Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Less content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

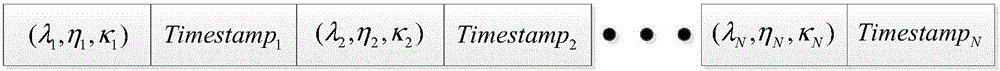

Directed attention digital video recordation

ActiveUS20070035623A1Less contentMinimizing dataTelevision system detailsColor television detailsDigital videoConnection type

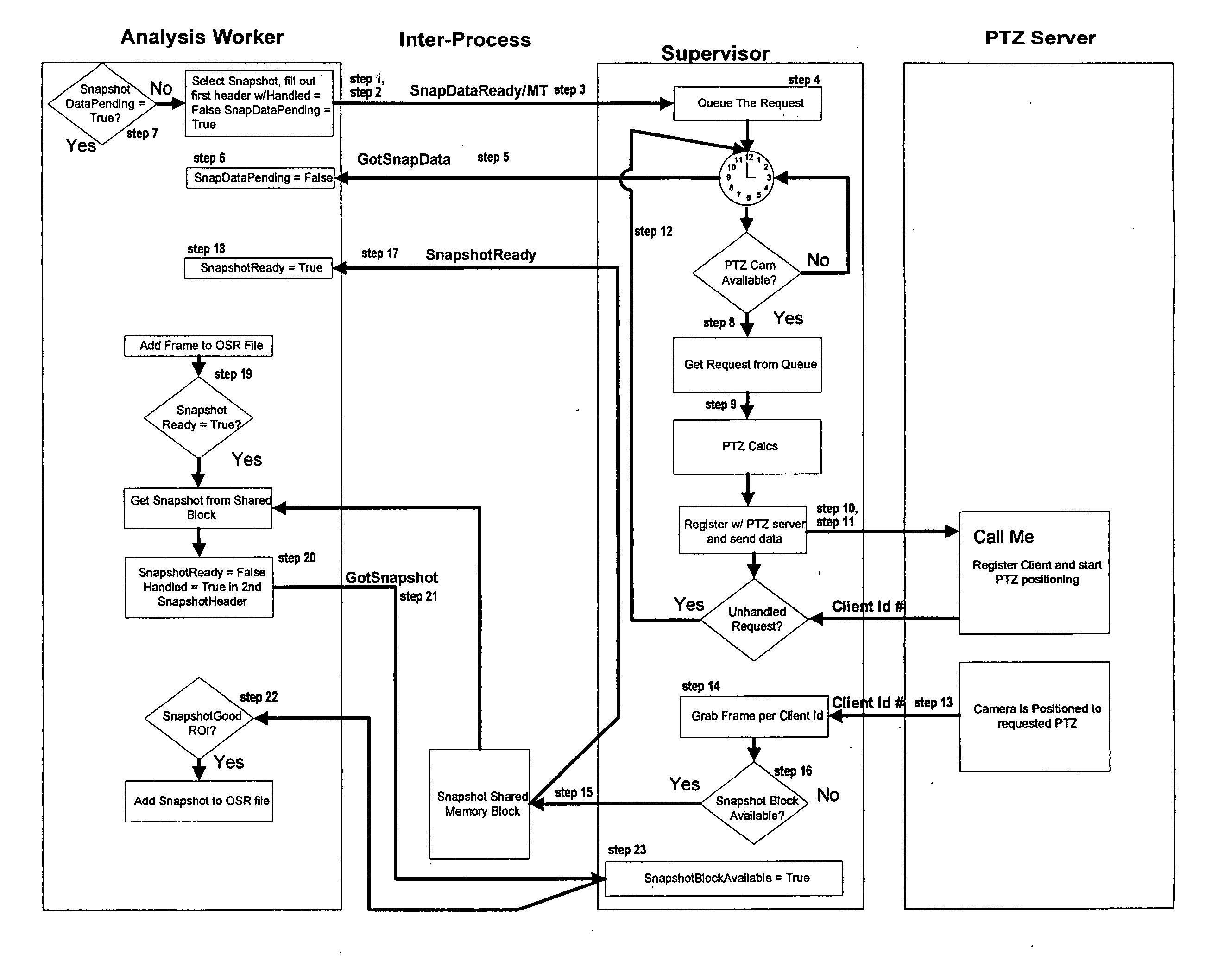

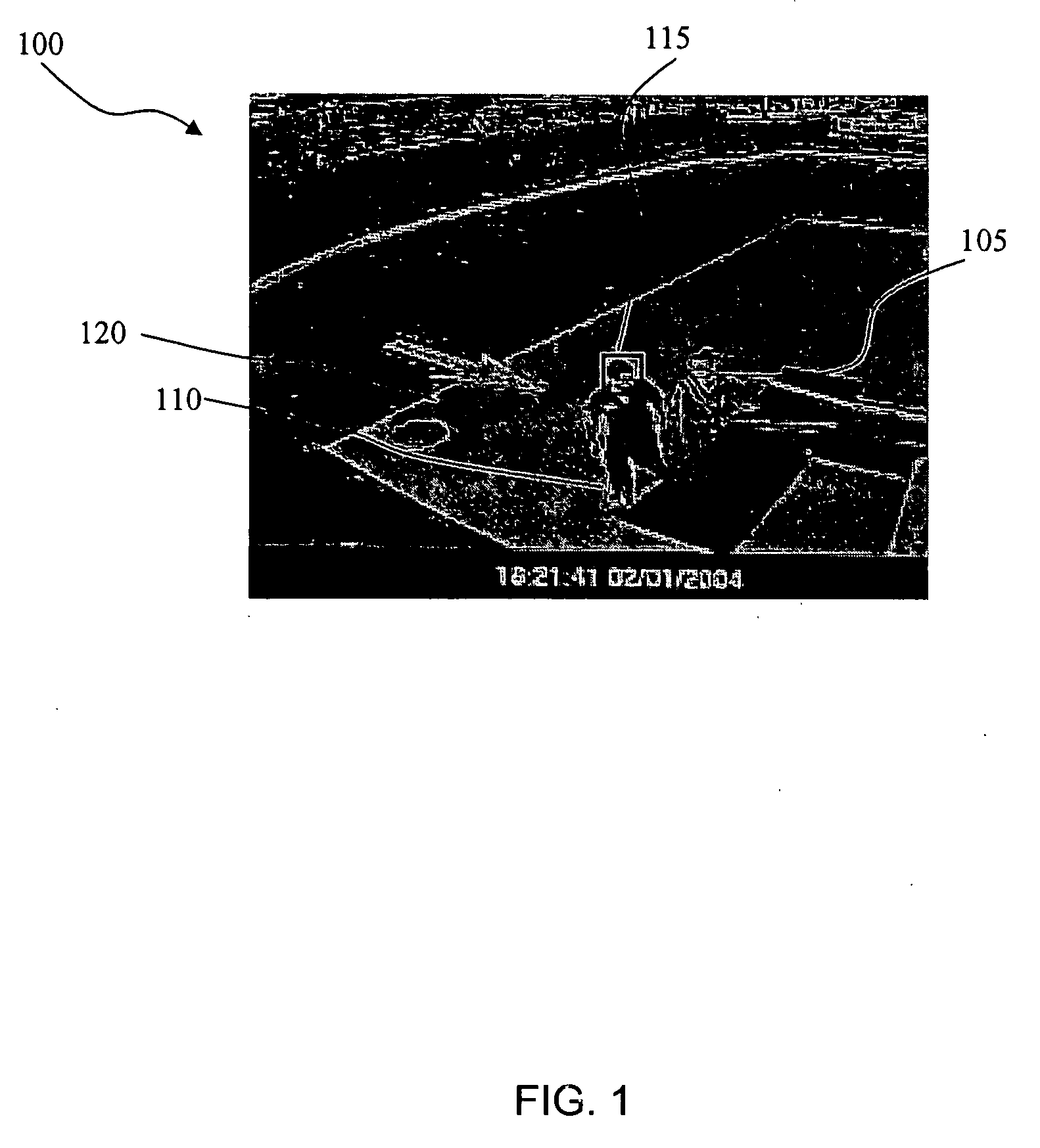

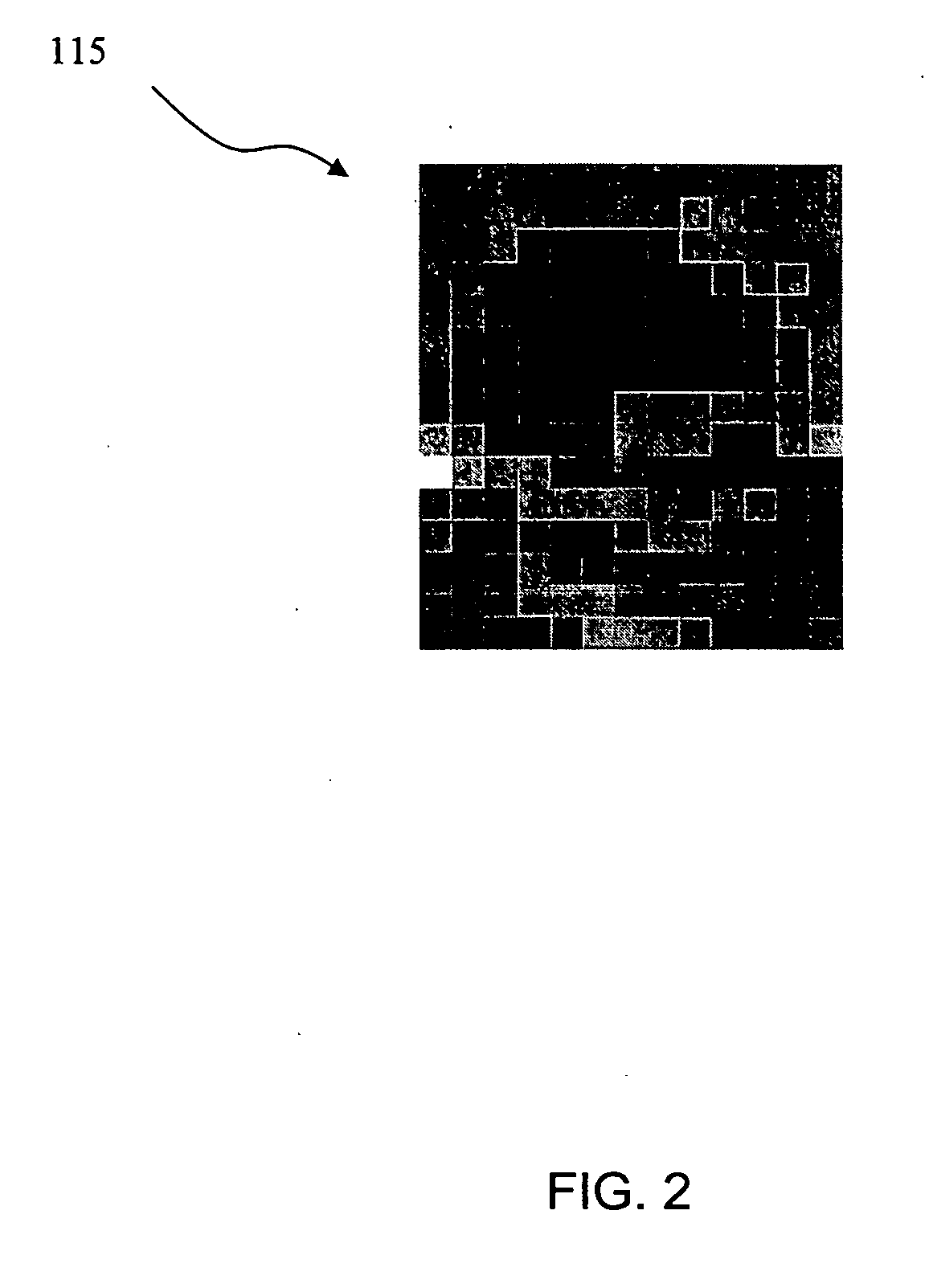

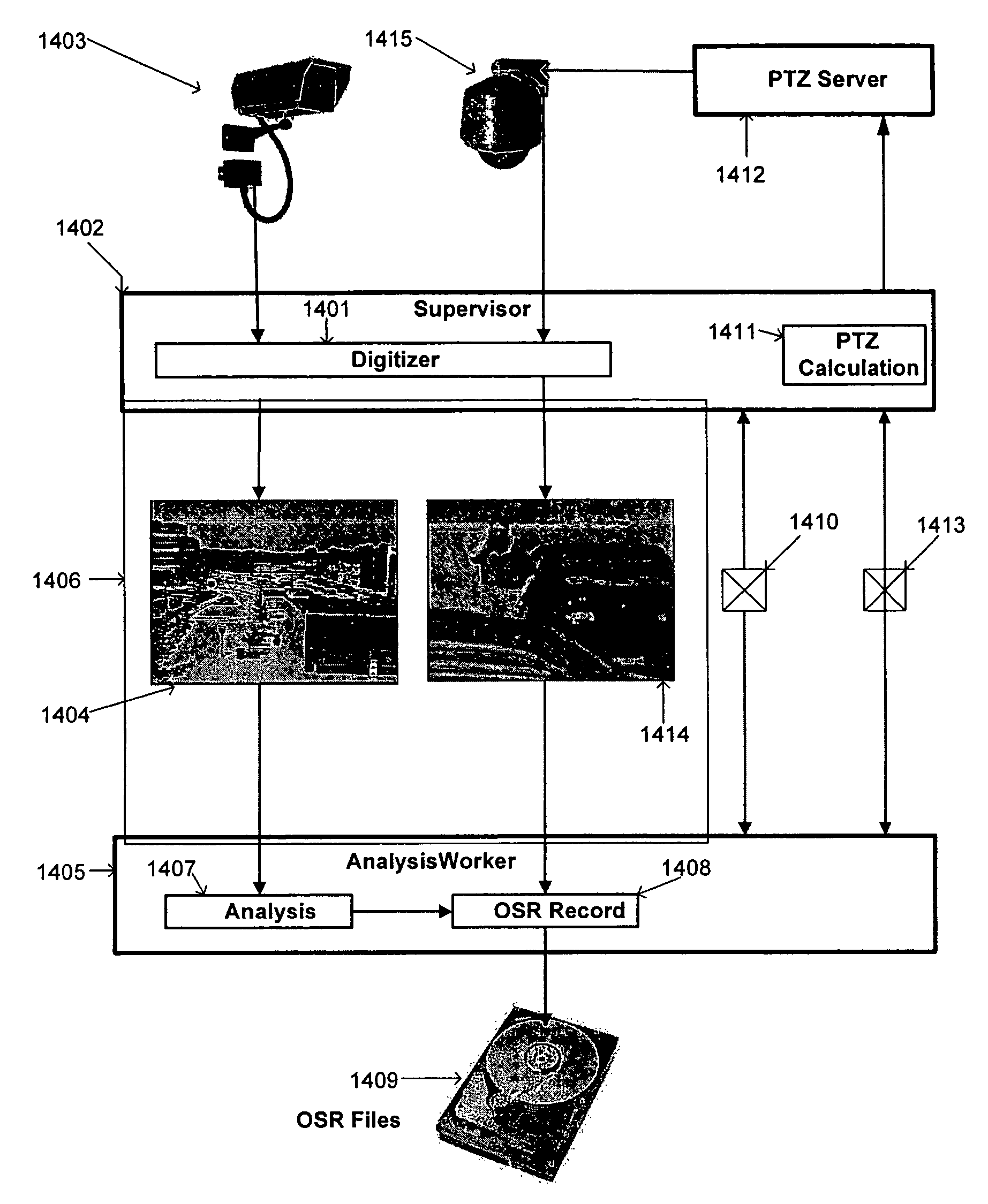

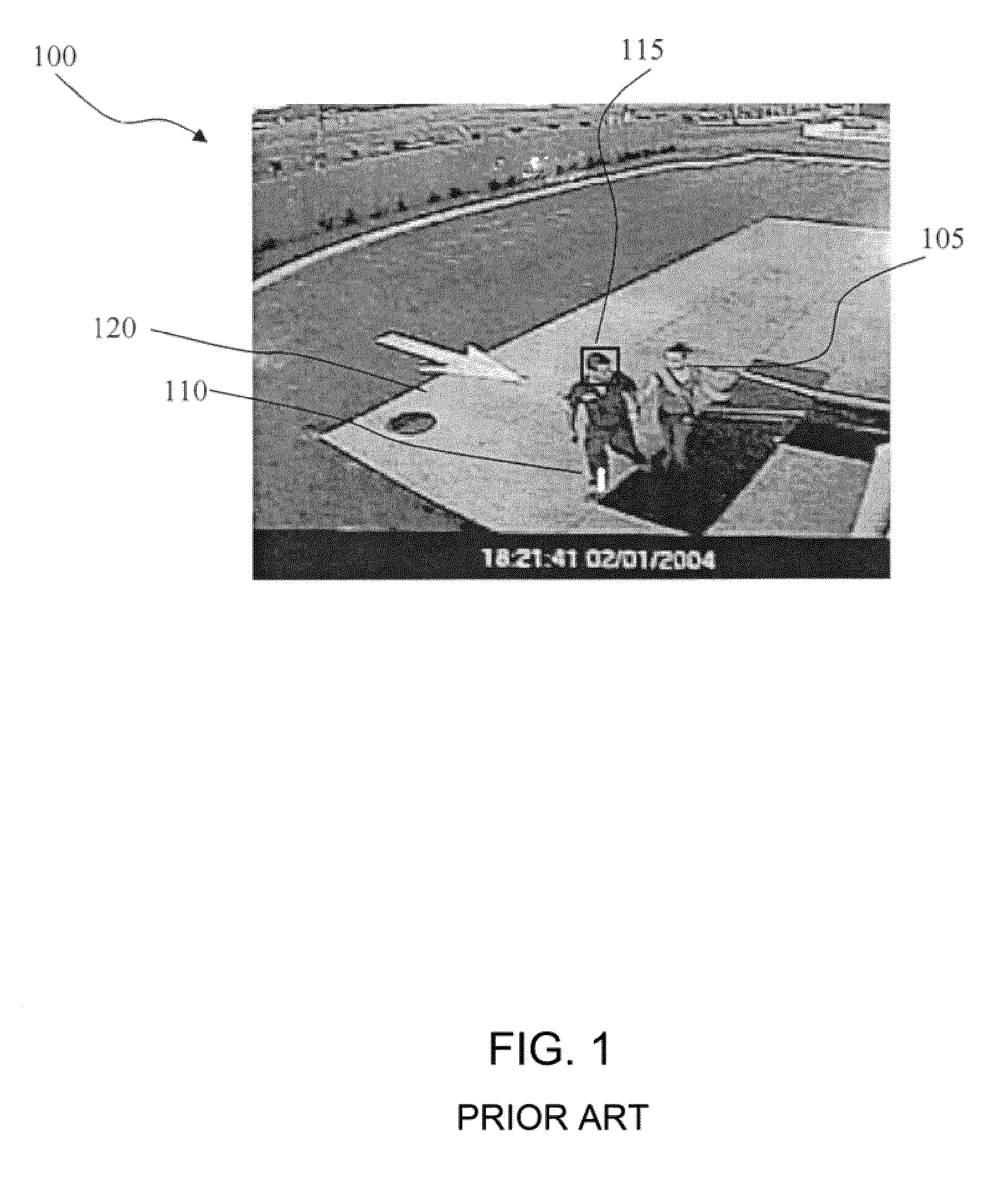

The present invention describes systems and methods of incorporating detailed snapshots of targeted areas of interest into a video or digitized recording of the overall scene including metadata to link the snapshots to the time and location in the overall scene from which the snapshot was acquired. A single fixed high-resolution scene camera or a fixed standard resolution scene camera of analog or IP connected type is used, co-located with at least one pan-tilt-zoom (PTZ) camera or by using the same scene camera in a mode where less than full resolution of the scene camera is used for video but snapshots of areas are captured by the same camera where higher resolution thereof is used for snapshots than for video. The area of interest is selected by the object-tracking feature of an intelligent video system, operated without human intervention, by electronically-implemented identification of the existence of area-specific subjects or targets of interest in the scene image field.

Owner:CHECKVIDEO

Website changes to scalability, capacity, server impact, bandwidth and end-user presentation based on a triggered event

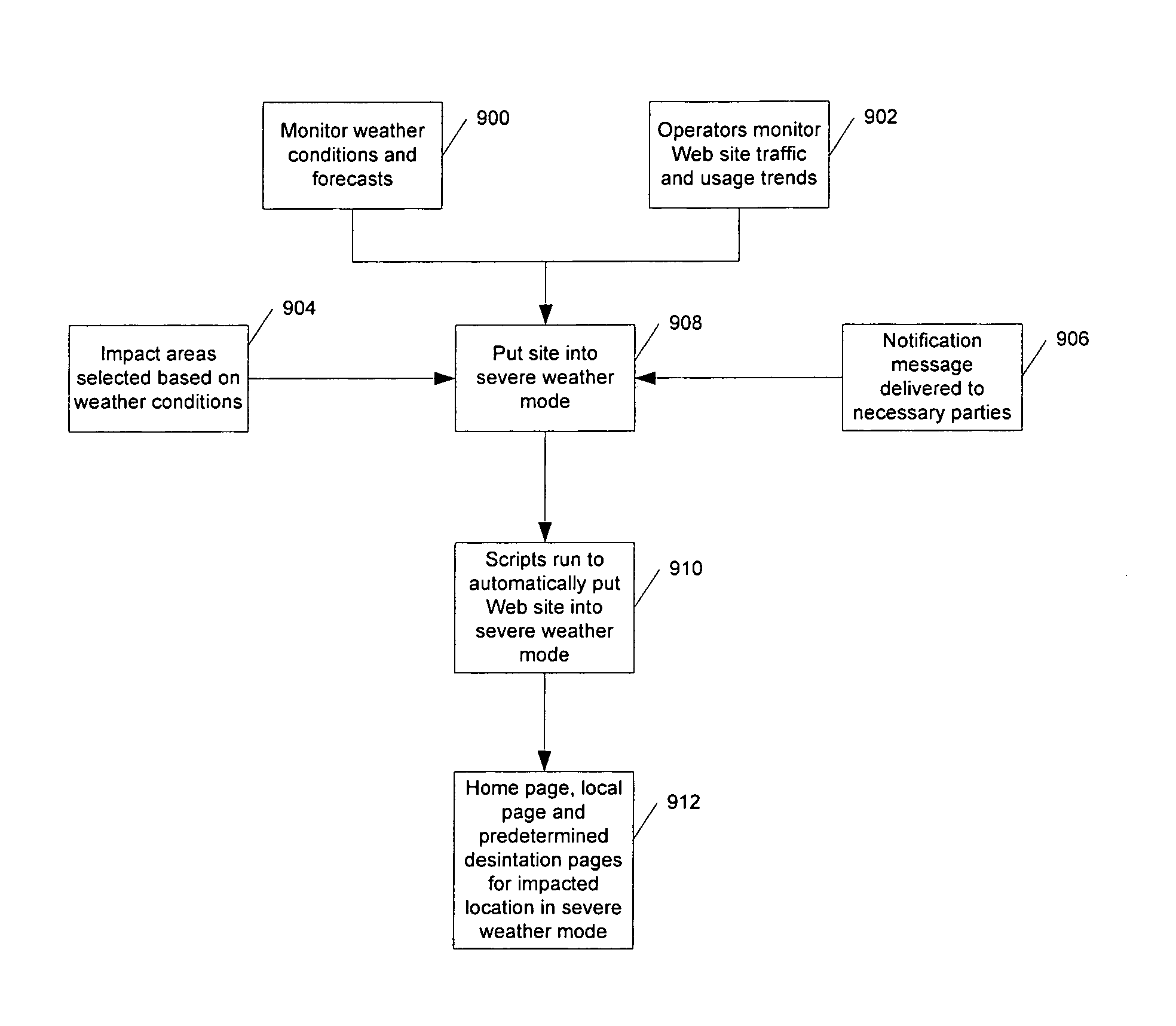

ActiveUS7529835B1Reduce the amount requiredReduced database callDigital data information retrievalMultiple digital computer combinationsServer loadWeb site

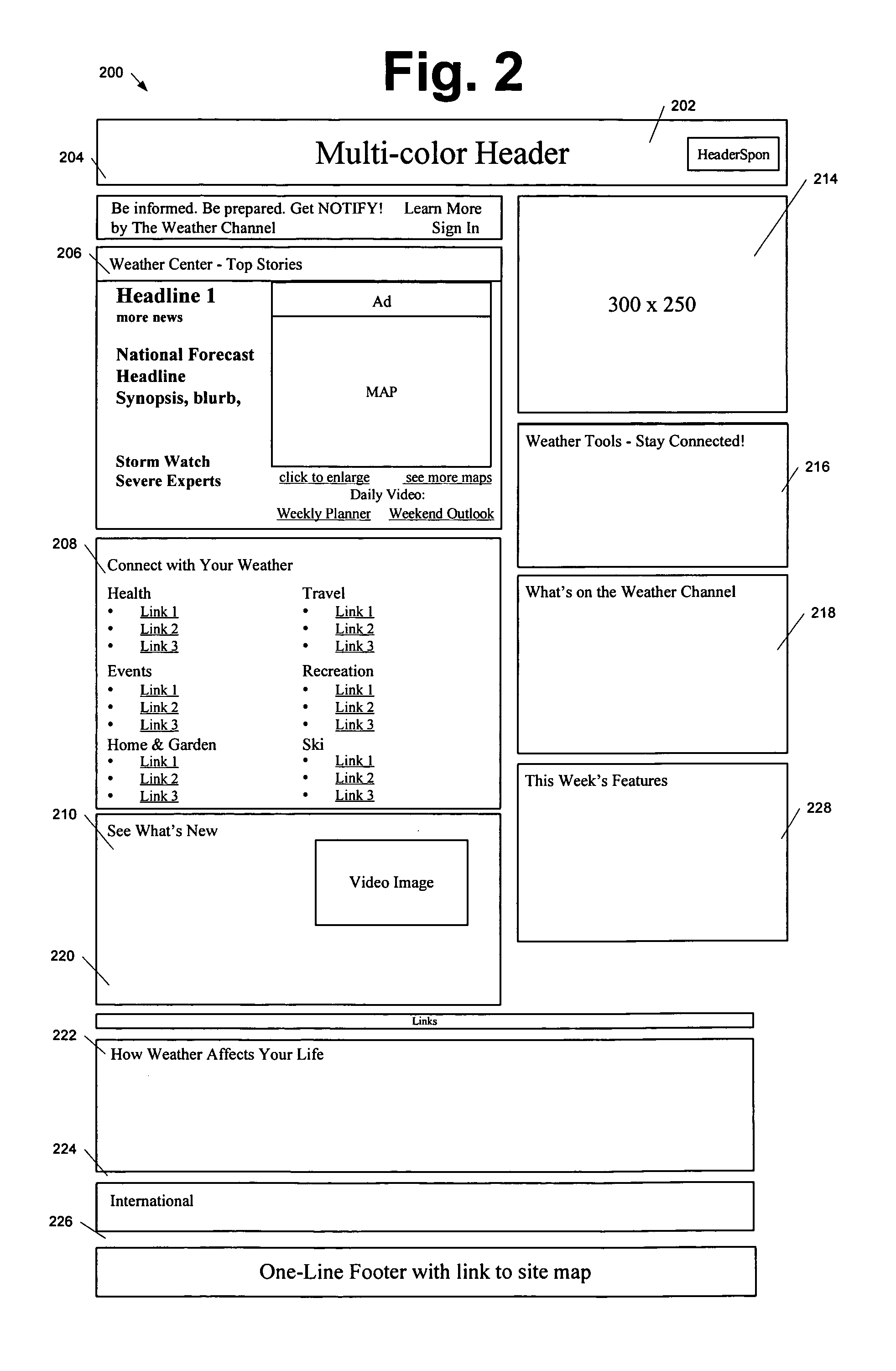

Methods for altering content on a Web site in accordance with triggering events. Normal and alternate versions of Web site content are created, where the alternate version is a less complex and computationally expense and utilizes a reduced amount of bandwidth to be transmitted to users. When an event occurs, all or portions of the Web site are switched from the normal version to their respective alternate versions to reduce server load and bandwidth requirements so a high number of users can be served the pages. The switch from normal to alternate versions may be for all visitors of selected classes of visitors, such as those from certain geographic regions.

