Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Increase the amount of material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

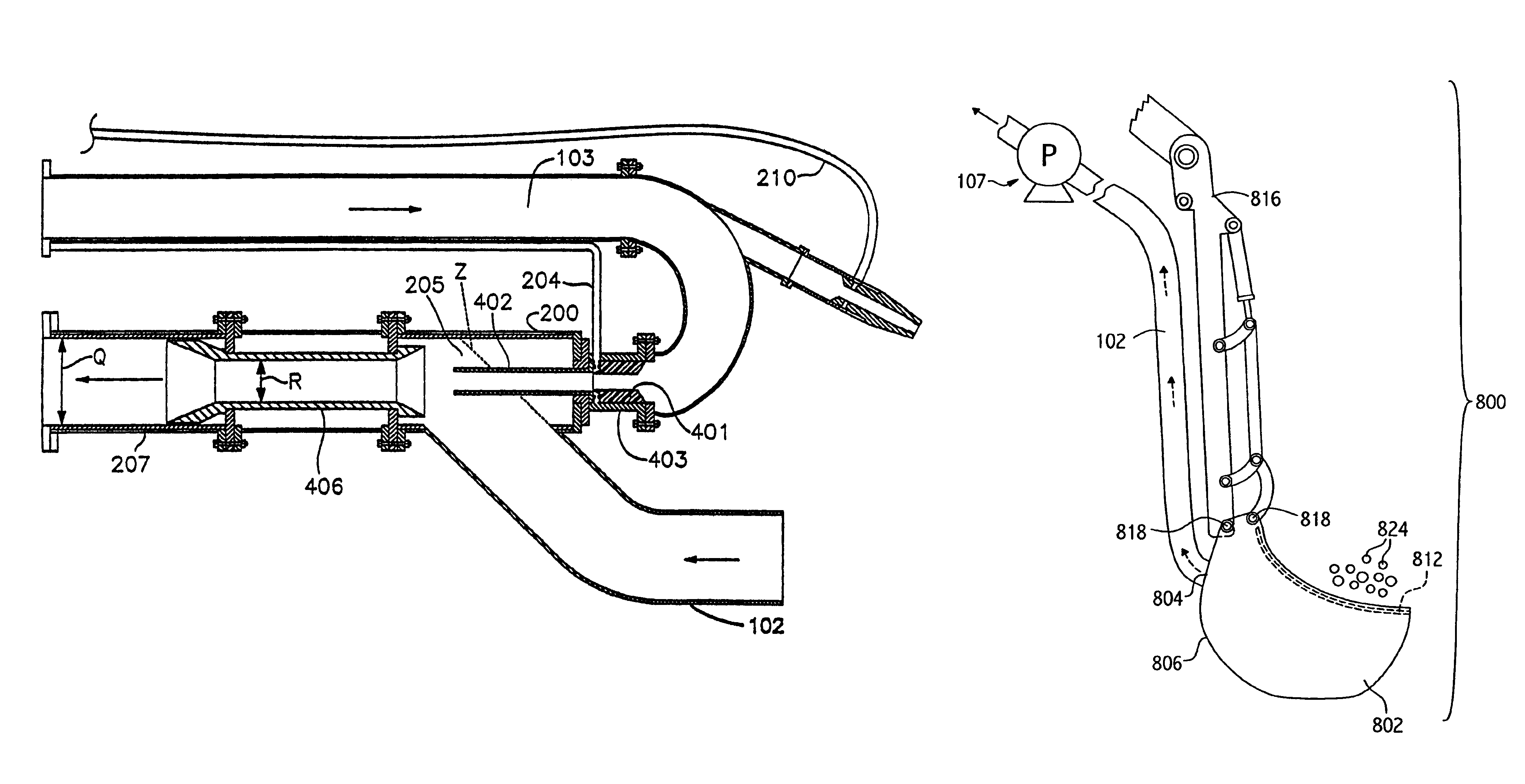

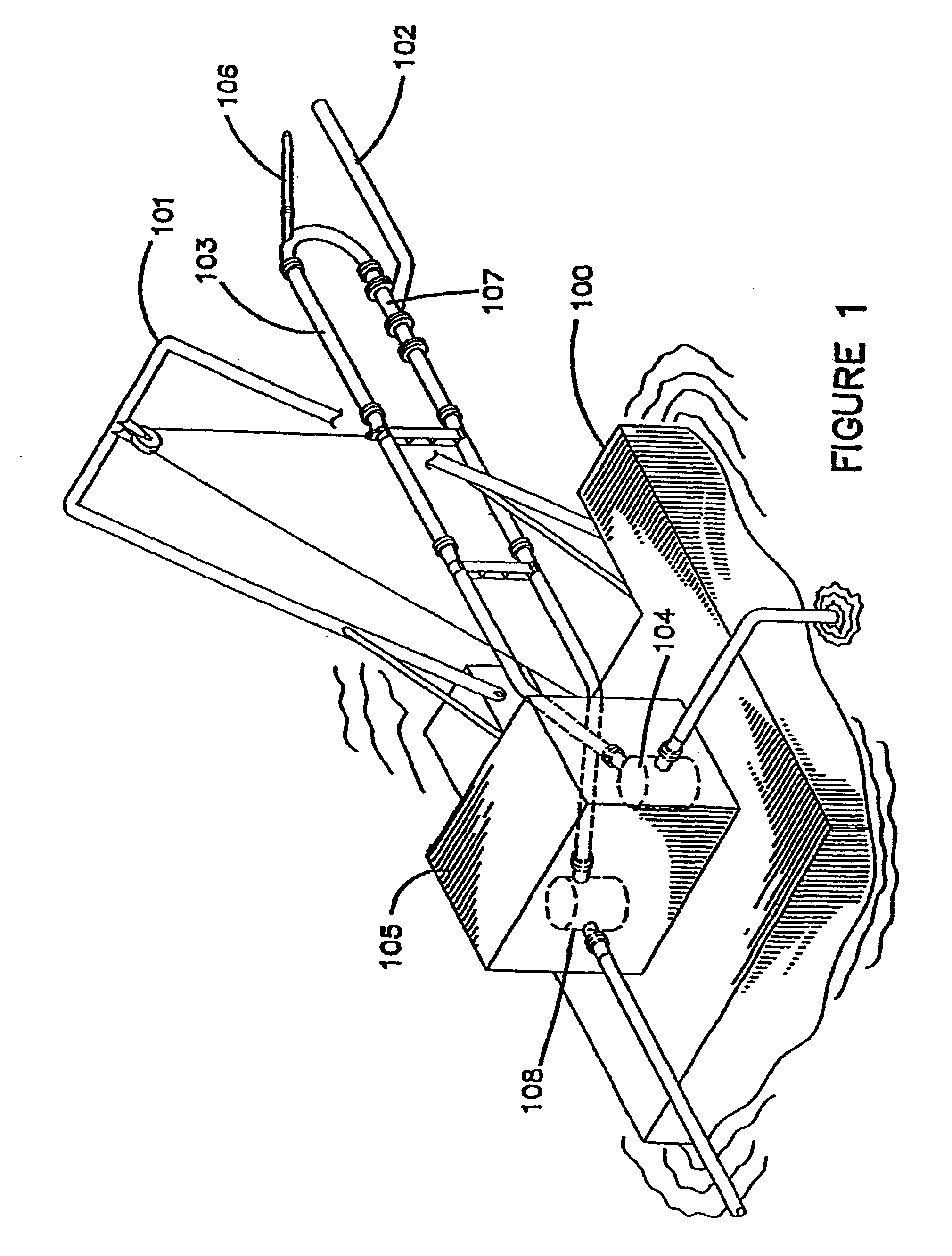

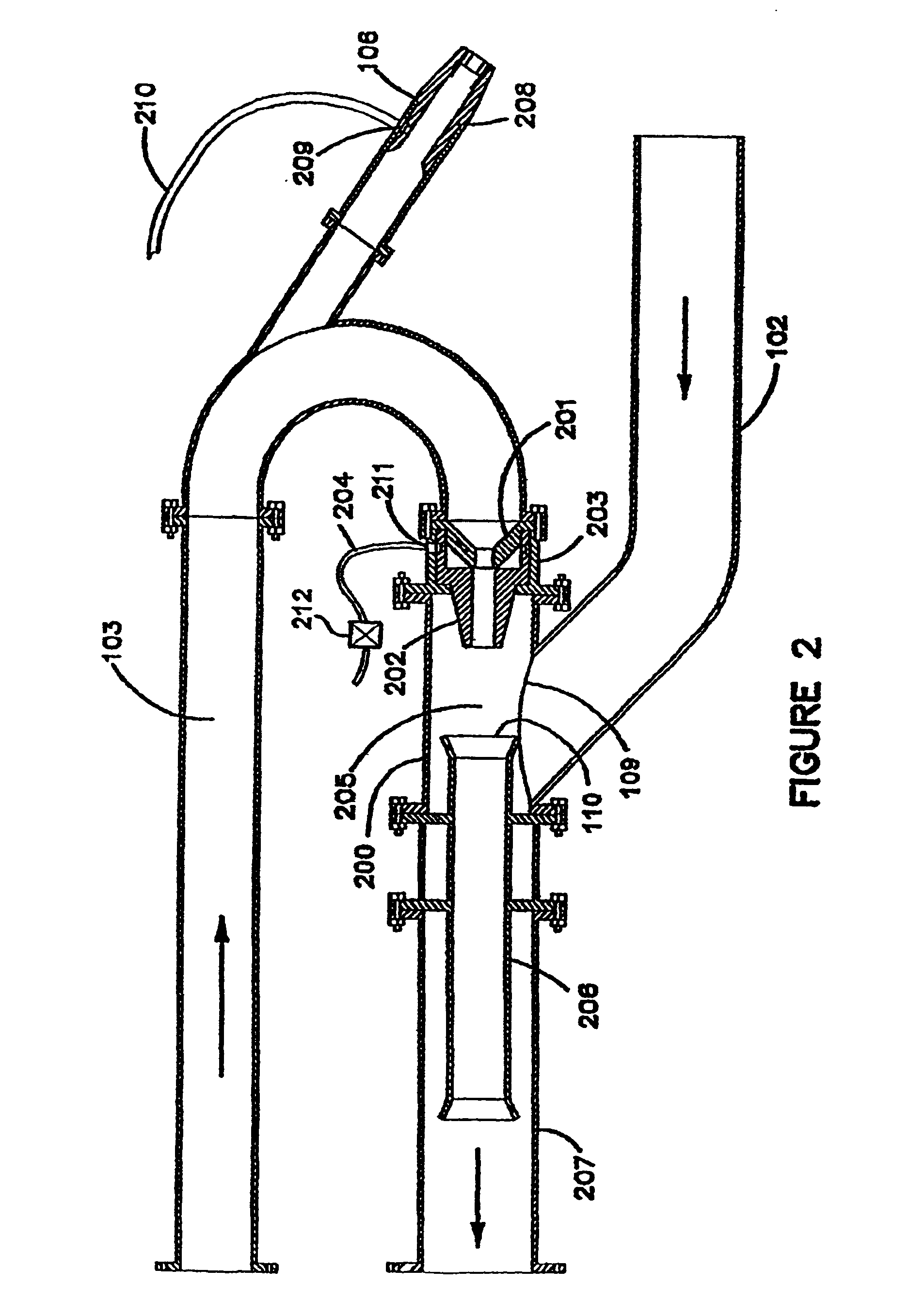

Excavation system employing a jet pump

InactiveUS6860042B2Efficient transportIncrease the amount of materialMechanical machines/dredgersVessel salvagingInjection pumpWaste management

An excavation system comprises a bucket, defining an outlet at its base, in fluid communication with a suction tube in fluid communication with a jet pump, configured to create a suction in the suction tube. A related method of excavating comprises loading excavation material into a bucket which defines an outlet at its base, sizing the excavation material by sieving action of a guard substantially covering the bucket outlet, and suctioning the sized material though the bucket outlet using a vacuum created by a jet pump.

Owner:WALKER DAWSON INTERESTS

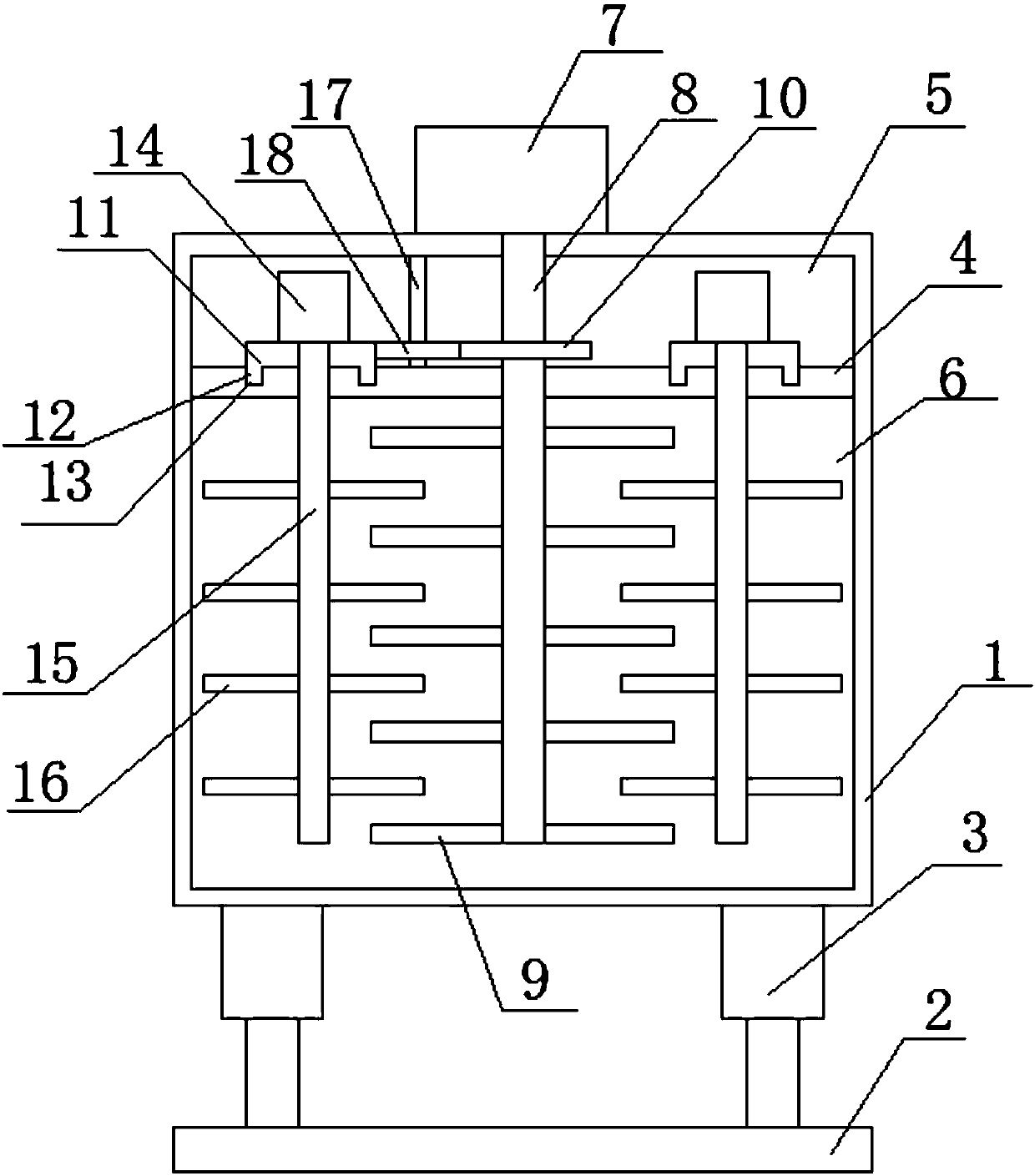

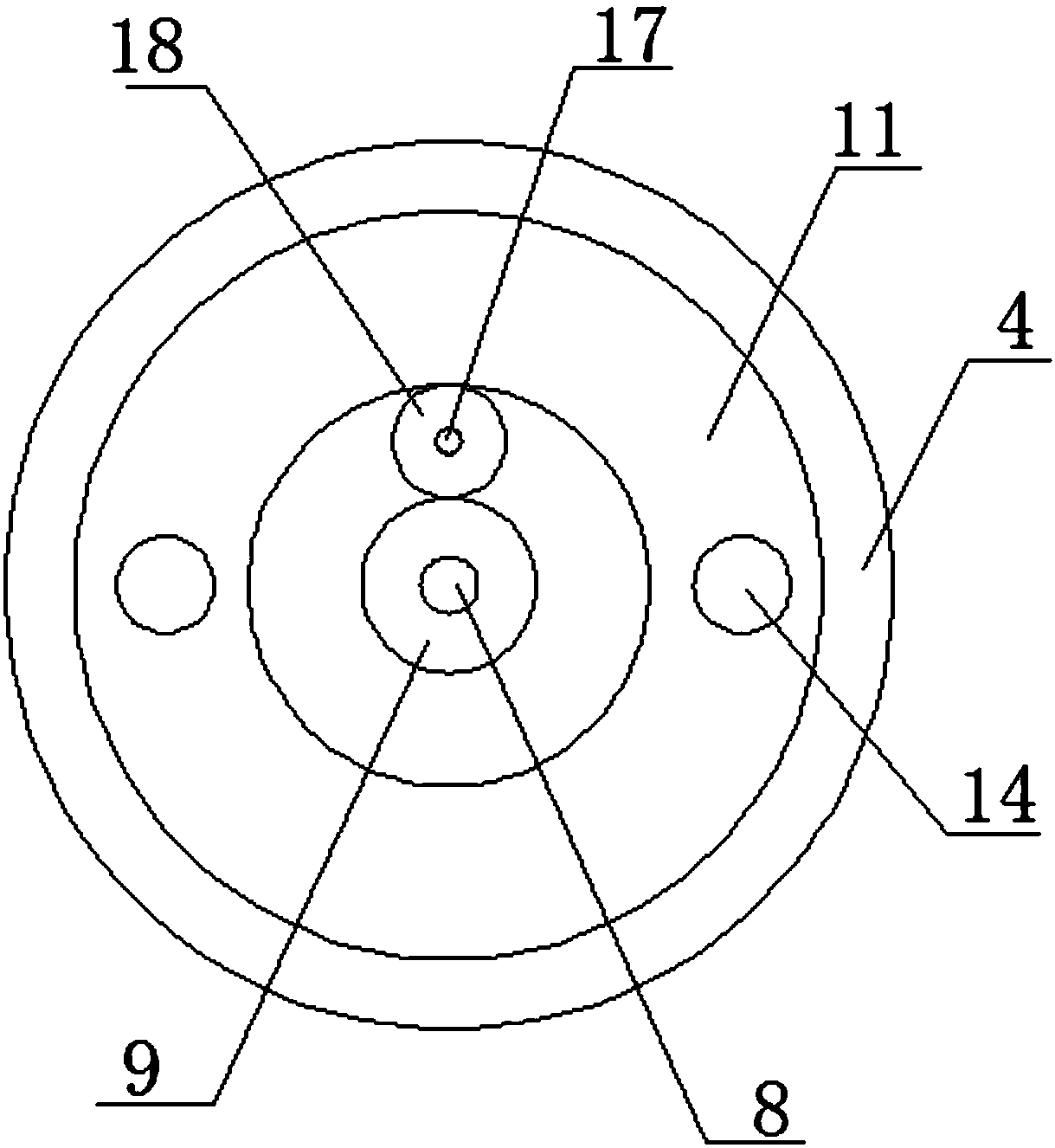

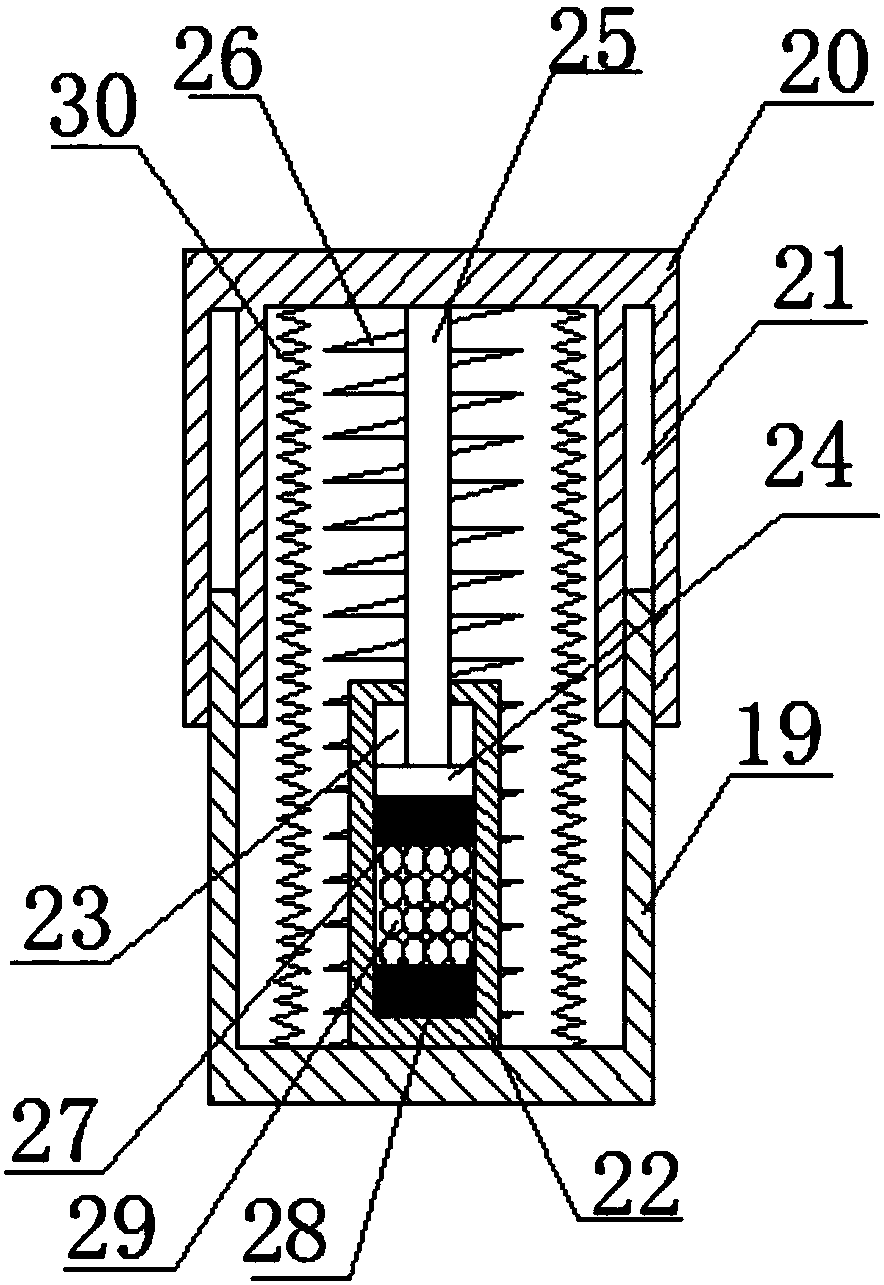

Chemical material mixing device

InactiveCN107583532AExtended service lifeAvoid enteringRotary stirring mixersMixer accessoriesDrive wheelEngineering

