Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Increased wrinkle recovery angle" patented technology

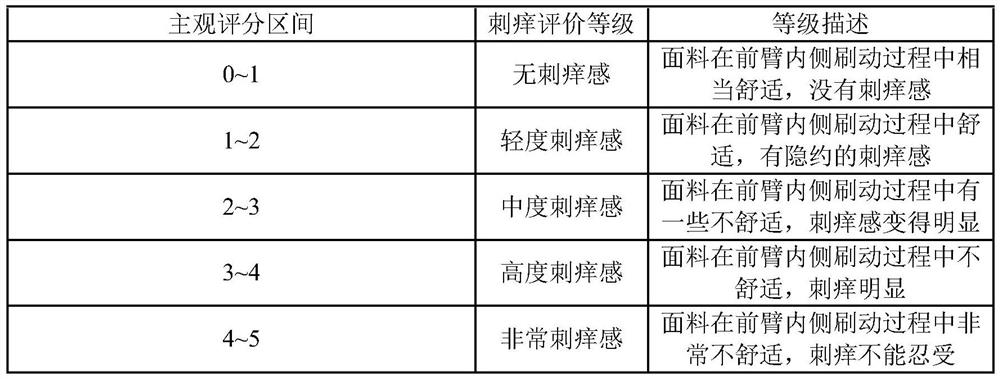

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment method for antibacterial and anti-ultraviolet cotton fabrics

ActiveCN106758216AImprove antibacterial propertiesImproves UV resistanceBiochemical fibre treatmentLight resistant fibresGrape seedUltraviolet

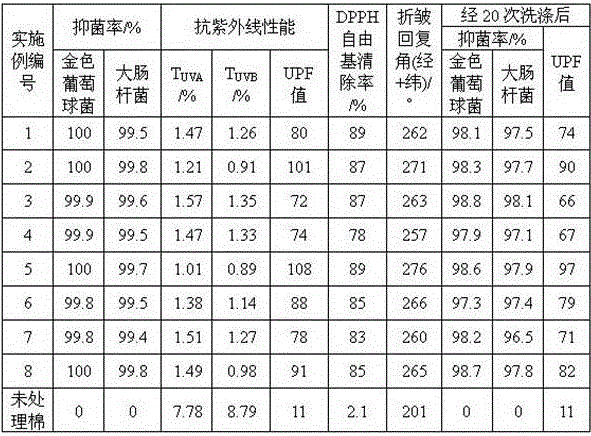

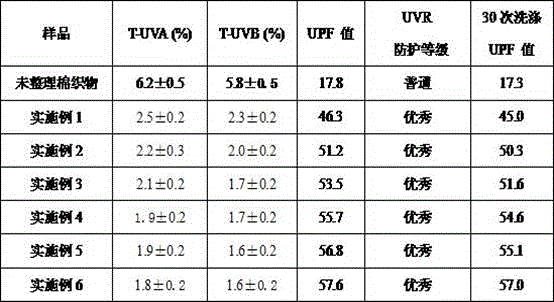

The invention discloses a treatment method for antibacterial and anti-ultraviolet cotton fabrics. The treatment method comprises the following steps: step 1, soaking the cotton fabrics with a nonionic surfactant; step 2, modifying the cotton fabrics with chitosan quaternary ammonium salt; step 3, dipping the cotton fabrics with antibacterial finishing liquid prepared by mixing 5-15 parts of a natural antibacterial agent composed of extracts of grape seeds, persimmon leaves, ginkgo leaves and licorice roots, 0.3-1 part of polyoxyethylene-40 hydrogenated castor oil and 1000 parts of water; step 4, soaking the cotton fabrics in a mixed aqueous solution containing 0.001-0.005mol / L of silver nitrate or silver sulfate or silver acetate and 1-3 g / L of soluble starch or hydroxyethyl cellulose to prepare the nano-silver attached antibacterial cotton fabrics. The prepared cotton fabrics not only have good antibacterial performance and anti-ultraviolet performance, but also have performance of resisting oxidation and scavenging free radicals, and have improved anti-wrinkle performance and good washing durability.

Owner:EASTERN LIAONING UNIV

Modified-chitosan-containing anti-ultraviolet finishing agent for cotton fabric and anti-ultraviolet cotton fabric obtained by aid of anti-ultraviolet finishing agent

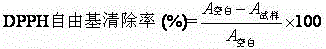

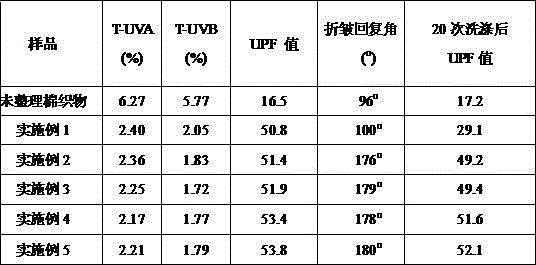

The invention provides a modified-chitosan-containing anti-ultraviolet finishing agent for cotton fabric and anti-ultraviolet cotton fabric obtained by aid of the anti-ultraviolet finishing agent. The modified-chitosan-containing anti-ultraviolet finishing agent for the cotton fabric is a uniformly mixed solution of 3,4,5-trimethoxybenzoyl chitosan, a crosslinking agent, a penetrant and an acetic acid or lactic acid solution, wherein the crosslinking agent is organic polycarboxylic acid or amino-modified silicone oil emulsion; the penetrant is either JFC or peregal O. The anti-ultraviolet cotton fabric with anti-ultraviolet, anti-bacterial and anti-crease finishing functions is obtained through double-dip double-nip, water washing and drying, the anti-ultraviolet, anti-bacterial and anti-crease finishing functions are high in durability, the cotton fabric still maintains the original style of the fabric after finishing, the hand feel, the strength, the whiteness and the color of the cotton fabric are not affected, and the original human body affinity is maintained; the finishing agent is simple in composition and easy to prepare, and a finishing process is simple and environment-friendly.