Owner:DTN LLC

Directed attention digital video recordation

ActiveUS8026945B2Less contentMinimizing dataTelevision system detailsColor television detailsDigital videoPan tilt zoom

The present invention describes systems and methods of incorporating detailed snapshots of targeted areas of interest into a video or digitized recording of the overall scene including metadata to link the snapshots to the time and location in the overall scene from which the snapshot was acquired. A single fixed high-resolution scene camera or a fixed standard resolution scene camera of analog or IP connected type is used, co-located with at least one pan-tilt-zoom (PTZ) camera or by using the same scene camera in a mode where less than full resolution of the scene camera is used for video but snapshots of areas are captured by the same camera where higher resolution thereof is used for snapshots than for video. The area of interest is selected by the object-tracking feature of an intelligent video system, operated without human intervention, by electronically-implemented identification of the existence of area-specific subjects or targets of interest in the scene image field.

Owner:CHECKVIDEO

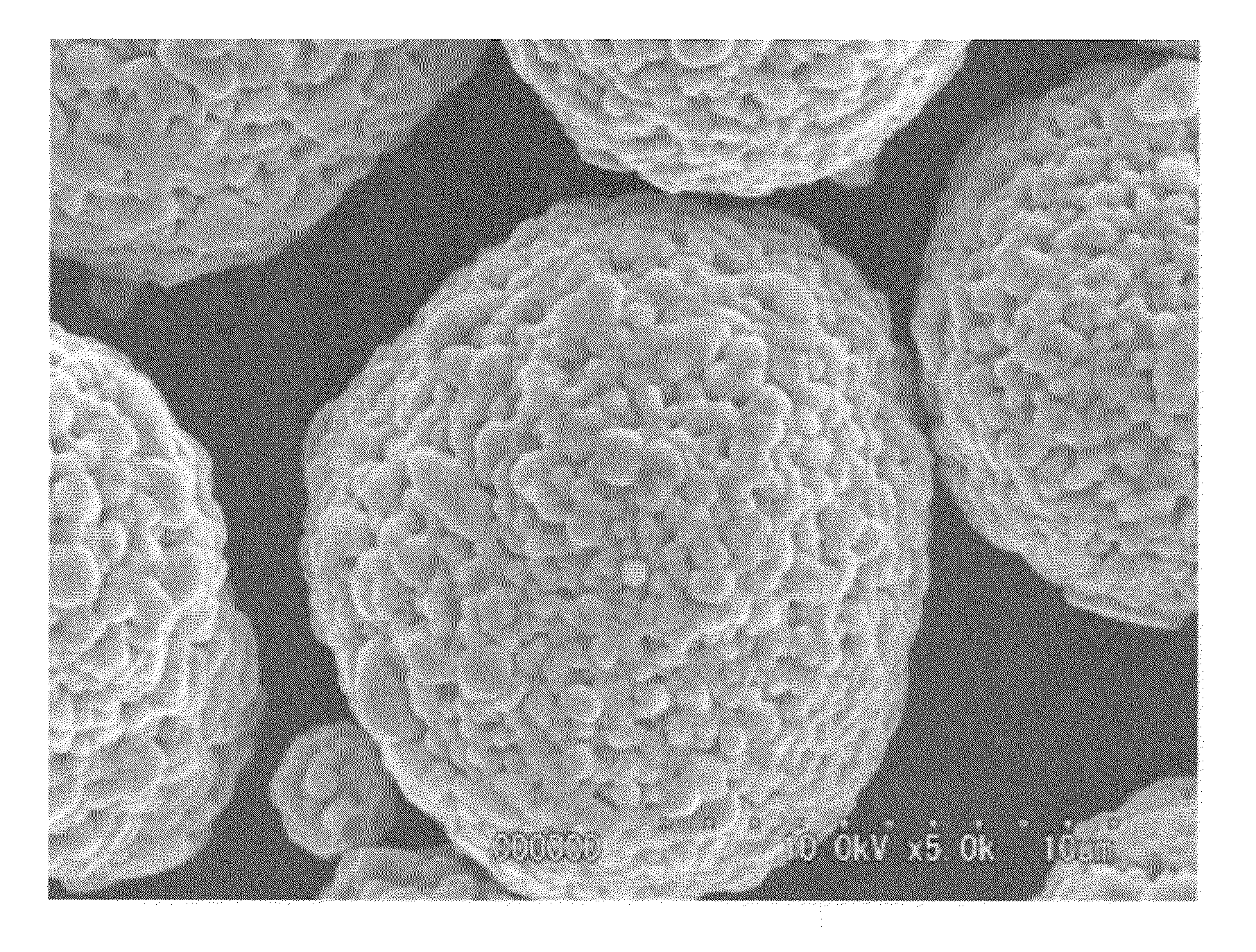

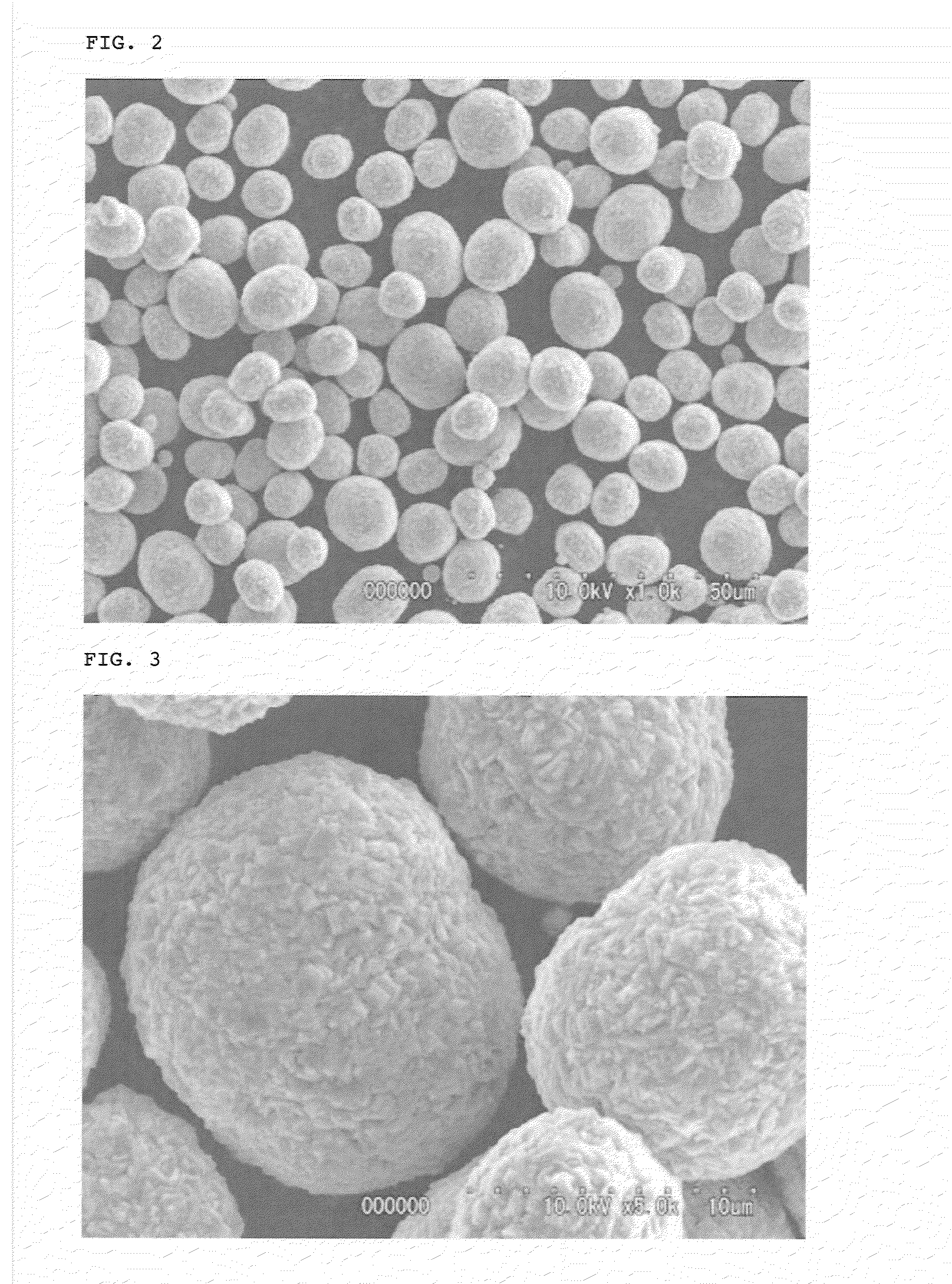

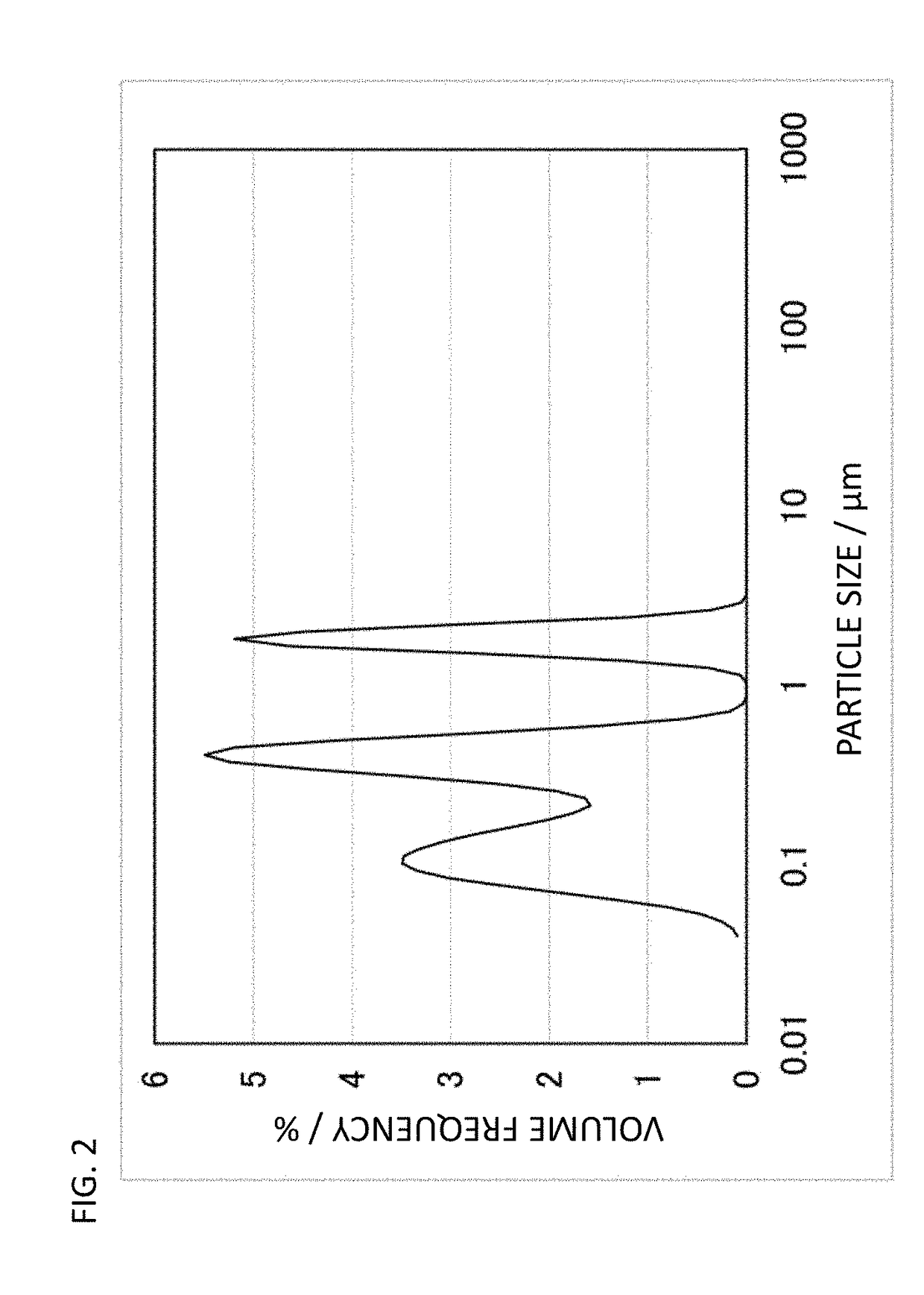

Nickel-cobalt-maganese-based compound particles and process for producing the nickel-cobalt-manganese-based compound particles, lithium composite oxide particles and process for producing the lithium composite oxide particles, and non-aqueous electrolyte secondary battery

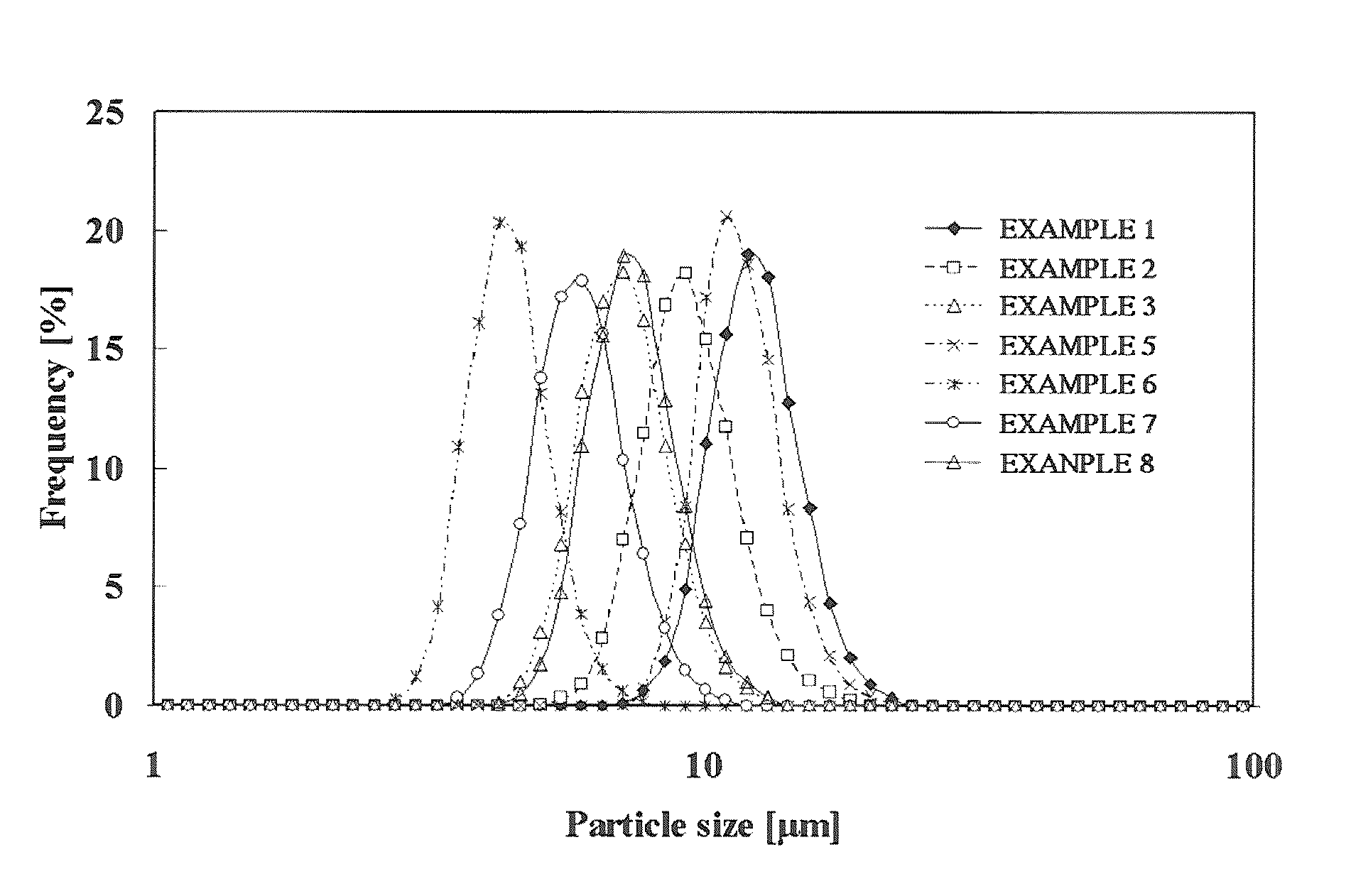

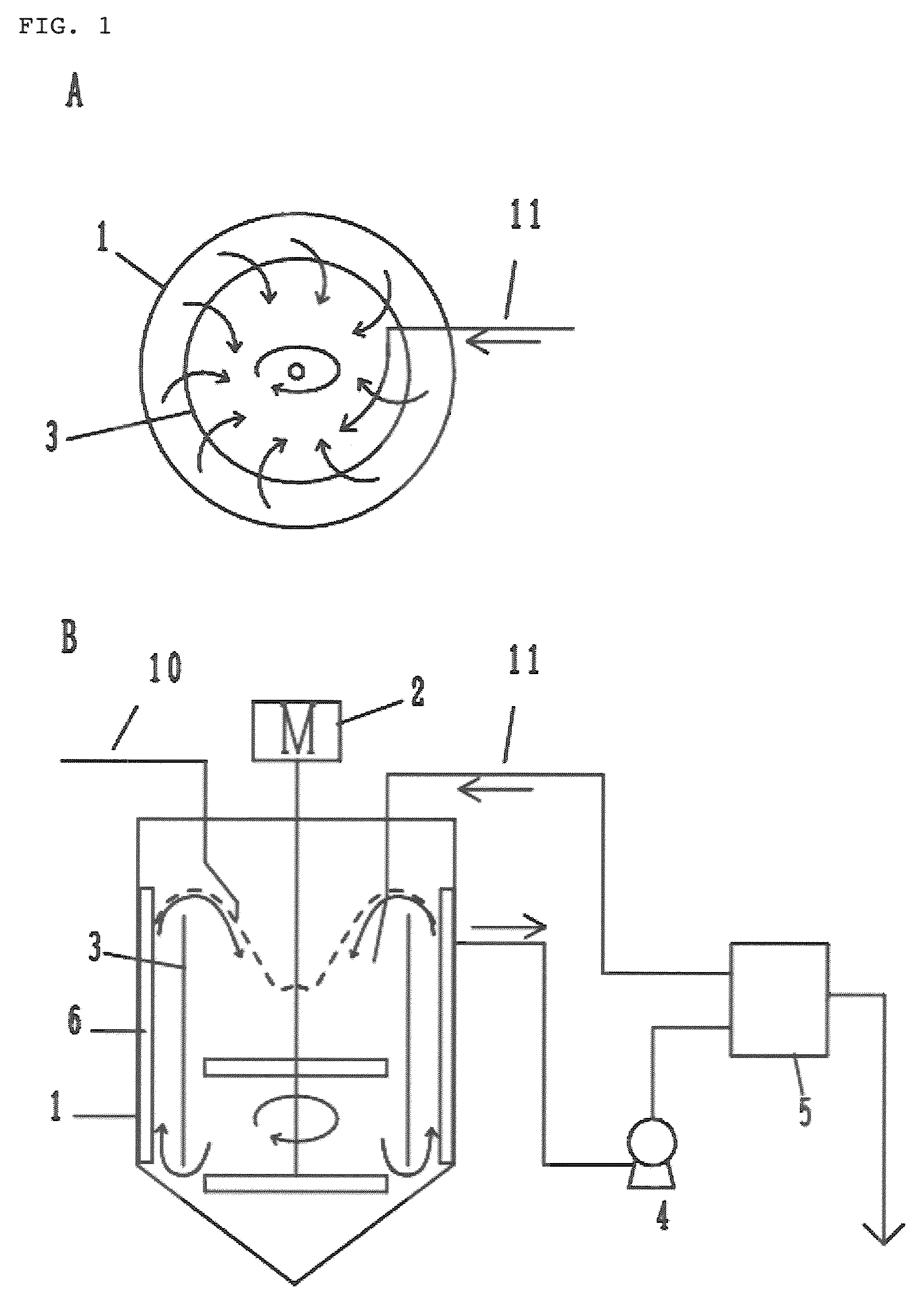

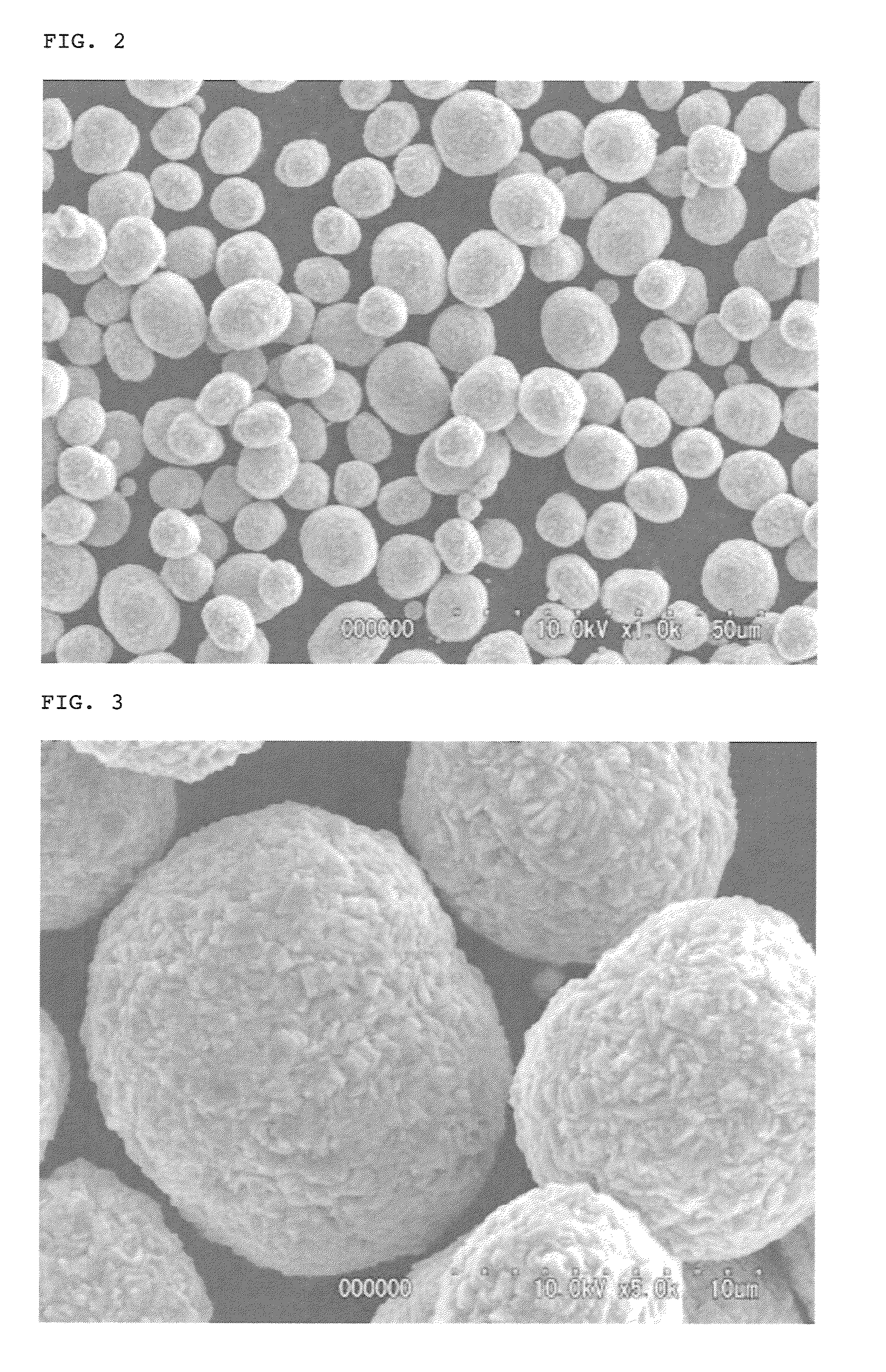

ActiveUS20130045421A1Good thermal stabilityLess thermal stabilitySynthetic resin layered productsCellulosic plastic layered productsComposite oxideChemistry

The present invention relates to nickel-cobalt-manganese-based compound particles which have a volume-based average secondary particle diameter (D50) of 3.0 to 25.0 μm, wherein the volume-based average secondary particle diameter (D50) and a half value width (W) of the peak in volume-based particle size distribution of secondary particles thereof satisfy the relational formula: W≦0.4×D50, and can be produced by dropping a metal salt-containing solution and an alkali solution to an alkali solution at the same time, followed by subjecting the obtained reaction solution to neutralization and precipitation reaction. The nickel-cobalt-manganese-based compound particles according to the present invention have a uniform particle size, a less content of very fine particles, a high crystallinity and a large primary particle diameter, and therefore are useful as a precursor of a positive electrode active substance used in a non-aqueous electrolyte secondary battery.

Owner:TODA IND

Release agent, adhesive laminate and adhesive laminated tape

InactiveUS20050271851A1Increase resistanceNarrow molecular weight distributionFilm/foil adhesivesAdhesive articlesPolyolefinViscosity

A release agent for forming a release layer contacting with an adhesive layer, comprising (A) a polyolefin having a weight-average molecular weight of not less than 1×104, which may contain a functional group, and (B) a hydrocarbon having a viscosity of 1 to 1×104 cP as measured at 23° C. according to JIS K-7117, a weight ratio of the polyolefin (A) to the hydrocarbon (B) being 97:3 to 60:40. Such a release agent provides a novel release agent that is usable as an alternative material of a silicone-based and fluororesin-based release agents.