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

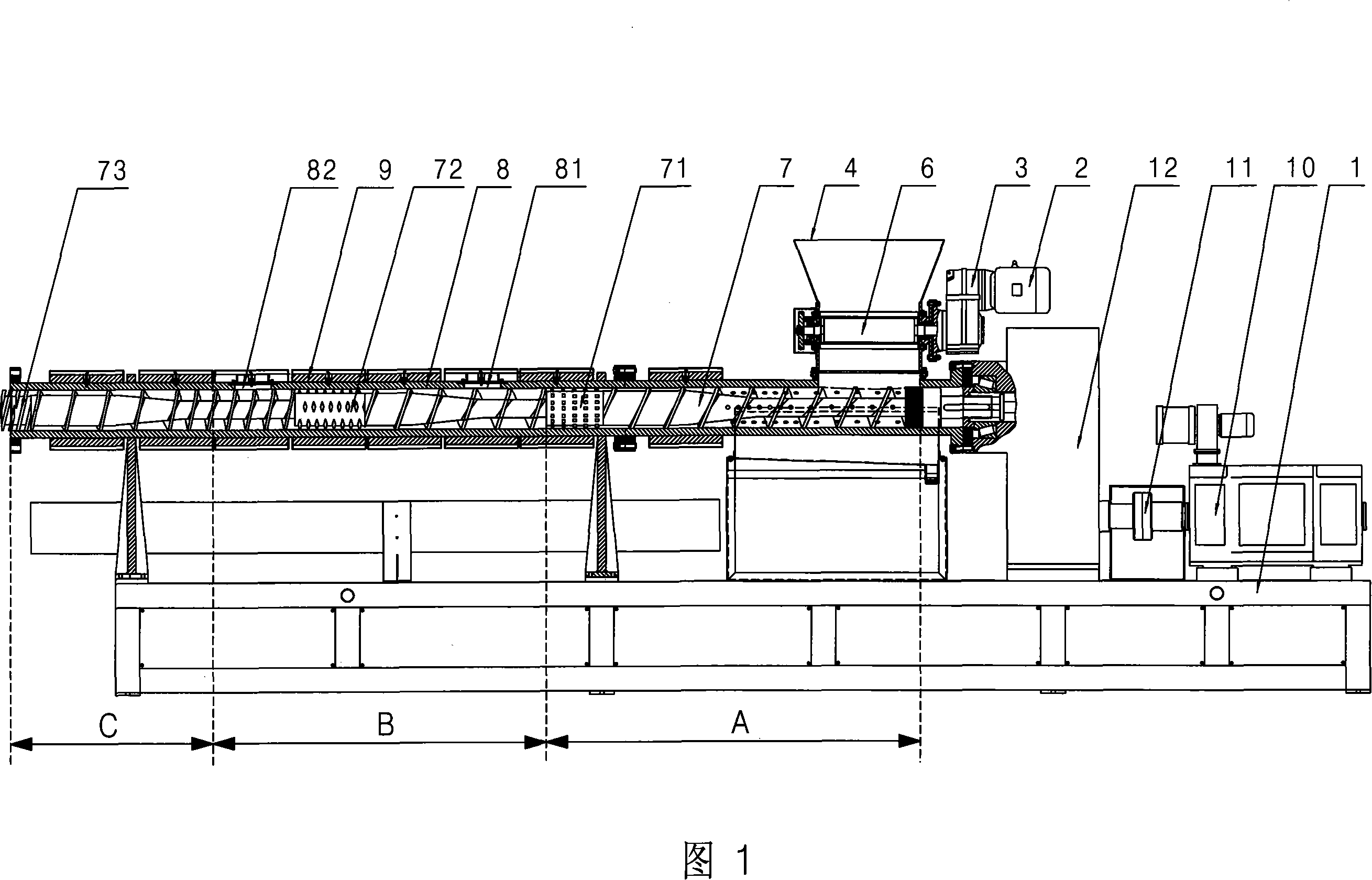

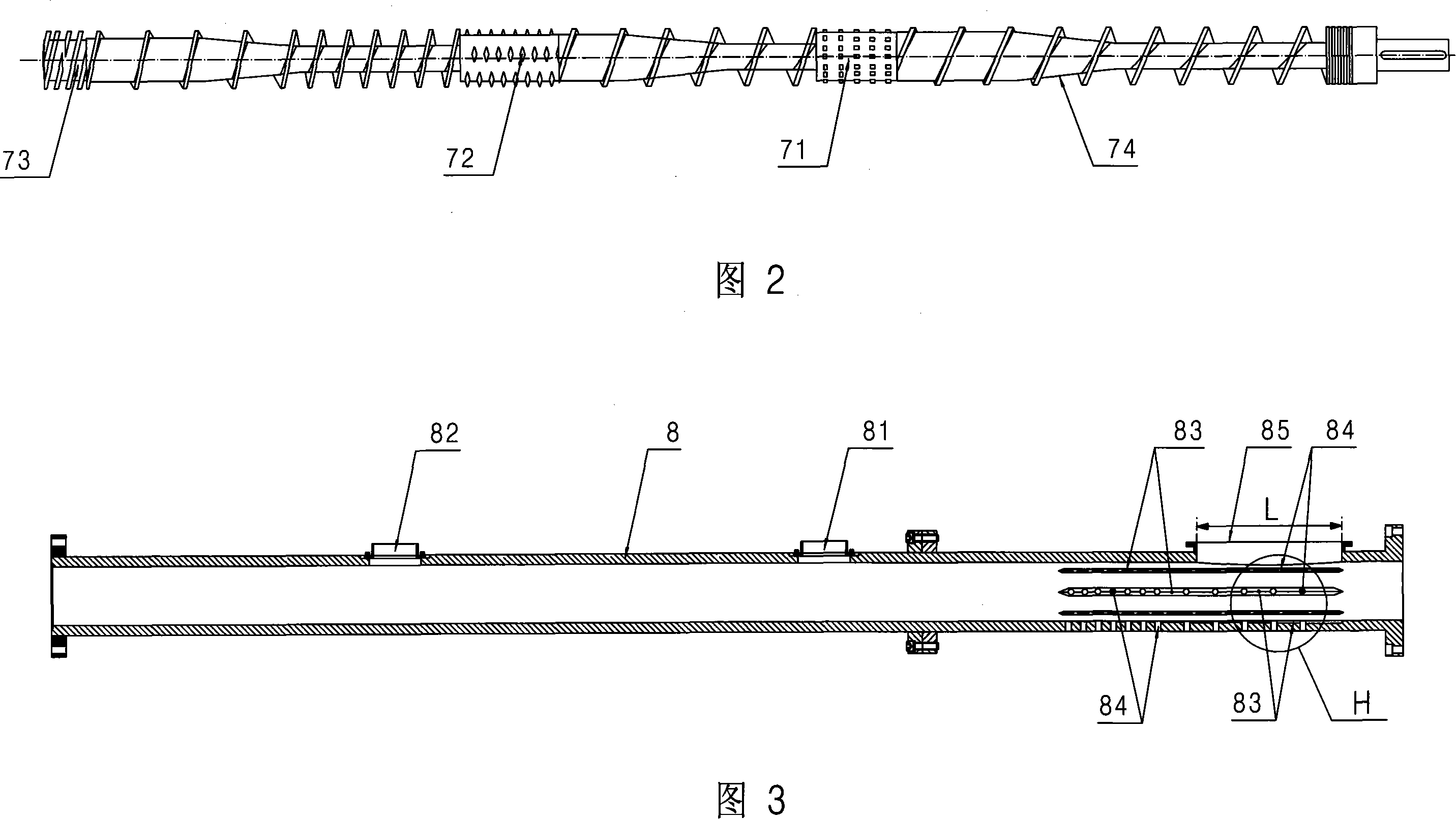

Extruder

Owner:ZHANGJIAGANG AMSTAR SANWA MACHINERY

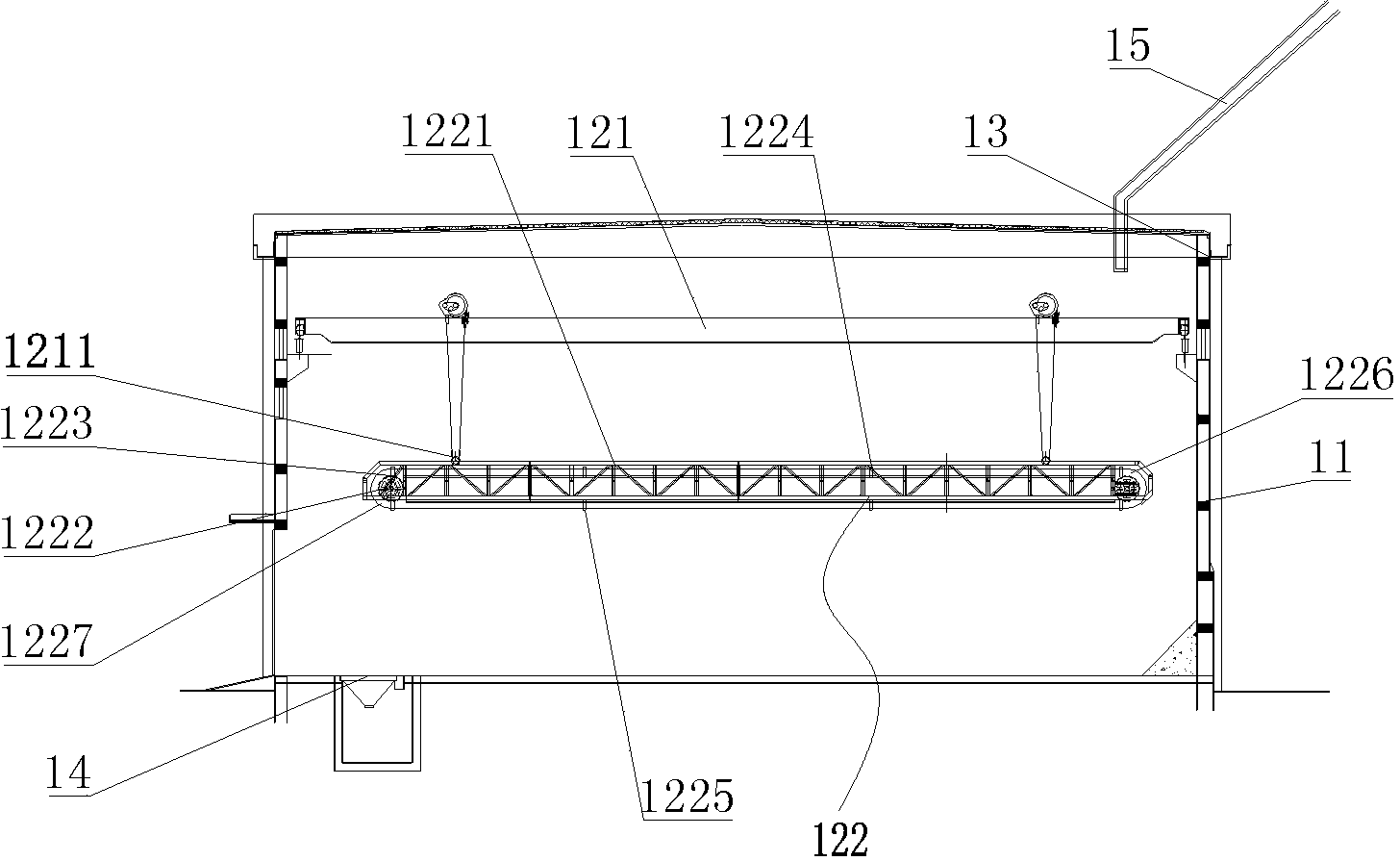

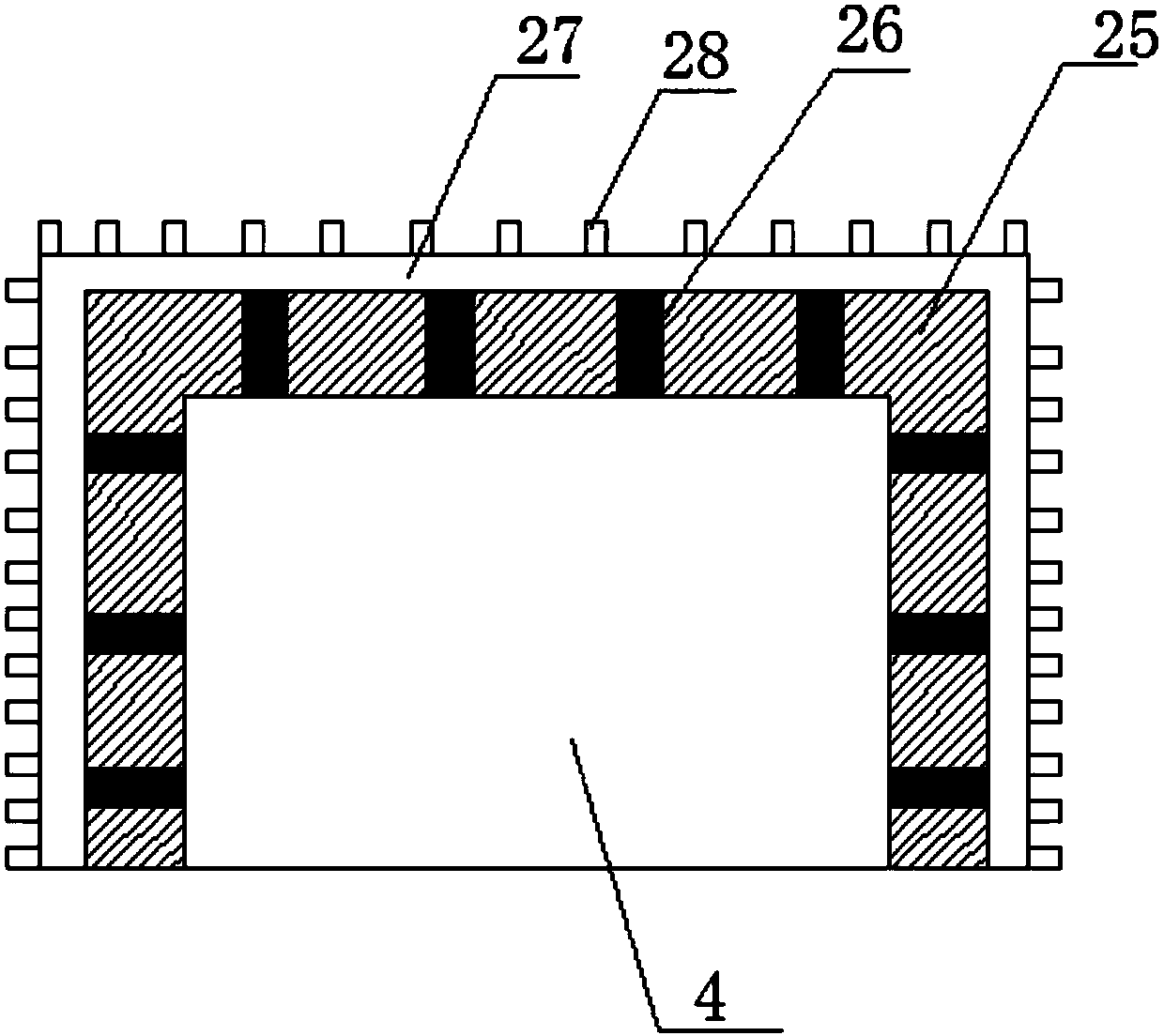

Material bin and bin leveling and unloading device thereof

InactiveCN104340697AReduce holdupIncrease the amount of outboundLarge containersLoading/unloadingEngineeringMechanical engineering

The invention discloses a material bin and a bin leveling and unloading device thereof. The material bin is characterized in that the bin leveling and unloading device is assembled in a bin chamber; a lifting mechanism for driving a movable bracket to move up and down is arranged on a bridge type crane of the bin leveling and unloading device; a horizontal chain or belt transmission type bin leveling and unloading scraper plate conveying mechanism is assembled on the movable bracket and is provided with an upper scraper plate rotating to the upper side and a lower scraper plate rotating to the lower side; an outward extension part extending out of the lower side of the movable bracket is arranged on the lower side of the lower scraper plate. According to the material bin, the bin leveling operation of the bin chamber is smoothly finished through traveling and lifting of the bin leveling and unloading scraper plate conveying mechanism in the bin chamber, and the bin unloading amount of materials in the bin unloading operation is increased.

Owner:郑州泰和粮油科技有限公司

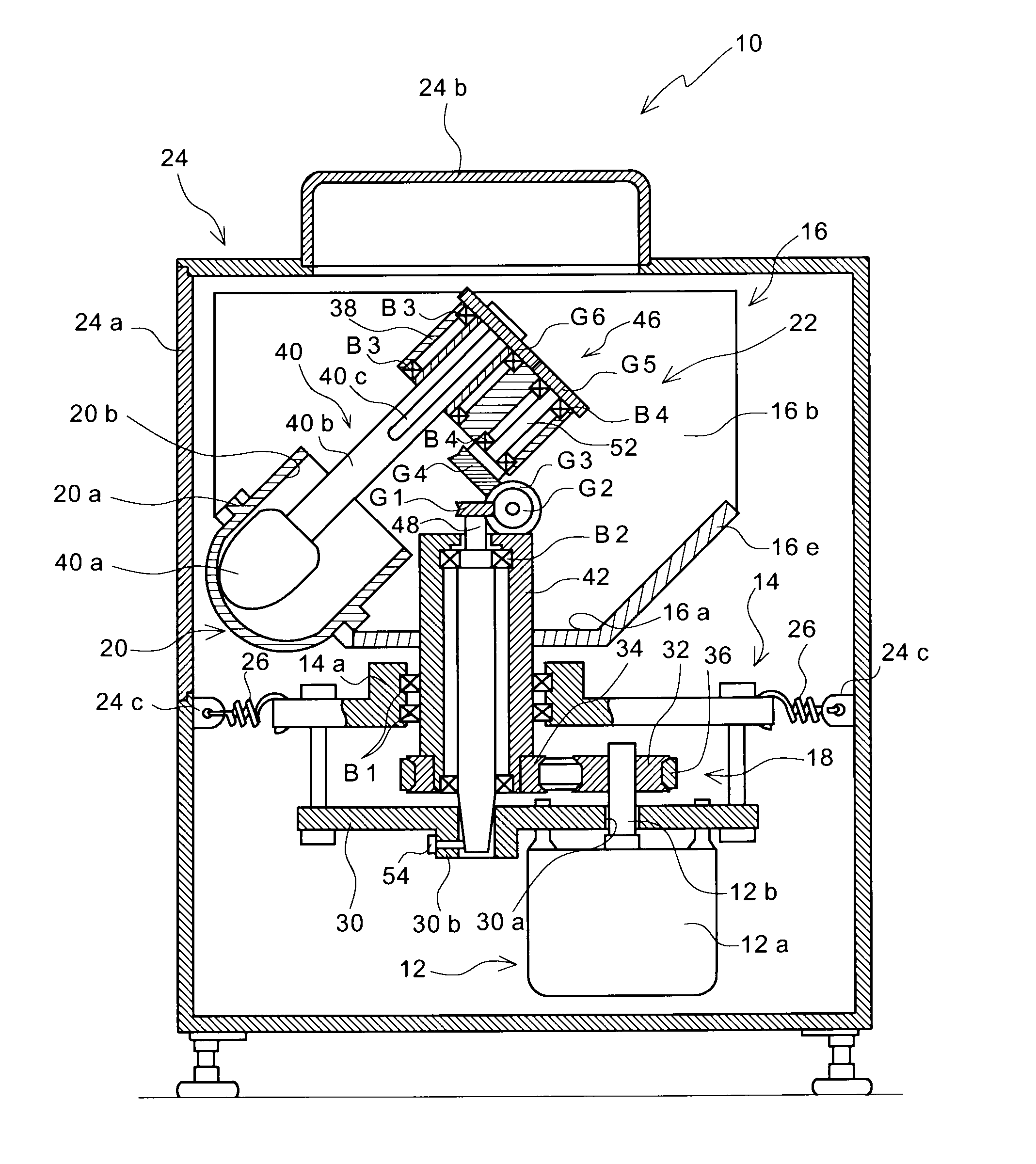

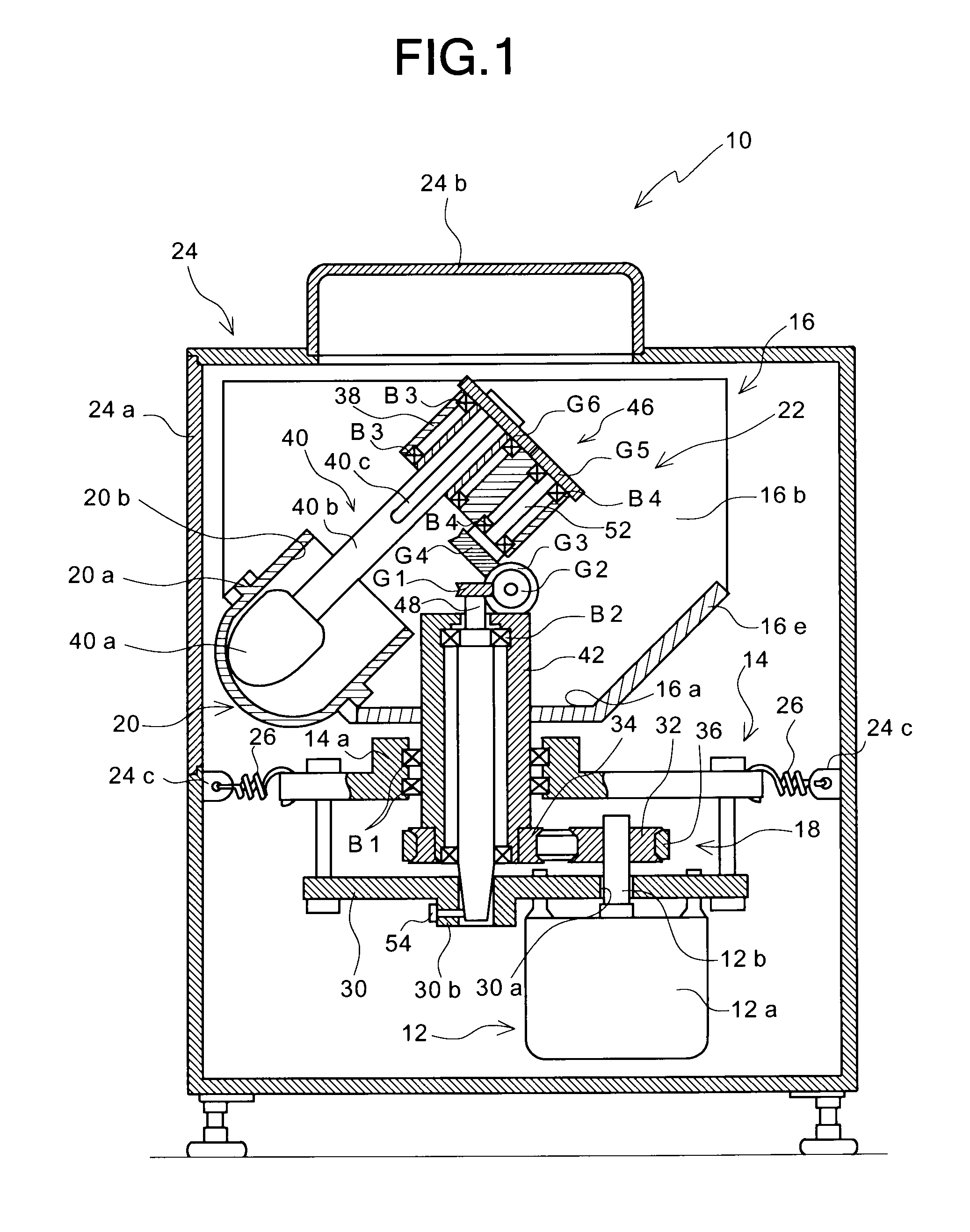

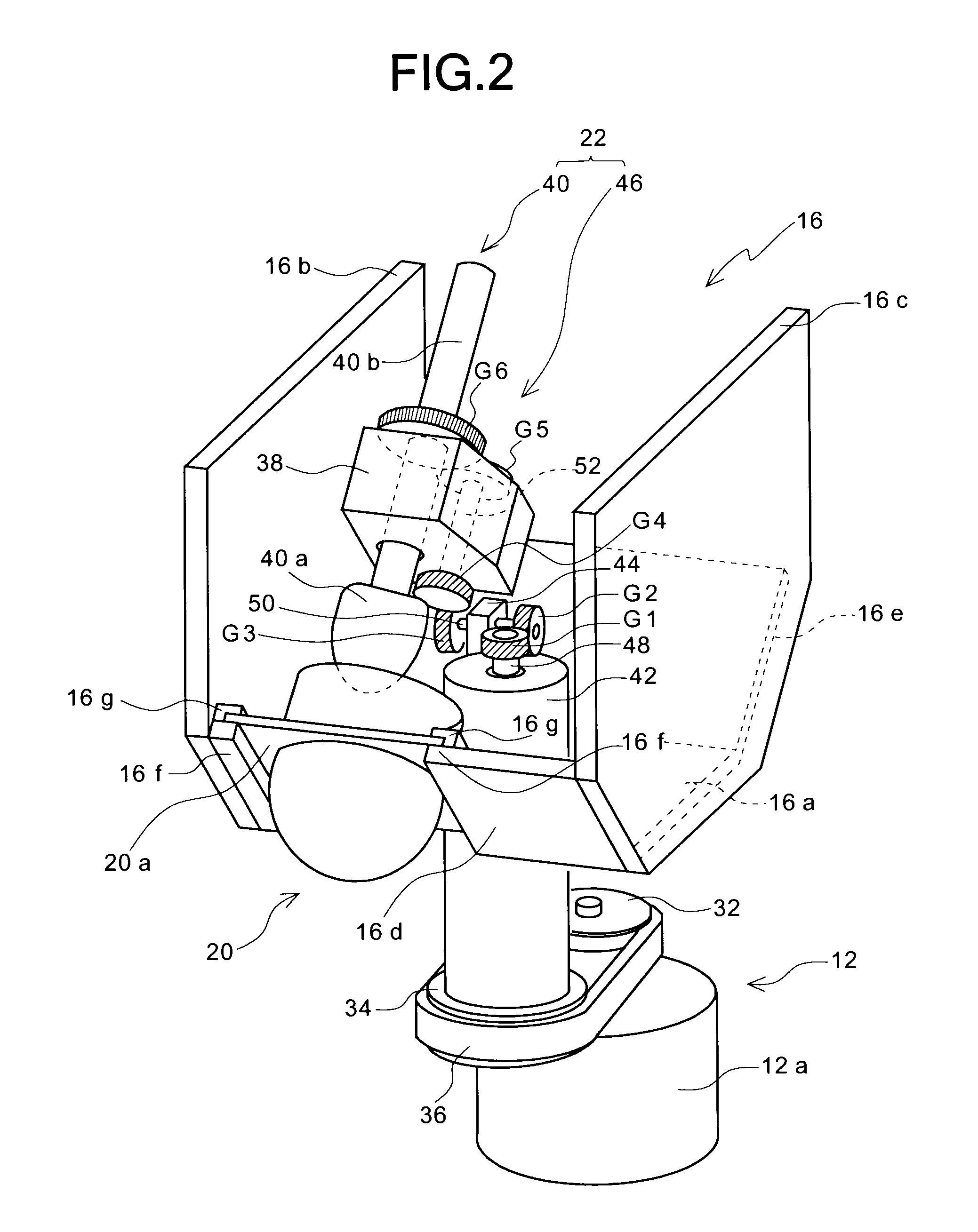

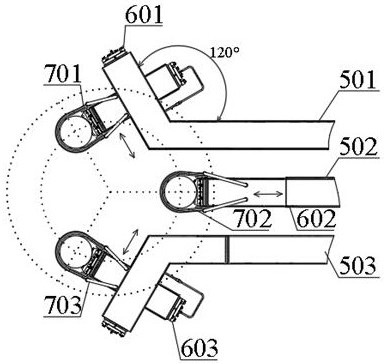

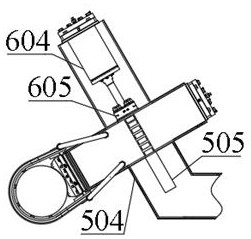

Mixing and degassing apparatus

InactiveUS20100265791A1Increase the amount of materialIncrease the number of revolutionsRotating receptacle mixersTransportation and packagingRotational axisEngineering

A mixing and degassing apparatus includes: a supporting member 14; a rotating base 16 supported on the supporting member so as to be rotatable on a first rotational axis Y1; a first rotating mechanism 18 for rotating the rotating base on the first rotational axis; a container 20 which is fixed to a peripheral portion of the rotating base and which is rotatable with the rotating base around the first rotational axis; a shearing stress applying member 40 having a shearing stress applying portion 40a which is arranged in the vicinity of a maximum centrifugal force applying region on the inner wall surface of the container and which is rotatable on a second rotational axis Y2; and a second rotating mechanism 46 for rotating the shearing stress applying portion of the shearing stress applying member on the second rotational axis to apply a shearing stress to a material to be treated in the container, wherein if the rotating base rotates on its own axis to revolve the container, the shearing stress applying portion rotates on its own axis while moving along the trajectory of revolution of the container, so that a shearing stress is applied to the material in the container to mix and degas the material.

Owner:THINKY

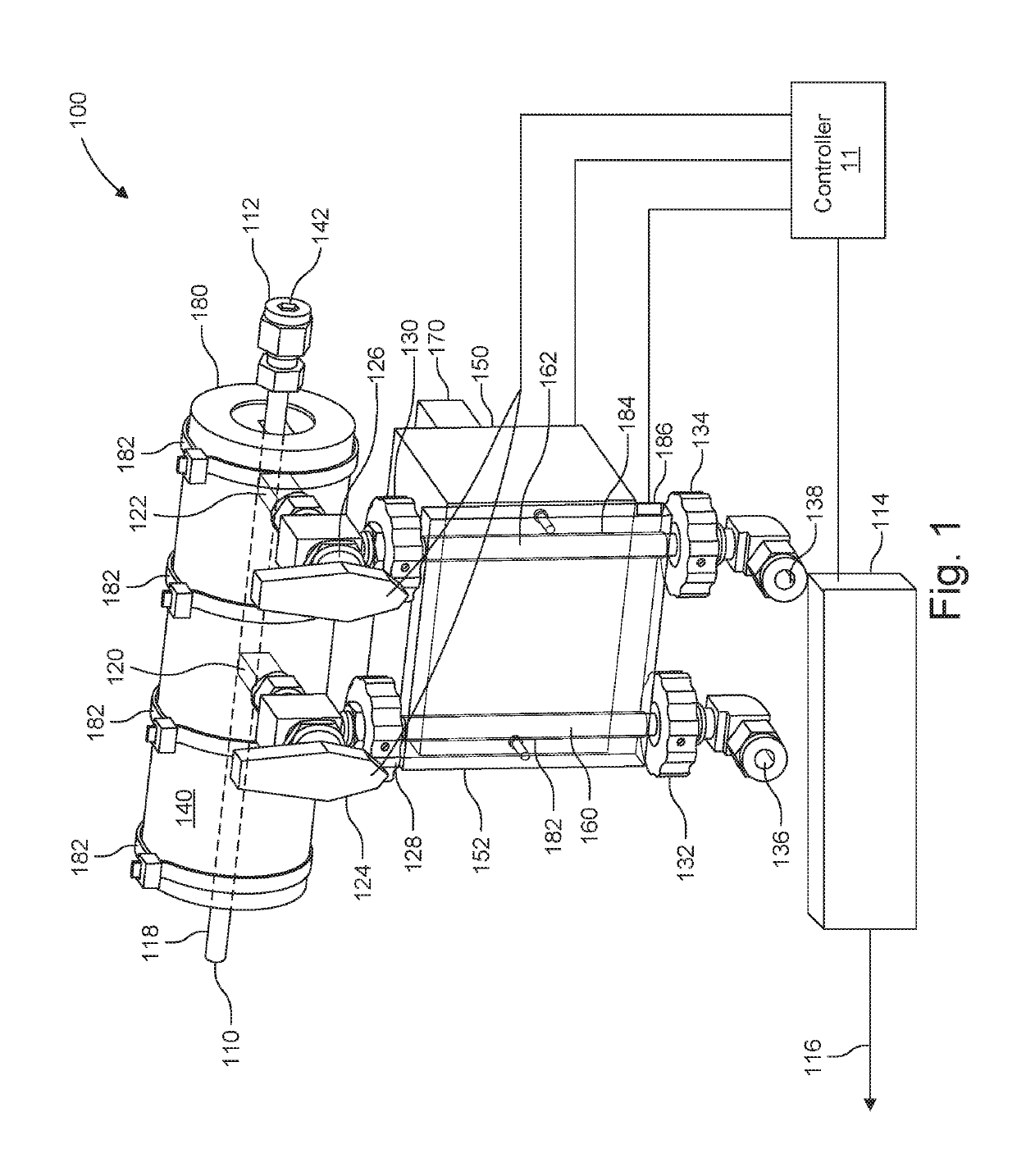

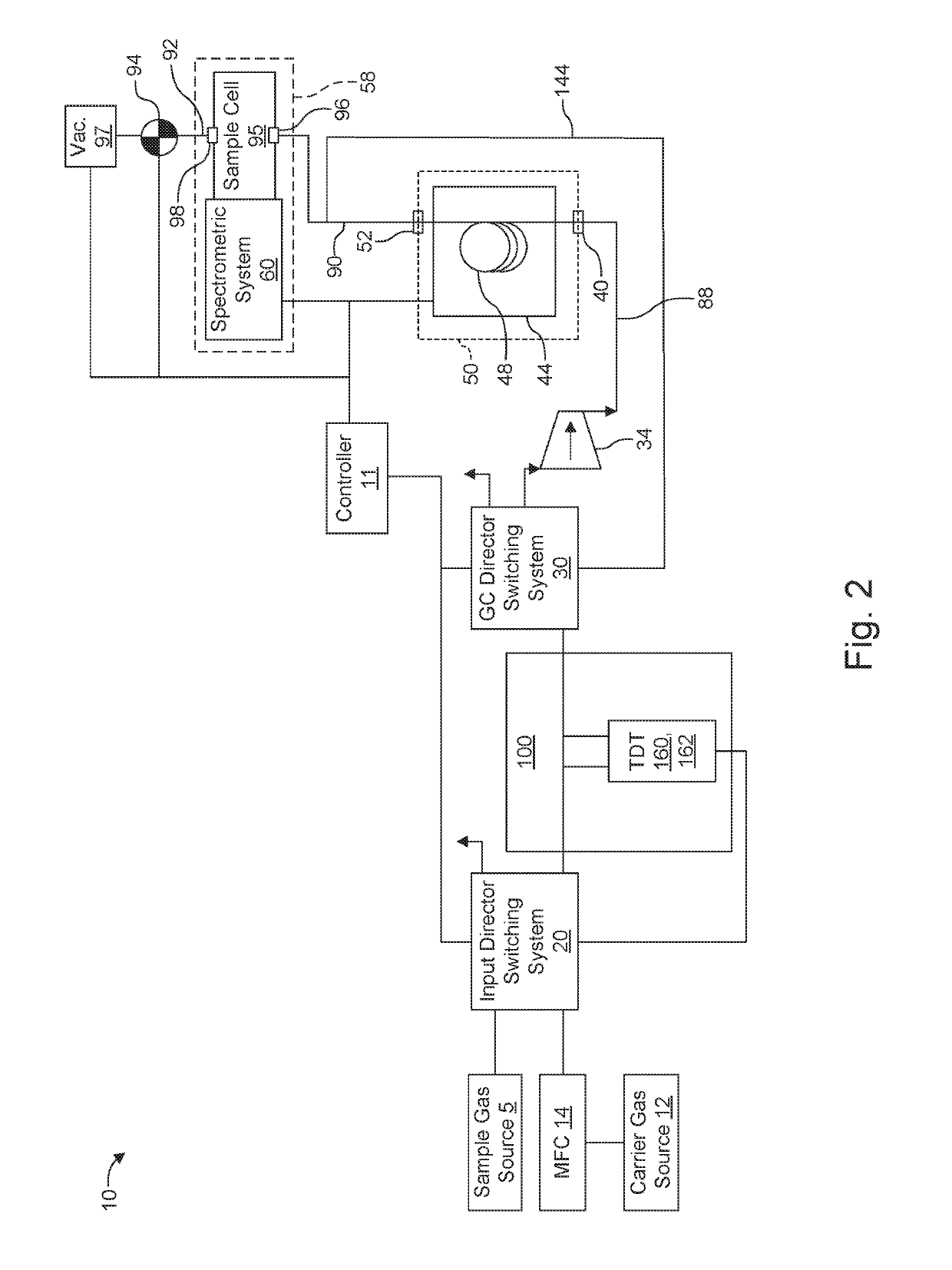

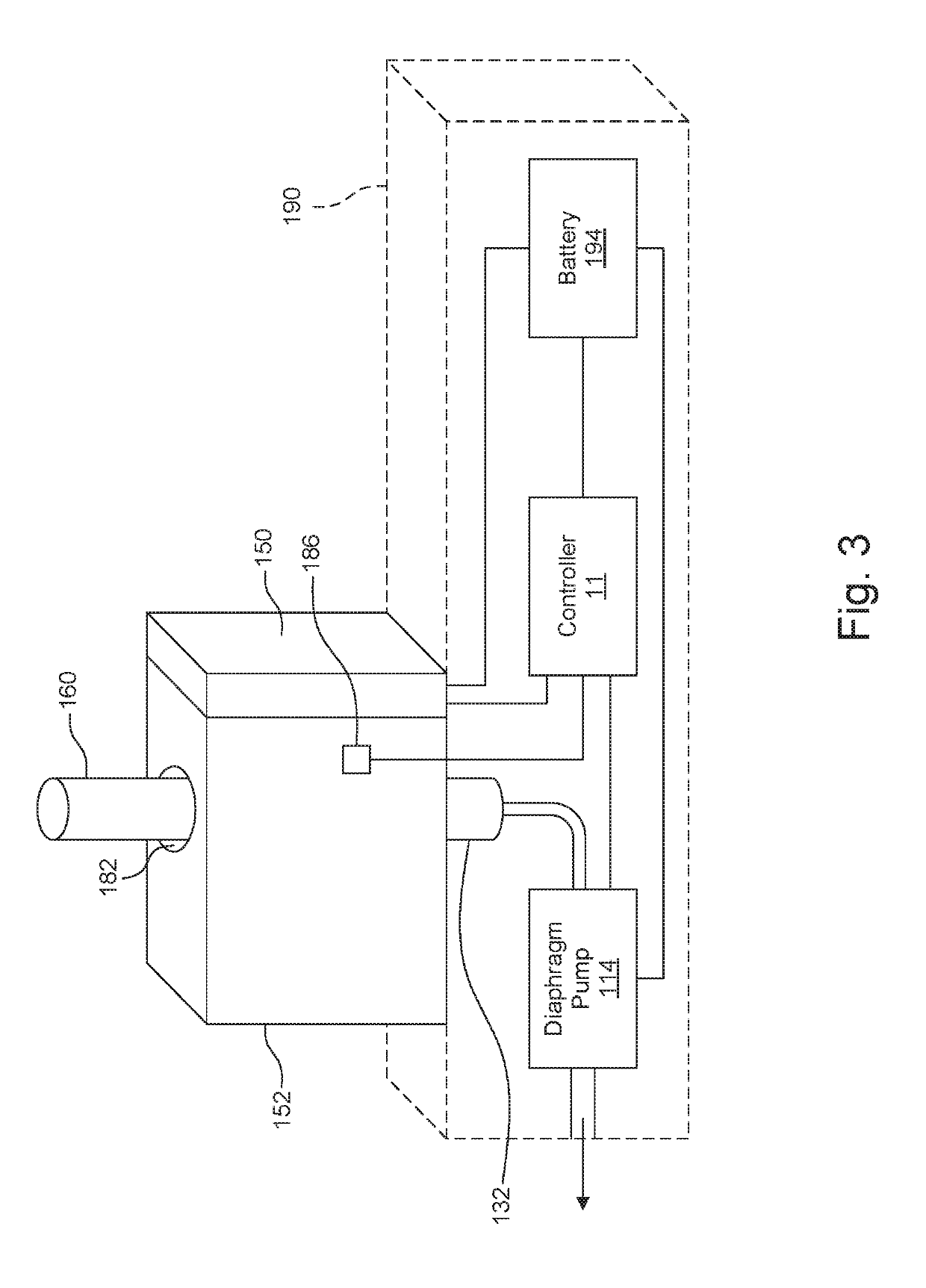

Thermal desorption tube collection system and method

ActiveUS20190265205A1Increase the amount of materialLow detection limitSamplingComponent separationGas phaseCollection system

