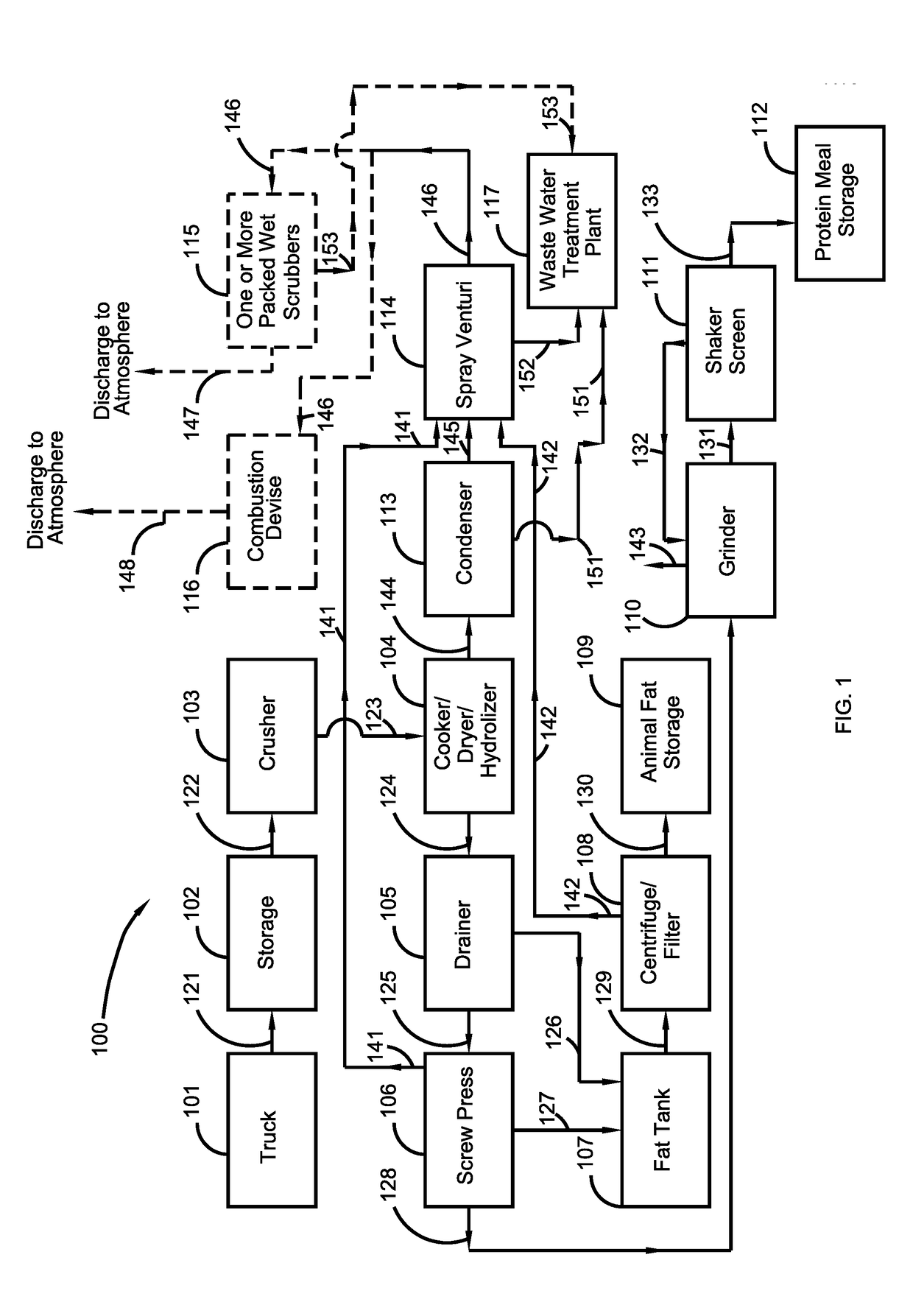

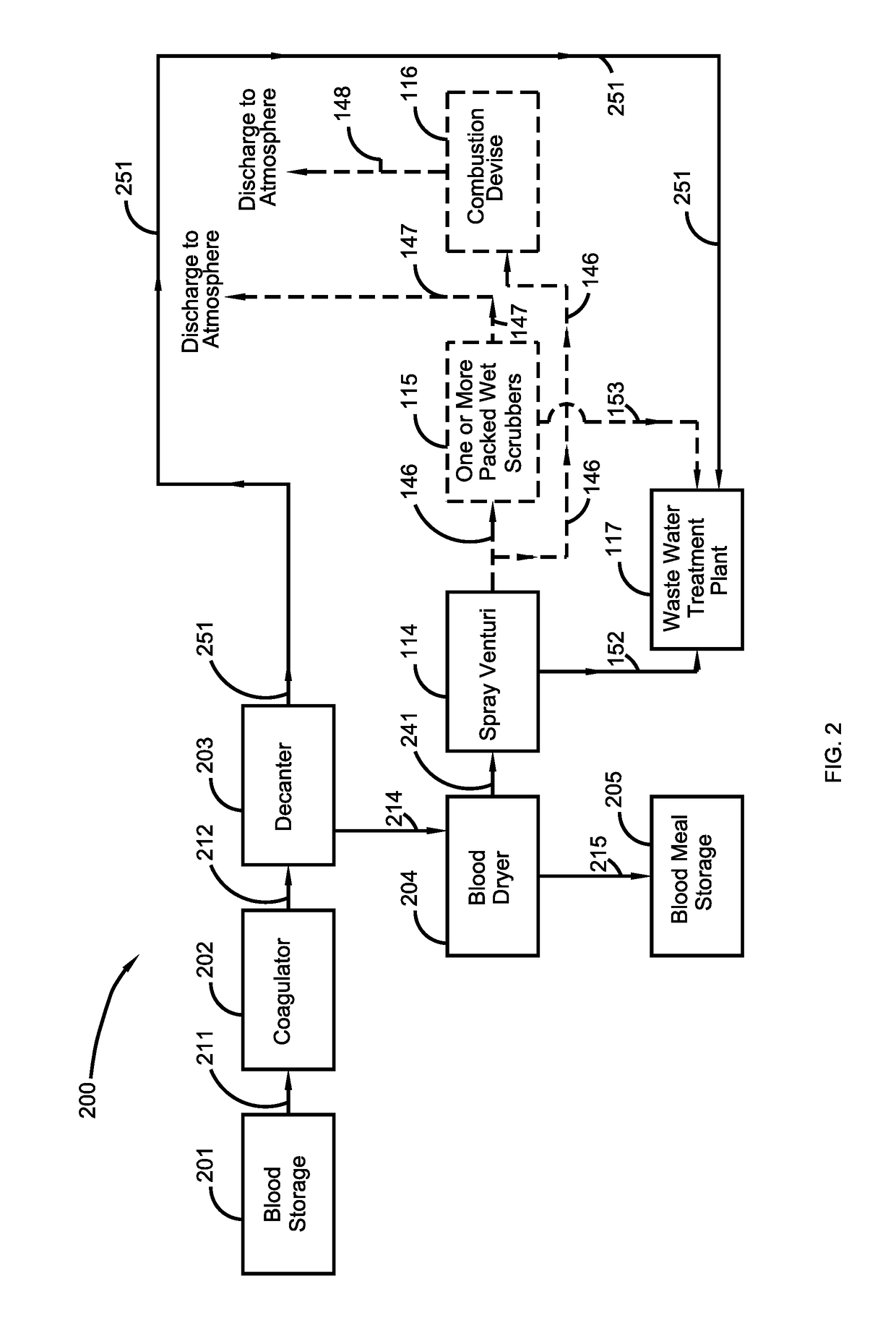

Methods for Treating Industrial Waste Streams and Recovering Certain Chemical Compounds

InactiveUS20170136386A1Easy to storeEasy to sellGas treatmentUsing liquid separation agentLiquid wasteWaste stream

The invention relates to methods and equipment for treating industrial vapor and liquid waste streams to remove certain compounds and concentrate those compounds to produce a chemical product. Specifically, the invention related to methods and equipment for condensing vapor waste streams and combining those streams with other liquid waste streams, and processing those combined streams to separate certain compounds for further processing into a chemical product, such as a fertilizer, and to thereby to reduce pollution, odor, and nutrient loading to air and water resources and wastewater processing systems.

Owner:TEMPLE STEPHEN R +1

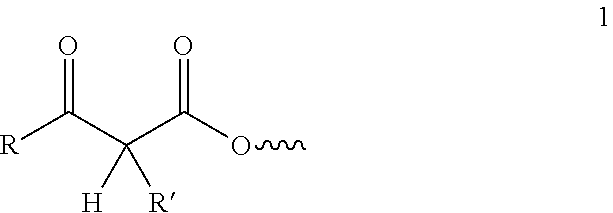

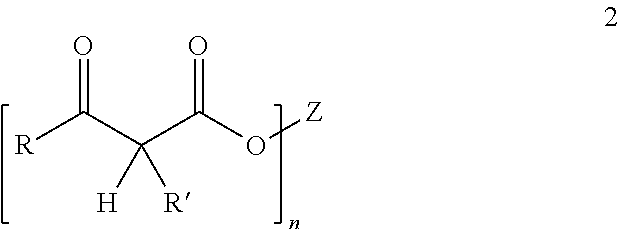

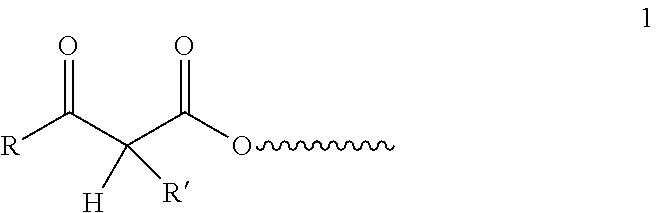

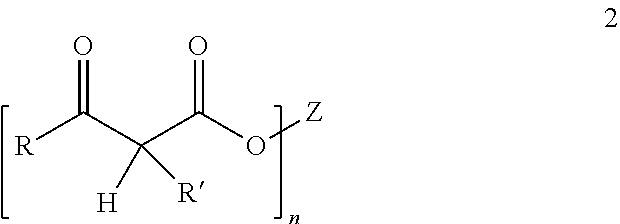

Curable compositions comprising acetoacetylated resins, aldehydes and certain amines

ActiveUS20200181395A1Improve adhesionReduce defectsAdhesive processesAldehyde/ketone condensation polymer adhesivesPolymer scienceMalonic acid

This invention relates to a curable composition comprising: comprising:I. a first component comprising a resin having at least one functional group selected from the group consisting of β-ketoester and malonate functional groups,II. a second component comprising at least one curing agent having at least one aldehyde functional group, andIII. a third component comprising at least one primary amine or at least one secondary amine, salts thereof, or combinations thereof.

Owner:EASTMAN CHEM CO

Controlled cure for compositions comprising acetoacetylated resins