Owner:MITSUBISHI POLYESTER FILM

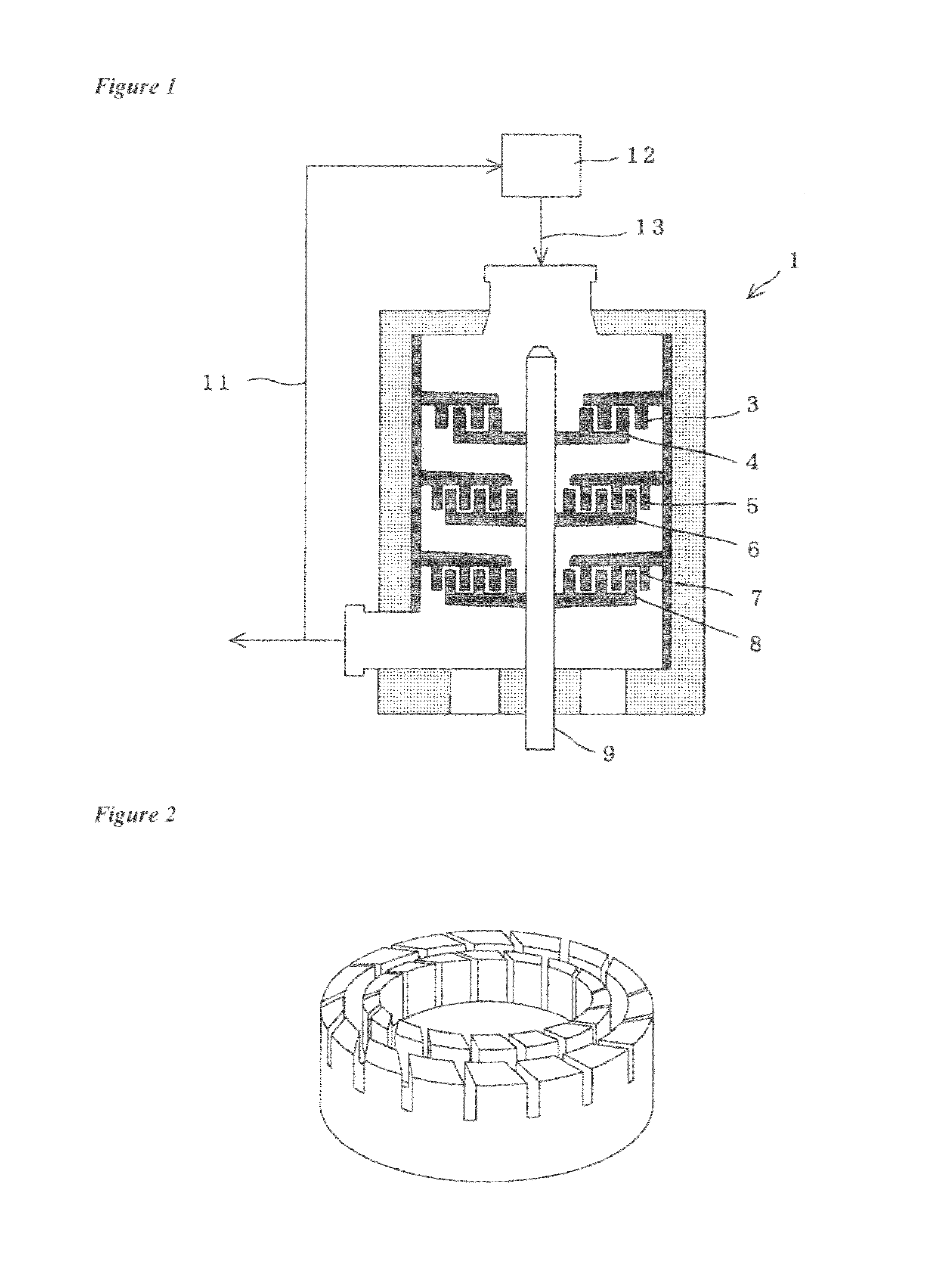

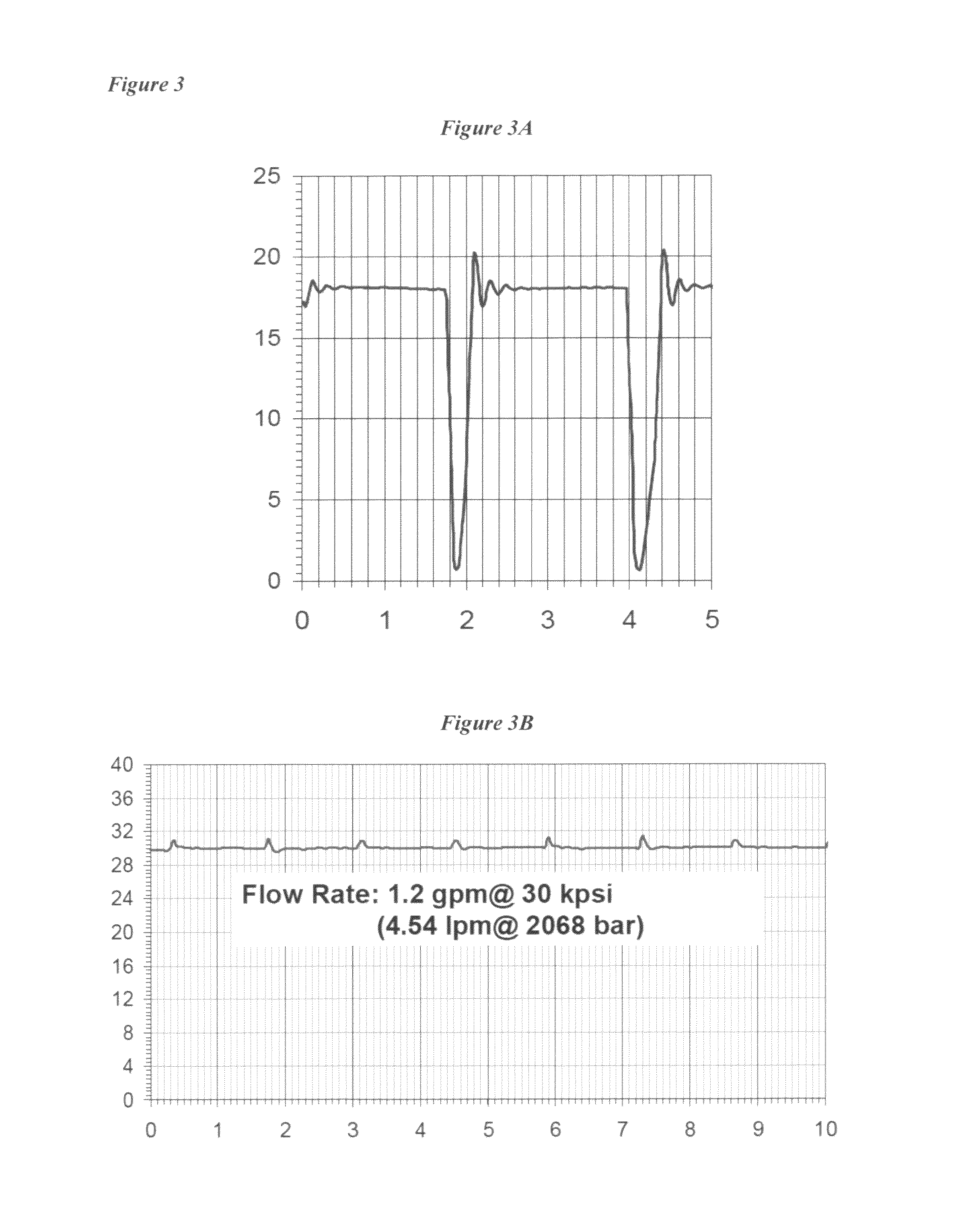

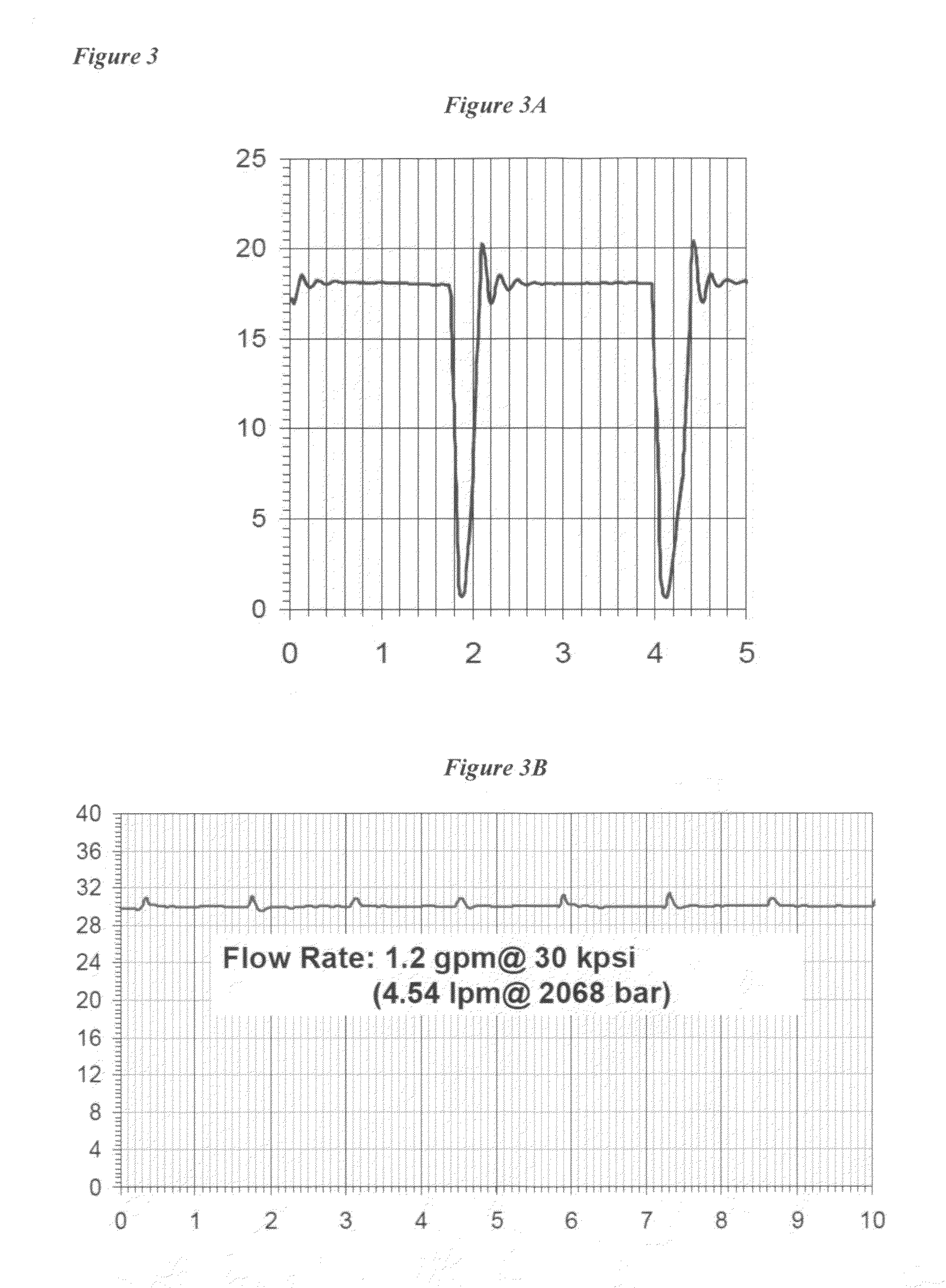

Methods for producing vaccine adjuvants

ActiveUS20110165193A1Eliminate needAvoid the needOrganic active ingredientsFlow mixersFiltrationImproved method

An improved method for the manufacture of an oil-in-water emulsion involves three procedures: (i) preparation of a preliminary emulsion; (ii) microfluidization of the preliminary emulsion to reduce its droplet size; and (iii) filtration of the microfluidized emulsion through a hydrophilic membrane.

Owner:NOVARTIS AG

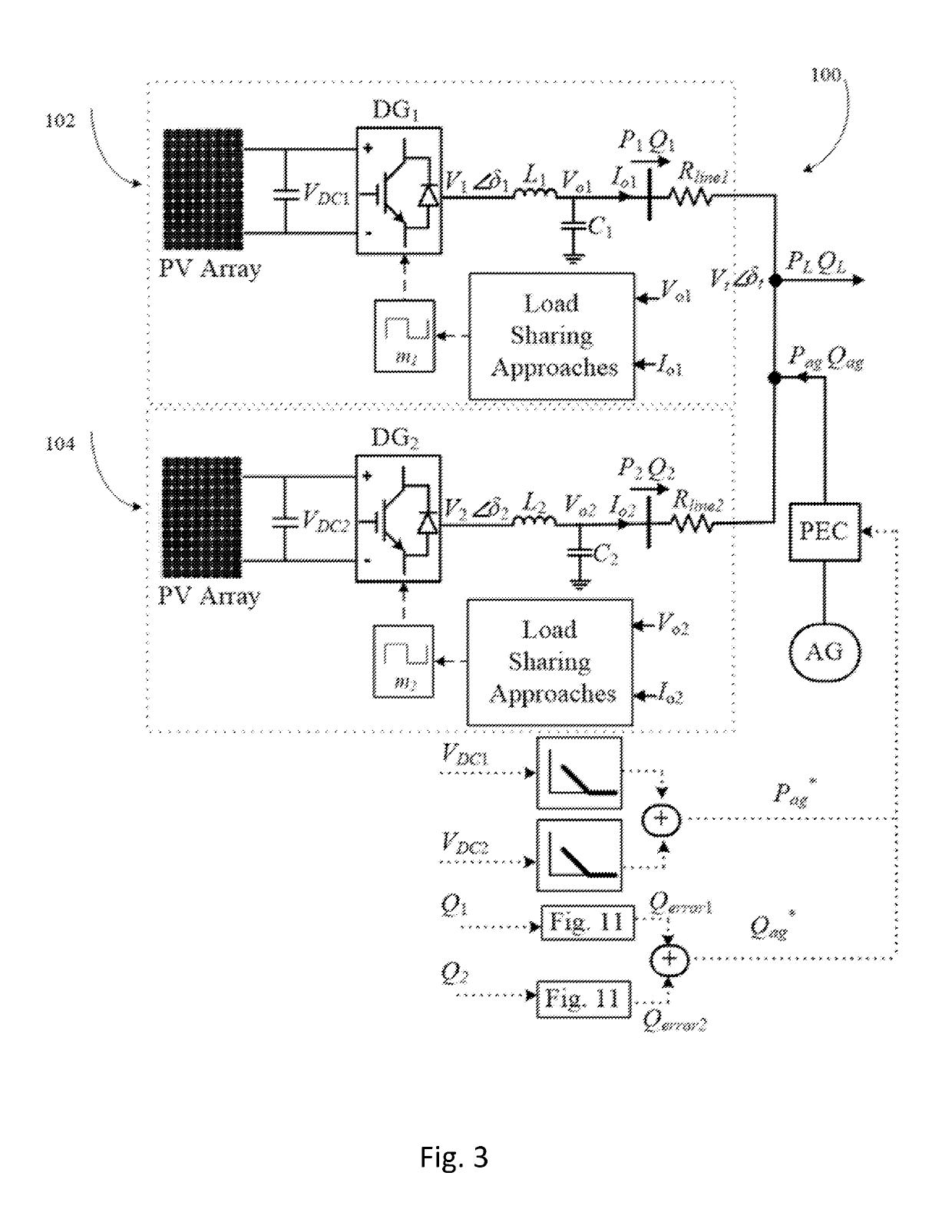

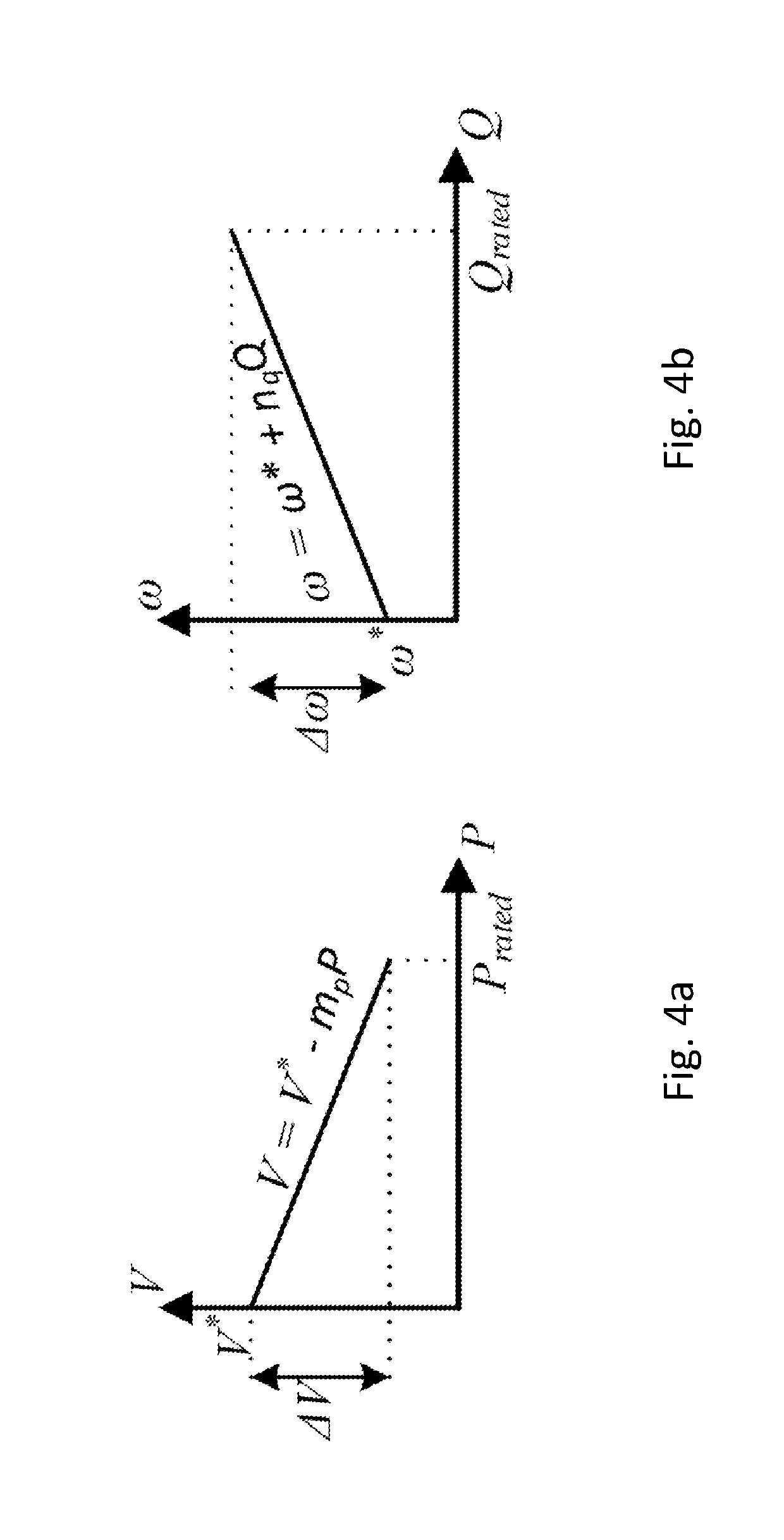

Dynamic active and reactive power load sharing in an islanded microgrid

InactiveUS20190207391A1Reduce the required powerLess contentEnergy industrySingle network parallel feeding arrangementsElectrical resistance and conductanceDistributed generator

A method of managing a microgrid and control system is provided, in which the virtual resistance control gains (in αβ frame) of each respective inverter is dynamically adjusted based on a variable related to the available power from each of a plurality of renewable distributed generators.

Owner:SWANSEA UNIV

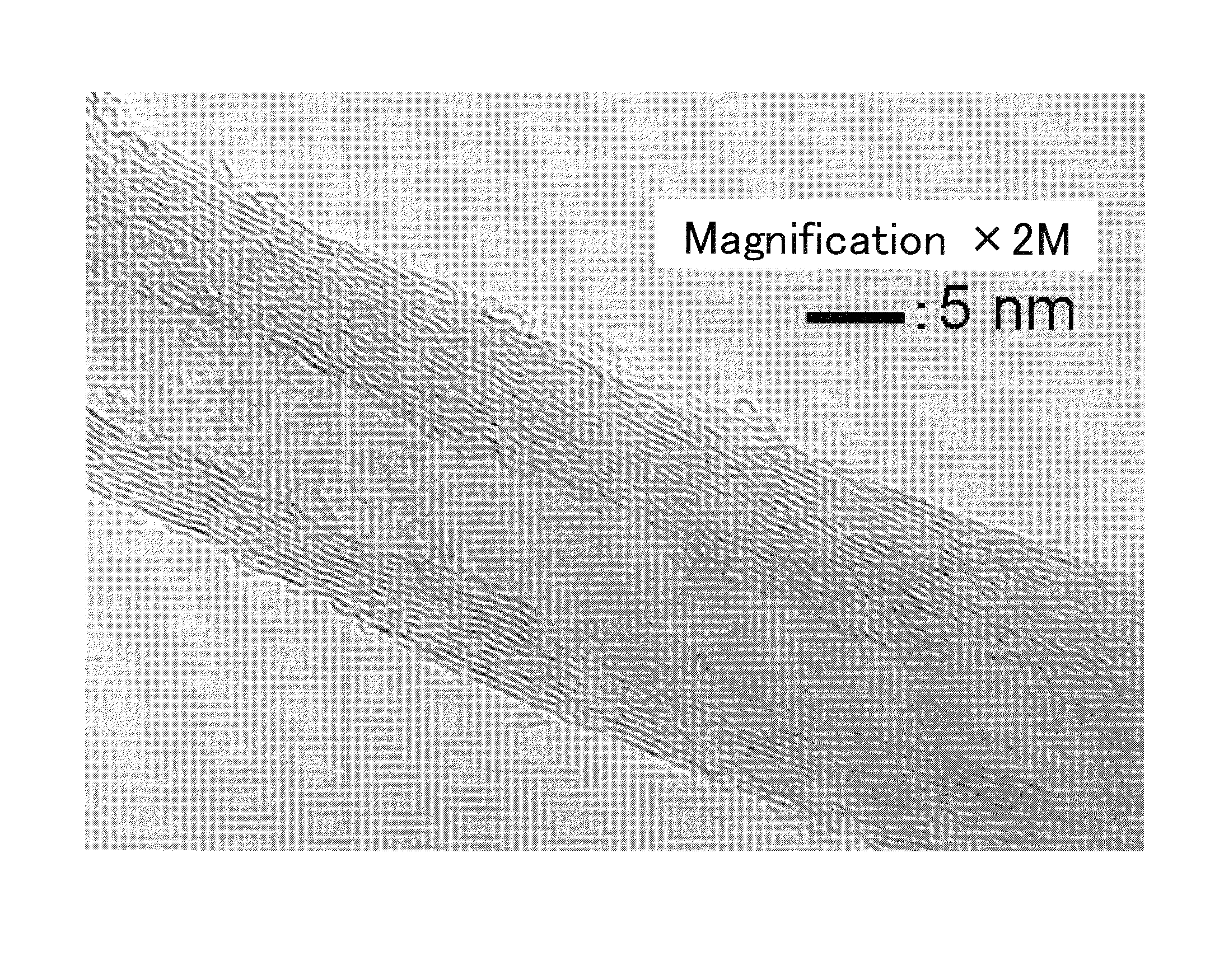

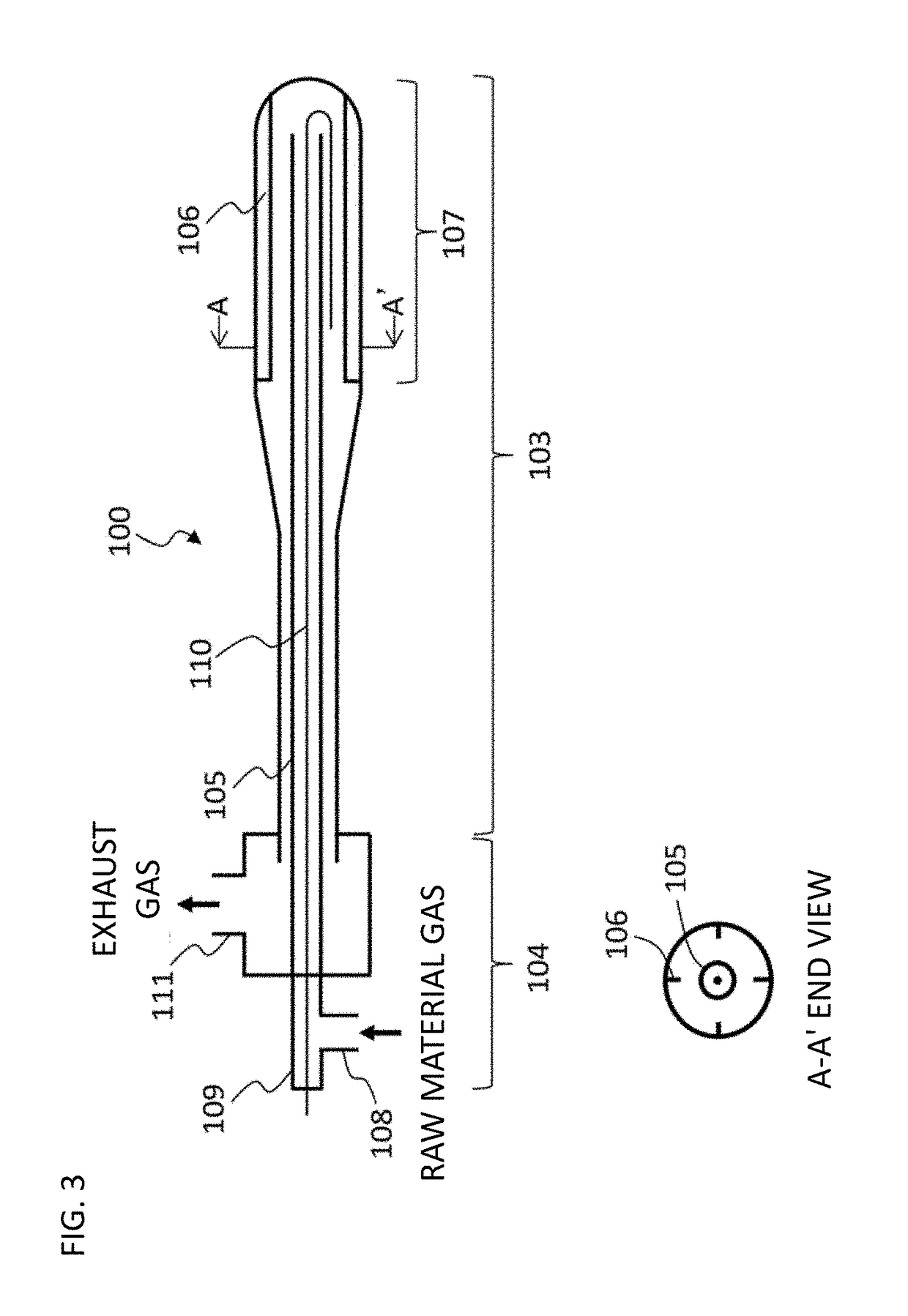

Carbon fiber and catalyst for production of carbon fiber

InactiveUS20110104490A1Simple processEffective massMaterial nanotechnologyCell electrodesFiberParticulates

A catalyst for production of a carbon fiber is obtained by dissolving or dispersing [I] a compound containing Fe element; [II] a compound containing Co element; [III] a compound containing at least one element selected from the group consisting of Ti, V, Cr, and Mn; and [IV] a compound containing at least one element selected from the group consisting of W and Mo in a solvent to obtain a solution or a fluid dispersion, and then by impregnating a particulate carrier with the solution or the fluid dispersion. By means of a step of bringing a carbon source into contact with the catalyst in a vapor phase, the carbon fiber is obtained which is tubular and in which a graphite layer is approximately parallel with the carbon fiber axis, and a shell is in a multi-walled structure.