A thermal desorption tube collection system uses a thermoelectric cooler to collect and concentrate gas samples. In some modes, the operation of the cooler is reversed to flow the concentrated sample directly into a separator such as a gas chromatography system. Components resolved in time by a thermal desorption separator accumulate in a sample cell and are analyzed by electromagnetic radiation-based spectroscopic techniques. Also presented are methods for analyzing biogas samples.

Owner:MLS ACQ INC

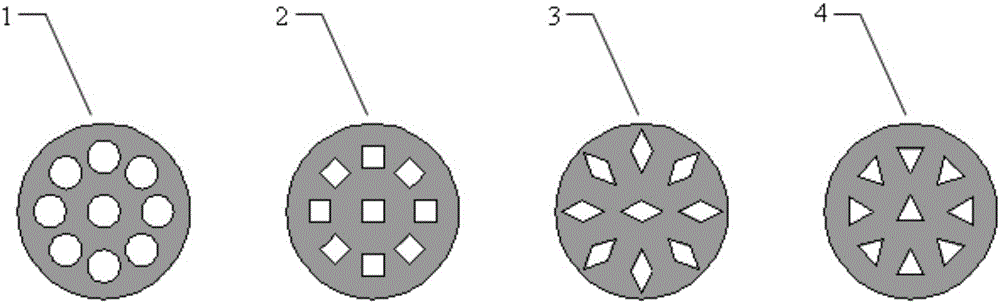

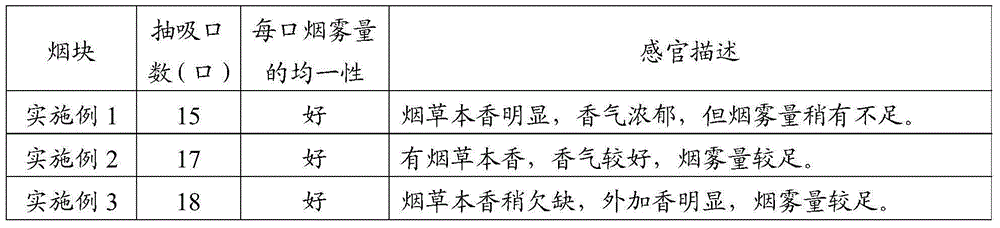

A kind of preparation method of heat-not-burn cigarette block

The invention discloses a preparation method for a heated non-combustion type cigarette block. The cigarette block is composed of 50% to 70% of tobacco powder, 5% to 20% of tobacco stem powder, 3% to 7% of tobacco flavor, 10% to 20% of deionied water, 7% to 11% of alginate and 1% to 2% of glycerinum. All the components are evenly mixed to form tobacco pulp which is formed through a die, and therefore the cylindrical cigarette block with holes can be formed; the formed cigarette block is dried in a drying oven at the temperature of 40 DEG C, the tobacco flavor accounting for, by weight, 1% to 3% of the cigarette block is evenly sprayed on the cigarette block, and the prepared cigarette block is balanced in a constant temperature humidity chamber. The cigarette block is used for a heated non-combustion type cigarette. The cigarette block fills in gaps in the aspect of heated non-combustion type cigarette preparation; meanwhile, the heating efficiency of the cigarette block can be improved, and the puff number of the cigarette can be obviously increased.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

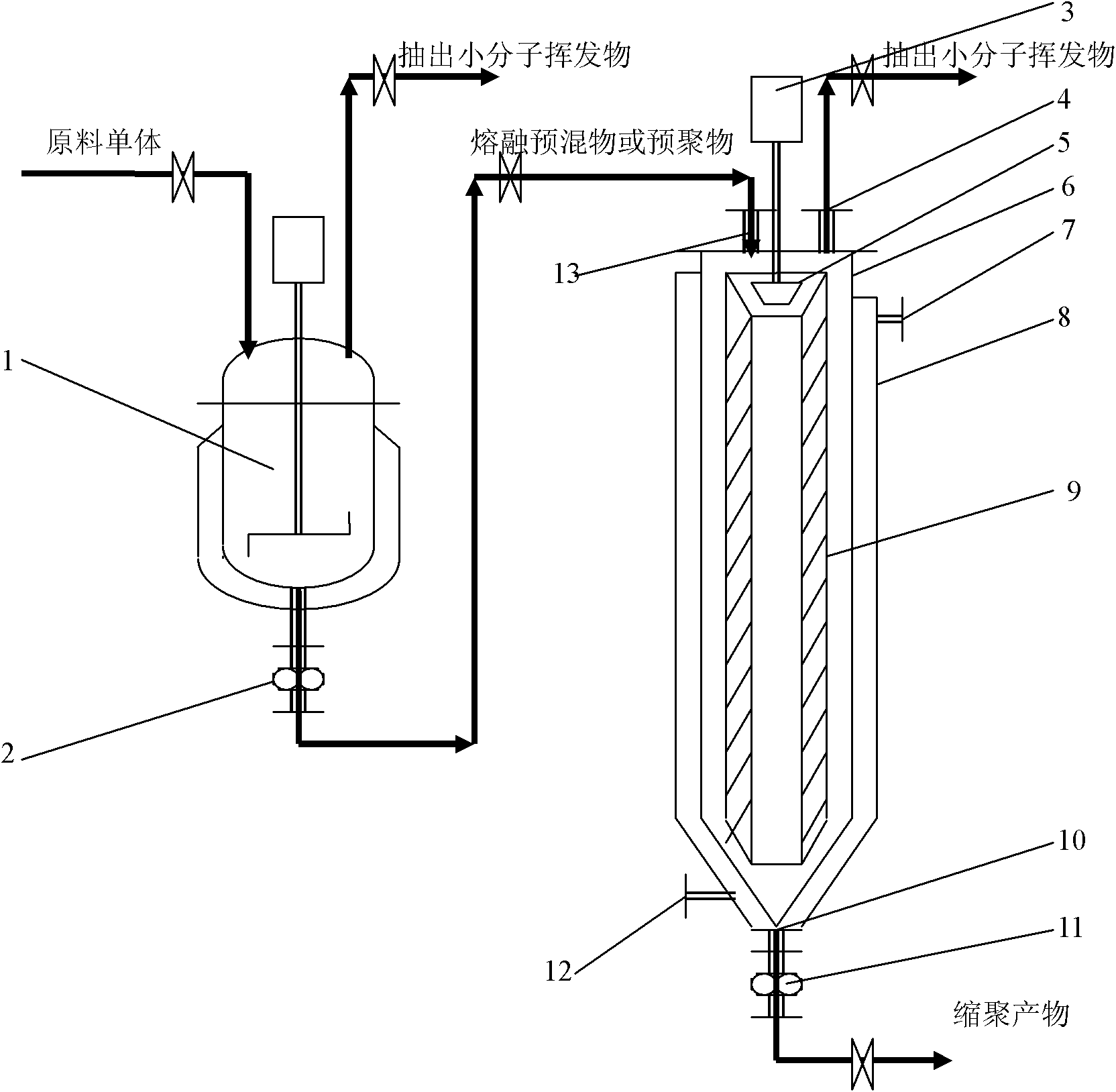

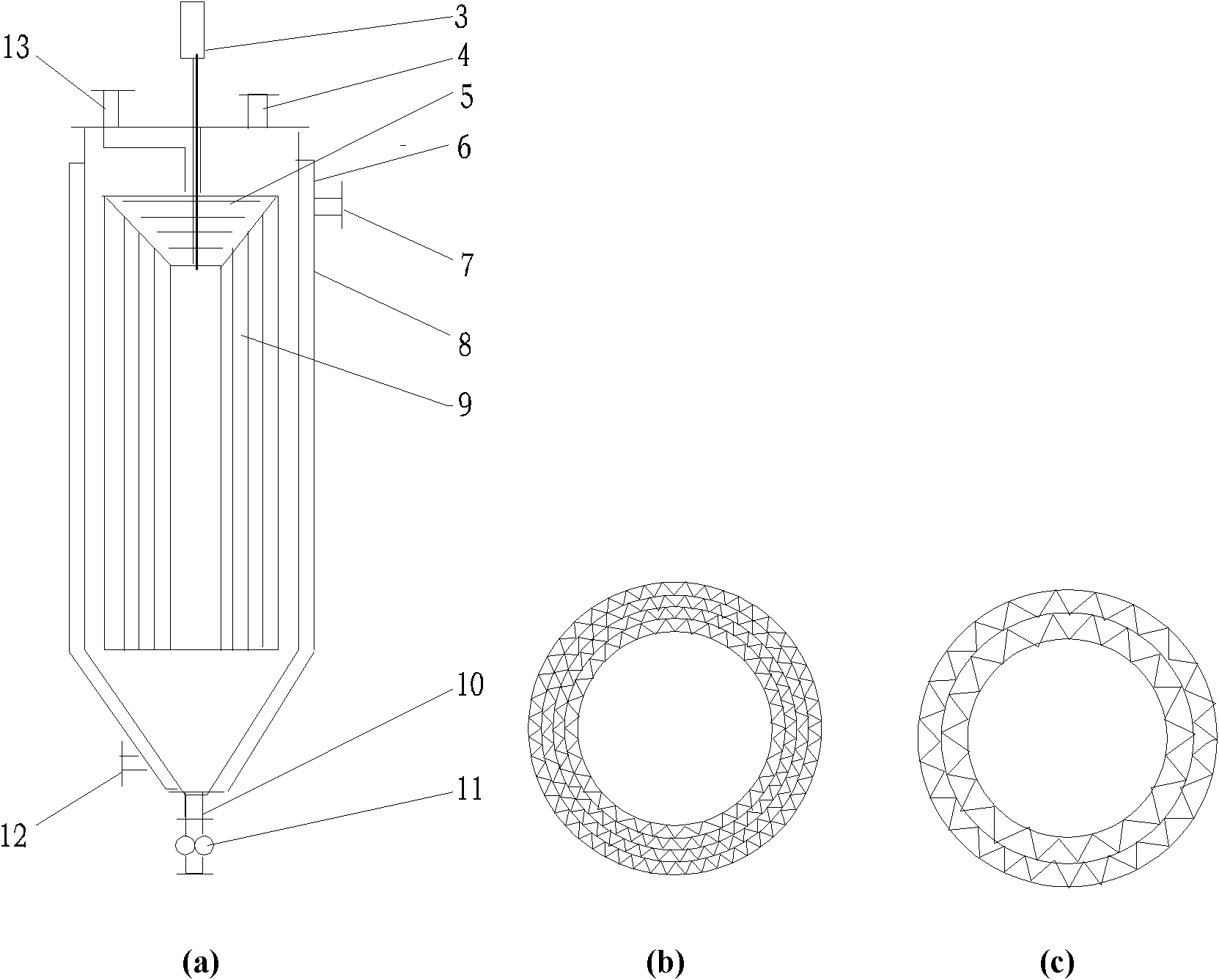

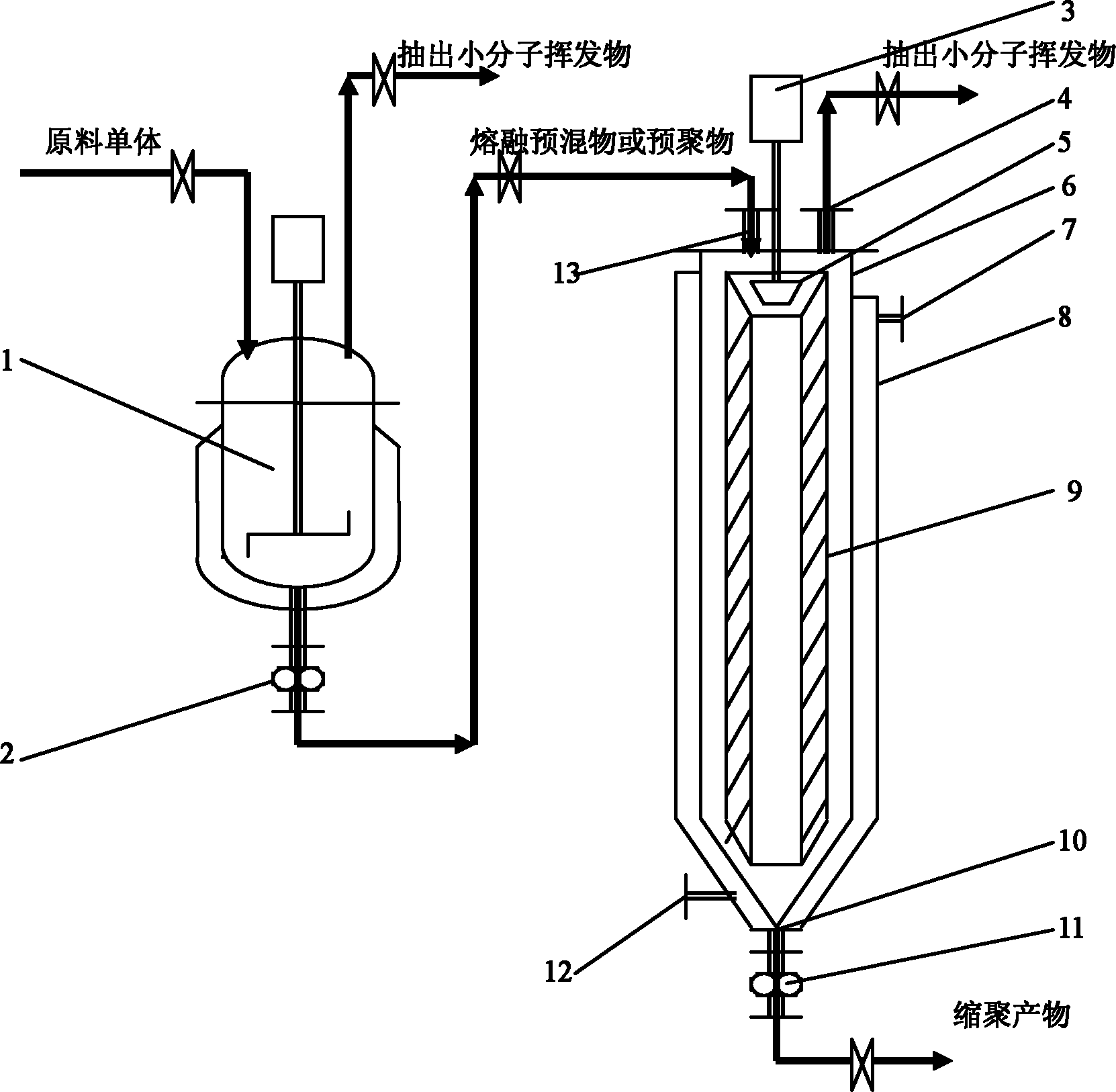

Method and equipment for preparing high molecular weight polycondensate

The invention relates to a method and equipment for preparing high molecular weight polycondensate. The method comprises the following steps of: feeding a fusion mixture of monomers serving as raw materials or a fusion prepolymer obtained by reacting the fusion mixture into vertical polycondensation reaction equipment; in the reaction equipment, under the required temperature, pressure and catalyst conditions, dispersing the fusion mixture or the fusion prepolymer in a special distributor; uniformly distributing the fusion mixture or the fusion prepolymer on a special metallic network structure which comprises a huge inside surface by space movement; allowing the fusion mixture or the fusion prepolymer to flow to the bottom part of the equipment along the metallic network surface in the structure circuitously under the action of gravity; and completing the specified polycondensation reaction during the movement to obtain a polycondensation product with the prospective molecular weight. The method has the characteristics of high equipment volume utilization rate, large liquid phase surface, small devolatilization resistance and excellent product quality.

Owner:TIANJIN UNIV

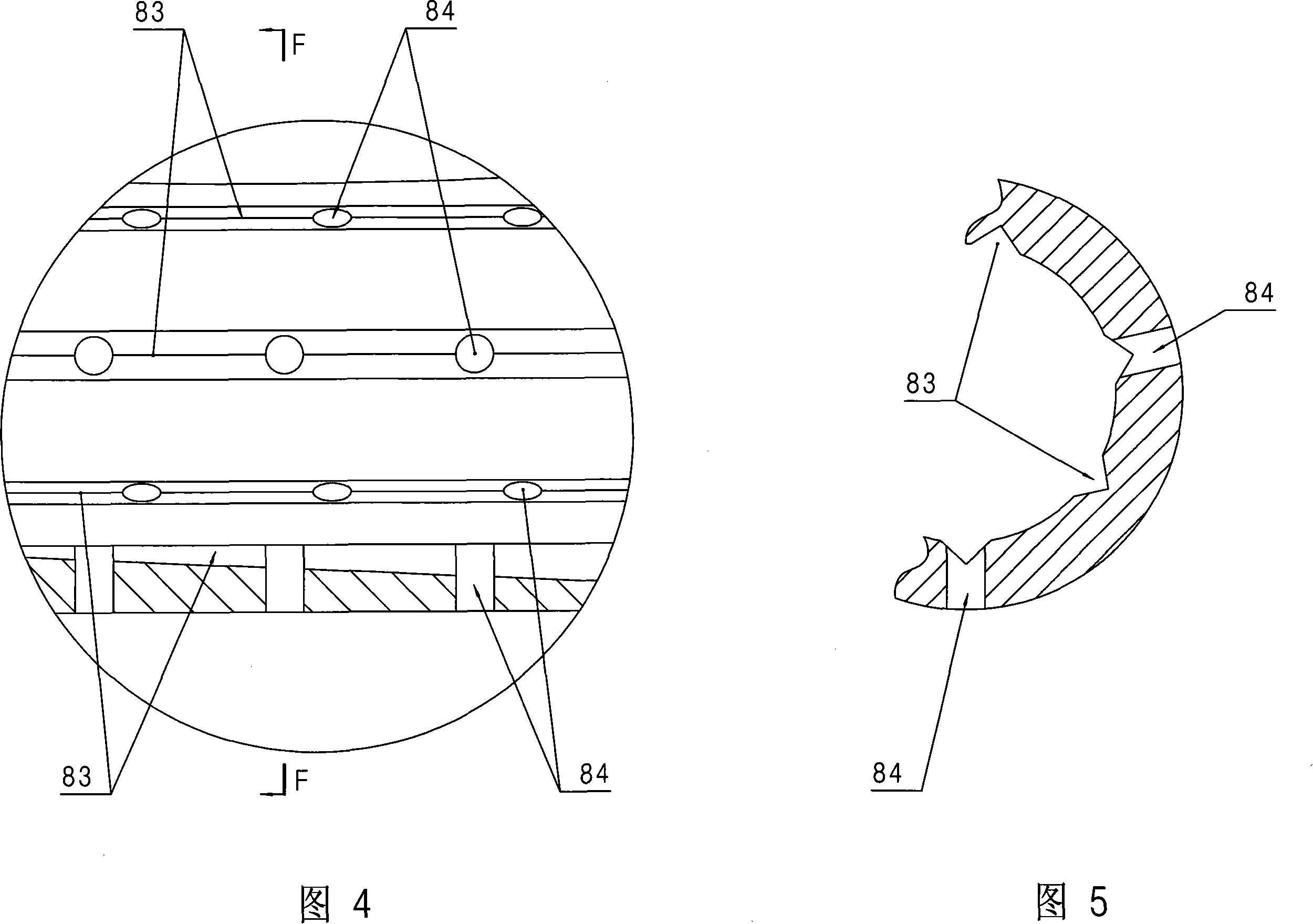

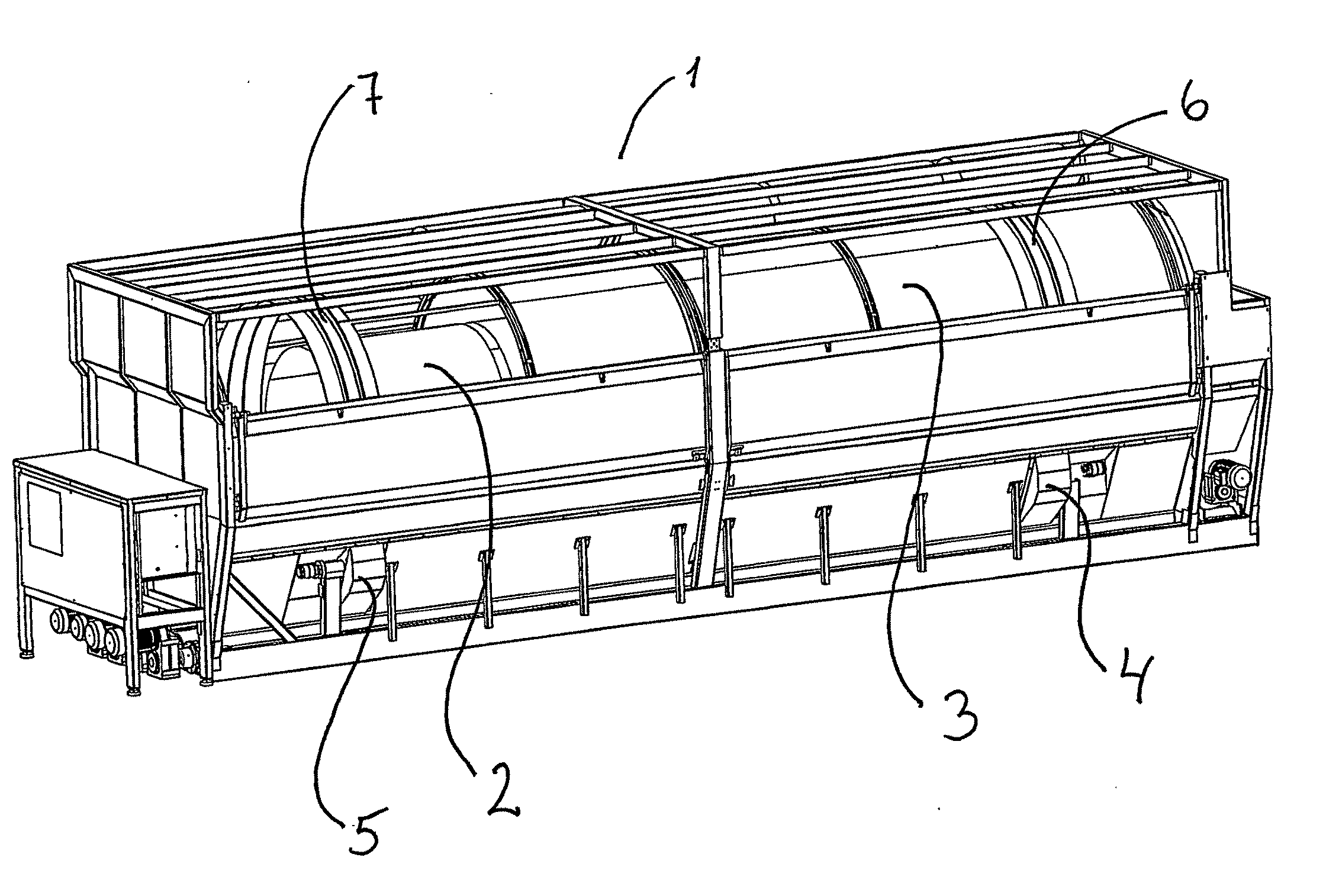

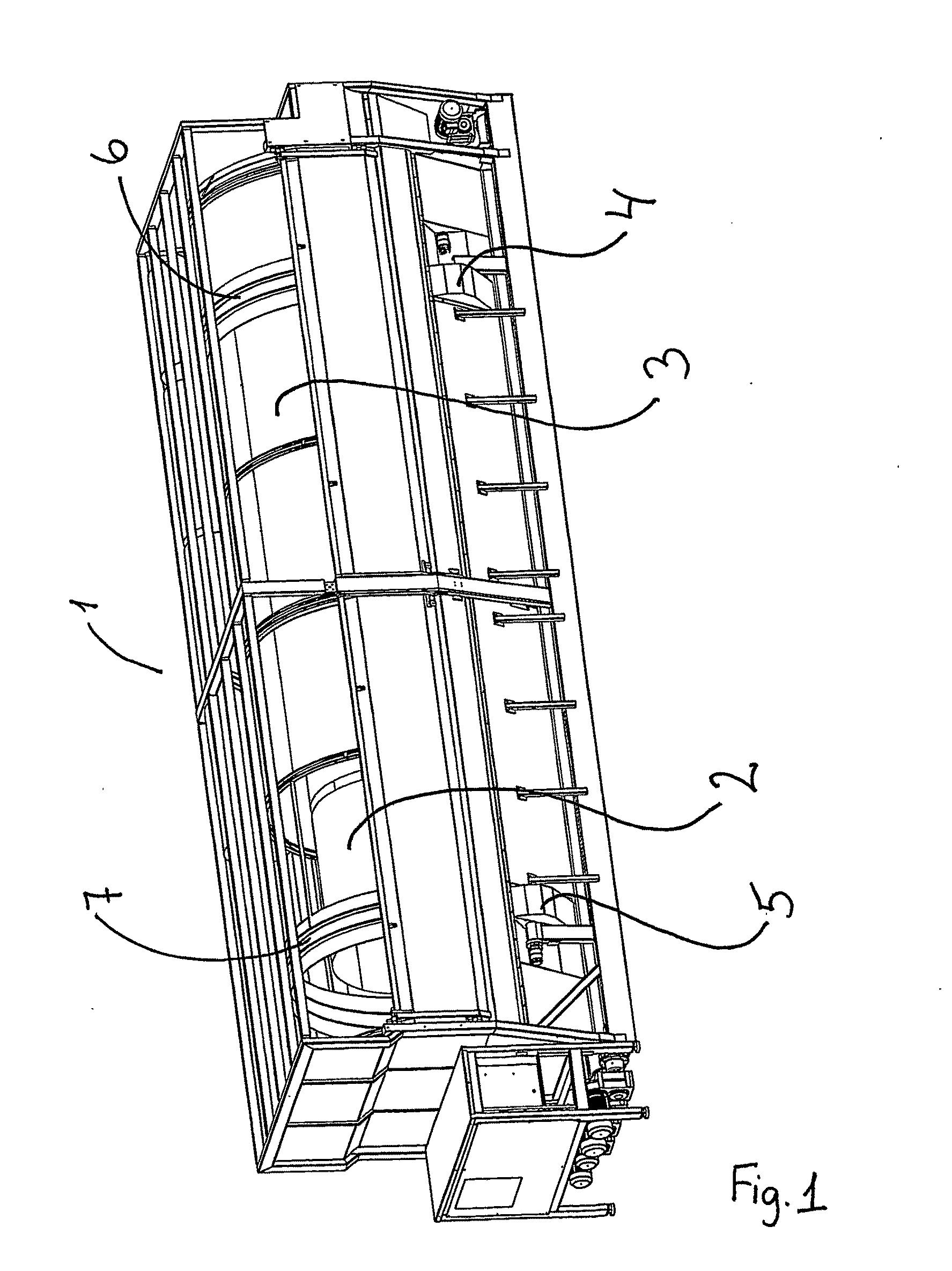

Double Wall Separating Drum

InactiveUS20090218256A1Improve separation qualityIncrease the amount of materialSievingConstruction waste recoveryDouble walledMechanical engineering

Separating device, comprising a rotatable double walled separating drum, where a first wall of the drum constituting the inner drum (2) is arranged concentrically inside and space from a second wall constituting the outer drum (3) of the separating drum, and that a plurality of apertures are provided in said drum walls, where the apertures in the first wall have larger openings than the apertures in the second wall, and that the axis about which the drum rotates may be arranged at an inclined angle in relation to a horizontal plane.

