Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Large pressure adjustment range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

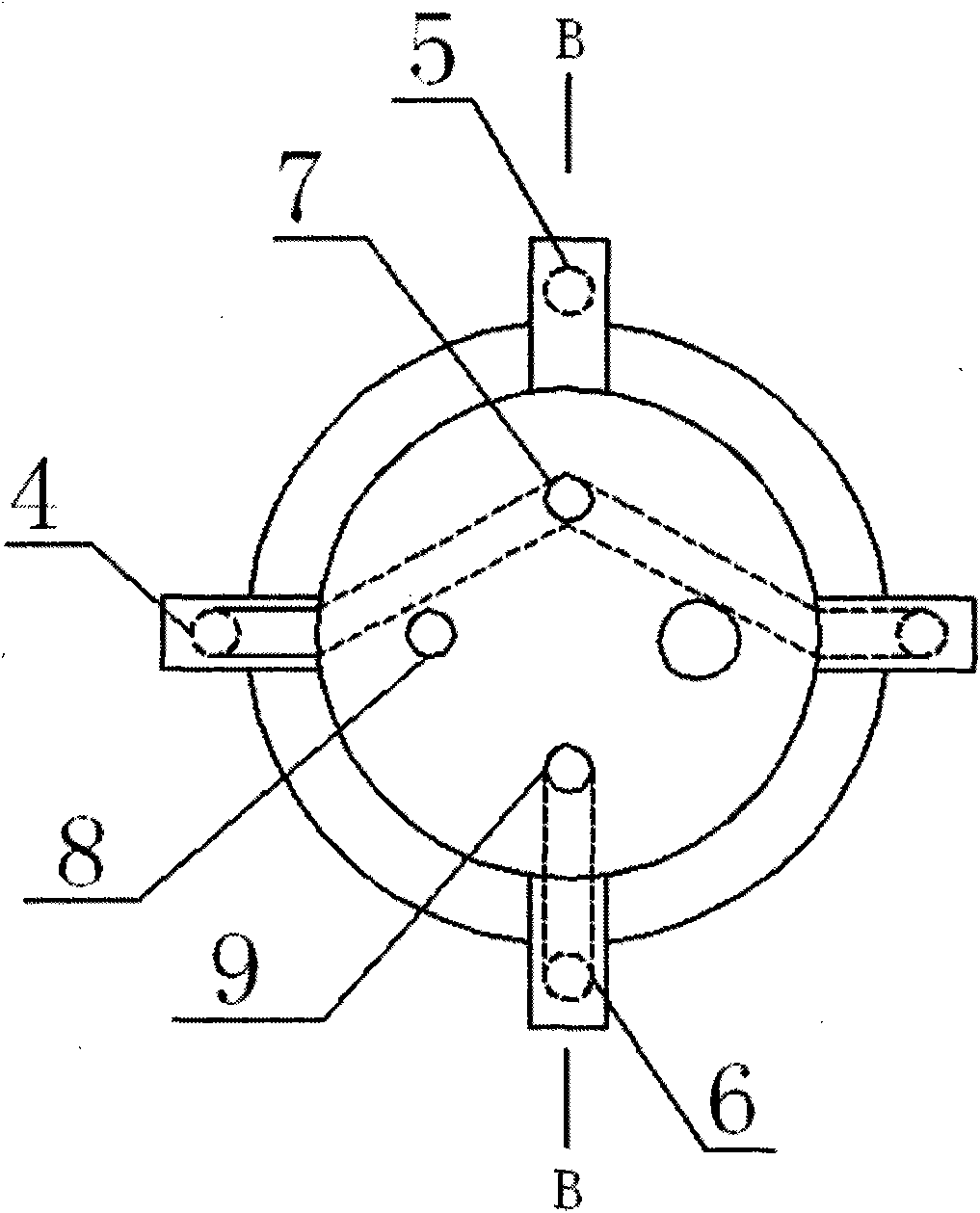

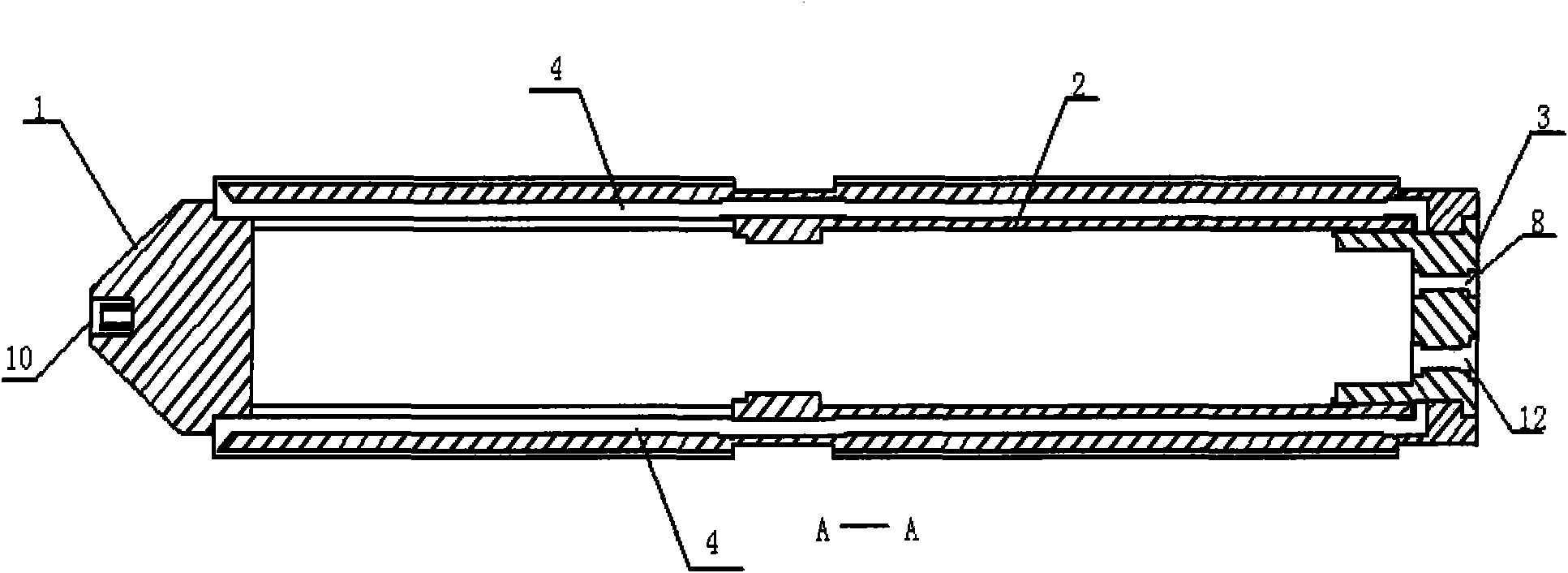

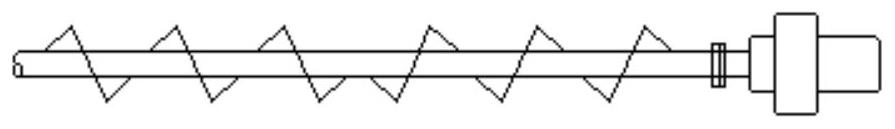

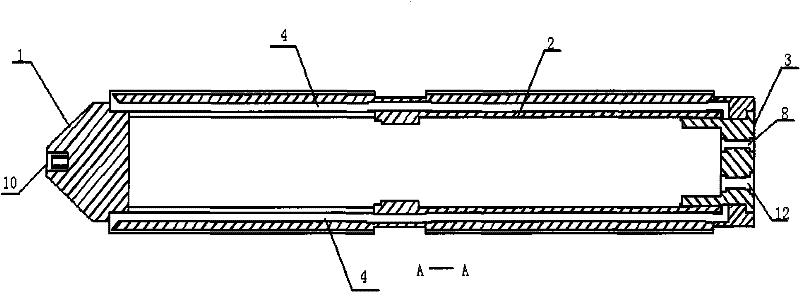

Dry-process vibroflot

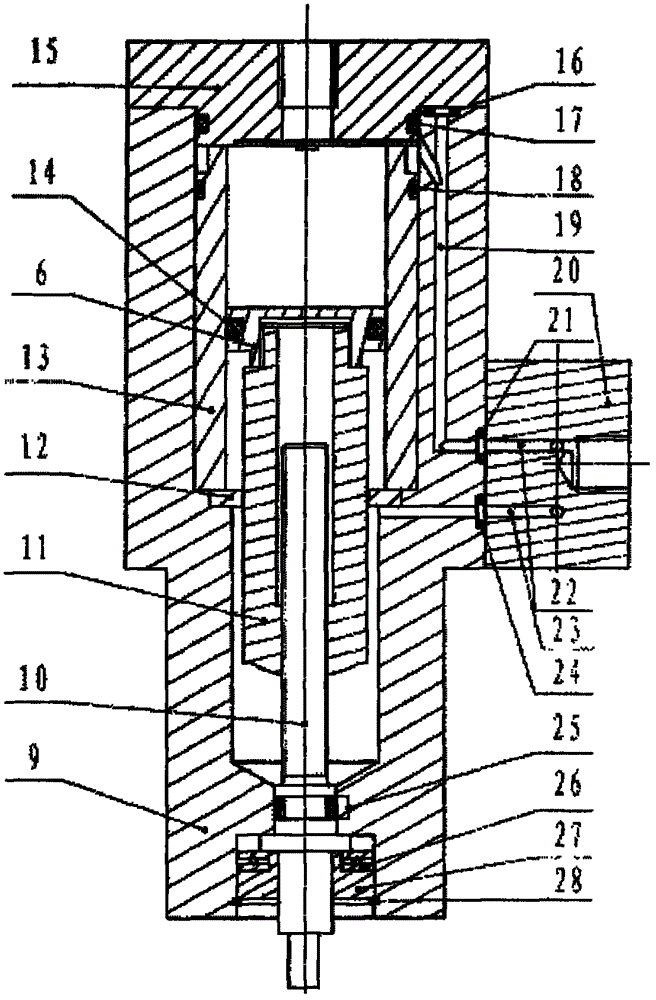

The invention relates to a dry-process vibroflot for compacting soft foundation by a vibroflotation method. The dry-process vibroflot comprises a vibroflotation head, a body and a motor gland, wherein the top of the body is connected with the vibroflotation head, while the tail is connected with the motor gland; an air-water channel, a water outlet channel and a water return channel are formed in the body; the motor gland is provided with an air inlet, a water inlet and a water return hole; the vibroflotation head is provided with a water outlet; the air-water channel is connected with an air inlet; the water outlet channel is connected with the water outlet; and the water return channel is connected with the water return hole. High pressure air is sprayed through the air-water channel, the water and air are mixed to impact the ground, and the pore forming rate is higher; the water outlet channel and the water inlet channel are self-circulated under certain pressure and water resources are saved; and water or air can pass through the air-water channel, so that a range of regulating the ground impacting pressure of the vibroflot is wider.

Owner:BEIJING VIBROFLOTATION ENG

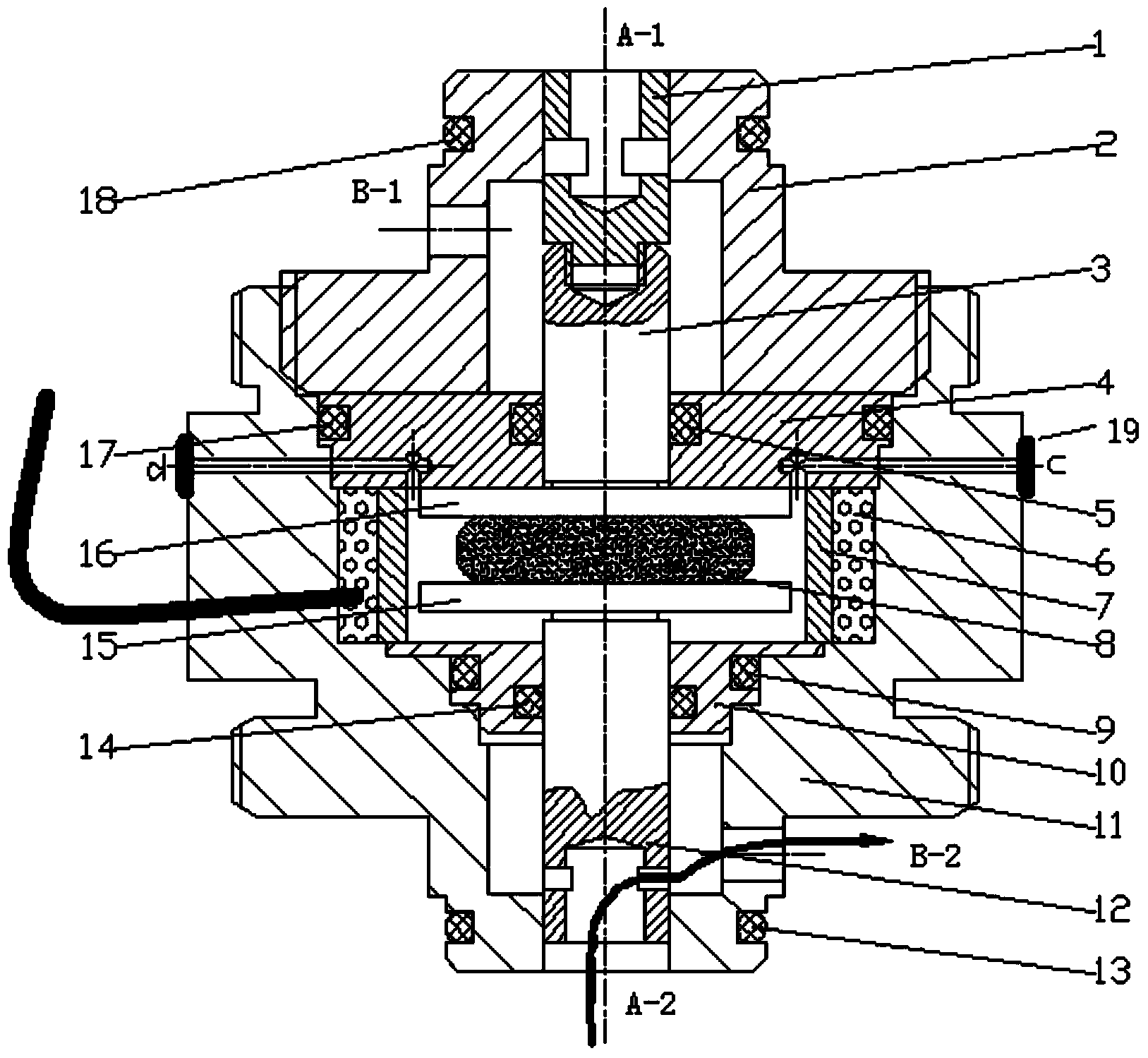

Gas pressure regulator and gas pressure regulation method

ActiveCN102135778AIncrease or decrease in massImprove control accuracyFluid pressure measurementFluid pressure control without auxillary powerEngineeringActuator