Owner:SHOWA DENKO KK

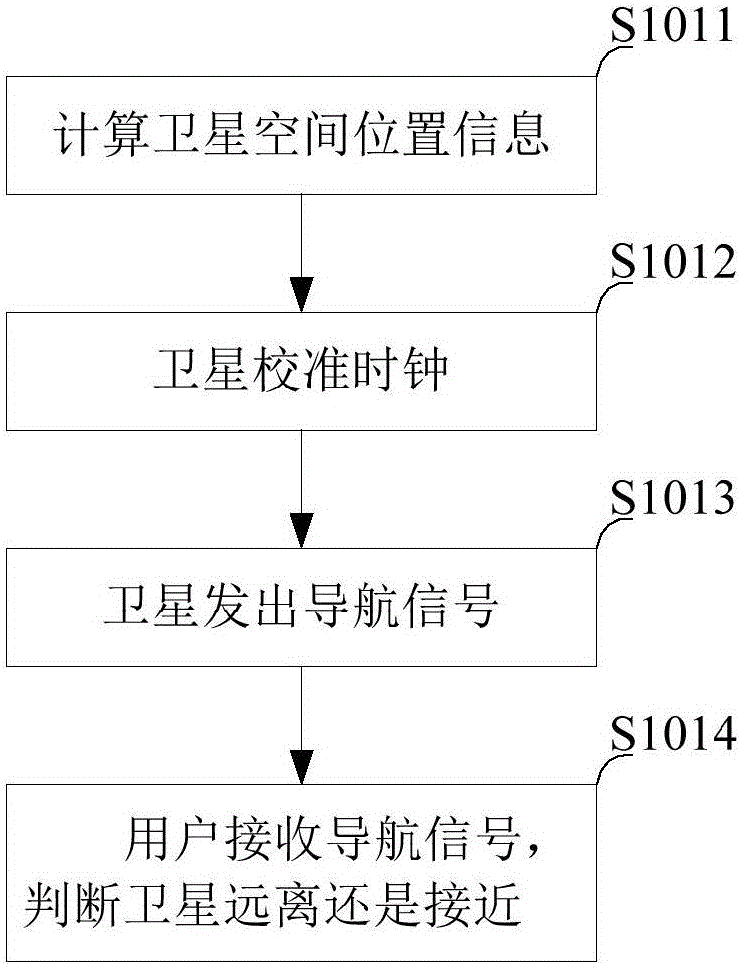

Circular orbit low orbit satellite zenith pass remaining visible duration prediction method

The invention discloses a circular orbit low orbit satellite zenith pass remaining visible duration prediction method. According to the method, operation work characteristics of a satellite are fully used; the spatial position of the satellite and corresponding time information are constantly calculated and updated; the information is broadcasted to a user on the ground in the form of a simple navigation signal; after the user on the ground receives the navigation signal, clock calibration and user positioning are carried out through a GPS receiving device; the elevation angle and the track angle of the satellite relative to the user are calculated in real time; and satellite zenith pass remaining visible duration is solved; the method is simple and effective; less navigation signal content is needed; the degree of dependence on satellite ephemeris is low; and on the premise of accurate and timely prediction duration, the hardware cost of the user is not increased.

