Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Inhibition of sinking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing sharp type epoxide resin binding agent diamond abrasive tool

ActiveCN103056788AImprove bindingInhibit sheddingAbrasion apparatusGrinding devicesFirming agentEpoxide

The invention discloses a method for preparing a sharp type epoxide resin binding agent diamond abrasive tool. A working layer is mainly made of diamond abrasive, an epoxide resin binding agent, a curing agent, an auxiliary abrasive, a filler and an auxiliary assistant. The method comprises steps of uniformly mixing 5-20 parts by mass of self-sharpening diamond, 5-28 parts by mass of auxiliary abrasive, 10-40 parts by mass of filler and 0.5-10 parts by mass of auxiliary assistant through a machine; uniformly mixing the mixture, 17-25 parts by mass of liquid epoxide resin and 5-25 parts of curing agent; injecting the fluid mixture to a plastic die through a pouring mode; and obtaining the sharp type epoxide resin binding agent diamond abrasive tool after curing. Compared with the method for preparing the abrasive tool through hot press molding, the method has the advantages that the process is simple, the energy is saved, the emission is reduced, the pollution of solid powder on the environment is reduced, the method is environment-friendly, the production speed is quick, the sharpening degree is high, the self-sharpening performance is good, the polishing effect is good and the service life is long.

Owner:惠安宇信金刚石工具有限公司

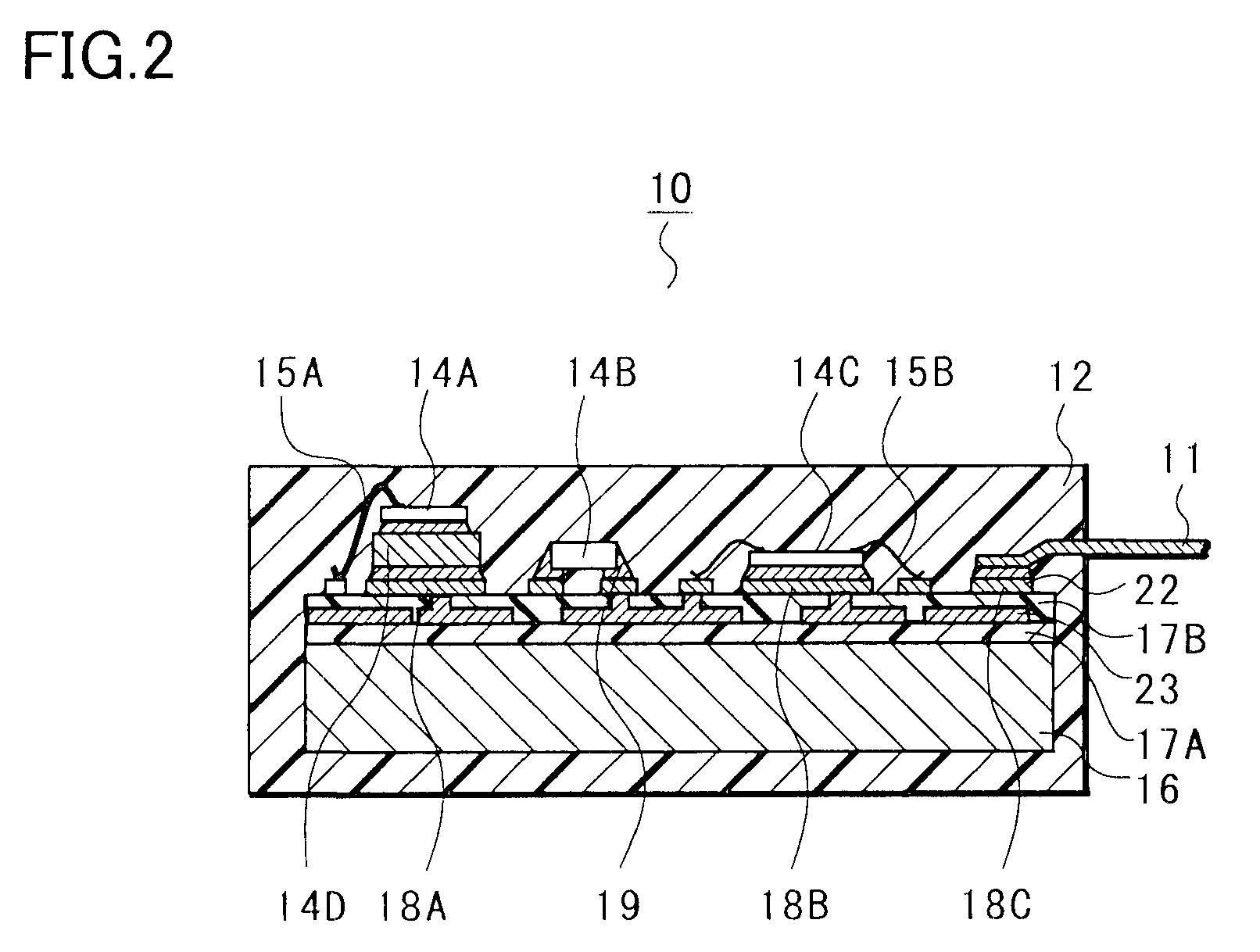

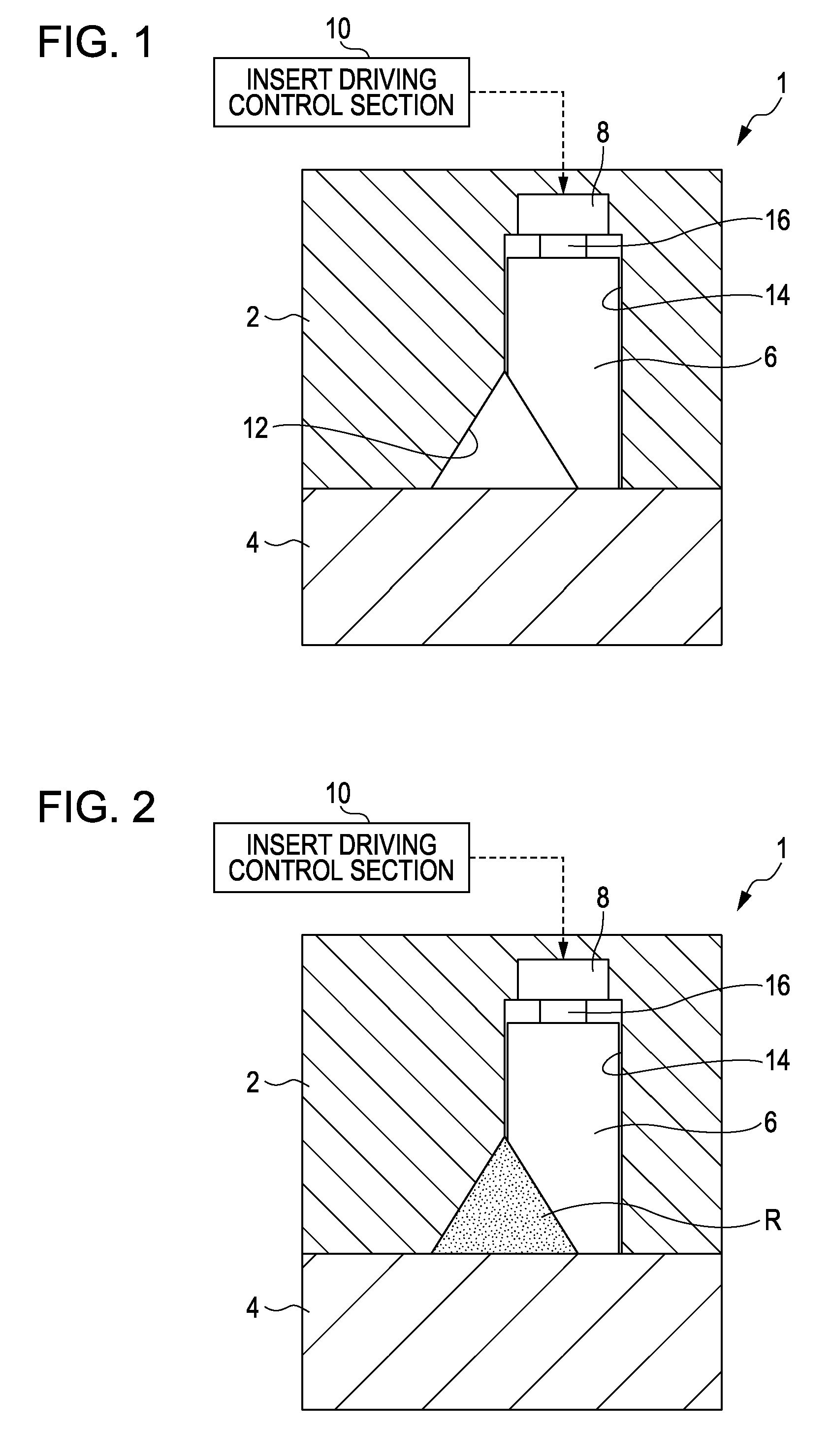

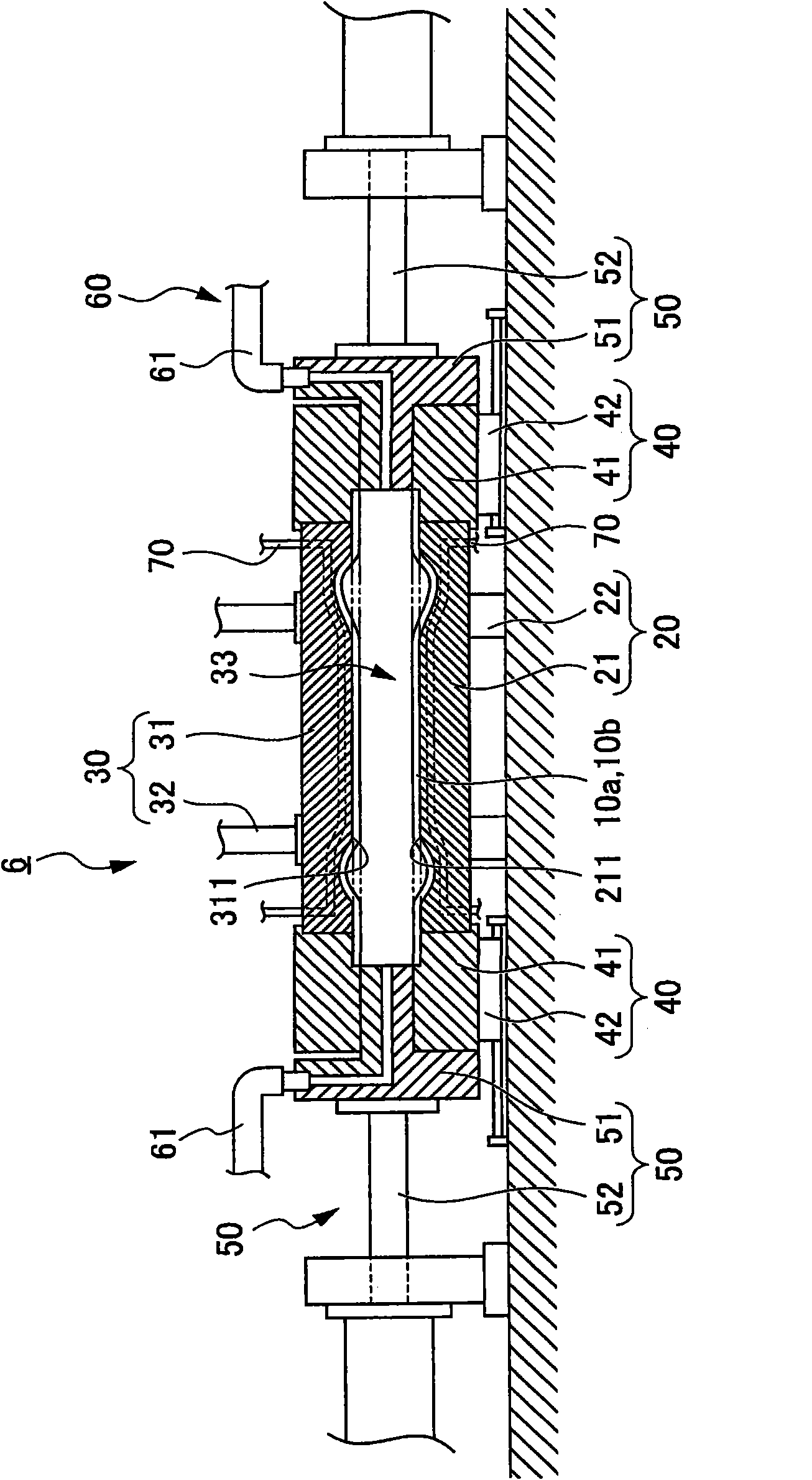

Circuit device and method of manufacturing the same

ActiveUS7936569B2Inhibition of sinkingFirmly connectedPrinted circuit assemblingFinal product manufactureAlloySoldering

In a hybrid integrated circuit device that is a circuit device of the present invention, a conductive pattern including pads is formed on a surface of a substrate. A first pad is formed to be relatively large since a heat sink is mounted thereon. A second pad is a small pad to which a chip component or a small signal transistor is fixed. In the present invention, a plated film made of nickel is formed on a surface of the first pad. Therefore, the first pad and a solder never come into contact with each other. Thus, a Cu / Sn alloy layer having poor soldering properties is not generated but a Ni / Sn alloy layer having excellent soldering properties is generated. Consequently, occurrence of sink in the melted solder is suppressed.

Owner:SEMICON COMPONENTS IND LLC

Multilayer solid wood composite door

InactiveCN101550796AOpposite sex reductionHigh static bending strengthWood working apparatusDoor leavesSolid woodEngineering

The invention relates to a multilayer solid wood composite door which is characterized in that a door body is of a single-board structure processed by clipping, carving, polishing and oiling multilayer solid wood composite boards. The method for manufacturing the multilayer solid wood composite board is as follows: (1) rotationally cutting logs into wood boards of 3 to 6 mm specification; (2) carrying out heat pressing and drying processes to the wood boards; (3) coating glue on two sides of the wood boards; (4) carrying out cold pressing; (5) carrying out heat pressing; and (6) sanding and polishing surfaces and carrying out final trimming and shaping. The invention has the beneficial effects of 1) obtaining the multilayer solid wood composite board with excellent physical mechanics property and machining property as the multilayer solid wood composite board is formed by hot-pressing multilayer rotationally-cut boards in a crisscross pattern; 2) obtaining integrated structure so as to restrict the sinking of door sides to the maximum extent; 3) gluing 5 to 11 layers of boards of 3 to 6 mm specification together so as to reduce the usage of glue and overcome the contamination caused by excessive formaldehyde; and 4) adopting the rotary-cutting technique to cut logs so as to enhance the utilization rate of wood.