The invention belongs to a static pressure measurement calibration instrument, and in particular relates to a gas pressure regulator which is designed by a new principle, and a gas pressure regulation method. The gas pressure regulator comprises a regulator main body, a transmission part, a piston assembly, a combination valve and a sealing piece. In the invention, mass regulation and capacity regulation are combined with each other, and the advantages of a mass gas pressure regulation method and a capacity gas pressure regulation method are combined together, so that higher control speed andhigher control accuracy can be realized by pressure regulation from a low range to a high range. The method comprises the following steps of: coarsely regulating a target pressure value in a mass gaspressure regulation mode and finely regulating the target pressure value in a capacity gas pressure regulation mode, namely increasing or reducing the mass of gas simultaneously for a front cavity and a rear cavity of the pressure regulator through the combination valve so as to make the target pressure value of the regulator coarsely realized; and driving a piston on a nut actuator to move back and forth in a main body cavity through a levorotatory guide screw rod and finely regulating to acquire the target pressure value.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

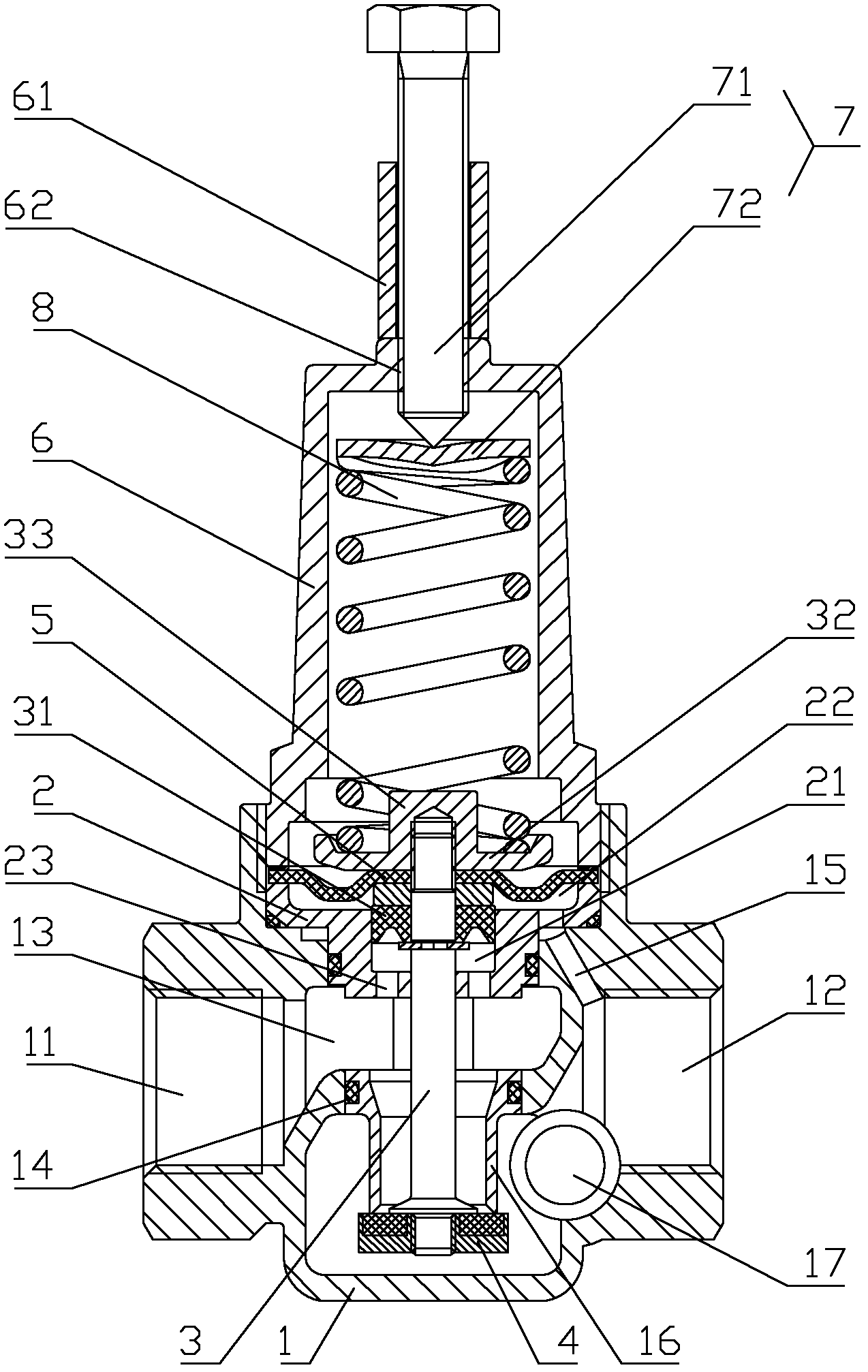

Adjustable high-flexibility low-pressure and stable-pressure pressure reducing valve

InactiveCN102425693ASimple structureReduce volumeEqualizing valvesSafety valvesCore componentEngineering

The invention discloses an adjustable high-flexibility low-pressure and stable-pressure pressure reducing valve, which comprises a valve body and a valve core component, wherein the valve body is provided with an inlet and an outlet; the valve core component is arranged in the valve body; a medium passage for communicating the inlet with the outlet is formed in the valve body; a throttling port is formed in the medium passage; the valve core component corresponds to the throttling port and is used for changing the medium pressure in front of and behind the throttling port; the valve core component comprises a valve core rack, a valve rod and a valve flap; the valve core rack is fixedly arranged in the valve body; the valve rod is arranged in the valve core rack; the valve flap is arranged at the lower end of the valve rod to change the flow rate of the medium passage; a sealing device is arranged between the valve rod and the valve core rack to isolate the upper part of the valve core rack from the lower part of the valve core rack; a pressure chamber in front of the valve is formed between the lower part of the valve core rack and the sealing device; the upper end of the valve core rack has a thin film structure, and a pressure chamber after the valve is formed between the upper end of the valve core rack and the upper part of the valve core rack; and a pressure adjusting structure is also arranged above the thin film structure. The valve has a simple and rational structure, is convenient to manufacture and mount, has high flexibility in pressure adjustment and has certain pressure stability, and the pressure adjustment range is adjustable.

Owner:ZHEJIANG DUNAN INTELLIGENT CONTROL TECH CO LTD

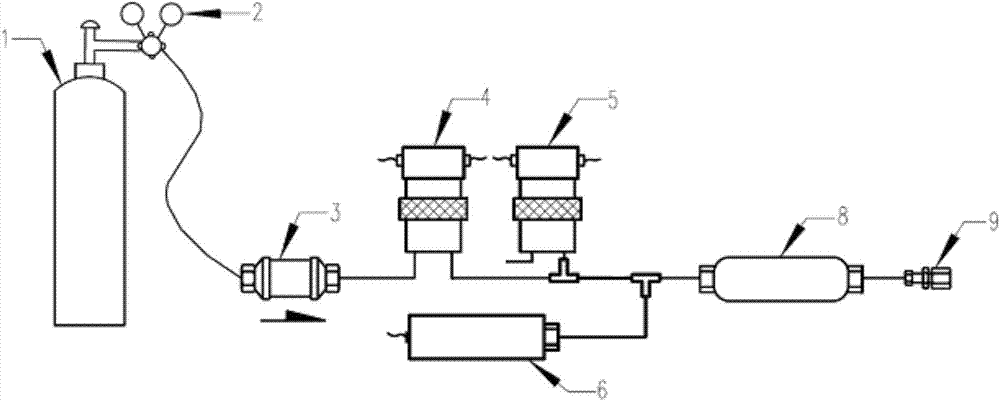

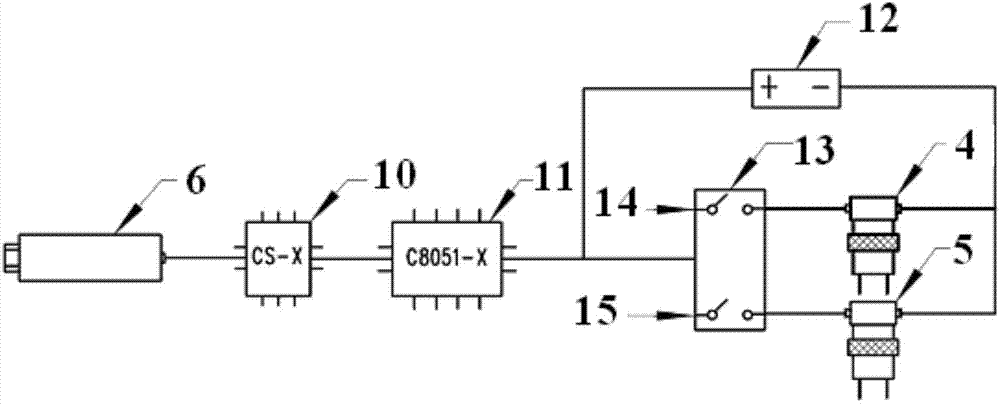

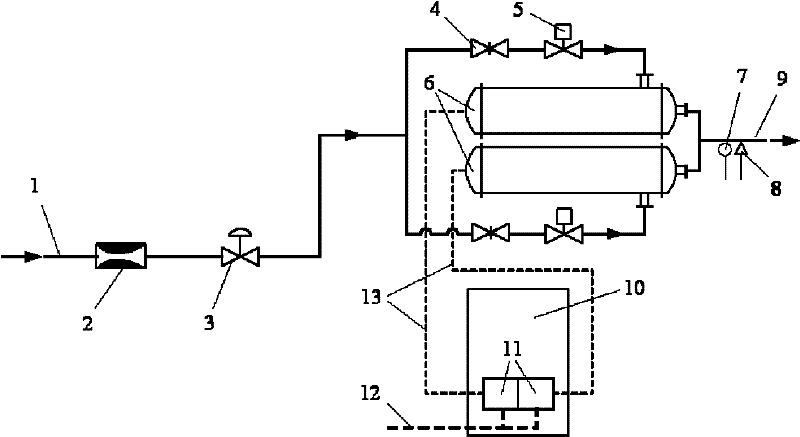

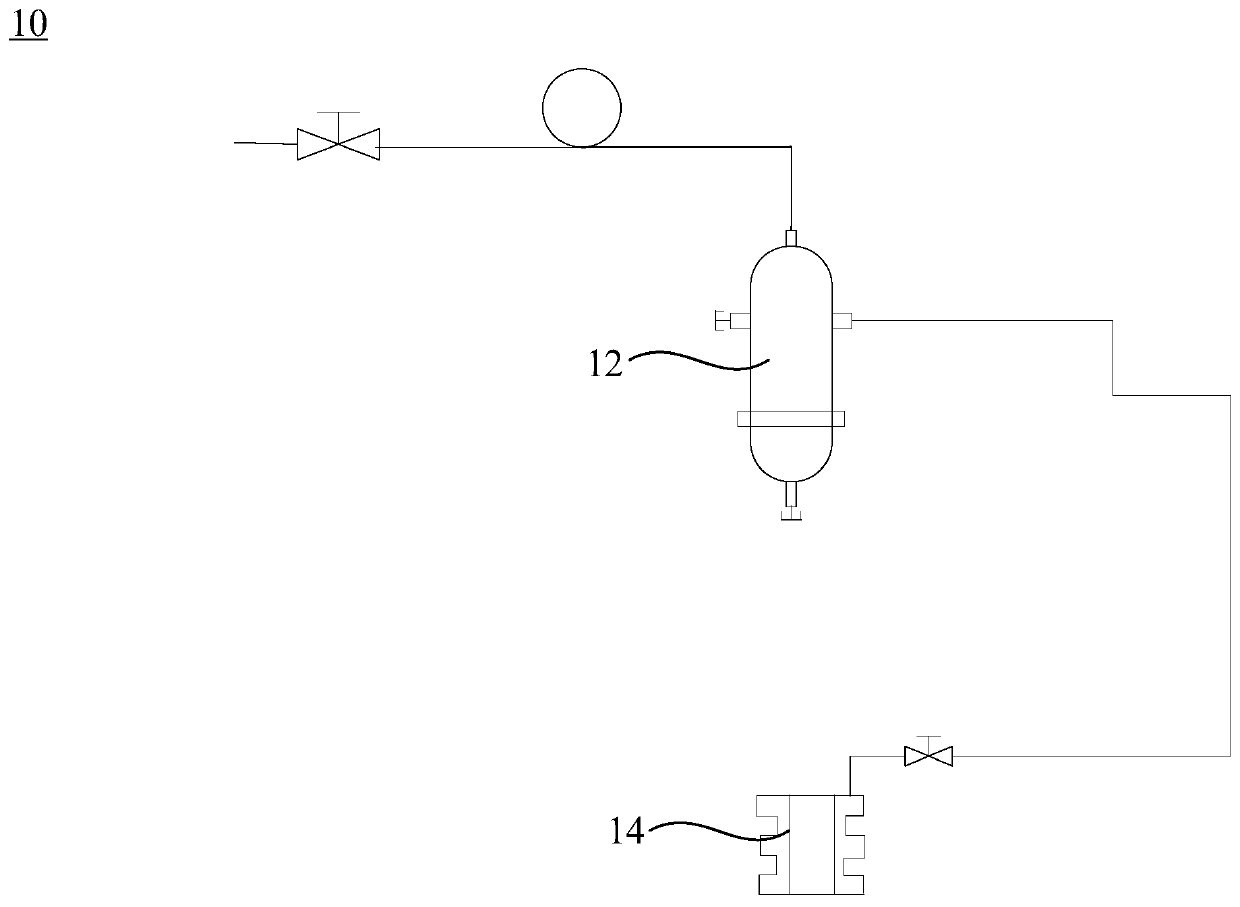

Gas pressure fast-regulating device and method based on pulse width modulation mode