Owner:PLA UNIV OF SCI & TECH

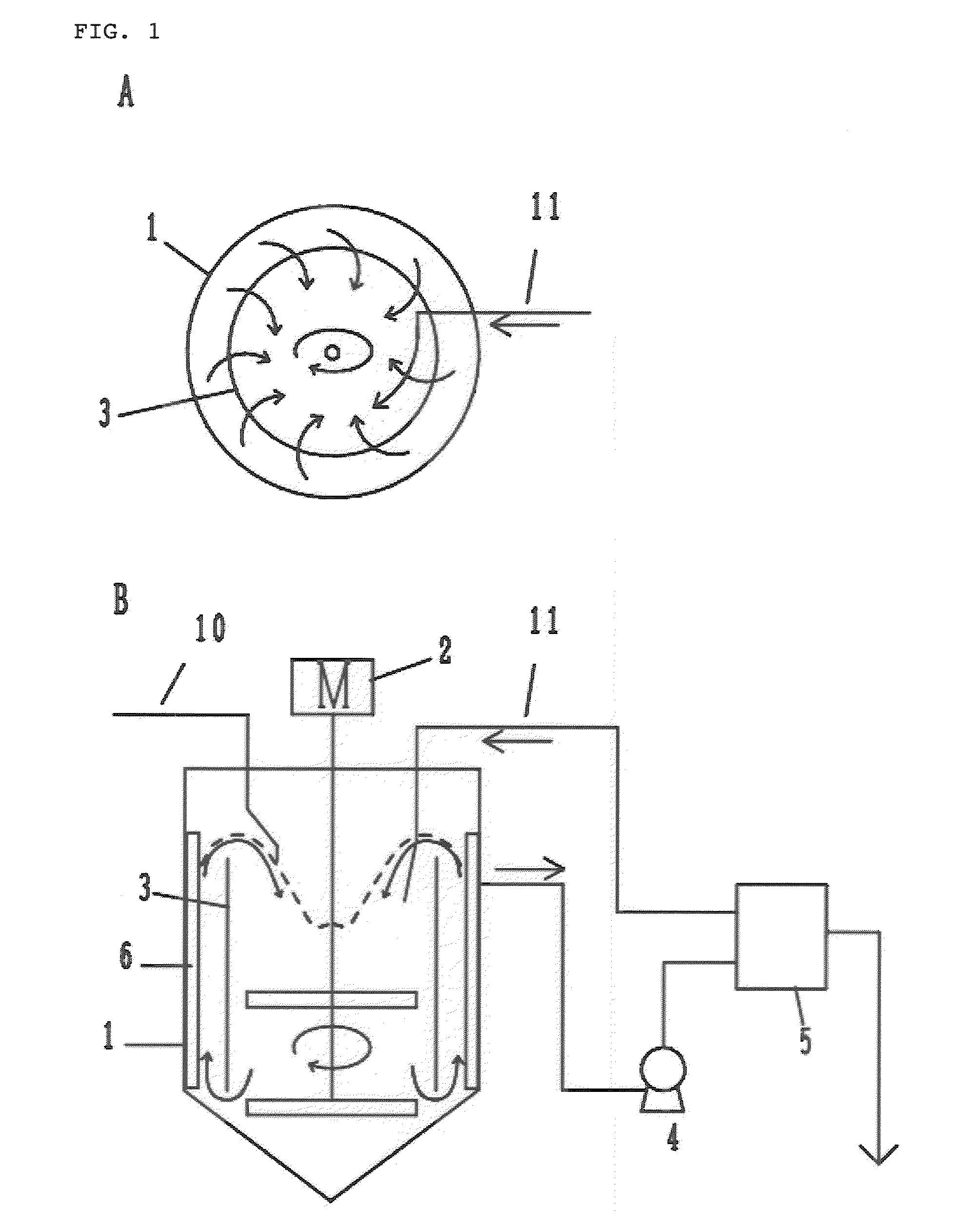

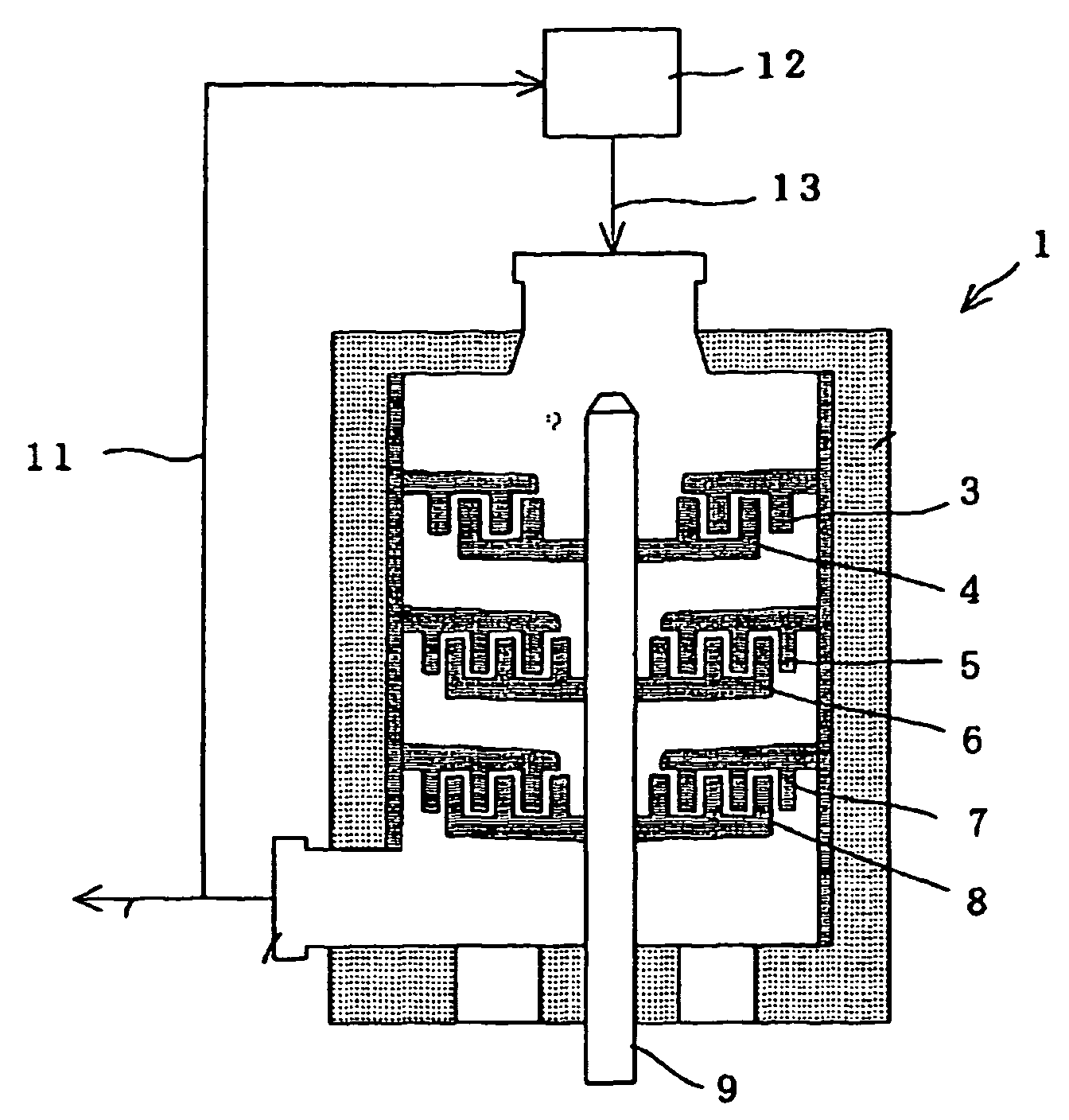

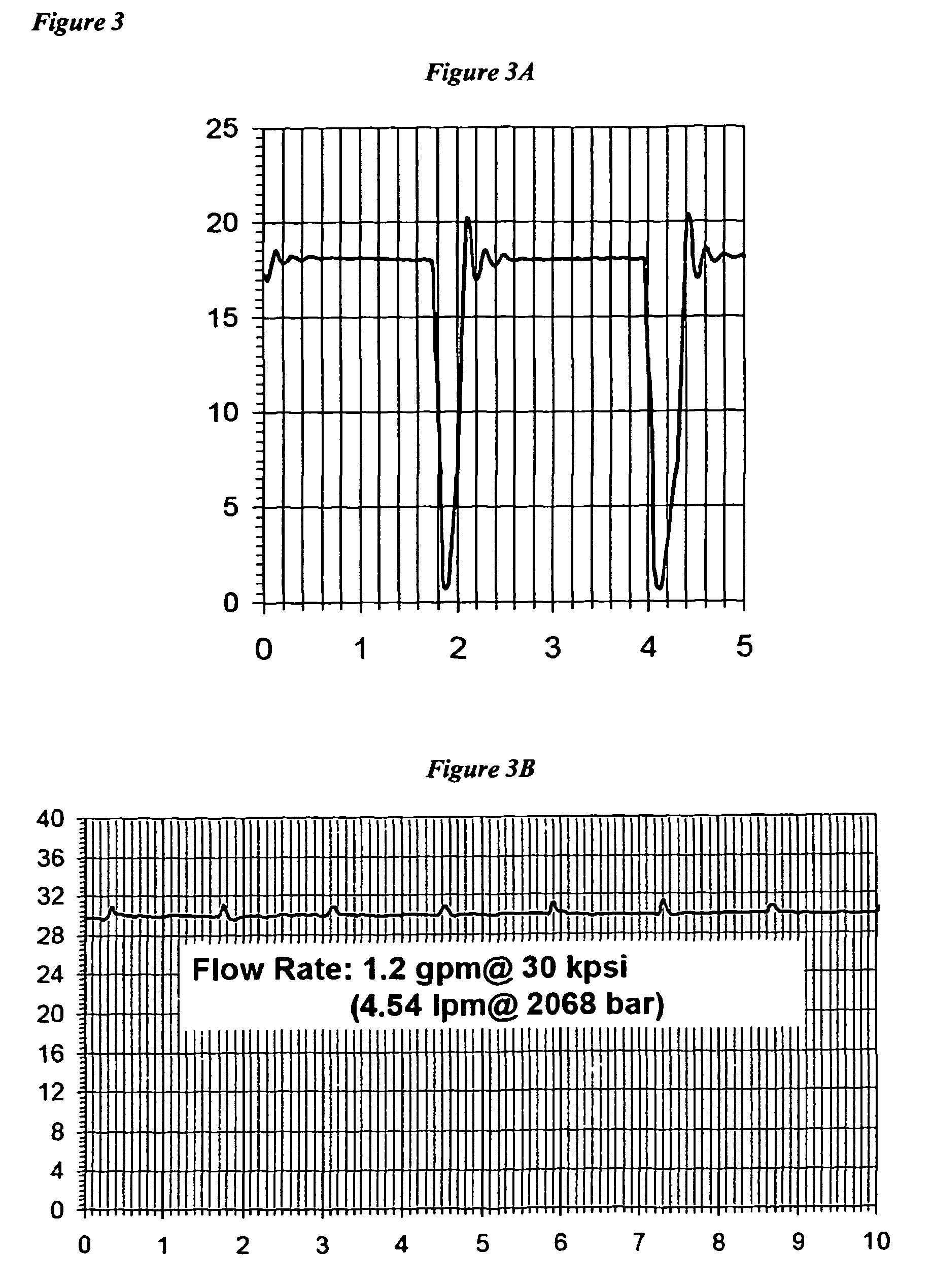

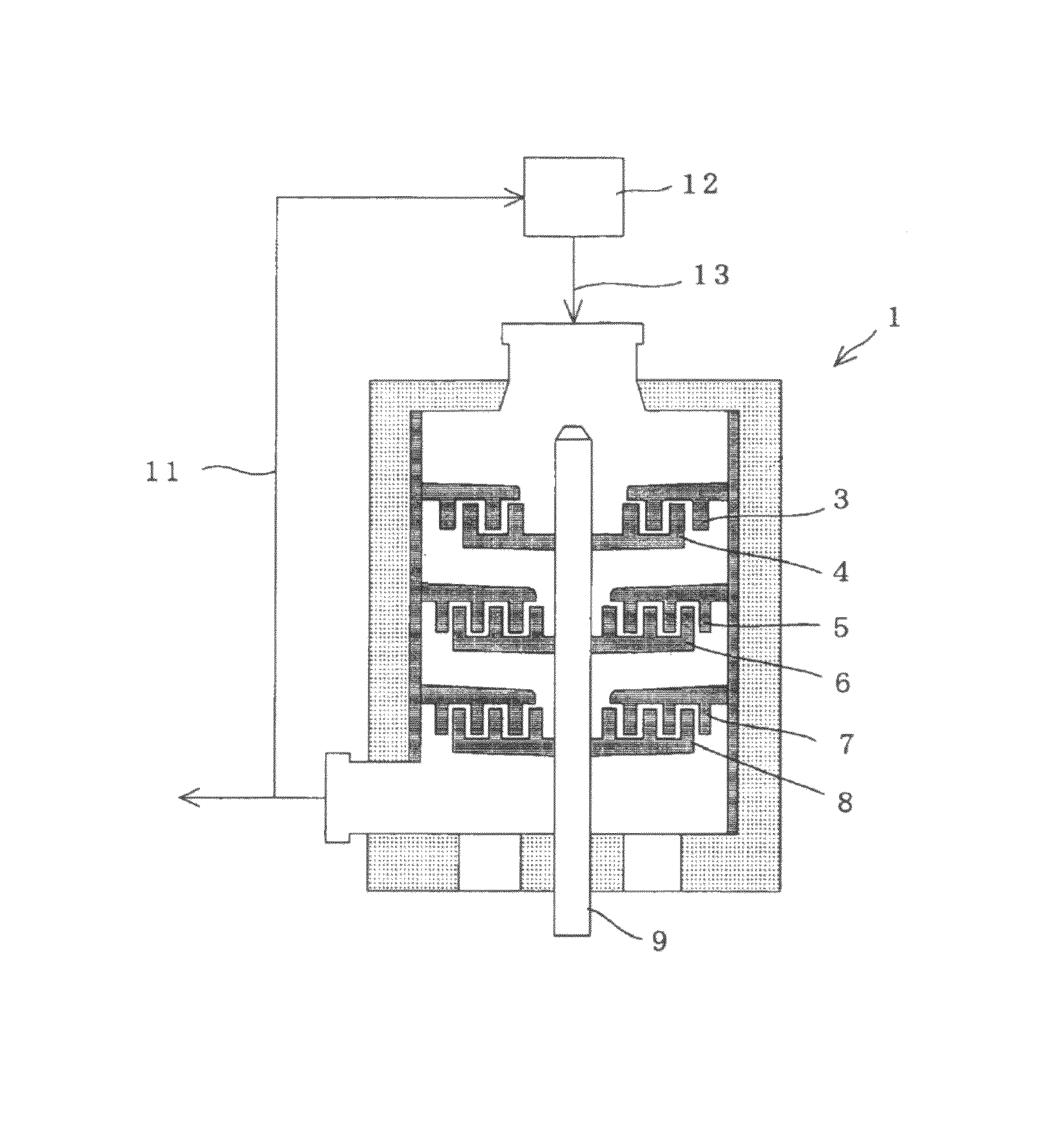

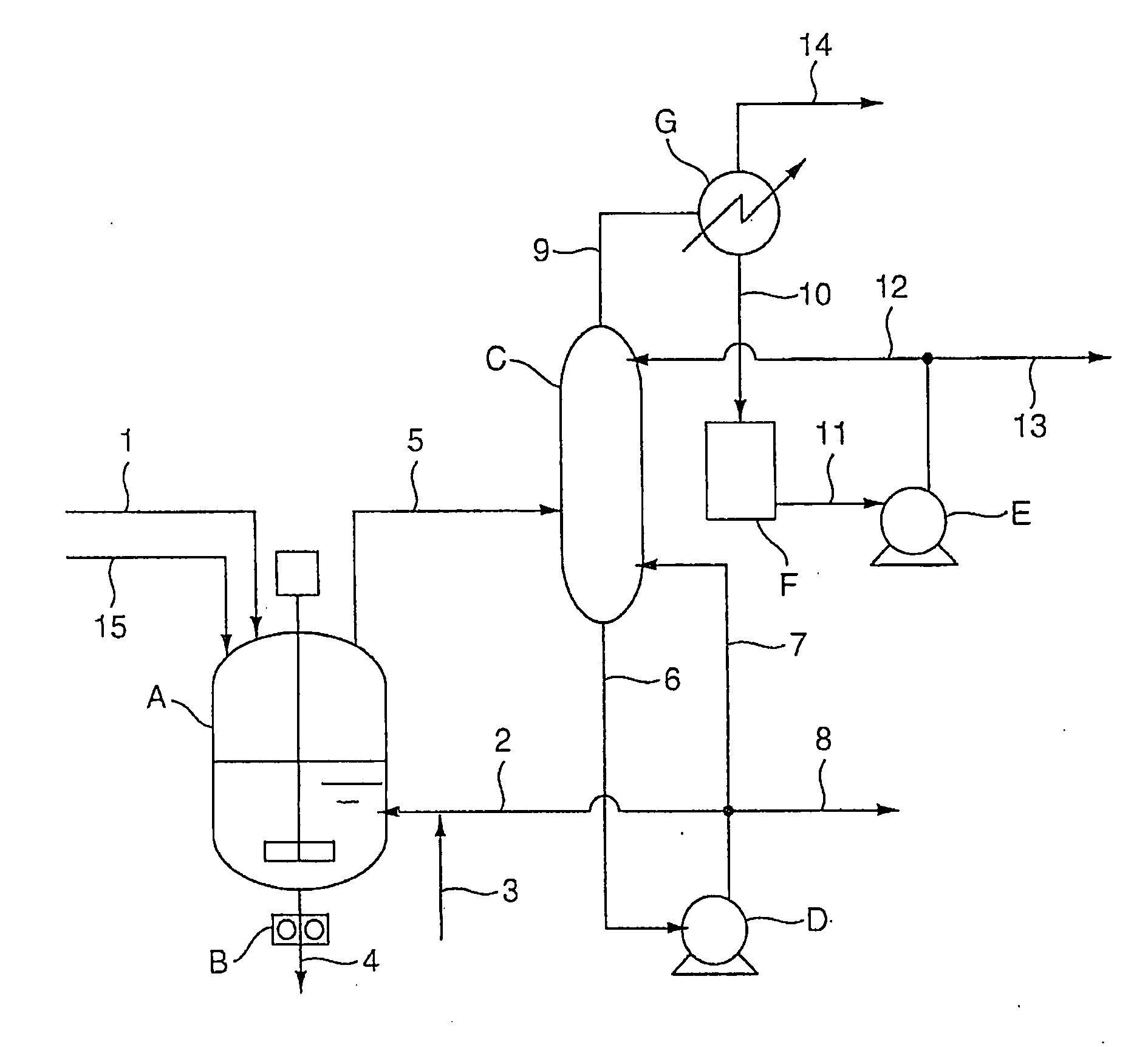

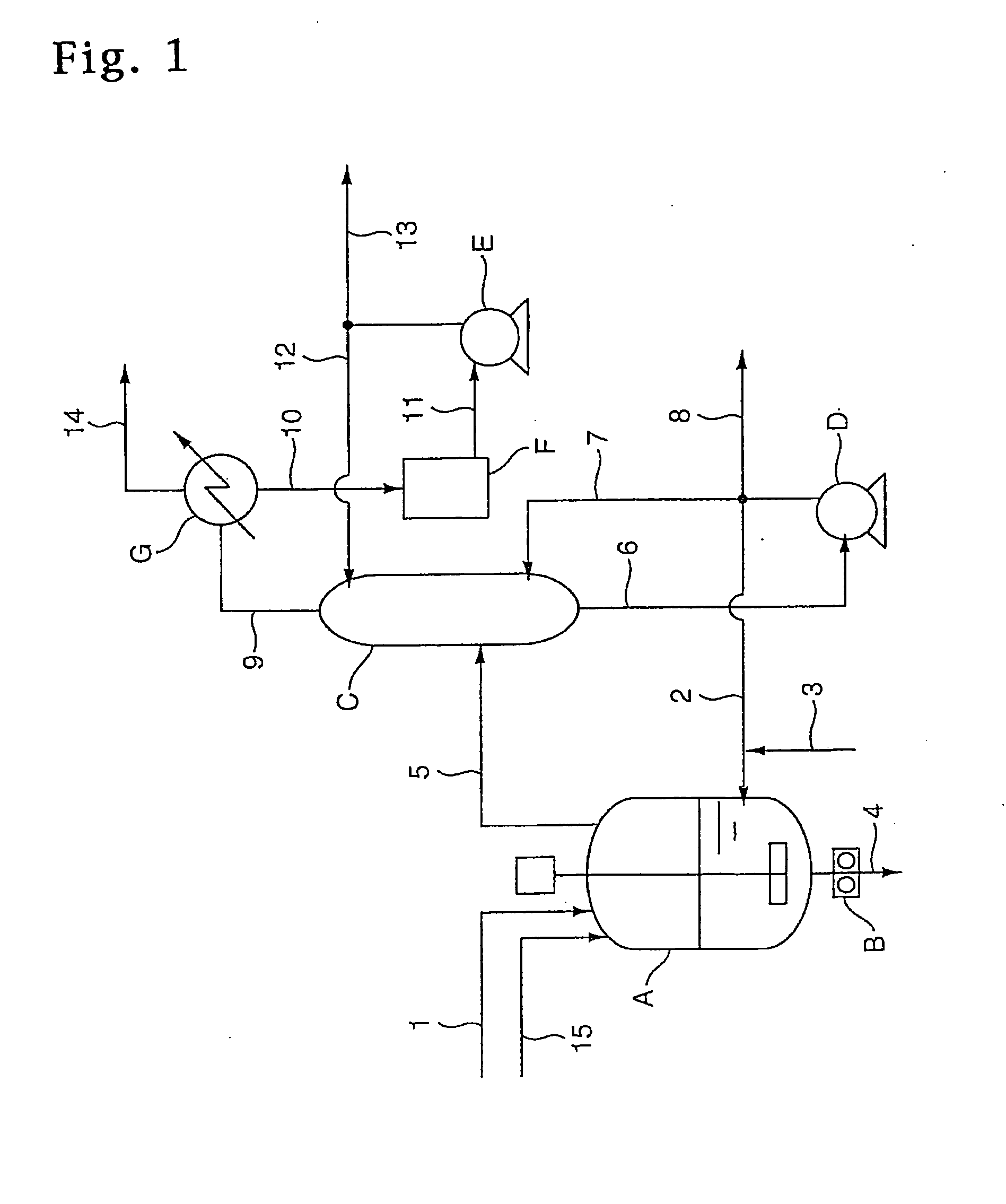

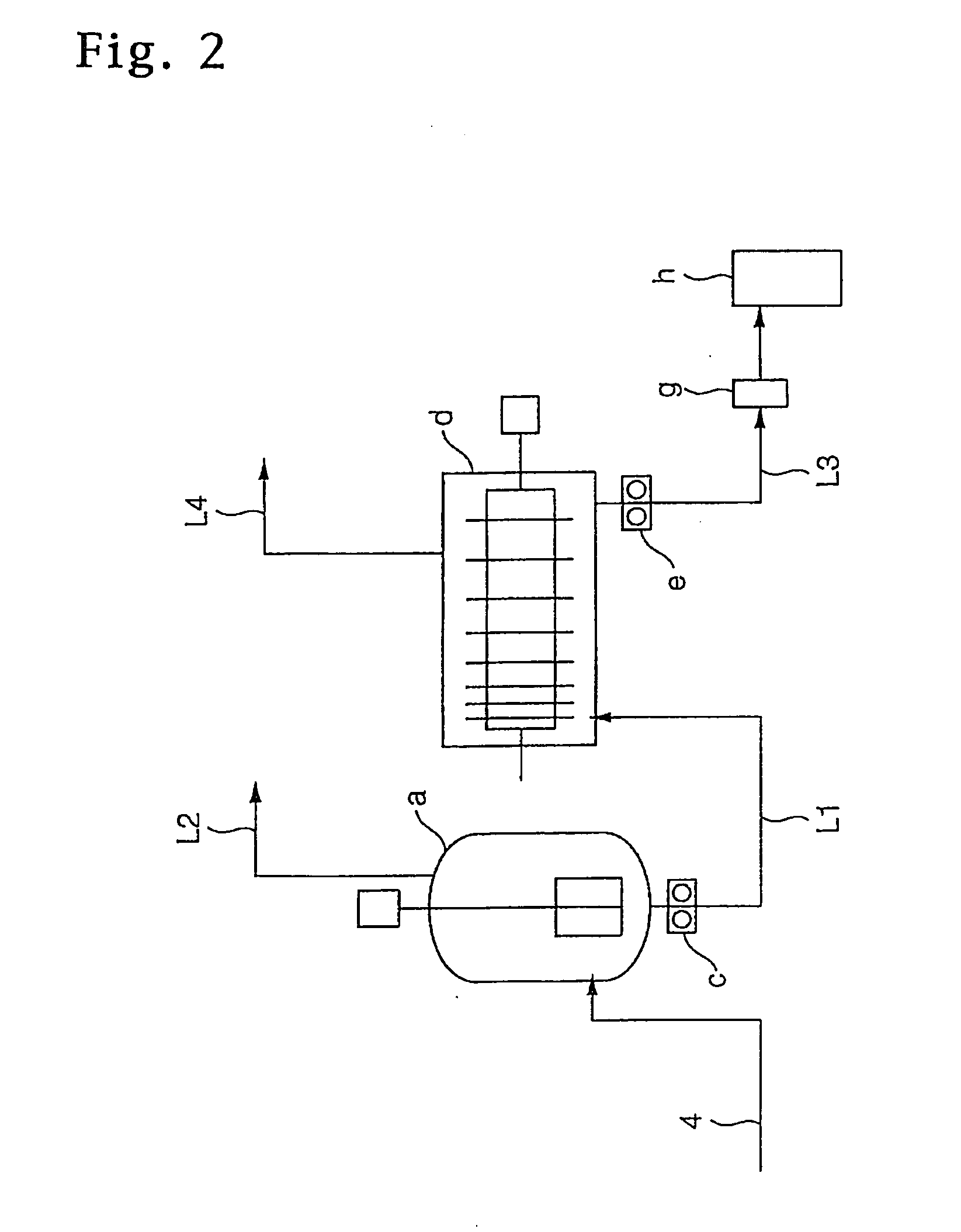

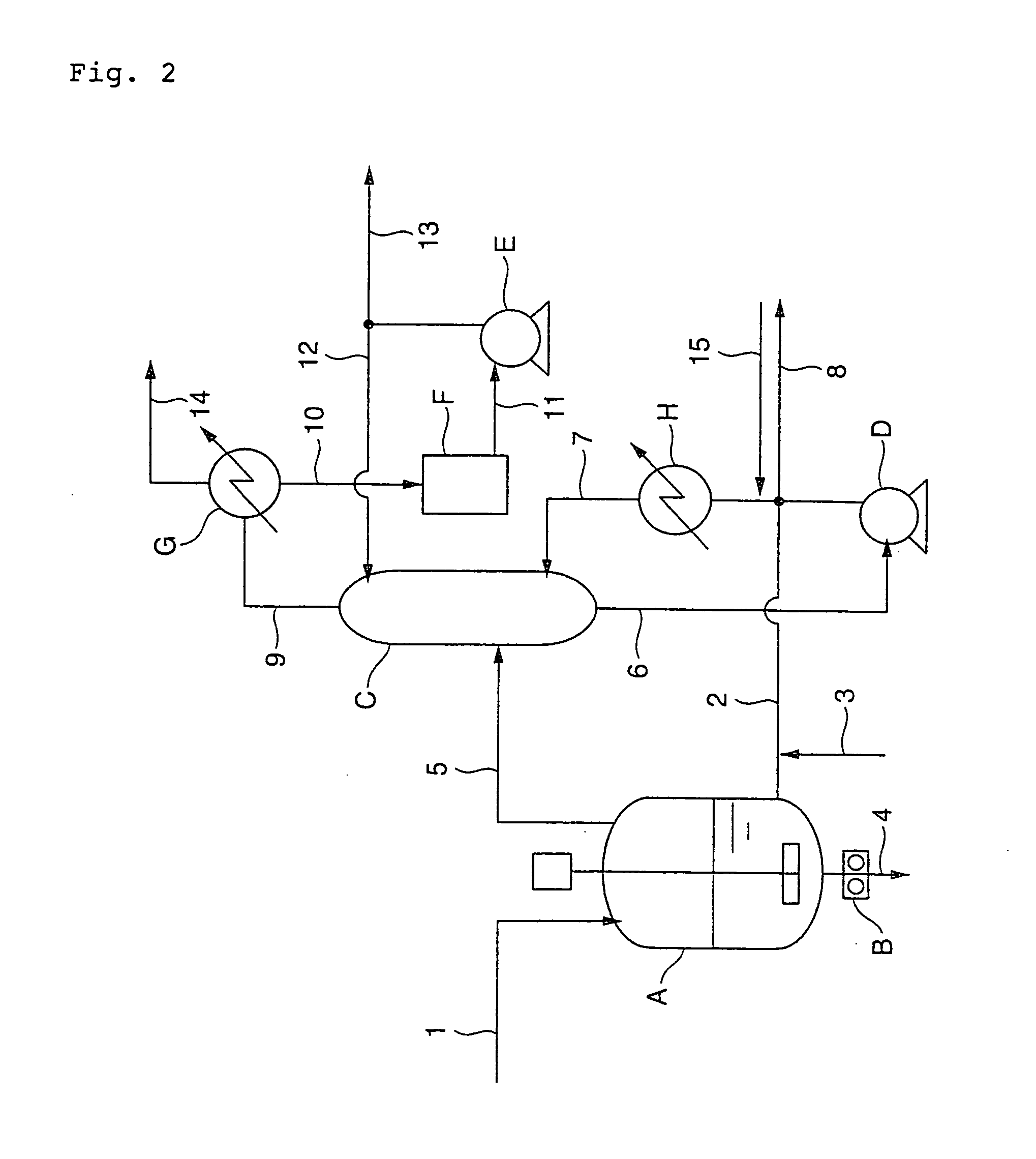

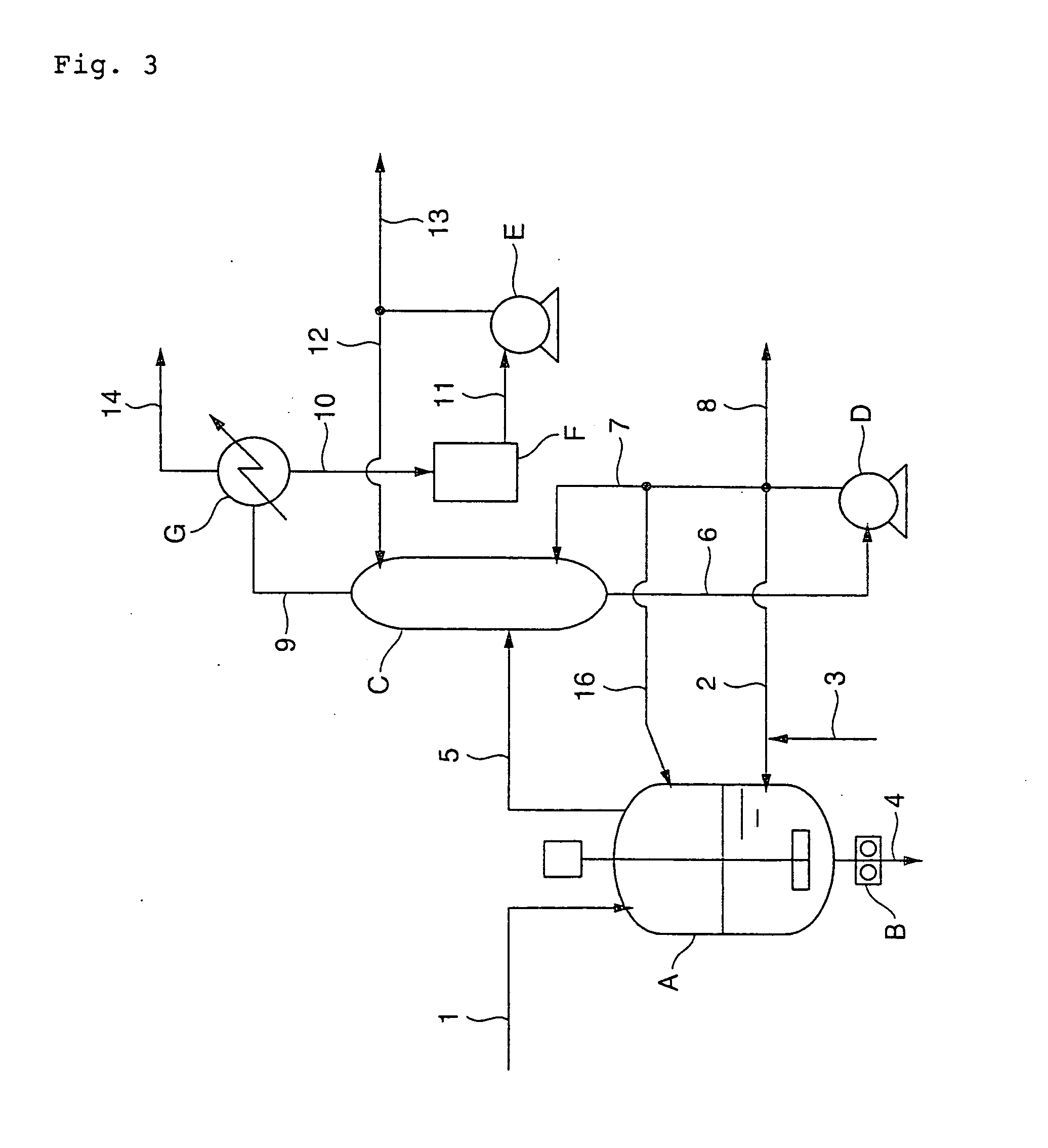

Circulation of components during homogenization of emulsions

InactiveUS8895629B2Small sizeReduce in quantityBiocideHydrocarbon active ingredientsEngineeringImproved method

An improved method for the manufacture of an oil-in-water emulsion involves circulation of emulsion components between a first container and a second container via a homogenizer and / or via a microfluidization device. Usefully, all of the emulsion components from the first container are emptied before being returned.

Owner:NOVARTIS AG

Methods for producing vaccine adjuvants

ActiveUS8871816B2Small sizeReduce in quantityBiocideHydrocarbon active ingredientsFiltrationImproved method

An improved method for the manufacture of an oil-in-water emulsion involves three procedures: (i) preparation of a preliminary emulsion; (ii) microfluidization of the preliminary emulsion to reduce its droplet size; and (iii) filtration of the microfluidized emulsion through a hydrophilic membrane.

Owner:NOVARTIS AG

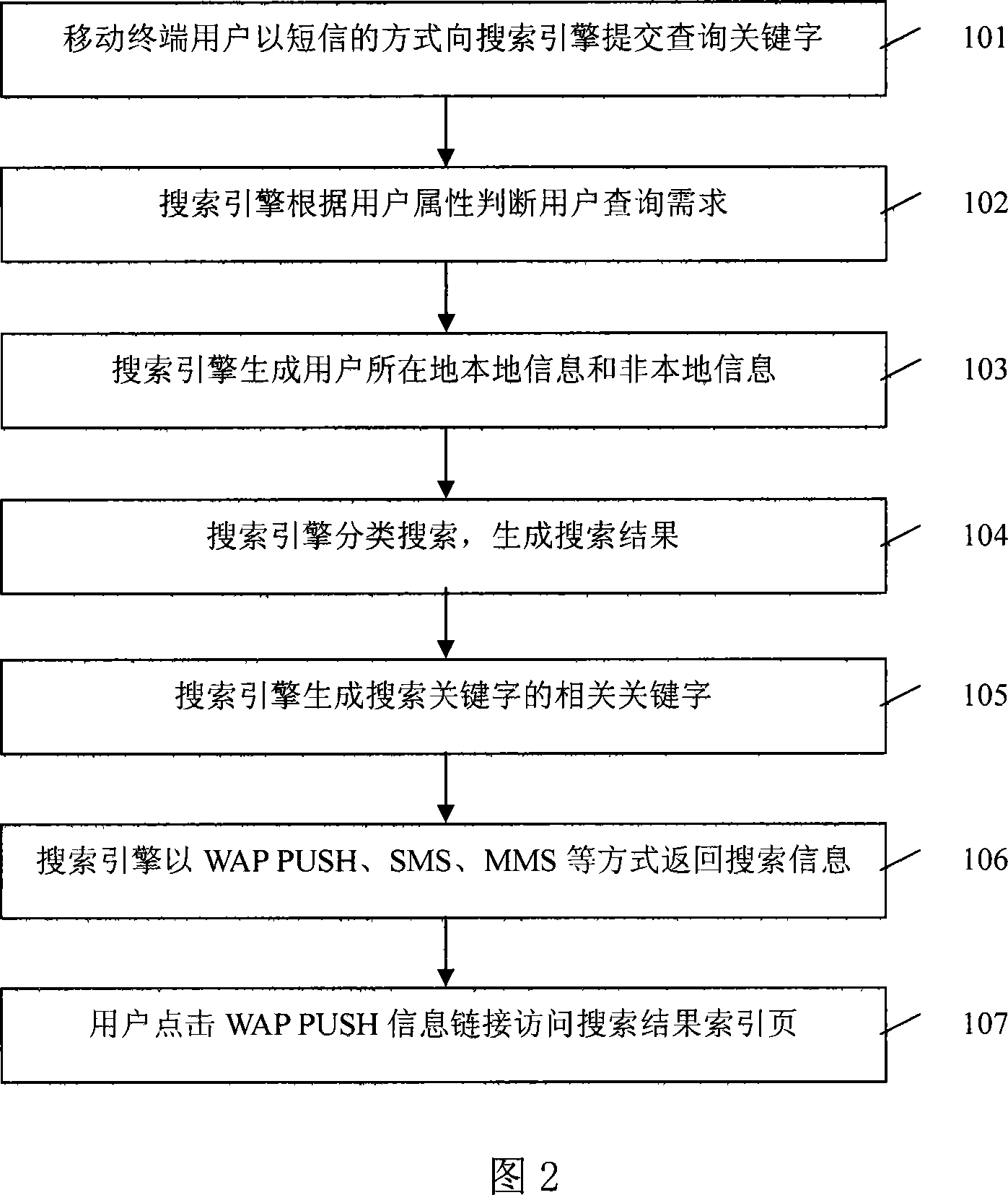

Wireless searching system and its wireless searching method

InactiveCN101052181AQuickly and accurately obtainPersonalized accessRadio/inductive link selection arrangementsMessaging/mailboxes/announcementsThe InternetEnd user

The method comprises: the mobile terminal user submits the searching key word to the search engine through by using short message through radio communication network; the search gets the attributes of said mobile terminal user from the user's attribute data base, and estimates the search needs of the user; the search engine gets and searches the information relating to the key work in internet, and according to the internet information and the search needs of user, generates search result, and sends the result to the mobile terminal. The system thereof comprises: a radio communication network used for submitting the key word to the search engine; a search engine connected to the radio communication network and internet and used for searching information relating to the key word and generating a search result, and sending the result to the mobile terminal.

Owner:CHINA MOBILE GROUP ZHEJIANG +1

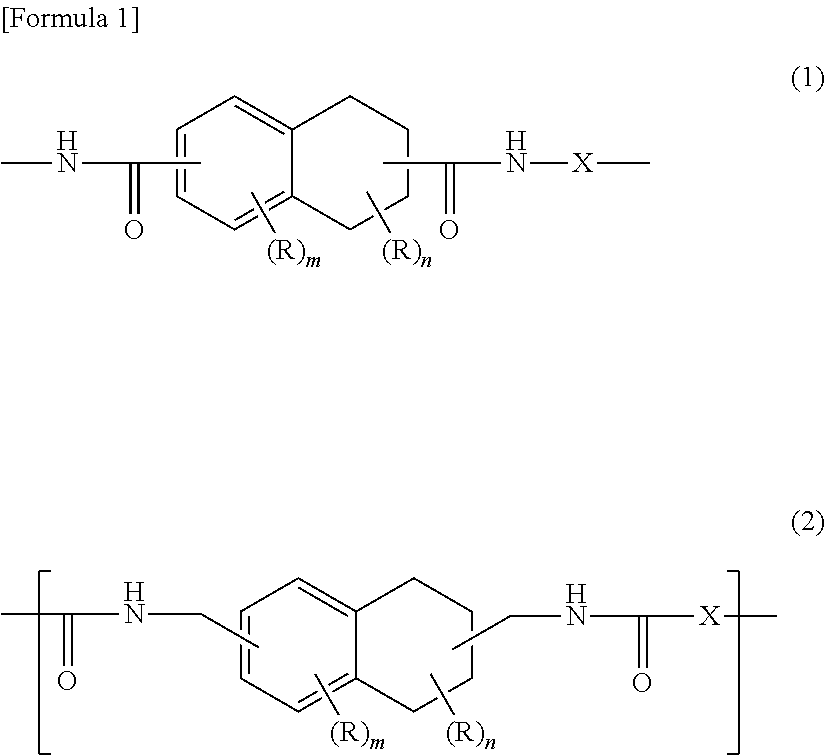

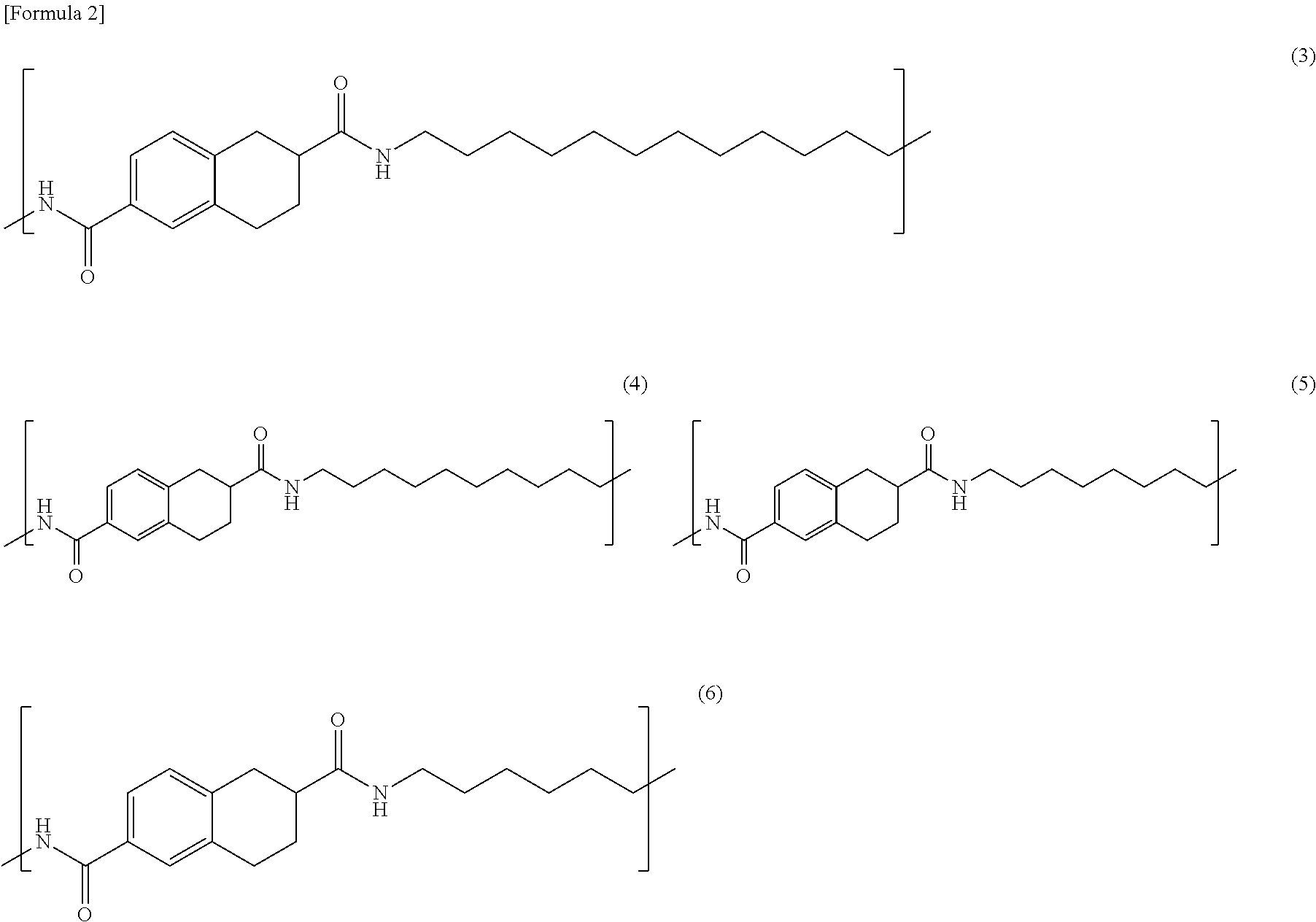

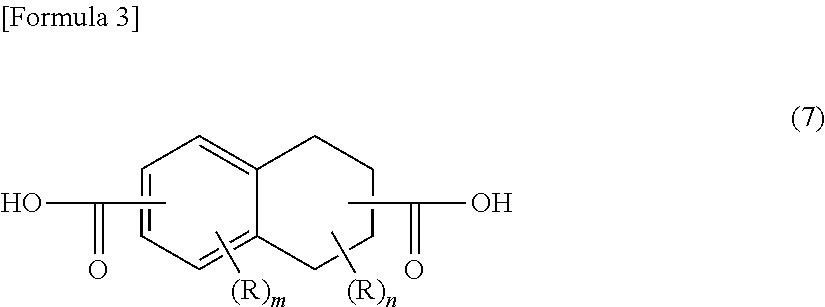

Oxygen-absorbing resin composition, and multilayer body, container, injection-molded body, and medical container using same

ActiveUS20150298887A1Improve performanceReduced strengthWrappersDiagnosticsPolymer scienceHigh humidity

Provided are a novel oxygen-absorbing resin composition not responsive to a metal detector, producing no odor after absorption of oxygen and having excellent oxygen-absorbing performance, and a multilayer body, container, injection-molded article and medical container using these. Further provided are an oxygen-absorbing resin composition etc. having excellent oxygen-absorbing performance in a wide range of humidity conditions from low humidity to high humidity. The oxygen-absorbing resin composition of the present invention is an oxygen-absorbing resin composition containing a polyamide compound and a transition metal catalyst, wherein the polyamide compound has at least one constituent unit having a tetralin ring. Moreover, the multilayer body, container, injection-molded article, medical container, etc. of the present invention are obtained by using the oxygen-absorbing resin composition of the present invention.

Owner:MITSUBISHI GAS CHEM CO INC

Polybutylene terephthalate

InactiveUS20090264611A1Excellent color toneImprove heat stabilityPolytetramethylene terephthalateFiber

Polybutylene terephthalate has an intrinsic viscosity of 0.7 to 1.0 dL / g and an end carboxyl group concentration of 0.1 to 18 μeq / g, which is produced in a presence of a catalyst comprising a titanium compound and a metal compound containing a metal of Group 2A of the Periodic Table. In the preferable embodiment of the present invention, the polybutylene terephthalate has a crystallization temperature of 170 to 195° C. as measured at a temperature drop rate of 20° C. / min using a differential scanning calorimeter, an end vinyl group concentration of not more than 10 μeq / g, and not more than 10% of a solution haze of a solution prepared by dissolving 2.7 g of said polybutylene terephthalate in 20 mL of a mixed solvent containing phenol and tetrachloroethane at a weight ratio of 3:2.The polybutylene terephthalate of the present invention exhibits excellent color tone, hydrolysis resistance, heat stability, transparency and moldability as well as a less content of impurities, which is suitably applicable to films, monofilaments, fibers, electric and electronic parts, automobile parts, etc.

Owner:MITSUBISHI CHEM CORP

Methods for producing vaccine adjuvants

ActiveUS8778275B2Small sizeReduce in quantityOrganic active ingredientsFlow mixersFiltrationImproved method

An improved method for the manufacture of an oil-in-water emulsion involves three procedures: (i) preparation of a preliminary emulsion; (ii) microfluidization of the preliminary emulsion to reduce its droplet size; and (iii) filtration of the microfluidized emulsion through a hydrophilic membrane.