Owner:GIPS RECYCLING

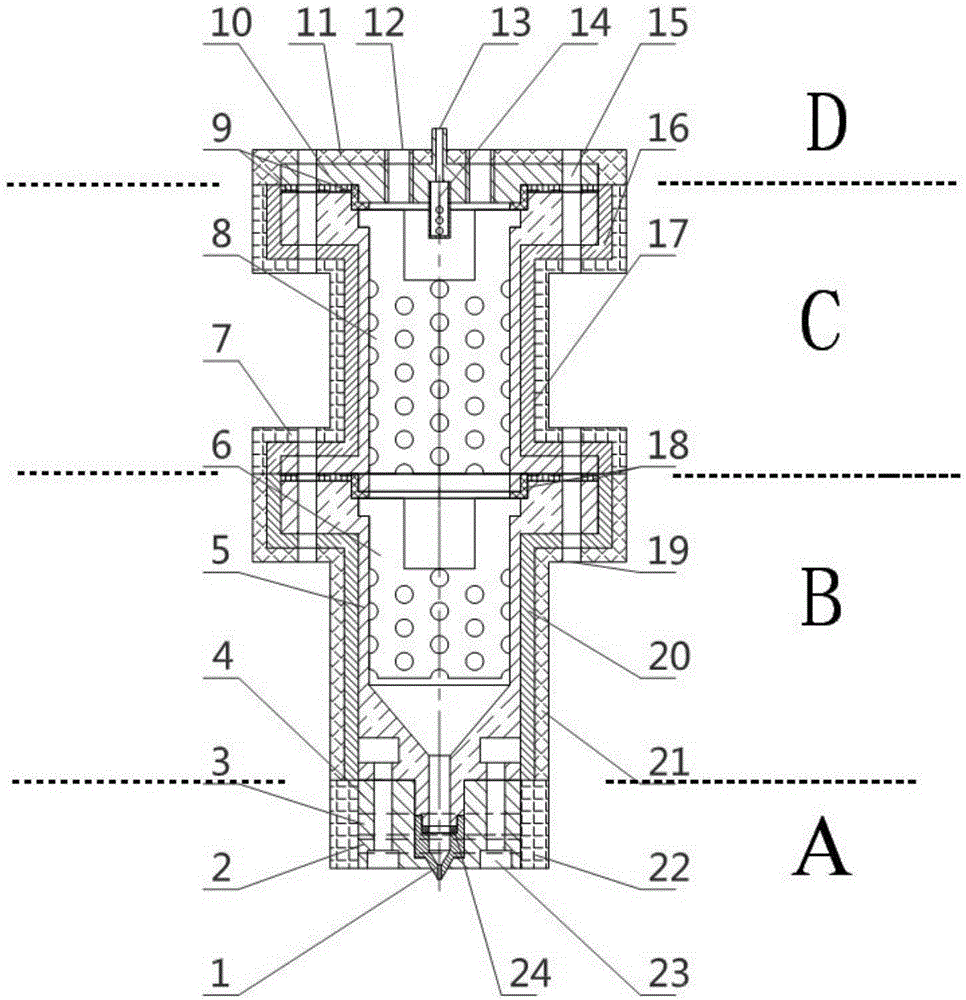

Air pressure type additive manufacturing spray head

ActiveCN106217868AIncrease total spaceShorten the time required for heatingAdditive manufacturing apparatusMultiple stagesInsulation layer

The invention discloses an air pressure type additive manufacturing spray head. The air pressure type additive manufacturing spray head comprises a nozzle and multiple stages of storage barrels sequentially connected to the input end of the nozzle. A nozzle heating unit and a nozzle heat insulation layer are sequentially arranged on the outer portion of the nozzle. A nozzle gasket is arranged between the nozzle and the connected barrels. Each stage of barrel is sleeved with an independent barrel temperature control unit. Heating cavities in all the stages of barrel temperature control units are sequentially connected together in series in the axial direction. A barrel heat insulation layer is arranged on the outer portion of each barrel temperature control unit. A material heat conduction unit is arranged in each stage of barrel. Each material heat conduction unit comprises a plurality of heat conduction plates evenly arranged in the corresponding barrel. Barrel gaskets are arranged between the adjacent barrels. The feeding end of the last stage of barrel far away from the nozzle is sequentially provided with the corresponding barrel gasket, a barrel upper cover and a barrel upper cover heat insulation layer. Each barrel upper cover is provided with a feeding and extrusion force stabilization device connector and an extrusion force control connector. The barrel upper cover heat insulation layers, the barrel heat insulation layers of all the stages of barrels and the primary nozzle heat insulation layer are connected into a whole in a sealed manner.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

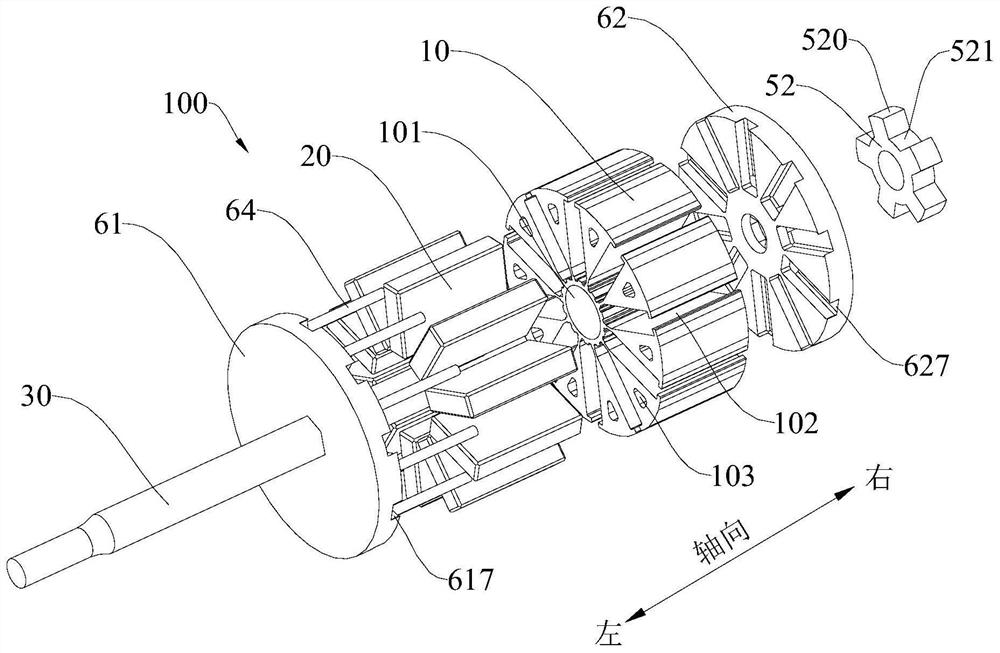

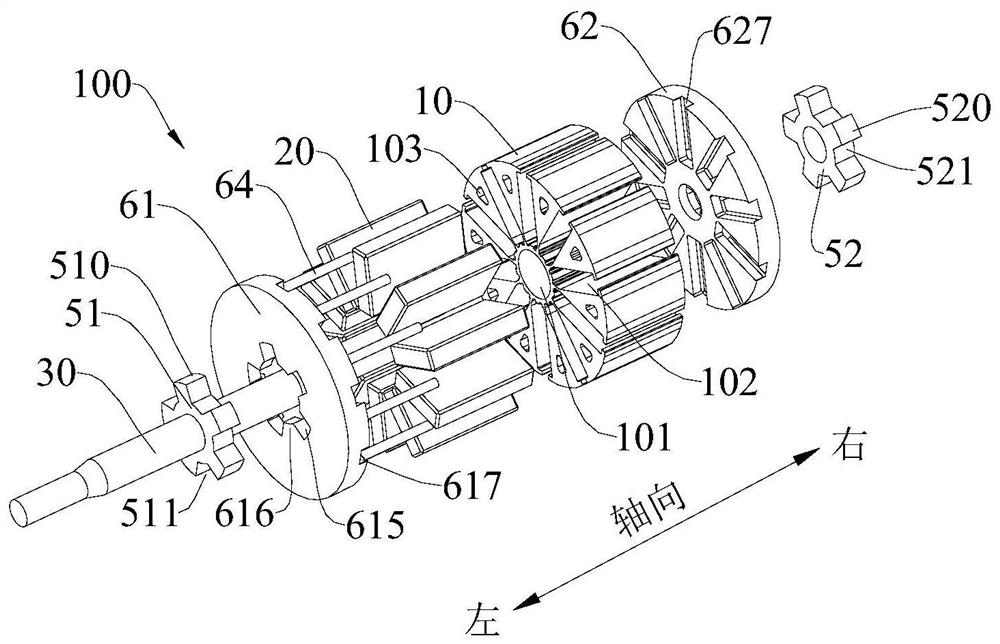

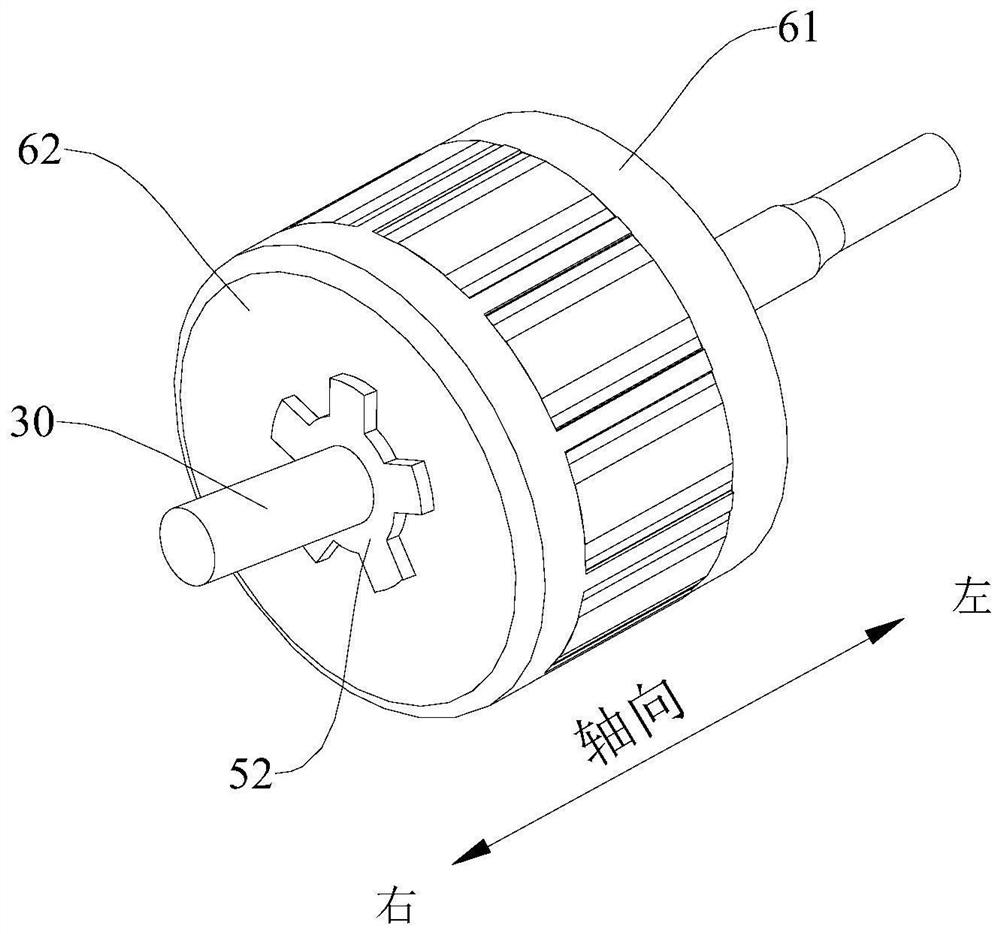

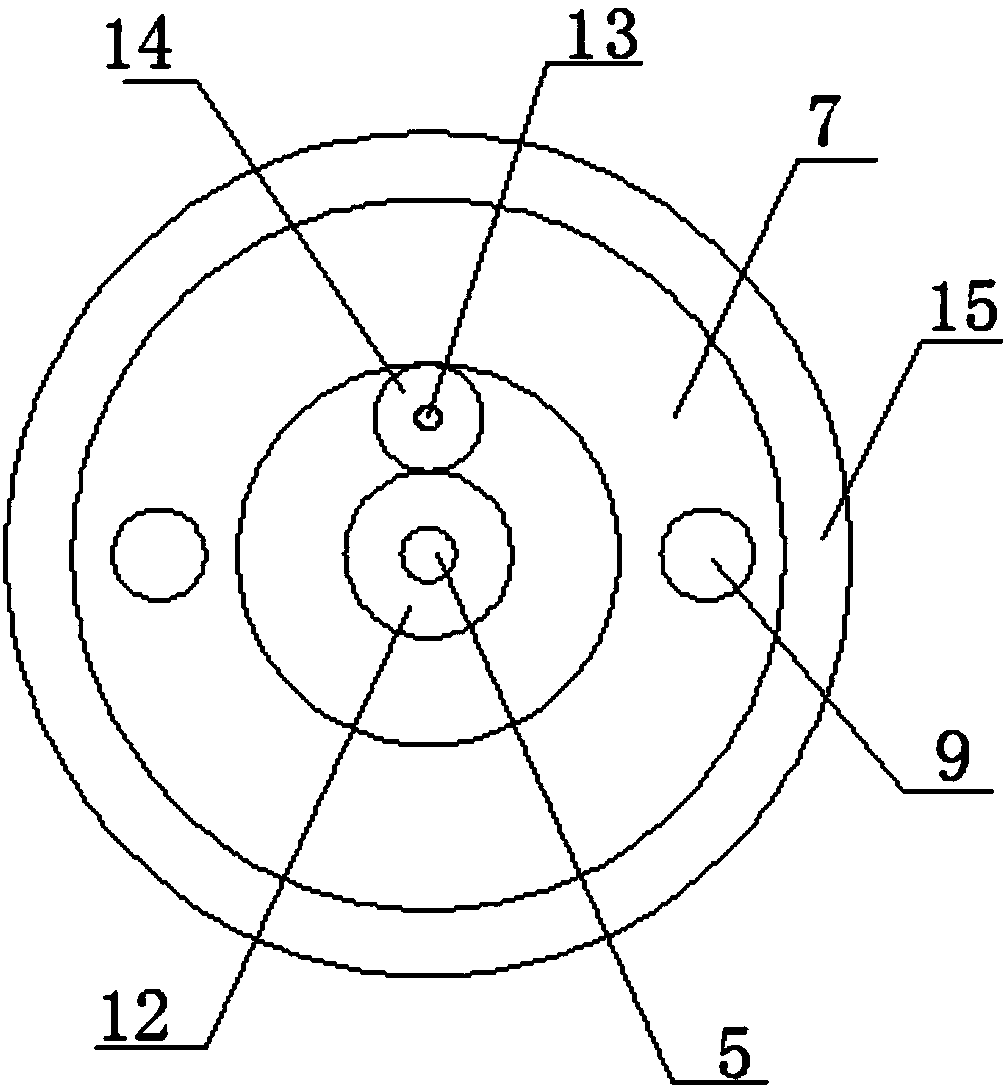

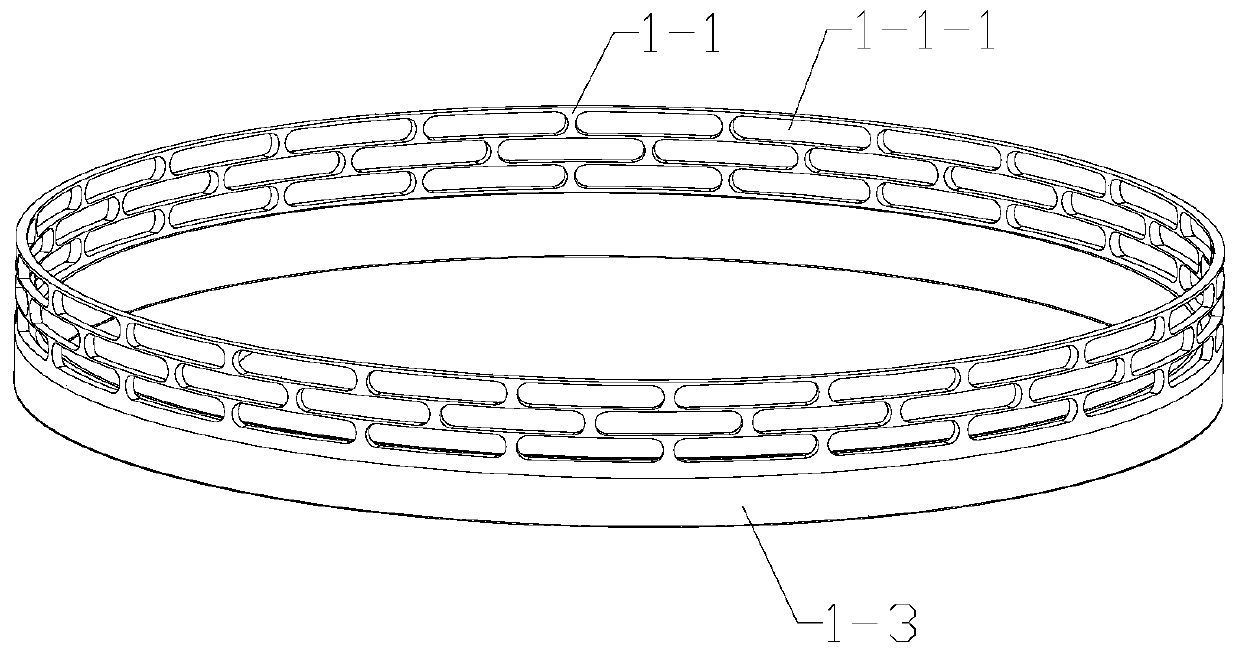

Vibration reduction rotor assembly and motor

PendingCN111769664AImprove vibration damping performanceReduce vibration and noiseMagnetic circuit rotating partsSupports/enclosures/casingsPhysicsElectric machinery

The invention discloses a vibration reduction rotor assembly and a motor. The vibration reduction rotor assembly comprises a rotor iron core, a permanent magnet, a rotating shaft and a first end vibration reduction piece. The rotor core is provided with magnet grooves and a rotating shaft hole. The permanent magnets are arranged in the magnet grooves. A rotating shaft is arranged in the rotating shaft hole. The first end and the second end of the rotating shaft extend out of the rotating shaft hole. A gap is formed between the rotating shaft and the rotor core. The first end part vibration reduction piece is arranged on the first end surface of the rotor iron core and is connected with the rotor iron core. On the axial direction of the rotor core, the first end of the permanent magnet extends out of the magnet groove and is matched in the first end vibration reduction piece or the first end of the permanent magnet retracts into the magnet groove so that one part of the first end vibration reduction piece can be matched in the magnet groove, and the first end vibration reduction piece is directly matched with the rotating shaft or matched with the rotating shaft through a first transmission piece arranged in the first end vibration reduction piece. According to the vibration reduction rotor assembly, the material amount of the vibration reduction part can be increased, the vibration reduction performance is good, and the vibration noise is low.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

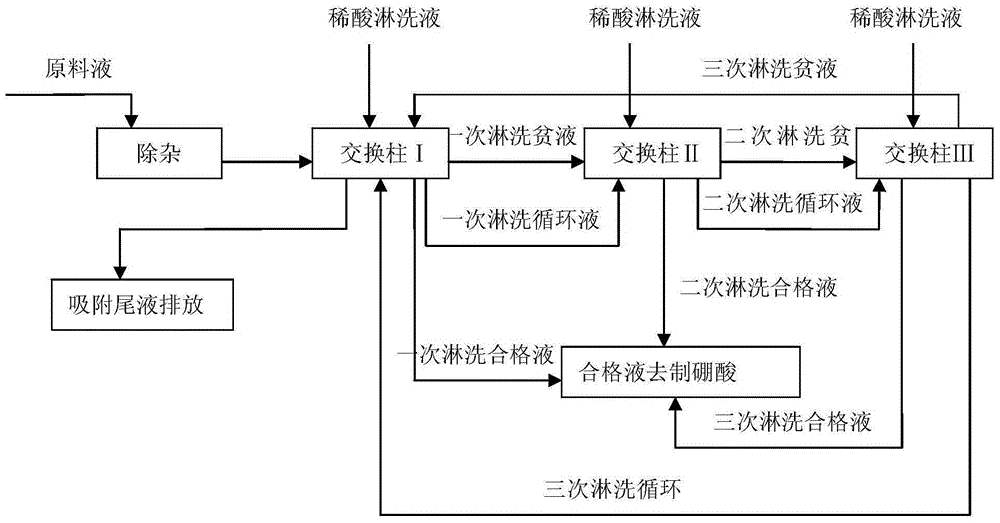

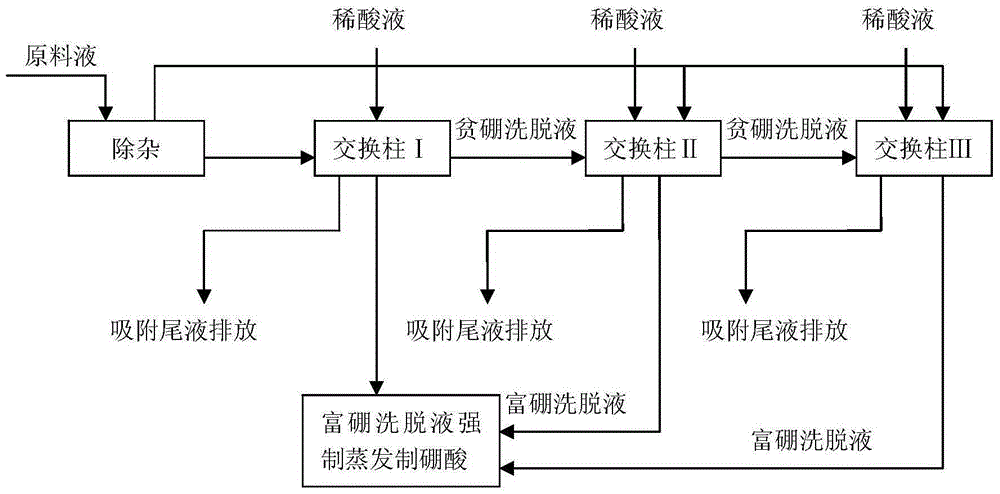

Method for separating and extracting boron from boron-containing solution

ActiveCN106167267AIncrease concentrationReduce energy consumptionIon-exchange column/bed processesIon-exchanger regenerationHigh concentrationDesorption

The invention relates to a method for separating and extracting boron from a boron-containing solution. The method comprises that a boron-containing raw material liquid flows through an ion exchange column to adsorb the boron in the raw material liquid to the exchange column, the tail liquid after the adsorbing is discharged, the ion exchange column is leached with a leaching liquid to leach out the boron on the exchange column after the adsorbing achieving a saturated state, the eluent with the B2O3 concentration of more than 20 g / L is collected as the raw material for evaporation production of boric acid, the eluent with the B2O3 concentration of more than or equal to 20 g / L and less than or equal to 15 g / L is collected as the leaching liquid of the subsequent boron saturation exchange column, the eluent with the B2O3 content of less than 15 g / L and the boron-containing raw material liquid are mixed, and the obtained mixture enters the exchange column again, wherein the leaching liquid comprises a dilute acid and the collected eluent with the B2O3 concentration of more than or equal to 20 g / L and less than or equal to 15 g / L during the previous boron saturation exchange column desorption process. According to the method of the present invention, the ion exchange technology is used to carry out multiple adsorption enrichment on the boron in the boron-containing solution to achieve the high concentration, such that the obtained material can be used as the raw material for the forced evaporation concentration production of the boric acid.