PendingUS20200181324A1Improve adhesionReduce defectsAdhesive processesAldehyde/ketone condensation polymer adhesivesPolymer scienceMalonic acid

This invention relates to a curable composition comprising:I. Component (I) comprising a resin having at least one functional group selected from the group consisting of β-ketoester and malonate functional groups;II. Component (II) comprising at least one curing agent having at least one aldehyde functional group, wherein said Component (II) is optionally latent;III. Component (III) comprising at least one amine, salts thereof, or combinations thereof;wherein before addition of Component (III), the reactivity of the composition is delayed by at least one of the following:(III)(a) at least one of said Components (I), (II), and (III), or any reaction product thereof, or any combination thereof is a solid; or at least one of Components (II) or (III) or any combination thereof is insoluble in the resin under pot life conditions; or(III)(b) at least one said amine is first reacted with at least one aldehyde, ketone, acetal or ketal, or mixtures thereof, optionally, to form a solid;(III)(c) at least one said amine is first reacted with a portion of Component (II), wherein the reaction product thereof is optionally reacted or combined subsequently with additional amounts of either or both of Components (II) and (III), and, prior to reaction of Components (I)-(III), and is optionally combined with at least one amine reactivity delayer; or(III)(d) at least one said amine is first reacted with all of Component (II) wherein the reaction product is a combination of Components (II) and (III) and no additional amounts of Component (II) or Component (III) are reacted with said composition; or combinations of reaction products as described in (III)(d); and optionally,IV. Component (IV) comprising at least one reactivity delayer which is combined with Component (II), or Component (III), or a combination thereof.