Owner:NOVARTIS AG

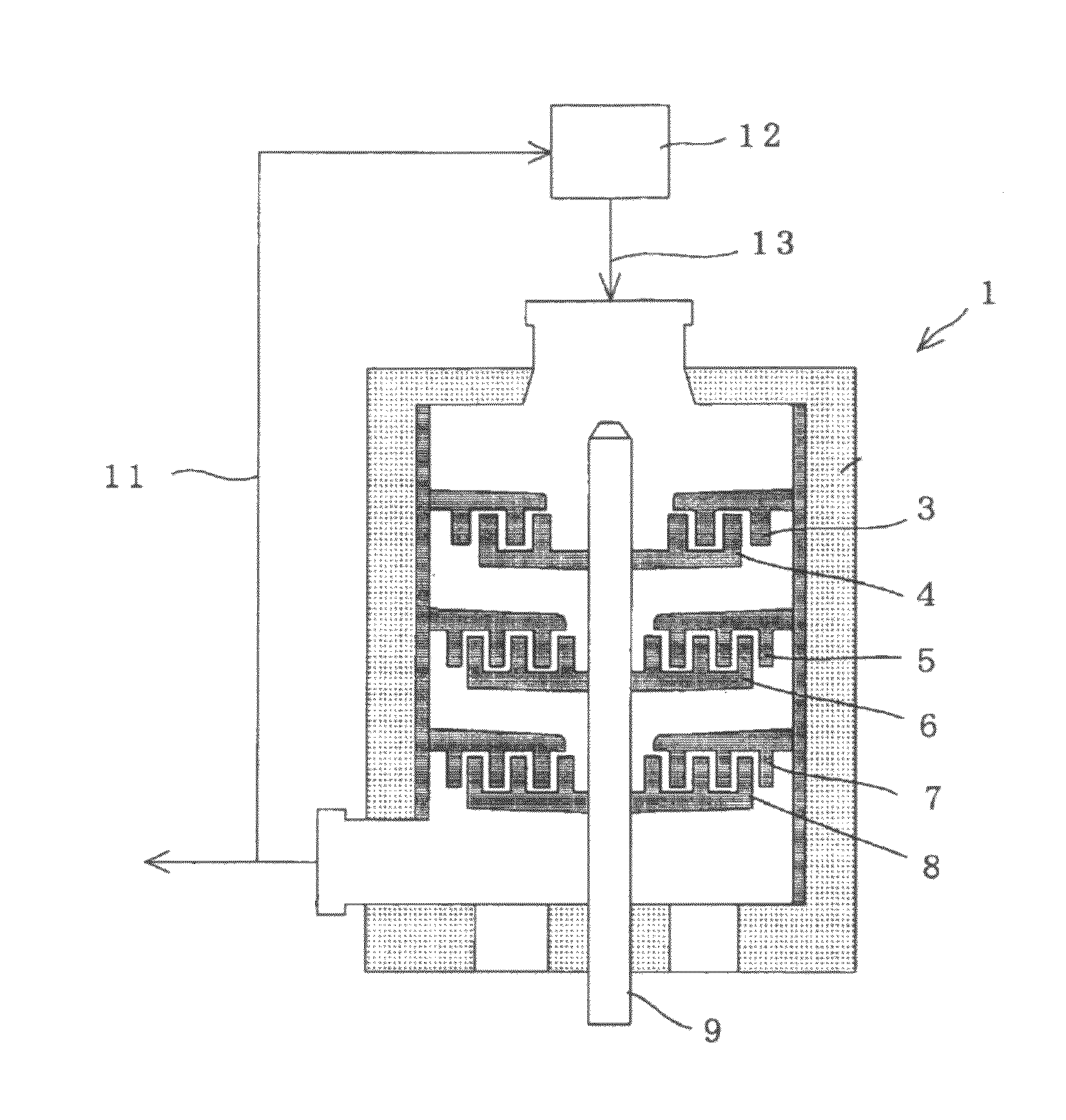

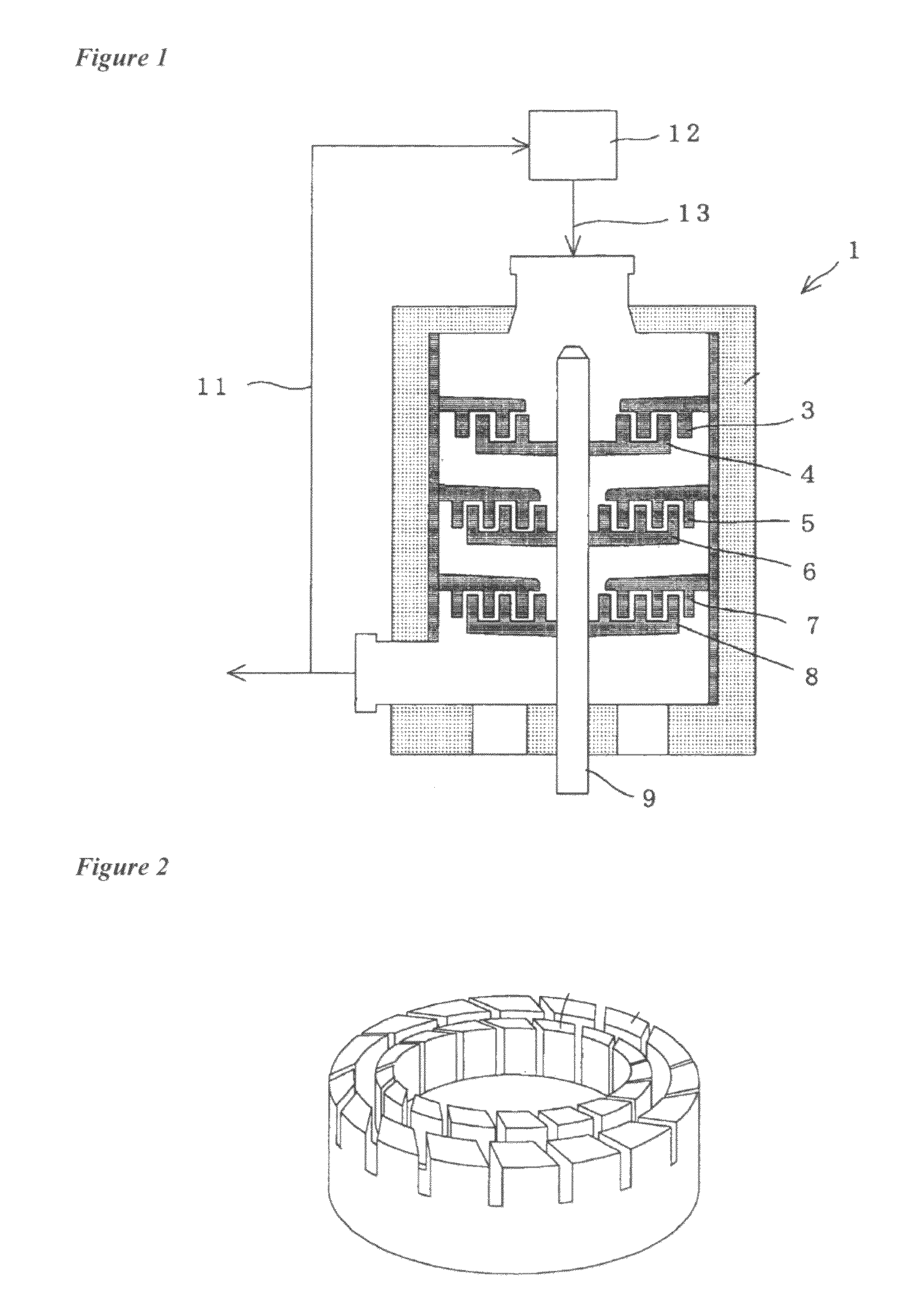

Arranging interaction and back pressure chambers for microfluidization

InactiveUS20130189311A1Eliminate needAvoid the needFlow mixersRotary stirring mixersImproved methodBiomedical engineering

An improved method for the manufacture of an oil-in-water emulsion comprises using a microfluidisation device whose interaction chamber comprises a plurality of Z-type channels upstream of a back pressure chamber.

Owner:NOVARTIS AG

A fluid purification system and method

ActiveUS20190047877A1Reduce heat loadOptimize allocationWater/sewage treatment by irradiationWater treatment compoundsEngineeringRadiation

An in-line fluid purification system uses a jacket (26) surrounding a fluid passageway (28), formed of a UV transmissive material. The jacket (26) may be surrounded by a UV reflective material (30). UV radiation (20) is coupled into the jacket (26), and the jacket (26) disperses and reflects the radiation over the entire cross section of the passageway (28). In this way, UV illumination of the full cross section of a fluid passageway (28) is ensured.

Owner:SIGNIFY HLDG BV

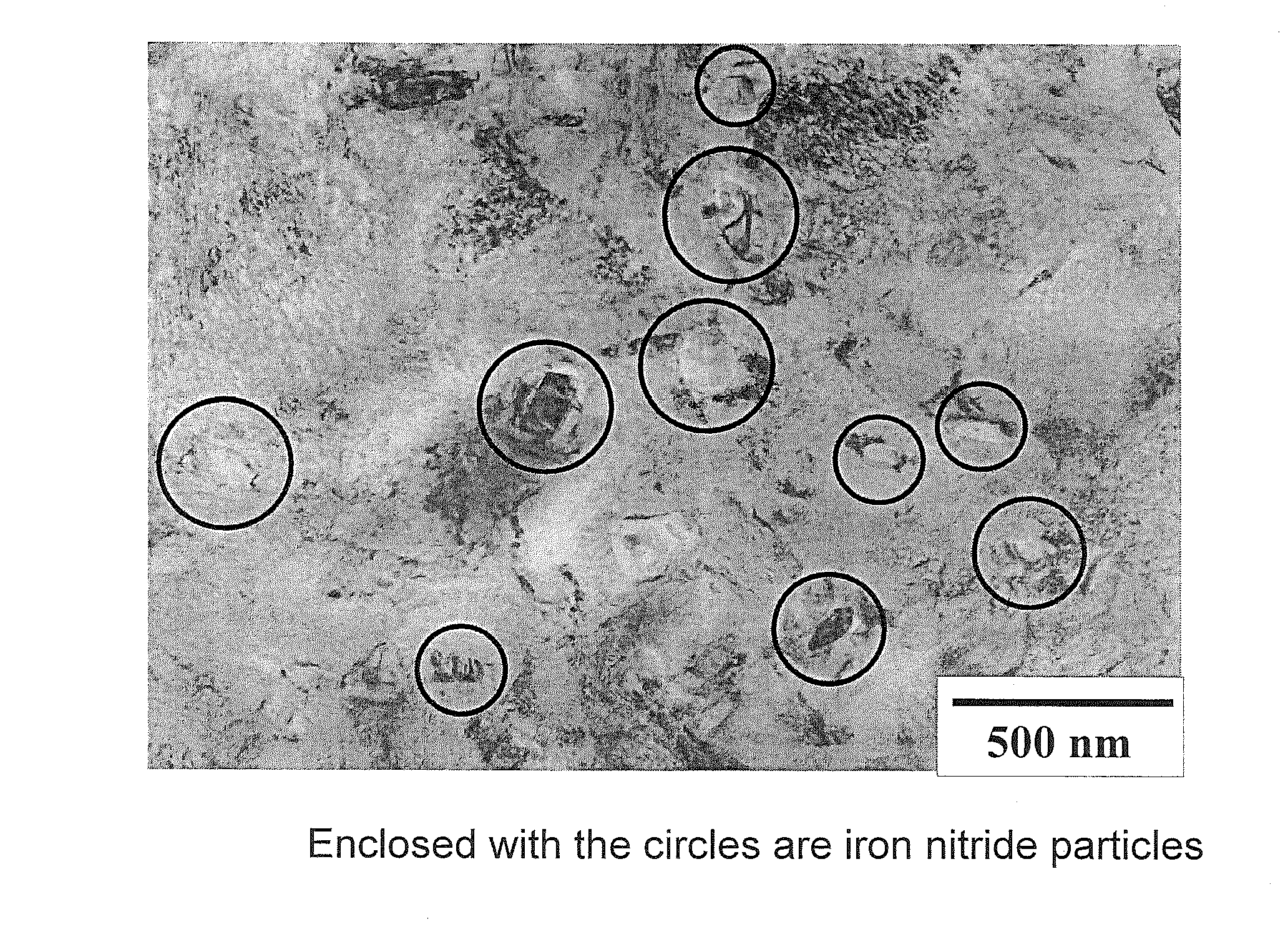

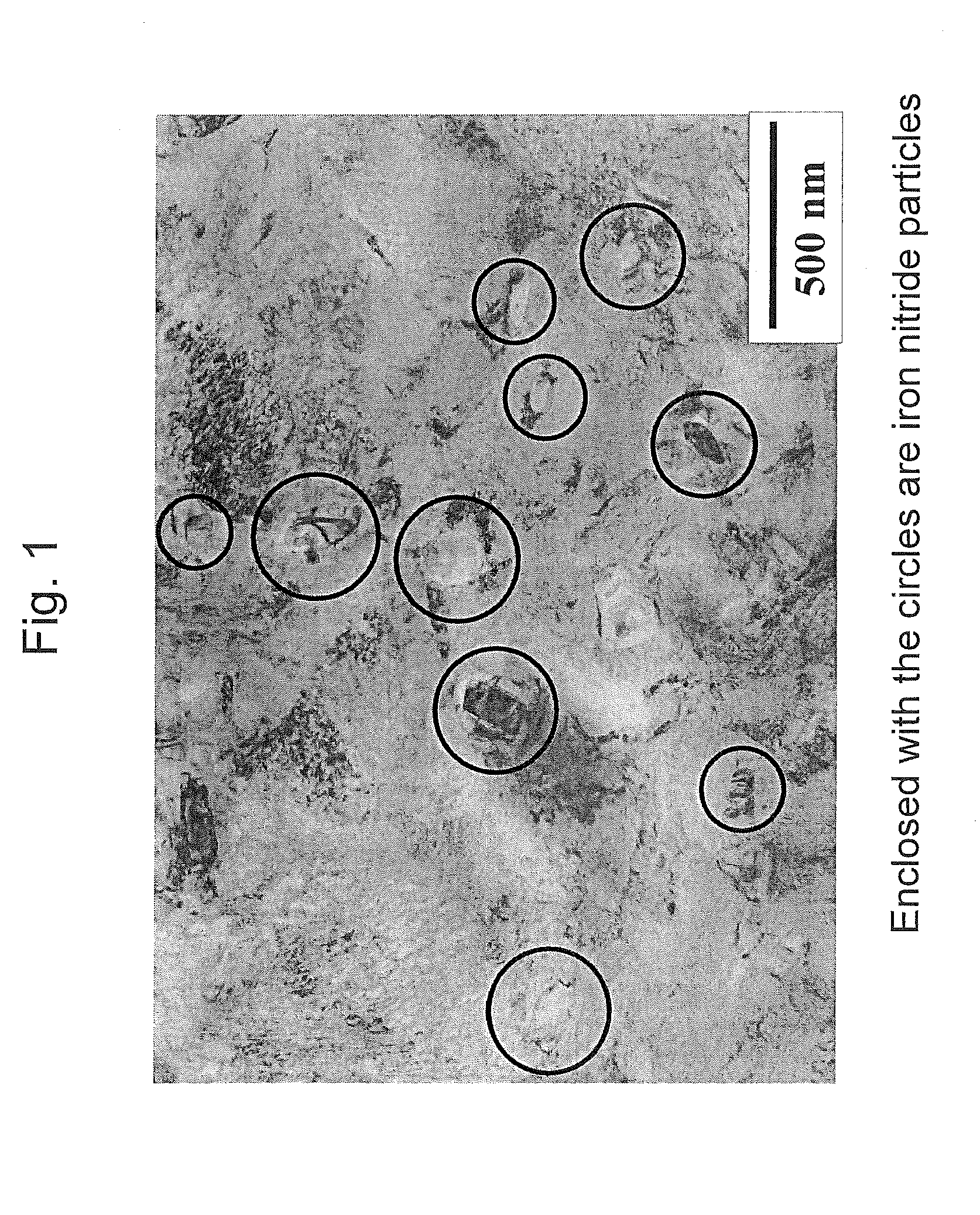

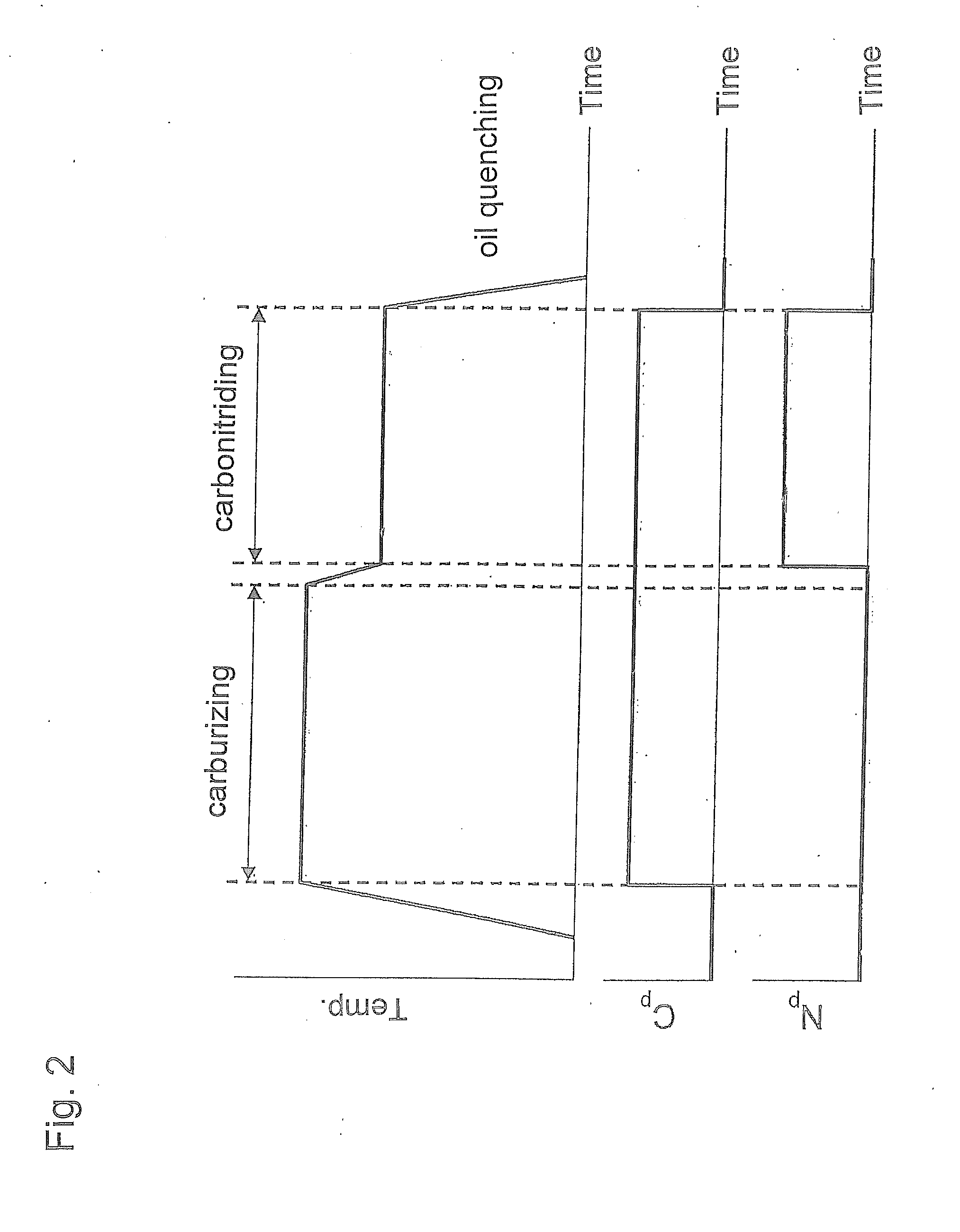

Carbonitrided part and process for producing carbonitrided part

InactiveUS20110284133A1Good wear resistanceHigh pitting strengthSolid state diffusion coatingFurnace typesNitrogenUltimate tensile strength

A carbonitrided part, where a base steel contains, in mass percent, C: 0.10 to 0.35%, Si: 0.15 to 1.0%, Mn: 0.30 to 1.0%, Cr: 0.40 to 2.0%, S≦0.05%, and according to need further Mo≦0.50%, with the balance being Fe and impurities, and in the region to a position of effective hardening depth from the surface of a hardened layer of the carbonitrided part, iron nitride particles of ε-Fe3N and / or ζ-Fe2N are dispersed, and retained austenite is decomposed into bainitic ferrite, Fe3C, and α″-Fe16N2 has excellent abrasion strength and high pitting strength, although the base steel is a low-cost one with less content of Mo of an expensive alloy element or without addition of Mo. This carbonitrided part can be produced, for example, by subjecting the base steel part to carburizing in which the base steel part is held in a carburizing atmosphere at 900 to 950° C. and successively to carbonitriding in which the base steel part is held in a carbonitriding atmosphere with a nitrogen potential of 0.2 to 0.6% at 800 to 900° C., subsequently quenching the base steel part, and thereafter tempering the base steel part by heating to a temperature in the range of more than 250° C. to not more than 350° C.

Owner:NIPPON STEEL CORP +1

Nickel-cobalt-maganese-based compound particles and process for producing the nickel-cobalt-manganese-based compound particles, lithium composite oxide particles and process for producing the lithium composite oxide particles, and non-aqueous electrolyte secondary battery

ActiveUS8592085B2Inhibit swellingUniform particle sizeSynthetic resin layered productsCellulosic plastic layered productsSubstance useManganese

The present invention relates to nickel-cobalt-manganese-based compound particles which have a volume-based average secondary particle diameter (D50) of 3.0 to 25.0 μm, wherein the volume-based average secondary particle diameter (D50) and a half value width (W) of the peak in volume-based particle size distribution of secondary particles thereof satisfy the relational formula: W≦0.4×D50, and can be produced by dropping a metal salt-containing solution and an alkali solution to an alkali solution at the same time, followed by subjecting the obtained reaction solution to neutralization and precipitation reaction. The nickel-cobalt-manganese-based compound particles according to the present invention have a uniform particle size, a less content of very fine particles, a high crystallinity and a large primary particle diameter, and therefore are useful as a precursor of a positive electrode active substance used in a non-aqueous electrolyte secondary battery.

Owner:TODA IND

Environment-friendly vegetable oil type ink and preparation process thereof

The invention discloses an environment-friendly vegetable oil type ink and a preparation process thereof. The environment-friendly vegetable oil type ink mainly comprises the following raw materials by weight: 20-35 parts of a coloring agent, 3-5 parts of auxiliary agents, 30-48 parts of rosin-modified phenolic resin and 20-30 parts of a solvent, wherein the auxiliary agents are mainly composed of1-5 parts of an anti-friction agent, 0.5-2 parts of a drying agent, 0.5-3 parts of an anti-drying agent and 3.5-4.5 parts of other auxiliary agents, and the solvent is mainly composed of soybean oil,linseed oil and tung oil. According to the ink in the invention, resin with low solubility and medium and low viscosity is selected and used, and vegetable oil esters having performance similar to the performance of mineral oil are elected and used, so the ink of the invention overcomes the problem of slow fixation speed, poor printability, too hard ink properties, great colloidality and too large yield value of conventional ink, has rich color and good effect, and accords with the development trend and the green development concept advocated at present.

Owner:张春松

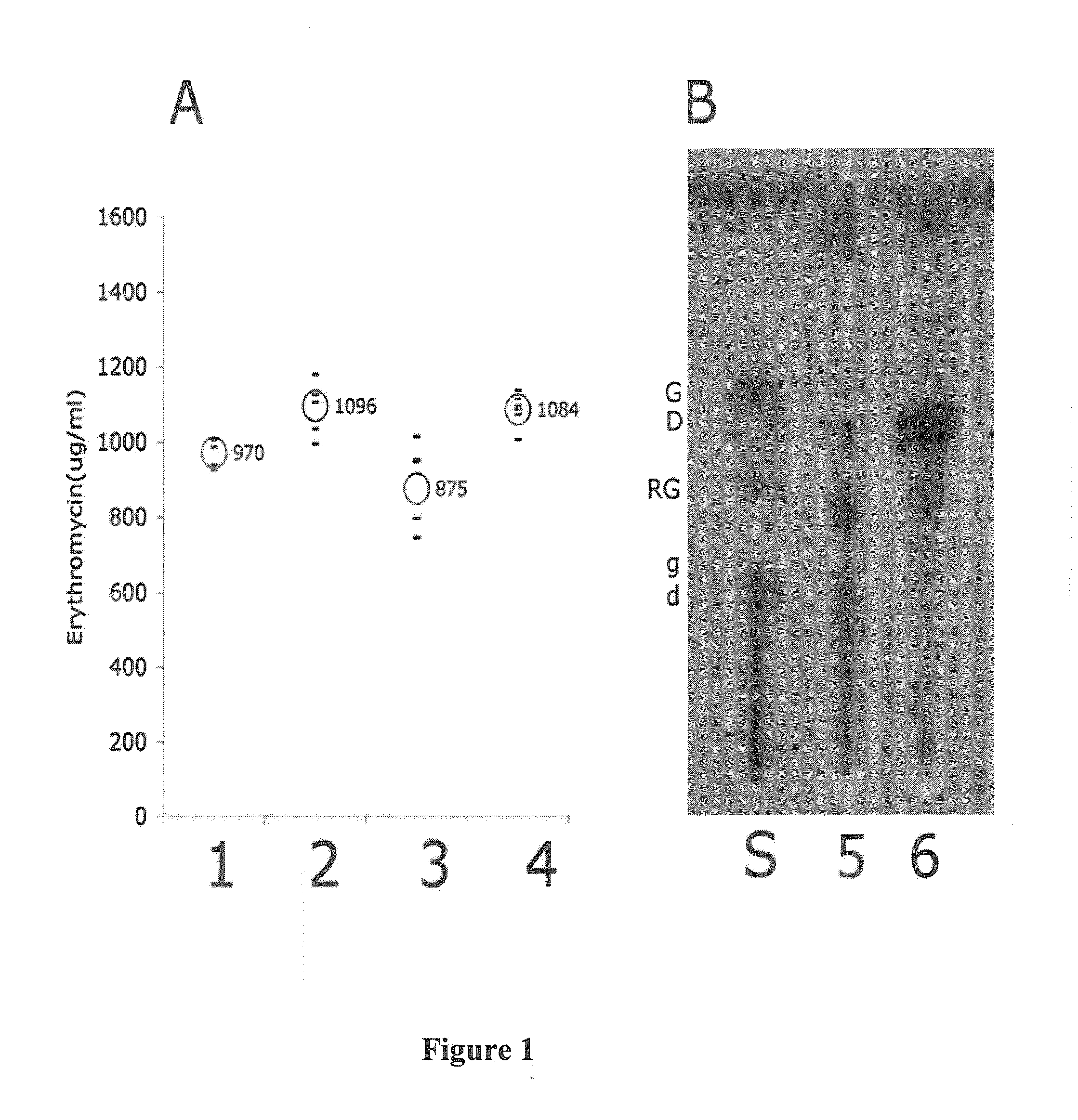

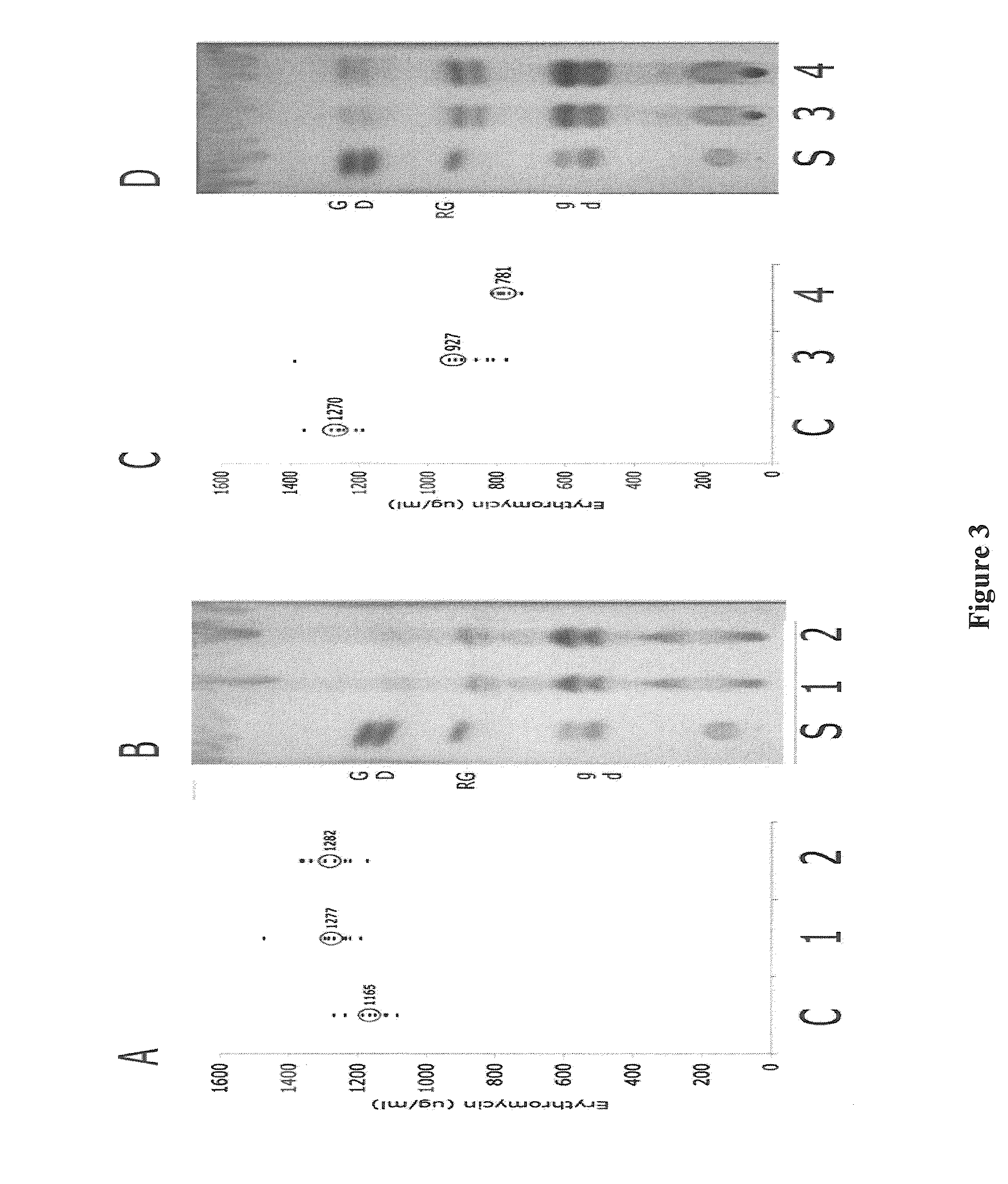

Soybean-Based Fermentation Media, Methods of Making And Use

ActiveUS20100279367A1Less contentFermentationChemical cell growth stimulationBiotechnologyIsoflavones