Owner:CHINA PETROCHEMICAL CORP +2

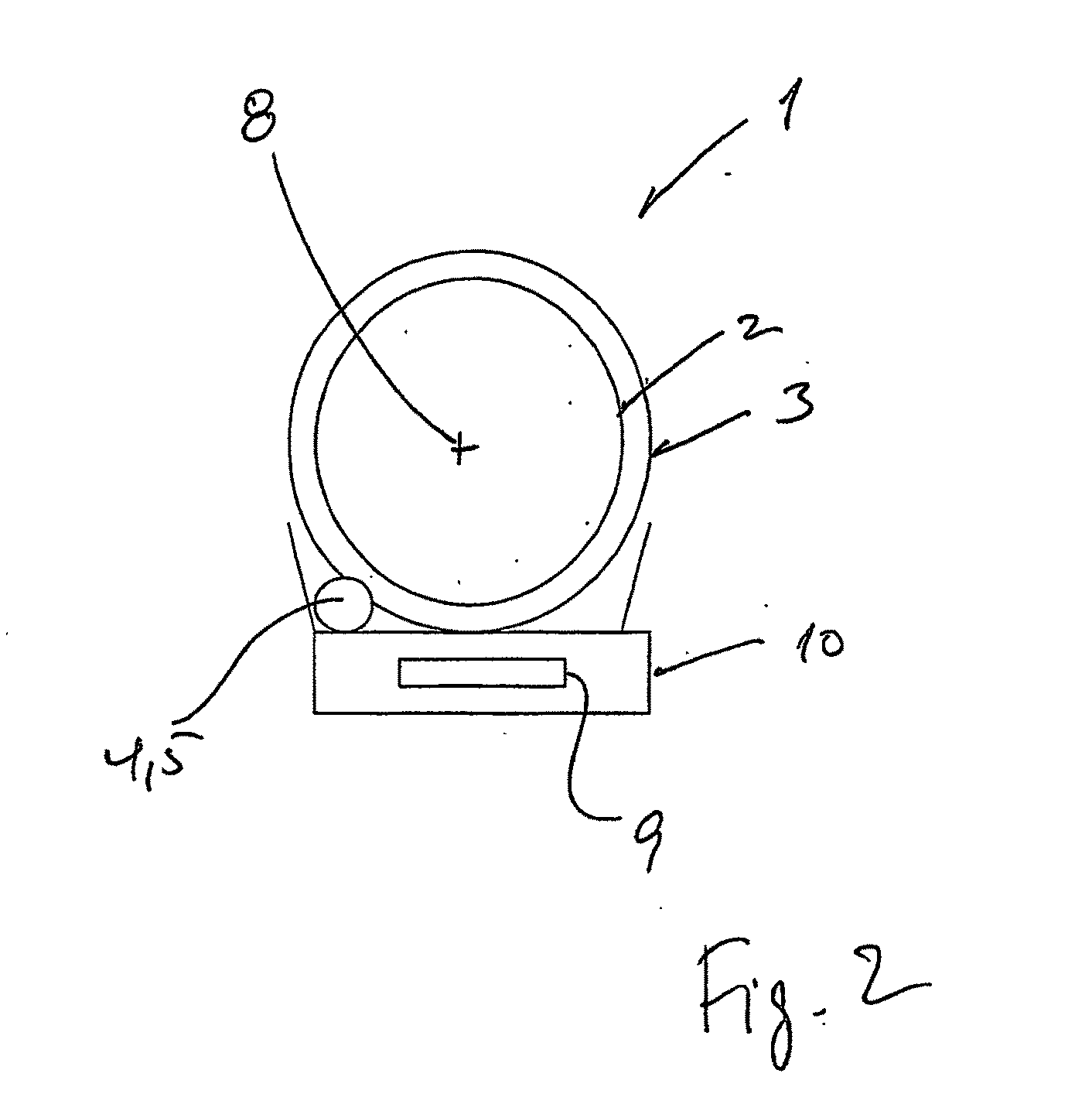

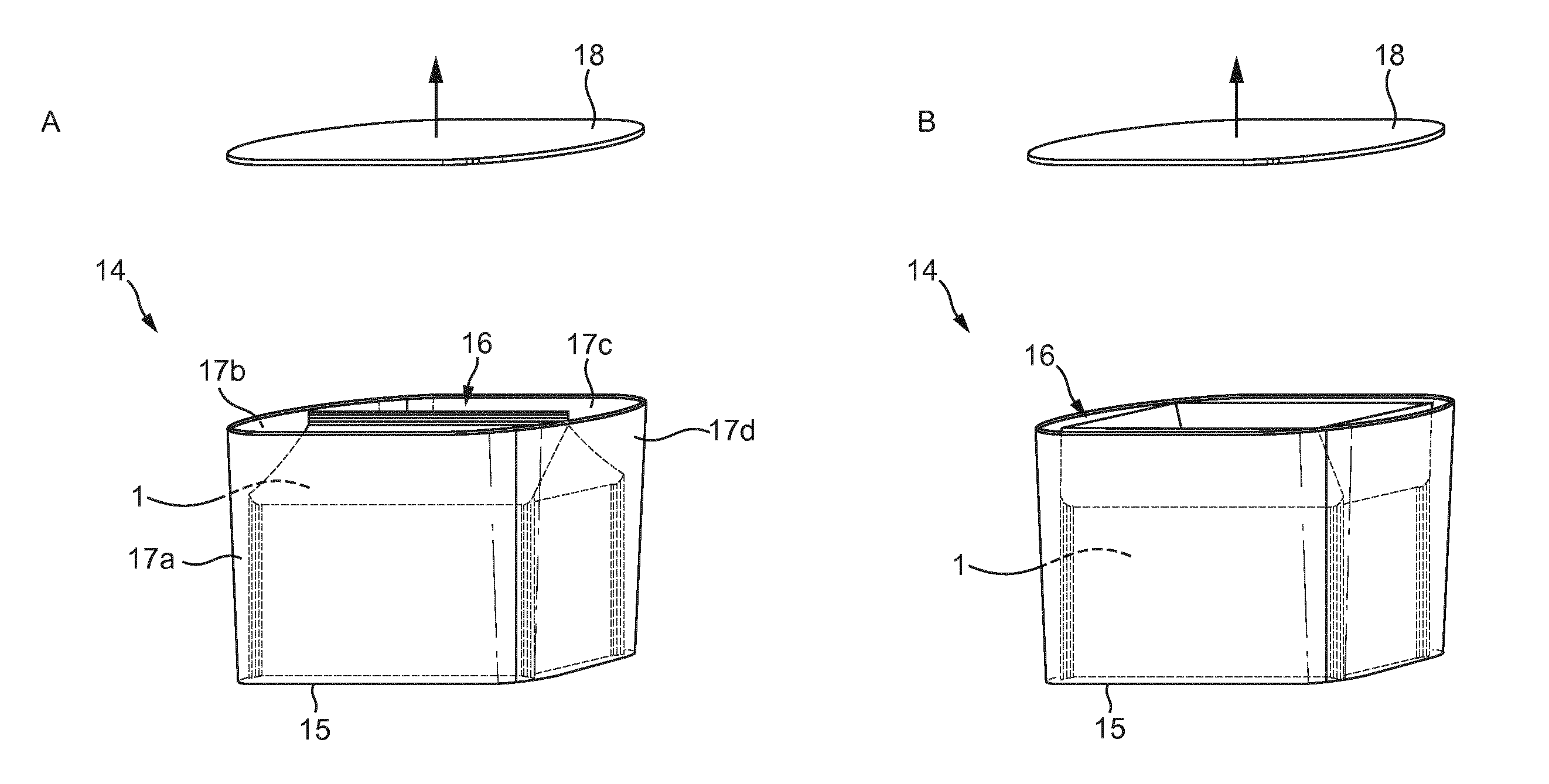

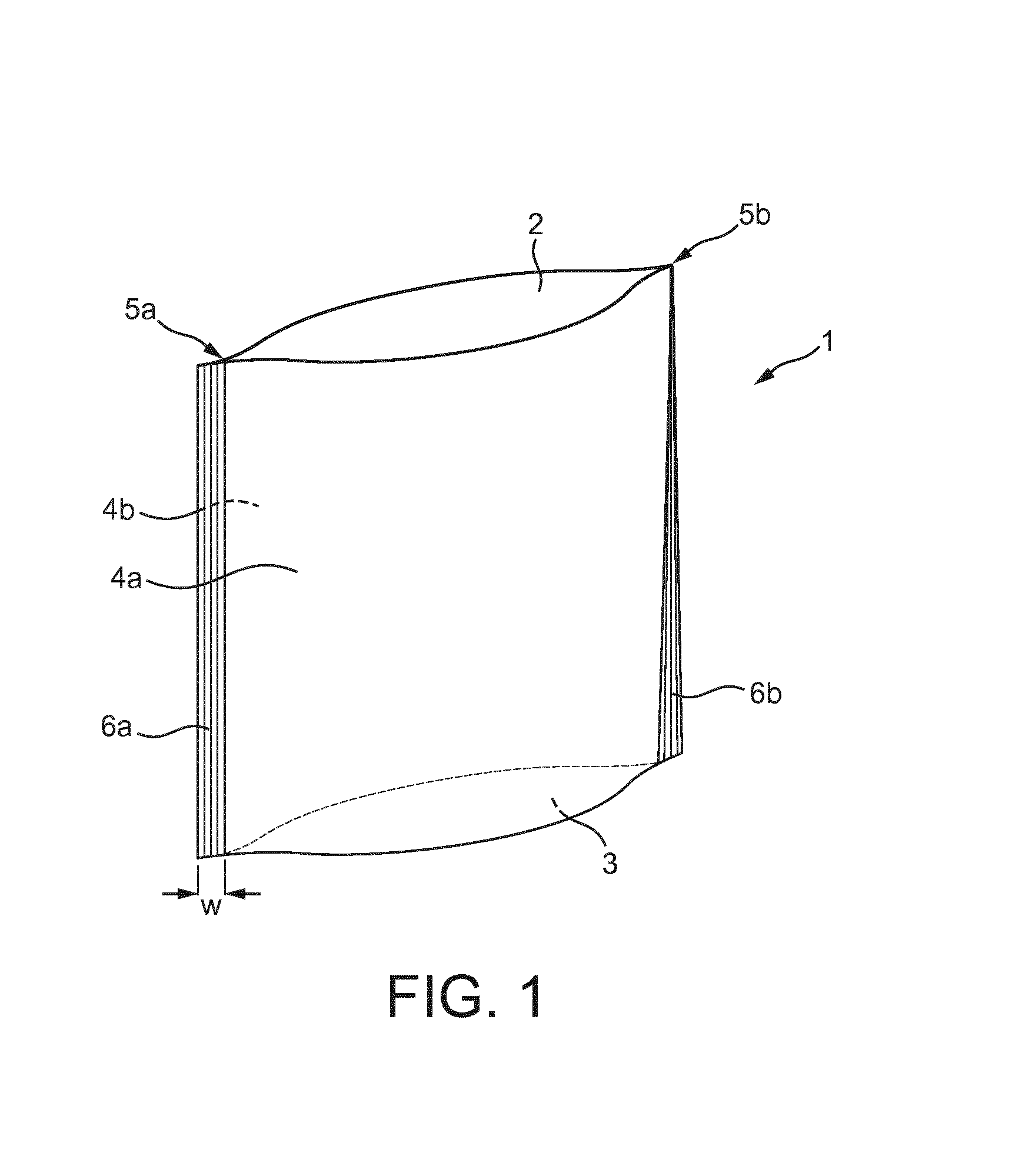

Flexible pouch with a larger opening

ActiveUS20150329259A1Large openingImprove accessibilityPower operated devicesLarge containersEngineeringMechanical engineering

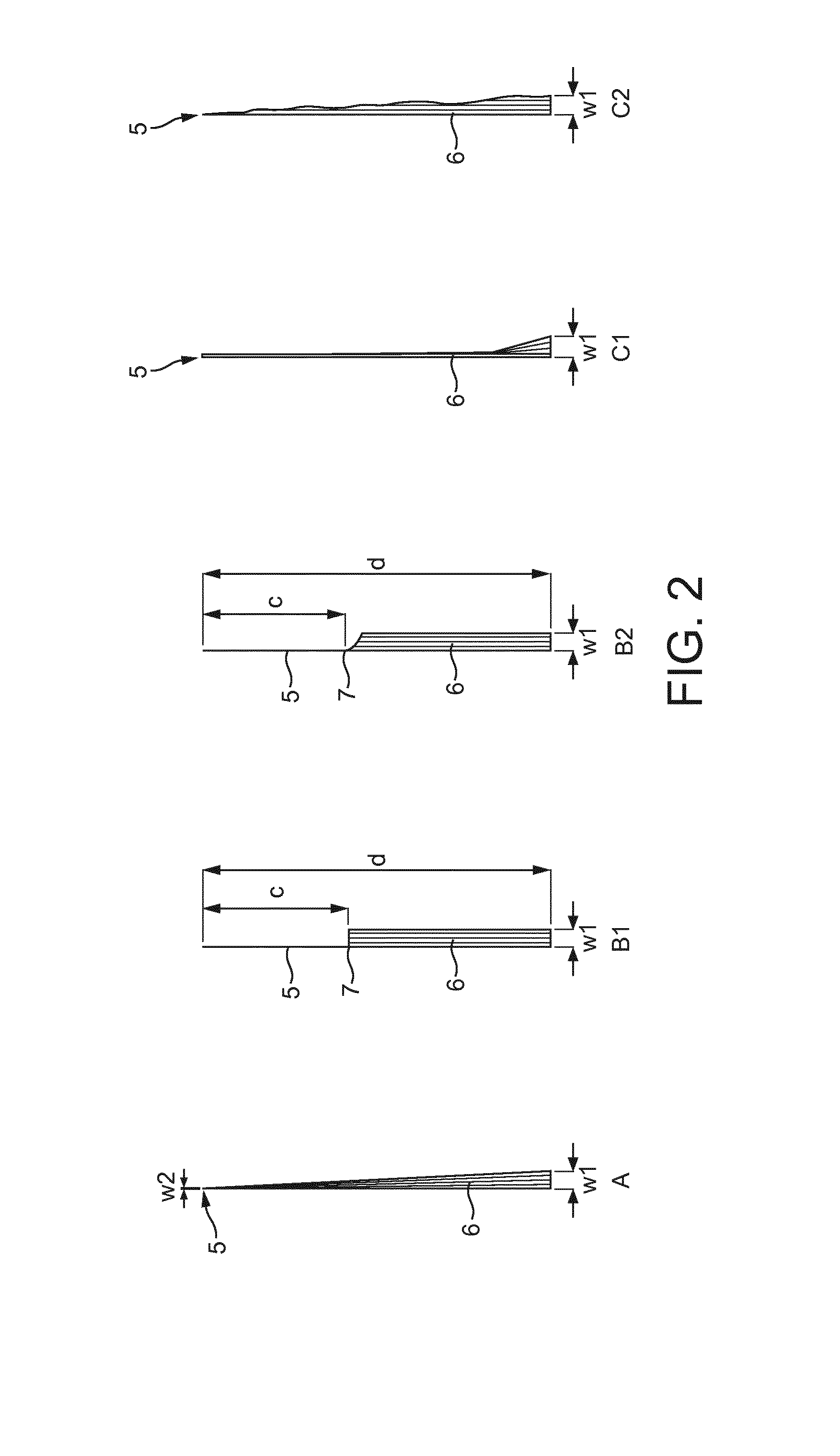

The present invention relates to a flexible pouch (1) having a wider opening (2) allowing to get a better access of the content of the pouch (1). The perimeter (a) of the opening (2) of the flexible pouch (1) is greater than the perimeter (b) of its bottom (3). At least one of the lateral folding lines (5) of the flexible pouch (1) comprises a welding line (6) of a width (w). A part or all of the lateral welding lines (6) of the flexible pouch (1) have a width (w) which is not constant along its length. The invention also relates to a kit-of-part comprising the flexible pouch (1) according to the invention and a container (14) adapted to receive said flexible pouch (1).

Owner:SOC DES PROD NESTLE SA

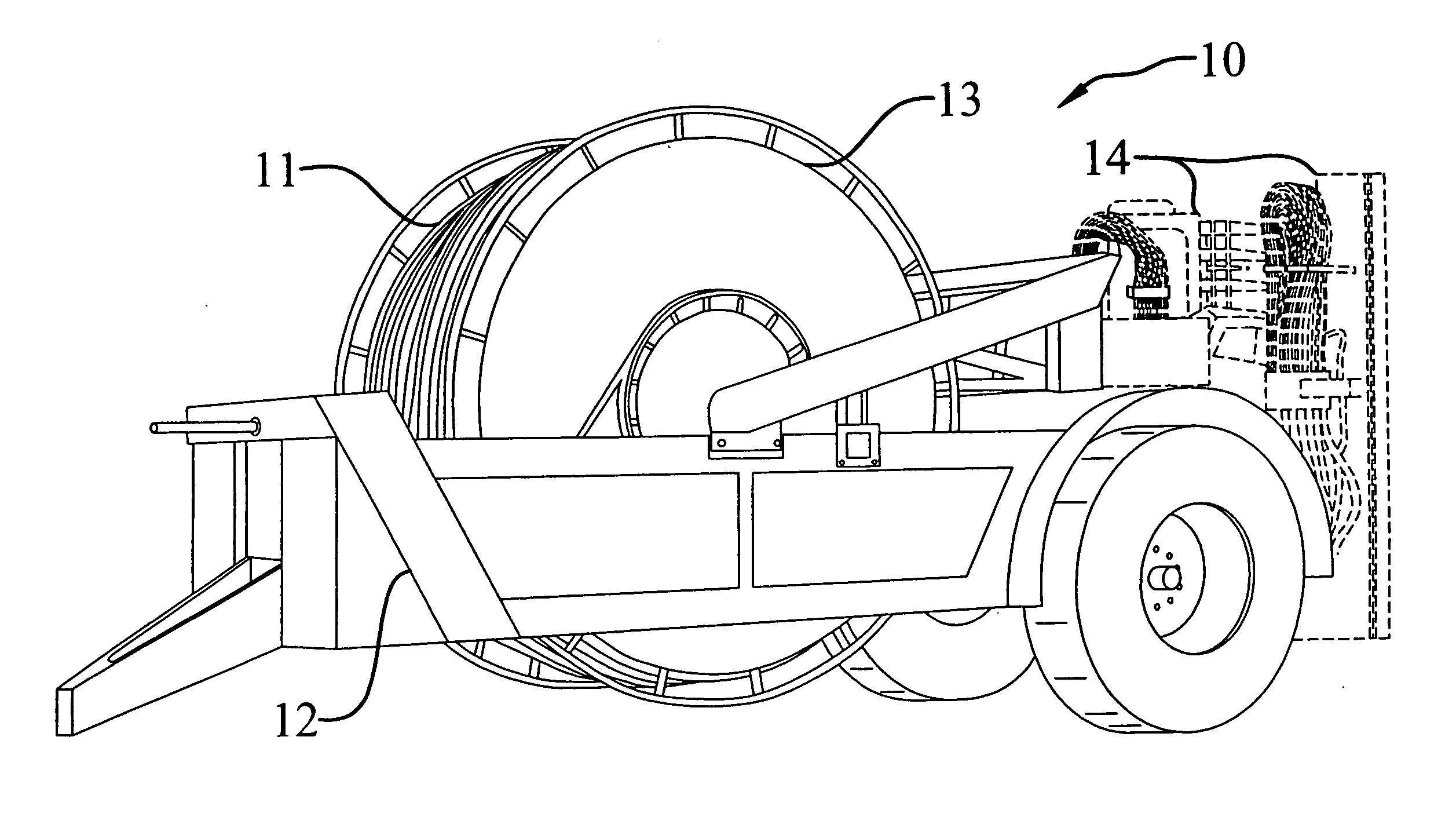

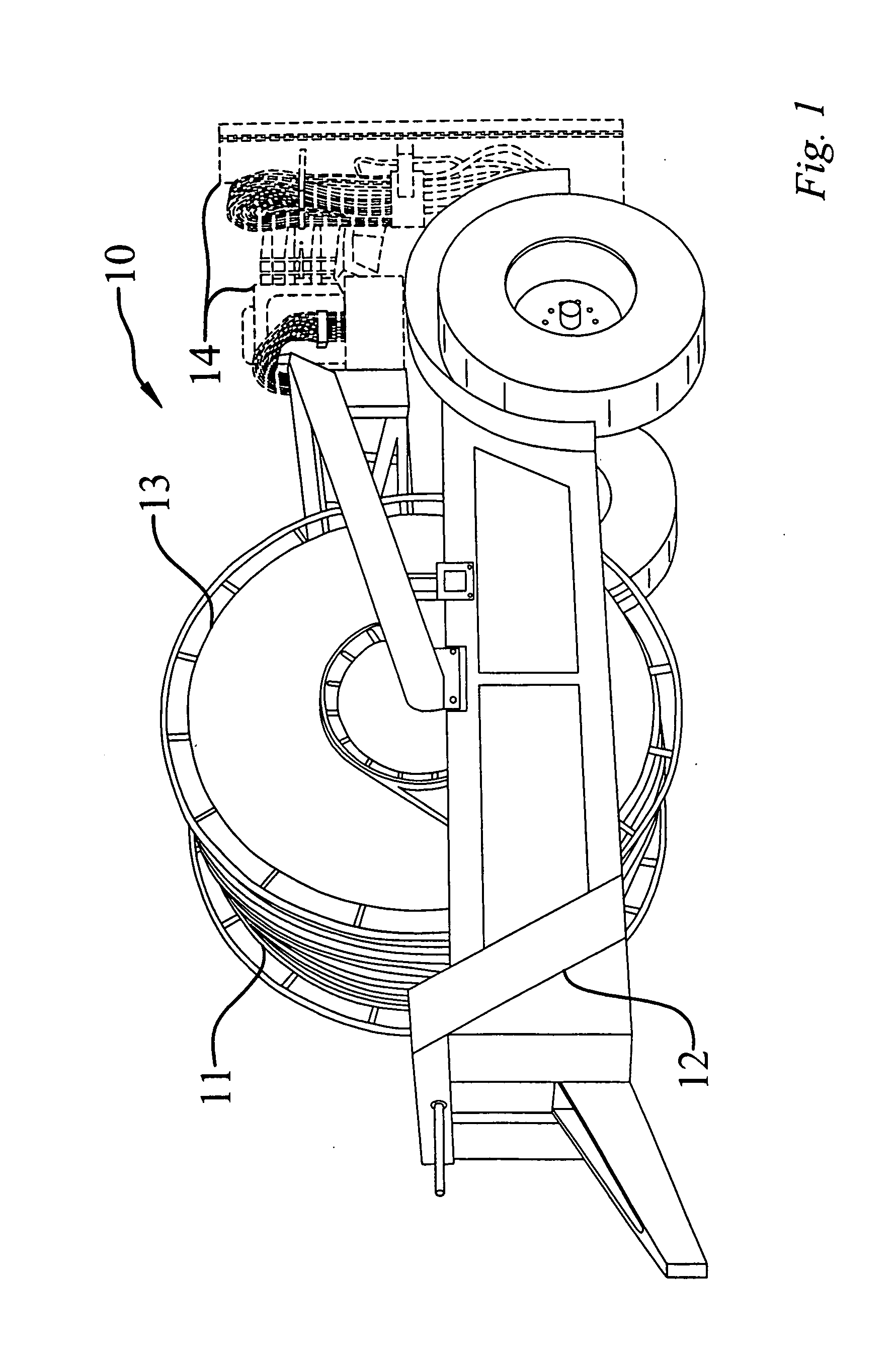

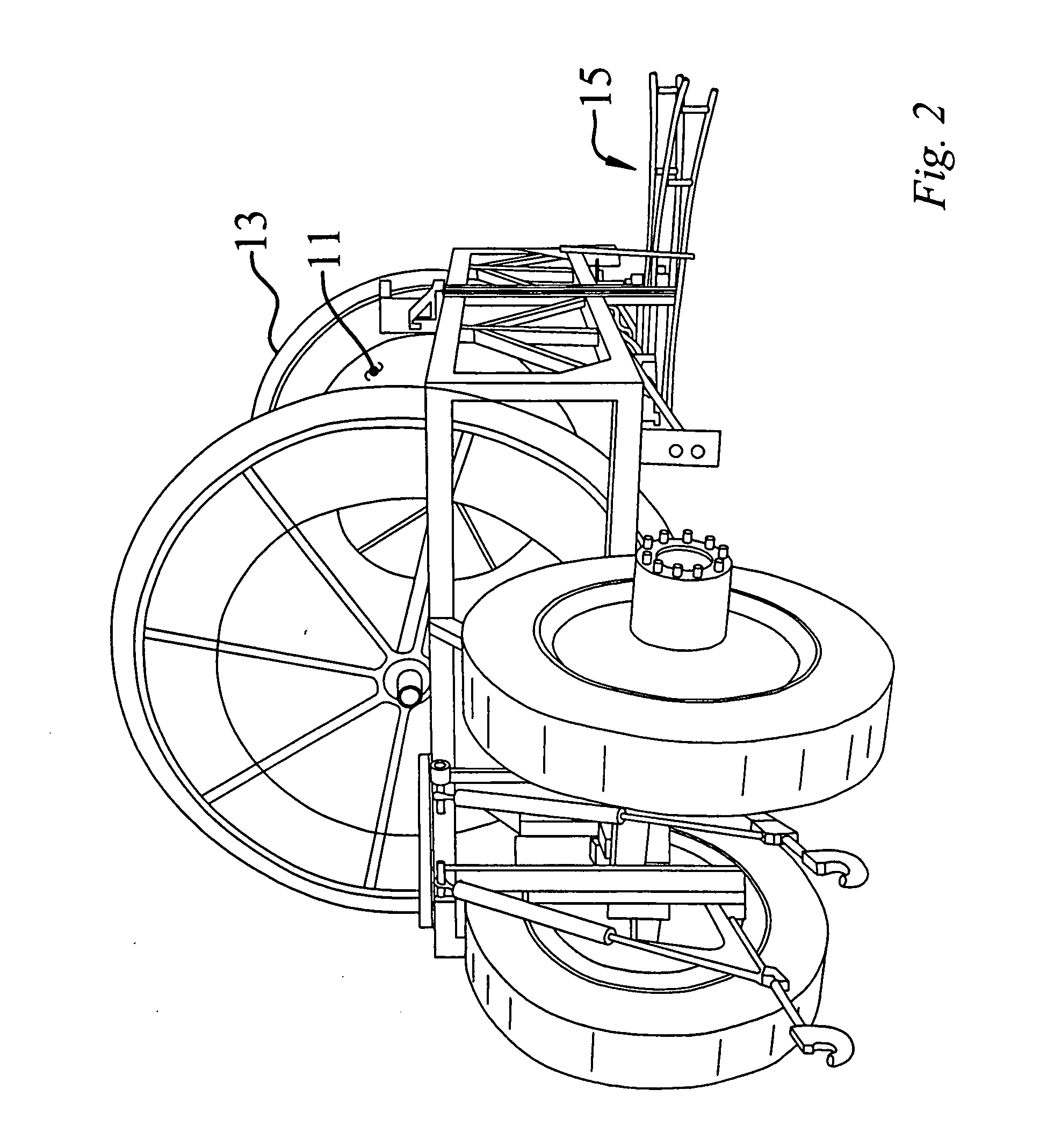

Liquid manure spreading apparatus

ActiveUS20090211504A1Increase the amount of materialAvoid spreadingLiquid fertiliser distributionWatering devicesFertilizerLiquid manure

This invention is directed to a device for applying slurry manure beneath the soil or on top of the soil with reduced crop displacement by a trailing feeder hose. More specifically, the invention is directed to an improvement of the prior art slurry reel system. The slurry reel system of the present invention places the axis of the reel spool parallel with the direction of travel instead of the conventional perpendicular orientation. This invention also utilizes a unique hose placement and retrieval apparatus or boom.

Owner:MANDERS WALTER J A +1

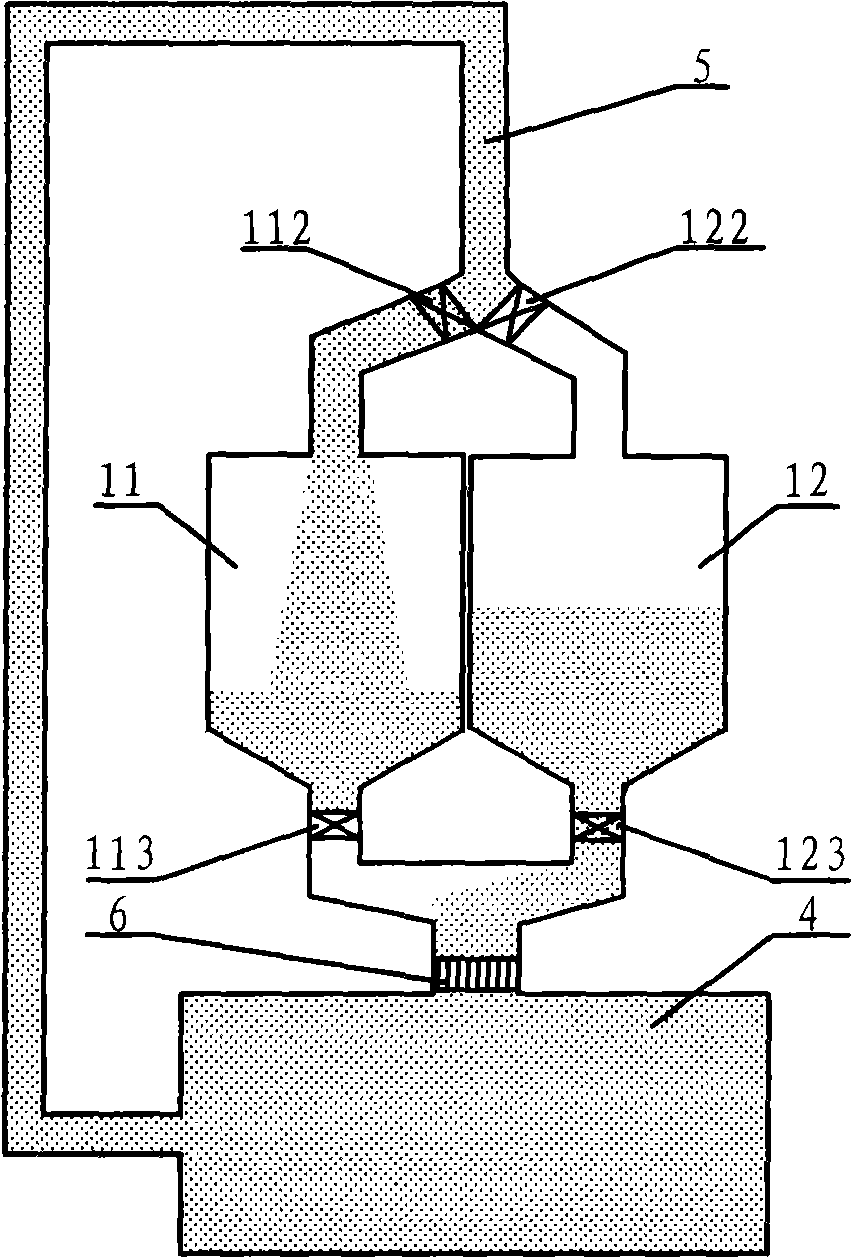

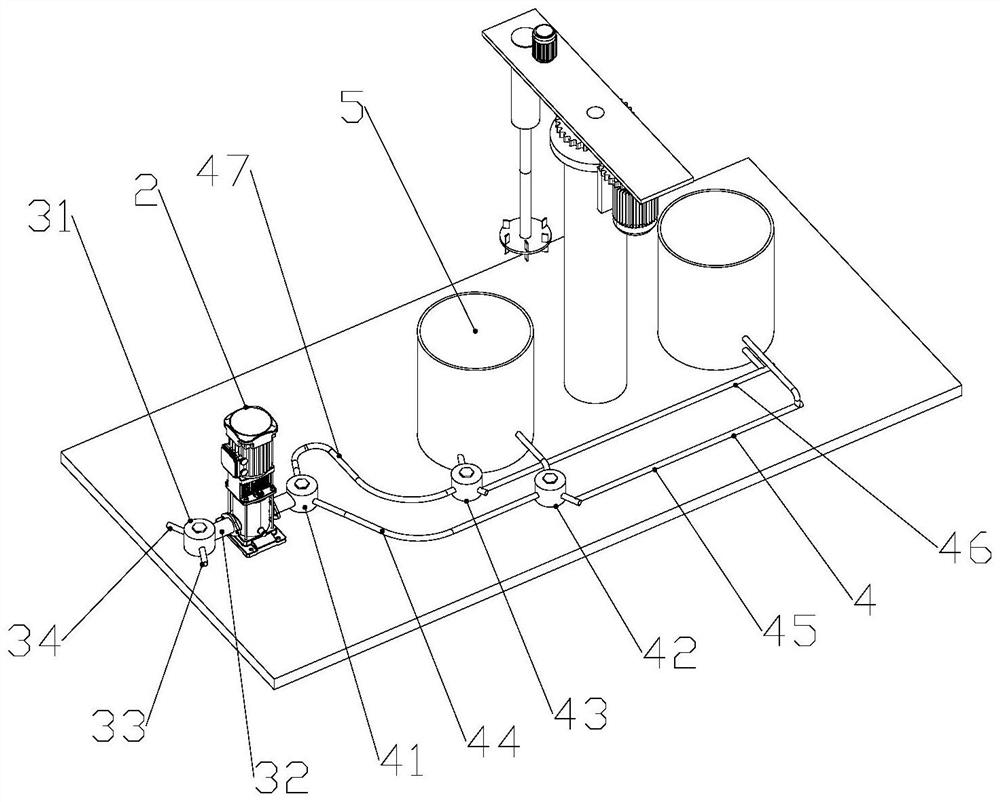

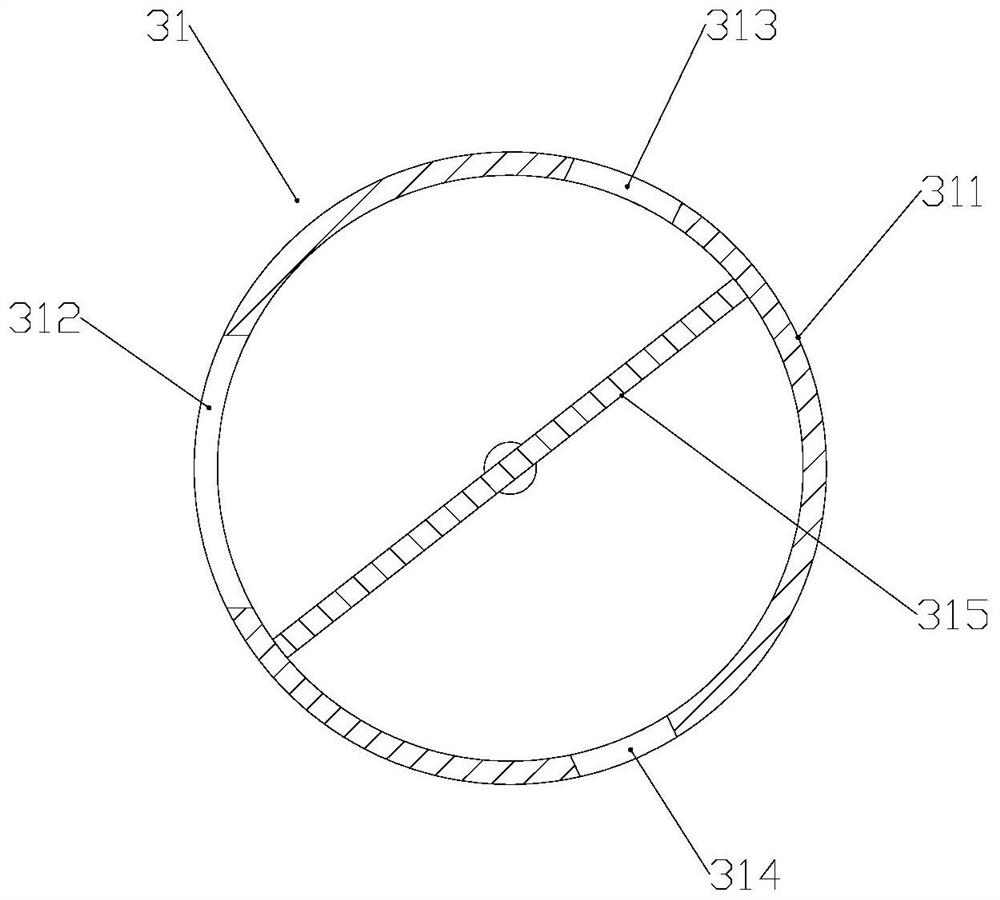

Device for circularly grinding and dispersing and method thereof

InactiveCN101279213AAvoid "dead zones"The same number of timesFlow mixersCocoaInlet valveEngineering

The invention relates to a cycle grind dispersing device, which comprises a sand cylinder used for grind dispersing treatment of materials, storage cylinders used for storing materials and a material circulating tube communicating the sand cylinder and the storage cylinder. The invention is characterized in that the storage cylinders are at least two outer material cylinders respectively used for storing materials treated by the sand cylinder in different grind dispersing cycles; one end of each outer material cylinder is communicated with the material circulating tube and is provided with an inlet valve used for controlling the materials to enter; the other end is communicated with the sand cylinder and is provided with an outlet valve used for controlling the materials to flow out. The invention also relates to a cycle grind dispersing method, which ensures that all the materials stored in the outer material cylinders are fully grinded and evenly dispersed, while the materials after the grind dispersing treatment has small particle size, equal particle size without materials with large particle size and with narrow particle size distribution, thus remarkably improving the dispersing quality and efficiency of the materials and having the advantages of large material quantity of a single grind dispersing, high quality of grind dispersing, high efficiency and so on.

