Resin composition and method for producing the same

一种树脂组合物、热塑性树脂的技术,应用在热塑性树脂的树脂组合物领域,能够解决透明性降低等问题,达到散发臭味少、熔融稳定性和长期使用性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

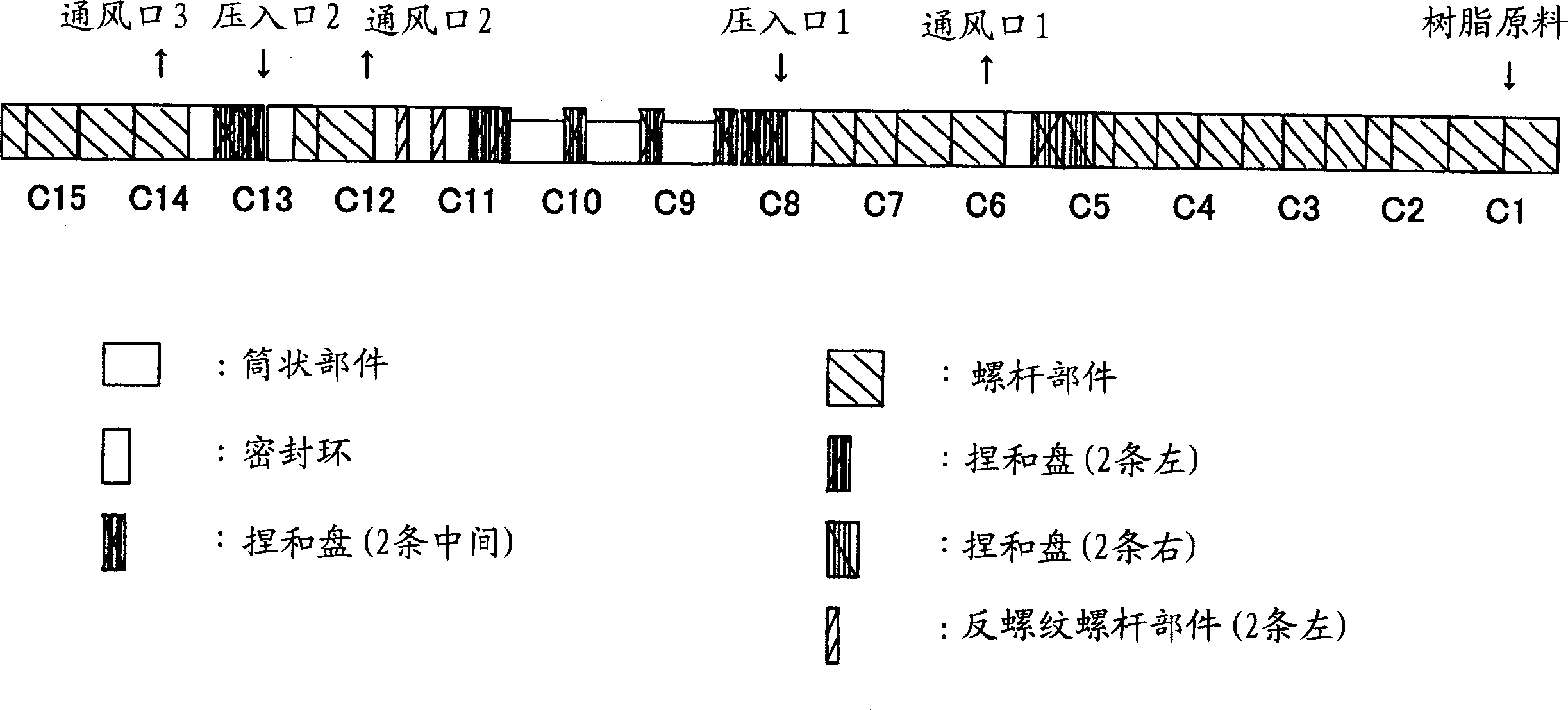

[0333] [Manufacture of EVOH resin composition (F)]

[0334] The 45% methanol solution of the ethylene-vinyl acetate copolymer with 50kg ethylene content of 32 mol % and the methyl alcohol of 129kg are packed in the saponification reactor of 470L capacity, while blowing into nitrogen in the reactor, internal temperature is set on the one hand Set at 60°C. Further, 29 L of methanol solution of sodium hydroxide (concentration: 80 g / L) was added thereto to start saponification reaction. During the saponification reaction, in order to improve the reaction efficiency, nitrogen is continuously blown into the reactor, so that the methyl acetate produced as a by-product in the reaction system is driven out of the reaction system together with the methanol in the reaction system. Based on the total amount of methyl acetate and methanol, the drive-out rate is about 20kg / hr. Use a condenser to condense and recover the drive-out liquid. After 2 hours from the start of the reaction, 29 L ...