Owner:孙伟范

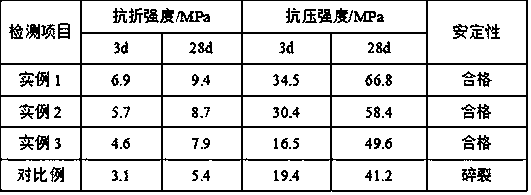

Modified steel slag cement

The invention discloses modified steel slag cement, and belongs to the technical field of building materials. A preparation method of the modified steel slag cement comprises the following steps: pulverizing and sieving steel slag to obtain steel slag powder; stirring the steel slag powder and sulfuric acid for reacting, performing cyclic freezing and unfreezing, and performing filtering and drying to obtain pretreated steel slag powder; performing ball milling, stirring and mixing on potassium permanganate and the pretreated steel slag powder, and performing high-temperature calcination to obtain calcined steel slag powder; performing ball milling, stirring and mixing on calcium carbonate, aluminum powder and the calcined steel slag powder, and performing combustion reaction to obtain modified steel slag powder; and adding cement, the modified steel slag powder, modified bagasse, a silane coupling agent and water to a mixer, and performing stirring and mixing to obtain the modified steel slag cement. The modified steel slag cement provided by the invention has excellent early strength, mechanical strength and stability.

Owner:湖州昂狮环保有限公司

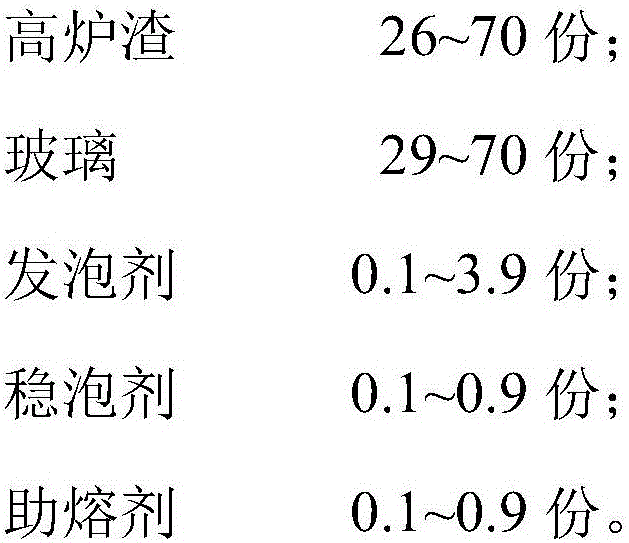

Method for producing foamed glass by melting blast furnace slag

The invention discloses a method for producing foamed glass by melting blast furnace slag. The method comprises the following steps: using the blast furnace slag as a main raw material to produce the foamed glass, wherein the blast furnace slag is metallurgical furnace slag produced online in the ironmaking process of a blast furnace; after acquiring the blast furnace slag from a slag discharge opening of the blast furnace, directly mixing with other raw materials in a high-temperature molten state; finally preparing the foamed glass. The method uses melting blast furnace slag with a high content of glass body as the main raw material, makes full use of residual heat of the melting blast furnace slag and secondary resources, and achieves purposes of energy conservation and environmental friendliness.

Owner:武汉钢铁有限公司

Modified alkali-resistant glass fiber reinforced concrete and preparation method thereof

The invention discloses modified alkali-resistant glass fiber reinforced concrete and a preparation method thereof and belongs to the technical field of building materials. The preparation method comprises steps as follows: alkali-resistant glass fibers and a peach gum liquid are stirred, mixed, soaked and filtered, a filtered product is washed, and soaked alkali-resistant glass fibers are obtained; the soaked alkali-resistant glass fibers are placed in a muffle furnace, nitrogen is introduced into the muffle furnace, the temperature is increased step by step for carbonization, heating reaction is continued, cooling is performed, and pretreated alkali-resistant glass fibers are obtained; the pretreated alkali-resistant glass fibers and a potassium permanganate solution are subjected to a stirred and mixed reaction, a product is filtered, a filtered product is washed and dried, and modified alkali-resistant glass fibers are obtained; river sand, cement, fly ash, silica fume, slag, waterand a silane coupling agent are stirred and mixed, the modified alkali-resistant glass fibers are added for stirring and mixing, and the modified alkali-resistant glass fiber reinforced concrete is obtained. The modified alkali-resistant glass fiber reinforced concrete has excellent impervious performance and mechanical property.

Owner:郦璋

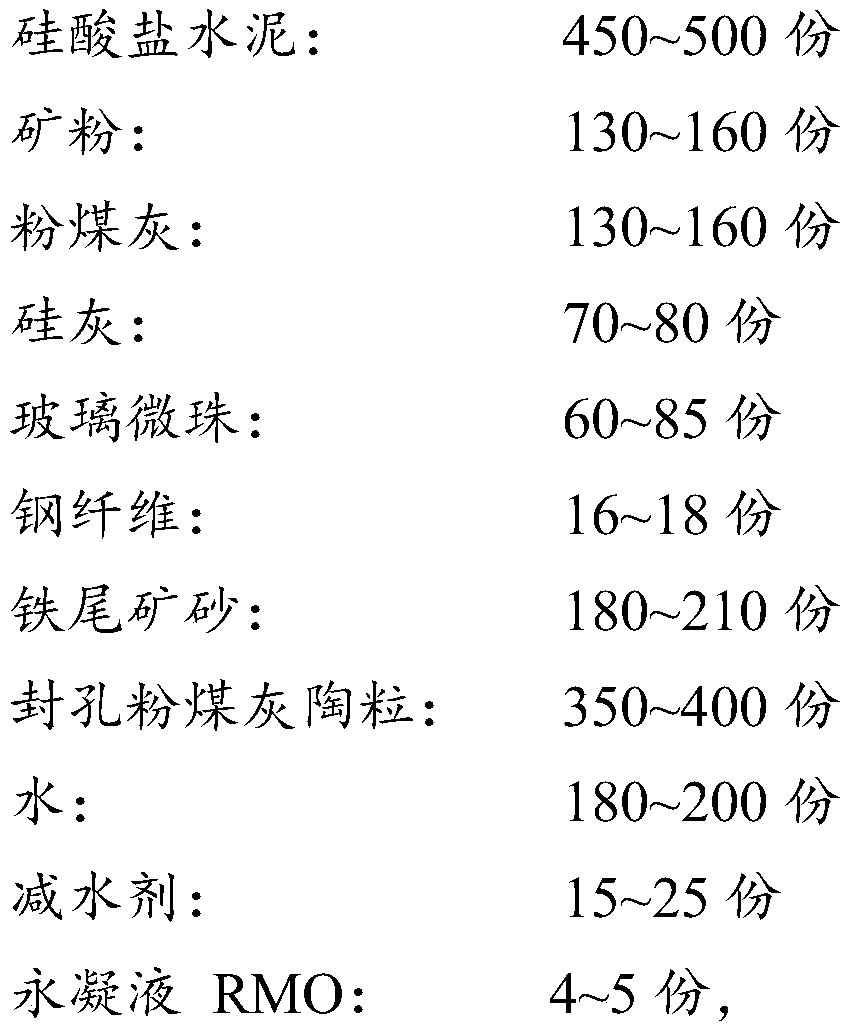

Lightweight high-strength waterproof concrete and preparation method thereof

The invention provides lightweight high-strength waterproof concrete and a preparation method thereof, and belongs to the field of concrete. The lightweight high-strength waterproof concrete comprisesthe following components in parts by mass: 450 to 500 parts of Portland cement, 130 to 160 parts of mineral powder, 130 to 160 parts of fly ash, 70 to 80 parts of silica fume, 60 to 85 parts of glassmicro-beads, 16 to 18 parts of steel fibers, 180 to 210 parts of iron tailing sand, 350 to 400 parts of pore-sealing fly ash ceramsite, 180 to 200 parts of water, 15 to 25 parts of a water reducing agent and 4 to 5 parts of a permanent solidification liquid RMO. The pore-sealing fly ash ceramsite is prepared by a method comprising the following steps: immersing fly ash ceramsite into a mixed solution of RMO and water, pre-wetting, draining off water after 1 hour, and then carrying out coating treatment by using a mixture of Portland cement and iron tailing sand powder, so as to obtain the pore-sealing fly ash ceramsite. The concrete disclosed by the invention has the properties of light weight, high strength and water resistance.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Modified coal gangue aggregate concrete

The invention discloses modified coal gangue aggregate concrete and belongs to the technical field of building materials. The modified coal gangue aggregate concrete is prepared by the following steps: taking coal gangue aggregate and hydrochloric acid to react; filtering, washing and drying to obtain first-time treated coal gangue and acid leaching filtrate; ultrasonically dispersing the pre-treated coal gangue, nano iron powder and a saturated sodium fluoride solution; filtering, washing and drying to obtain second-time treated coal gangue; carrying out high-temperature reaction on the second-time treated coal gangue and cooling to obtain third-time treated coal gangue; mixing the third-time treated coal gangue and the acid leaching filtrate and stirring and mixing; then dropwise addingammonia water and filtering and washing to obtain fourth-time treated coal gangue; adding the fourth-time treated coal gangue into a tubular furnace and carrying out high-temperature reaction; coolingto obtain modified coal gangue crushed aggregates; stirring and mixing the modified coal gangue crushed aggregates, cement, fly ash, silicon ash, slag, water, a silane coupling agent and a water reducing agent to obtain the modified coal gangue aggregate concrete. The modified coal gangue aggregate concrete provided by the invention has excellent anti-freezing and dry shrinkage performance.

Owner:江西新纪元混凝土有限公司

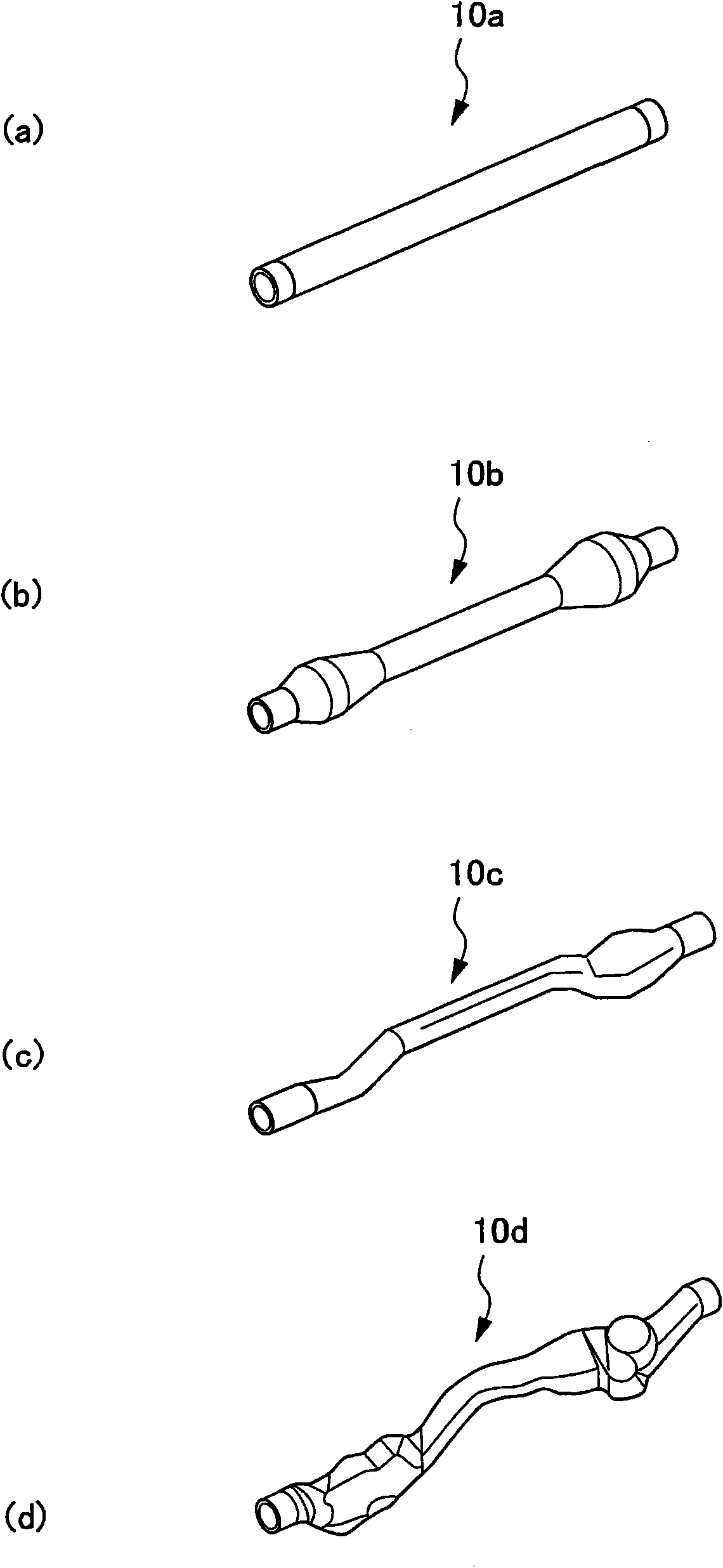

Injection molding method, injection-molded product, optical element, optical prism, ink tank, recording device, and injection mold

InactiveUS20120306972A1Inhibition of sinkingQuality improvementEnvelopes/bags making machineryPrismsPrismInjection molding machine

Owner:SEIKO EPSON CORP

Hot bulge forming apparatus, a hot bulge forming method and a product formed through hot bulge forming

InactiveCN101987337ACircumference smallReduce curvatureShaping toolsEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

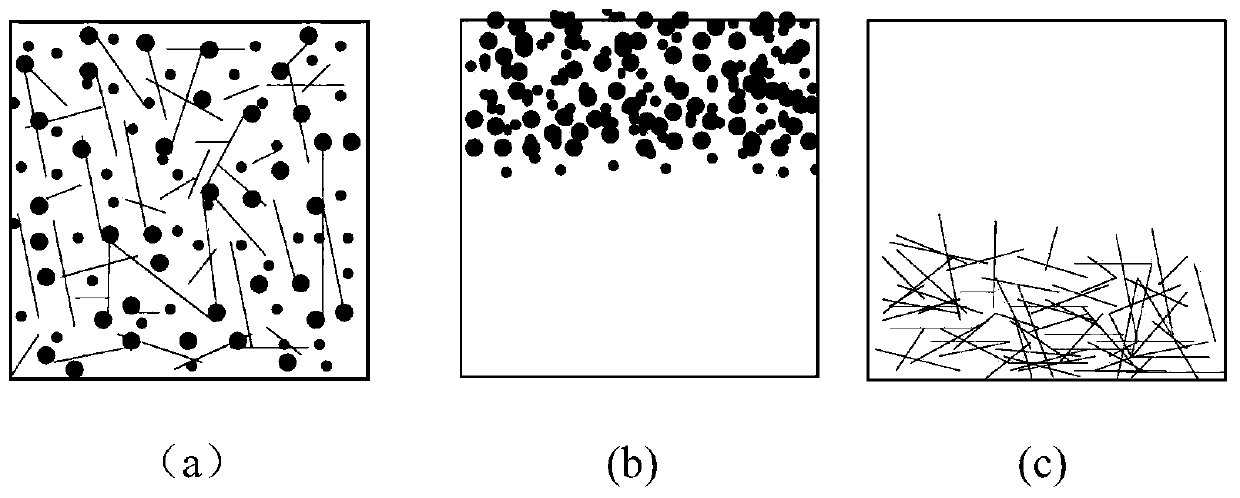

Method for preparing inorganic fibers by compounding of slag and coal gangue

InactiveCN107973531AHigh early chemical activityImprove early chemical activityGlass making apparatusFiberSlag

The invention discloses a method for preparing inorganic fibers by compounding of slag and coal gangue. According to the method provided by the invention, firstly, desulfurization gypsum and CaO are used as activators, the coal gangue and fly ash are subjected to chemical / thermal composite excitation treatment, the coal gangue and the fly ash are excited by heat, so that the structure of glass networks of the coal gangue and the fly ash is destroyed, active SiO2 and Al2O3 are dissolved out, the dissolved-out active SiO2 and Al2O3 and CaO are subjected to a solid phase reaction, a new substancewith hydraulic activity is generated, and the activity of a pozzolanic reaction of the material is improved; and then the active material and blast furnace slag are mixed and ground, melt centrifugation drawing is performed, so that the inorganic fibers are prepared, the slag and other raw materials are introduced in the manner of fibers, the fibers can be uniformly distributed into a hardened slurry, and a grid structure can be formed, so that the problem of bleeding of concrete is improved, the compactness of the hardened slurry is improved, and the compressive strength and durability of the concrete are improved.