ActiveCN103488203ALarge pressure adjustment rangeShorten the timeFluid pressure control using electric meansSolenoid valveEngineering

The invention relates to a gas pressure fast-regulating device and method based on the pulse width modulation mode and belongs to the technical field of static pressure measurement and calibration. The device comprises a gas channel part and a circuit part. The gas channel part comprises a gas source (1), a pressure relief valve (2), a filter (3), a pressurizing solenoid valve (4), a pressure relief solenoid valve (5), a pressure transmitter (6), a gas capacitor (8) and a test port (9). According to the device and method, through the flow control mode, a wider pressure regulating range is obtained, the solenoid valves are driven by adopting the relatively cheap pressure transmitter and reasonable circuit design and combining the pulse width modulation mode to save a large amount of time for digital acquisition and pressure control, and preceding-stage fast control is provided for higher accuracy gas pressure control.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

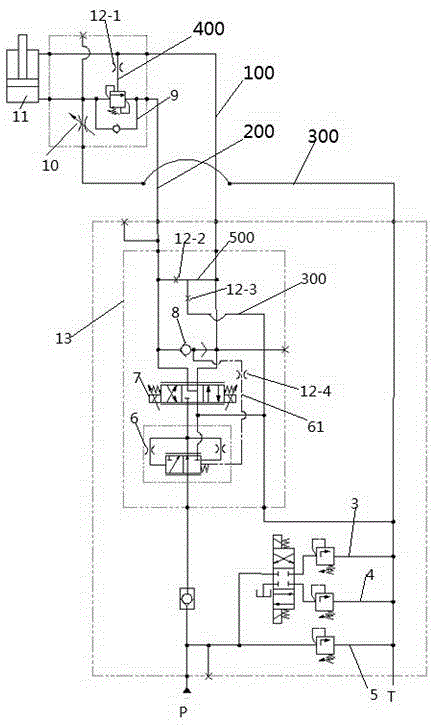

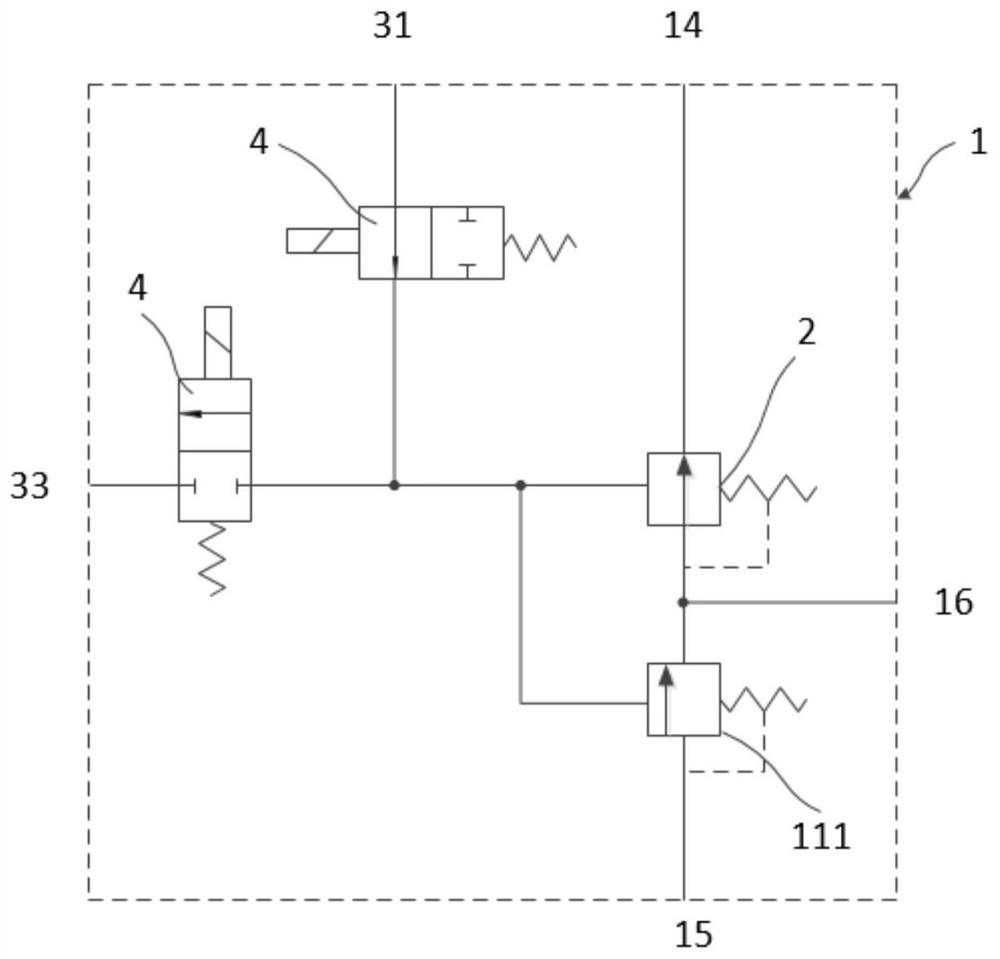

Piston lifting mechanism and hydraulic control device thereof

ActiveCN104879334AAvoid piston movement chatterGood lifting stabilityServomotor componentsServomotorsPistonPiston cylinder

The invention provides a piston lifting mechanism and a hydraulic control device thereof. The hydraulic control device comprises a first oil way and a second oil way, the first oil way is used for communication with a rod cavity of a piston cylinder in the piston lifting mechanism, and the second oil way is used for communication with a rodless cavity of the piston cylinder in the piston lifting mechanism. The second oil way is provided with a balance valve, the balance valve is provided with two operation ports and a control oil port, the two operation ports are in butt-joint communication with the second oil way, and the control oil port is communicated with the first oil way through a hydraulic control oil way with a damping hole section. When the hydraulic control device is applied to the piston lifting mechanism, a piston moves towards the rodless cavity, namely the piston moves downwards, hydraulic oil in the rodless cavity flows out slowly due to slow and stable opening of the balance valve, the piston moves slowly under the action of a load and high-pressure oil in the rod cavity, and high lifting stability is realized.

Owner:凯迈(洛阳)测控有限公司

Metal glass melt cast moulding method and its device

The invention discloses a forging moulding method and device of metal glass flux, which comprises the following steps: adding the alloy in the melting furnace; adjusting the temperature; extracting the gas in the mould when reaching the casting temperature; generating 5-15 KPa negative pressure; attracting the metal glass flux in the mould cavity to mould element. The device is characterized by the following: connecting the crucible in the melting furnace with the mould through attraction pipe; connecting the negative pressure generator with the top of mould through connection pipe; setting control valve, pressure measuring device and negative pressure stable device on the connection pipe sequently. The method can force gas pressure on the flux surface, which promotes the moulding course of metal glass flux.

Owner:HUAZHONG UNIV OF SCI & TECH

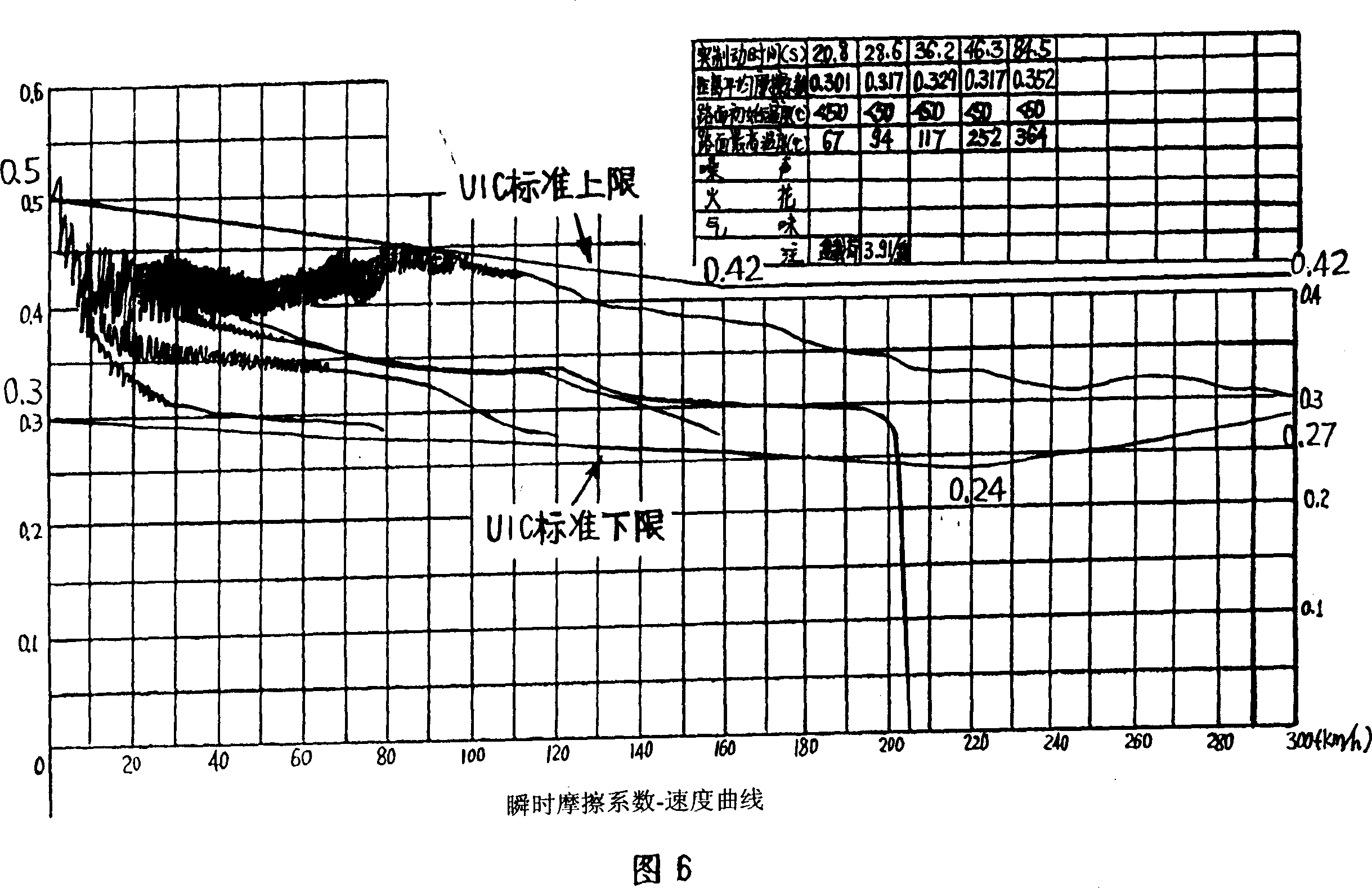

Production process of metal based sintered friction plate

InactiveCN1994628AHigh densityHigh dimensional accuracyOther chemical processesManufacturing technologyDying processes

The invention relates to a metal-base sinter abrasion blade production, wherein said blade uses copper, iron, etc as base, with abrasion adjust components as rigid particles and graphite particles, via powder mixing, cold compression, current heating dieing, to be processed into abrasion block. The invention uses current heating dieing process to improve the density, to adjust the abrasion property and reduce the abrasion. And the inventive method has high efficiency, low cost and high accuracy.