Embodiment 2

[0349] [Preparation of EVOH resin composition (F)]

[0350] Be that 45% methanol solution of the ethylene-vinyl acetate copolymer of 27 mol % with 50kg ethylene content and the methyl alcohol of 129kg pack in the saponification reactor of 470L capacity, blow into nitrogen in the reactor on one side, set internal temperature to Set at 60°C. Further, 29 L of methanol solution of sodium hydroxide (concentration: 80 g / L) was added thereto to start saponification reaction. During the saponification reaction, in order to improve the reaction efficiency, nitrogen is continuously blown into the reactor, so that the methyl acetate produced as a by-product in the reaction system is driven out of the system together with the methanol in the reaction system. Based on the total amount of methyl acetate and methanol, the drive-out rate is about 20kg / hr. Use a condenser to condense and recover the drive-out liquid. After 2 hours from the start of the reaction, 29 L of methanol solution of ...

Embodiment 3

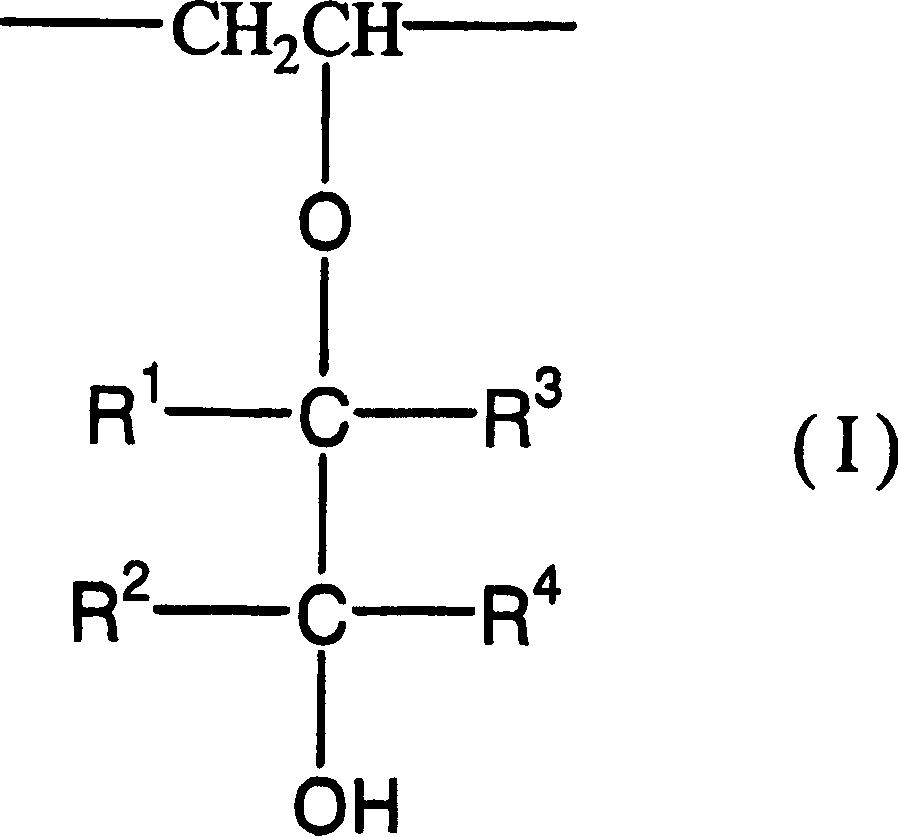

[0370] [Preparation of Modified EVOH (G3)]

[0371] Modified EVOH (G3) was prepared according to the method described below. The raw material EVOH and the resulting modified EVOH (G3) were analyzed in accordance with the method described in International Publication No. 02 / 092643 pamphlet.

[0372] 28 parts by weight of zinc acetylacetonate hydrate and 957 parts by weight of 1,2-dimethoxyethane were mixed to obtain a mixed solution. While stirring, 15 parts by weight of trifluoromethanesulfonic acid was added to prepare a catalyst solution. That is, a solution in which 1 mol of trifluoromethanesulfonic acid was mixed with 1 mol of zinc acetylacetonate hydrate was prepared.