Fermentation media containing an isoflavone-depleted soybean meal or isoflavone-depleted soybean meal product and at least one exogenous added ingredient that comprises a substrate for microbial growth are provided. Methods of making a fermentation medium comprising an isoflavone-depleted soybean meal or isoflavone-depleted soybean meal product and methods for obtaining a fermentation product are also provided. The present invention is further directed to fermentation broths obtained by the media and methods. The present invention is also directed to feed additives produced from fermentation broths obtained by the methods.

Owner:FERMALOGIC

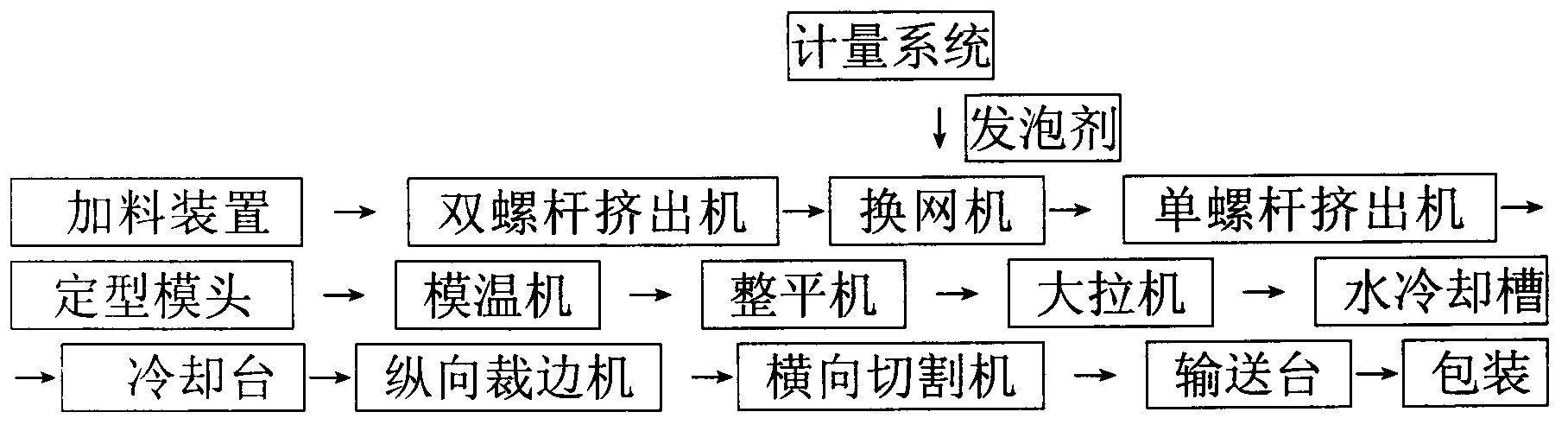

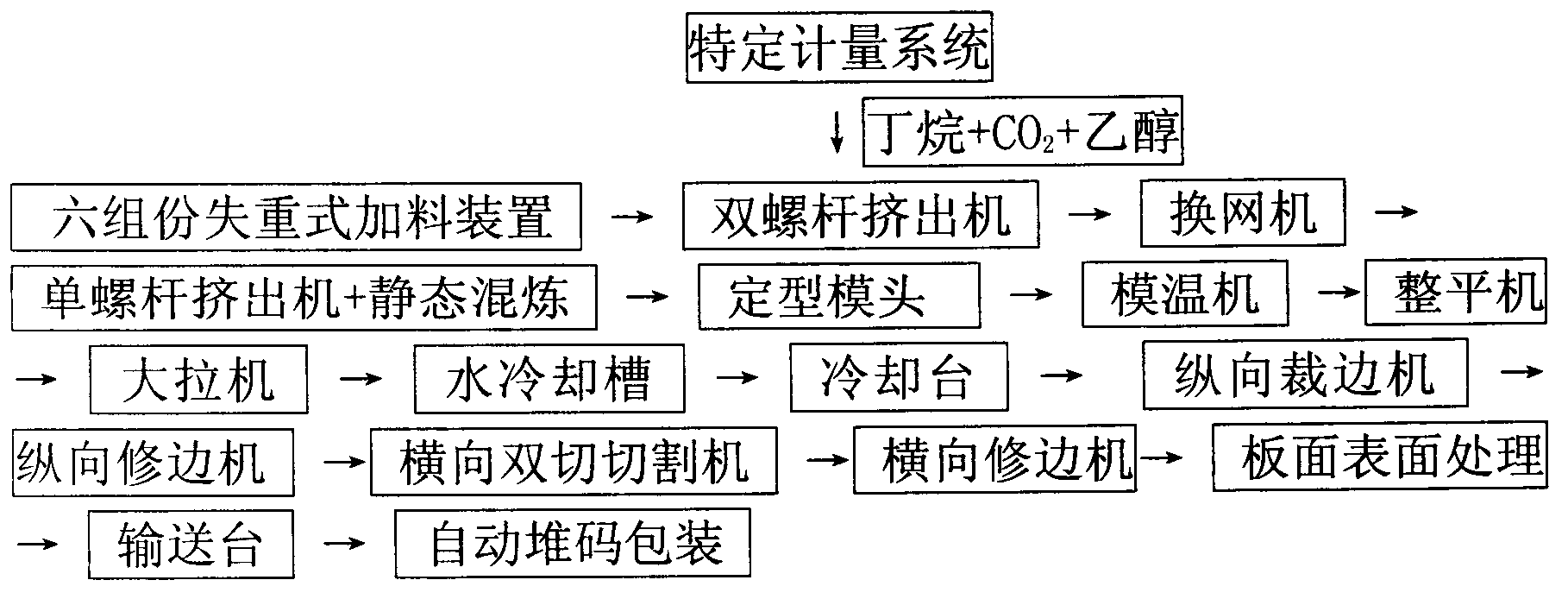

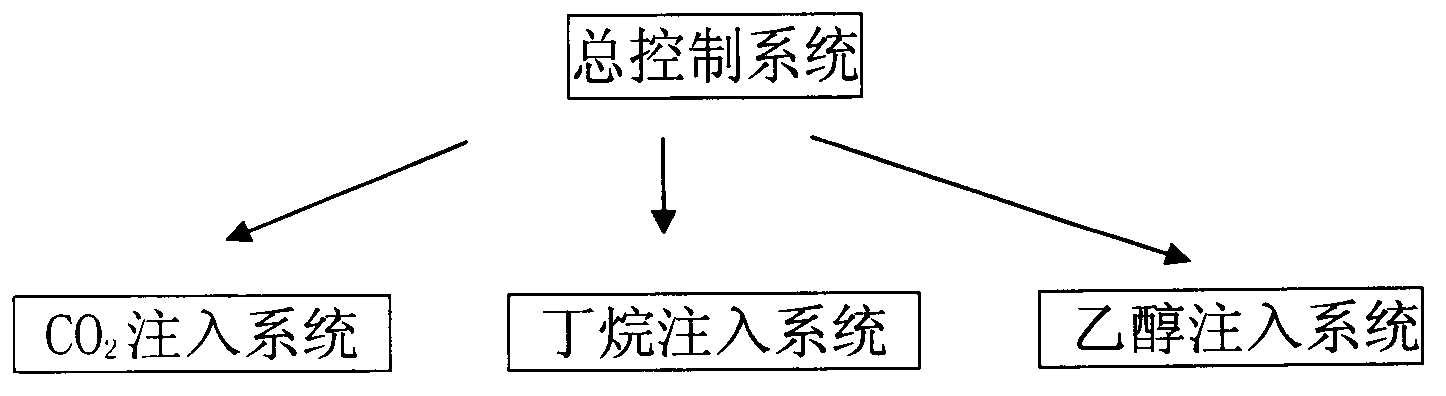

Process for production of extruded polystyrene foam plate by CO2 foaming

Relating to the technical field of extruded polystyrene foam plates, the invention provides a process for production of an extruded polystyrene foam plate by CO2 foaming. The production technology process includes: adding raw materials into a double-screw extruder through a six-component weight loss type feeding device, injecting butane, CO2 and ethanol into the double-screw extruder to conduct foaming through a specific metering system; extruding the foamed material to a net change machine by the double-screw extruder, conveying the material to a single screw extruder by the net change machine and conducting static mixing, letting the single screw extruder to extrude the mixed material to a shaping mold head, shaping a foam plate on the shaping mould head by a mold temperature controller, leveling the shaped foam plate by a leveling machine, stretching the leveled foam plate by a heavy drawing machine, cooling the stretched foam plate by a cooling stage and conveying it to the cooling stage. The process provided by the invention has the advantages of production cost reduction, time saving, accurate control, convenient operation, and ensures process stability.

Owner:上海新兆塑业有限公司

Process for producing ferromagnetic metal particles and magnetic recording medium

InactiveUS20100035087A1Uniform particle sizeGood dispersionMaterial nanotechnologyMetal-working apparatusMetal particleMaterials science

The present invention relates to ferromagnetic metal particles having an average major axis diameter (L) of 10 to 100 nm which satisfy a relationship between the average major axis diameter (L) and a particle SFD represented by the following formula:Particle SFD≦0.0001 L2−0.0217 L+1.75;a process for producing the ferromagnetic metal particles; and a magnetic recording medium using the ferromagnetic metal particles.

Owner:TODA IND

Process for Producing Polybutylene Terephthalate

A process for producing polybutylene terephthalate comprising the steps of continuously subjecting terephthalic acid and 1,4-butanediol to esterification reaction in the presence of a titanium compound catalyst using one-stage or plural-stage esterification reaction vessel(s) and then subjecting the resultant reaction product to polycondensation reaction, wherein the esterification reaction between terephthalic acid and 1,4-butanediol is conducted in the presence of a titanium compound having a specific concentration under a specific pressure at a specific molar ratio between the raw materials.The process of the present invention can be prevented from undergoing undesirable side reactions upon continuously conducting esterification reaction using terephthalic acid as a raw material, and can minimize loss of raw materials.

Owner:MITSUBISHI CHEM CORP

Lithium-transition metal oxide powder and method of producing the same, positive electrode active material for lithium ion battery, and lithium ion secondary battery

InactiveUS20160043391A1Inhibition formationIncrease resistanceMaterial nanotechnologyCell electrodesLithium niobateLithium-ion battery

There is provided a lithium-transition metal oxide powder with a coating layer containing lithium niobate formed on a part or the whole part of a surface of a lithium-transition metal oxide particle and having a low powder compact resistance, and a positive electrode active material for a lithium ion battery containing the lithium-transition metal oxide powder. Specifically, there is provided the lithium-transition metal oxide powder composed of a lithium-transition metal oxide particle with a part or the whole part of a surface coated with a coating layer containing lithium niobate, wherein a carbon-content is 0.03 mass % or less.

Owner:DOWA HLDG CO LTD

Conductive polymer material and molded article using same

ActiveUS20170365372A1Improve conductivityHigh crystallinityConductive materialNon-conductive material with dispersed conductive materialConductive polymerCarbon nanofiber

By using CNF excellent in dispersibility, conductivity, and crystallinity, a conductive polymer material having high conductivity even with a low CNF content and a shaped article thereof and a conductive polymer material with a less CNF content for same conductivity and a shaped article thereof are provided. A conductive polymer material with high conductivity is produced by using carbon nanofiber with a median diameter D50 value from 0.1 to 8 μm, powder resistivity of 0.03 Ωcm or less measured under a load of 9.8 MPa, and D / G from 0.5 to 1.3.

Owner:DENKA CO LTD

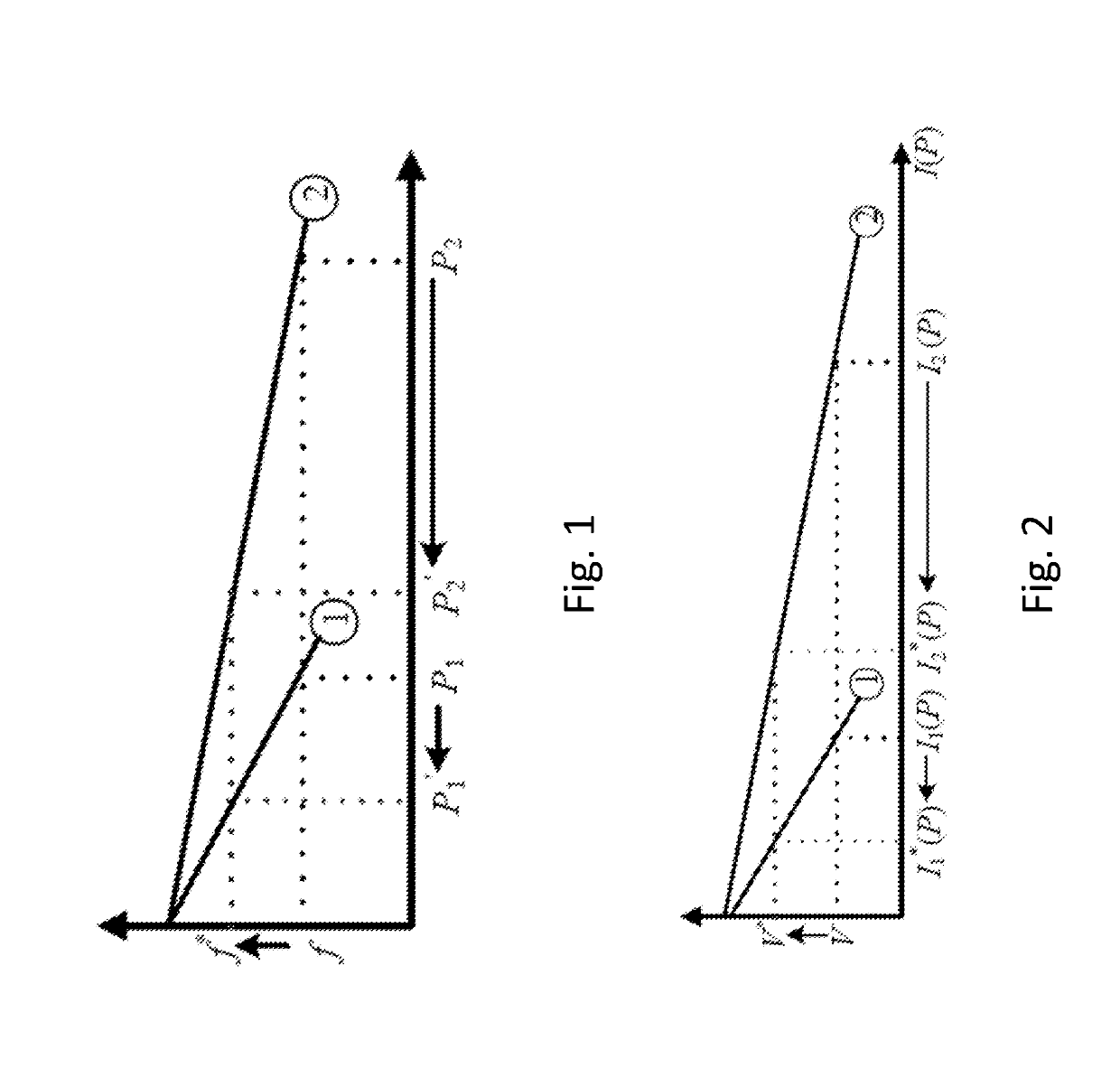

Apparatus for displaying medical image data of a body part

ActiveUS20180199902A1Simple technologyShorten the timeUltrasonic/sonic/infrasonic diagnosticsImage enhancementComputer visionImaging data

The present invention relates to an apparatus for displaying medical image data of a body part. It is described to provide (12) medical data of a body part, and subsets of medical image data from the medical data are determined (14). A plurality of measures of information content for the subsets of medical image data is determined (16), wherein a measure of information content is associated with a subset of medical image data. A plurality of weighting factors for the subsets of medical image data is determined (18), wherein a weighting factor is associated with a subset of medical image data and the weighting factor is determined as a function of the measure of information content for that subset of medical image data. Data representative of the subsets of medical image data is output (22) as a function of the plurality of weighting factors.

Owner:KONINKLJIJKE PHILIPS NV

Li—Ni composite oxide particles and process for producing the same, and non-aqueous electrolyte secondary battery

ActiveUS9764962B2Improve featuresExcellent cycle characteristicsCell electrodesNickel compoundsHigh temperature storagePhysical chemistry

Owner:TODA IND

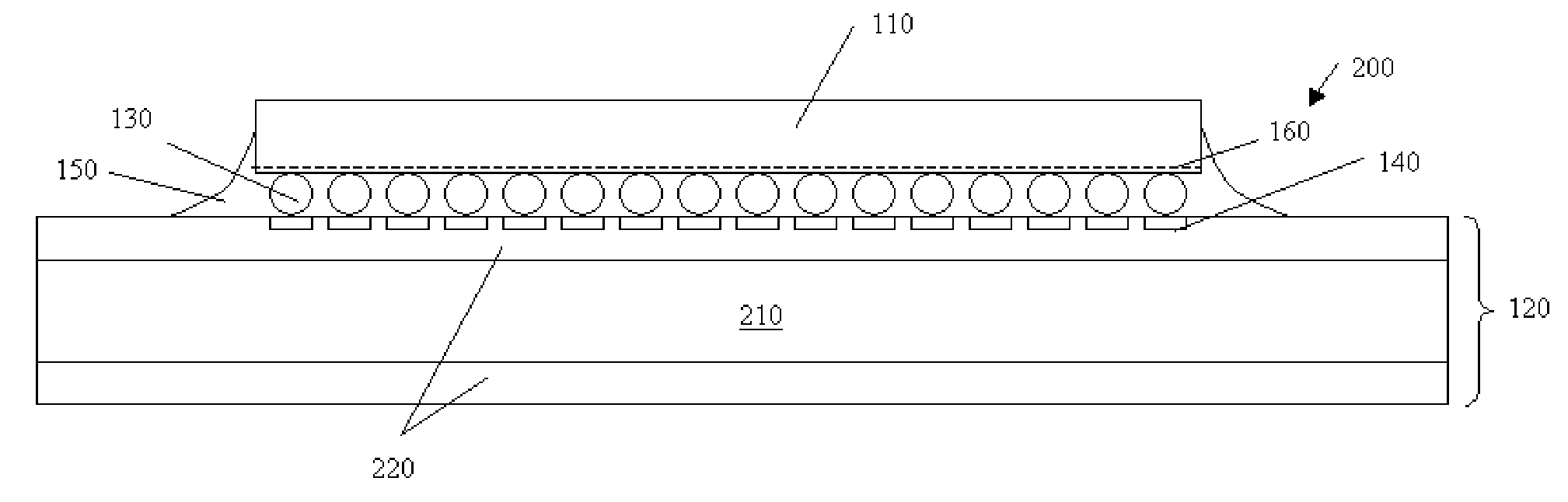

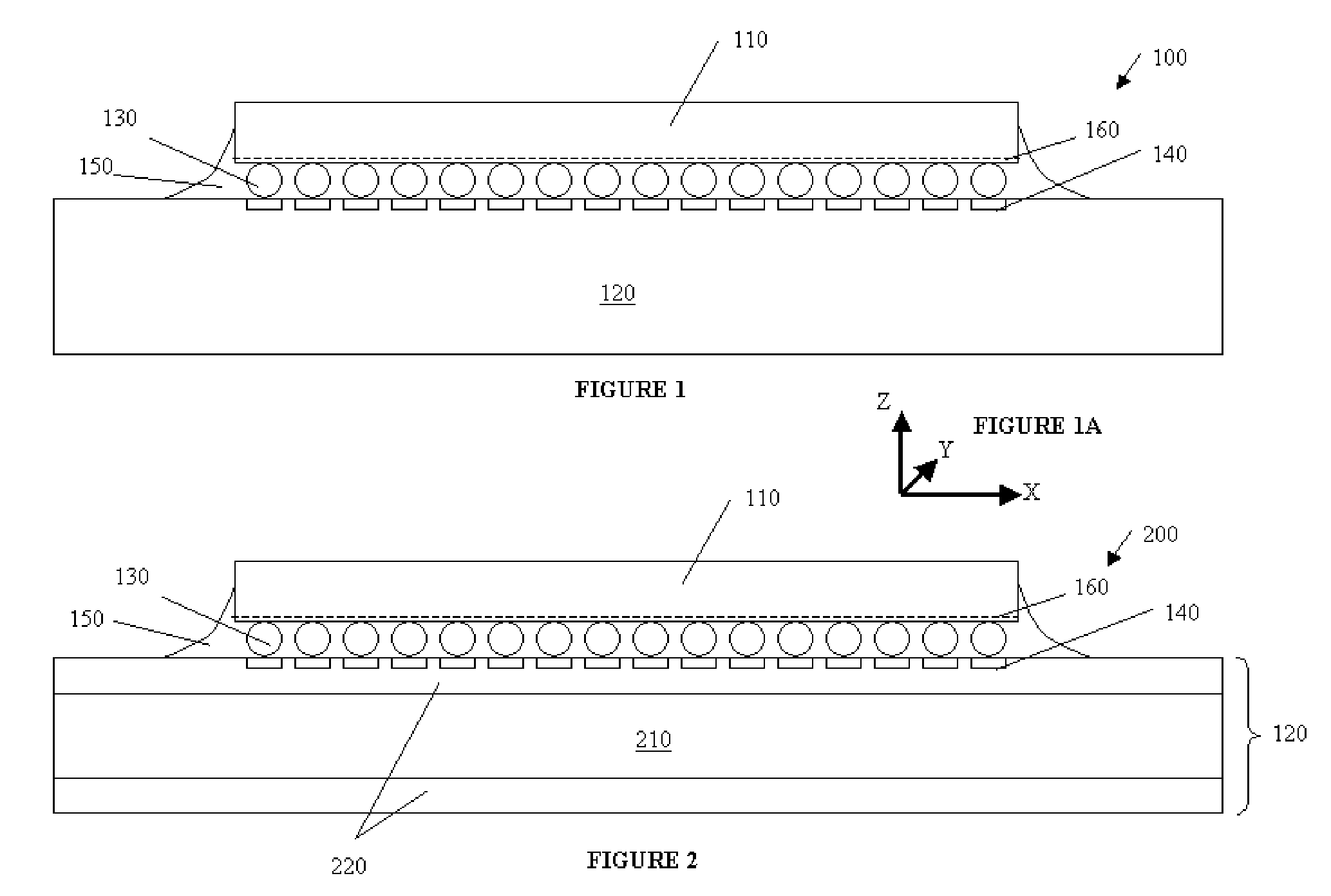

Low CTE substrates for use with low-k flip-chip package devices

ActiveUS20070007649A1Decrease in CTE mismatchGood coplanaritySemiconductor/solid-state device detailsPrinted circuit aspectsDevice materialCoupling

Disclosed are techniques that teach the replacement of the typical organic, plastic, or ceramic package substrate used in semiconductor package devices with a low-CTE package substrate. In one embodiment, a semiconductor device implementing the disclosed techniques is provided, where the device comprises an integrated circuit chip having at least one coupling component formed on an exterior surface thereof. Also, the device includes a package substrate having a mounting surface with bonding pads that are configured to receive the at least one coupling component. In such embodiments, the package substrate is selected or manufactured such that it has a coefficient of thermal expansion in a direction perpendicular to its mounting surface that is less than approximately twice a coefficient of thermal expansion along a plane parallel to its mounting surface.