Owner:DALIAN JIAOTONG UNIVERSITY

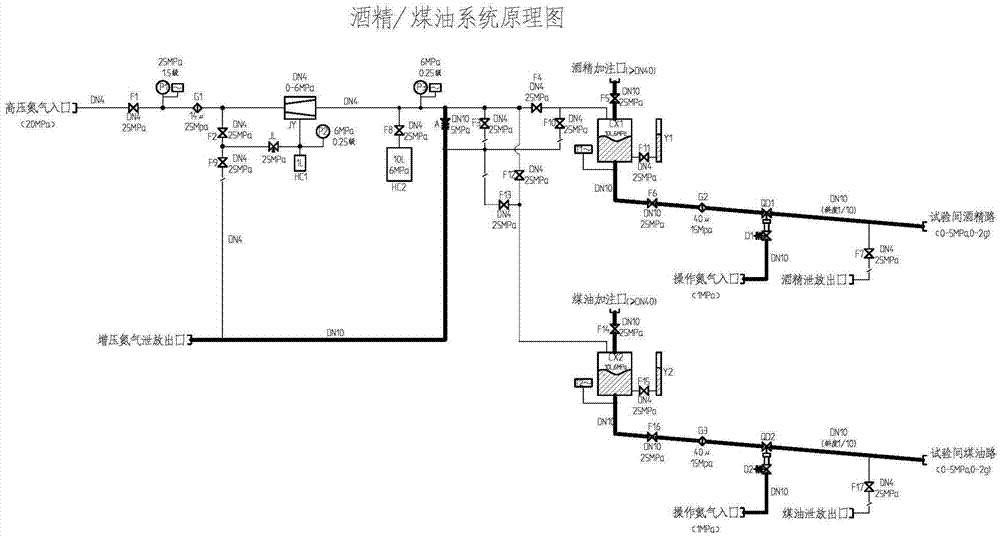

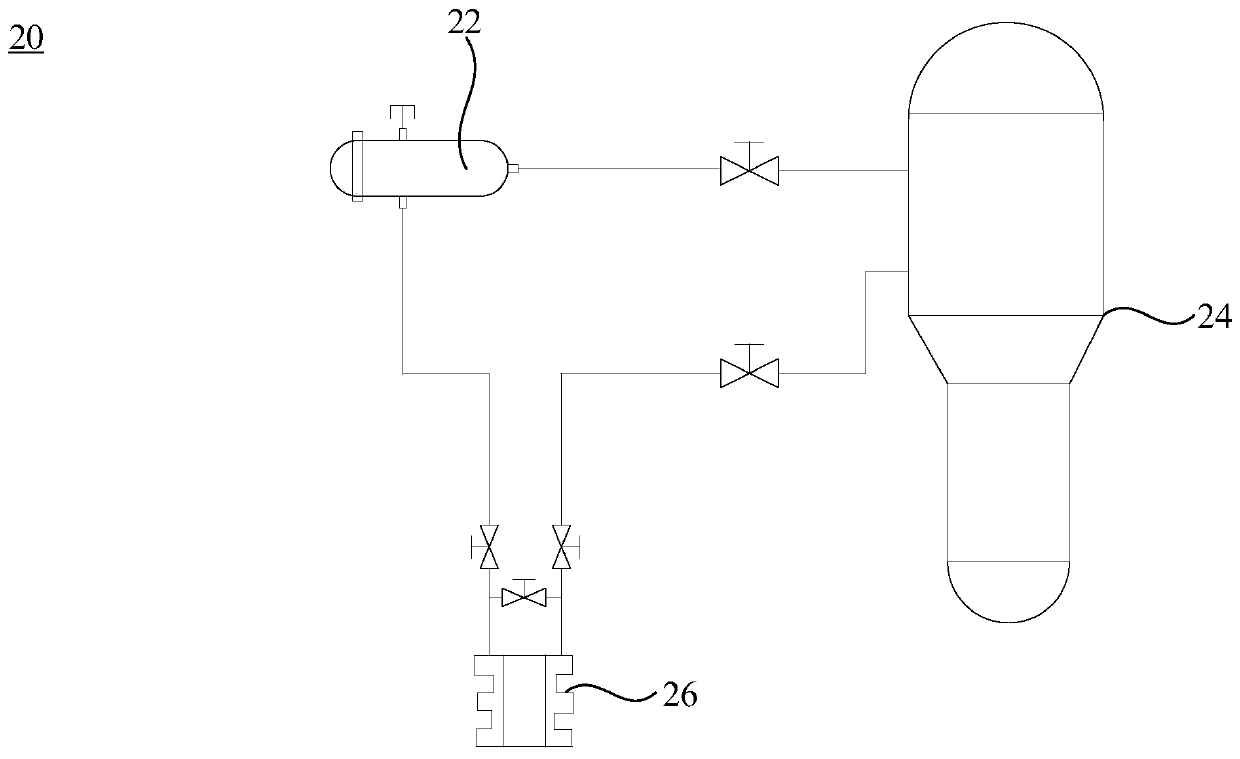

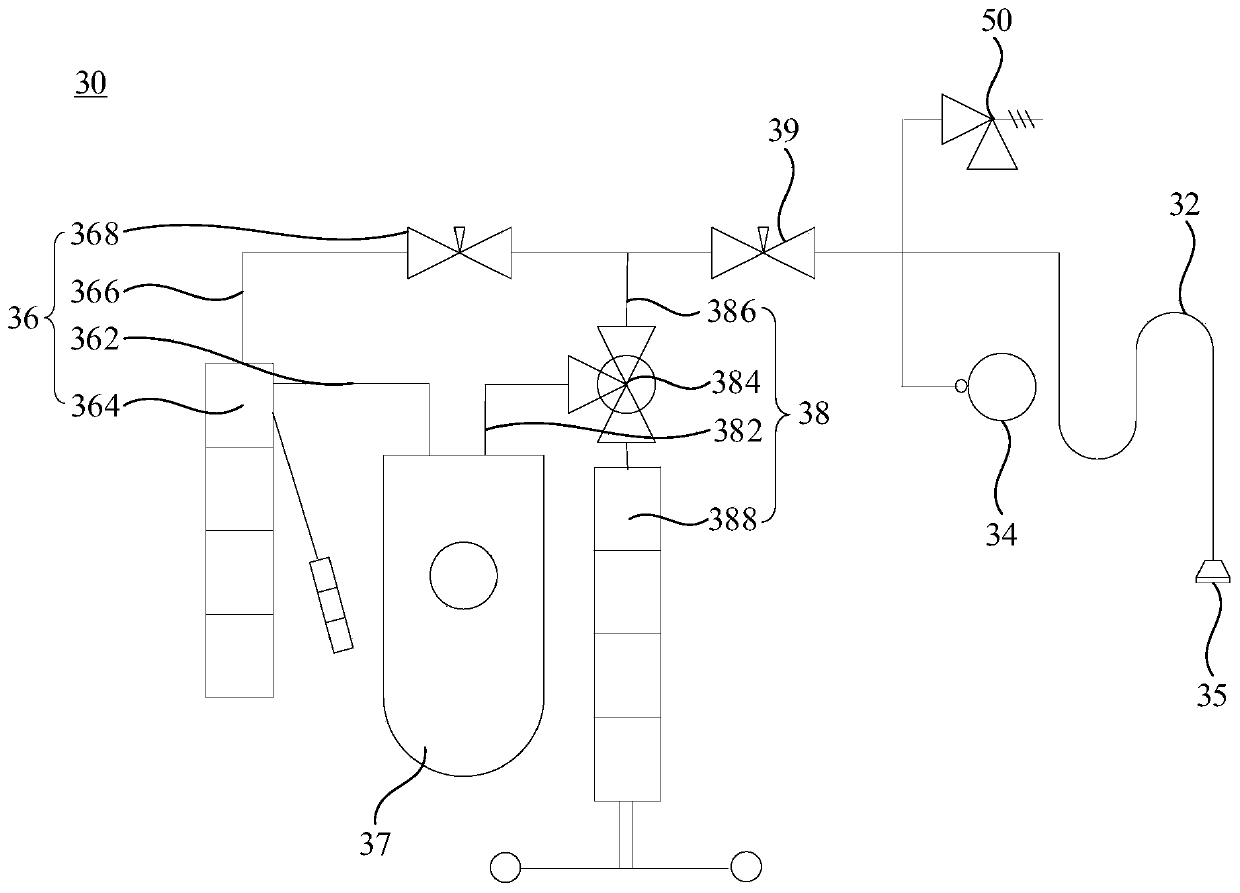

Alcohol/kerosene system of vacuum plume effect experiment system

InactiveCN103499427AQuick responseAccurate pressureGas-turbine engine testingAerodynamic testingAlcoholKerosene

The invention discloses an alcohol / kerosene system of a vacuum plume effect experiment system. The alcohol / kerosene system comprises a high-pressure nitrogen path, a commanding / replacing air path, a low-pressure nitrogen path, an alcohol path and a kerosene path. During a higher-pressure and larger-flow experiment, a working medium is boosted by directly utilizing an air regulation type pressure reducer, so that the pressure and flow responding speed of the working medium is higher; during a lower-pressure and small-flow experiment, the working medium is boosted by utilizing a pressure storage buffering tank matched with the air regulation type pressure reducer, so that the pressure and flow supplied by the working medium are more accurate, and small and mini flow experiments are especially suitable; therefore the pressure regulation range of the system is wide, and the suitability is strong. According to the alcohol / kerosene system of the vacuum plume effect experiment system, the high-pressure nitrogen path provides the air source for the air regulation type pressure reducer, and also provides a displacement function for the system; before the system feeds the working medium, the air in the pipeline is replaced by nitrogen, so that the safety accident caused by the reaction of the working medium and the air in the pipeline is avoided, the system is simplified, and the safety is improved.

Owner:BEIHANG UNIV

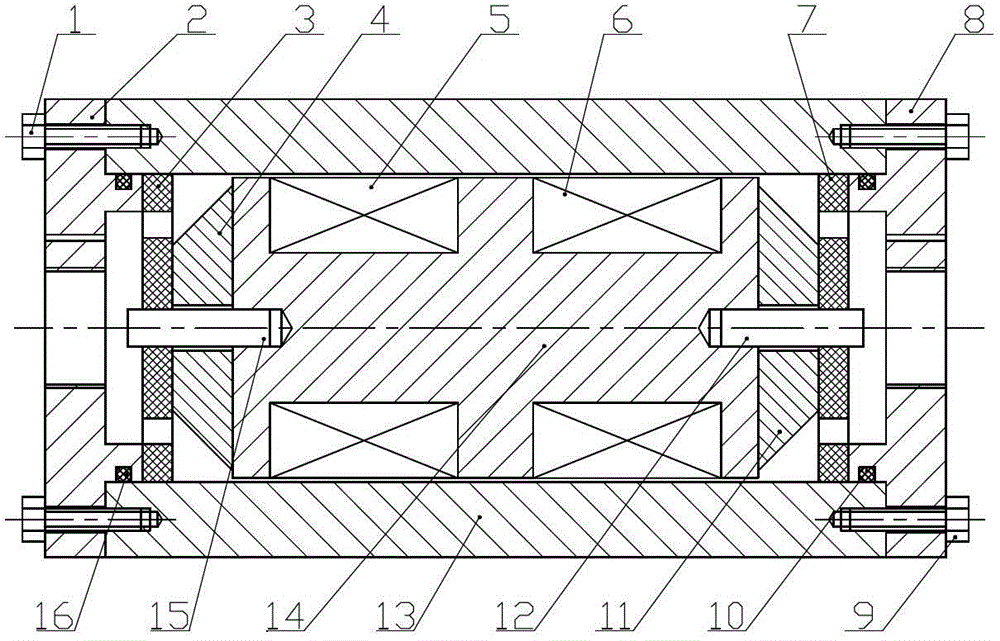

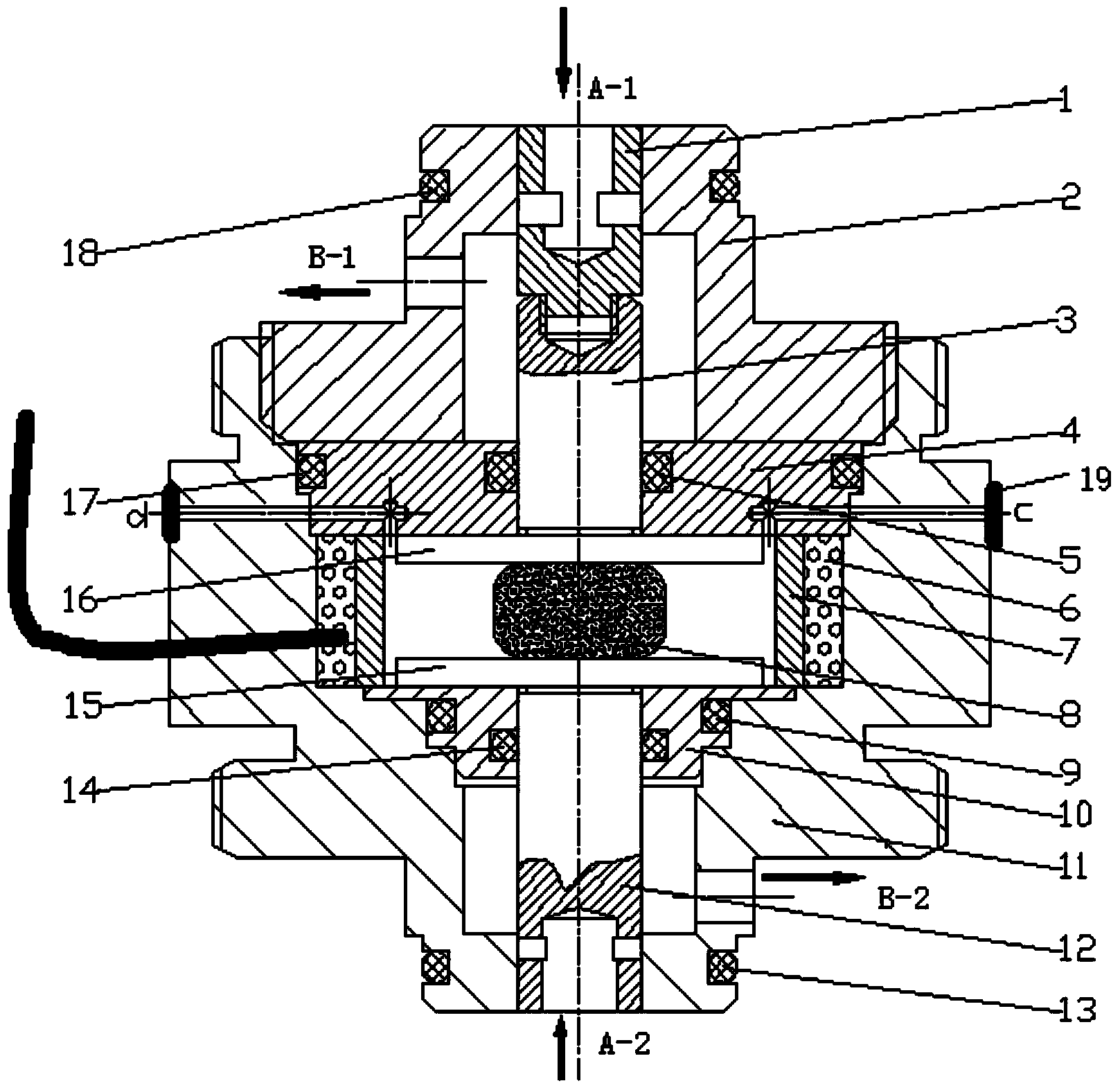

Three-stage pressure regulating double-coil type magneto-rheological valve

InactiveCN102691688BIncrease pressure differenceLarge pressure adjustment rangeServomotor componentsMagnetic currentPower flow

The invention discloses a three-stage pressure regulating double-coil type magneto-rheological valve which is composed of an end cover, a valve core, a valve body, a positioning block, a guide block, a positioning pin, a coil I, a coil II, a sealing ring, a screw and the like. When current with certain direction and size is input into the coil I and the coil II, a magnetic field can be generated in three damping gaps formed by the valve core and the valve body; and the direction of the magnetic field is vertical to the direction of a flowing direction of magneto-rheological liquid. When the magneto-rheological liquid flows into the damping gaps of the magneto-rheological valve, the magneto-rheological liquid is rapidly changed into a semi-solid state under the effect of the magnetic field; the viscosity of the magneto-rheological liquid is rapidly increased along the magnetic induction strength so as to cause that a pressure difference between two ends of the damping gaps to be increased; and therefore, the flowing of the magneto-rheological liquid is slowed or stopped. The pressure difference between the two ends of the damping gaps is controlled through controlling the size and the direction of the current input into the two coils, so as to form three-stage pressure regulation and control a pressure difference between an inlet and an outlet of the magneto-rheological valve. The magneto-rheological valve is applicable to a multi-stage low-pressure small-flow hydraulic control system with an adjustable pressure.