Owner:EASTERN LIAONING UNIV

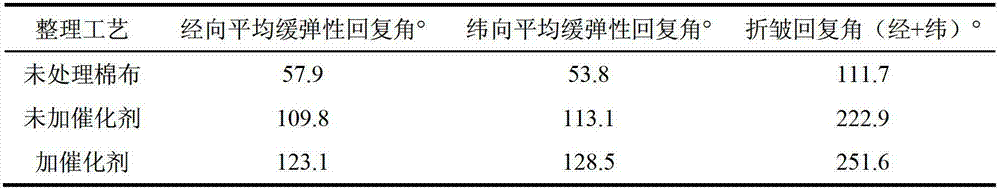

Modification finishing process of cellulose fibre fabric

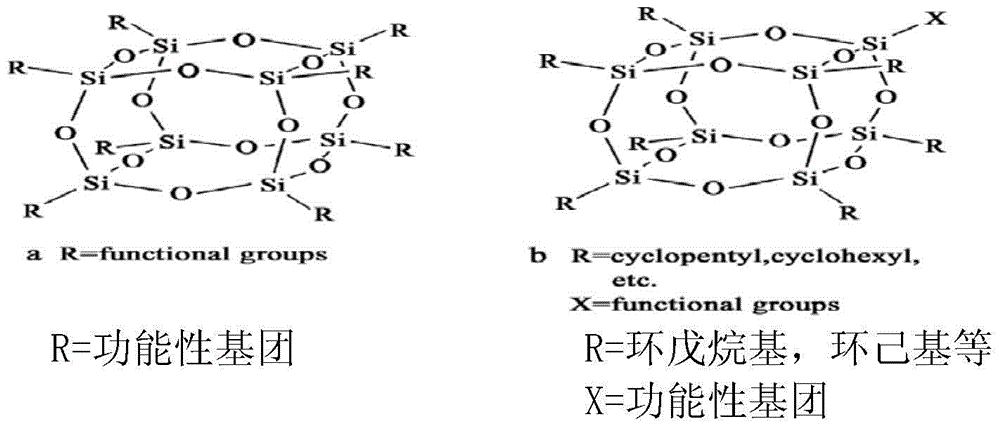

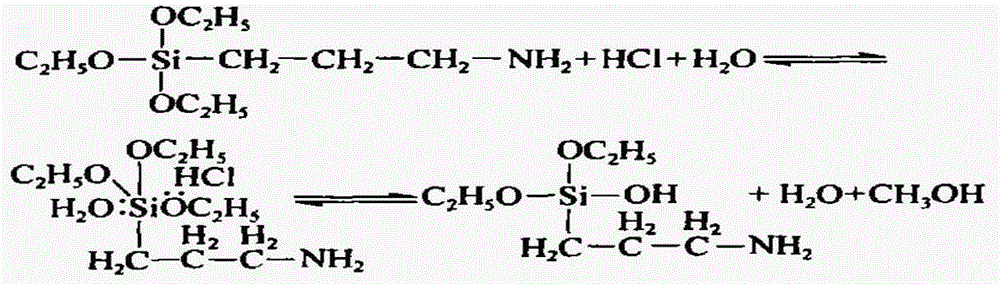

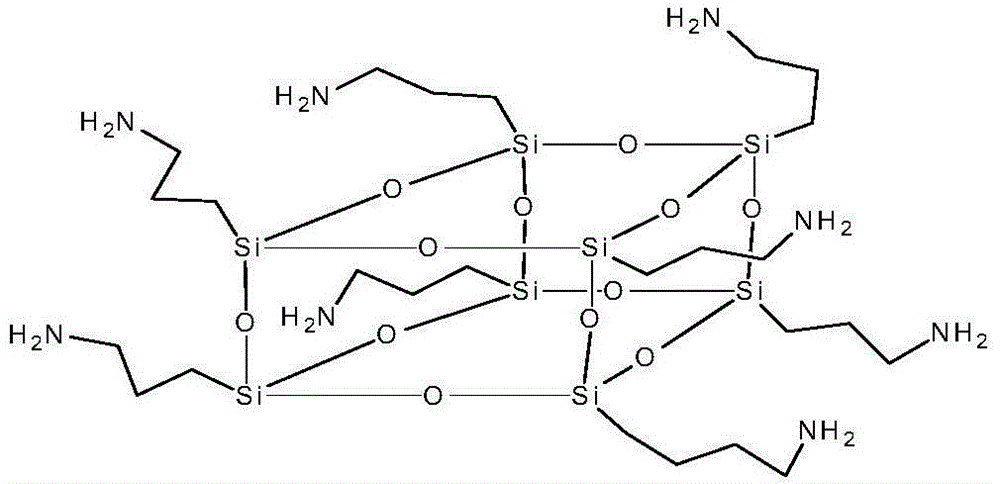

InactiveCN104480711ABreak dependenciesBreak the blockadeSilicon organic compoundsVegetal fibresWrinkle skinFormylation reaction

The invention discloses a modification finishing process of a cellulose fibre fabric. The technological process is as follows: by using gamma-aminopropyl triethoxysilane as a raw material, synthesising out poly-gamma-aminopropyl polyhedral oligomeric silsesquioxane POSS-NH2 with a regular octa-amino-group-containing cage structure through acidification catalysis, hydrolysis and condensation, preparing reactive multi-N-methoxyl cage-like silsesquioxane POSS-N(CH2(OH))2 through formylation reaction, and then carrying out padding cross-linking modification finishing, drying and roasting on the mixture solution of the cellulose fibre fabric and the POSS-N(CH2(OH))2, thus the elastic recovery performance of the finished cellulose fibre fabric is effectively improved, and with the increasing of the concentration of the POSS-N(CH2(OH))2, the (warp-directional and weft-directional) wrinkle recovery angles of the finished cellulose fibre fabric are obviously increased, thus improving the shrink-proof and wrinkle-proof performances of the fabric.

Owner:FUJIAN ZHONGHE

Dyeing and finishing method for durable press bombasine yarn dyed fabric

ActiveCN103451917ALittle strengthHigh surface finishBiochemical fibre treatmentDyeing processFiberCellulose

Belonging to the application technology field of yarn dyed fabric dyeing and finishing in the textile industry, the invention provides a dyeing and finishing method for a durable press bombasine yarn dyed fabric, and aims to solve the technical problems of easy fiber damage, undesirable antiwrinkling effect and poor washfastness, easy generation of formaldehyde residue and other ecological pollution. The method provided in the invention combines a chemical technique and a biological enzyme technique to carry out scouring and bleaching and dyeing on a bombazine fabric, that is to say, caustic soda, cellulose and catalase are taken for cotton fiber scouring and bleaching, soda ash, protease and lipase are taken for raw silk degumming and dyeing, and an active dye and laccase are employed to perform bombazine fiber dyeing and aftertreatment. Meanwhile, formaldehyde-free antiwrinkling resin is employed to perform liquid ammonia moist crosslinking on the fabric so as to improve the wrinkle resilience of the fabric. By applying the method provided in the invention to perform dyeing and finishing on the bombasine yarn dyed fabric, the fabric has a smooth surface and soft handfeel, also, the chroma of a dyeing waste liquid is reduced. When high antiwrinkling performance is acquired, the fabric strength is less reduced. The treatment process is safe and environment-friendly, thus being in line with the processing requirements of ecological textiles.

Owner:NANTONG XINLAI SILK GARMENTS

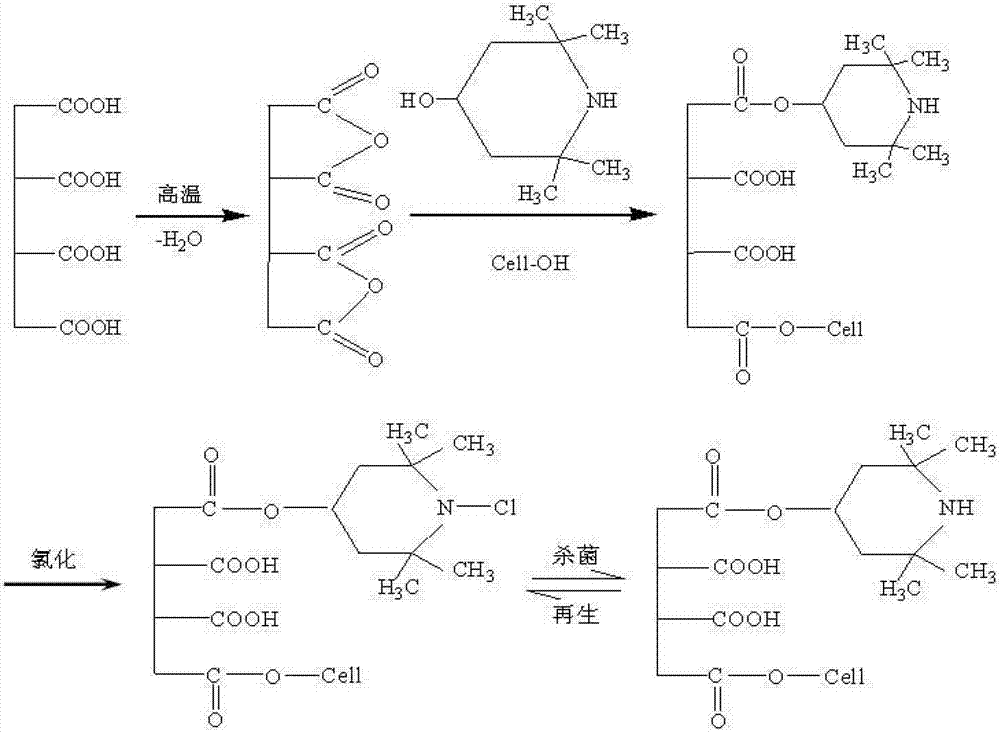

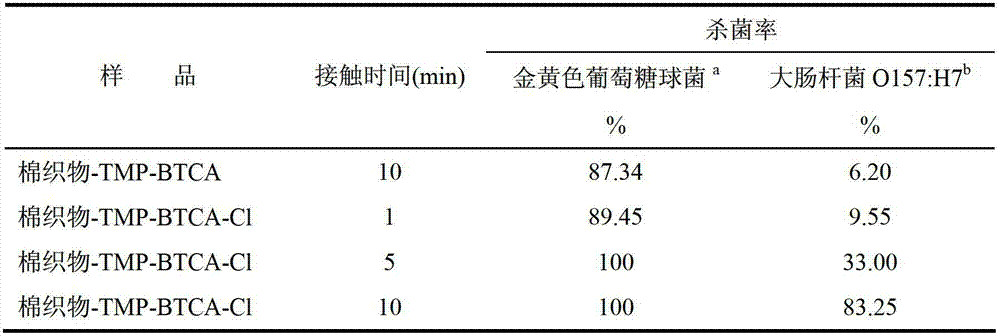

Anti-bacterial and anti-wrinkling finishing method for cotton fabric

ActiveCN102733186AGood antibacterial functionHigh antibacterial efficiencyVegetal fibresHalogenPolyphosphate

The invention provides an anti-bacterial and anti-wrinkling finishing method for cotton fabric, comprising the following steps of: dissolving catalyst, and equimolar 2, 2, 6, 6-tetramethyl-4-pipradrol and butanetetracarboxylic acid in water, so that finishing bath foam can be formed; and soaking the cotton fabric in the finishing bath foam, treating the cotton fabric by the working procedures such as rolling and baking, soaping, washing by water, drying, halogenating and drying, wherein the catalyst is one of the sodium dihydrogen phosphate, disodium hydrogen phosphate, sodium polyphosphate and sodium hypophosphite, the halogenating treatment comprises the step of soaking the dried cotton fabric in active halogen-containing solution, and the drying temperature is 150-200DEG C. The cotton fabric which is finished by the method in an anti-bacterial and anti-wrinkling finishing way has the dual performances such as bacterial resistance and wrinkling resistance, is high in anti-bacterial efficiency, good in anti-wrinkling performance, and free from formaldehyde release.

