Alcohol/kerosene system of vacuum plume effect experiment system

A technology of plume effect and experimental system, applied in the field of liquid pressure control, can solve the problems of being unsuitable for low-pressure and small-flow engines, large adjustment range, large flow rate, etc., to achieve the effect of wide pressure adjustment range, improved safety, and simplified system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0046] Connection relationship:

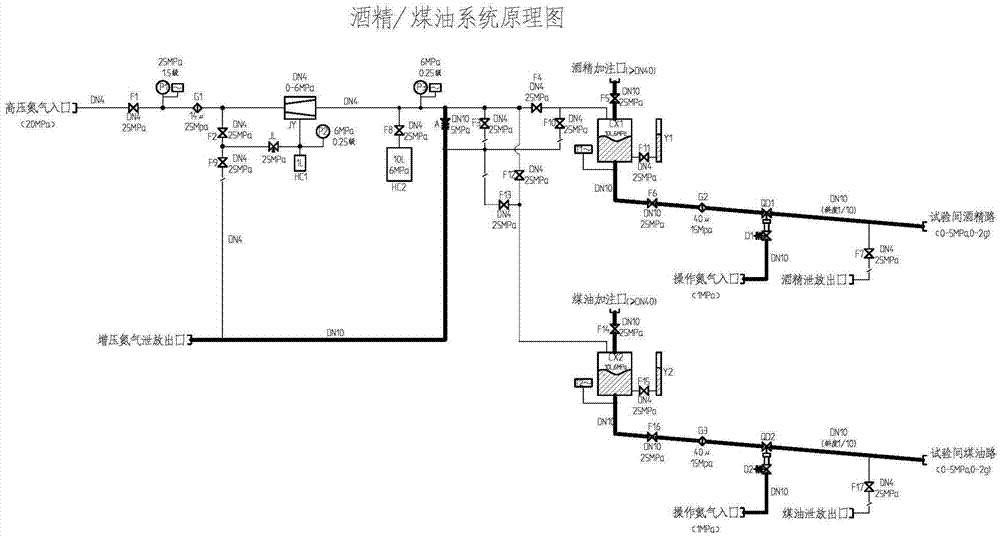

[0047] The present invention is a vacuum plume effect experimental system alcohol / kerosene system, such as figure 1 As shown, including high pressure nitrogen line, pilot / displacement air line, low pressure nitrogen line, alcohol line and kerosene line.

[0048] The high-pressure nitrogen circuit includes the high-pressure intake hand valve F1, the high-pressure gauge P1 and its pressure sensor, and the high-pressure filter G1.

[0049] The inlet of the high-pressure intake hand valve F1 is connected to the high-pressure nitrogen source, and the outlet is connected to the high-pressure filter G1; the high-pressure gauge P1 and its pressure sensor are connected to the pipeline between the high-pressure intake hand valve F1 and the high-pressure filter G1; the high-pressure filter The outlet of G1 is connected to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com