Owner:EASTMAN CHEM CO

Method for treating biochemical sludge or poultry and livestock manure by using earthworm

InactiveCN102557370BPromote decomposition and conversion functionFavorable for biological treatmentBiological sludge treatmentLivestock manureFeces

Owner:宁波福晨环保科技有限公司

Hot melt adhesive composition for bookbinding

ActiveUS20160376479A1Good ink resistance performanceEasy to processMineral oil hydrocarbon copolymer adhesivesMixingWaxHot-melt adhesive

The present invention provides a hot melt adhesive composition for bookbinding comprising a base polymer, a wax and / or an oil, a tackifier, a stabilizer and optionally a filler; wherein the base polymer comprises a propylene-based elastomer, an amorphous poly-α-olefin (APAO), and optionally, an ethylene-based or propylene-based plastomer.

Owner:HENKEL KGAA

Image forming apparatus, image forming method, and process cartridge

ActiveUS7960083B2Low-temperature stabilityLess odorElectrographic process apparatusDevelopersMeth-Alcohol

Owner:RICOH KK

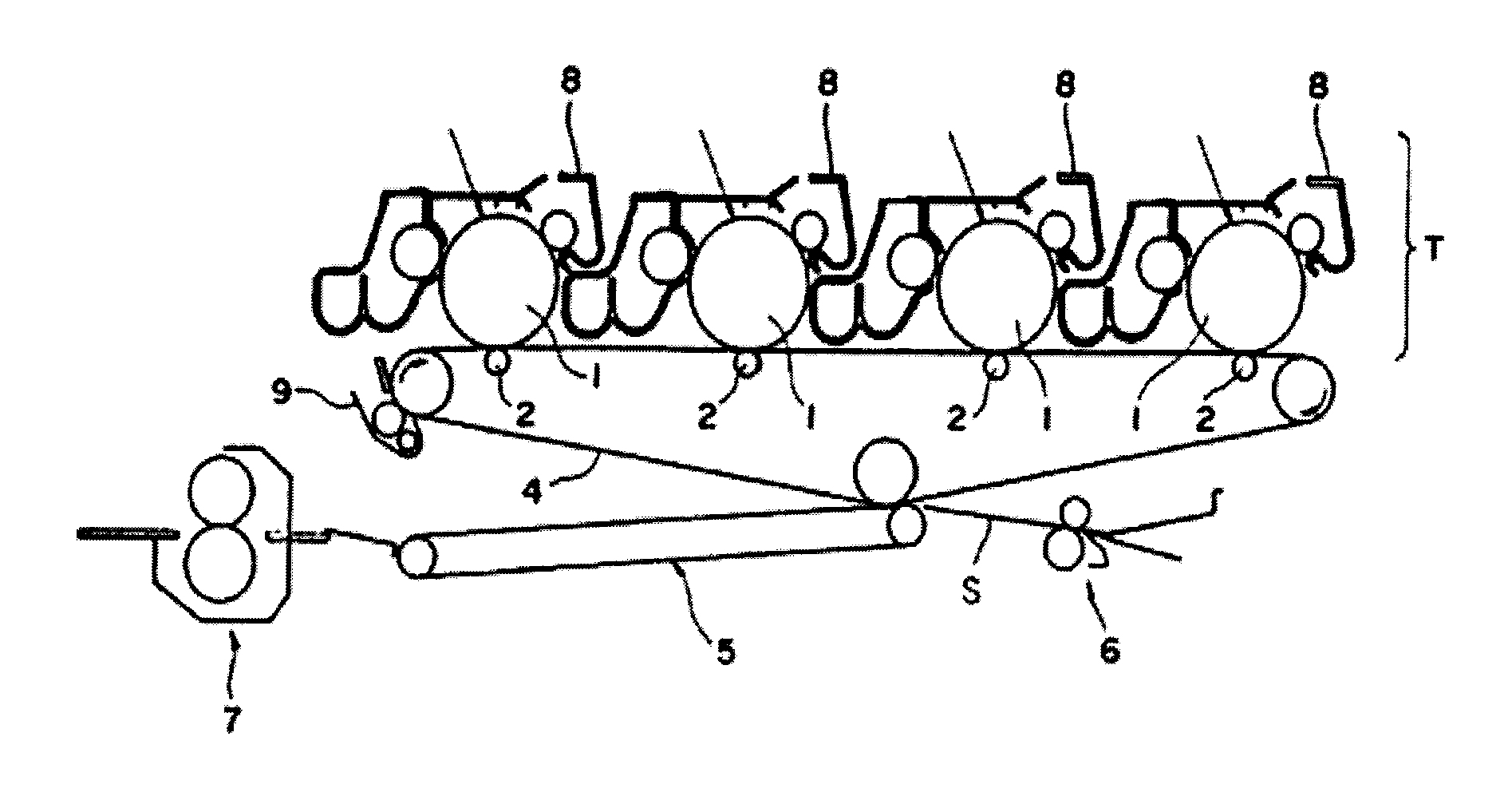

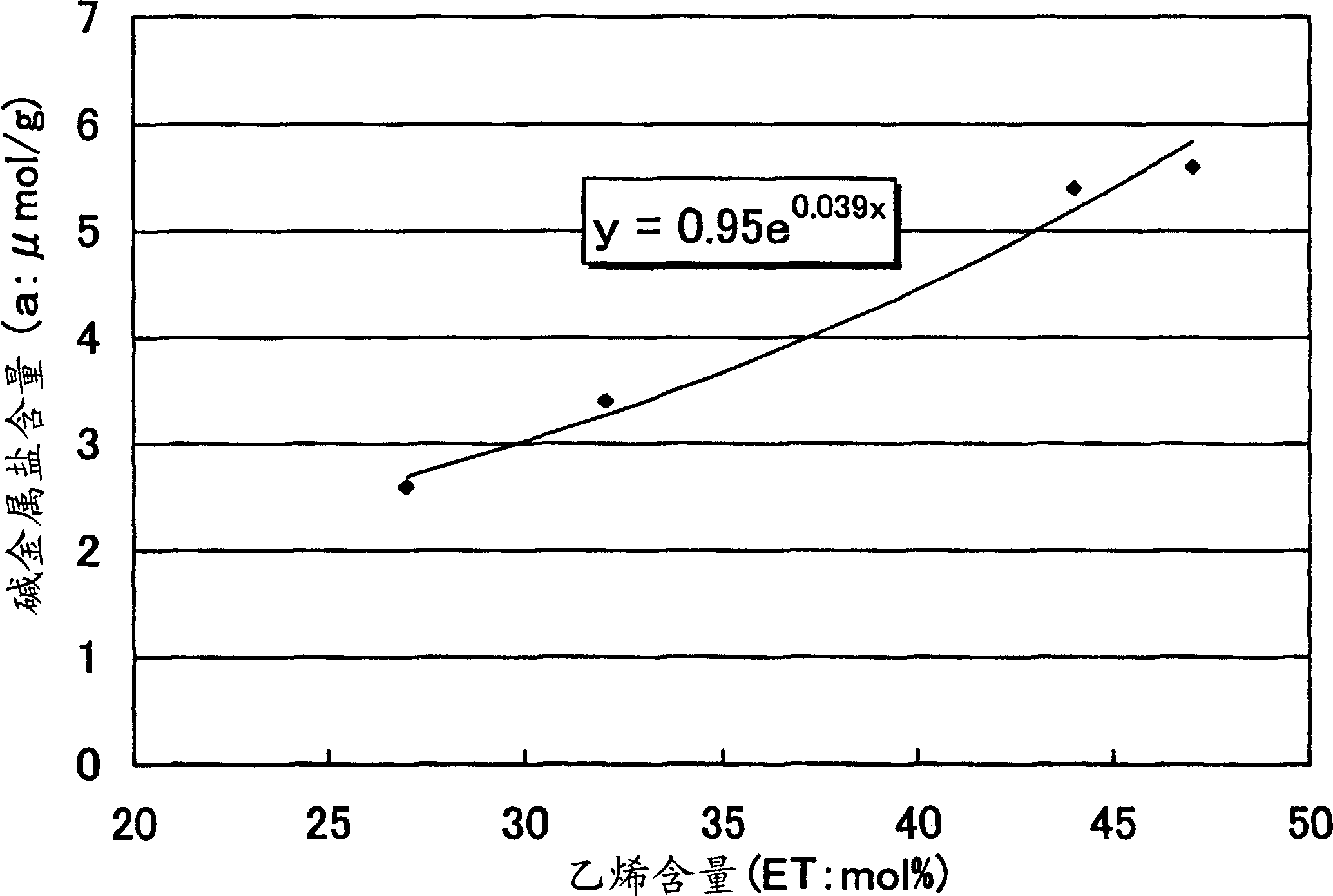

Steric net-like fiber aggregation

There is provided a steric net-like fiber aggregation, comprising fibers having a fineness of 150 to 100000 dtex, the fibers being made of a resin comprising a propylene-based polymer(a), wherein a multitude of the fibers are in a fusion bonding with each other due to a random orientation of melted fibers, and wherein the propylene-based polymer(a) has a structural unit of 51 to 95 percent by mole of a propylene and 5 to 49 percent by mole of an α-olefin with respect to 100 percent by mole of the total monomers of the propylene-based polymer(a).