Owner:JIANGNAN UNIV

Multifunctional finishing agent

ActiveCN109457475AImprove antibacterial propertiesImproves UV resistanceHeat resistant fibresVegetal fibresEgg proteinPolyvinyl alcohol

The invention discloses a multifunctional finishing agent which comprises chitosan, sericin, titanium dioxide, hydrosol, aloin, tea polyphenol, quaternary ammonium salt, ethylenediamine tetraacetic dianhydride, polyatomic acid, glucose, hexa (4-amino phenoxy) cyclotriphosphazene, ammonium polyphosphate, guanidine carbonate, graphene oxide, montmorillonoid, magnesium chloride, egg protein, polyvinyl alcohol, coupling agents, acetic acid and solvents. The multifunctional finishing agent is reasonable in formula, and a finished fabric is good in antibacterial property, excellent in flame resistance, soft in hand feeling, resistant to creasing and washable.

Owner:JILIN NORMAL UNIV

Production process of jeans

ActiveCN108560241ANot easy to fadeInhibition of dissolutionDry-cleaning apparatus for textilesGrip property fibresSulfonateHydrogen

The invention discloses a production process of jeans. The production process comprises the steps of denim yeast-washing, jeans sewing and jeans snow-washing, wherein the denim yeast-washing step comprises the following steps: (I) de-sizing; (II) soaking in mixed liquid composed of a color fixing agent and an elastic protectant; (III) soaking in mixed liquid composed of an anti-dyeing agent, an enzyme elastic protectant and water; (IV) soaking in mixed liquid composed of sodium carbonate, caustic soda, sodium hypochlorite and water; (V) soaking in mixed liquid of oxalic acid, hydrogen peroxideand water; (VI) soaking in soft oil and silicon oil; the jeans snow-washing step comprises the following steps: soaking in mixed liquid composed of an anti-dyeing agent, a neutral enzyme and water; (II) soaking in mixed liquid composed of sodium hypochlorite, sodium carbonate and water; (III) soaking in mixed liquid of fatty acid methyl ester sulfonate and water; (IV) stir-frying in potassium permanganate; therefore, the jeans are more colorful, outstanding in old feeling and capable of keeping colorfast for a long time.

Owner:广州市创兴服装集团有限公司

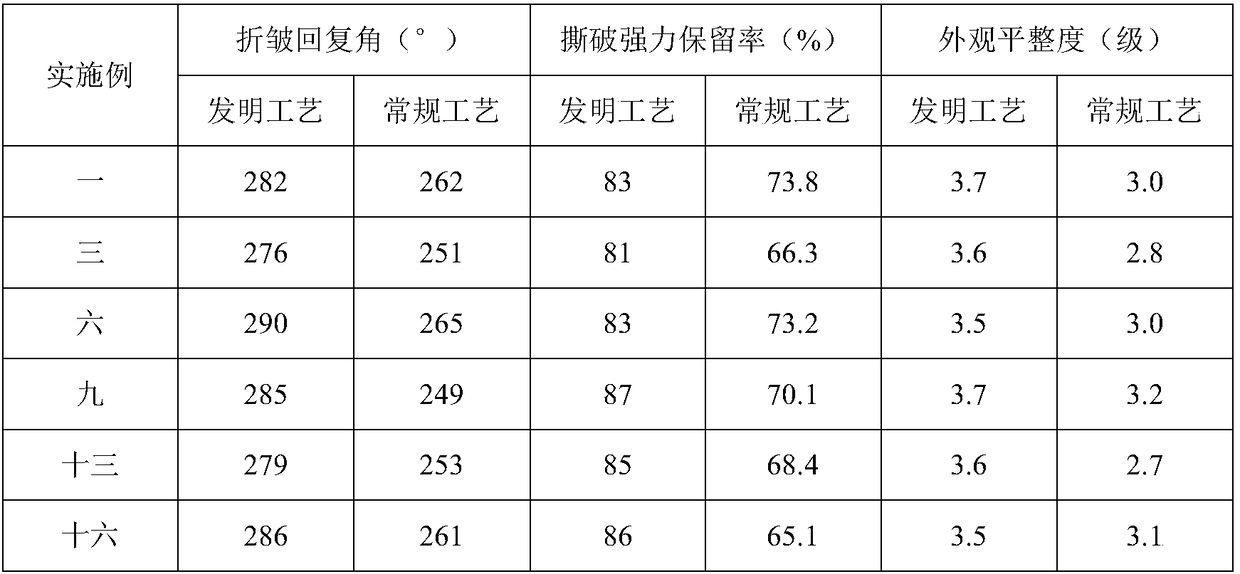

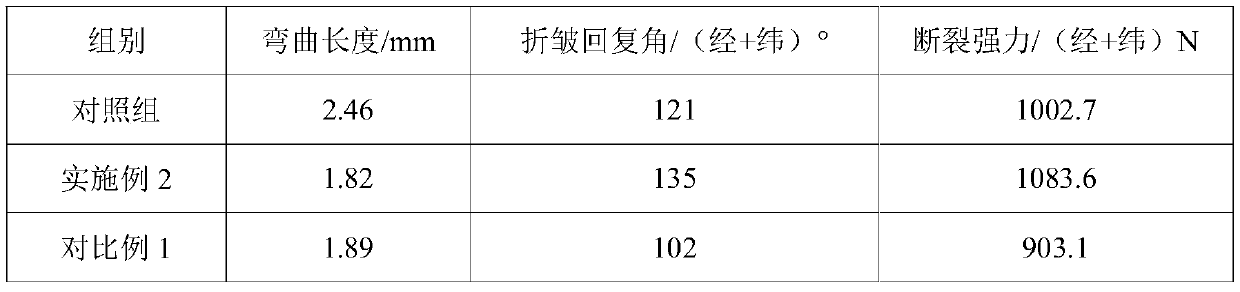

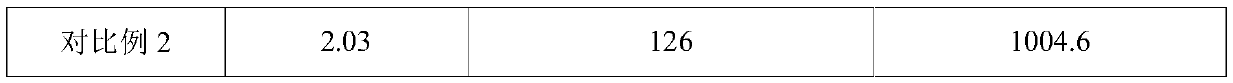

Anti-crease finishing method for improving strength and hand feeling of cotton fabric

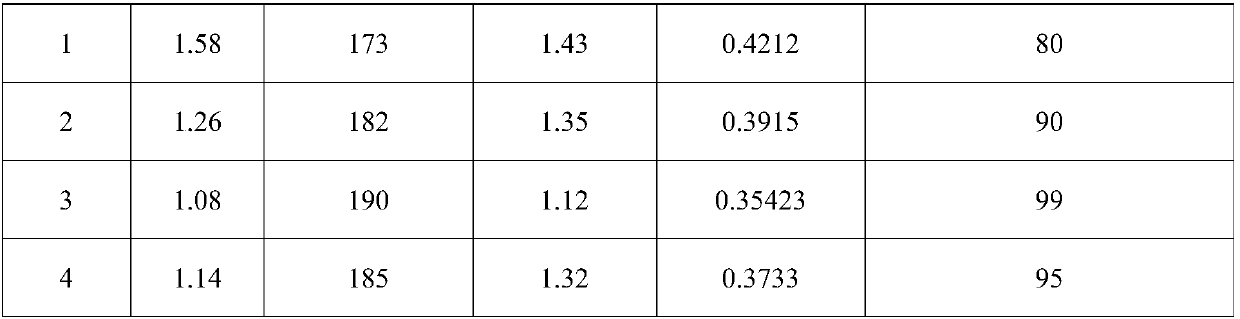

ActiveCN108517689AIncreased wrinkle recovery angleHigh strengthWrinkle resistant fibresGrip property fibresLiquid ammoniaEngineering

The invention relates to an anti-crease finishing method for improving the strength and the hand feeling of a cotton fabric, and belongs to a textile printing and dyeing post-finishing technology. Thepurpose of the invention is to provide the method for changing the anti-crease finishing process of the cotton fabric. A non-iron finished cotton fabric is sequentially subjected to liquid ammonia finishing, non-iron finishing and liquid ammonia finishing, so the anti-crease effect of the cotton fabric is greatly improved, and the strength and the hand feeling of the cotton fabric are improved. The method fully shows the original advantages of the cotton fabric, and also can modify and optimize the cotton fabric, increase the creasy recovery angle of the cotton fabric, increase the strength of the cotton fabric, improve the flatness and improve the hand feeling of the cotton fabric, so the non-ironing effect is achieved, and the quality of the cotton fabric and the grade of the obtained product are greatly improved. The method has a simple process and a good anti-crease effect, is a clean production technology meeting environmental protection requirements, and has extremely high social and economic benefits.