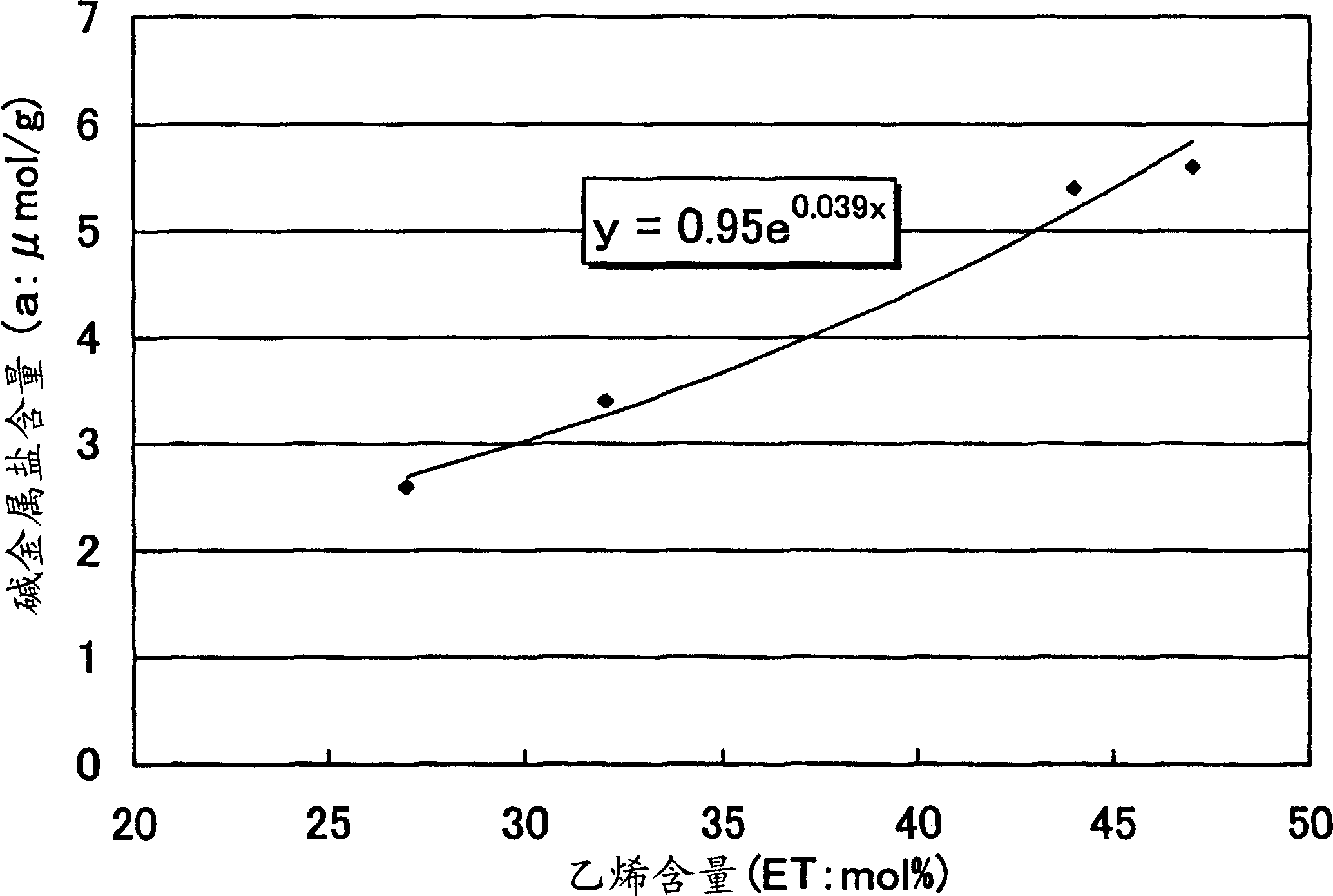

[0373] EVOH with an ethylene content of 44 mol%, a degree of saponification of 99.8%, an intrinsic viscosity of 0.096L / g, and an MFR of 5g / 10min (at 190°C under a load of 2160g) was used {Acetic acid content of 53ppm, sodium content of 1ppm (in terms of metal elements) , Potassium content 8ppm (metal el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com