Owner:TAIWAN SEMICON MFG CO LTD

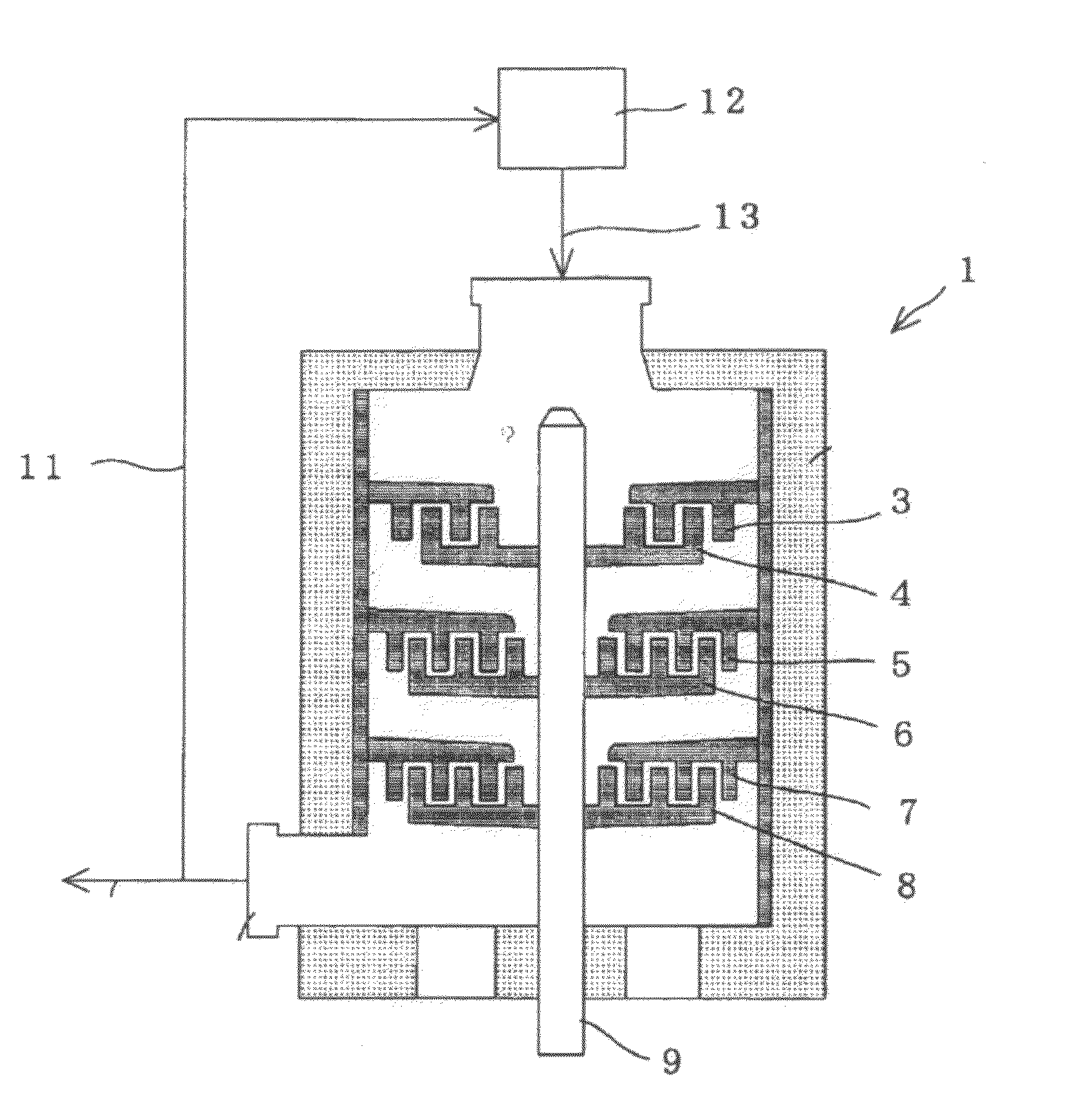

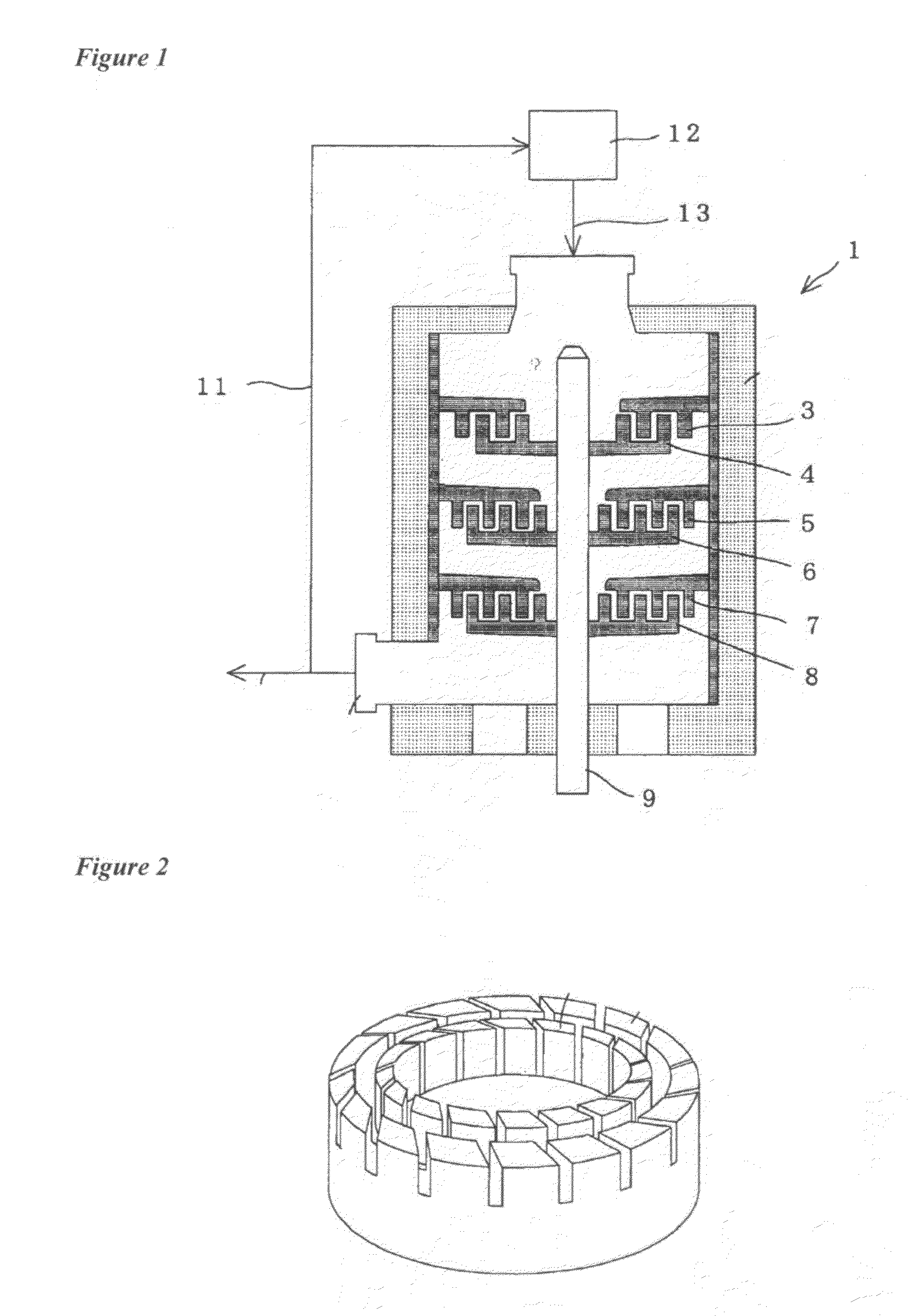

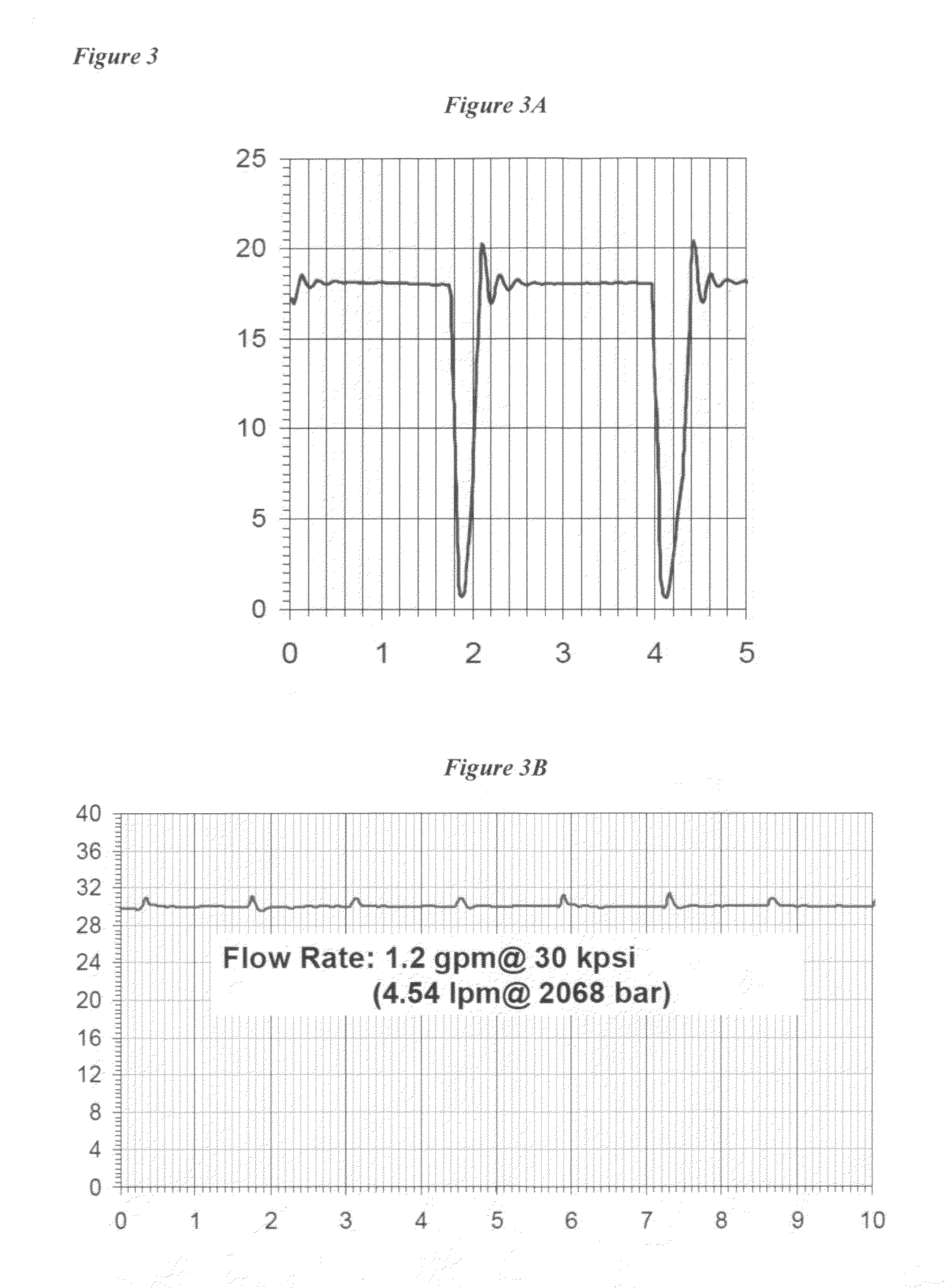

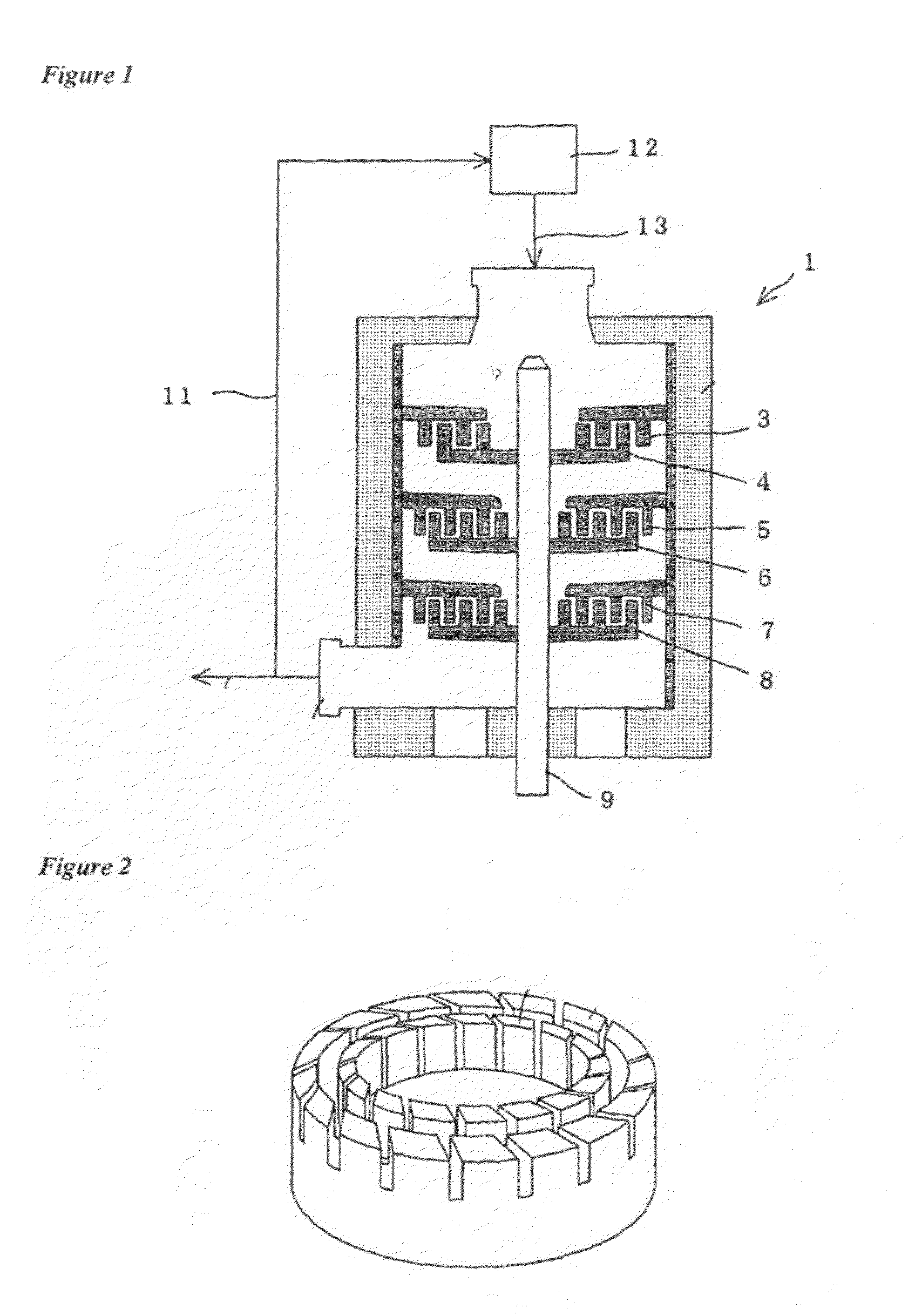

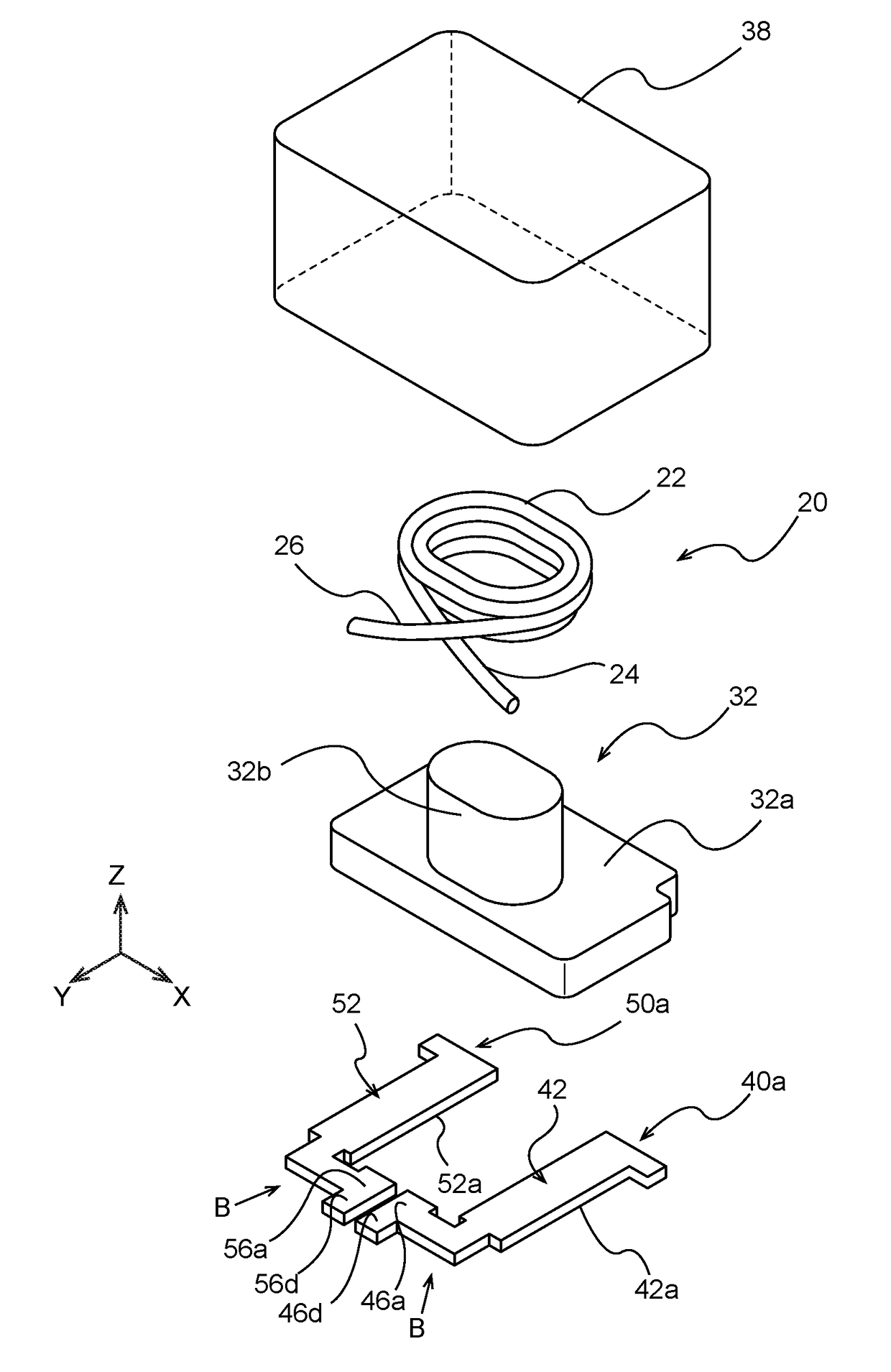

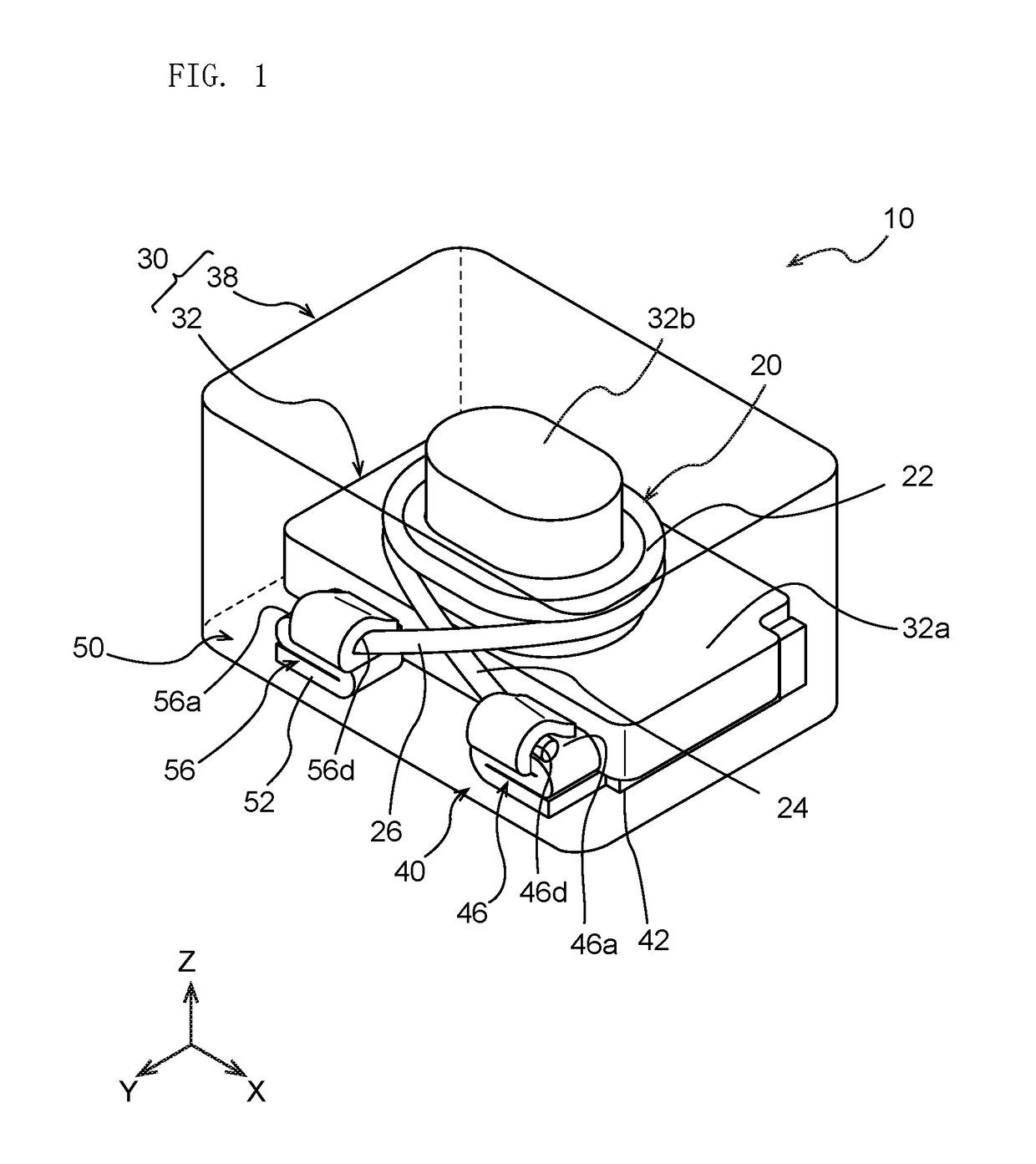

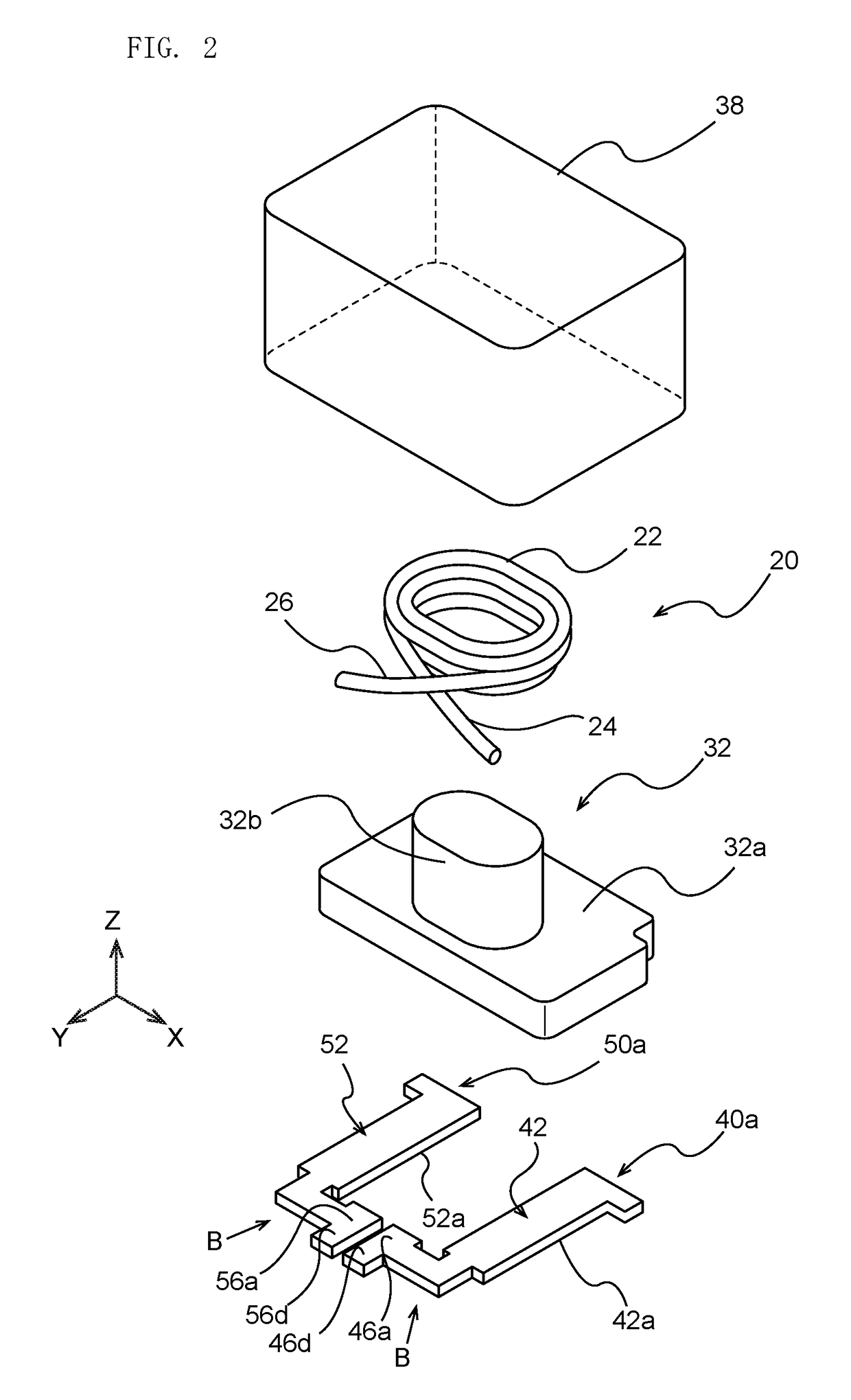

Coil device

ActiveUS20170229232A1Add partsInductance can be improvedTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresConductive materialsMechanical engineering

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com