Owner:WUHAN TEXTILE UNIV

Efficient and poor yellow-changing citric acid non-iron finishing liquid and application thereof

InactiveCN103409992AImprove finishing effectInhibition of decarboxylationVegetal fibresChemistryFormaldehyde free

The invention relates to an efficient and poor yellowing-changing citric acid non-iron finishing liquid and the application thereof. The finishing liquid is a citric acid aqueous solution containing a polyatomic alcohol chain extendor, a penetrating agent, a softening agent and an esterized catalyst. The application is as follows: a piece of fabric is in padding into finishing liquid, after padding, the liquid carrying rate can reach 50 to 80 percent, pre-baking and baking are performed, and then water washing and drying are carried out, so as to obtain a piece of finished fabric. According to the invention, by adding the polyatomic alcohol chain extendor, two problems of yellowing and poor resilience in citric acid DP (durable press) finishing to pure cotton fabric can be solved at the same time, as a result, the citric acid non-iron finishing having a cost advantage can meet the requirements of replacing 2D resin finishing in performance, and has a great significance to the popularization of polybasic carboxylic acid formaldehyde-free nonironing.

Owner:DONGHUA UNIV

Antistatic after-finishing process for woolen fabric

InactiveCN104294604AImprove stabilityEvenly distributedAnimal fibresAntibacterial activityEngineering

The invention discloses an antistatic after-finishing process for woolen fabric. The process includes the steps of: soaking in a first finishing solution, primary squeezing, soaking in a second finishing solution, secondary squeezing, drying, shearing and decating, etc. The woolen fabric produced by the antistatic after-finishing process has good stability, nanoscale metal oxides are uniformly distributed on the cloth and not easy to fall off, and the woolen fabric has excellent antistatic and antibacterial functions. By employing citric acid to perform antibacterial finishing on wool fabric, the antibacterial activity of a wool textile is greatly improved, the creasy recovery angle of the wool textile is enhanced, and also the crease resistance of the wool textile is improved.

Owner:JIANGSU SUNSHINE

Softening finishing method for fabric

InactiveCN104420214AReduce warp and weft bending stiffnessFeel goodBiochemical fibre treatmentVegetal fibresEngineeringCellulase

The invention discloses a softening finishing method for a fabric. The method comprises the steps of pre-treating the fabric with cellulase with concentration being 2.5% (o.w.f) for 50-60min under the conditions that the bath ratio is 1:20, the pH value is 4-4.5 and the temperature is 45 DEG C; and performing impregnation softening treatment on the fabric by adopting a 50g / L Klein softening agent MCT and a 1g / L penetrant JFC, performing two times of impregnation and rolling with the liquor detention of 85%, and drying for 3-5min at 100 DEG C. By adopting the method, the handfeel of the fabric is improved, the softness of the fabric is improved, meanwhile, the physical and mechanical properties of the fabric are influenced little, and the service life of the fabric is guaranteed.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

Black rice anthocyanin-based cotton fabric anti-ultraviolet finishing agent

ActiveCN105113219AIncreased wrinkle recovery angleImprove wrinkle resistanceDyeing processVegetal fibresCotton fibreCarboxylic acid

The invention provide a black rice anthocyanin-based cotton fabric anti-ultraviolet finishing agent, which is prepared from the raw materials in total volume: black rice anthocyanin extracting solution, 0-5g / L of organic polybasic carboxylic acid, 0-5g / L of sodium citrate, 1g / L of sodium sulfate and 0.5g / L of penetrant JFC. According to the technical solution, cotton fiber and a fabric thereof are endowed with three finishing functions by a one-time finishing technology, and the fabric has the advantages of comfortable handfeel, environment friendliness, no pollution, low cost and capability of more fitting a human body.

Owner:EASTERN LIAONING UNIV

Crease-resist finishing method of fabric

InactiveCN103556456AIncreased wrinkle recovery angleSoft touchLiquid/gas/vapor removalHeating/cooling textile fabricsResistPulp and paper industry

The invention relates to a crease-resist finishing method of a fabric. The crease-resist finishing method of the fabric comprises the following steps: drying a fabric gray cloth, adding a specific amount of clear water into a reactor firstly, then adding a finishing agent, stirring continuously, adjusting the pH value to be 5-6, starting to add sizing mill liquid after complete reaction, then cross-linking, roasting, washing, softening, dewatering, adding a smoothening-softening agent, stentering for thermal forming, inspecting and packaging. The finishing agent is prepared from the following components in percentage by weight: 70%-80% of citric acid, 15%-25% of maleic anhydride and 5%-8% of nano TiO2; meanwhile, the finishing agent accounts for 20wt%-40wt% of the clear water. After being processed by the crease-resist finishing method, the cotton textile fabric is soft and smooth in hand feeling, strong in anti-shrinking and anti-creasing capability, and excellent in air permeability.

Owner:HUZHOU JINTADI TEXTILE MILL

Textile fabric post-finishing process with antistatic function

InactiveCN104775257AImprove stabilityEvenly distributedFibre treatmentSingeingRoom temperatureFatty alcohol

The invention discloses a textile fabric post-finishing process with an antistatic function. The textile fabric post-finishing process with the antistatic function comprises the work procedures of boiling off, singeing, washing, dipping, mangling, stirring, second mangling and drying, wherein the dipping procedure is to dip in a first finishing solution for 35-45 min at room temperature, the components and the weight percentage of each component of the first finishing solution comprise 5-10 percent of polyurethane resin, 1.5-3 percent of softening agent, 0.1-0.3 percent of fatty alcohol polyoxyethylene ether and 1.5-3 percent of citric acid, the rest is water, and the mangling rates of the mangling and the second mangling are 65-80 percent. The fabric generated by the antistatic post-finishing process is good in stability, the nanoscale metallic oxide is uniformly distributed on cloth and not prone to falling off, and excellent antistatic and antibiotic functions are achieved; the citric acid performs antibiotic finishing on wool fabric, not only is the bacteriostatic property of the fabric greatly improved, but also the creasy recovery angle of the fabric is improved, and the crease resistant performance of the fabric is improved.

Owner:NANTONG YOUKAI TEXTILE TECH

Anti-crease finishing process of cotton fabric after dyeing

InactiveCN102747601AIncreased wrinkle recovery angleSoft touchHeating/cooling textile fabricsVegetal fibresMaleic anhydrideSizing

The invention discloses an anti-crease finishing process of cotton fabric after dyeing, belonging to the technical field of a fabric dyeing and finishing process. The anti-crease finishing process comprises the steps of drying dyed grey fabric, adding clean a specified amount of water into a reactor, then adding a finishing agent, stirring continuously, adjusting the PH value to be 5-6, reacting completely, then sizing and rolling liquid, crosslinking, baking, cleaning, softening, dewatering, coating a smooth softening agent, stentering and hot-sizing, checking and packaging, wherein, the finishing agent is prepared from the following components by weight percent: 70-80% of citric acid, 15-25% of maleic anhydride and 5-8% of nano TiO2, and meanwhile, 20-40% of the finishing agent is contained in clean water. The cotton fabric processed by the anti-crease finishing process disclosed by the invention has soft handfeeling, is smooth, and extremely good in air permeability and has a strong anti-contraction and anti-crease capability.

Owner:SHAOXING UNIVERSITY

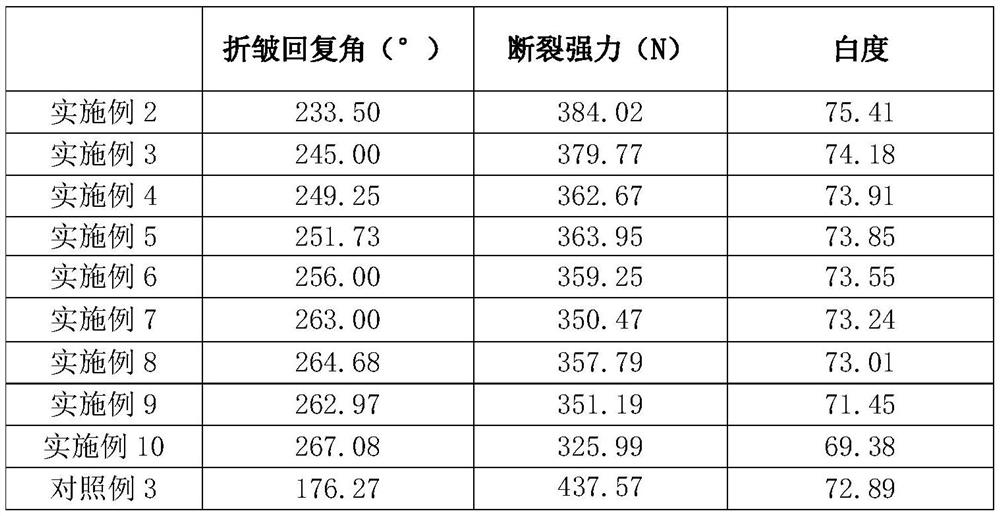

Crease resistant finishing agent for cotton fabric and crease resistant finishing method

InactiveCN111041815AReduce usageReduce the weakening of strengthWrinkle resistant fibresGrip property fibresPolymer scienceSodium phosphates

The invention provides a crease resistant finishing agent for cotton fabric and a crease resistant finishing method, and relates to the technical field of garment fabric finishing. The crease resistant finishing agent for the cotton fabric is prepared from the following raw materials in parts by weight: 6-13 parts of butanetetracarboxylic acid, 3-7 parts of pyromellitic dianhydride, 3-6 parts of ethylenediamine tetraacetic acid, 3-7 parts of chitosan, 0.005-0.03 part of nano dioxide, 0.3-0.6 part of silane coupling agent, 4-8 parts of softening agent, 6-10.5 parts of sodium hypophosphite, 3-8parts of polyethylene glycol 500, 30-60 parts of propylene glycol and 1000 parts of water. Under the condition that a small amount of butanetetracarboxylic acid and sodium hypophosphite are used, thecotton fabric can be endowed with excellent comprehensive performance and is good in crease resistant effect, large in recovery angle, high in tear strength retention rate and good in whiteness.