Owner:MAANSHAN BAOLONG NEW BUILDING MATERIALS

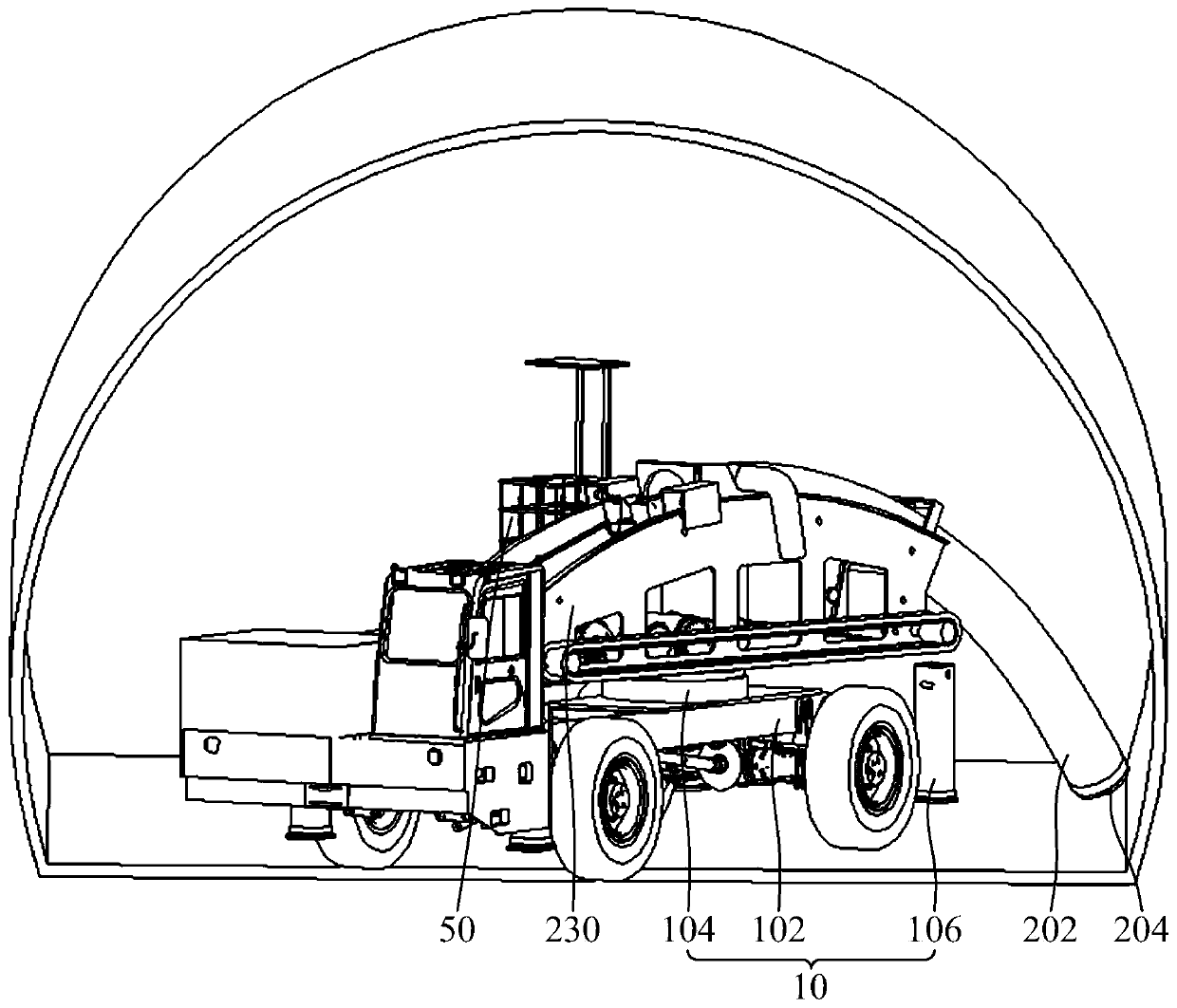

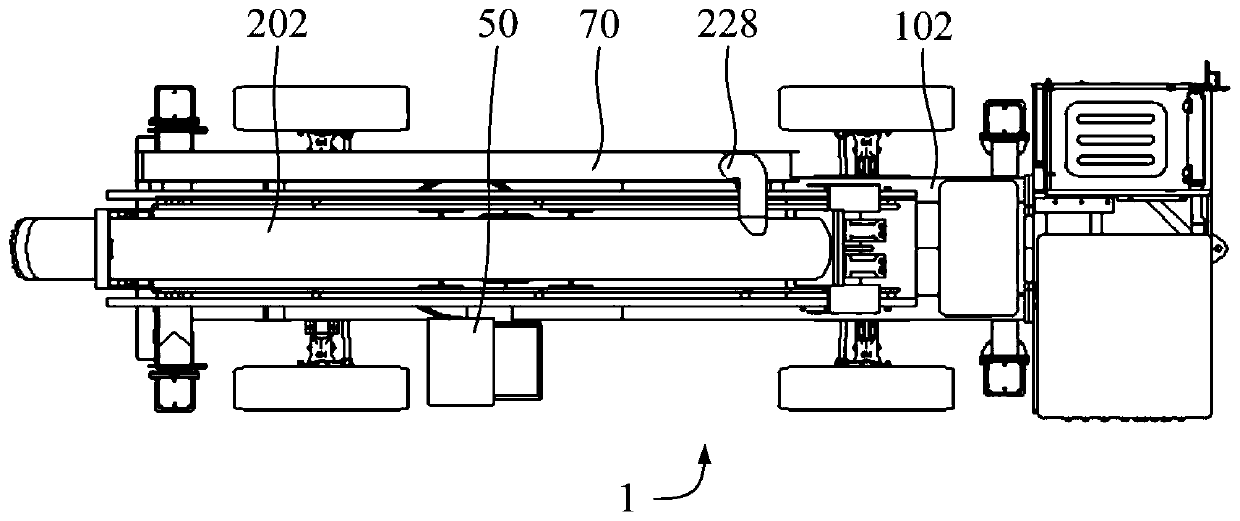

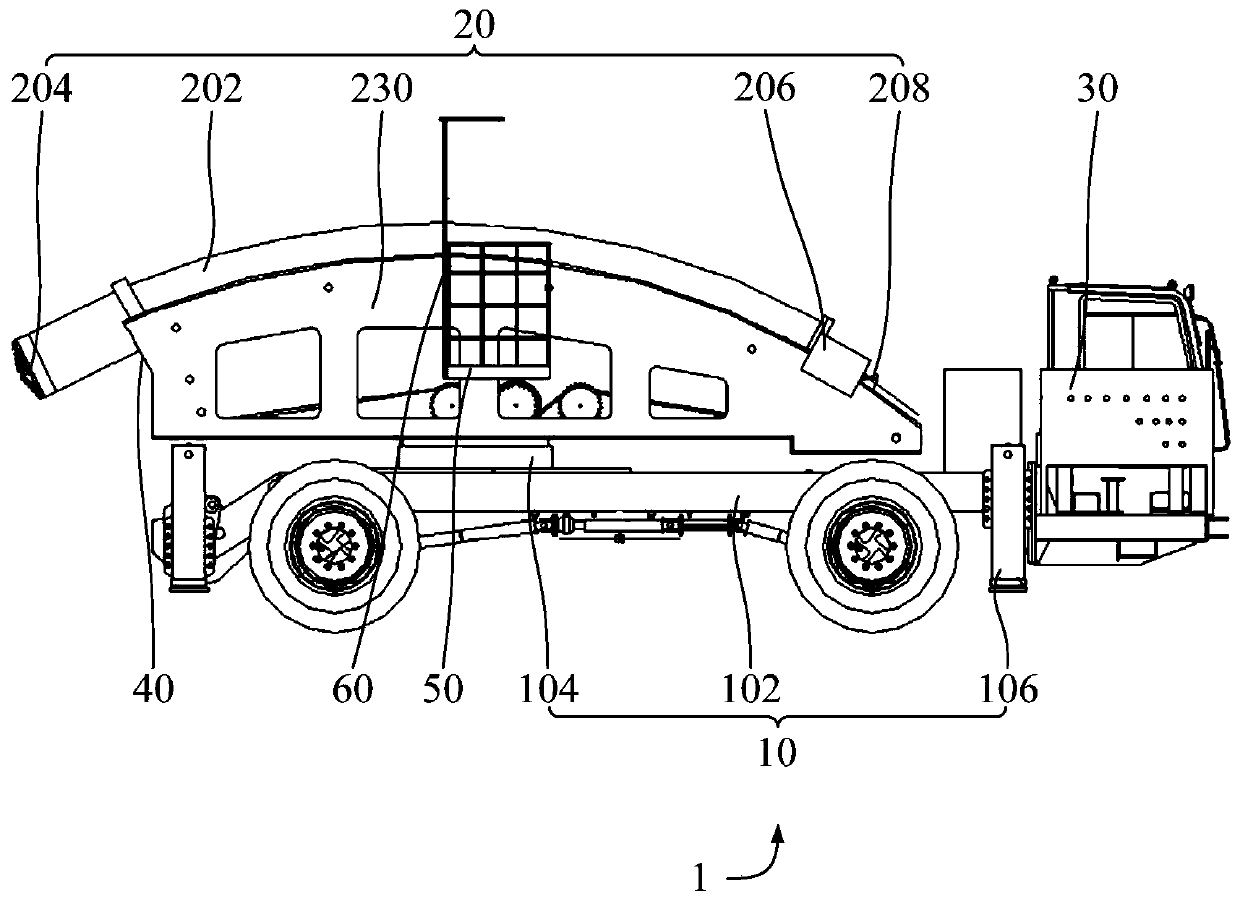

Tunneling equipment and control method of tunneling equipment

PendingCN110080679AControllable bendingEnsure controllabilityDrilling rodsUnderground chambersCurve shapeControl curve

The invention provides tunneling equipment and a control method of the tunneling equipment. The tunneling equipment comprises a walking assembly, a main machine and a controller. The main machine is arranged on the walking assembly, the main machine is provided with a guide rail, a curve-shaped guide part and a drill bit, the curve-shaped guide part is arranged on the guide rail, and the drill bitis connected with the curve-shaped guide part; the controller is connected with the walking assembly and the main machine, wherein the controller controls the drill bit to rotate and controls the curved guide part to move along the guide rail after controlling the walking assembly to move to a preset position. The structure of the tunneling equipment is reasonably arranged, the tunneling equipment tunnels and drills along the curve shape of the surrounding rock, therefore, the drilling depth can be increased in a targeted mode according to the specific actual use condition, so as to meet thehole forming depth requirement, the tunnel arch foot reinforcing requirement can be met, meanwhile, the structure provides a structure foundation for achieving fore-reinforcement and forepoling functions, and then the purposes of preventing arch feet from sinking and improving the surrounding rock stability can be achieved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