Owner:PANEFURI INDS

Resin composition and method for producing the same

The present invention provides a resin composition which comprises EVOH and a thermoplastic resin other than EVOH and which generates less odor and therefore is suitable for food packaging applications. The invention also provides an environmentally friendly method for producing a resin composition, without releasing any carboxylic acid such as acetic acid to the peripheral environment. A resin composition containing less carboxylate group is obtained by contacting an ethylene-vinyl alcohol copolymer resin with an aqueous solution containing both carbon dioxide gas and at least one additive selected from the group consisting of an alkali metal salt (A) and a boron compound (B) and then melt kneading with a thermoplastic resin (G) other than EVOH.

Owner:KURARAY CO LTD

Hot melt adhesive composition for bookbinding

InactiveUS10227509B2Easy to processLess odorMineral oil hydrocarbon copolymer adhesivesBookbinding adhesiveElastomerWax

The present invention provides a hot melt adhesive composition for bookbinding comprising a base polymer, a wax and / or an oil, a tackifier, a stabilizer and optionally a filler; wherein the base polymer comprises a propylene-based elastomer, an amorphous poly-α-olefin (APAO), and optionally, an ethylene-based or propylene-based plastomer.

Owner:HENKEL KGAA

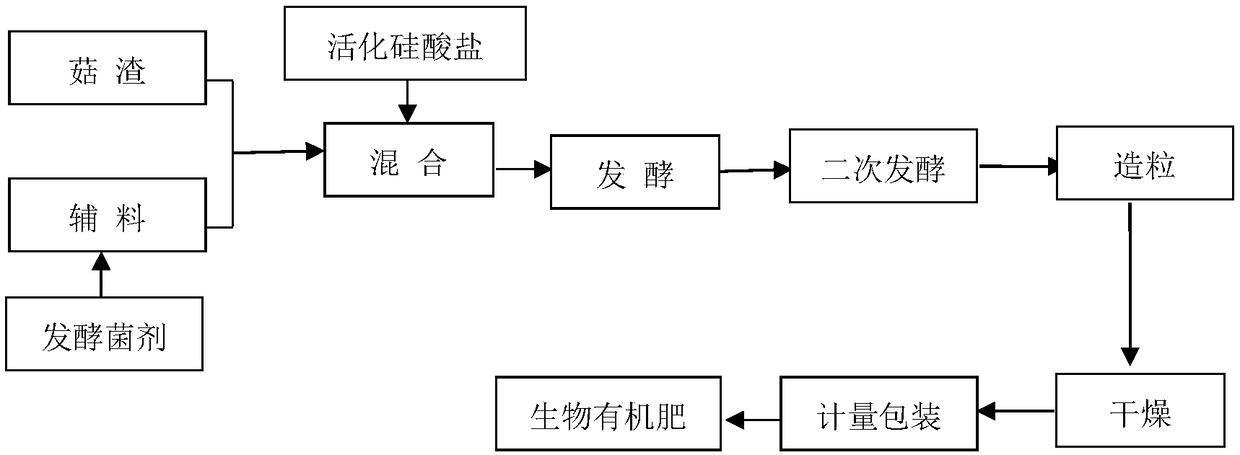

Production process for biological organic fertilizer on basis of mushroom residue

