Gas pressure fast-regulating device and method based on pulse width modulation mode

A Gas Pressure, Pulse Width Modulation Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

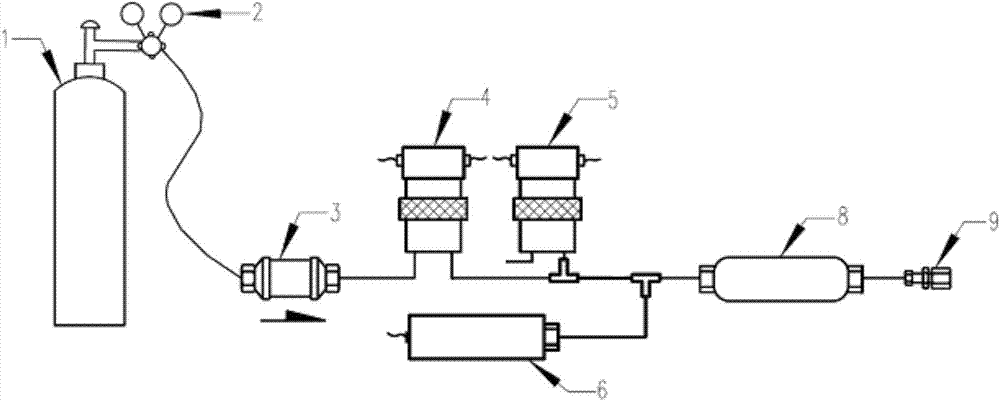

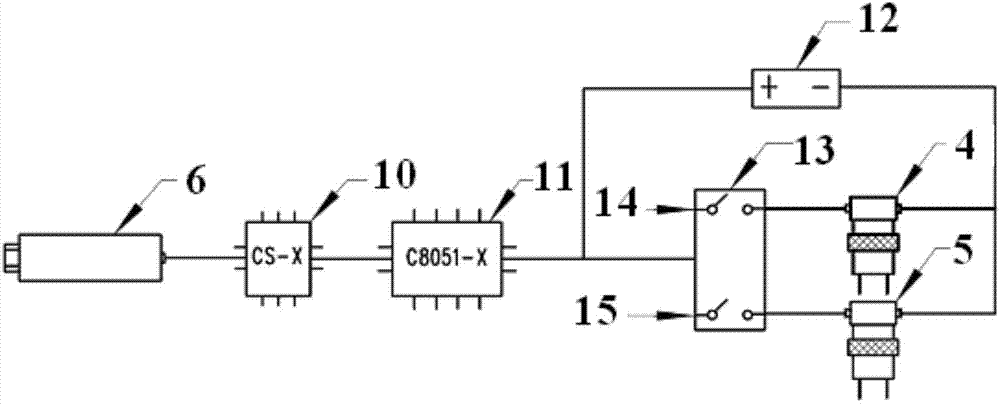

[0042]Gas pressure rapid adjustment device based on pulse width modulation, the device includes a gas circuit part and a circuit part; the gas circuit part includes a gas source 1, a pressure reducing valve 2, a filter 3, a boost solenoid valve 4, and a pressure relief solenoid valve 5 , pressure transmitter 6, gas capacity 8 and test port 9;

[0043] The booster solenoid valve 4 and the pressure relief solenoid valve 5 are all normally closed solenoid valves, which are respectively driven by pulse width modulation, that is, the switching frequency of the solenoid valve is adjusted by changing the period of the control pulse train, and the width of the control pulse is changed. Or the duty cycle, to adjust the length of time for the solenoid valve to be opened or closed;

[0044] The gas source 1 is connected to the pressure reducing valve 2 through a pipeline, the pressure reducing valve 2 is connected to the filter 3 through a pipeline, the outlet of the filter 3 is connecte...

Embodiment 2

[0066] The gas pressure rapid adjustment method based on the pulse width modulation method, the steps are:

[0067] Step 1: The input target pressure value is 0.5MPa, adjust the pressure reducing valve 2, so that the output pressure of the air source 1 is 1.5MPa, and the single-chip microcomputer 11 converts the input target pressure value into a voltage value V proportional to it 1 =2.5V, the pressure transmitter 6 measures the current pressure as 1MPa, and the AD sampling chip 10 collects the voltage value V fed back by the pressure transmitter 6 2 =5.0V, and sent to the single-chip microcomputer 11, the single-chip microcomputer 11 pairs voltage value V 1 , V 2 is compared, the result is V 2 greater than V 1 , immediately the current pressure is greater than the target pressure, the channel B15 of the solid state relay 13 is closed, the 12V voltage is applied to the pressure relief solenoid valve 5, the pressure boost solenoid valve 4 is closed, the pressure relief solen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com