Owner:BOE TECH GRP CO LTD

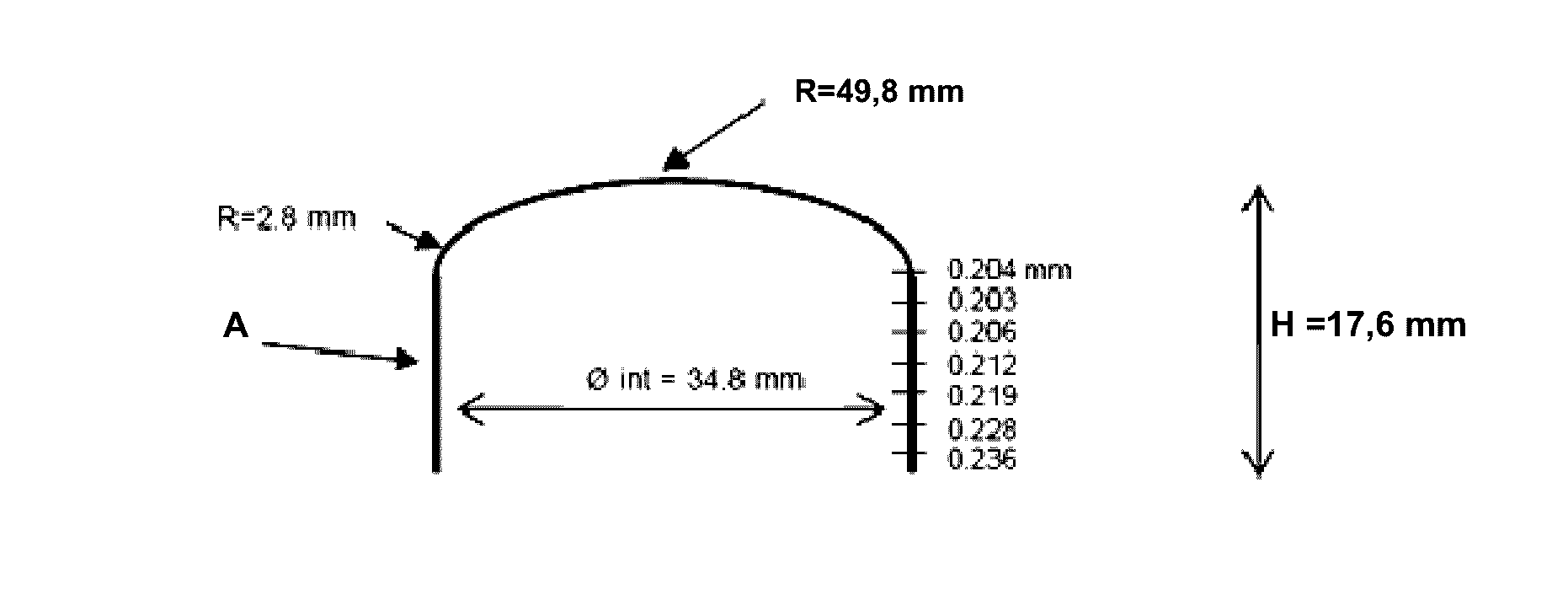

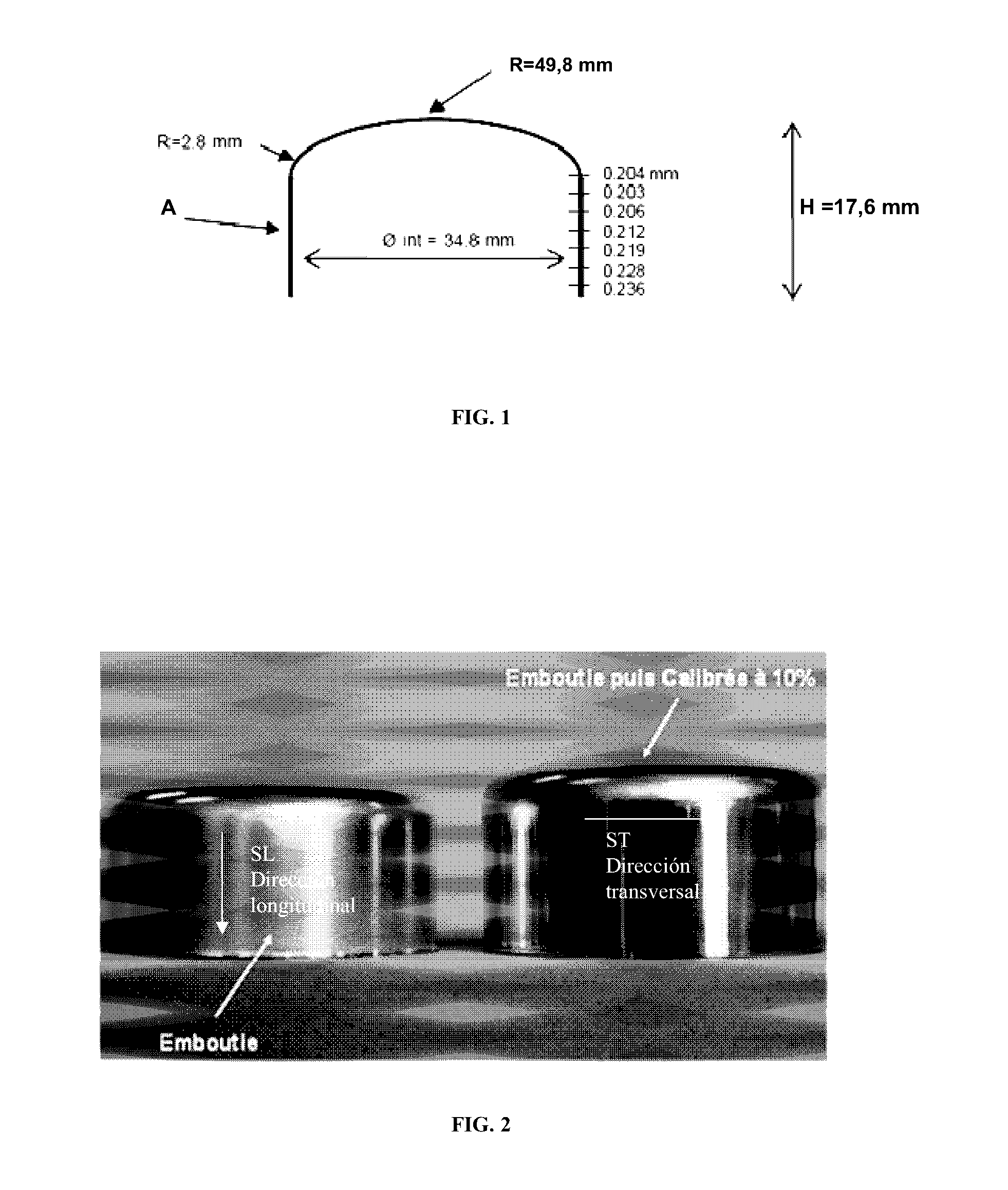

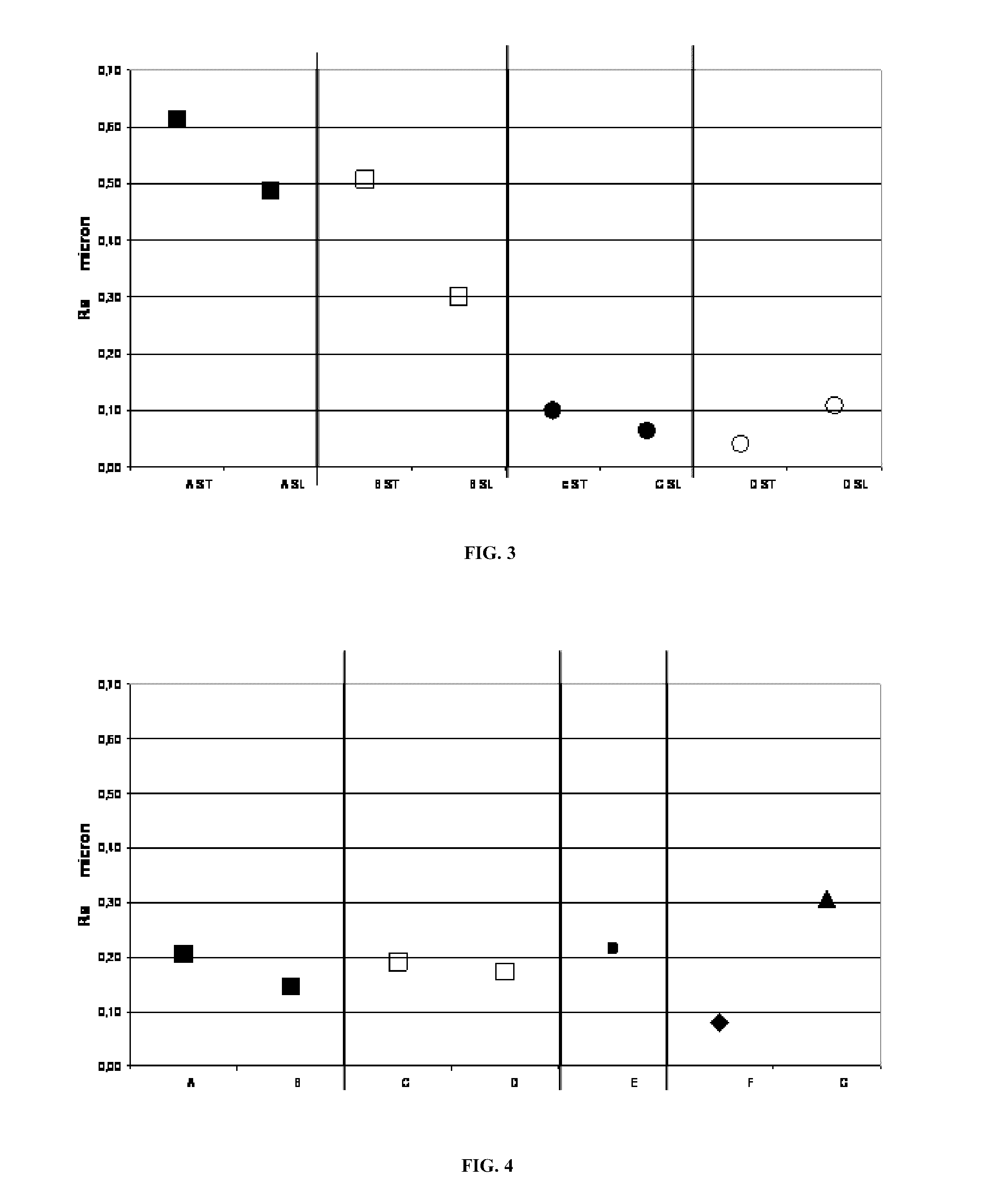

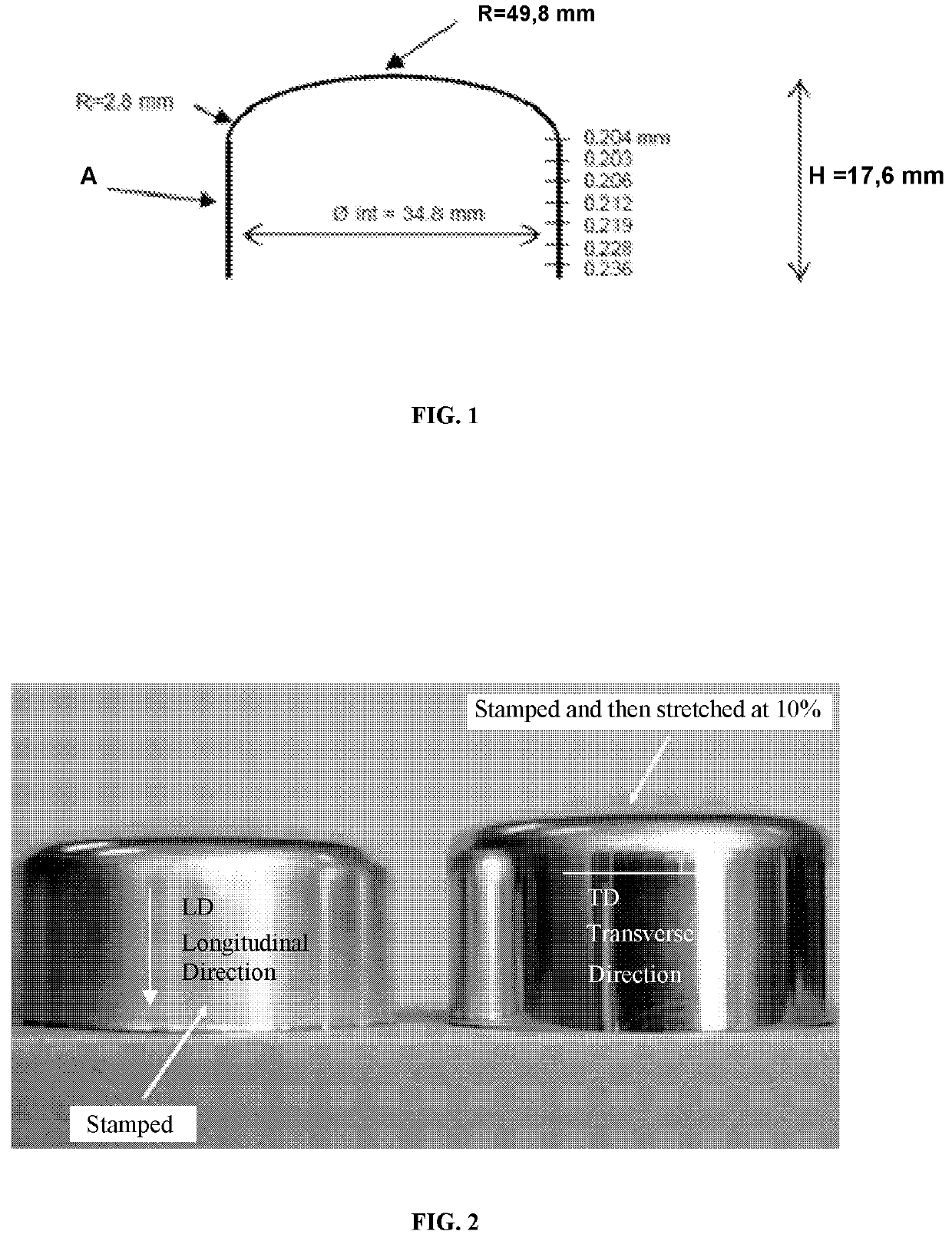

Method for manufacturing brilliant metal sealing caps

ActiveUS20160288195A1Increase the amount of materialUniform levelClosure capsHollow articlesAlloyVarnish

A method for manufacturing metal sealing caps comprising providing a strip or sheet of aluminum alloy of the grade known to a person skilled in the art as “brilliant” or “grand brilliant”, typically being coated on at least one of the two surfaces thereof, generally the surface intended for the inside of the cap, with a layer of stamping varnish is described herein.

Owner:CONSTELLIUM ROLLED PROD SINGEN GMBH & CO KG

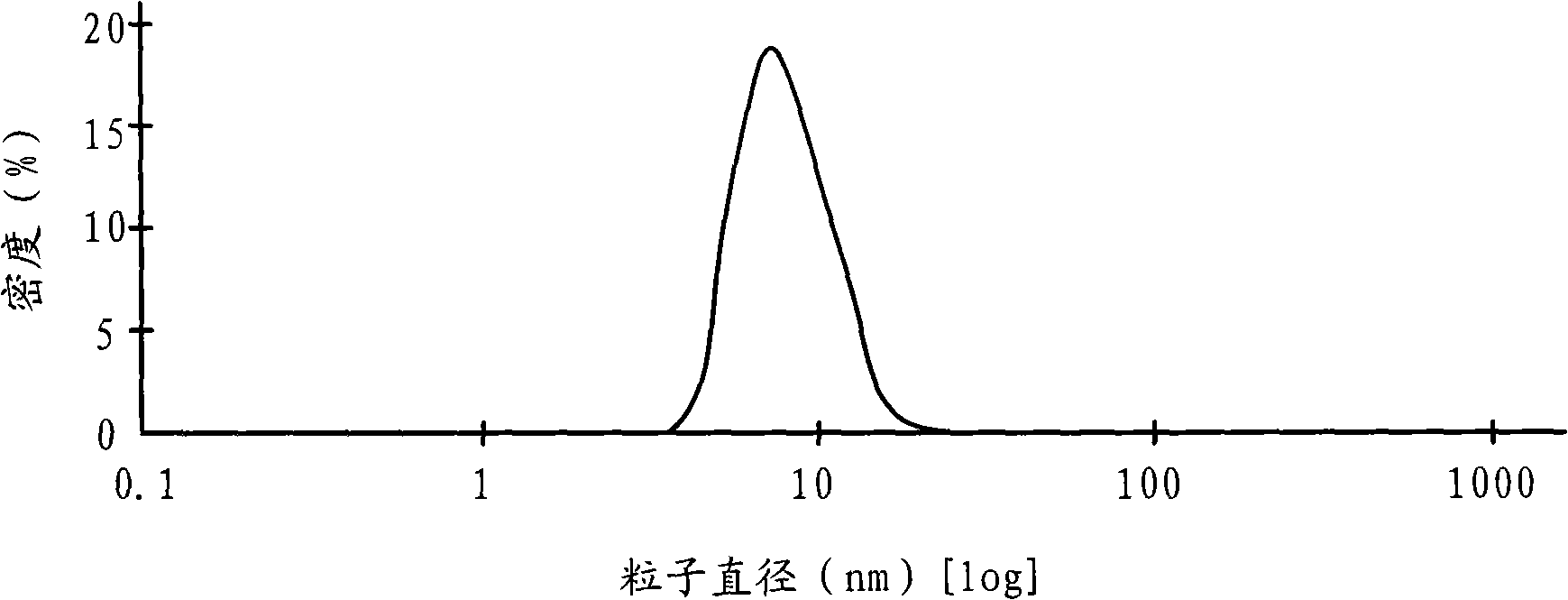

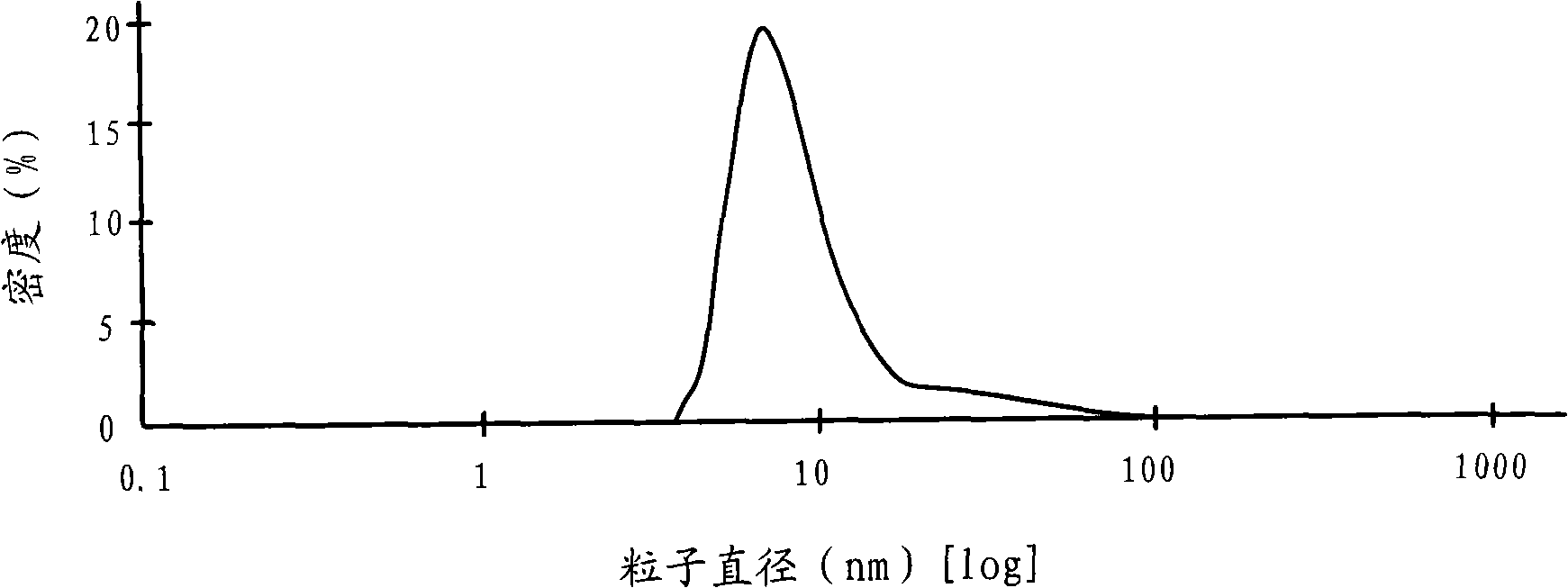

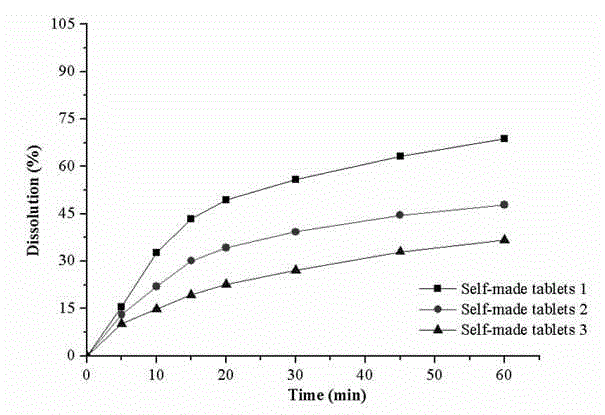

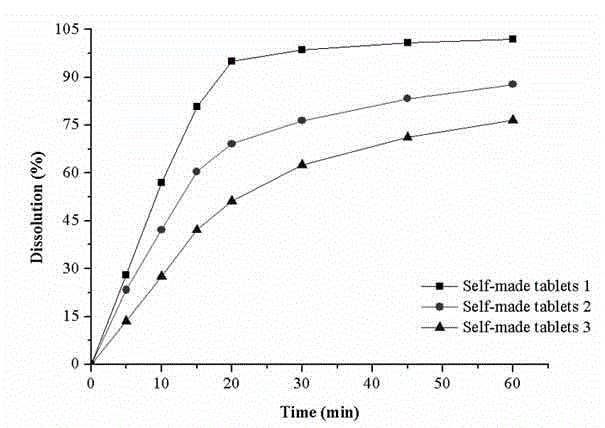

Preparation and application of drug powder

ActiveCN104606139AGood dispersionInhibit aggregationPowder deliveryOrganic active ingredientsMicrometerDissolution

Belonging to the field of pharmaceutical preparations, the invention provides a preparation method for a drug A (formula 1) powder and its application in oral solid preparations. The method includes: dispersing the crude drugs of drug A in a hydrophilic suspending aid solution, employing wet grinding to reduce the particle size to less than 5 micrometers, adding a spray-drying support agent, and combining spray drying, thus obtaining the drug A powder with an average particle size of less than 20 micrometers. The drug A powder prepared by the invention has high surface hydrophilicity, small particle size and good redispersibility in water. Compared with the crude drugs, the oral solid preparations prepared from the drug A powder and suitable auxiliary materials can significantly improve the dissolution rate. The preparation method for the drug A powder provided by the invention is suitable for industrial production and has high application value. (formula I).