InactiveCN109279989AEasy to disperseOdor suppressionCalcareous fertilisersBio-organic fraction processingMushroomChemistry

The invention discloses a production process for a biological organic fertilizer on the basis of mushroom residue. According to the invention, the production process has short fermentation time and generates less odor; an organic fertilizer produced by using the production process provided by the invention can improve the fertilizer supply capacity of biological bacteria, and can release phosphorus and potassium fixed by soil out of the soil, so improvement of the utilization rate of a fertilizer and reduction of the usage amount of the fertilizer are realized, and non-point source pollution is reduced; condition parameters in each step of the production process provided by the invention are adjusted and determined by experiments, so the process of producing the biological organic fertilizer by using the mushroom residue as a base material is standardized; and a resourceful technology capable of realizing the resource value of the mushroom residue and utilizing a large amount of wastematerials is provided.

Owner:广东华智星技术服务有限公司

Acoustic damping composition

InactiveUS20160379615A1Easy to optimizeImprove damping performanceBuilding constructionsSound producing devicesPolyolefinPolymer science

The present invention provides an acoustic damping composition comprising a propylene-based polyolefin, a tackifier, a filler and a stabilizer, wherein the density of the propylene-based polyolefin is in the range of 0.8 to 1.2 g / m3, preferably 0.8 to 1.0 g / m3, measured according to ASTM D1505, and the propylene content in the propylene-based polyolefin is more than 50 wt %, preferably more than 60 wt %, more preferably more than 70 mol %.

Owner:HENKEL KGAA

Cellulose fiber thermoplastic composition having a cosmetic appearance and molding thereof

ActiveUS20180037724A1Brighter and glossier surface appearanceEasy constructionAdditive manufacturing apparatusThermoplasticPolyolefin

A inventive method to process an organic compound with a thermoplastic alloy composition comprising of a high heat hydrophilic polymer, a polyolefin, preferably with a compatibilizer that is without maleic content. A compressed pellet will be generated at low temperatures for producing a cellulose thermoplastic alloy composition improving the ability to color and replace existing compositions that are challenged by toxicity and performance. This composition can be re fractured into fine particles if necessary, to produce 3 D printed parts well beyond the degradation of the specified organic compound for cosmetic, automotive or medical markets.

