Honeycomb glass pumice formula and production process thereof

A technology of glass pumice and production technology, which is applied in glass production, glass molding, glass manufacturing equipment, etc., can solve problems such as labor-consuming, low production efficiency, and increased production costs, so as to reduce the number of water changes and enhance shock resistance High performance and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

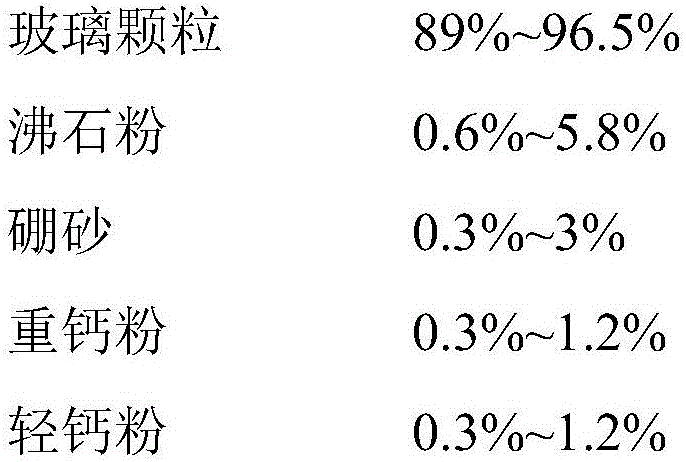

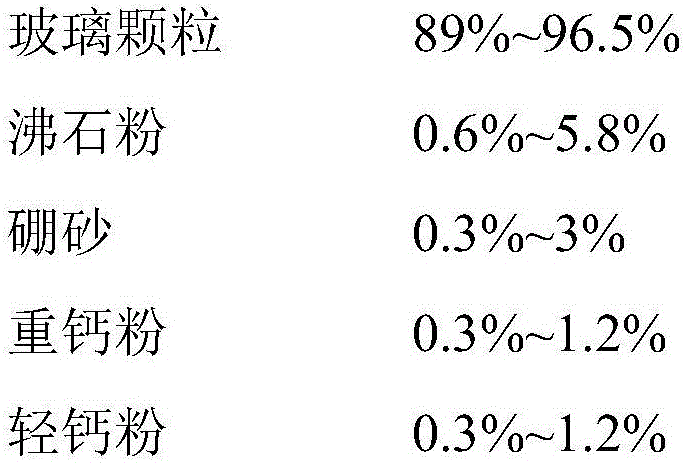

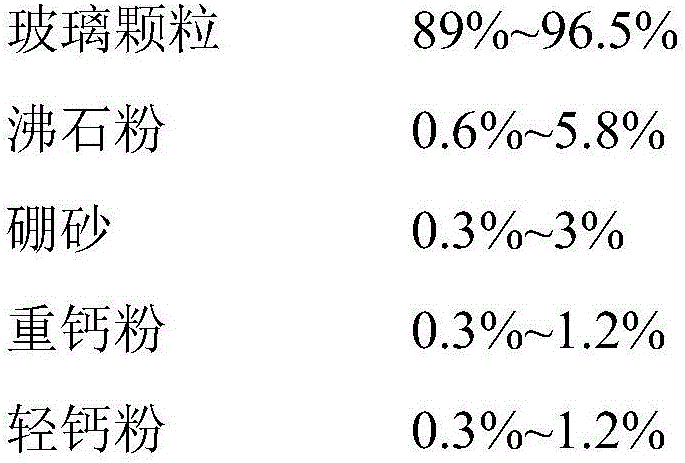

Embodiment 1

[0049] Mix 89 kg of glass powder with a fineness of 80-200 mesh, 5.6 kg of zeolite powder of 200-350 mesh, 3 kg of borax of 120-220 mesh, 1.2 kg of heavy calcium powder of 120-220 μm, and 1.2 kg of light calcium powder of 120-220 mesh, As a sponge foam glass raw material. In order to ensure that the materials are mixed evenly, it is required that the ratio of the batching materials be added with high accuracy, and all additives and glass powder must be fully stirred before entering the heating furnace.

[0050] Spread it evenly on the conveyor belt of the sintering furnace, with a tile thickness of 10mm; control the conveying speed of the conveyor belt at 0.65-0.8m / min, and control the temperature in the sintering furnace so that the temperature in the sintering furnace during the preheating stage is 750°C , the duration is 4min; then enter the softening stage, the temperature in the sintering furnace is 820°C, and the duration is 10min; then enter the foaming stage, the tempe...

Embodiment 2

[0053] Mix 92kg of glass powder with a fineness of 80-200 mesh, 4.5kg of zeolite powder of 200-350 mesh, 2kg of borax of 100-150 mesh, 0.75kg of heavy calcium powder of 120-220 mesh, and 0.75kg of light calcium powder of 120-220 mesh, As a sponge foam glass raw material. In order to ensure that the materials are mixed evenly, it is required that the ratio of the batching materials be added with high accuracy, and all additives and glass powder must be fully stirred before entering the heating furnace.

[0054] Spread it evenly on the conveyor belt of the sintering furnace, the thickness of the laying is 12mm. Control the transmission speed of the conveyor belt at 0.75-0.9m / min, control the temperature in the sintering furnace so that the temperature in the sintering furnace in the preheating stage is 750°C, and the duration is 3 minutes; after the softening stage, the temperature in the sintering furnace is 830℃, the duration is 67.2min; then enter the foaming stage, the temp...

Embodiment 3

[0057] Mix 94.5kg glass powder with a fineness of 80-200 mesh, 3kg zeolite powder with 200-350 mesh, 1.5kg borax with 100-150 mesh, 0.5kg heavy calcium powder with 120-220 mesh, and 0.5kg light calcium powder with 120-220 mesh Mixed, as a sponge foam glass raw material. Spread it evenly on the conveyor belt of the sintering furnace, the thickness of the tile is 13mm, control the conveying speed of the conveyor belt at 0.7-0.85m / min, control the temperature in the sintering furnace so that the temperature in the sintering furnace during the preheating stage is 760°C, The duration is 2.5-3.5min; then after the softening stage, the temperature in the sintering furnace is 850°C, and the duration is 8min; then after the foaming stage, the temperature in the sintering furnace is 1080°C, and the duration is 18min, and then enters annealing stage, the temperature in the sintering furnace is 320°C, and the duration is 6 minutes to obtain a sintered expanded foamed heating material. Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com