Composite reinforced all-recycled brick aggregate concrete as well as optimization method and preparation method thereof

An optimization method and technology of recycled bricks, applied in complex mathematical operations, sustainable manufacturing/processing, forecasting, etc., can solve the problems of low comprehensive utilization rate of cement, large shrinkage rate of fully recycled brick aggregate concrete, and limited application, etc., to achieve Improve the efficiency of secondary hydration, improve the comprehensive utilization rate, and increase the effect of regeneration usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A C40 composite reinforced fully recycled brick aggregate concrete, composed of cement, active reinforcing agent, recycled brick coarse aggregate, recycled brick fine aggregate, steel fiber, cellulose fiber and water in a weight ratio of 1:0.015:0.808:0.347: 0.163:0.001:0.340 formulation.

[0071] The formula for calculating the mixing ratio is as follows:

[0072] 1. Calculation of water-cement ratio

[0073] (1) Weighted cement hydration degree calculation

[0074] Cement is P.O 42.5 Ordinary Portland Cement, where C 3 S=53%, C 2 S=16%, C 3A =8%, C 4 AF=10%, other admixtures are 13%.

[0075]

[0076] (2) Activity index and activity enhancement

[0077] Recycled brick aggregate activity coefficient K pc =78.80%.

[0078] The active enhancer is: Ca(OH) 2 , the dosage is 1% of the mass of the recycled brick coarse aggregate and 2% of the recycled brick fine aggregate, and the activity enhancement coefficient α EC = 1.109.

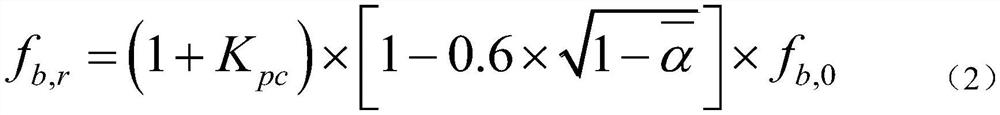

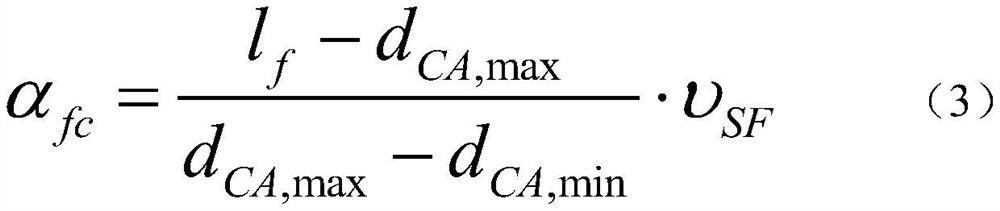

[0079] (3) Cement strength f ...

Embodiment 2

[0105] A C35 composite reinforced fully recycled brick aggregate concrete, composed of cement, active reinforcing agent, recycled brick coarse aggregate, recycled brick fine aggregate, steel fiber, cellulose fiber and water, in a weight ratio of 1:0.018:1.055:0.390 :0.129:0.002:0.390 formulated.

[0106] The formula for calculating the mixing ratio is as follows:

[0107] 1. Calculation of water-cement ratio

[0108] (1) Weighted cement hydration degree calculation

[0109] Cement is P.O 42.5 Ordinary Portland Cement, where C 3 S=55%, C 2 S=18%, C 3 A=10%, C 4 AF=8%, other admixtures are 9%.

[0110]

[0111] (2) Activity index and activity enhancement

[0112] Recycled brick aggregate activity coefficient K pc = 80.00%.

[0113] The active enhancer is: Ca(OH) 2 , the dosage is 1% of the mass of the recycled brick coarse aggregate and 2% of the recycled brick fine aggregate, and the activity enhancement coefficient α EC = 1.074.

[0114] (3) Cement strength f ...

Embodiment 3

[0140] A C30 composite reinforced fully recycled brick aggregate concrete, composed of cement, active reinforcing agent, recycled brick coarse aggregate, recycled brick fine aggregate, steel fiber, cellulose fiber and water, in a weight ratio of 1:0.023:1.339:0.495 :0.150:0.002:0.430 formulated.

[0141] The formula for calculating the mixing ratio is as follows:

[0142] 1. Calculation of water-cement ratio

[0143] (1) Weighted cement hydration degree calculation

[0144] Cement is P.O 42.5 Ordinary Portland Cement, where C 3 S=50%, C 2 S=20%, C 3 A=12%, C 4 AF=6%, other admixtures are 12%.

[0145]

[0146] (2) Activity index and activity enhancement

[0147] Recycled brick aggregate activity coefficient K pc =77.186%.

[0148] The active enhancer is: Ca(OH) 2 , the dosage is 1% of the mass of the recycled brick coarse aggregate and 2% of the recycled brick fine aggregate, and the activity enhancement coefficient α EC = 1.074.

[0149] (3) Cement strength f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com