Owner:INNOVATIVE PLASTICS & MOLDING

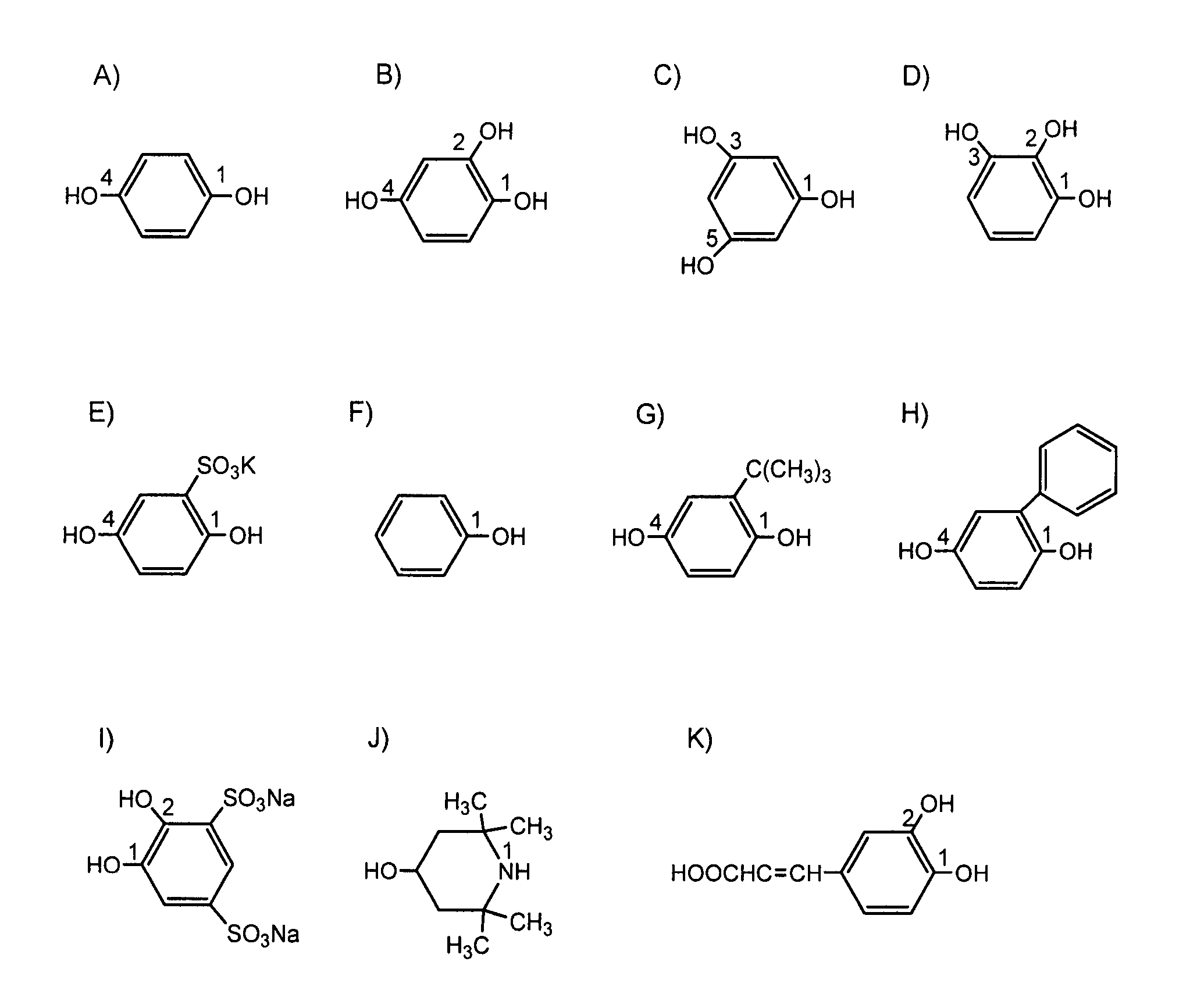

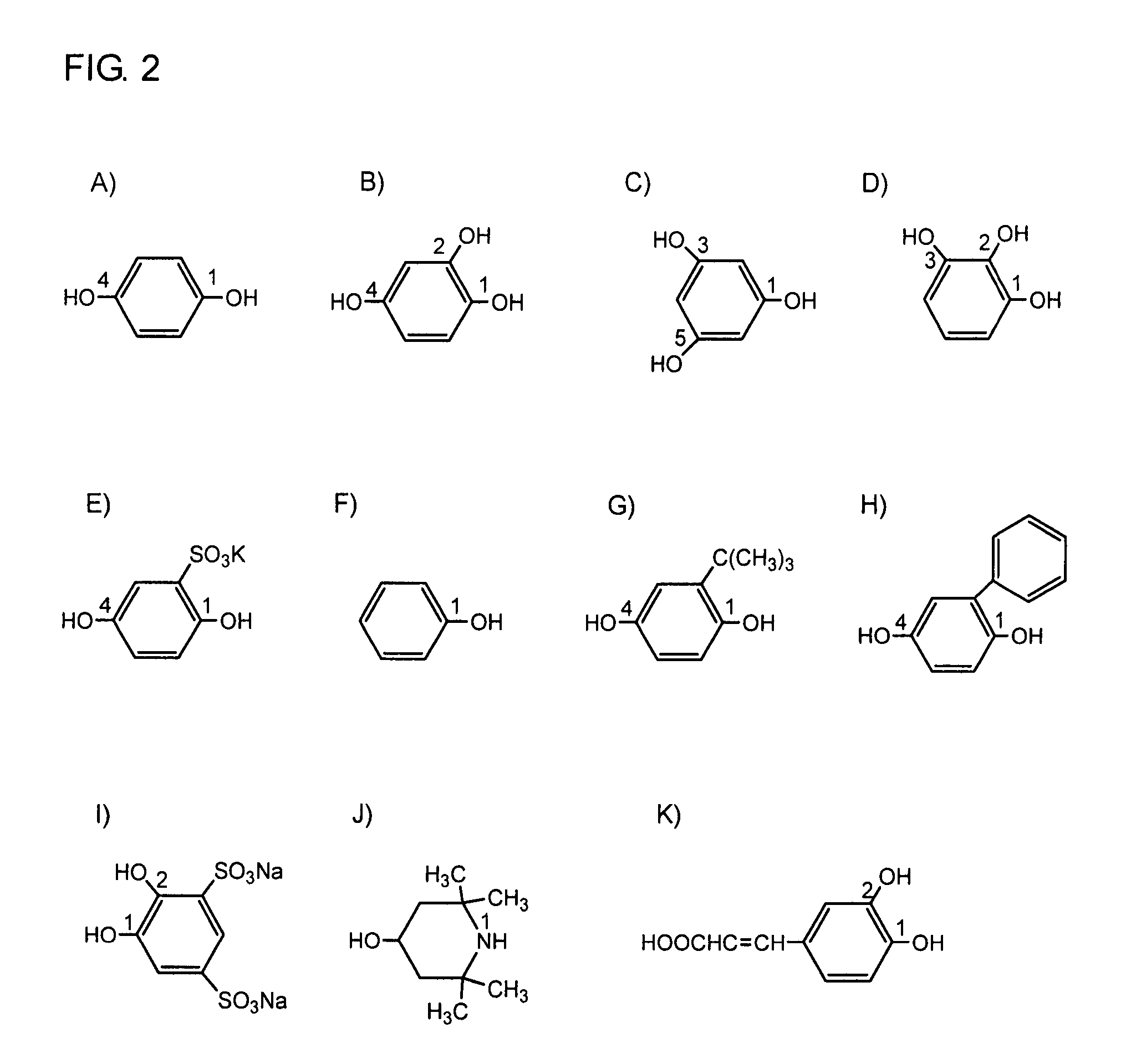

Production method of toner for developing electrostatic image

ActiveUS8092974B2Increase production capacityShelf stabilityDevelopersMonomer compositionActivation energy

A production method of a toner includes a suspension process in which a polymerizable monomer composition is dispersed in an aqueous dispersion medium; and a polymerization process in which suspension polymerization is performed with the suspension in the presence of a polymerization initiator to obtain colored resin particles. In the suspension process an inhibitor of small diameter microparticle production is contained in the aqueous dispersion medium. A minimum reaction activation energy Emin of the inhibitor of small diameter microparticle production is 7 kcal / mol or less and an octanol-water partition coefficient log P is 2 or less. The minimum reaction activation energy Emin is a minimum value of a reaction activation energy “E” which is required when a phenylpropane radical represented by the following Formula 1 acts on the inhibitor of small diameter microparticle production:

Owner:ZEON CORP

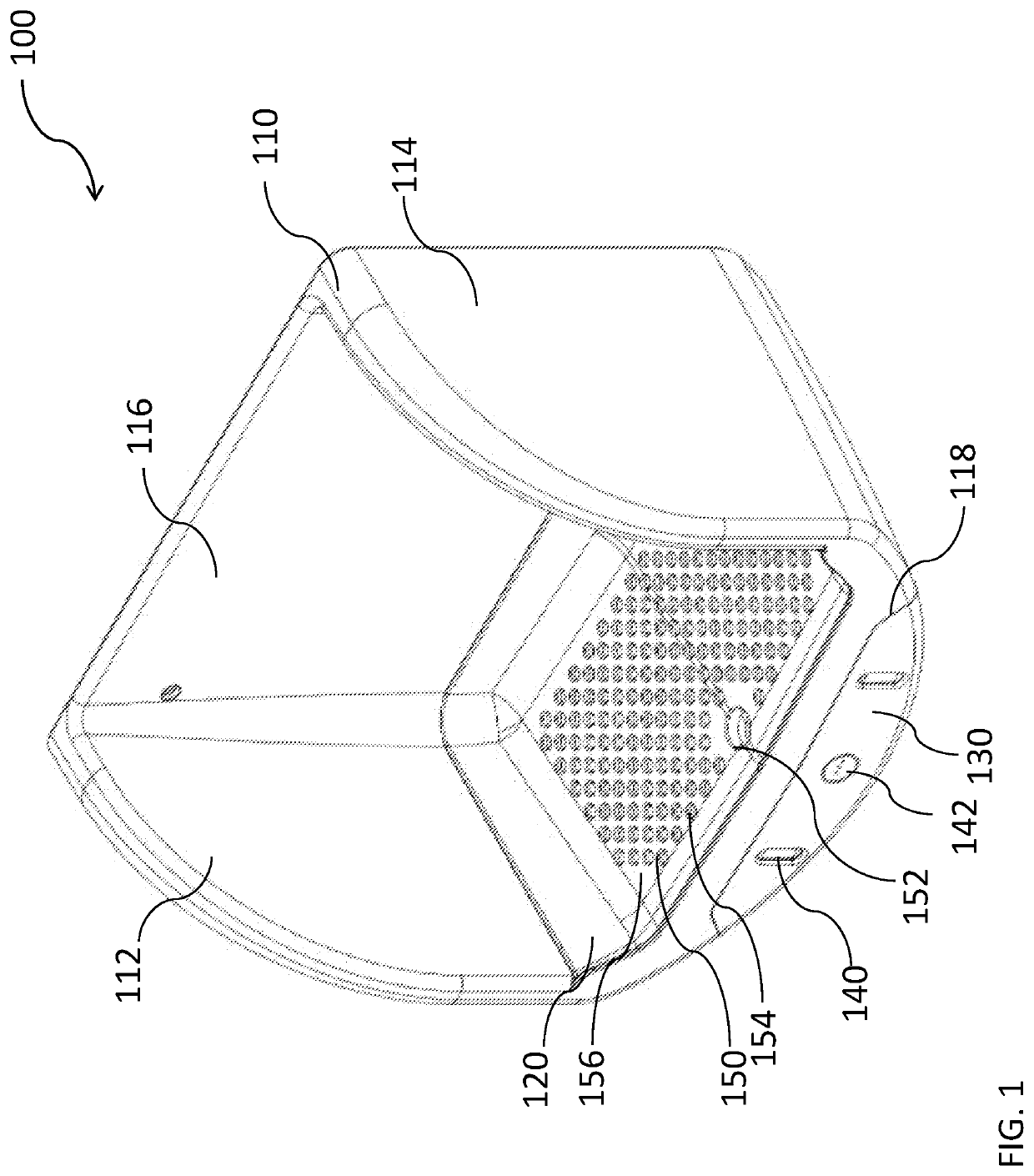

Hand dryer splash guard

PendingUS20220257069A1Easy to disassemblePrevent splashDomestic applicationsMechanical engineeringAnti reflective

The invention discloses a splash guard that may be retrofitted to a hand dryer device to avoid spraying of water on the floor and on the walls. The splash guard is attached underneath the dryer device and is configured to catch the water displaced from a user's drying wet hands. The splash guard is formed of a housing that has side walls, a base, a perforated drip tray and a drawer arrangement to hold the displaced water. The housing is hollow and open fronted, for users to place their hands under the dryer device. The surface of the drip tray is anti-reflective and has perforations that stop water from splashing. The displaced water is directed to drip into the drawer that store up the exiting water to be removed at a later time. The drawer has transparent windows to indicate the level of water in the drawer.