Owner:EAST CHINA JIAOTONG UNIVERSITY

An electric heating system to replace high temperature gas in turbocharger test

InactiveCN102288414ASimple system structureImprove safety and reliabilityEngine testingInlet temperatureElectric heating

An electric heating system for replacing high-temperature gas in a turbocharger test, characterized in that it includes: an electric heater (group) (6), a power regulator (group) (11), a power regulating cabinet (10), a flow meter (2), regulating valve (group) (3), etc. By using the electric heating system to generate high-temperature gas, it replaces the traditional high-temperature gas to impact the turbine to do work and drive the supercharger to run. Compared with the traditional method, the electric heating system of the turbocharger test of the present invention has the advantages of simple system, safety and reliability; clean and pollution-free, and will not overheat and burn out the turbine; the temperature stability of the turbine inlet is high, and the accuracy of temperature regulation is also high. Higher; wider flow and turbine inlet pressure adjustment range, higher precision; longer life, convenient use and maintenance, high economy and many other advantages.

Owner:BEIHANG UNIV

Gunpowder combustion gas component test apparatus

ActiveCN105911220ALarge pressure adjustment rangeLess quantityAnalysing gaseous mixturesWater bathsSensor array

The invention discloses a gunpowder combustion gas component test apparatus. The apparatus comprises a closed combustion chamber, an igniting controller, a pressure and temperature adjusting device, a flow control device, a sensor array, a data acquisition and analysis device, a standard gas cylinder array and a water bath constant temperature device. The apparatus solves the problems of difficult collection of a gunpowder combustion generation gas, and tedious steps and low automatic degree of multiple gas components. The apparatus can accurately adjust the initial state of gunpowder combustion, automatically collects the gas and tests the concentrations of the multiple gas components in a gunpowder combustion product, so the apparatus is suitable for testing the concentrations of the multiple gas components in the combustion product of solid propellants and propellant powder at a specific initial temperature under an initial pressure, and is of great significance to research the gunpowder combustion mechanism and the formula and technological design of the propellants and the propellant powder.

Owner:XIAN MODERN CHEM RES INST

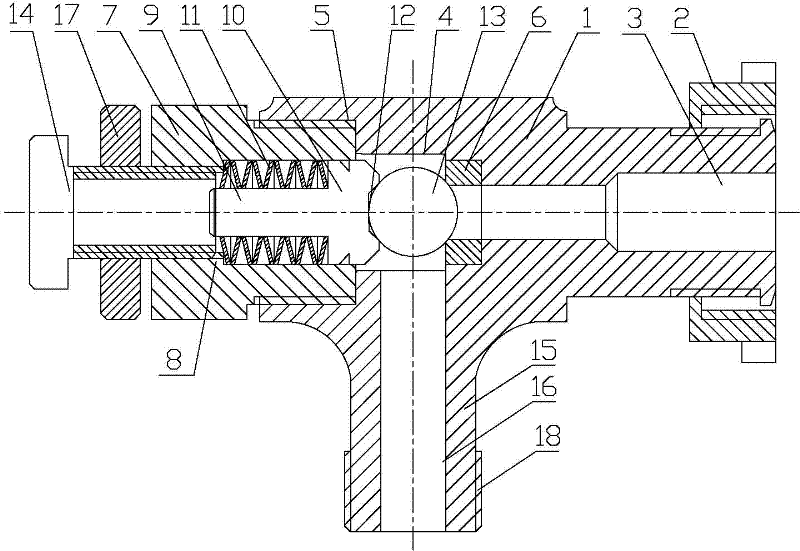

High-precision pressure stabilizing combination valve

PendingCN107606240ALarge pressure adjustment rangeHigh adjustment accuracyCheck valvesEqualizing valvesSystem pressureEngineering

The invention discloses a high-precision pressure stabilizing combination valve. The high-precision pressure stabilizing combination valve is composed of a safety valve, a one-way valve, a shell and acontact which are mutually connected through threads. A safety shutter is arranged in a valve element of the safety valve, a spring is arranged in the safety shutter, a spacer is placed at the upperend of the spring, the safety valve is formed by adjusting the thread of a screw to be connected with an insert, and the safety valve is fixedly connected with the shell through the thread. An air inlet at the upper end of the shell and a throttle hole are integrated, a one-way shutter is arranged in a valve element of the one-way valve, a spring is arranged in the one-way shutter, the spring is fixed to the shell through the thread of the contact, and the other end of the contact is connected with a system. According to the technical scheme of the high-precision pressure stabilizing combination valve, the structure is compact, the size is small, the requirements for a large inlet pressure fluctuation range and stable outlet pressure can be met, meanwhile the functions of pressure overloadprotection and reverse pressure cut-off are achieved, accurate adjustment is conducted on system pressure, the pressure adjustable range is large, and the adjustment precision is high.

Owner:XINXIANG HUAHANG AVIATION HYDRAULIC EQUIP

Device for ink-jet printing gel microsphere, and printing method

PendingCN111605186AUniform sizeImprove efficiency3D object support structuresManufacturing data aquisition/processingSpray nozzleThree dimensional motion

The invention discloses a device for ink-jet printing a gel microsphere, and a printing method. The device for ink-jet printing the gel microsphere comprises a computer, a three-dimensional motion system, a first ink box, a second ink box, a first multi-orifice piezoelectric spray nozzle and a second multi-orifice piezoelectric spray nozzle. The first ink box and the second ink box are arranged ina pressurization device; the pressurization device is used for providing liquid outlet pressure to the first ink box and the second ink box; the first multi-orifice piezoelectric spray nozzle communicates with a liquid outlet of the first ink box; the second multi-orifice piezoelectric spray nozzle communicates with a liquid outlet of the second ink box; the first multi-orifice piezoelectric spray nozzle and the second multi-orifice piezoelectric spray nozzle are arranged on the three-dimensional motion system; the computer is electrically connected with the three-dimensional motion system, the first multi-orifice piezoelectric spray nozzle and the second multi-orifice piezoelectric spray nozzle; a nd the computer is used for controlling the three-dimensional motion system to move, and isalso used for controlling the first multi-orifice piezoelectric spray nozzle and the second multi-orifice piezoelectric spray nozzle to jet ink. The invention provides the device with high manufacturing efficiency, simplicity and convenience in operation, and capability on accurately controlling the forming of the gel microsphere.

Owner:GENERAL HOSPITAL OF PLA +1

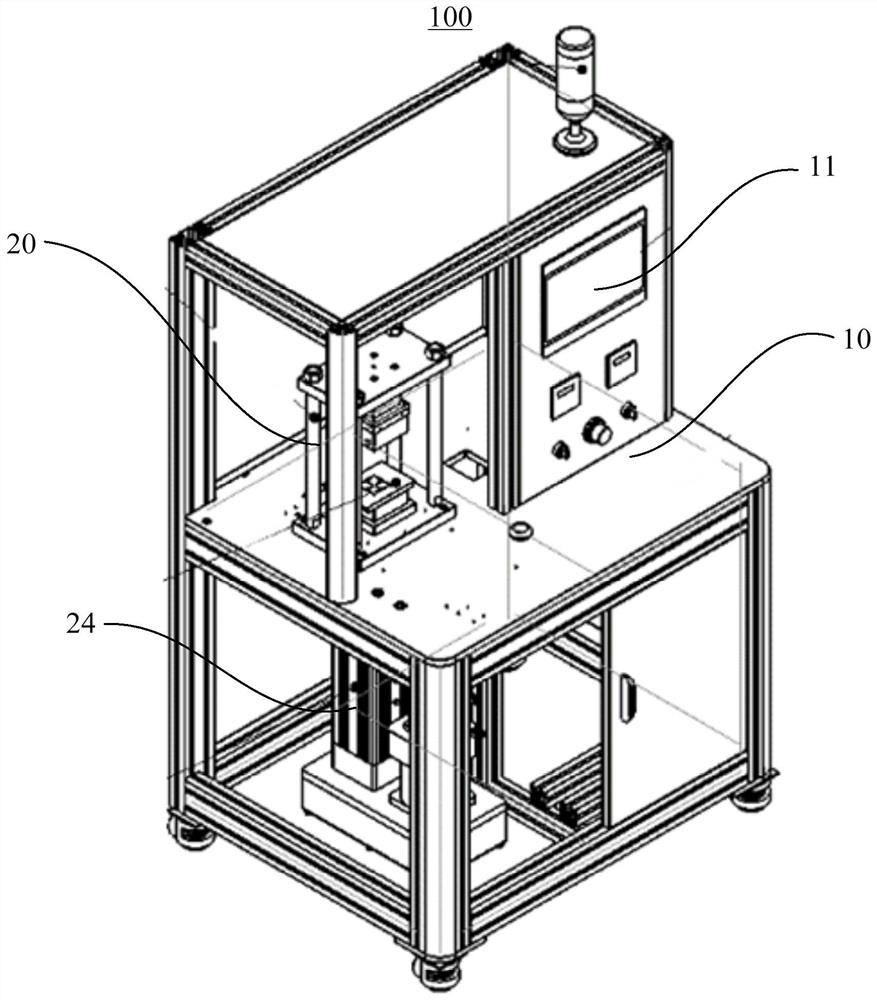

Pressure cylinder, pressurizing device and hot-pressing sintering equipment

PendingCN111980988ALarge pressure adjustment rangeMeet pressurization needsSemiconductor/solid-state device manufacturingFluid-pressure convertersDevice materialEngineering

The invention provides a pressure cylinder, a pressurizing device applying the pressure cylinder and hot-pressing sintering equipment applying the pressurizing device. The pressure cylinder comprisesa cylinder body and a plurality of piston rods, wherein a plurality of pressure cavities are formed in the cylinder body; every two adjacent pressure cavities communicate with each other through a first through hole; a second through hole communicating with one pressure cavity is further formed in the cylinder body; the second through holes and the first through holes are coaxially formed; a plurality of air inlet holes and a plurality of air outlet holes are formed in the cylinder body; one air inlet hole and one air outlet hole communicate with one pressure cavity; each piston rod is movablyarranged in one pressure cavity and penetrates through one first through hole to extend into another pressure cavity, so that the piston rods are sequentially propped against one another; and one piston rod penetrates through the second through hole to extend out of the cylinder body. According to the technical scheme, the pressure adjusting range of the hot-pressing sintering equipment is enlarged, and the pressurizing requirements of different types of semiconductor devices are met.

Owner:深圳市先进连接科技有限公司

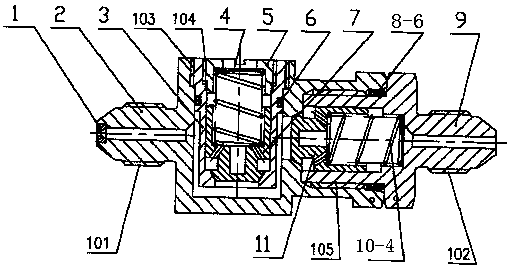

Two-way flow control valve

ActiveCN103899810AQuick responseLarge pressure adjustment rangeOperating means/releasing devices for valvesSpringsControl valvesVALVE PORT

The invention discloses a two-way flow control valve. The two-way flow control valve comprises an upper valve body 2 and a lower valve body 11 which are coaxially and fixedly connected with each other. An upper valve core 1, an upper thrust bar 3 and an upper inner valve body 4 are sequentially installed in the upper valve body 2 from top to bottom. A lower thrust bar 12, a lower inner valve body 10, a coil 6 and a non-magnetic sleeve 7 are sequentially and coaxially installed in the lower valve body 11 from bottom top, and the coil 6 and the non-magnetic sleeve 7 are arranged in a nested mode. An upper pole plate 16, a magnetorheological elastomer 8 and a lower pole plate 15 are sequentially installed in the non-magnetic sleeve 7 and located between the upper thrust bar 3 and the lower thrust bar 12 from top to bottom. The two-way flow control valve is further provided with two oil inlet and oil outlet sets. By means of the two-way flow control valve, continuous control over flow and control over valve opening pressure can be achieved by controlling magnetic field intensity, and the valve opening pressure can be changed according to external use conditions; besides, two-way pressure control is achieved through one coil, and therefore the two-way flow control valve can serve as two one-way flow control valves; the two-way flow control valve is high in response speed and wide in pressure control range.

Owner:JILIN UNIV

Spring sheet type pressure release valve

InactiveCN102418497ACompact and reasonable structureEasy to useWell/borehole valve arrangementsSealing/packingWell drillingWell cementing

The invention relates to the technical field of emergency pressure release tools in well drilling and cementation operations, in particular to a spring sheet type pressure release valve. The pressure release valve comprises a valve body, a ball seat, a cavity spring seat, a mounting body, a spring sheet, a ball and an adjusting lead screw; an axial passage is formed in the valve body; a first ring slot, the inside diameter of which is greater than that of the axial passage, is formed in the middle part of the valve body; the ball seat is clamped on the right part of the first ring slot; the inner part of the ball seat is communicated with the axial passage; a second ring slot, the inside diameter of which is greater than that of the first ring slot, is formed in the valve body on the left part of the first ring slot; the right part of the cavity spring seat is fixedly arranged in the second ring slot; and a mounting head, the outside diameter of which is greater than that of the mounting body, is fixed at the right end of the mounting body. The pressure release valve is reasonable and compact in structure and convenient to use; automatic opening and closing of the valve are realized by using the spring sheet; through the pressure release valve, overpressure protection on the personnel safety and a high pressure system can be realized without halting, the pressure adjusting range is enlarged, and the released pressure can be randomly adjusted; and the pressure release valve is convenient to assemble and disassemble.