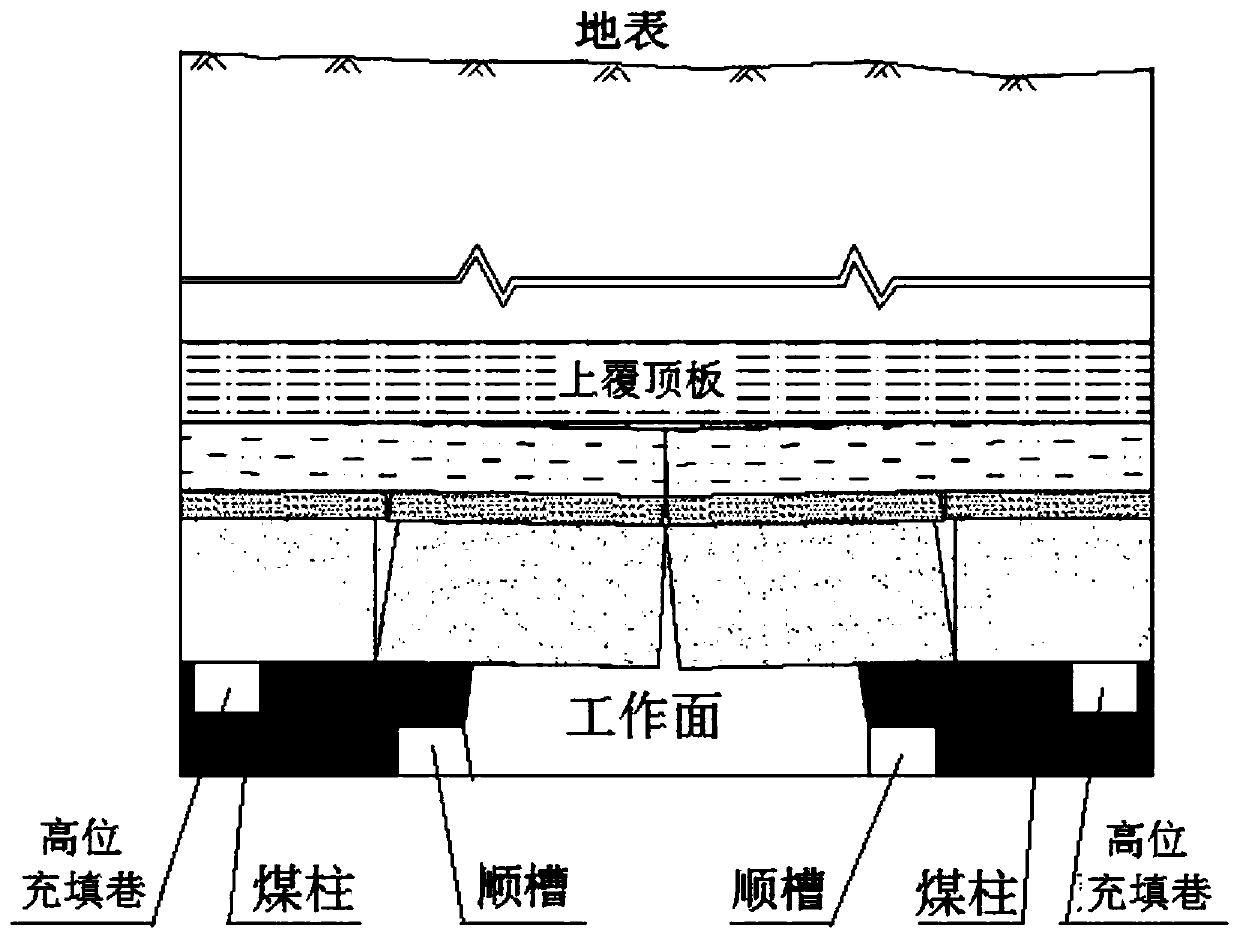

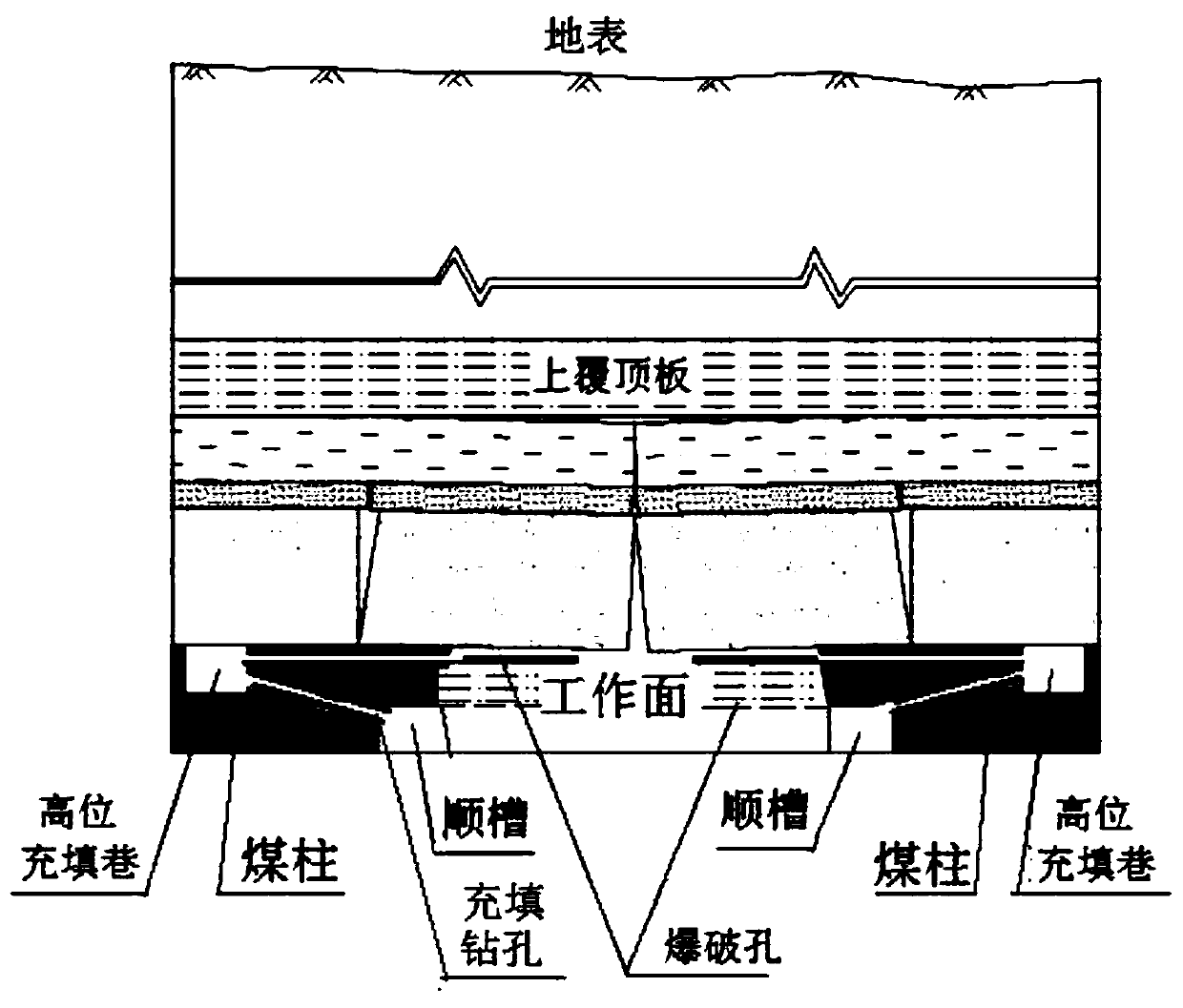

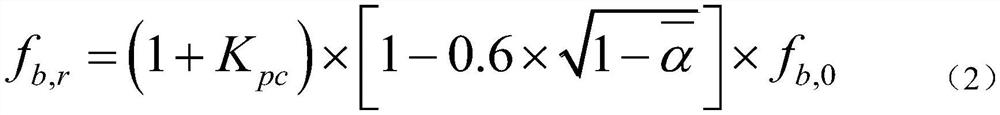

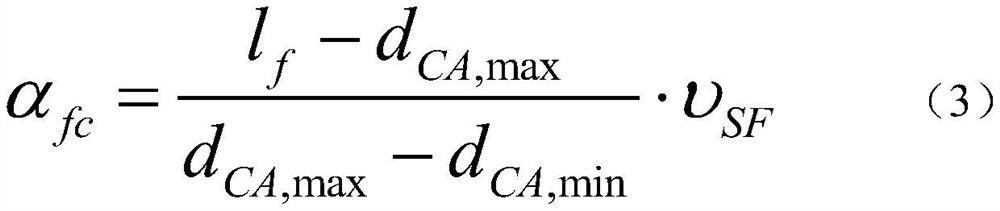

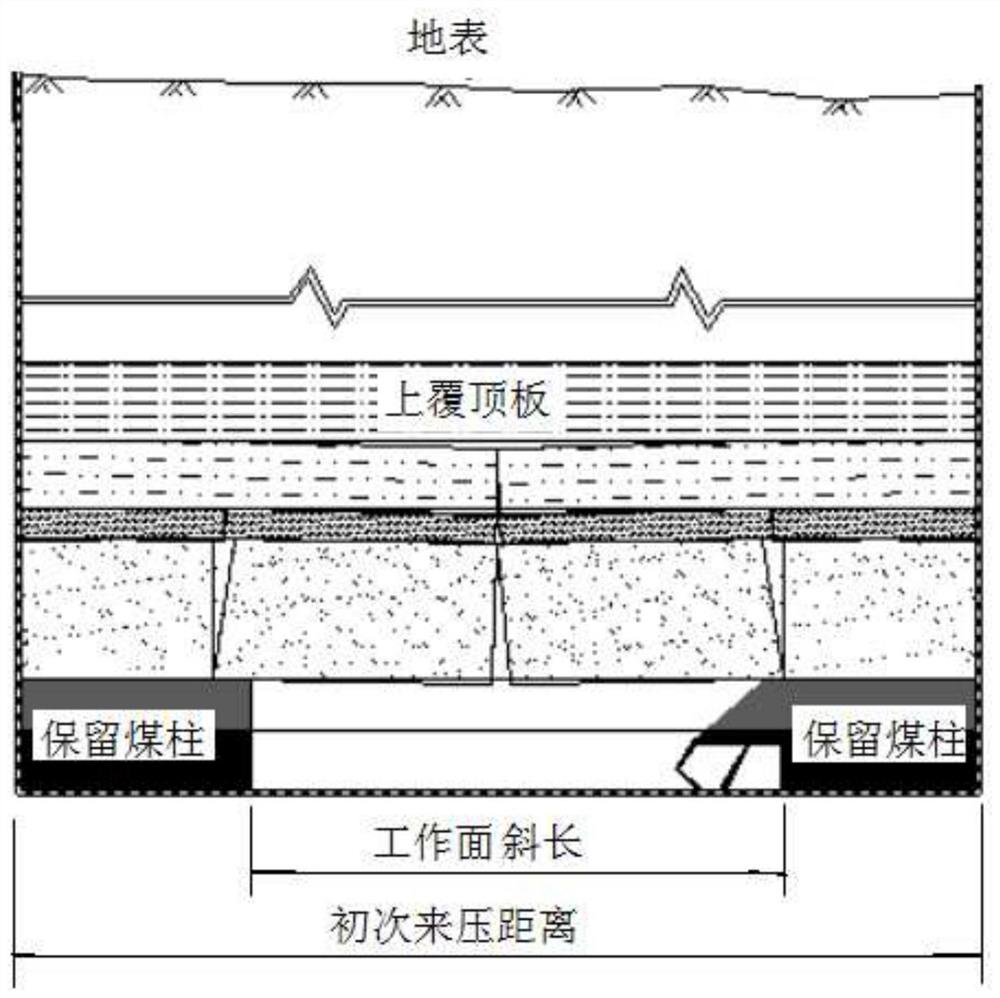

Strip fully-mechanized top coal caving high cut and fill mining method of thick coal seam under coal mine railway

ActiveCN110359910AAvoid breakingInhibition of fractureUnderground miningSurface miningEconomic benefitsCut and fill

The invention discloses a strip fully-mechanized top coal caving high cut and fill mining method of a thick coal seam under a coal mine railway. A strip type working face mining method is adopted; anda fully-mechanized top coal caving technology is adopted for mining. The strip fully-mechanized top coal caving and high-position cut and fill mining method is characterized in that the first weighting distance is taken as the basis of designing the inclination length of a strip type working face; a high filling roadway is constructed before the mining of the working face; a blasthole and a filling drill hole are constructed in the high filling roadway; a top coal area is blasted in advance through the blasthole, and a goaf is filled through the filling drill hole, so that the caving of overlying rocks is reduced, and the ground depression is suppressed; and pressing coal under the railway is converted into recoverable reserves, thus, the recovery rate of resources and the economic benefits are increased, and the length of service of the mine is prolonged.

Owner:XINWEN MINING GROUP

Sponge body foamed glass formula and production process thereof

InactiveCN104909576AImprove water absorptionFine and uniform pore sizeGlass shaping apparatusFurnace temperatureGlass particle

The invention discloses a sponge body foamed glass formula and a production process thereof. The sponge body foamed glass comprises the following components in percentage by weight: 96-99 percent of glass particles, 0.1-3.9 percent of potassium feldspar powder, 0.1-0.9 percent of shell powder and 0.1-0.9 percent of slaked lime. The process for producing the sponge body foamed glass comprises the following steps: S1, preparing materials; S2, sintering and bulking; and S3, cooling. According to the formula and the production process of the sponge body foamed glass disclosed by the invention, the defect that the traditional foamed glass production process is complicated is improved; and moreover, the formula of the sponge body foamed glass serves as a production raw material, and according to the production process of the sponge body foamed glass, the speed of a conveyor belt of a sintering furnace and the furnace temperature are controlled, and the sponge body foamed glass of which the specific gravity is 0.3-1.3, the water absorption rate is 1-110 percent and the pore size is 1.2-420 microns can be prepared.

