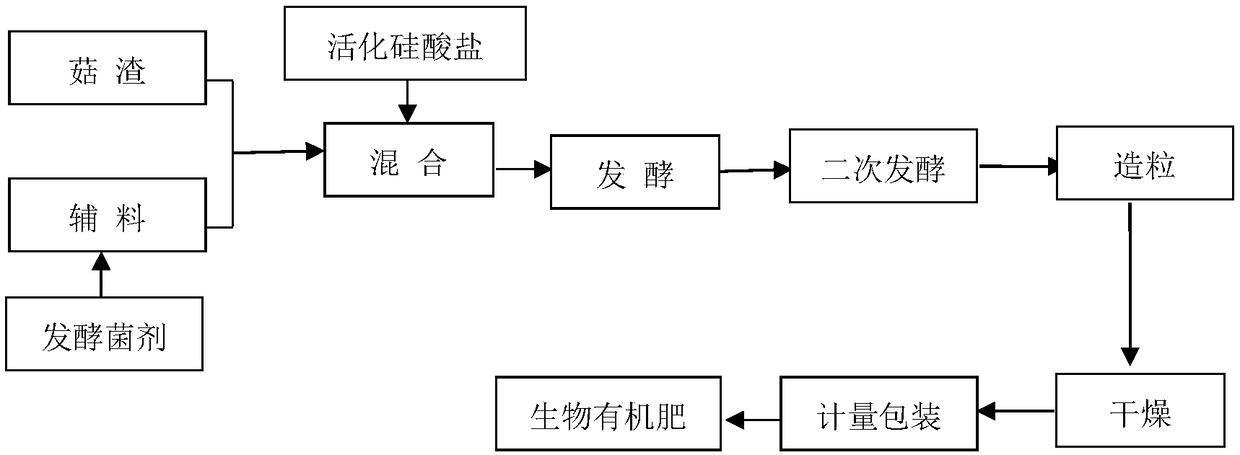

Production process for biological organic fertilizer on basis of mushroom residue

A bio-organic fertilizer and production process technology, applied in the field of fertilizers, can solve problems such as difficult processing, differences in physical and chemical properties, lack of standardization, and factory production, and achieve the goals of improving fertilizer supply capacity, less odor, and improving fertilizer utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The raw material comprises the following components in parts by weight: 75 kg of mushroom dregs, 8 kg of wheat bran, 5 kg of peanut bran, 12.3 kg of active silicate, 25 g of starter, 30 g of phosphorus-dissolving functional bacteria, and 15 g of potassium-dissolving functional bacteria;

[0028] making process:

[0029] a. Put 8kg of wheat bran and 3kg of peanut bran into the mixing system, and at the same time add 25g of starter and 55.2kg of water into the mixing system and mix evenly;

[0030] b. After step a is completed, put 75kg of mushroom dregs into the mixing system for stirring, and at the same time gradually add active silicate to stir and mix. When the pH value of the mixture in the kettle is measured to be 5.5-8.5, stop adding active silicate, and the activity The actual amount of silicate is 12.3kg, so that the mixture in the kettle is stirred evenly to obtain the mixed material to be fermented;

[0031] c. Put the mixed material to be fermented into the ...

Embodiment 2

[0035] The raw material comprises the following components in parts by weight: 63 kg of mushroom dregs, 10 kg of wheat bran, 6 kg of peanut bran, 10.6 kg of active silicate, 25 g of starter, 30 g of phosphorus-dissolving functional bacteria, and 15 g of potassium-dissolving functional bacteria;

[0036] making process:

[0037] a. Put 10kg of wheat bran and 6kg of peanut bran into the mixing system, add 25g of starter and 49.32kg of water into the mixing system and mix evenly;

[0038] b. After step a is completed, put 63kg of mushroom dregs into the mixing system and stir, and at the same time gradually add active silicate to stir and mix. When the pH value of the mixture in the kettle is measured to be 5.5 to 8.5, stop adding active silicate. The actual amount of silicate is 10.6kg, so that the mixture in the kettle is stirred evenly to obtain the mixed material to be fermented;

[0039] c. Put the mixed material to be fermented into the fermenter, feed air into the ferment...

Embodiment 3

[0043]The raw material comprises the following components in parts by weight: 80 kg of mushroom dregs, 8 kg of wheat bran, 8 kg of peanut bran, 13.2 kg of active silicate, 30 g of starter, 30 g of phosphorus-dissolving functional bacteria, and 15 g of potassium-dissolving functional bacteria;

[0044] making process:

[0045] a. Put 8kg of wheat bran and 8kg of peanut bran into the mixing system, and at the same time add 30g of starter and 60.1kg of water into the mixing system and mix evenly;

[0046] b. After step a is completed, put 80kg of mushroom dregs into the mixing system for stirring, and at the same time gradually add active silicate to stir and mix. When the pH value of the mixture in the kettle is measured to be 5.5-8.5, stop adding active silicate. The actual amount of silicate is 13.2kg, so that the mixture in the kettle is stirred evenly to obtain the mixed material to be fermented;

[0047] c. Put the mixed material to be fermented into the fermenter, feed ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com