Owner:CNPC XIBU DRILLING ENG

Method for preparing high-performance-fiber-reinforced hard bulletproof composite material

The invention discloses a method for preparing a high-performance-fiber-reinforced hard bulletproof composite material. According to the method, woven fabrics of high-performance carbon fibers, aramid fibers and high-strength polyethylene fibers serve as prefabricated members, the reinforcing effect of the high-performance carbon fibers and the aramid fibers and the bonding effect of high-strength polyethylene molten into a matrix at a certain temperature are fully used, the prefabricated members are compression-molded through a compression molding device, and the composite material of the carbon fibers, the aramid fibers and the high-strength polyethylene fibers is obtained. The obtained composite material has different mixing synergistic effects, the bulletproof performance and the mechanical property can be effectively improved, and the composite material has good observability and a wide pressure regulation range. The quality of the inner structure of the composite material is easy to guarantee, the boundary dimension accuracy is high, and therefore the composite material is widely applied to the field of industrial composite materials.

Owner:ZHEJIANG SCI-TECH UNIV

Pressurized belt type deep dehydrator and application method thereof

InactiveCN113754226AEven by forceExtended service lifeSludge treatmentMoving filtering element filtersFluid phaseHigh energy

The invention provides a pressurized belt type deep dehydrator which comprises a main body frame and a filter belt, wherein the main body frame is internally provided with a feeding module, a filter pressing module and a discharging module; the feeding module comprises a uniform distribution mechanism, the uniform distribution mechanism is arranged above the filter belt, and a feeding opening is formed in the upper portion of the uniform distribution mechanism; the filter pressing module comprises a supporting roller and a squeezing mechanism, and the filter belt is wound on the supporting roller and the squeezing mechanism; the discharging module comprises a discharging device and a flushing mechanism; the working surface of the washing mechanism covers the filter belt; and the main body frame is internally provided with a plurality of sets of tensioning mechanisms, and the tensioning mechanisms have various different tensioning pressures including low, medium, high and ultrahigh tensioning pressure. According to the properties of different materials, the acting force on the materials is changed by adjusting the tensioning pressure of the filter belt, and solid-phase and liquid-phase separation of the materials is achieved. The pressure adjusting range is wide, low energy consumption and high energy efficiency are truly achieved, the pretreatment process is combined with various solid waste treatment technologies, the solid waste treatment problem is solved, and the ecological environment is improved.

Owner:上海凌逍环保科技有限公司

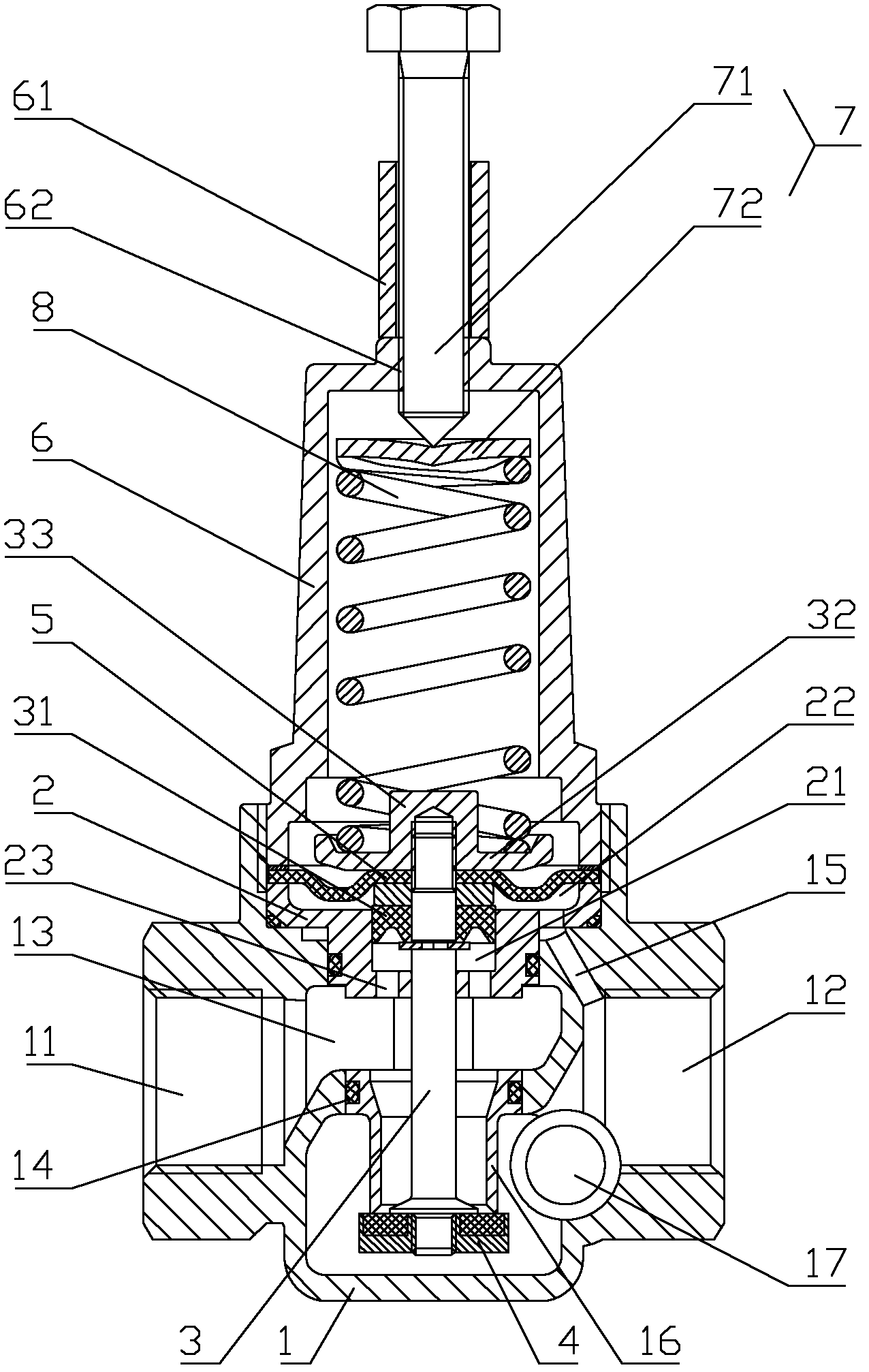

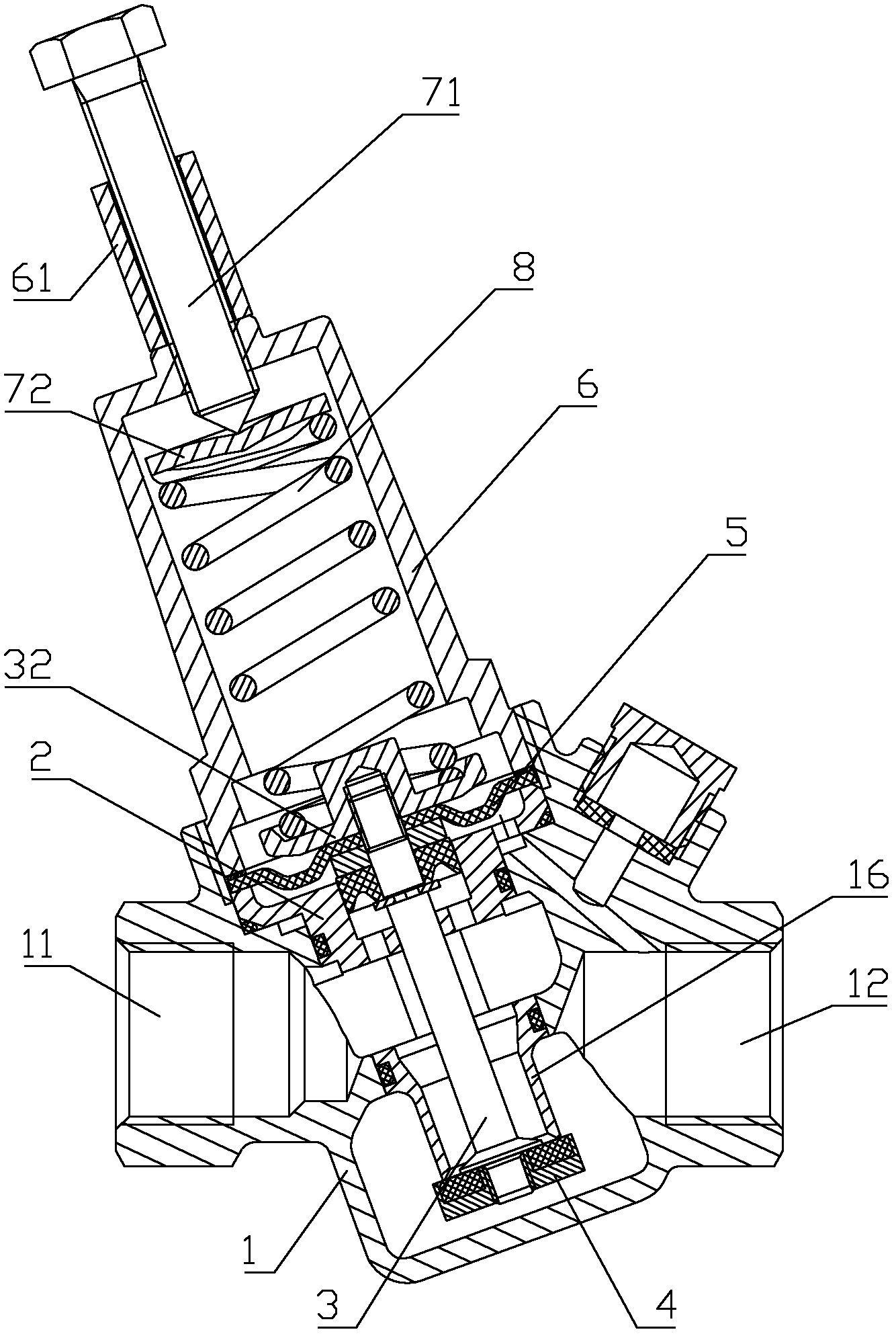

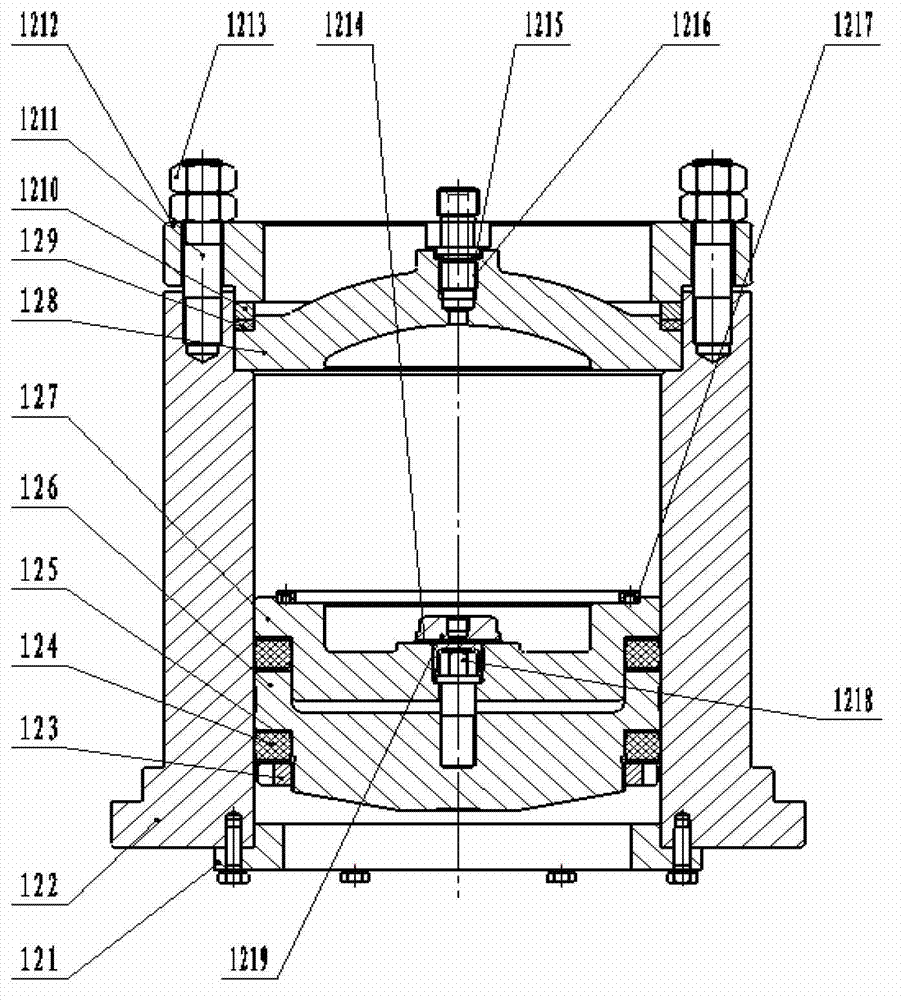

Hydraulic drive pressure reducing valve for wind tunnel

ActiveCN103115154AGood airflow symmetryLarge pressure adjustment rangeOperating means/releasing devices for valvesLift valveEngineeringPiston

The invention discloses a hydraulic drive pressure reducing valve for a wind tunnel. The hydraulic drive pressure reducing valve for the wind tunnel comprises an air inlet, an air outlet, a valve body (6), a closing piston (12), a pressure adjusting piston (5), a rod (16), an oil pipe mouth (22) and a plate base (17). The pressure adjusting piston (5) includes a piston body (51), plates (52), gaskets (53), nuts (54), seal rings (55, 56) and an upper cover (57). The closing piston (12) comprises a cover (128), inner pistons (127), outer pistons (126), roller bodies (122) and a filler neck (1216). According to the hydraulic drive pressure reducing valve for the wind tunnel, the profile curves of the plates are designed to be elliptic characteristic curves, and therefore the pressure reducing valve in the working state is enabled to obtain linear or close to linear regulating characteristics. Meanwhile, the hydraulic drive pressure reducing valve for the wind tunnel has the advantages of being good in airflow symmetry properties, wide in adjusting range, short in time of full opening and full closing , and capable of completing a wind tunnel blowing experimental task with a mach number range of 5-8.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Gas pressure regulator and gas pressure regulation method