Owner:安徽捷融数据科技有限公司

Cotton fabric delayed baking non-ironing finishing process

ActiveCN113235292AGood storage stabilityReduced stabilitySolvent-treatmentSucessive textile treatmentsIndustrial engineeringLiquid ammonia

The invention relates to the technical field of textile after-finishing, in particular to a cotton fabric delayed baking non-ironing finishing process. The cotton fabric delayed baking non-ironing finishing process comprises the following steps of singeing, desizing, liquid ammonia treatment, mercerizing, liquid ammonia treatment and after-baking finishing. According to the method, the stability of the delayed baking sensitized fabric in delayed baking is remarkably improved, the problem caused by slow reaction in the storage process of the delayed baking sensitized fabric is solved, and the product quality can be improved.

Owner:JIANGNAN UNIV +1

Method for performing formaldehyde-free non-ironing treatment on fabric by using ionic liquid as catalyst for concerted catalysis

InactiveCN103821007BEasy to operateEasy to realize industrial productionFibre treatmentRoom temperatureIonic liquid

The invention relates to a method for performing formaldehyde-free non-ironing treatment on a fabric by using ionic liquid as a catalyst for concerted catalysis. The method comprises the steps as follows: a finishing bath is prepared at the room temperature, and comprises 5-100g / L of a formaldehyde-free non-iron finishing agent, 0.05-1g / L of ionic liquid and 5-50 g / L of a catalyst; the fabric is respectively immersed and rolled for two times, the water retention is 50-100 percent, and the fabric is dried at 85-100 DEG C for 3-8 minutes, and is finally baked at 50-180 DEG C for 0.5-5 minutes. The method is simple to operate, and the realization of industrial production is facilitated. An obtained non-iron production has a fabric wrinkle recovery angle, which is improved over 10 DEG C compared with a common formaldehyde-free non-iron product, and the fabric strength of the non-iron product is equal to that of the fabric subjected to common formaldehyde-free non-iron finishing.

Owner:DONGHUA UNIV

Preparation method of natural nano-functional finishing agent for silk

InactiveCN109957970AImprove featuresImprove antibacterial propertiesBiochemical fibre treatmentLight resistant fibresWrinkle skinCross-link

The invention provides a preparation method of a natural nano-functional finishing agent for silk. The natural nano-functional finishing agent for the silk is prepared from finishing agent liquid A, finishing agent liquid B, finishing agent liquid C and finishing agent liquid D, wherein the finishing agent liquid A is prepared from modified nano-particles, the finishing agent liquid B is preparedfrom a silane coupling agent, the finishing agent liquid C is mixed liquid of natural extracts and modified silicon emulsion, and the finishing agent liquid D is prepared from glutaraldehyde. During fabric finishing, the liquid B firstly reacts with the fabric, the liquid A is then used for treating, and the liquid D is cross-linked on the fabric by using the liquid C. Compared with the untreatedfabric, the fabric treated by using the finishing agent has higher ultraviolet resistance, softness, wrinkle resistance, antistatic property, yellowing resistance and antibacterial property; therefore, the finishing agent has an important application value in the aspect of silk fabric finishing.

Owner:SUZHOU INST OF TRADE & COMMERCE

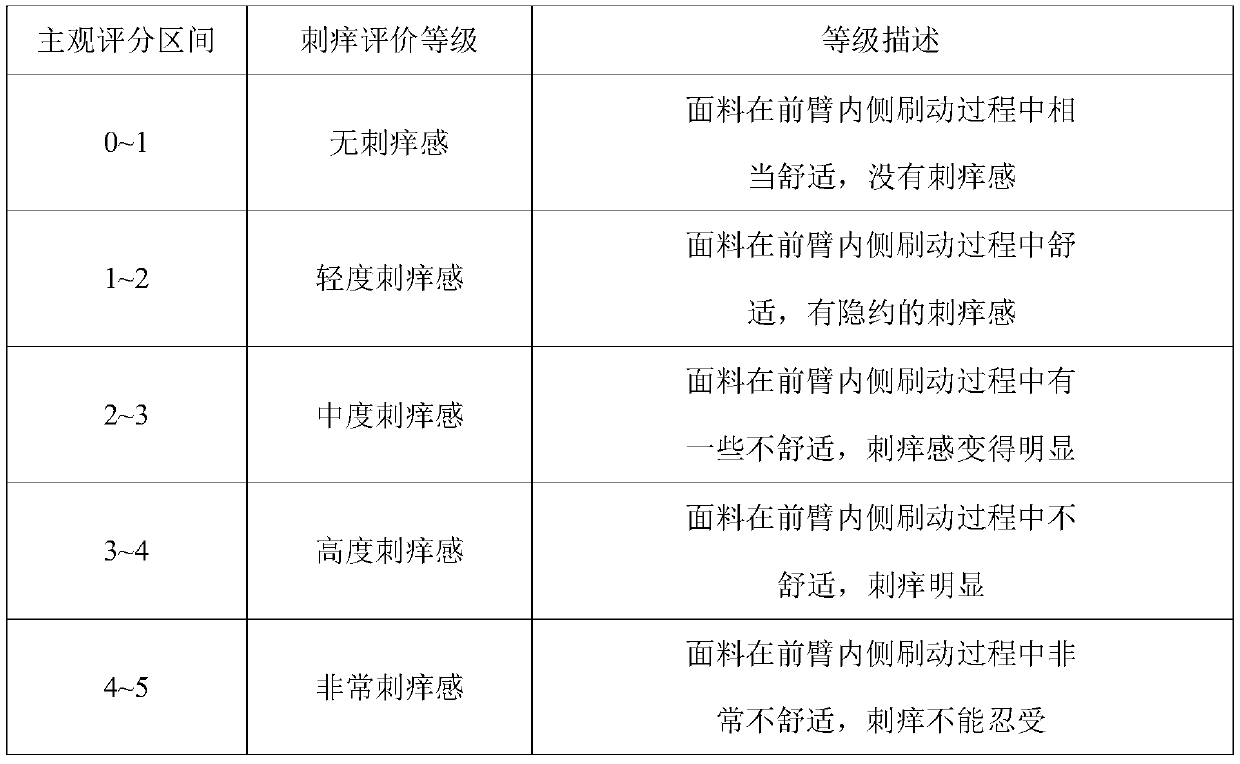

Anti-wrinkle ramie fabric with low itch

ActiveCN110253972BRelieve itchingIncrease elasticityPhysical treatmentLaminationPolymer scienceLanolin