Owner:DALIAN SHENGMINGZHISHI NEW MATERIAL

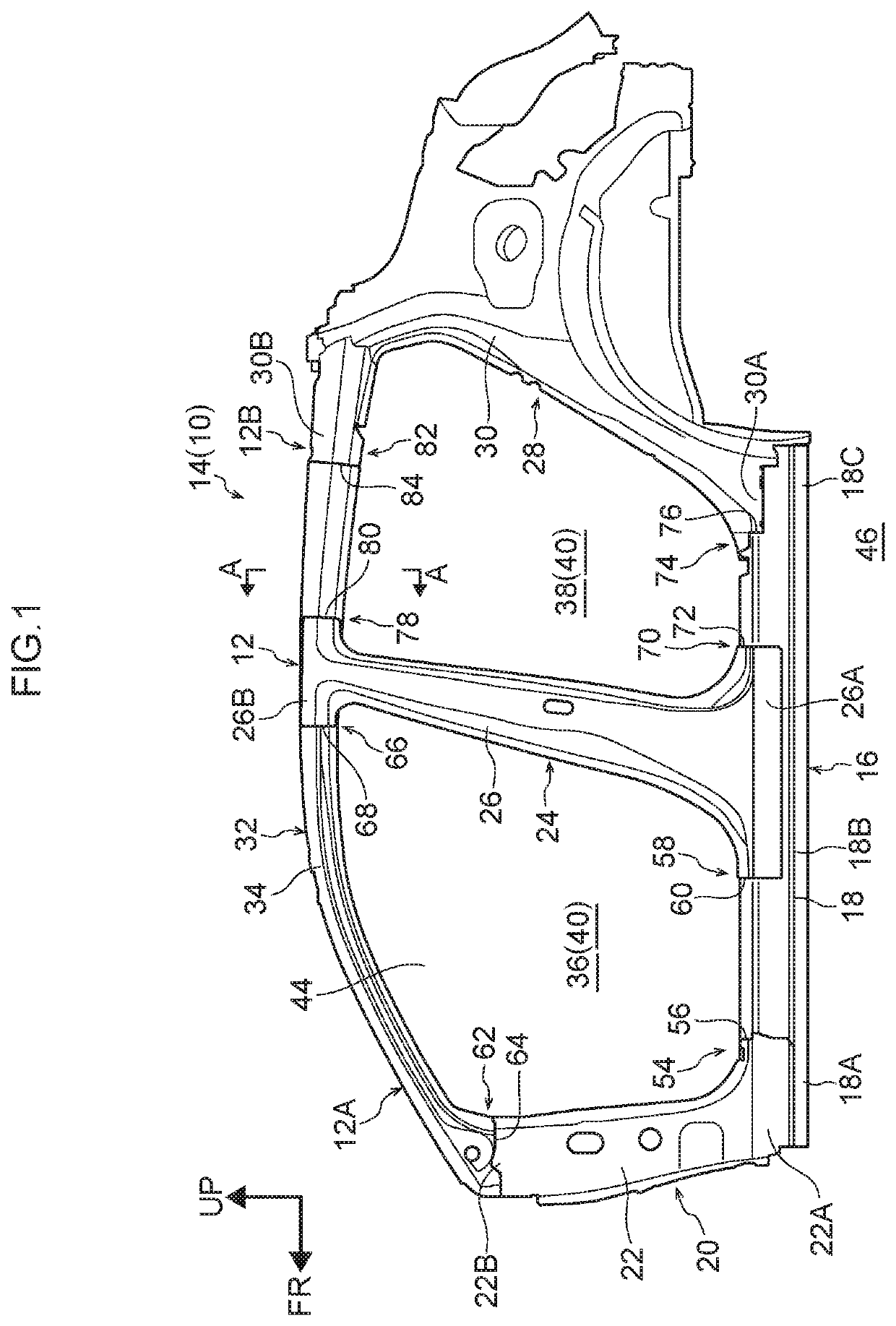

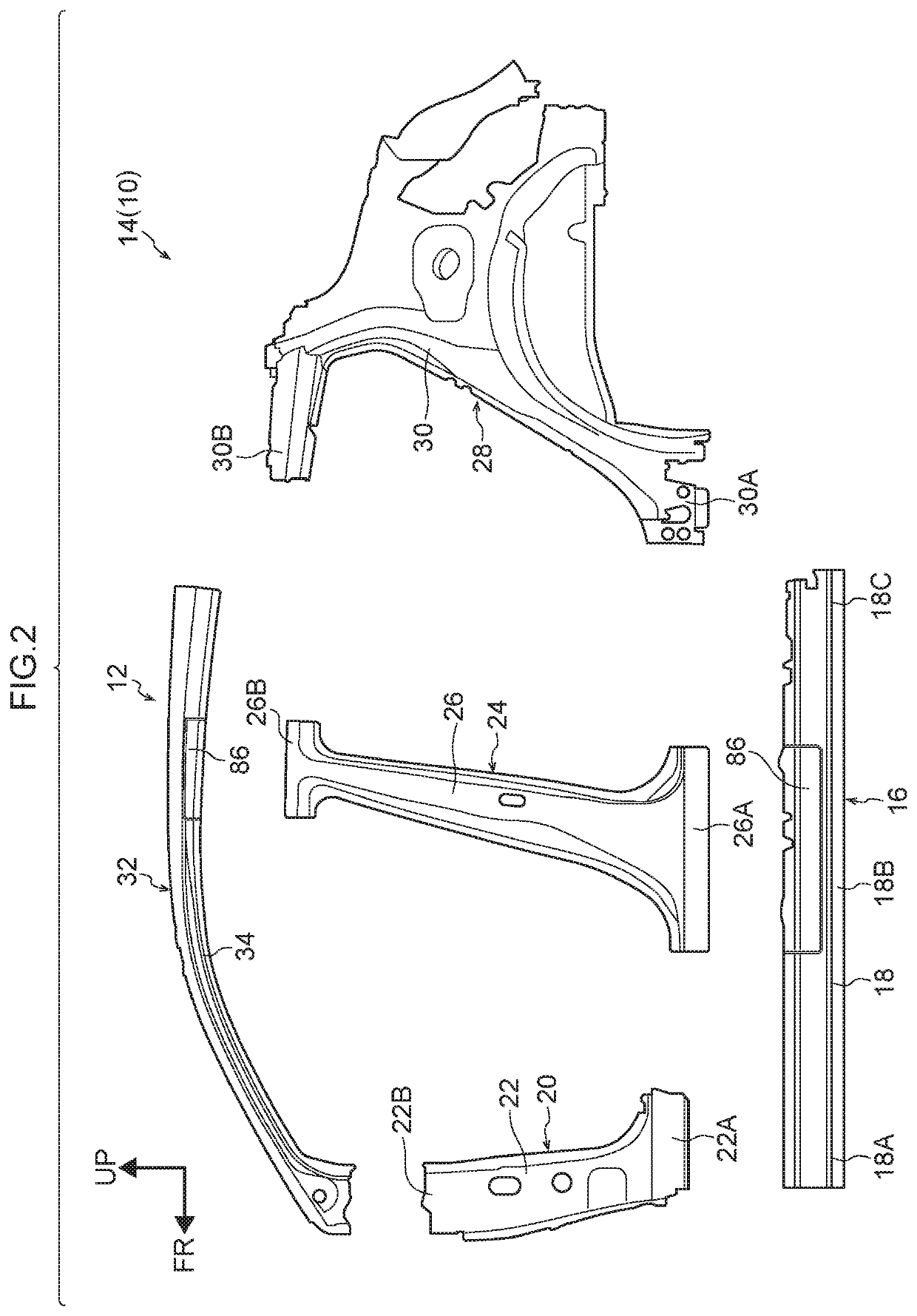

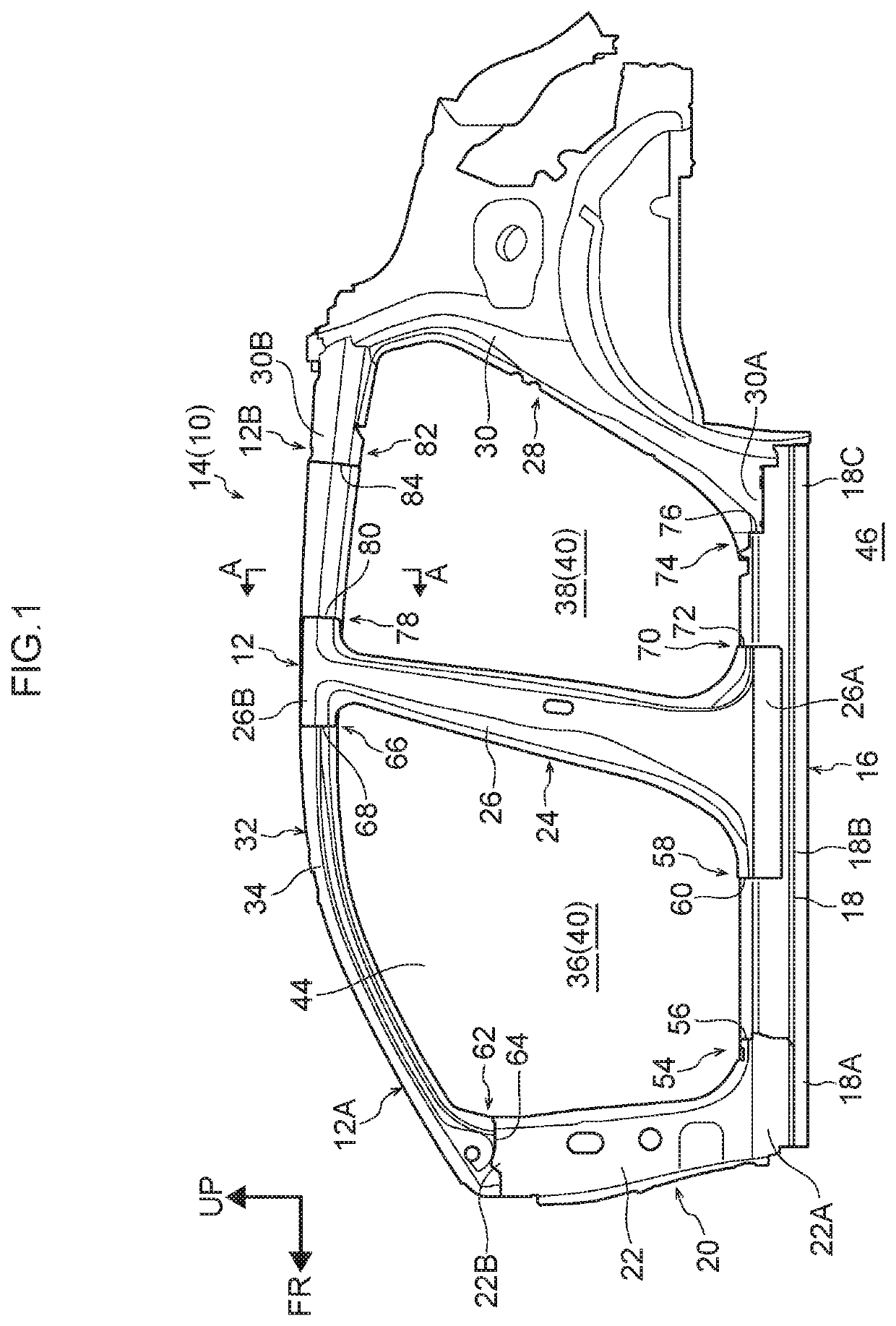

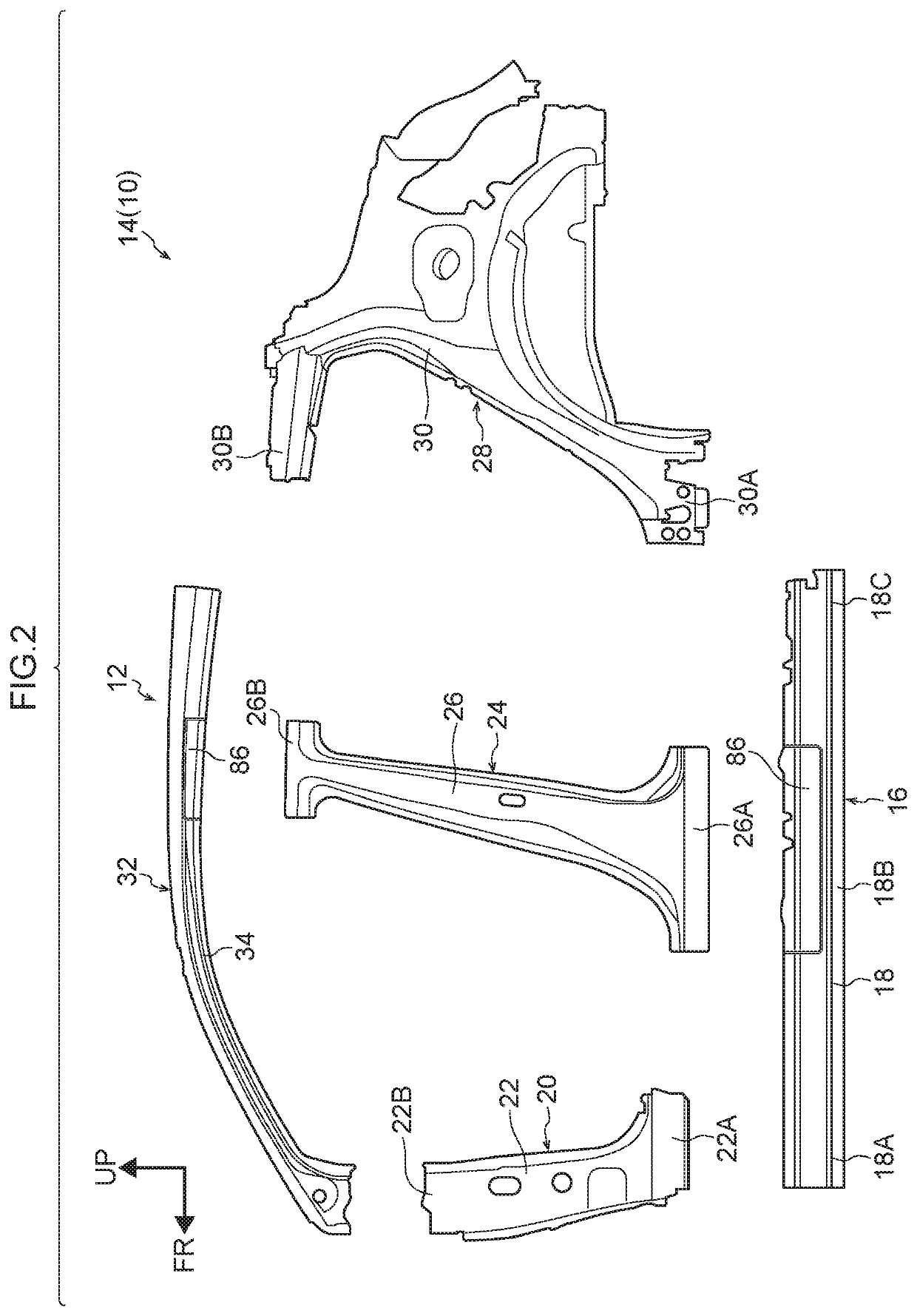

Vehicle body member manufacturing method and vehicle body member joint portion seal structure

ActiveUS20200070636A1Inhibition of sinkingEngine sealsSuperstructure subunitsMechanical engineeringAutomotive engineering

Owner:TOYOTA JIDOSHA KK

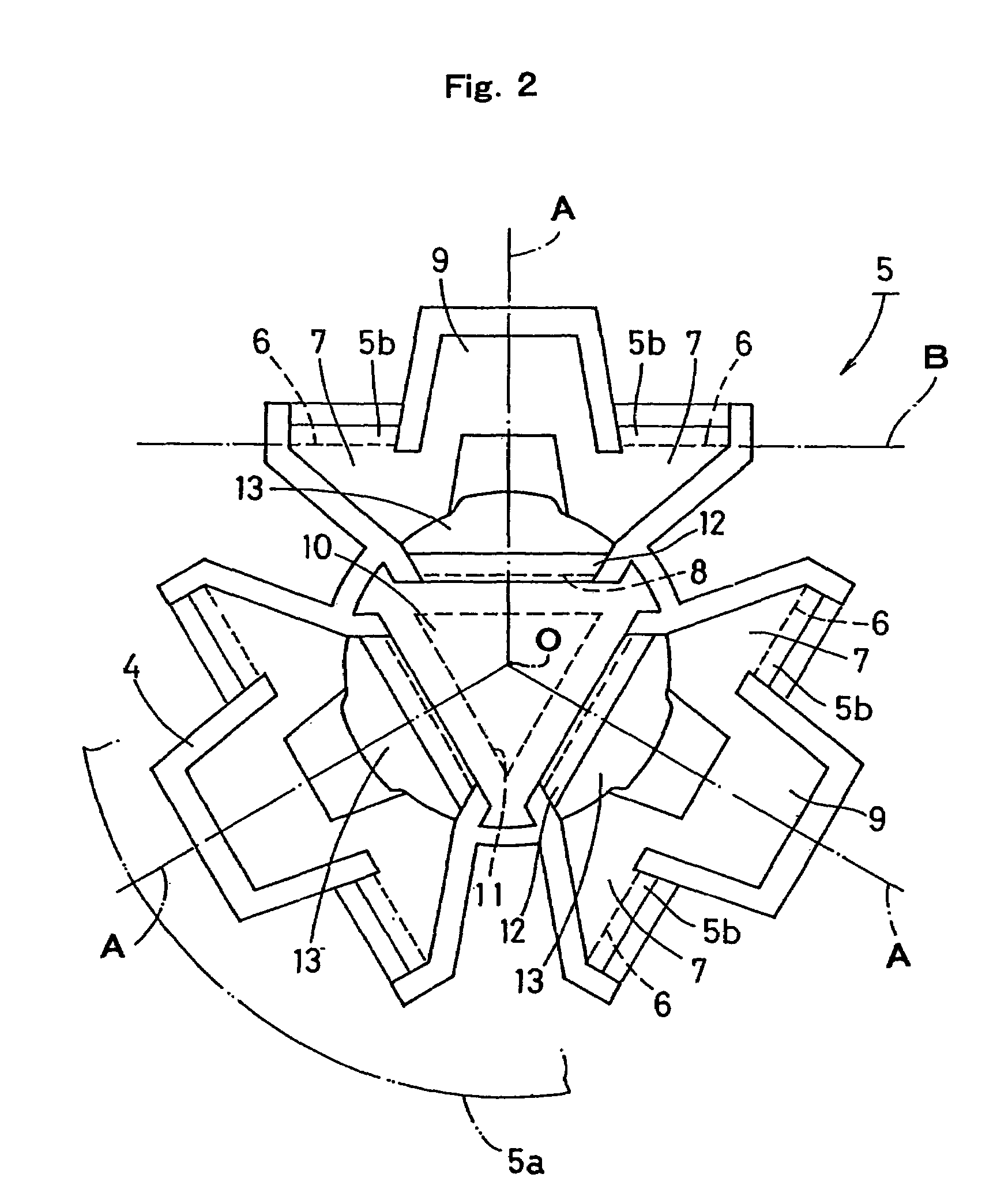

Double-shouldered welding device for the friction stir welding of parts, and welding method

ActiveUS7931185B2Resisting compressionPrevents racingWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

The invention relates to a double shouldered welding device for the friction stir welding of parts, in which at least one shoulder has two concentric rings providing two plane concentric bearing surfaces, the rings being arranged so that the smaller-diameter ring is capable of compressing the stirred material of the parts to be welded during advance of the welding device and so that the larger-diameter ring is capable of forming a sink-in stop for the smaller-diameter ring. The invention also relates to a method of friction stir welding by means of the welding device according to the invention, in which said device is force-driven.