ActiveCN102135778BIncrease or decrease in massImprove control accuracyFluid pressure measurementFluid pressure control without auxillary powerEngineeringActuator

The invention belongs to a static pressure measurement calibration instrument, and in particular relates to a gas pressure regulator which is designed by a new principle, and a gas pressure regulation method. The gas pressure regulator comprises a regulator main body, a transmission part, a piston assembly, a combination valve and a sealing piece. In the invention, mass regulation and capacity regulation are combined with each other, and the advantages of a mass gas pressure regulation method and a capacity gas pressure regulation method are combined together, so that higher control speed andhigher control accuracy can be realized by pressure regulation from a low range to a high range. The method comprises the following steps of: coarsely regulating a target pressure value in a mass gaspressure regulation mode and finely regulating the target pressure value in a capacity gas pressure regulation mode, namely increasing or reducing the mass of gas simultaneously for a front cavity and a rear cavity of the pressure regulator through the combination valve so as to make the target pressure value of the regulator coarsely realized; and driving a piston on a nut actuator to move back and forth in a main body cavity through a levorotatory guide screw rod and finely regulating to acquire the target pressure value.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

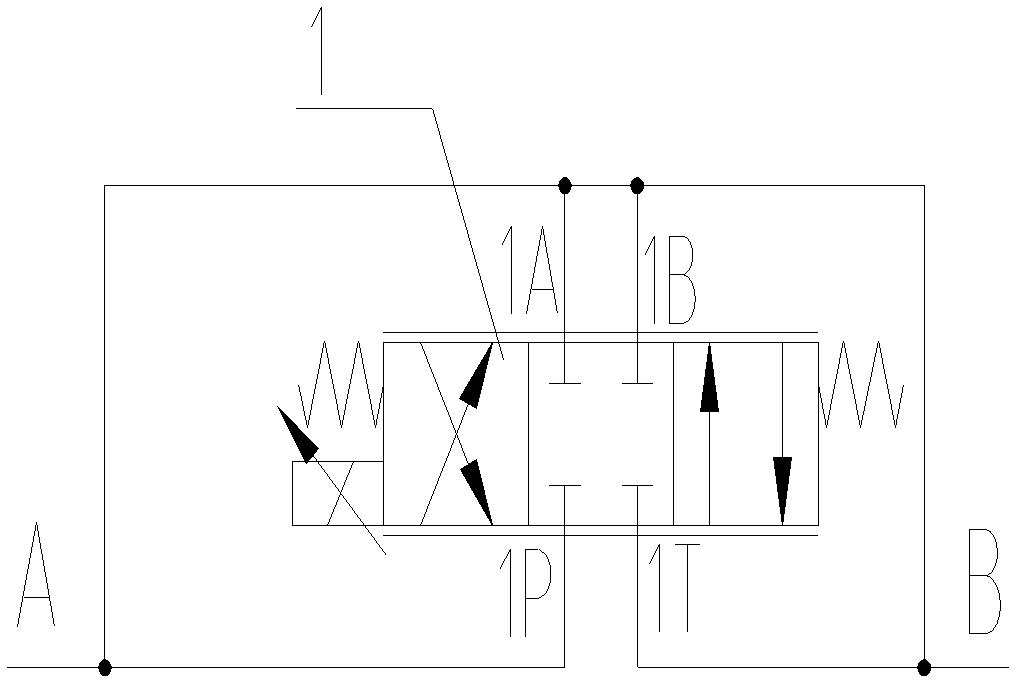

Throttle loop

ActiveCN102536942AAdjust flow capacityRealize concatenationServomotor componentsThrottleControl theory

The invention discloses a throttle loop. The throttle loop comprises a first working port (A), a second working port (B), a directional flow control valve (1) and four switch valves (21, 22, 23, 24), wherein the first working port (A) is communicated with the pressure oil port (1P) of the directional flow control valve (1); the four switch valves (21, 22, 23, 24) are connected between the first working port (A) and the first working oil port (1A) of the directional flow control valve (1), between the first working oil port (1A) and the second working oil port (1B) of the directional flow control valve (1), between the second working oil port (1B) and the second working port (B) of the directional flow control valve (1) and between the second working port (B) and the oil return port (1T) of the directional flow control valve (1) in series respectively. The through-current capability of the throttle loop can be regulated, so that the throttle loop is applicable for a relatively wide pressure regulation range.

Owner:ZOOMLION HEAVY IND CO LTD

Damping-clearance mechanical adjustable double-coil magnetorheological valve

InactiveCN103062146BAdjustable distanceLarge pressure adjustment rangeServomotor componentsMagnetic currentPower flow

Owner:EAST CHINA JIAOTONG UNIVERSITY

Gas high-sealing intermediate-speed pressure regulating system and method

ActiveCN110439792AHigh neutron fluxReduce absorptionFlexible member pumpsEnergy storageGas cylinderMetallic materials

The invention discloses a gas high-sealing intermediate-speed pressure regulating system and method. The gas high-sealing intermediate-speed pressure regulating system is composed of an inflation tank, a deflation tank, a pneumatic compressor, a drive gas cylinder, a vacuum pump, a gas storage tank, a valve, a pipeline, an instrument and the like. The whole system is in all metal material seal, and a multi-level anti-leakage measure is set. The pressure of a reaction gas screen is increased or reduced at an intermediate speed through a gas loop in the intermediate-speed inflation and deflationprocesses of the inflation tank and the deflation tank. A pneumatic compressor is a metal bellows diaphragm compressor under the dual effects of gas pressure drive and vacuum drive, the drive gas inflow and exhaust processes are achieved through an inflow pipeline connected with the drive gas bottle and an exhaust pipeline connected with a ventilator, process gas in the deflation tank is repeatedly sucked to be compressed into intermediate-pressure gas to be exhausted into the inflation tank, the pneumatic compressor can be driven under vacuum through the vacuum pump in turns so that the process gas with the pressure lower than normal pressure in the deflation tank can be sucked, the process gas is driven under gas pressure, compressed and pressurized into the inflation tank, and residuesare reduced. The gas high-sealing intermediate-speed pressure regulating system and method can be used for gas drive liquid lifting, a nuclear fuel power transient-state test and the like.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Pressure testing device for pipeline

InactiveCN109946015AWatch for leaksEasy to adjustMeasurement of fluid loss/gain rateFluid pressure measurementInternal pressureLine tubing

The invention relates to a pressure testing device for a pipeline. The device comprises a connecting pipe, a pressure detector, a rough adjusting device, a fine adjusting device and a first control valve, wherein the connecting pipe is used for connecting the pipeline to be tested; the pressure detector is used for detecting the pressure in the connecting pipe; the rough pressure regulating deviceis used for conveying testing liquid to the connecting pipe and the pipeline to be tested in order to enable the connecting pipe and the pipeline to be tested to be full of liquid and keep the innerpressure at first preset pressure value; the fine pressure regulating device is used for conveying the testing liquid to the connecting pipe and the pipeline to be tested in order to enable the innerpressure of the connecting pipe to increase from the first preset pressure value to the second preset pressure value which is beyond the first preset pressure value; the first control valve is arranged at the connecting pipe and is used for opening and closing communication between the pipeline to be tested and the rough pressure regulating device as well as the communication between the pipelineto be tested and the fine adjusting device. The pressure testing device is wide in pressure regulating range, high in accuracy, and more intuitive in leaking condition observation.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +2