Owner:SHENYANG PHARMA UNIVERSITY +2

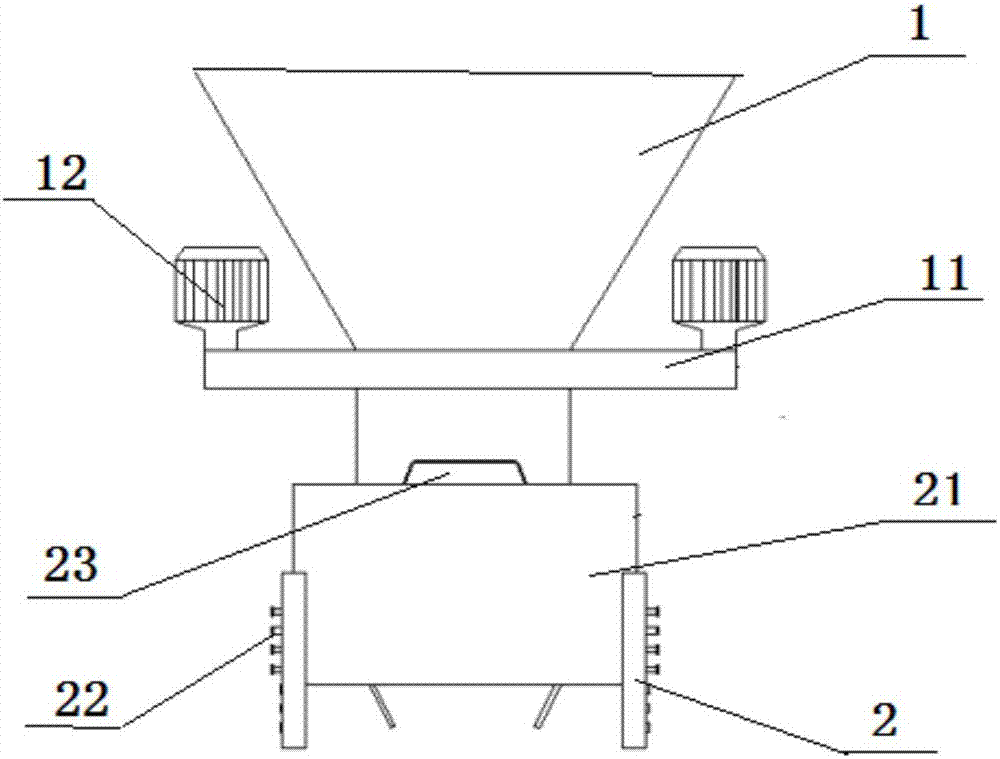

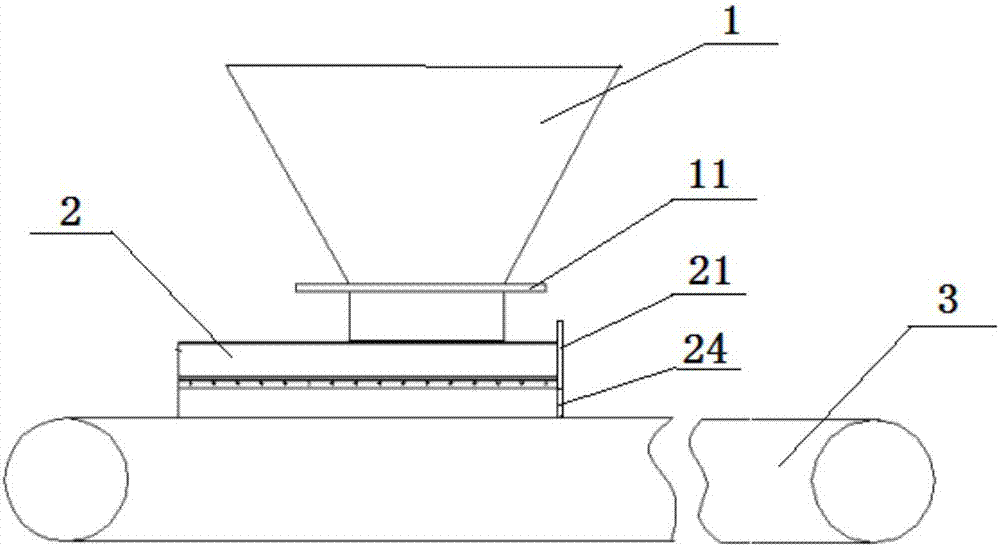

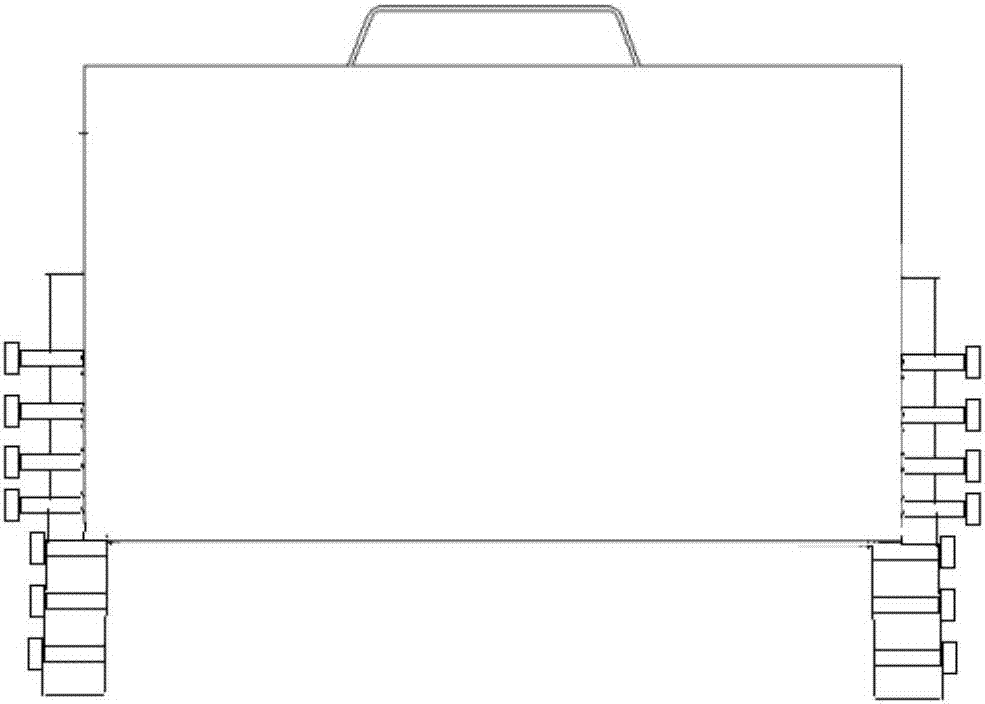

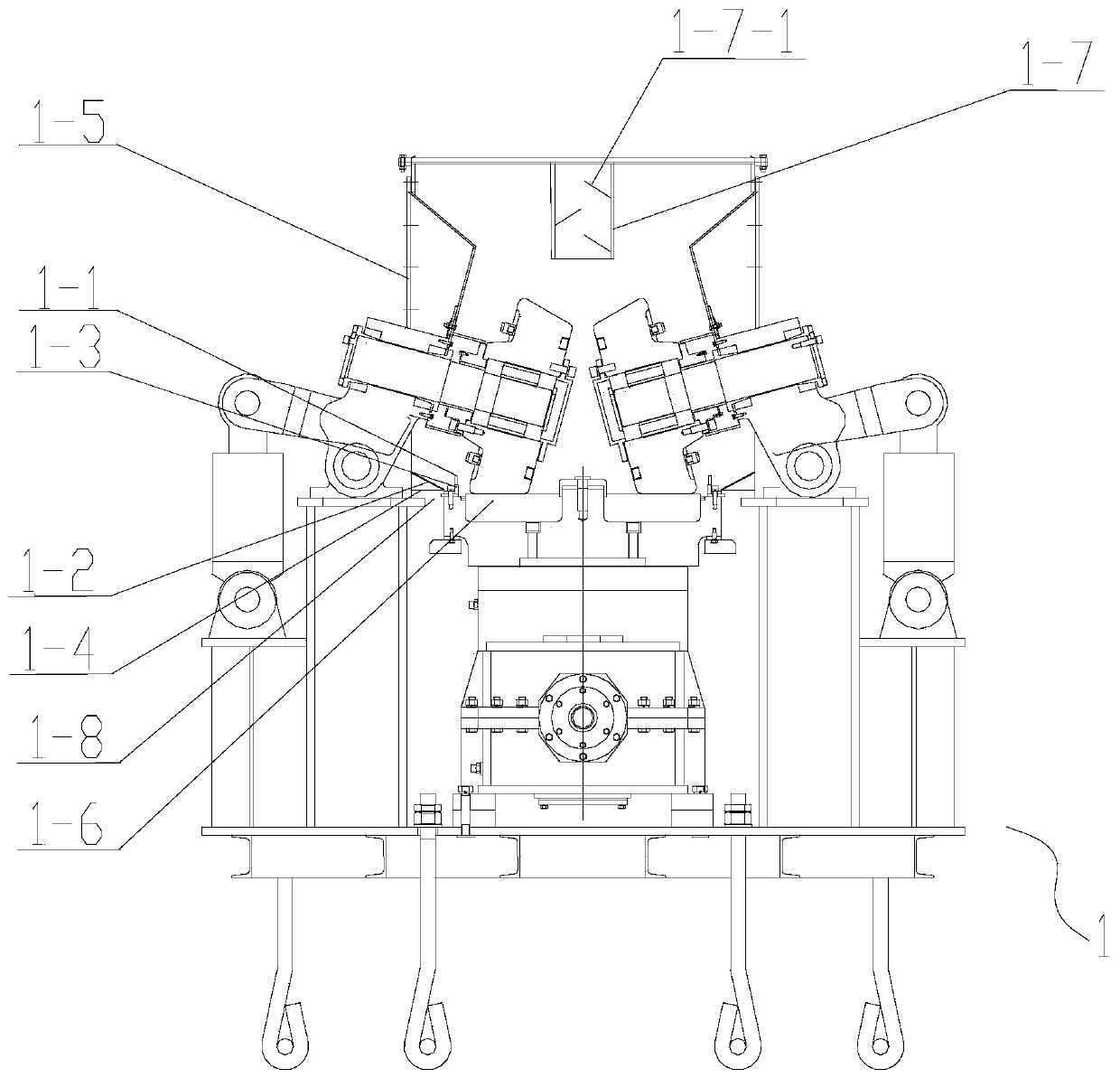

Device and method for controlling feeding amount of machine-made sand equipment

PendingCN107539755AIncrease the amount of materialReduce the amount of materialConveyor partsControl engineeringControl theory

The invention discloses a device for controlling the feeding amount of machine-made sand equipment. The device comprises a hopper, a belt conveyor, a wedge disc, a guide chute and a controller, wherein the wedge disc is used for controlling the opening size of a discharge opening of the hopper, the guide chute is connected with the discharge opening and located on the upper portion of the belt conveyor, the guide chute and the upper portion of the belt conveyor form a cavity for preventing materials from overflowing, a discharge port enabling the materials in the cavity to be discharged underconveying of the belt conveyor is formed in the guide chute, and a material level detecting meter used for detecting the material amount in the cavity is arranged in the cavity; and the controller isused for controlling work of the wedge disc according to the material amount detected by the material level detecting meter. The invention further discloses a method for controlling the feeding amountof the machine-made sand equipment. The method comprises the following steps that the first feeding amount of the machine-made sand equipment is obtained; whether the first feeding amount is smallerthan a preset feeding amount threshold value or not is judged; and if yes, the rotating speed of the belt conveyor used for providing the materials for the machine-made sand equipment is increased.

Owner:CHINA RAILWAY CONSTR HEAVY IND

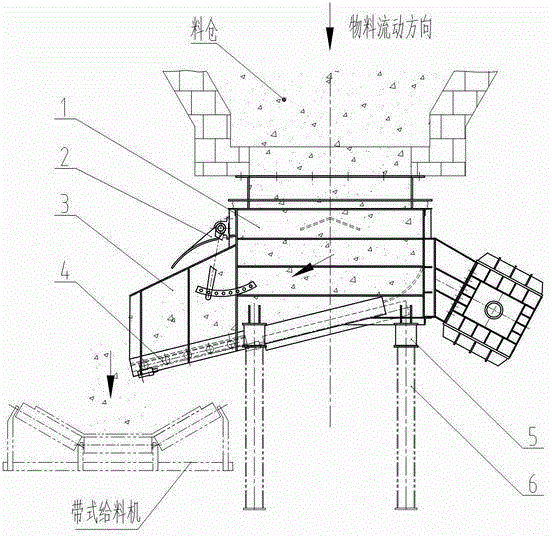

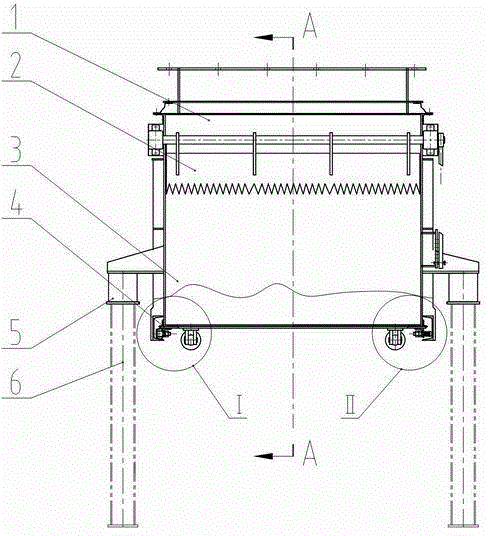

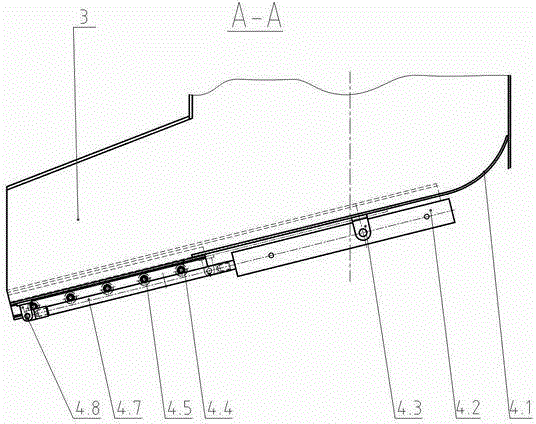

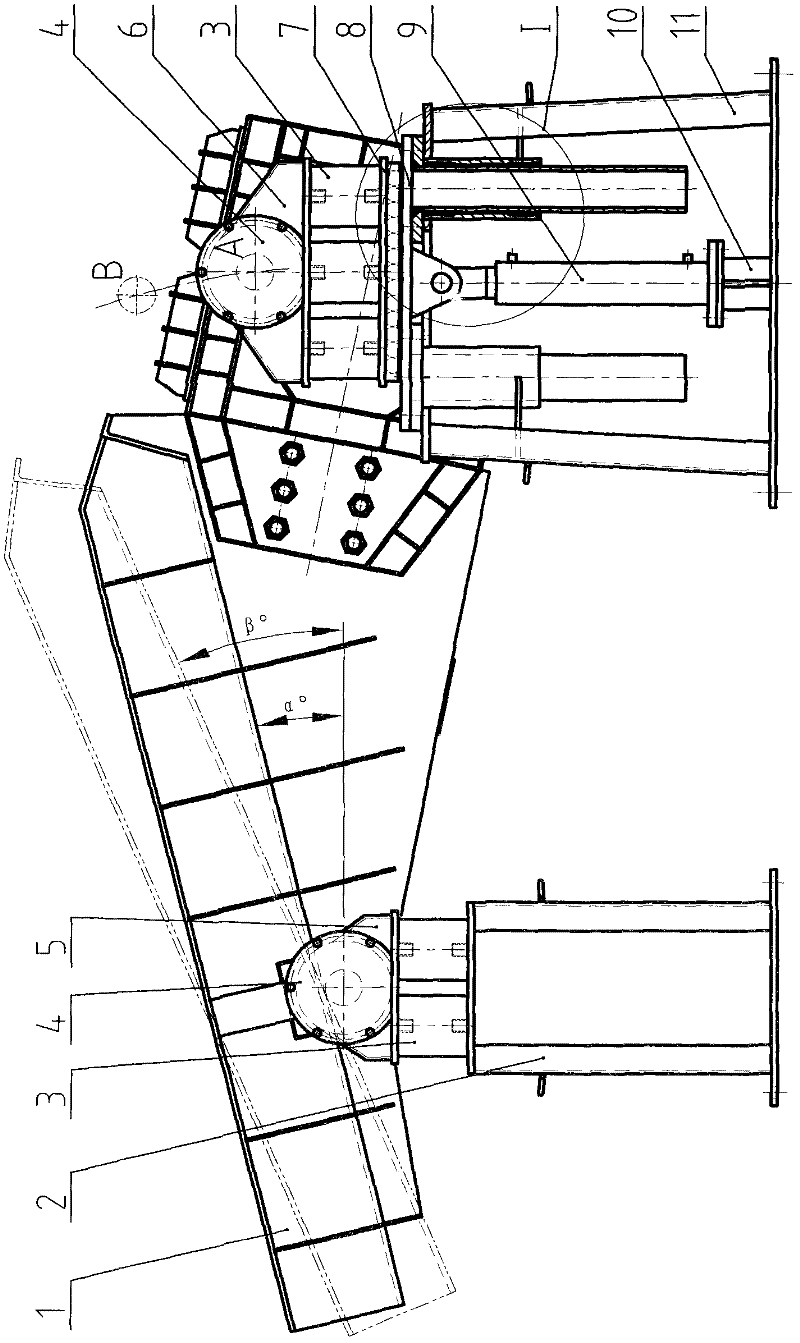

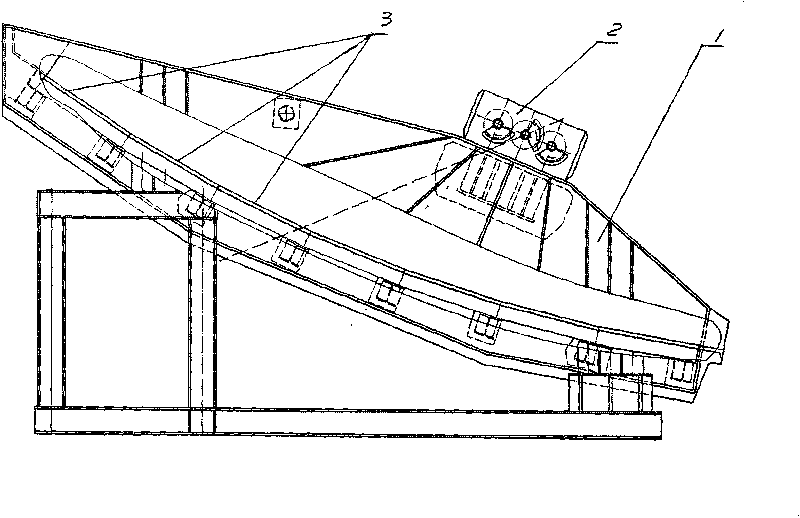

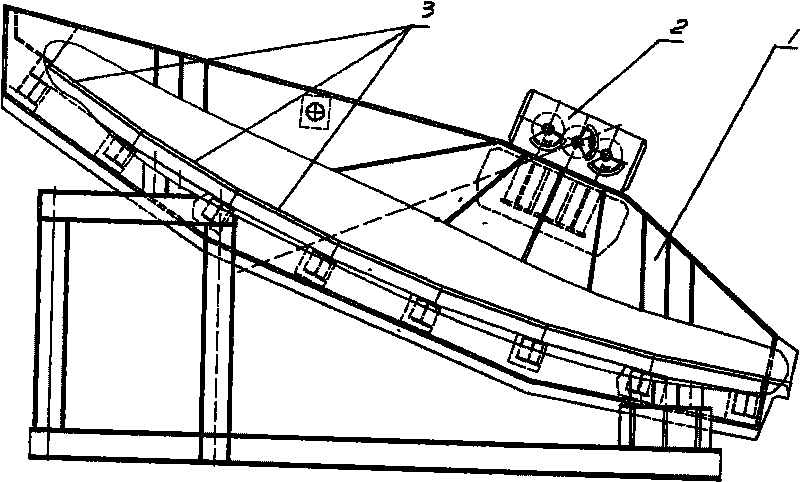

Novel draw-type activation vibration feeder

InactiveCN104085650ASimple structureIncrease productivityLoading/unloadingJigging conveyorsBuilding materialCoal

The invention relates to a novel draw-type activation vibration feeder which is composed of an activation vibration feeder body, an overturning plate gate, a lateral guide plate and a draw-type base plate device. The draw-type base plate device is composed of a fixed base plate and a movable base plate, the movable base plate performs draw movement through a hydraulic cylinder, the feeding amount can be adjusted to the maximum degree at any time, the production capacity can be greatly improved, and material mixing and material locking can be carried out in cooperation with the overturning plate gate. The novel draw-type activation vibration feeder is particularly suitable for technical transformation of oil mines, no device needs to be additionally arranged for the occasions where certain horizontal distances exist between stock bins and material receiving points, and the feeding amount can be conveniently multiplied on the original basis. Compared with an activation vibration feeder in the same specification, the feeding amount can be increased by one to two times. The novel draw-type activation vibration feeder is small in operation power, light in weight and good in sealing performance, feeding can be carried out in any direction, the feeding amount can be adjusted at will, and the novel draw-type activation vibration feeder is mainly used for the middle transferring process of stock bin materials of the industries such as coal mines, metallurgy, building materials, electric power and chemical engineering.

Owner:鹤壁市煤化机械有限责任公司

Cement mixing device used for buildings

InactiveCN107618110AReduce intensityExtended service lifeDischarging apparatusCement mixing apparatusEngineeringCement

The invention discloses a cement mixing device used for buildings. The cement mixing device used for buildings comprises a box, wherein the box is divided into a driving cavity and a stirring cavity by a partition; a first motor is arranged at the upper end of the box; a first stirring shaft which extends into the stirring cavity is arranged at an output end of the first motor; a plurality of stirring blades are arranged on the first stirring shaft; an annular groove is formed in the partition; an annular seat is arranged on the upper side of the annular groove; second motors are symmetricallyarranged on the upper side of the annular seat in the left-right direction; a second stirring shaft is arranged at an output end of each second motor; the second stirring shafts penetrate through theannular groove and extend into the stirring cavity; a plurality of stirring blades are arranged on each stirring shaft; sound-proof housings are separately arranged on the first motor and the secondmotors; a plurality of heat-conduction rods are arranged in each sound-proof housing; the inner end of each heat-conduction rod is in contact with the first motor; a heat-dissipation cover is arrangedon the outer side of each sound-proof housing; and the outer end of each heat-conduction rod is in contact with the corresponding heat-dissipation cover. The cement mixing device used for buildings is simple in structure, good in stirring effect and high in stirring efficiency; the work difficulty is reduced; and the service life is long.

Owner:张佩春

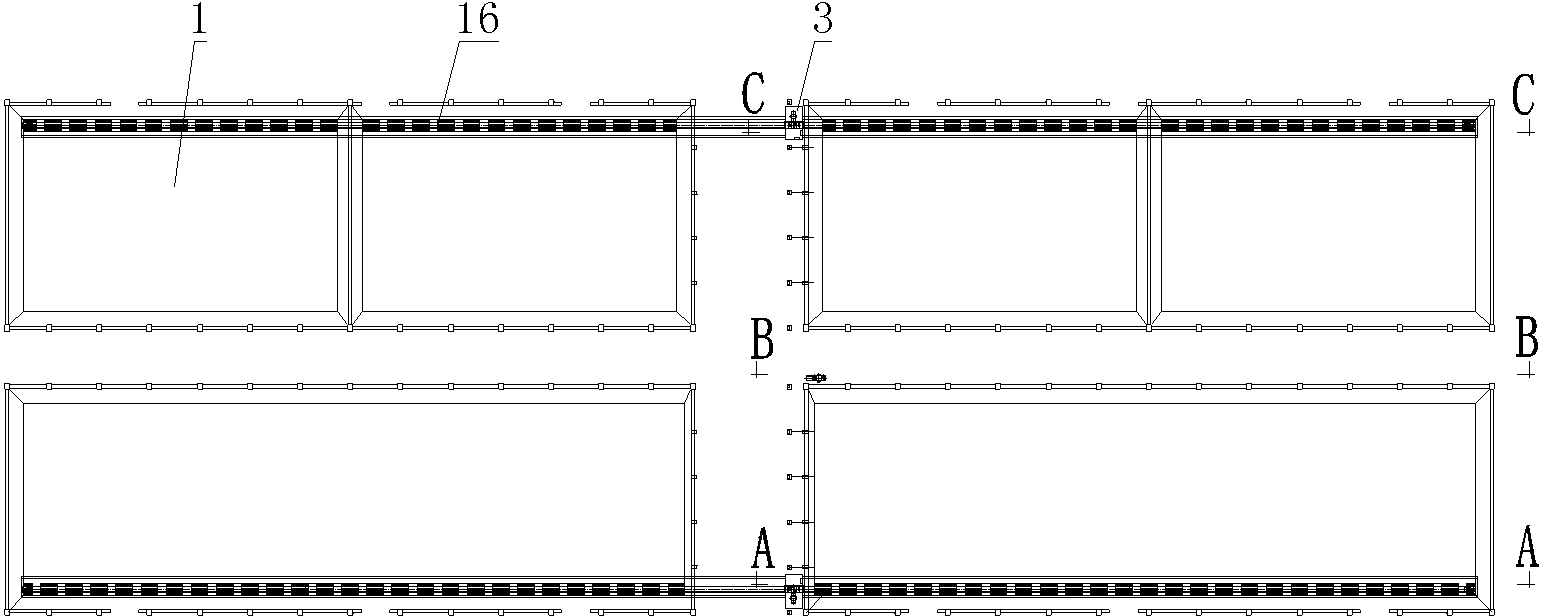

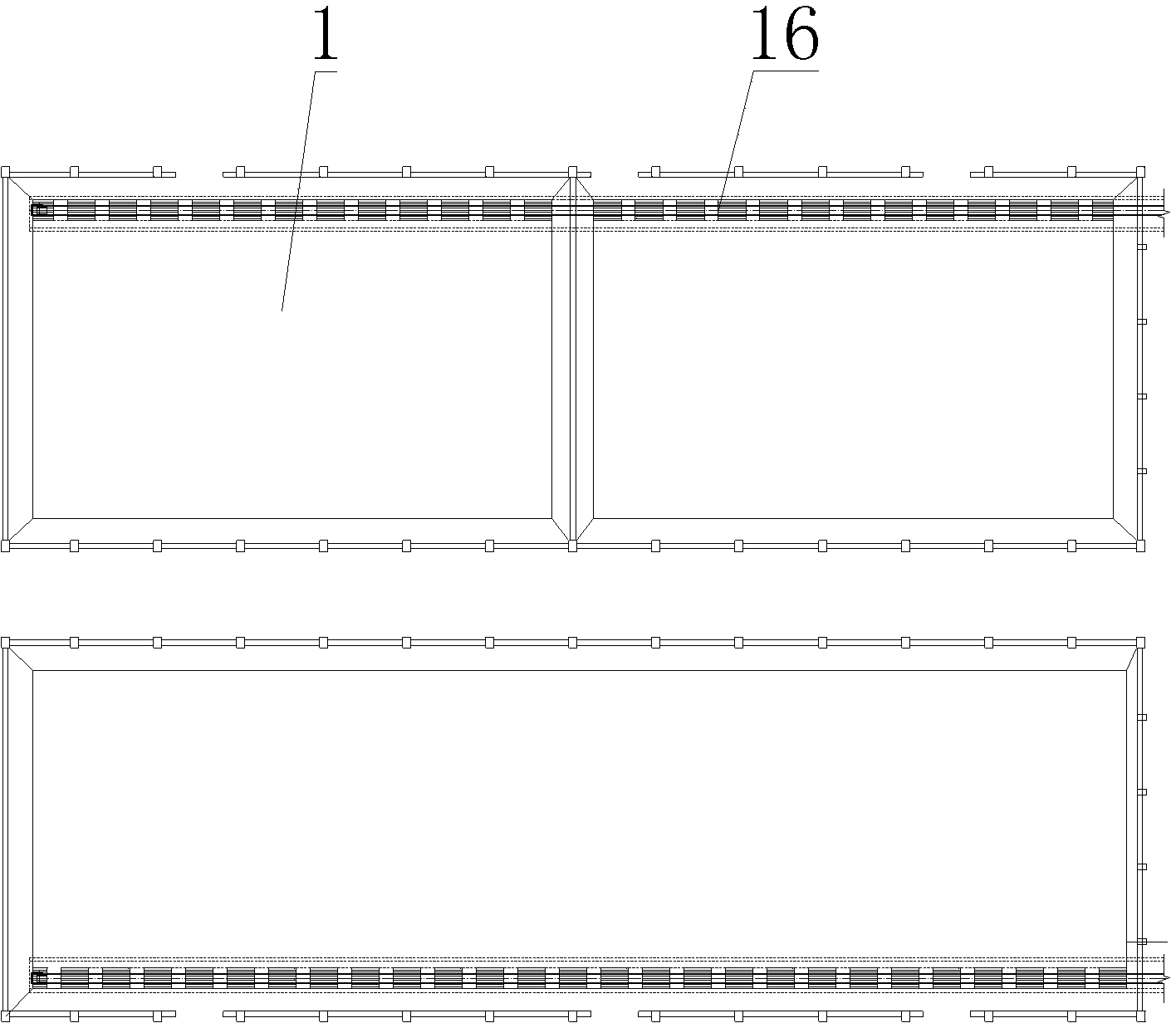

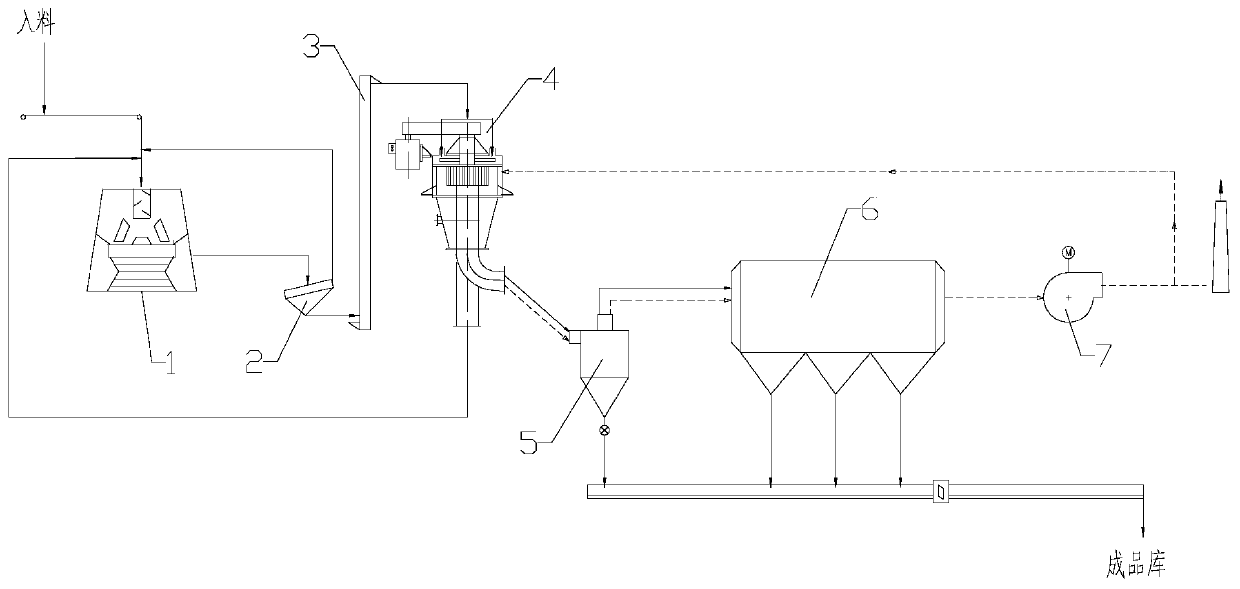

Raw material outer circulation final grinding system using self-screening function vertical mill and application

The invention relates to a raw material outer circulation final grinding system using a self-screening function vertical mill and an application, and belongs to the technical field of building material machinery. The raw material outer circulation final grinding system comprises the vertical mill, a vibrating screen, a lifting machine, a powder selecting machine, a cyclone cylinder, a dust collector and a fan; the vertical mill and the vibrating screen are connected to form a circulation system; the vertical mill, the vibrating screen, the lifting machine and the powder selecting machine are sequentially connected to form a circulation system; the vertical mill, the vibrating screen, an elevator, a powder concentrator and the cyclone cylinder are sequentially connected to form a raw material final grinding system; and the powder concentrator, the cyclone cylinder, the dust collector and the fan are sequentially connected to form a circulation system. The vertical mill has a self-screening function and comprises a screening device, the screening device is used for returning raw materials or large materials which are not ground to a grinding disc for further grinding; and the screening device is fixed on a material blocking ring and / or an air ring. According to the raw material outer circulation final grinding system, unpolished materials are reduced to enter the elevator, the system cycle load is reduced, the system energy consumption is reduced, the height of a workshop is reduced, and the investment cost is reduced.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