Owner:HAIYAN SHUOCHUANG CLOTHING RES INST

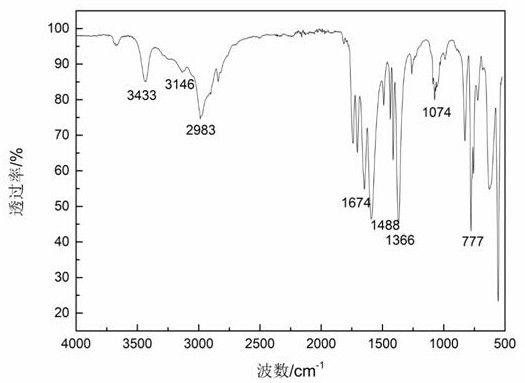

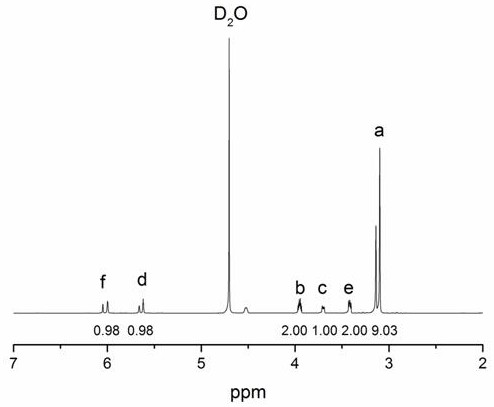

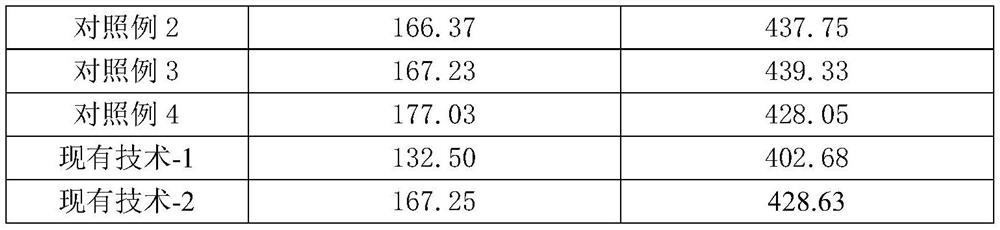

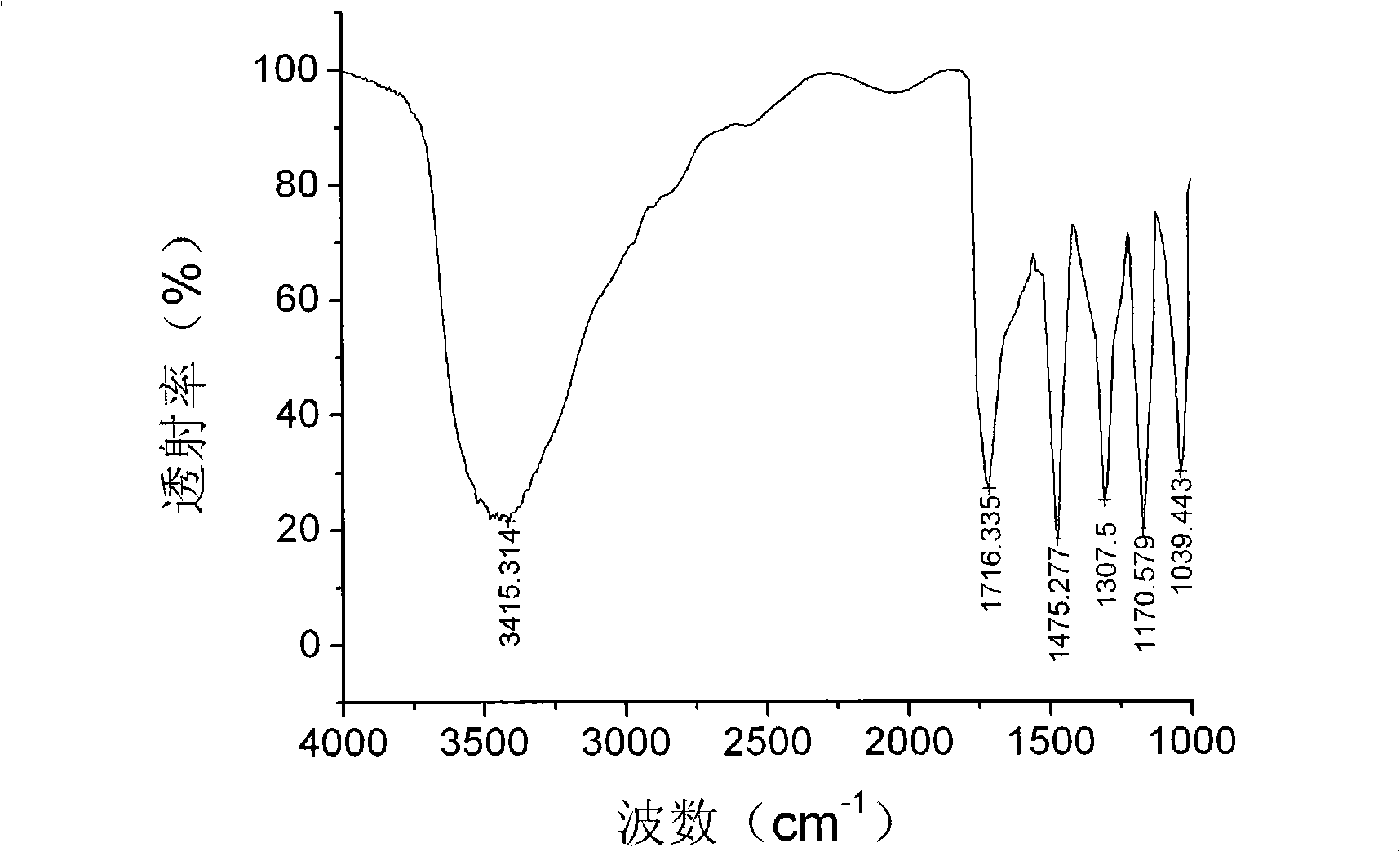

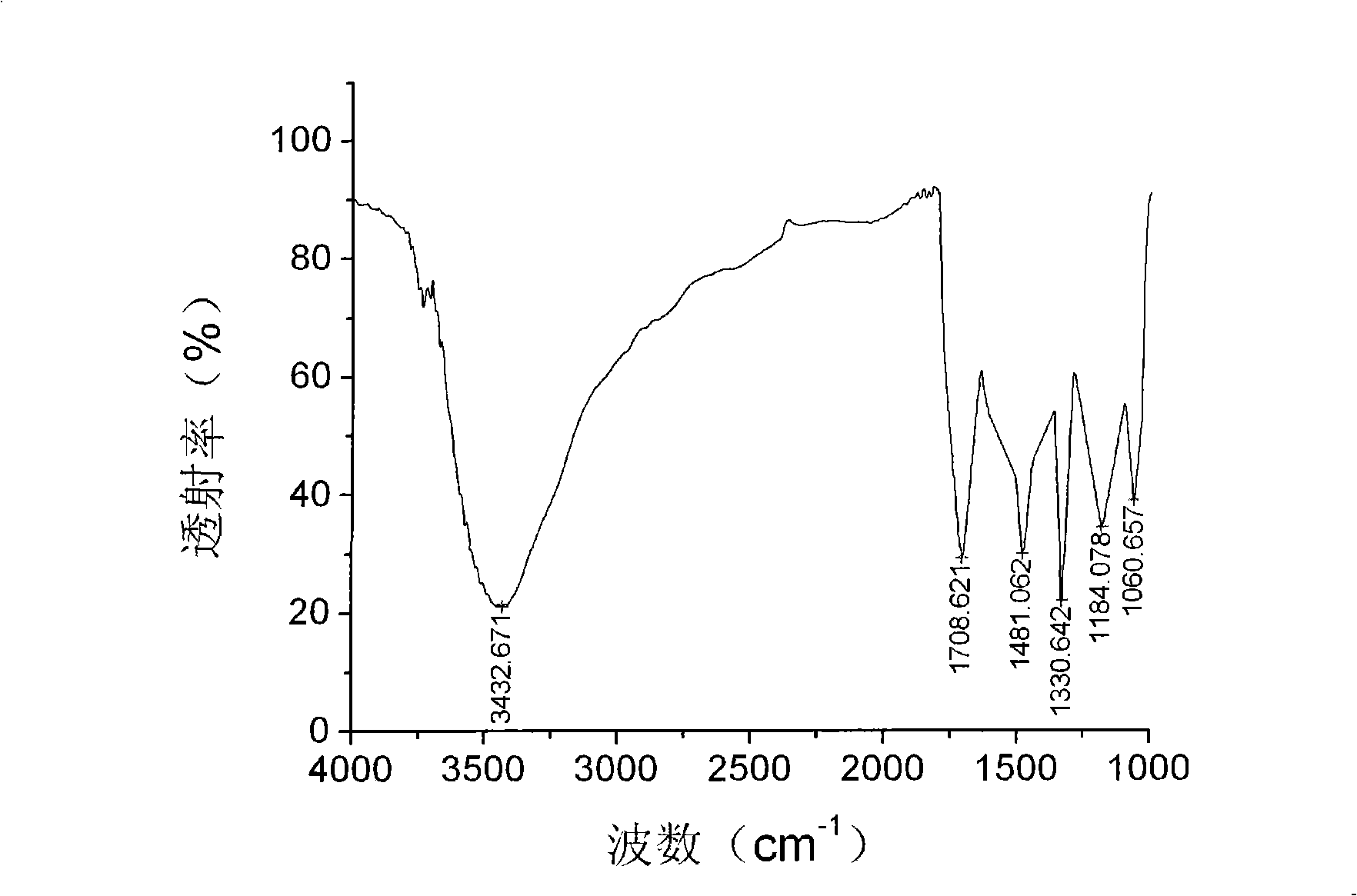

Preparation method and application of cationic modifier TCTAC

ActiveCN113373691ATest mechanical propertiesTest stabilityBiochemical fibre treatmentWrinkle resistant fibresCyanuric chlorideAnti bacterial