Owner:EURON AERONAUTIC DEFENCE & SPACE

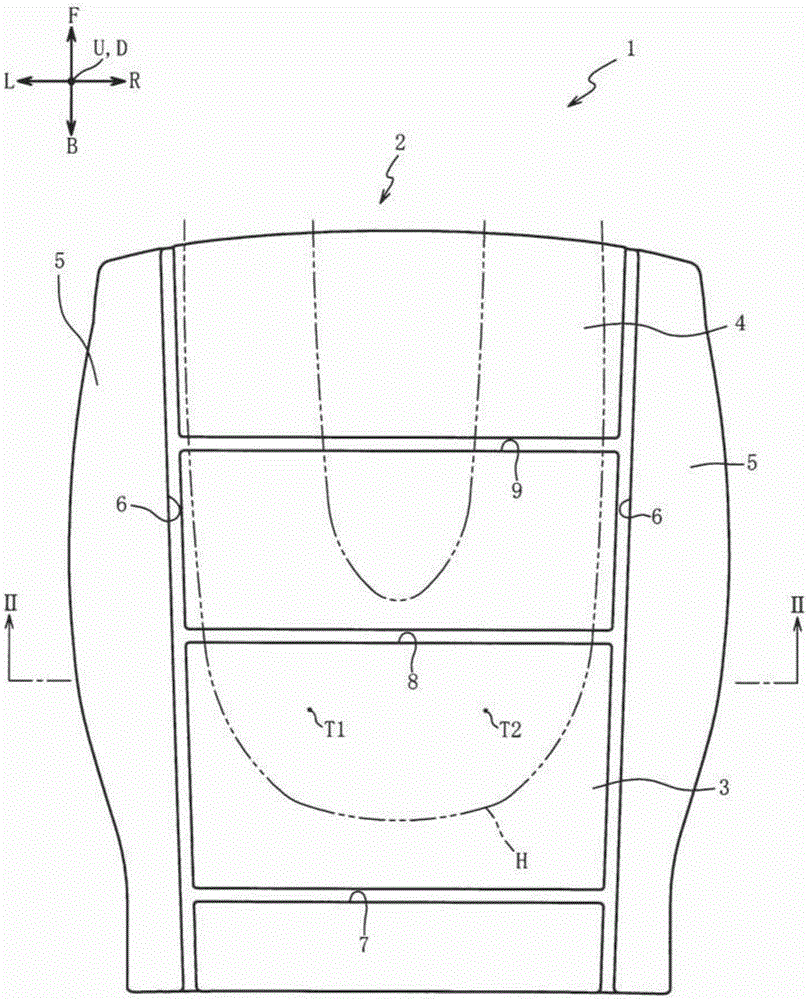

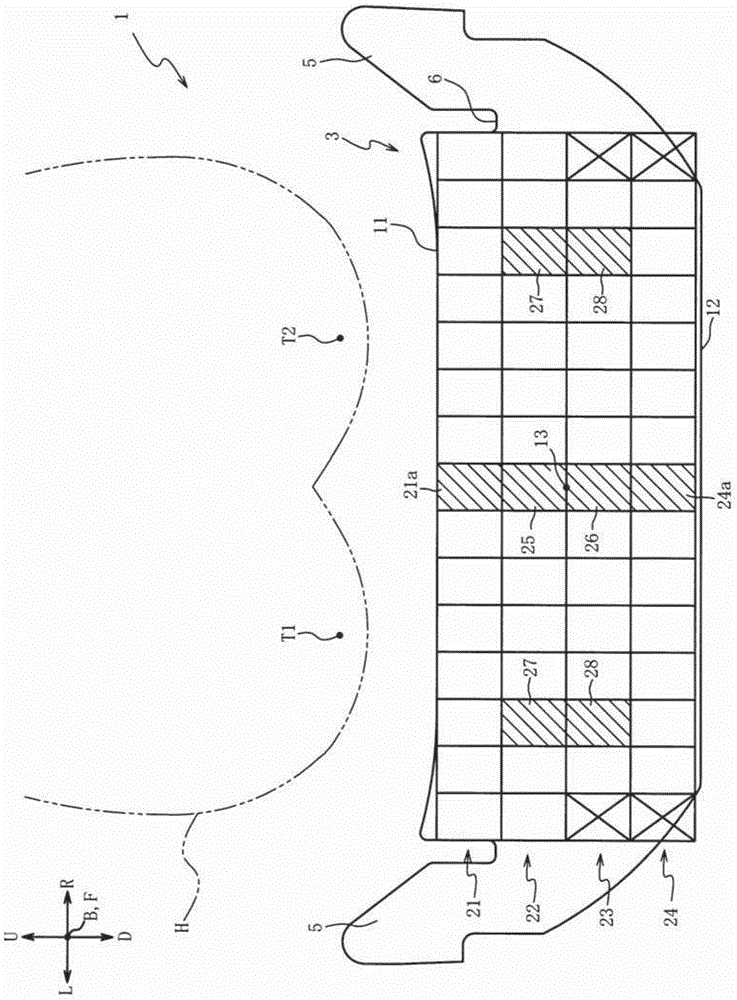

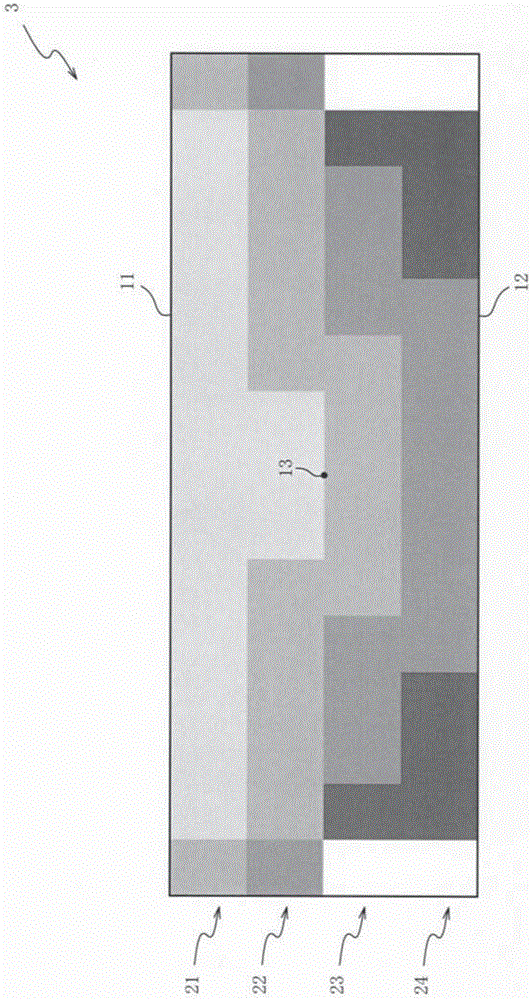

Cushion pad

ActiveCN105326246AEnsure tightnessImprove holdVehicle seatsStuffed mattressesLow frequency bandEngineering

The invention provides a cushion pad that reduces the wobbling feeling. Regarding the test piece sampled from a core portion (22, 23, 32, 33), the measured deflection under a load of 100 N during compression is equal to or less than 30 mm. The measured static spring constant under a load of 300 N at a pulling rate of 20 mm / minute is equal to or less than 25 N / mm. In the case of a vibration input in a low frequency band in the lateral direction, the compressive stress in the vertical direction due to the weight of a seated person (H) and the tensile stress due to the vibration input in the lateral direction act on the support portion (2). The direction (gradient) of the resultant force as a combination of the compressive stress and the tensile stress can be closer to the vertical direction. This allows reducing the wobbling feeling.

Owner:TOYO TIRE & RUBBER CO LTD

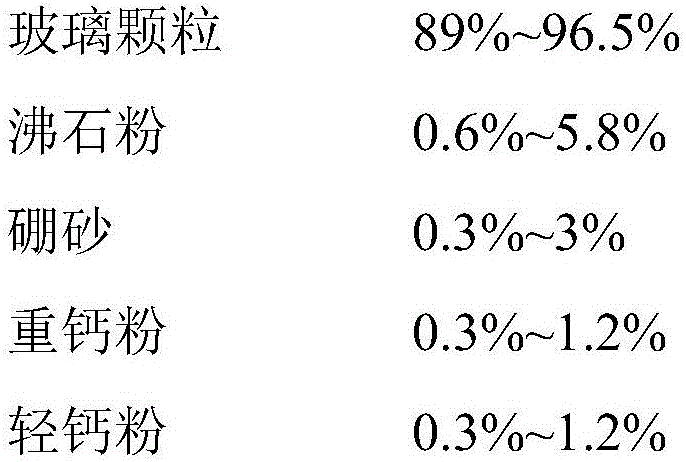

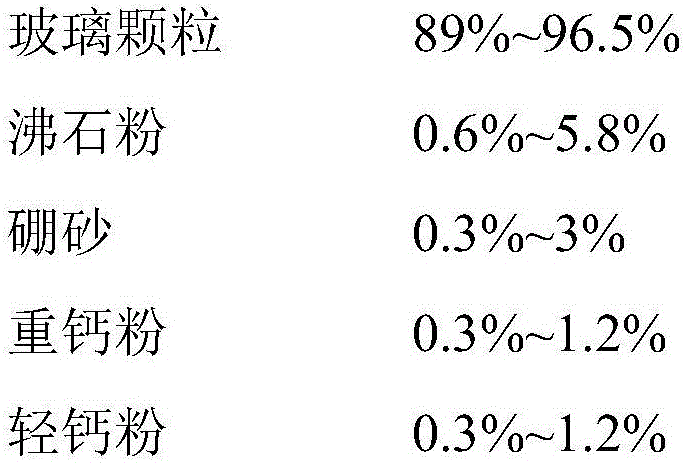

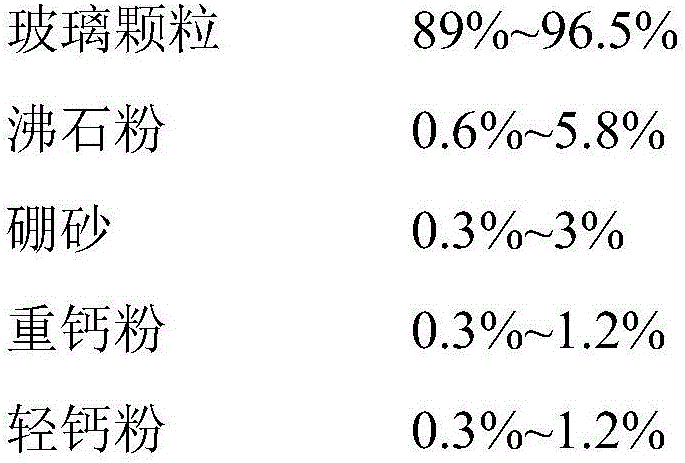

Honeycomb glass pumice formula and production process thereof

ActiveCN106746627AImprove water absorptionFine and uniform pore sizeGlass shaping apparatusGlass productionHoneycombGlass particle

The invention discloses a honeycomb glass pumice formula and a production process thereof. The formula comprises the following components in percentage by weight: 89 to 96.5 percent of glass particles, 0.6 to 5.8 percent of zeolite powder, 0.6 to 3 percent of borax, 0.3 to 1.2 percent of heavy calcium carbonate powder and 0.3 to 1.2 percent of light calcium carbonate powder. The production process comprises the following four steps of preparing materials; sintering and puffing at high temperature; cooling; smashing and screening. Accurate furnace internal temperature control is realized by increasing the material mixing accuracy and strictly controlling the conveying belt speed of a sintering furnace, so as to realize uniform porosity of honeycomb glass pumice, and the honeycomb glass pumice which is 0.25 to 1.25 in specific weight, 0.8 to 120 percent in water absorption and 0.8 to 450 mu m in aperture can be prepared. Raw materials are derived from waste white transparent glass, so that environmental pollution is prevented in production and use processes, and utilization of renewable solid waste resources is realized.

Owner:大连长兴恒泰新材料科技有限公司

Novel simulation artificial bait

InactiveCN103947622AExtend sink timeImprove the simulation effectBaitDifferential pressureWater flow

The invention discloses novel simulation artificial bait. The novel simulation artificial bait mainly comprises a bait body and a fishhook, wherein a rotating body is arranged at the bottom of the bait body and comprises an annular basal body and a plurality of longitudinal rotating blades which are annularly distributed on the annular basal body; a horizontal connecting sheet is arranged between every two adjacent longitudinal rotating blades; a horizontal through hole and a longitudinal through hole are formed in each horizontal connecting sheet; an opening in one end of each horizontal through hole extends until being communicated with the corresponding longitudinal through hole; the longitudinal rotating blades and the horizontal connecting sheets are subjected to flow resistance, so that the sinkage is restrained, the simulation artificial bait is located at a water lever where fish is easily trapped, and the success rate of capturing large-size fish is improved; water flow in the horizontal holes in the horizontal connecting sheets and water flow in the longitudinal holes in the horizontal connecting sheets form a differential pressure, bubbles are produced at the openings of the horizontal holes or the longitudinal holes, thus the bait has an effect that the bait breathes and exhales like real fish, the simulation effect of the bait is greatly improved, the large-size fish is easily attracted to rise to the bait, and the fish capturing effect is better.

Owner:SHISHI CITY GT BIO FISHING TACKAL

Vehicle body member manufacturing method and vehicle body member joint portion seal structure

ActiveUS11198351B2Inhibition of sinkingEngine sealsSuperstructure subunitsMechanical engineeringAutomotive engineering