Owner:LAL HUSSAN

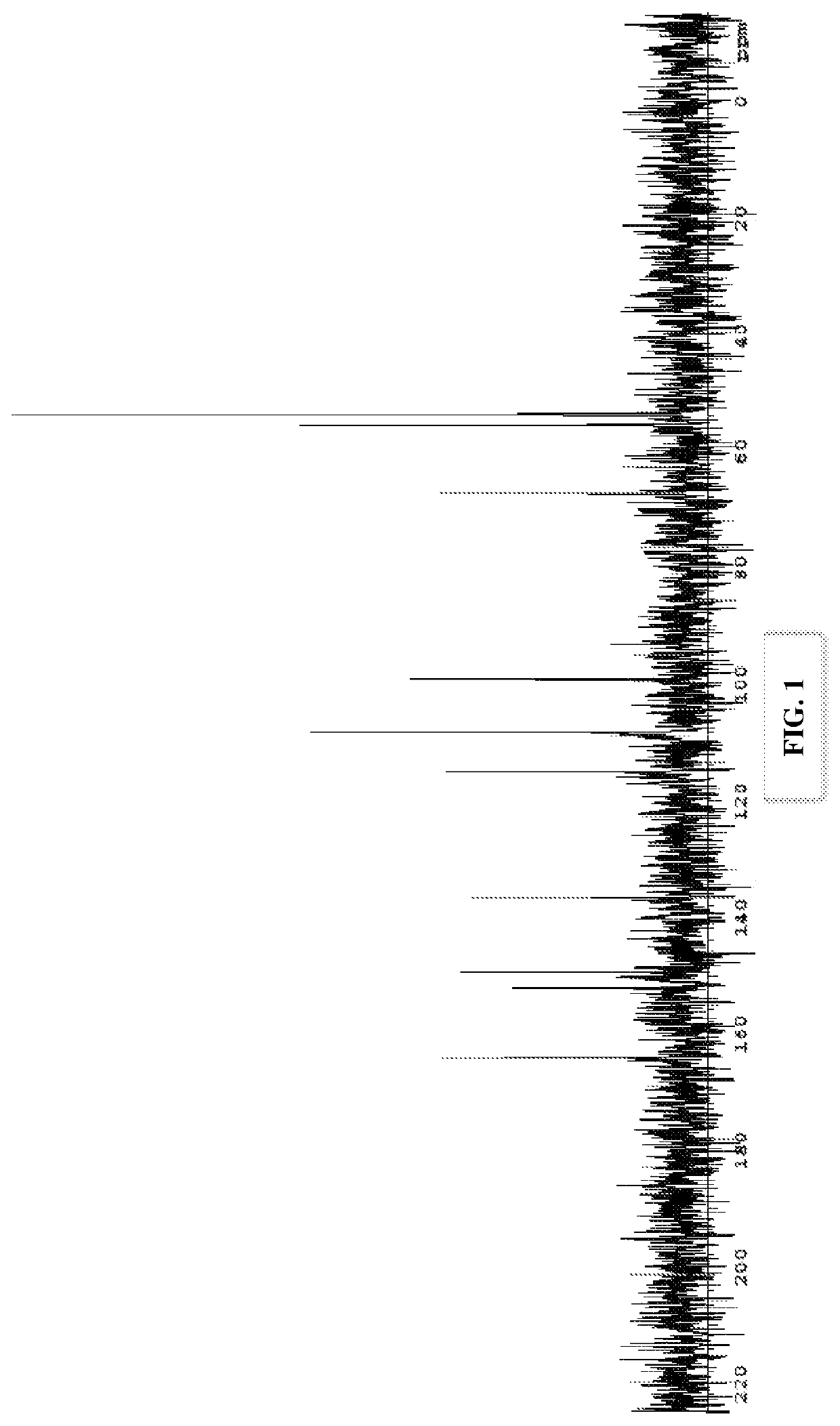

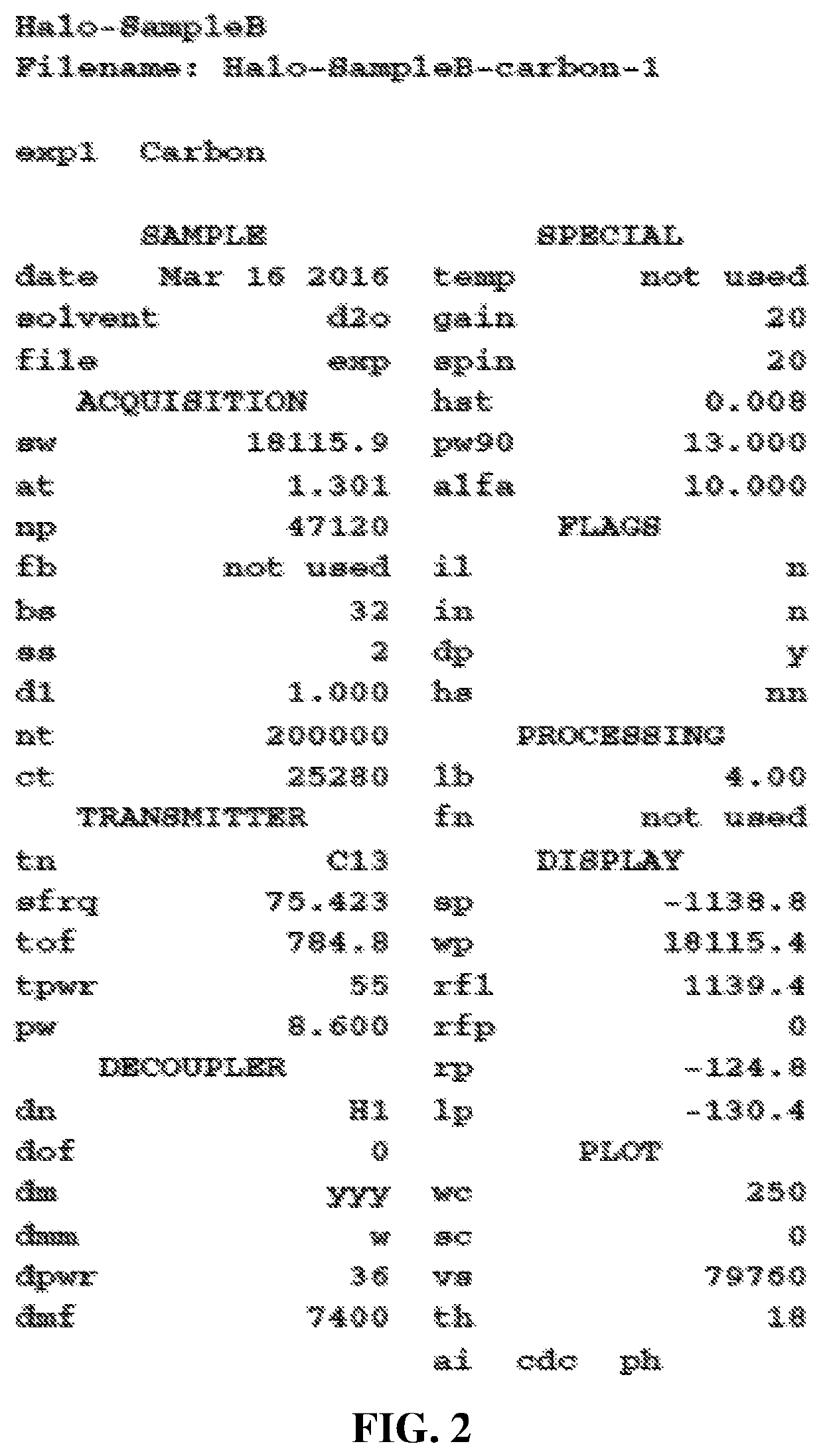

Methods of making low odor choline salts of an organic compound

ActiveUS10981928B2Less odorHigh purityNervous disorderOrganic chemistryOrganic compoundMedicinal chemistry

Methods of making low odor choline salts of an organic compound, for example, choline ellagate compound(s), and uses and formulations thereof.

Owner:HALO LIFE SCI LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com