The invention discloses a preparation method and application of a cationic modifier TCTAC, and relates to the technical field of anti-wrinkle and antibacterial finishing of cotton fabrics. The preparation method comprises the following steps of dissolving 2,3-epoxy hydroxypropyl trimethyl ammonium chloride in deionized water, dropwise adding ammonia water, heating and stirring for a reaction, and dissolving in deionized water to form a 1-amino-3-hydroxypropyl trimethyl ammonium chloride aqueous solution; and dissolving cyanuric chloride in acetone, dropwise adding the 1-amino-3-hydroxypropyl trimethyl ammonium chloride aqueous solution, adjusting the pH value to 6-7 by using a sodium carbonate aqueous solution, stirring for a reaction until the reaction is finished, performing salting-out purification and drying to obtain the cationic modifier TCTAC. According to the method, the synthesis period is short, the yield is high, the novel cationic modifier is synthesized, the cationic modifier can be used for carrying out anti-wrinkle / antibacterial dual-function treatment on a cotton fabric, and relative slippage among fibers can be effectively inhibited, so that the wrinkle recovery capability is improved, and the cotton fabric with excellent dry and wet wrinkle resistance can be obtained.

Owner:JIANGSU LIANFA TEXTILE +1

Method for preparing high-strength crease-resisting cotton fabric under alkaline condition

InactiveCN106758209AImproved tear strength retentionStrong drop problem improvedWrinkle resistant fibresVegetal fibresChemistryRetention rate

The invention relates to a method for preparing a high-strength crease-resisting cotton fabric under an alkaline condition. The method comprises the following steps: dissolving acrylamide para-ester serving as an alkaline finishing agent into water, and adding alkaline as a catalyst to obtain alkaline crease-resisting finishing liquid; immersing the cotton fabric into the alkaline crease-resisting finishing liquid, uniformly impregnating, then impregnating for two times and rolling for two times, wherein the pickup ratio is 70 to 80 percent; drying and steaming to obtain a finished product. The tear strength retention rate of the fabric prepared by the method disclosed by the invention is remarkably improved, and the problem of strength declination of a current crease-resisting finishing fabric is remarkably improved; the method has a broad application prospect and market prospect.

Owner:DONGHUA UNIV +1

Natural antistatic smooth softener and preparation method thereof

InactiveCN107724059ARelieve stiffnessReduce stiffnessLight resistant fibresWrinkle resistant fibresWrinkle skinSodium bicarbonate

The invention discloses a preparation method for a natural antistatic smooth softener. The natural antistatic smooth softener comprises the following raw materials by weight: 5-10 parts of dimethyl epoxy silane, 20-30 parts of carnauba wax, 3-5 parts of an emulsifier, 5-10 parts of Turkey red oil, 5-10 parts of borax, 3-5 parts of triethanolamine, 10-20 parts of ethanol, 5-10 parts of sodium bicarbonate, 5-10 parts of hydroxymethyl cellulose, 5-10 parts of polyoxyethylene diamine, 3-5 parts of polyethylene terephthalate, 5-10 parts of styrene and 30-50 parts of deionized water. After application of the natural antistatic smooth softener, the stiffness, shear stiffness and bending stiffness of a fabric are greatly reduced, the wrinkle recovery angle of the fabric is substantially increased,the smoothness and softness of the fabric are greatly improved, and the antistatic property of the fabric is improved by 80% or more compared with an original fabric. The preparation method for the natural antistatic smooth softener is simple in process and easy to operate; the raw materials are inexpensive and easily available; and the natural antistatic smooth softener is non-toxic, harmless, non-irritant to the body, and low in volatility.

Owner:JIANGSU NEW REBA TECH CO LTD

Finishing method for improving resin finishing wrinkle recovery angle

InactiveCN111826958AImprove permeabilityPenetrate fastWrinkle resistant fibresVegetal fibresFiberPolymer science

The invention belongs to the technical field of textile finishing and processing, and particularly relates to a finishing method for improving the resin finishing wrinkle recovery angle. The finishingmethod for improving the resin finishing wrinkle recovery angle comprises the following steps of (1) pretreating a fabric; (2) padding with a resin finishing liquid; and (3) sequentially carrying outpre-drying, needling, high-temperature baking reaction, water washing, tentering and pre-shrinking on the padded fabric to obtain a finished fabric, wherein the resin finishing liquid is prepared from the following raw material components of 100 to 200g / L of high-temperature resin, 30 to 60g / L of catalyst, 20 to 40g / L of fiber protective agent, 2 to 6g / L of polyvinyl alcohol, 1 to 2g / L of citricacid and the reset of water. The process is simple, the wrinkle recovery performance of the fabric is further improved; the effect that no wrinkle exists on the washed fabric surface is achieved; thewearability and attractiveness of the fabric are improved; the quality is stable; and good popularization prospect is achieved.

Owner:鲁丰织染有限公司

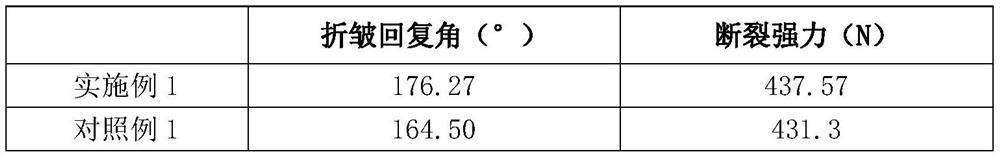

Cotton fabric treatment process based on liquid ammonia and mercerizing combined finishing

ActiveCN113373684AImprove performanceEasy to takeMercerising of indefinite length fabricsDry-cleaning apparatus for textilesPulp and paper industryOrganic chemistry

The invention relates to the technical field of textile after-finishing, in particular to a cotton fabric treatment process based on liquid ammonia and mercerizing combined finishing. The cotton fabric treatment process based on liquid ammonia and mercerizing combined finishing comprises the following steps of singeing, desizing, liquid ammonia treatment, mercerizing, liquid ammonia treatment, tentering and preshrinking. The comprehensive physical and mechanical properties of the wrinkle recovery angle and the breaking strength of the cotton fabric are improved, and meanwhile, the hand feeling style of the cotton fabric is further improved. The cotton fabric treatment process based on liquid ammonia and mercerizing combined finishing is relatively simple and feasible, and is suitable for industrial large-scale production.