Owner:TOYOTA JIDOSHA KK

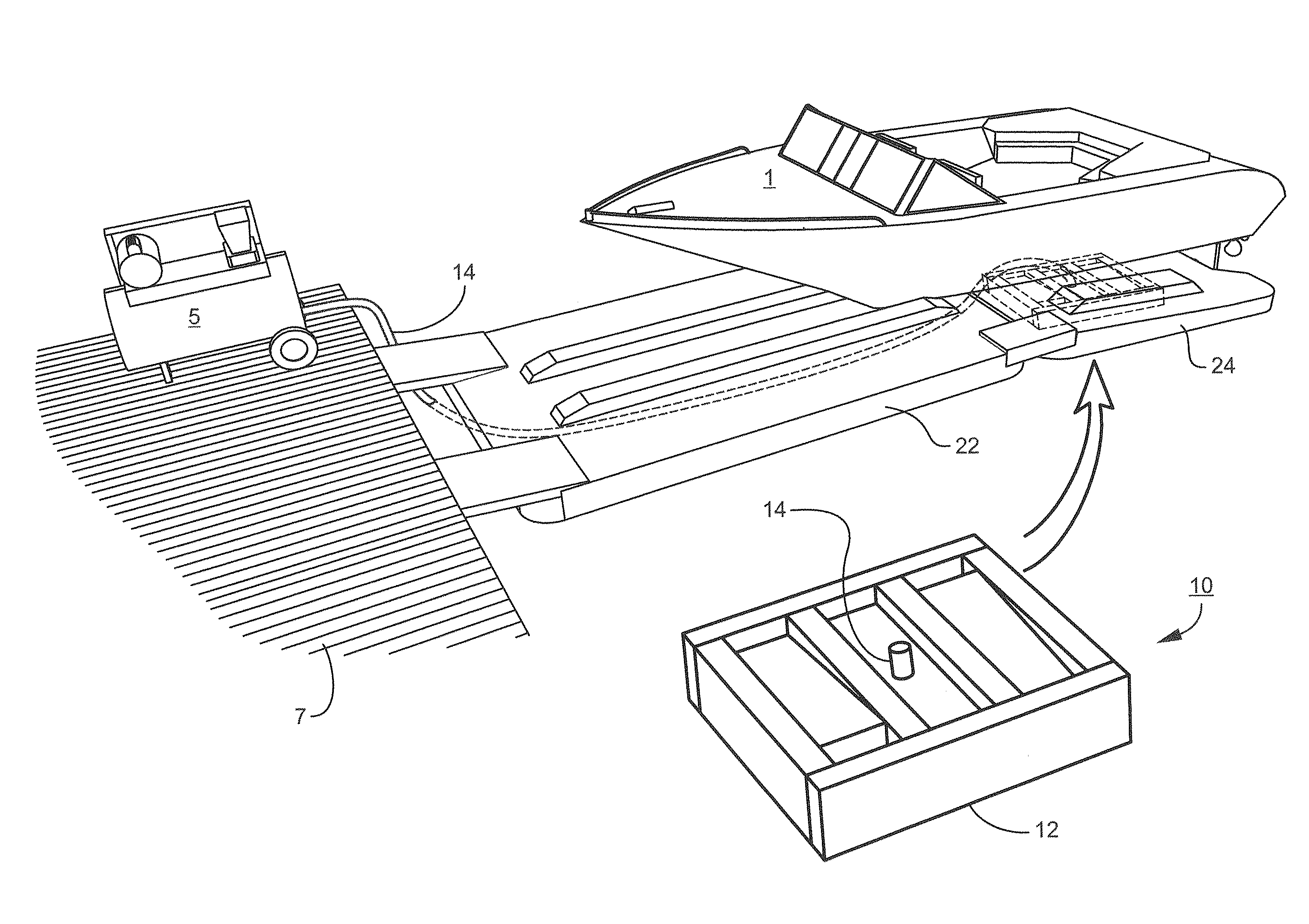

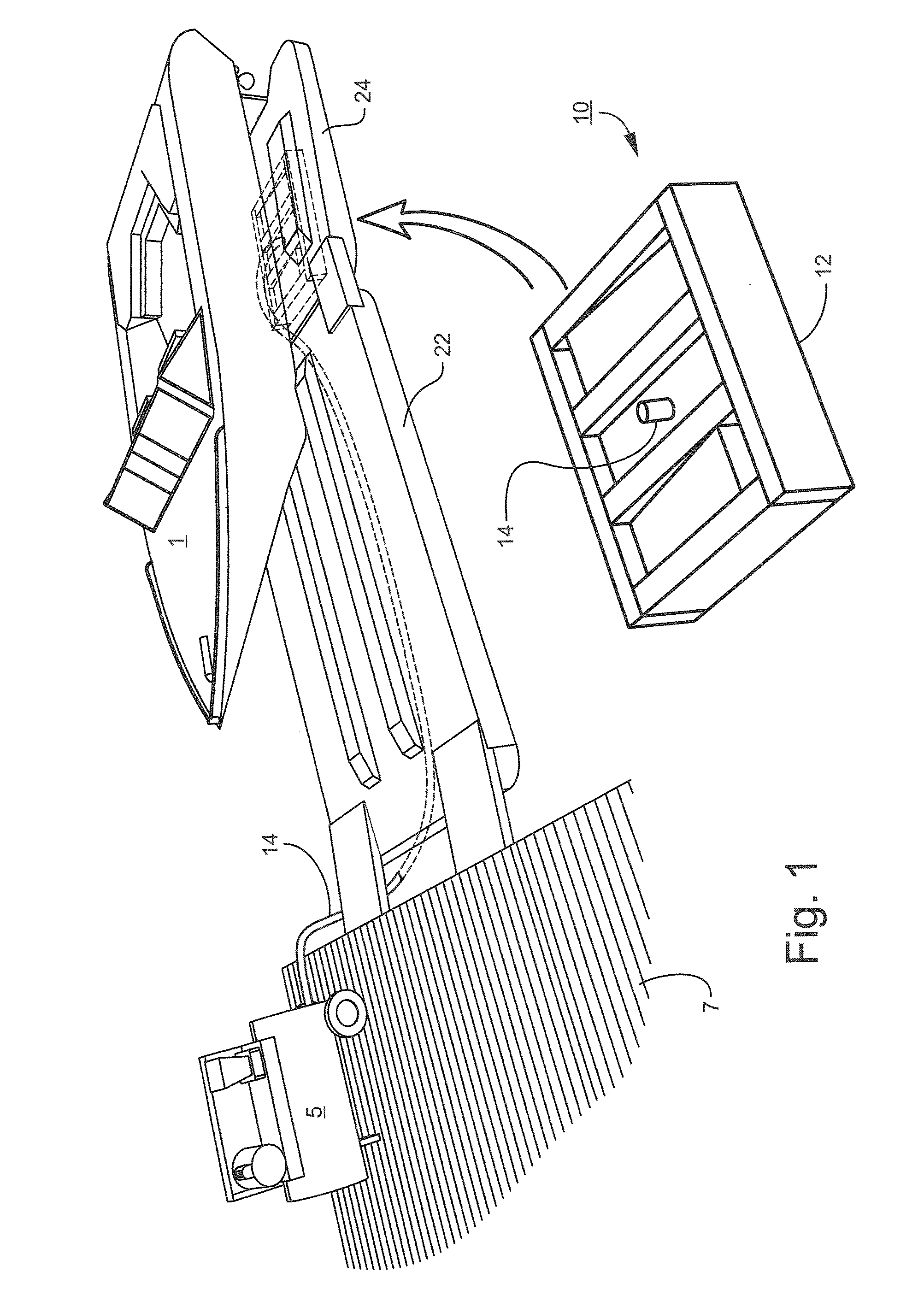

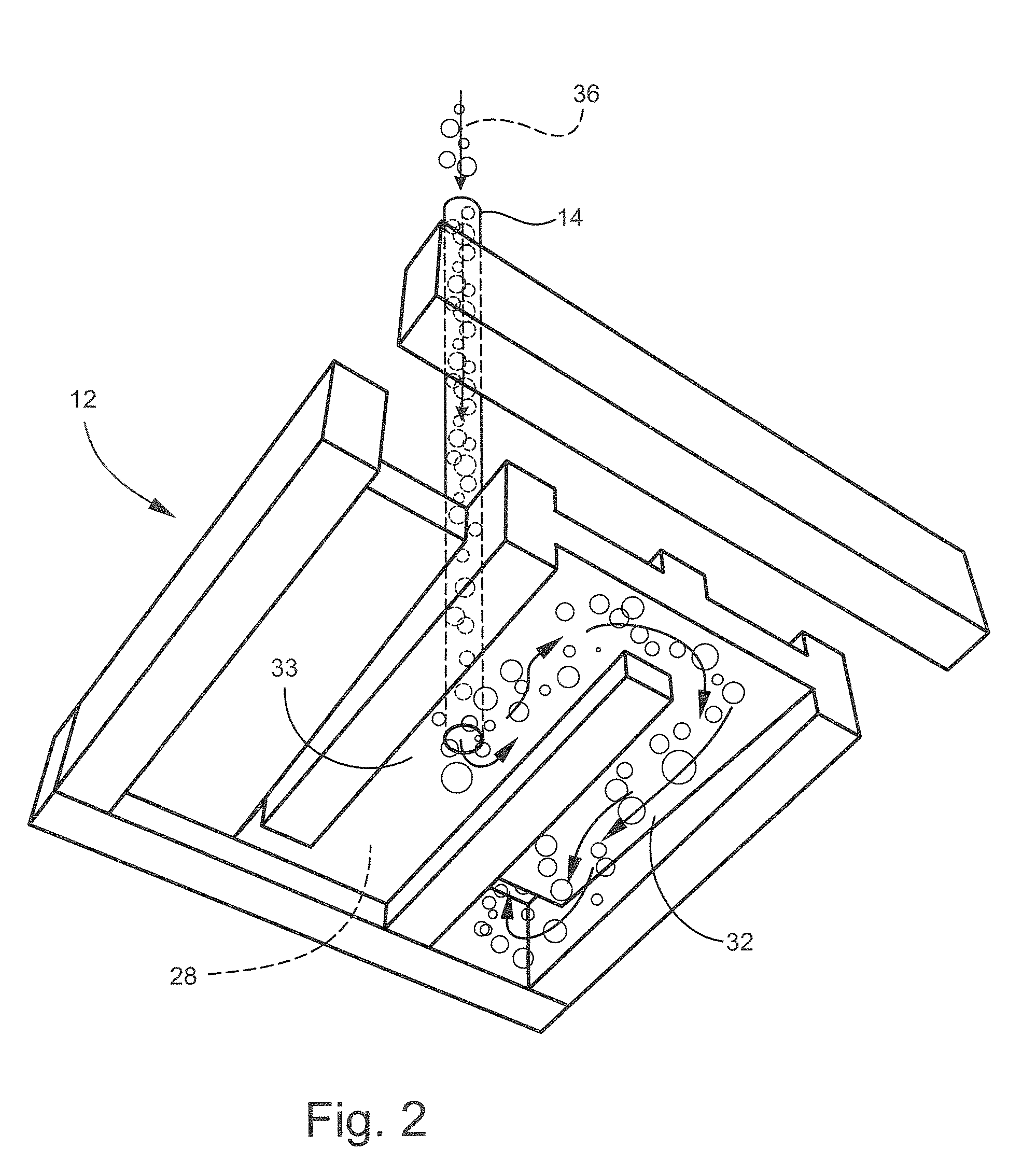

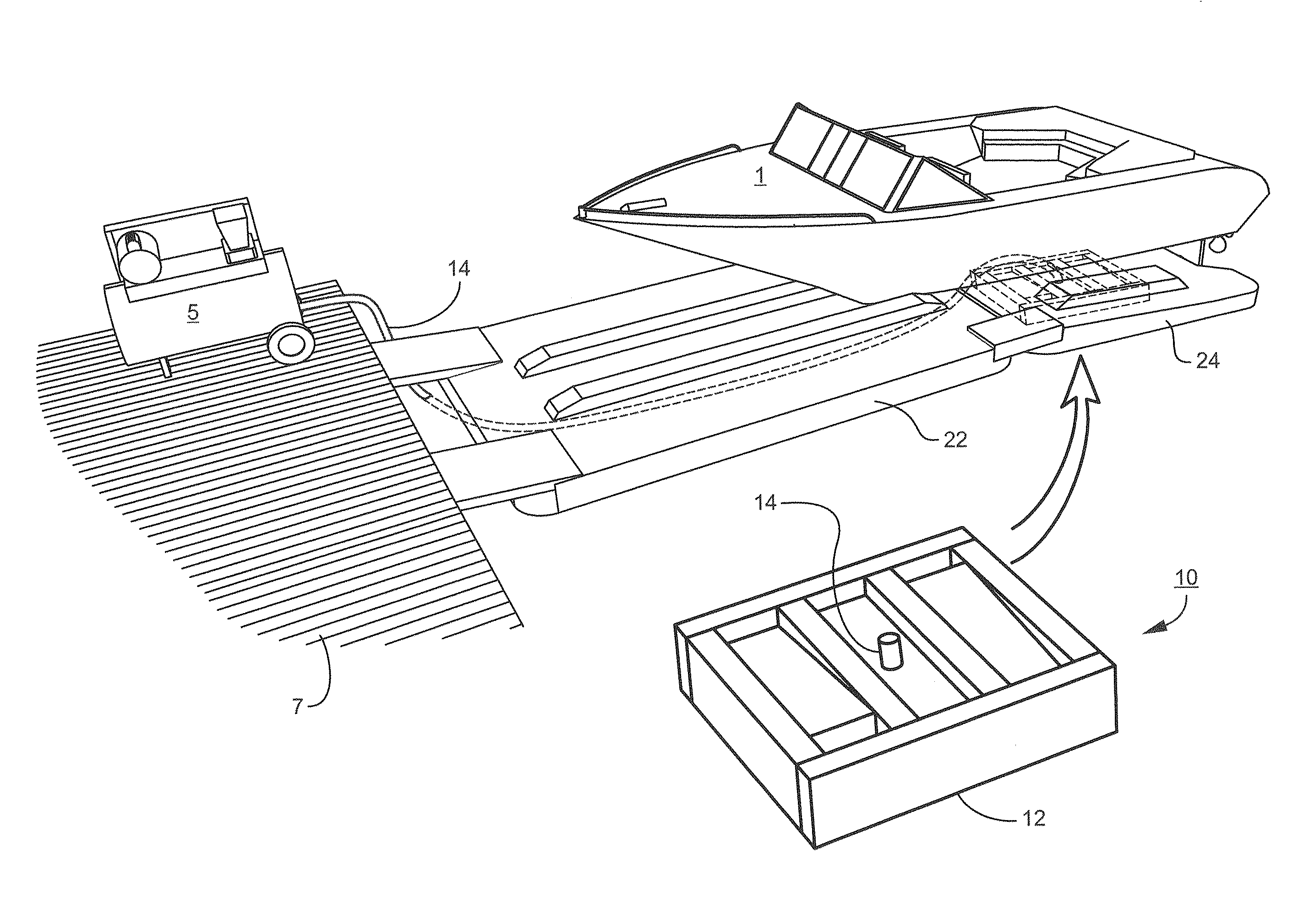

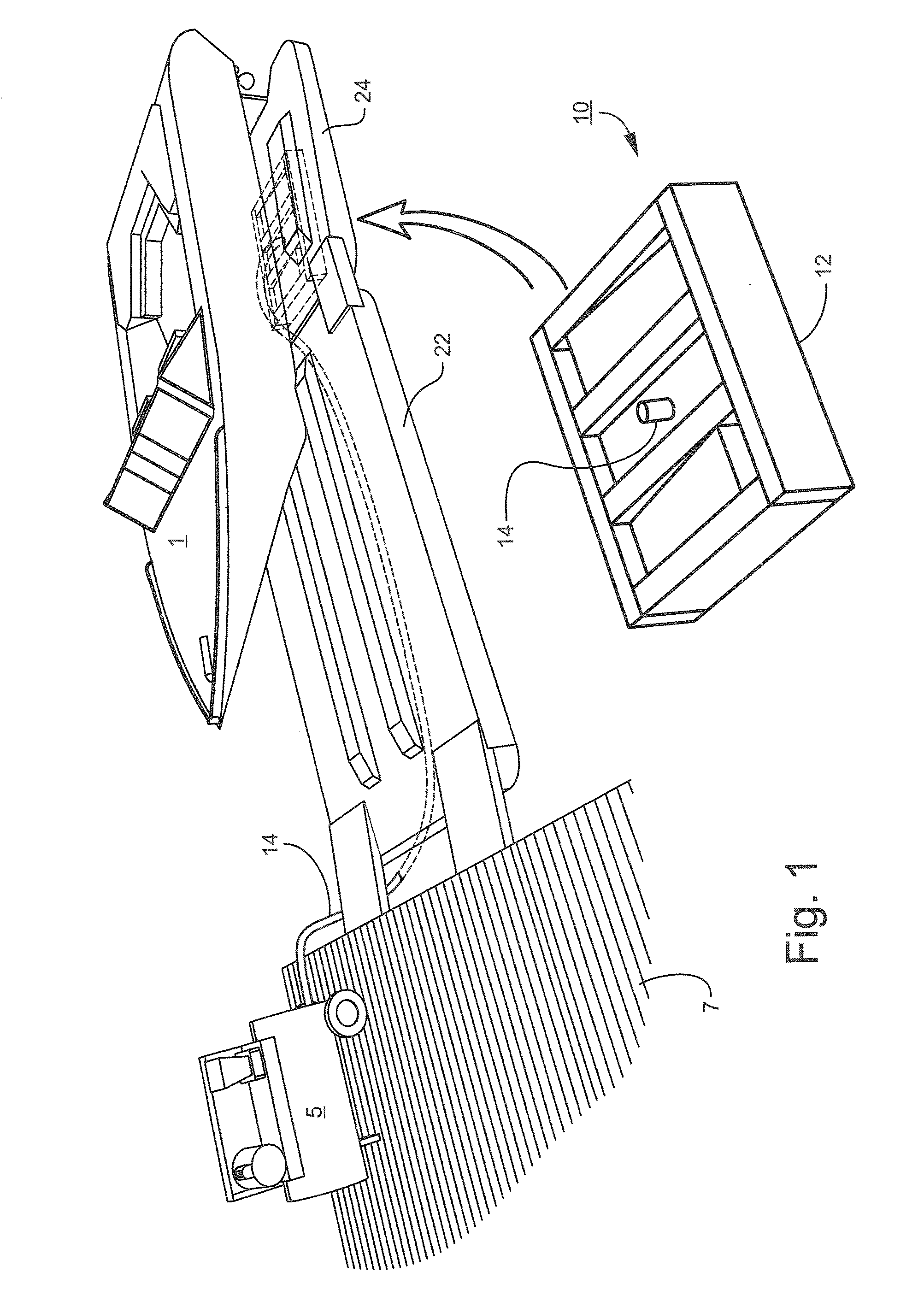

Self leveling dry dock lift

InactiveUS8887653B2Easy to processEasy to installDry-dockingFloating buildingsWind directionDry dock

An air direction device is submerged under a dry dock. The device imitates the orientation of the dry dock and is in communication with an air source, which pipes air under the device. The air travels to the most elevated portion of the device, which in turn directs the air into a depressed tank to correct dry dock imbalance.