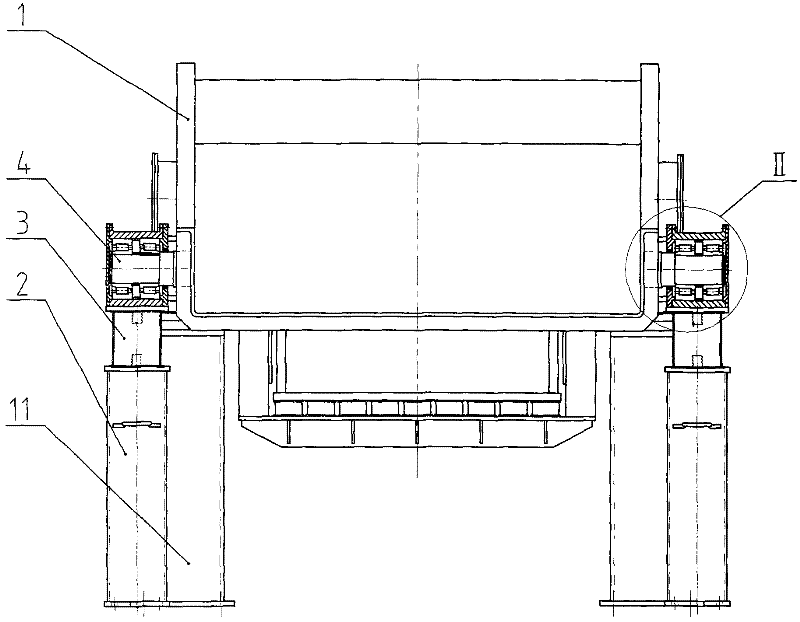

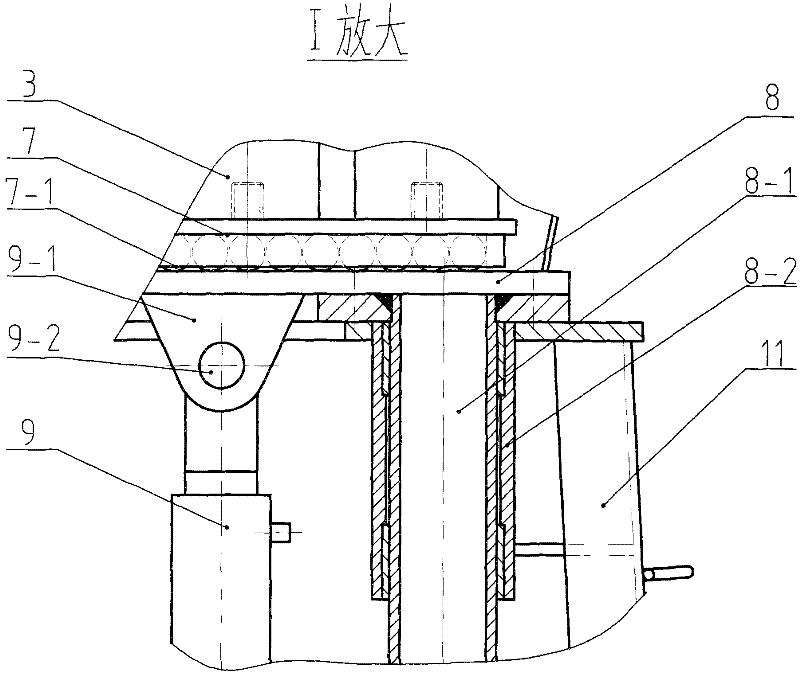

Super-large variable vibrating feeder

ActiveCN102514893AIncrease sliding forceRealize the purpose of super large feeding volumeJigging conveyorsHydraulic cylinderElectrical control

The invention discloses a super-large variable vibrating feeder. A front support, an anti-vibrating spring, a front pressing plate and a bearing are mounted on each of two sides of the front end of the feeder, a bearing and a rear pressing plate are mounted on each of two sides of the rear end of the feeder, the lower surfaces of the rear pressing plates are connected with displacement devices through anti-vibrating springs, and oil cylinders and lifting plates are mounted on rear supports. When the feeding quantity needs to be adjusted, the lifting plates are pushed up by push rods of the oil cylinders, by the means, downward sliding force of materials in a trough of the feeder is greatly increased, and feeding of the materials is realized by means of resultant action of the downward sliding force and excitation force, so that super-large feeding quantity is realized. The super-large variable vibrating feeder is a breakthrough on production capacity, the feeding quantity can increase by 3-5 times on an original basis under the conditions that the size of a trough, power and excitation force of an original machine type are unchanged, the dip angle of a feeding trough body is wide in adjustment range and is freely adjustable within the range from -30 degrees to 0 degree, lifting of a hydraulic cylinder can be electrically controlled in real time, and real-time adjustment and long-range control of the feeding quantity are realized. The super-large variable vibrating feeder is mainly used for the fields of intermediate transfer and uniform feeding of various materials in various industries such as coal, metallurgy mines, chemical engineering, building materials and the like.

Owner:鹤壁市煤化机械有限责任公司

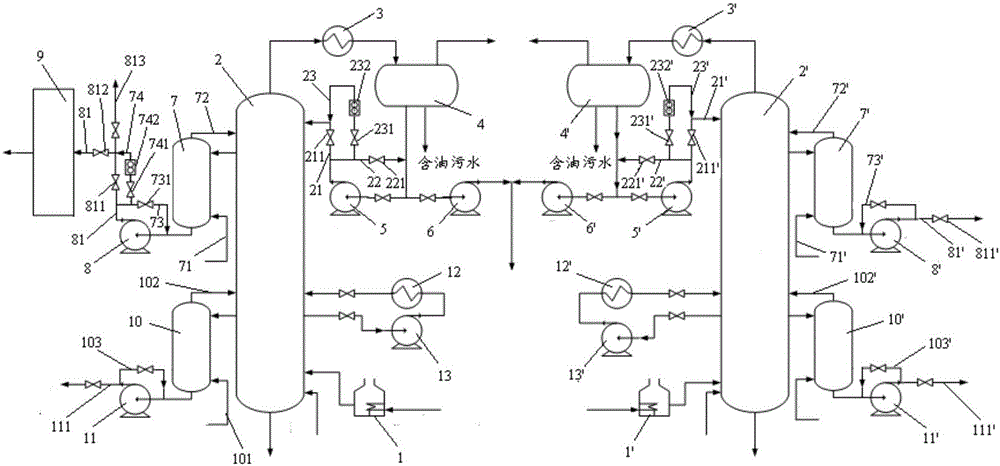

Fischer-Tropsch synthesis system and method for Fischer-Tropsch synthesis by utilizing Fischer-Tropsch synthesis system

ActiveCN106753525AReduce product volumeReduce the reflux ratioTreatment with plural serial refining stagesHydrocarbon oils treatment productsFischer–Tropsch processProcess engineering

The invention provides a Fischer-Tropsch synthesis system which comprises a rectification unit, wherein the rectification unit comprises a first heating furnace, a rectification tower, a first diesel oil stripper, a first diesel oil pump, a first overhead condenser, a first overhead reflux tank, a first reflux pump and a first naphtha pump. The invention also provides a method for Fischer-Tropsch synthesis by utilizing the Fischer-Tropsch synthesis system. The Fischer-Tropsch synthesis system provided by the invention can be obtained only by transforming a small part on a basis of the existing device, and therefore, the investment is less, and the cost is low; and the invention provides the novel method for obtaining diesel oil by Fischer-Tropsch synthesis, and fractions can be segmented only by adjusting technological parameters, and therefore, the cost is lowered, the yield of naphtha is increased, and the additional value of the diesel oil obtained by Fischer-Tropsch synthesis is increased.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

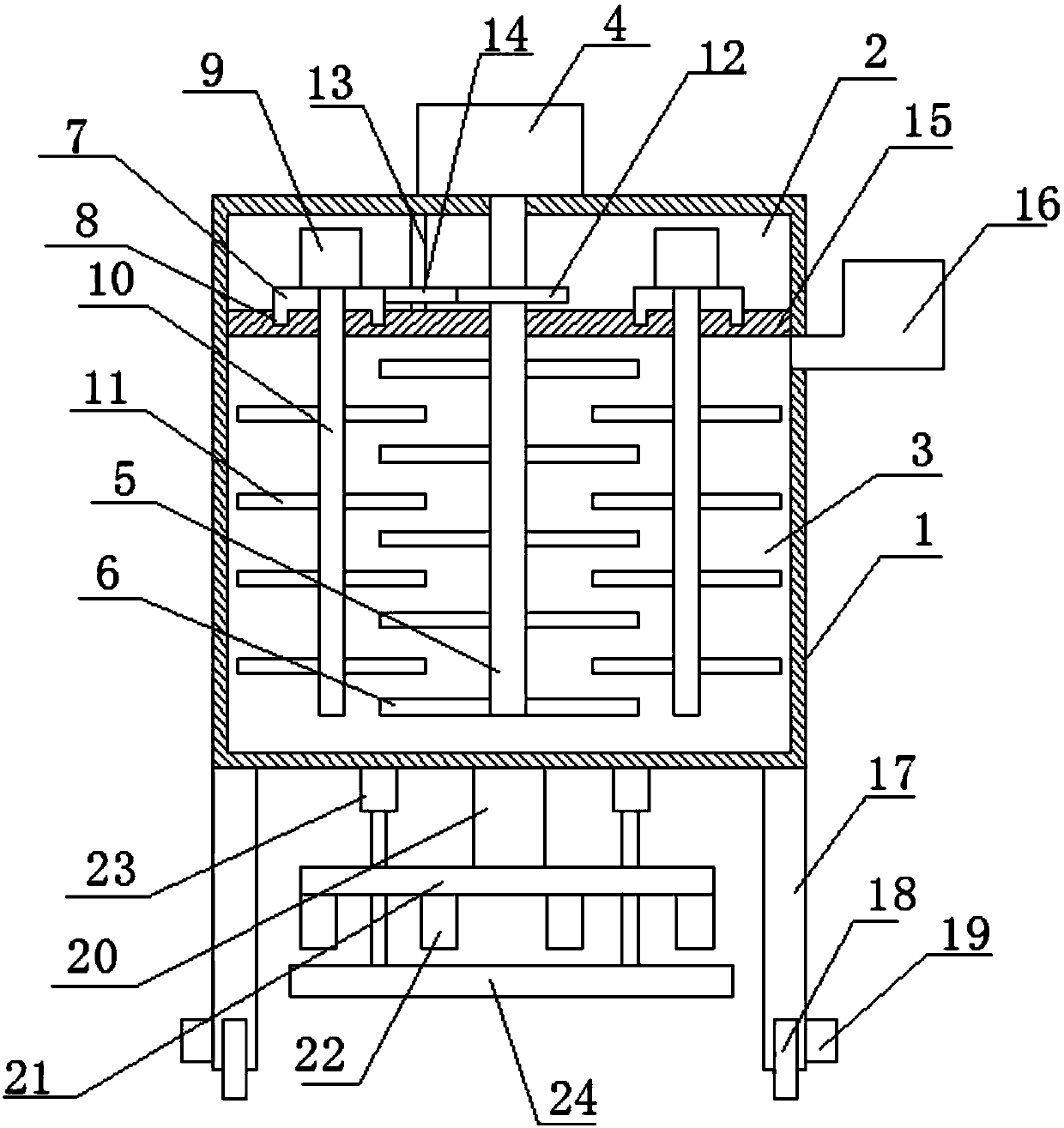

Electric furnace electrode control system

PendingCN112781391AAvoid heat concentrationIncrease the amount of materialElectric heating for furnacesControl devices for furnacesElectric arc furnaceControl system

The invention discloses an electric furnace electrode control system, and belongs to the field of electric furnace automation control. The system can realize continuous adjustment of the diameter of an electrode circle, and has a function of independently lifting the height of a three-phase electrode. A hardware part of the control system comprises a bearing shell, a mounting base, a lifting device, a station adjusting device, a cross arm, an electrode circle adjusting device, an electrode clamping device and the like, and the station adjusting device can drive the bearing shell, the lifting device and the cross arm to rotate integrally to achieve continuous heating of a plurality of steel ladles. Compared with the prior art, the energy consumption can be obviously reduced, the production efficiency can be improved, the conditions of electric arc furnace burning and the like are avoided, and uniform temperature distribution in the furnace is ensured.

Owner:牛蓉

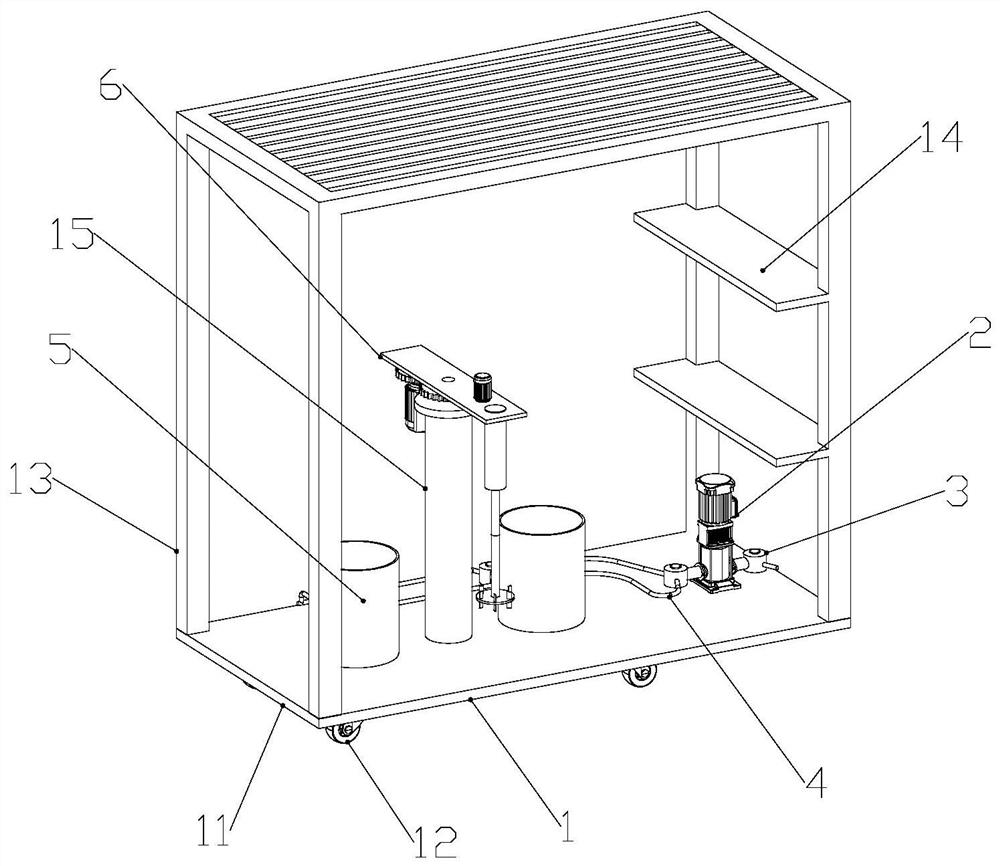

Movable slurry material treatment device

PendingCN113731231AEasy to operateShorten the timeTransportation and packagingRotary stirring mixersHydraulic cylinderElectric machinery

The invention discloses a movable slurry material treatment device which comprises a moving part; wherein a pump body is arranged on the moving part, one side of the pump body is communicated with a first control part, the other side of the pump body is communicated with a feeding part, the moving part is provided with stirring barrels which are symmetrically distributed, and weighing sensors are arranged at the bottoms of the stirring barrels; a stirring piece is arranged between the symmetrically distributed stirring barrels; the stirring part comprises a hydraulic cylinder, an output shaft of the hydraulic cylinder is fixedly connected with a guide frame, a rotating part is rotationally arranged on the guide frame, and a first motor is arranged on the guide frame. The treatment device is convenient to operate; through forward and reverse rotation of the pump body and cooperation with the control valve, mutual non-interference of feeding and discharging of the stirring box is controlled. Therefore, the slurry can be prepared according to production requirements, and the time consumed for preparing the slurry is shortened. The device is high in flexibility, and the weighing sensor is arranged, so that the time and the quantity of auxiliary materials can be controlled to be increased according to a set threshold value, and thereby guaranteeing the quality of the slurry.

Owner:安徽中科日升科技有限公司

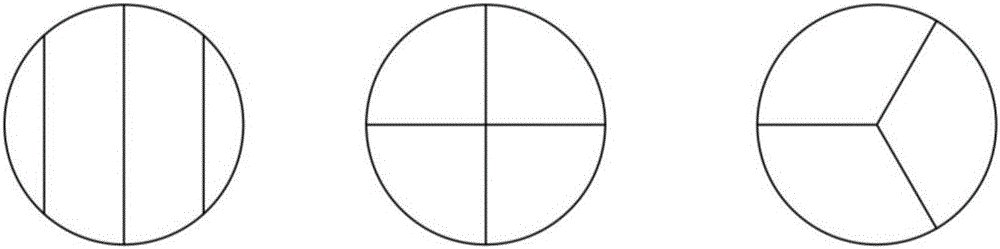

Elliptical vibrating screen with multi-section polygonal line screen surface

The invention discloses an elliptical vibrating screen with a multi-section polygonal line screen surface. The invention relates to a vibrating screen. The invention aims to provide the elliptical vibrating screen with the multi-section polygonal line screen surface, wherein the impact to a screen plate by a material is small, the material is difficult to stack and the material volume is large. The technical scheme of the invention is that the elliptical vibrating screen comprises a tri-axial elliptical vibration exciter, and the screen surface comprises at least four different inclination angle screen surfaces. The elliptical vibrating screen with a multi-section polygonal line screen surface is applied to vibrating screens.

Owner:河南万泰机械有限公司

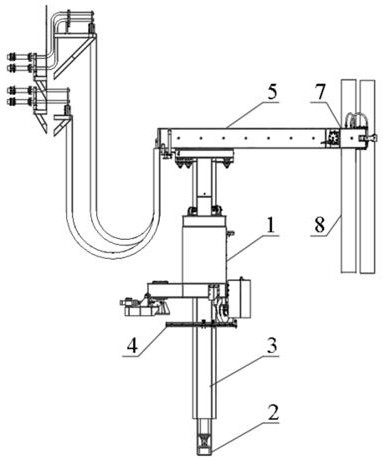

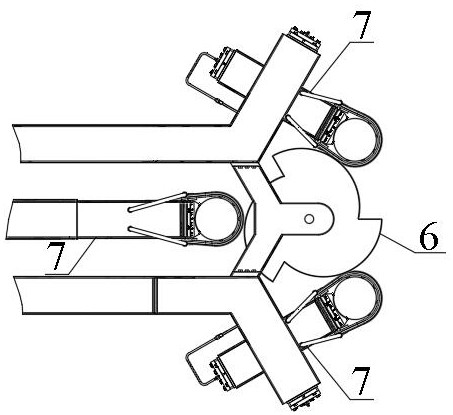

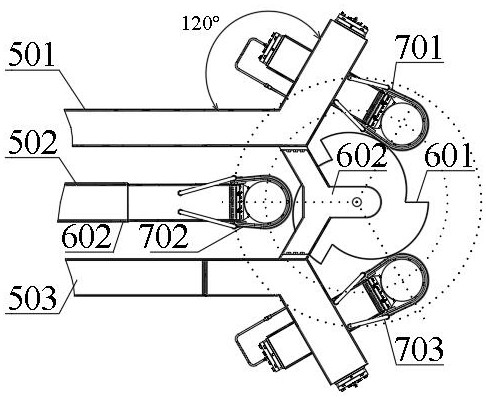

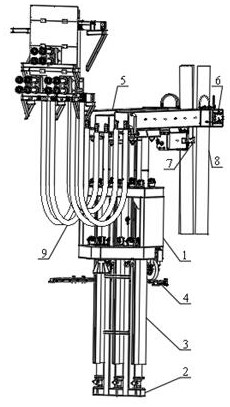

Automatic electrode control system

ActiveCN112689348AAvoid heat concentrationIncrease the amount of materialElectric discharge heatingIncreasing energy efficiencyElectric arc furnaceAutomatic control

The invention discloses an automatic electrode control system, belongs to the technical field of electric furnace control, and particularly relates to a multi-dimensional electrode fine control system which can achieve independent lifting of three-phase electrodes and continuous adjustment of electrode circle diameters and is further provided with a plurality of working positions to meet continuous heating of a plurality of steel ladles. A hardware part of the control system comprises a moving base frame, a base, a lifting device, a station adjusting device, a cross arm, an electrode circle adjusting device and an electrode clamping device, a software part of the electrode automatic control system adopts an impedance control strategy, and meanwhile a sectional type moving method and a boundary linkage control method are designed in the implementation process. Compared with the prior art, the control system has the advantages that the energy consumption can be remarkably reduced, the production efficiency is improved, the interference of an electric furnace to a power grid is reduced, electric arc furnace burning and other conditions are avoided, and uniform temperature distribution in the furnace is ensured.

Owner:西安中天冶金工程有限公司

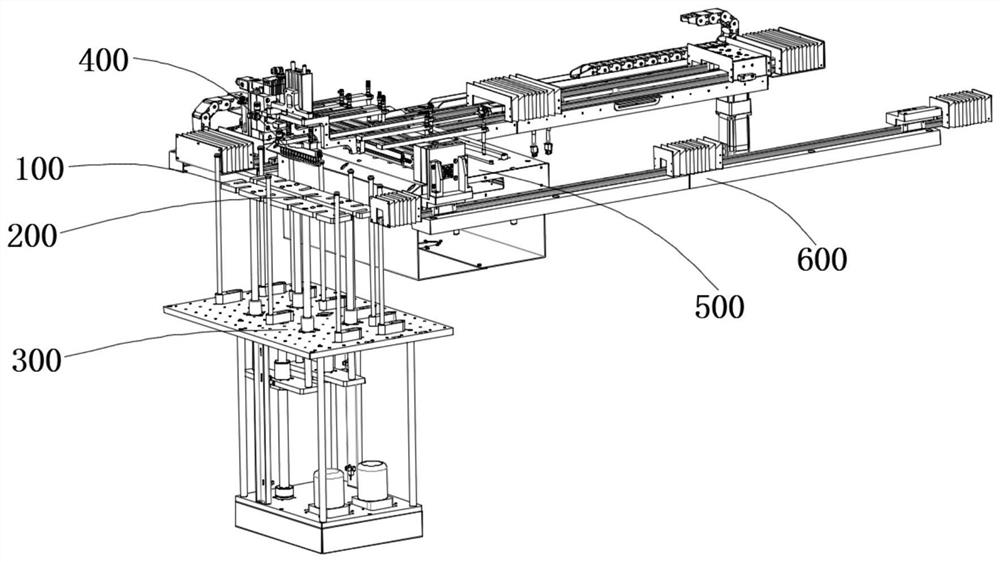

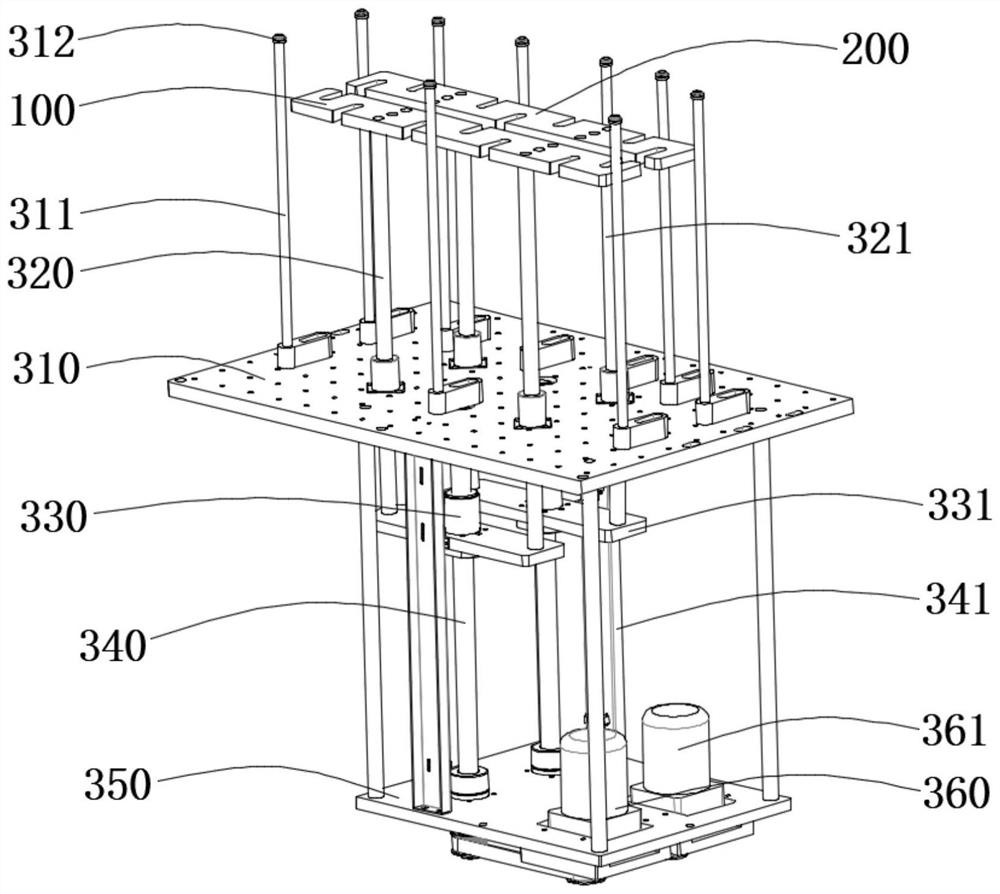

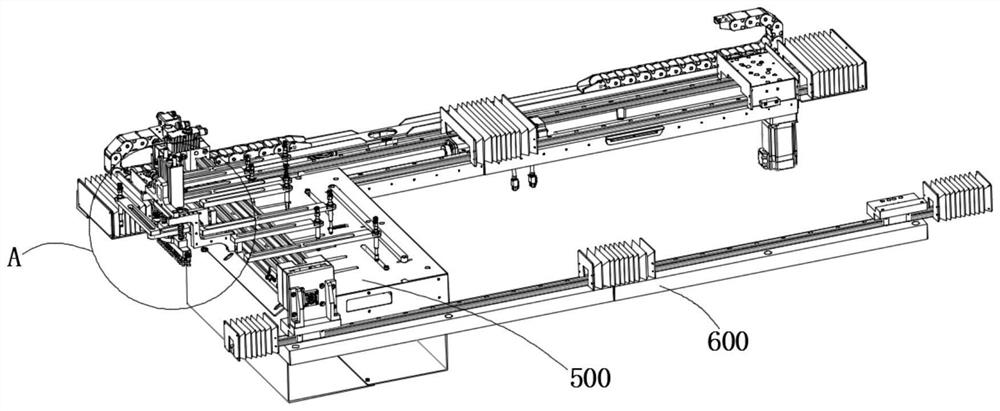

Automatic feeding and positioning device for three-layer combined soft board

InactiveCN112938481AReduce test misjudgmentsIncrease the amount of materialConveyorsControl devices for conveyorsMechanical engineeringPhysics

The invention provides an automatic feeding and positioning device for a three-layer combined flexible board. The automatic feeding and positioning device for the three-layer combined soft board comprises a first ejector plate, a second ejector plate, an ejector plate driving assembly for driving the first ejector plate and the second ejector plate to move up and down, a suction cup assembly, a positioning platform for secondarily positioning materials and a driving sliding rail, wherein the ejector plate driving assembly is arranged on the lower side of the first ejector plate and the lower side of the second ejector plate, one end of the suction cup assembly is slidably connected to the driving sliding rails, the other end of the suction cup assembly extends to the first ejector plate, the positioning platform is fixedly connected between the two driving sliding rails, and a vacuum suction cup in the suction cup assembly is a self-closing suction cup. According to the material feeding device, it is guaranteed that after the multiple vacuum suction cups make contact with materials, enough air can firmly suck the materials, meanwhile, through cooperation of the first ejector plate and the second ejector plate, the tops of the materials can be kept flat under the condition that the feeding amount is large, and therefore the feeding amount is increased.

Owner:深圳市鹏达电子有限公司

Method for manufacturing brilliant metal sealing caps

A method for manufacturing metal sealing caps comprising providing a strip or sheet of aluminum alloy of the grade known to a person skilled in the art as “brilliant” or “grand brilliant”, typically being coated on at least one of the two surfaces thereof, generally the surface intended for the inside of the cap, with a layer of stamping varnish is described herein.

Owner:CONSTELLIUM ROLLED PROD SINGEN GMBH & CO KG

Elastic hook pin device

The invention belongs to the field of machinery, and particularly relates to an elastic hook pin device which comprises an elastic pull buckle pin, the elastic pull buckle pin comprises an elastic hook pin or an elastic buckle rivet or a non-return elastic hook pin, the elastic hook pin comprises a pin shaft blocking table, a pin penetrating shaft and a pin shaft retaining table, and the elastic buckle rivet comprises a rivet outer retaining barrel and an elastic hook pin. The rivet outer retaining barrel comprises a rivet penetrating outer barrel and a rivet outer barrel retaining table, the elastic hook pin comprises an elastic blind rivet retaining table, an elastic blind rivet barrel and an elastic buckle outer barrel retaining table, and the rebounding hook pin comprises a winding drum inner hole and a winding drum inner rebounding piece; the elastic pull buckle pin does not retreat or fall off, is fast to install, durable, few in parts, low in manufacturing cost, long in service life and high in use safety performance, saves a large amount of manpower and material resources, and improves the comprehensive safety performance and the use efficiency of equipment.

Owner:JINING CITY CUSTOMKEY ELECTROMECHANICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com