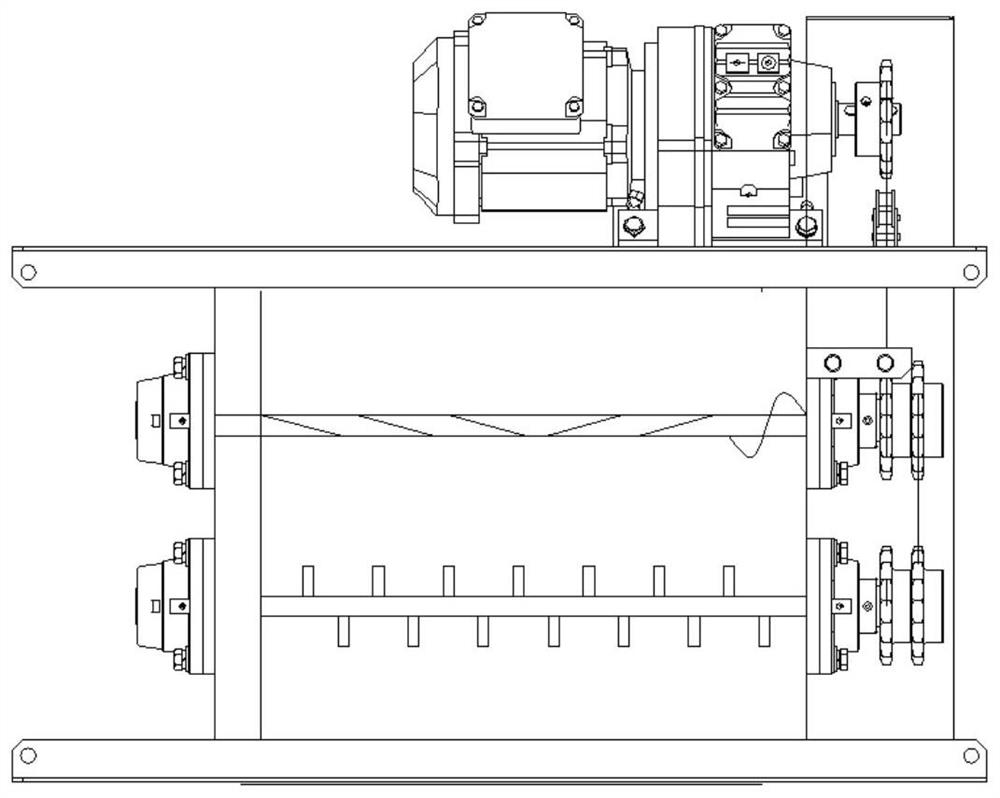

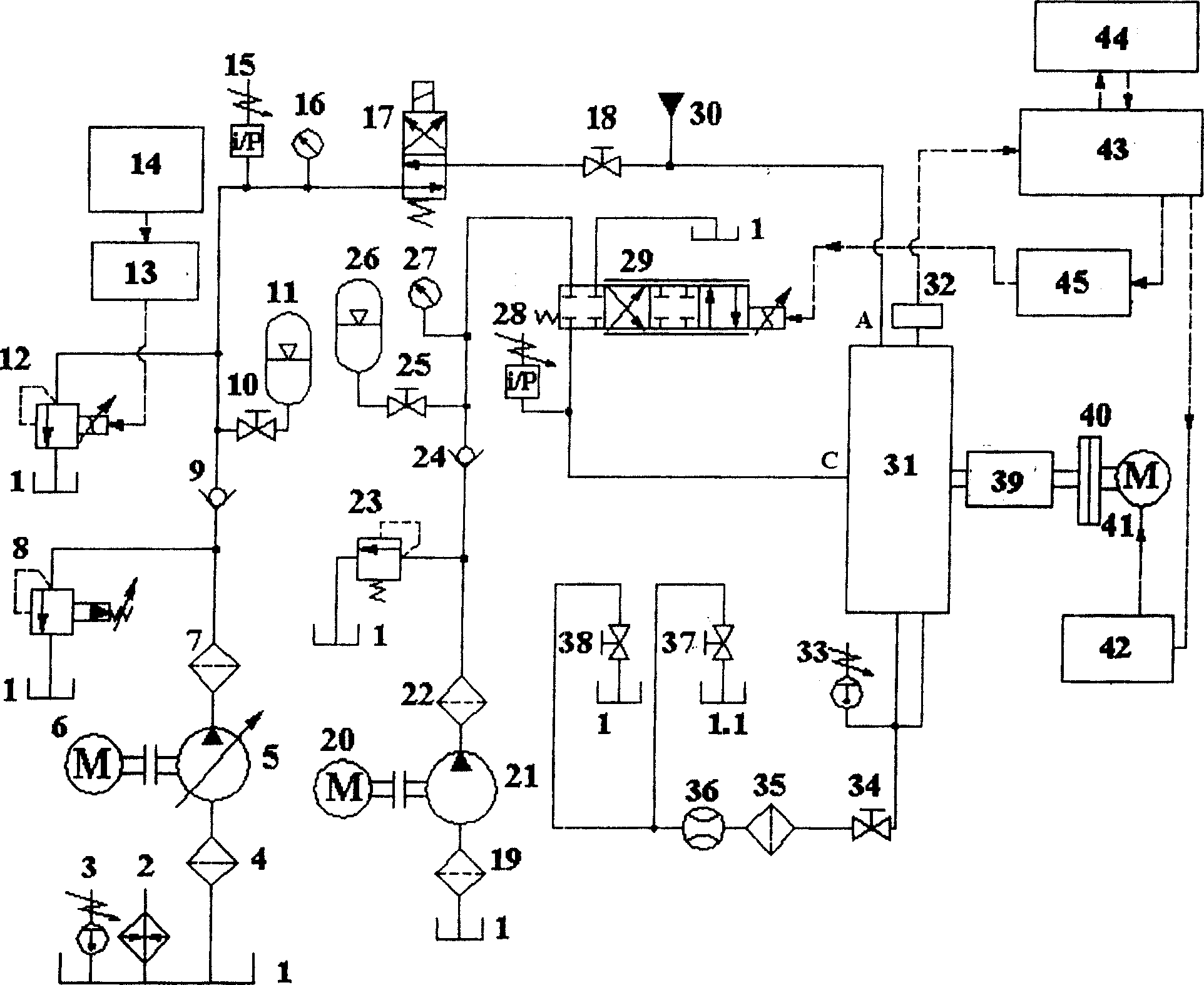

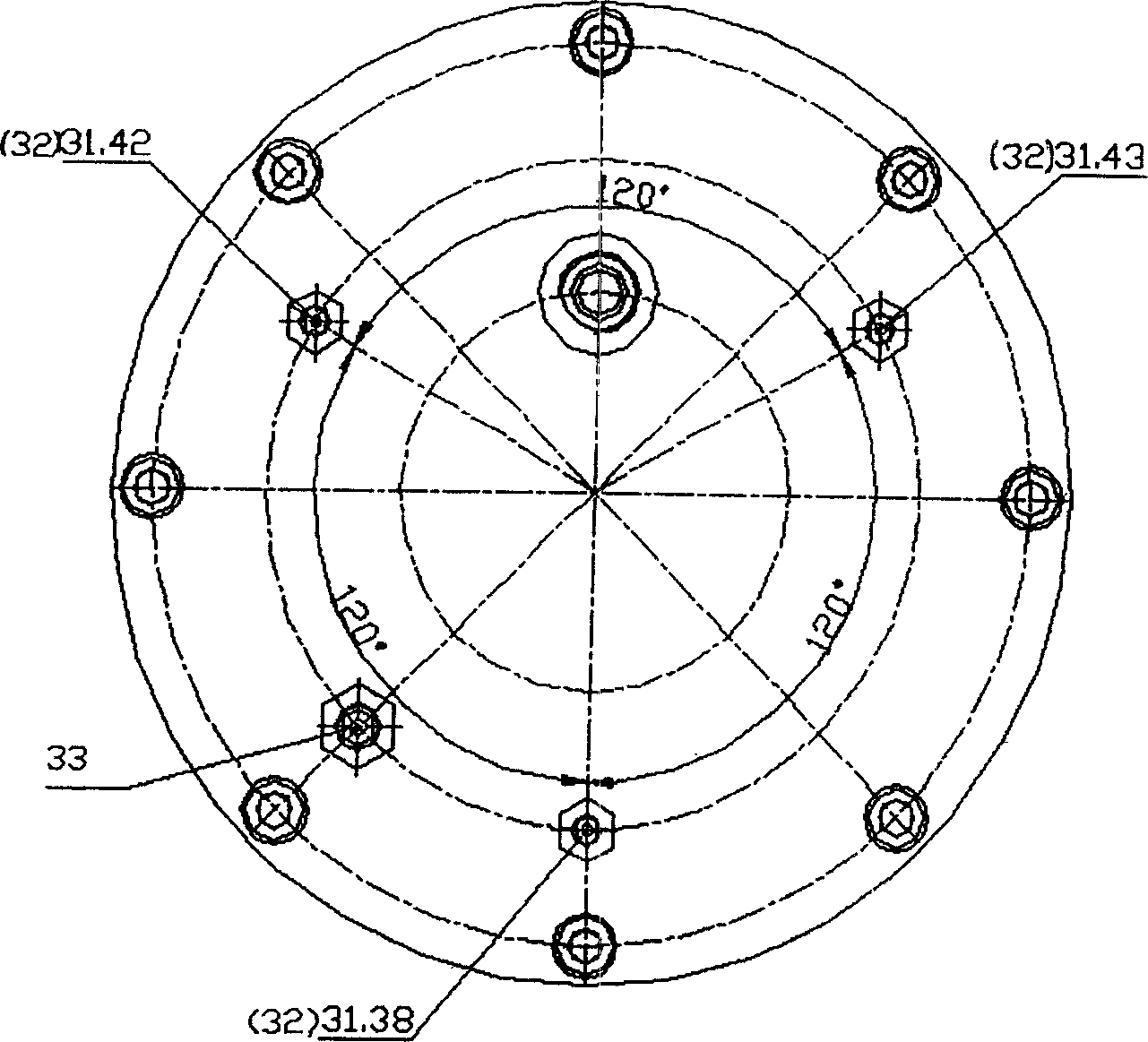

Lubricating property testing device for distribution flow pair of axial plunger pump

InactiveCN1235032CImplement Feedback ControlReal-time monitoring of experiment statusUsing mechanical meansMaterial analysisTest fixtureFeedback control

This invention discloses an apparatus for measuring the lubrication of axial plunger pump auxiliary. Its hydraulic power system is composed of main oil line and loading oil line, wherein main oil line serves to provide hydraulic oil to test bench of lubricant film, and loading oil line serves to provide relevant pressing force to auxiliary to balance hydraulic backward thrust from seal band; test bench of lubricant film is to test auxiliary lubrication under various working situations; monitoring and controlling system is to monitor the experiment status in real time and to collect multiple working parameters during the experiment to accomplish the analysis and process of the datum in measuring experiment. Computer is employed to accomplish the on-line monitoring of various working situations to ensure high safety and stability.

Owner:ZHEJIANG UNIV

Supply pressure adjusting device

InactiveCN113719360AFlexible to meet the needs of differential pressure workFast pressure regulation responseInternal combustion piston enginesEngine controllersPressure differencePilot valve

The invention discloses a supply pressure adjusting device, and belongs to the technical field of automobile engines. A control shell is arranged at the end, close to an energy storage cavity, of a valve body in a sealed mode, and a pressure medium inlet, the energy storage cavity and a pressure medium outlet which are communicated are formed in the control shell. A gas inlet cavity, a first installation cavity and a second installation cavity are sequentially and coaxially arranged in the valve body, the outer circumferential face of a pilot valve element and the inner circumferential face of the second installation cavity are matched in a sealed mode, a gas pressure adjusting cavity is separated, and stop valves are arranged at the pressure medium inlet and the pressure medium outlet of the control shell. According to the control strategy, the stop valves of the pressure medium inlet and the pressure medium outlet are rapidly controlled, a pressure medium is supplemented or released for the energy storage cavity storing the pressure medium, therefore, the pressure adjusting response is fast, the control precision is high, the pressure adjusting range is wide, and the pressure difference range of the energy storage cavity and the gas pressure adjusting cavity can be freely and accurately adjusted.

Owner:FAW JIEFANG AUTOMOTIVE CO

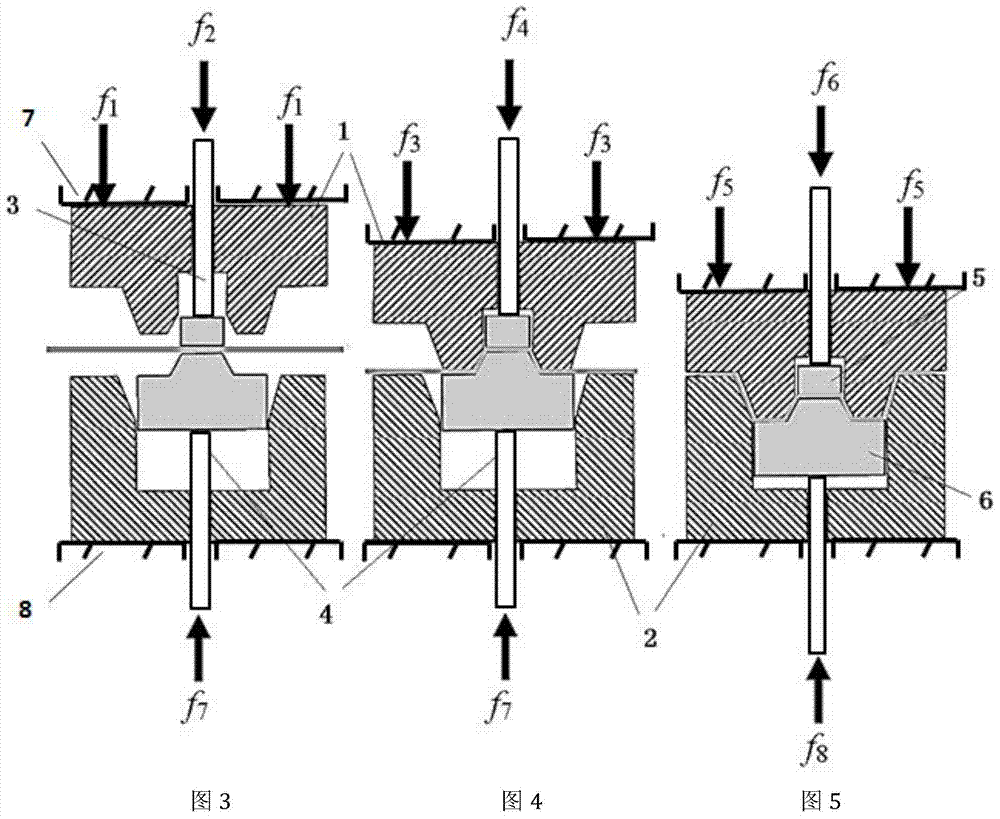

Pressure cooling process of segmented reinforcing type parts of hot forming steel plate, and pressing machine servo ejector rod devices

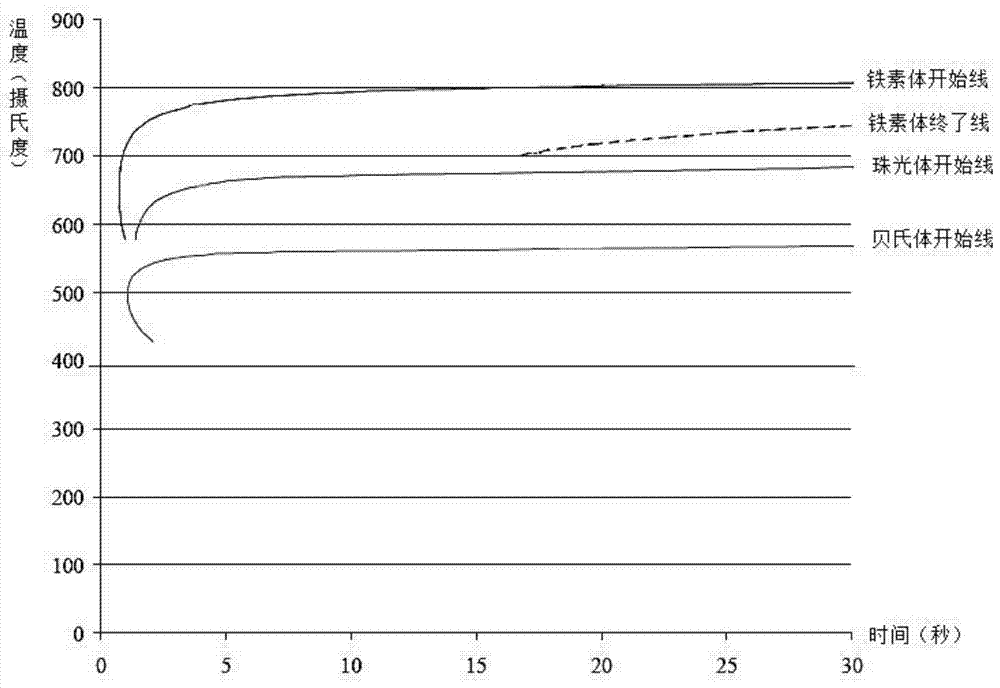

ActiveCN103785733AModes of Controlling Collision FailuresProtection securityShaping toolsSheet steelCooling speed

The invention discloses a pressure cooling process of segmented reinforcing type parts of a hot forming steel plate, and pressing machine servo ejector rod devices. Through the independent pressing machine servo ejector rod devices, the magnitude of loading force borne by a workpiece and / or force bearing and pressure keeping time for the workpiece are adjusted, and therefore the cooling speed of each sub-area of the workpiece is controlled, different types of material mechanical performance of the sub-areas of the workpiece are obtained. Required material characteristics can be achieved for any area according to the design requirements, no additional die heating device needs to be arranged, and production cost and procedure complexity are greatly reduced.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

Vibroflot

Owner:BEIJING VIBROFLOTATION ENG

Gas decompressor

InactiveCN109611572ADecompression achievedSimple structurePlug valvesOperating means/releasing devices for valvesHigh pressure chamberMechanical engineering

The invention relates to the technical field of gas pipeline control, and discloses a gas decompressor. The gas decompressor comprises a decompressor shell, a valve element, a valve cover and a stepping motor; the decompressor shell comprises a high-pressure chamber, a low-pressure chamber, a decompressor inlet communicating with the high-pressure chamber and a decompressor outlet communicating with the low-pressure chamber; the stepping motor is connected with the valve element and used for controlling circumferential motion of the valve element in the decompressor shell, the valve cover restricts axial motion of the valve element, and a circumferential slit groove is formed in the cylinder surface, communicating with the decompressor shell, of the valve element; and when the valve element rotates to the condition that the slit groove is in contact with the high-pressure chamber, and gas coming from the decompressor inlet and entering from the high-pressure chamber through throttlingof the slit groove enters the low-temperature chamber and flows out from the decompressor outlet. The pressure of the decompressor outlet can be adjusted in a wide-range and high-precision mode, and decompression of the gas is realized.

Owner:BEIJING AEROSPACE TECH INST

Hot-blast stove with multiple spraying holes

The invention discloses a hot-blast stove with multiple spraying holes. The hot-blast stove comprises a burning section, a first air mixing section and a second air mixing section. A main nozzle is arranged at the front end of the burning section, and an automatic ignition nozzle and a recirculating air induced pipe used for ventilation towards the inside of the burning section are arranged outside the burning section. The first air mixing section comprises an outer tube body and a metal multiple-spraying-hole air mixing barrel which is coaxial with the outer tube body and serves as an inner tube body. An annular gap or annular space is reserved between the outer tube body and the multiple-spraying-hole air mixing barrel serving as the inner tube body to be used as an air intake chamber. A plurality of spraying holes are evenly distributed in the wall of the multiple-spraying-hole air mixing barrel. The front end of the multiple-spraying-hole air mixing barrel, serving as the inner tube body, of the first air mixing section is connected with the rear end of the burning section in a sealing mode. A first hot-air outlet is formed in the rear end of the multiple-spraying-hole air mixing barrel. A recirculating air inlet is formed in the wall of the outer tube body of the first air mixing section and is connected with a recirculating air hose. By means of the hot-blast stove with the multiple spraying holes, high-temperature NOx generation is reduced, fast and uniform mixing of circulation cooling air and high-temperature hot air is guaranteed, the whole equipment is compact and small in size, and the hot-blast stove can be arranged flexibly according to production needs.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com