Owner:ROGERSON L KEITH

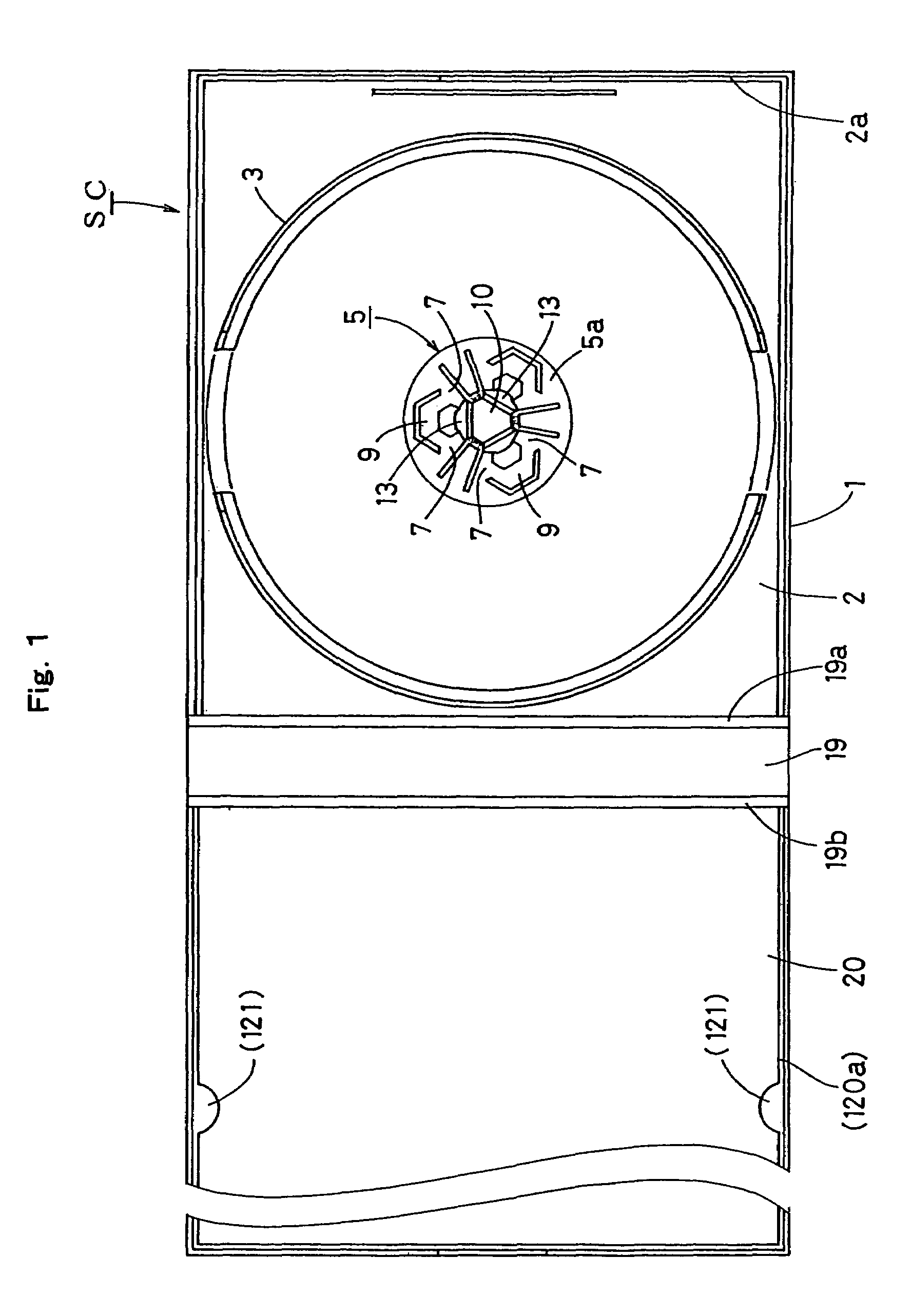

Case for disc-shaped recording medium with function of preventing dropout of holder

InactiveUS7398878B2Low production costPrevent dropoutApparatus modification to store record carriersRecord information storageEngineeringMechanical engineering

A case for accommodating a disc-shaped recording medium such as CD or DVD is disclosed. The case included a front lid opened and closed and a body formed with a central button and a holder including an annular piece formed with an engagement groove for engaging a fixing hole of the disc-shaped recording medium with legs. The annular piece is disposed around the button and the holder further includes a spring portion. A force acting so that an upper side of the disc-shaped recording medium is pressed such that the recording medium is depressed and rendered against a force acting so that the button is pushed upward via a second hinge by the spring portion. As a result, the button is prevented from being pushed over its toggle dead point and the disc-shaped recording medium is re-fixed to the annular piece by reduction and / or elimination of the external force.

Owner:NIHON VIDEO CENT

A kind of honeycomb glass pumice and its production process

ActiveCN106746627BImprove water absorptionFine and uniform pore sizeGlass shaping apparatusGlass productionHoneycombGlass particle

The invention discloses a honeycomb glass pumice formula and a production process thereof. The formula comprises the following components in percentage by weight: 89 to 96.5 percent of glass particles, 0.6 to 5.8 percent of zeolite powder, 0.6 to 3 percent of borax, 0.3 to 1.2 percent of heavy calcium carbonate powder and 0.3 to 1.2 percent of light calcium carbonate powder. The production process comprises the following four steps of preparing materials; sintering and puffing at high temperature; cooling; smashing and screening. Accurate furnace internal temperature control is realized by increasing the material mixing accuracy and strictly controlling the conveying belt speed of a sintering furnace, so as to realize uniform porosity of honeycomb glass pumice, and the honeycomb glass pumice which is 0.25 to 1.25 in specific weight, 0.8 to 120 percent in water absorption and 0.8 to 450 mu m in aperture can be prepared. Raw materials are derived from waste white transparent glass, so that environmental pollution is prevented in production and use processes, and utilization of renewable solid waste resources is realized.

Owner:大连长兴恒泰新材料科技有限公司

A kind of preparation method of cement-based composite insulation board

ActiveCN108424168BImprove insulation effectImprove mechanical propertiesCeramicwareGlass fiberPolymer

The invention discloses a manufacture method of a cement-based composite heat-insulating board, and belongs to the technical field of building materials. The manufacture method includes subjecting thesurface of a foamed cement heat-insulating board core to spray finishing, roller painting and starching by polymer sizing, adhering alkali-resisting glass fiber gridding cloth to the board core, andscrapping and drying the board core; subjecting the foamed cement heat-insulating board core to spray finishing, roller painting and starching by the polymer sizing, adhering the alkali-resisting glass fiber gridding cloth to the board core, and scrapping and drying the board core; brushing the polymer sizing to upper and lower surfaces of the foamed cement heat-insulating board core with the alkali-resisting glass fiber gridding cloth through spray finishing, roller painting and starching, and performing drying and dehydration to acquire the cement-based composite heat-insulating board. The cement-based composite heat-insulating board prepared according to the manufacture method has the advantages of excellent mechanical property and heat insulation performance, thereby having wide prospect in technological industry development of the building materials.

Owner:陈昱见

A modified steel slag cement

The invention discloses modified steel slag cement, and belongs to the technical field of building materials. A preparation method of the modified steel slag cement comprises the following steps: pulverizing and sieving steel slag to obtain steel slag powder; stirring the steel slag powder and sulfuric acid for reacting, performing cyclic freezing and unfreezing, and performing filtering and drying to obtain pretreated steel slag powder; performing ball milling, stirring and mixing on potassium permanganate and the pretreated steel slag powder, and performing high-temperature calcination to obtain calcined steel slag powder; performing ball milling, stirring and mixing on calcium carbonate, aluminum powder and the calcined steel slag powder, and performing combustion reaction to obtain modified steel slag powder; and adding cement, the modified steel slag powder, modified bagasse, a silane coupling agent and water to a mixer, and performing stirring and mixing to obtain the modified steel slag cement. The modified steel slag cement provided by the invention has excellent early strength, mechanical strength and stability.

Owner:湖州昂狮环保有限公司

A modified coal gangue aggregate concrete

The invention discloses modified coal gangue aggregate concrete and belongs to the technical field of building materials. The modified coal gangue aggregate concrete is prepared by the following steps: taking coal gangue aggregate and hydrochloric acid to react; filtering, washing and drying to obtain first-time treated coal gangue and acid leaching filtrate; ultrasonically dispersing the pre-treated coal gangue, nano iron powder and a saturated sodium fluoride solution; filtering, washing and drying to obtain second-time treated coal gangue; carrying out high-temperature reaction on the second-time treated coal gangue and cooling to obtain third-time treated coal gangue; mixing the third-time treated coal gangue and the acid leaching filtrate and stirring and mixing; then dropwise addingammonia water and filtering and washing to obtain fourth-time treated coal gangue; adding the fourth-time treated coal gangue into a tubular furnace and carrying out high-temperature reaction; coolingto obtain modified coal gangue crushed aggregates; stirring and mixing the modified coal gangue crushed aggregates, cement, fly ash, silicon ash, slag, water, a silane coupling agent and a water reducing agent to obtain the modified coal gangue aggregate concrete. The modified coal gangue aggregate concrete provided by the invention has excellent anti-freezing and dry shrinkage performance.

Owner:江西新纪元混凝土有限公司

A kind of preparation method of sharp epoxy resin bonded diamond abrasive tool

ActiveCN103056788BImprove bindingInhibit sheddingAbrasion apparatusGrinding devicesPolymer scienceFirming agent

The invention discloses a preparation method of a sharp epoxy resin bonded diamond abrasive tool, the working layer of which is mainly made of diamond abrasives, epoxy resin binders, curing agents, auxiliary abrasives, fillers and auxiliary additives; Mix 5~20 parts of self-sharpening diamond, 5~28 parts of auxiliary abrasive, 10~40 parts of filler, 0.5~10 parts of other auxiliary agents, and mix them uniformly with 17~45 parts of liquid epoxy resin, curing agent After 5-25 parts are mixed and stirred evenly, the above-mentioned mixture with fluidity is injected into a plastic mold by pouring, and a sharp epoxy resin bonded diamond abrasive tool is obtained after curing; the above parts are mass percentages. Compared with the abrasive tools prepared by hot pressing, the present invention has simple preparation process, energy saving and emission reduction, can reduce the environmental pollution of solid dust, is green and environmentally friendly, and has high production speed. Compared with the existing foreign products, the present invention has high sharpness , Strong self-sharpening, good polishing effect, long life and so on.

Owner:惠安宇信金刚石工具有限公司

Composite reinforced all-recycled brick aggregate concrete as well as optimization method and preparation method thereof

ActiveCN114394799AIncreased pozzolanic activityIncrease profitSolid waste managementEnergy industryAggregate (composite)Clinker (waste)

The invention relates to the technical industry related to energy conservation, environmental protection and new materials, and particularly discloses an optimization method for full-recycled brick aggregate concrete under the coupling action of volcanic ash activity enhancement and hybrid fiber enhancement, which comprises the following steps: firstly, carrying out chemical enhancement optimization on recycled brick aggregate to promote the effective active components of the recycled brick aggregate to react with Ca (OH) 2 to generate C-S-H gel; the compactness of the C-S-H gel is improved, the variety of the C-S-H gel is improved, the primary hydration rate of cement clinker in a certain range of the recycled brick aggregate is improved, and secondary hydration of the cement clinker is promoted; the recycled brick aggregate is further physically enhanced and optimized, and hybrid fibers of different materials and specifications are specifically selected to enhance the concrete in different dimensions. According to the optimization method and the corresponding concrete mix proportion, the defects of the all-recycled brick aggregate concrete are comprehensively improved, the performance of the all-recycled brick aggregate concrete is improved, resource utilization of the building waste sintered clay bricks is achieved, the comprehensive utilization rate of cement is remarkably increased, and the performance of the cement is fully exerted.

Owner:ANYANG NORMAL UNIV

High level filling mining method of fully mechanized caving in thick coal seam under railway in coal mine

ActiveCN110359910BAvoid breakingInhibition of fractureUnderground miningSurface miningResource recoveryCut and fill

The invention discloses a strip fully-mechanized top coal caving high cut and fill mining method of a thick coal seam under a coal mine railway. A strip type working face mining method is adopted; anda fully-mechanized top coal caving technology is adopted for mining. The strip fully-mechanized top coal caving and high-position cut and fill mining method is characterized in that the first weighting distance is taken as the basis of designing the inclination length of a strip type working face; a high filling roadway is constructed before the mining of the working face; a blasthole and a filling drill hole are constructed in the high filling roadway; a top coal area is blasted in advance through the blasthole, and a goaf is filled through the filling drill hole, so that the caving of overlying rocks is reduced, and the ground depression is suppressed; and pressing coal under the railway is converted into recoverable reserves, thus, the recovery rate of resources and the economic benefits are increased, and the length of service of the mine is prolonged.

Owner:XINWEN MINING GROUP

Self Leveling Dry Dock Lift

InactiveUS20140069310A1Easy to processEasy to installDry-dockingFloating buildingsWind directionDry dock

An air direction device is submerged under a dry dock. The device imitates the orientation of the dry dock and is in communication with an air source, which pipes air under the device. The air travels to the most elevated portion of the device, which in turn directs the air into a depressed tank to correct dry dock imbalance.

Owner:ROGERSON L KEITH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com