Owner:JIANGNAN UNIV

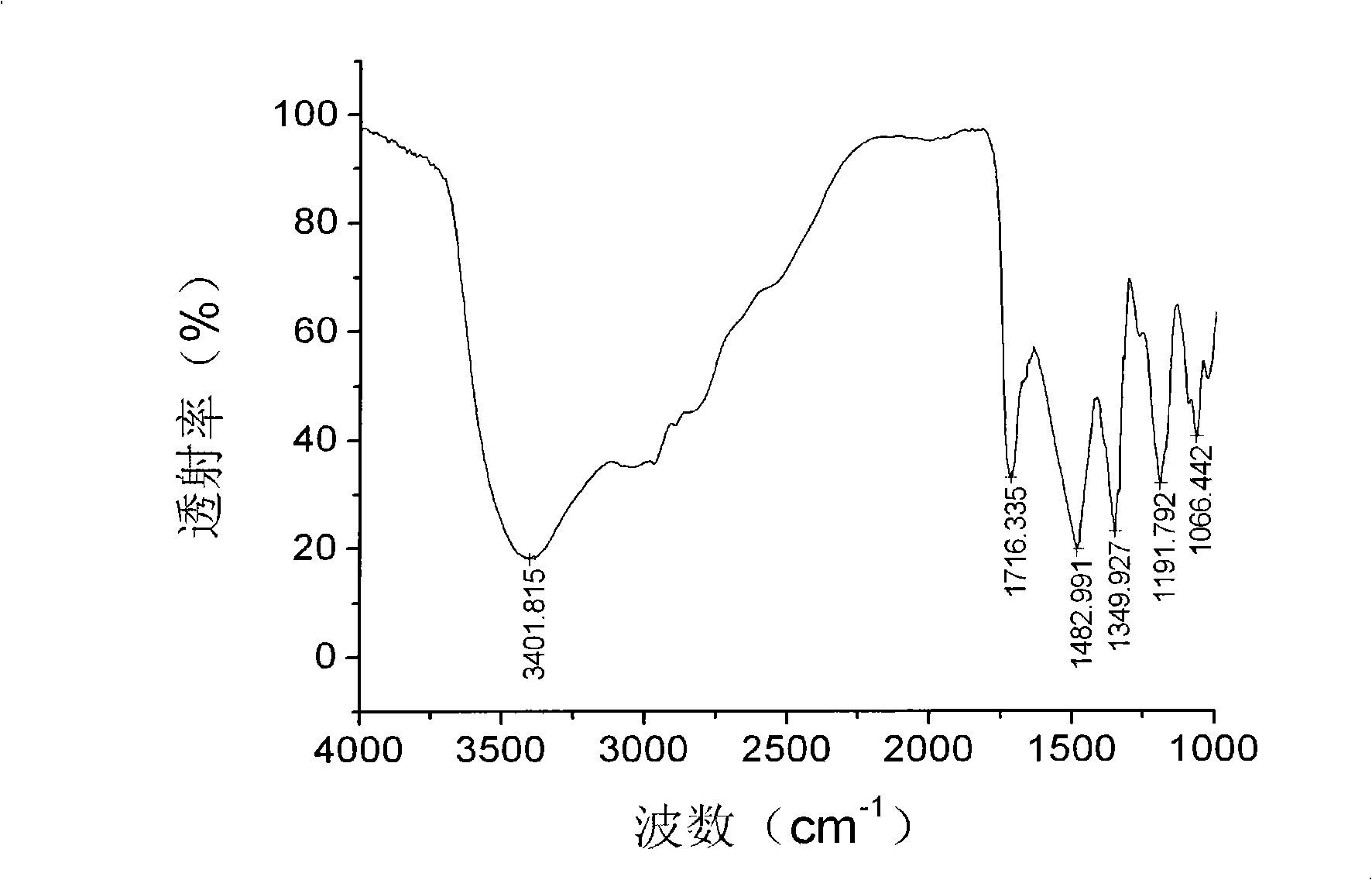

Anti-creasing agent used for cellulosic fiber fabric and its synthesizing method

InactiveCN101403188AAffect the breaking strengthAffect whitenessVegetal fibresBreaking strengthItaconic acid

The invention discloses an anti-creasing agent used in cellulose fiber fabrics, the structural general formula is expressed as above, and in the formula, a is less than or equal to 20 and more than or equal to 5, b is less than or equal to 20 and more than or equal to 0, c is less than or equal to 20 and more than or equal to 0 and d is less than or equal to 10 and more than or equal to 0, a plus b plus c plus d is less than or equal to 40 and more than or equal to 10, and b ,c and d can not be 0 simultaneously; the average molecular weight Mn is more than or equal to 1300, and K is less than or equal to 3 and more than or equal to 1. The anti-creasing agent is obtained by adopting saturated fatty alcohol and saturated di-fatty alcohol amine for modification after itaconic acid is polymerized. The cellulose fiber fabrics that are finished by the anti-creasing agent have better durable anti-creasing effect, the anti-creasing agent can not release formaldehyde when in use, and the fabrics are less in original breaking strength change.

Owner:SUZHOU UNIV

Low-scratchiness anti-crease ramie fabric

The invention provides a low-scratchiness anti-crease ramie fabric, and belongs to the field of clothing processing. The fabric comprises a fabric body (1), and the material of the fabric body (1) is ramie; the upper surface of the fabric body (1) is provided with a longitudinally arranged hollow-out jacquard layer (2), anti-crease polyurethane strips (3) are arranged in the hollow-out jacquard layer (2), and the anti-crease polyurethane strip (3) have a memory function; and the lower surface of the fabric main body (1) is a bottom fabric (4), and the bottom fabric (4) is prepared from a thermoplastic resin-containing resin composition, degraded chitosan, lanolin and D-phenylglycinol. The fabric of the invention is a laminated fabric, the surface of the fabric is provided with the anti-crease polyurethane strips, the main body undergoes low temperature plasma treatment, and the anti-crease bottom fabric is produced, so the anti-crease effect of the main body ramie fabric is enhanced; the low temperature plasma treatment is used to reduce the scratchiness of the fabric; and the ramie fabric is soft and comfortable, resists crease, is not prone to deform, and also has anti-shrinkage, antistatic, easy cleaning and decontaminating effects.

Owner:HAIYAN SHUOCHUANG CLOTHING RES INST

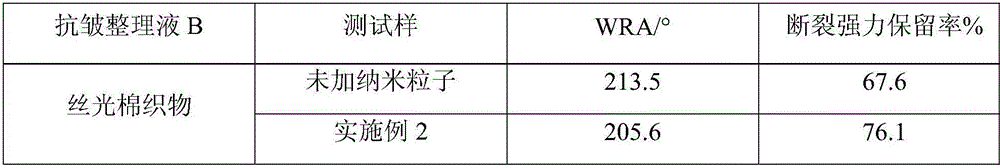

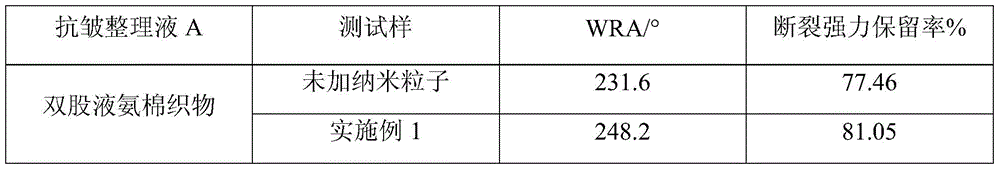

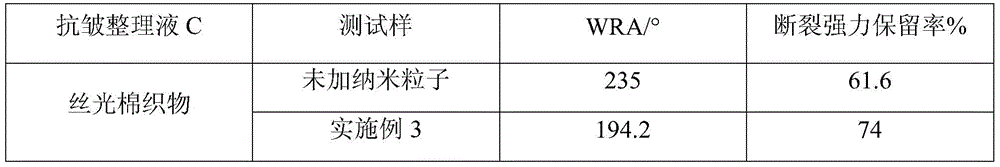

A kind of nanometer material strengthens cotton fabric anti-wrinkle finishing solution and application thereof

InactiveCN103572588BEnhanced tensile breaking strengthIncreased wrinkle recovery angleHeating/cooling textile fabricsLiquid/gas/vapor removalCooking & bakingBreaking strength

The invention relates to a nano-material reinforced cotton fabric anti-wrinkle finishing solution and its application. The finishing solution comprises: nano-material, anti-wrinkle finishing agent, catalyst, initiator, strong protective agent and solvent water. The treatment method includes: immersing the cotton fabric in an anti-wrinkle finishing solution, immersing it for 3-5 minutes, then dipping and rolling twice, with a liquid rate of 80-85%, drying and baking. The anti-wrinkle finishing solution of nano-material reinforced cotton fabrics prepared by the invention is better than the conventional anti-wrinkle finishing solution, and the characteristics are that the tensile breaking strength of the fabric can be significantly improved, and the problem of the strength reduction of the current anti-wrinkle finishing fabric can be obviously improved, and there are a wide range of application prospects and market prospects.

Owner:DONGHUA UNIV +1

A single piece of jeans production process

ActiveCN108560241BNot easy to fadeInhibition of dissolutionDry-cleaning apparatus for textilesGrip property fibresSulfonateDenim

The invention discloses a production process of jeans. The production process comprises the steps of denim yeast-washing, jeans sewing and jeans snow-washing, wherein the denim yeast-washing step comprises the following steps: (I) de-sizing; (II) soaking in mixed liquid composed of a color fixing agent and an elastic protectant; (III) soaking in mixed liquid composed of an anti-dyeing agent, an enzyme elastic protectant and water; (IV) soaking in mixed liquid composed of sodium carbonate, caustic soda, sodium hypochlorite and water; (V) soaking in mixed liquid of oxalic acid, hydrogen peroxideand water; (VI) soaking in soft oil and silicon oil; the jeans snow-washing step comprises the following steps: soaking in mixed liquid composed of an anti-dyeing agent, a neutral enzyme and water; (II) soaking in mixed liquid composed of sodium hypochlorite, sodium carbonate and water; (III) soaking in mixed liquid of fatty acid methyl ester sulfonate and water; (IV) stir-frying in potassium permanganate; therefore, the jeans are more colorful, outstanding in old feeling and capable of keeping colorfast for a long time.

Owner:广州市创兴服装集团有限公司

Anti-ultraviolet finishing agent for cotton fabrics based on black rice anthocyanins

ActiveCN105113219BStrong UV resistanceIncreased wash resistanceDyeing processVegetal fibresFiberCarboxylic acid

The invention provide a black rice anthocyanin-based cotton fabric anti-ultraviolet finishing agent, which is prepared from the raw materials in total volume: black rice anthocyanin extracting solution, 0-5g / L of organic polybasic carboxylic acid, 0-5g / L of sodium citrate, 1g / L of sodium sulfate and 0.5g / L of penetrant JFC. According to the technical solution, cotton fiber and a fabric thereof are endowed with three finishing functions by a one-time finishing technology, and the fabric has the advantages of comfortable handfeel, environment friendliness, no pollution, low cost and capability of more fitting a human body.

Owner:EASTERN LIAONING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com