Method and equipment for preparing high molecular weight polycondensate

A technology of high molecular weight and condensation polymers, applied in the field of polymers, can solve the problems of low equipment volume efficiency, small volume of molten materials, short residence time, etc., to achieve uniform distribution, increase the amount of molten materials, and increase the surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

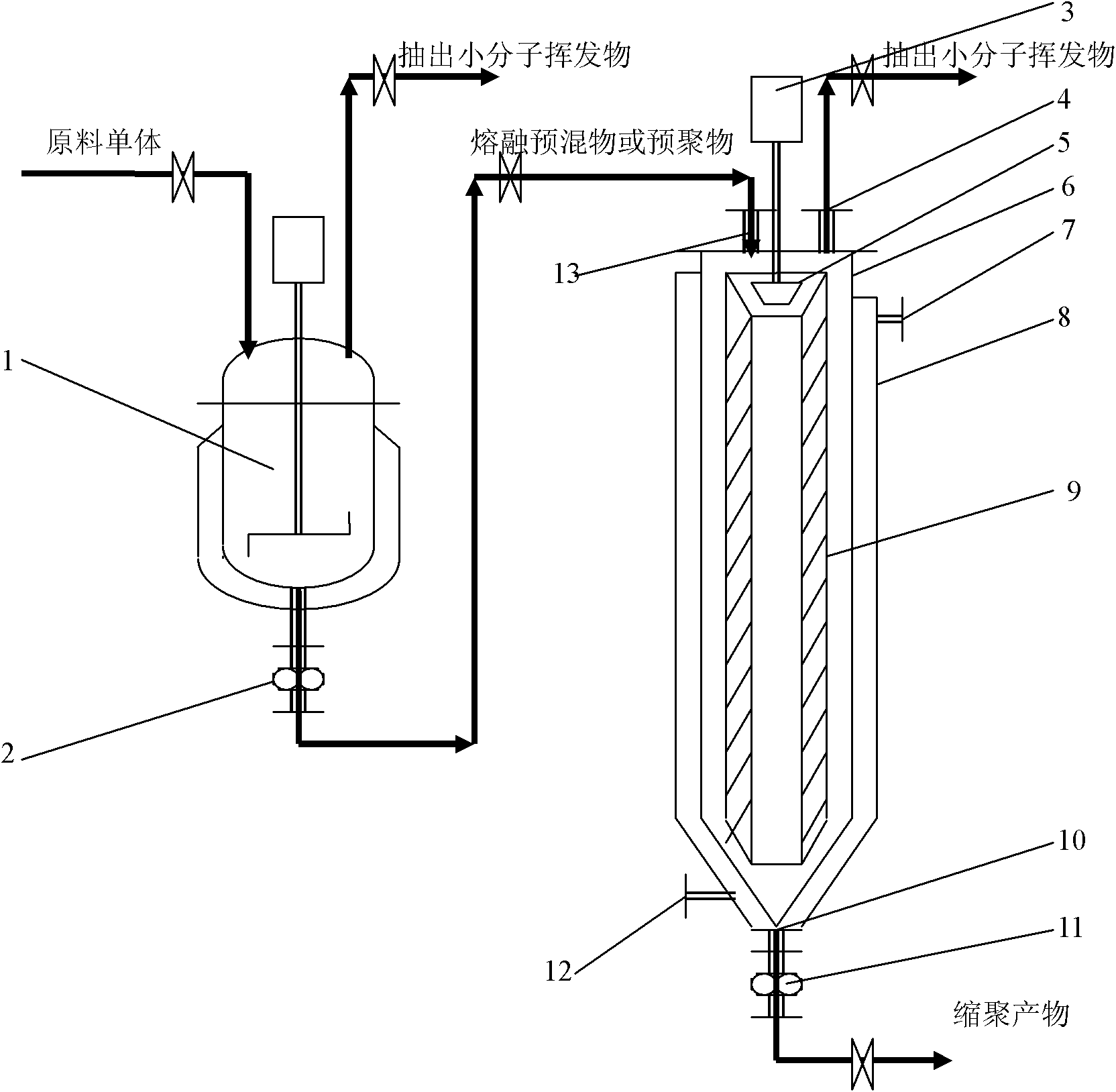

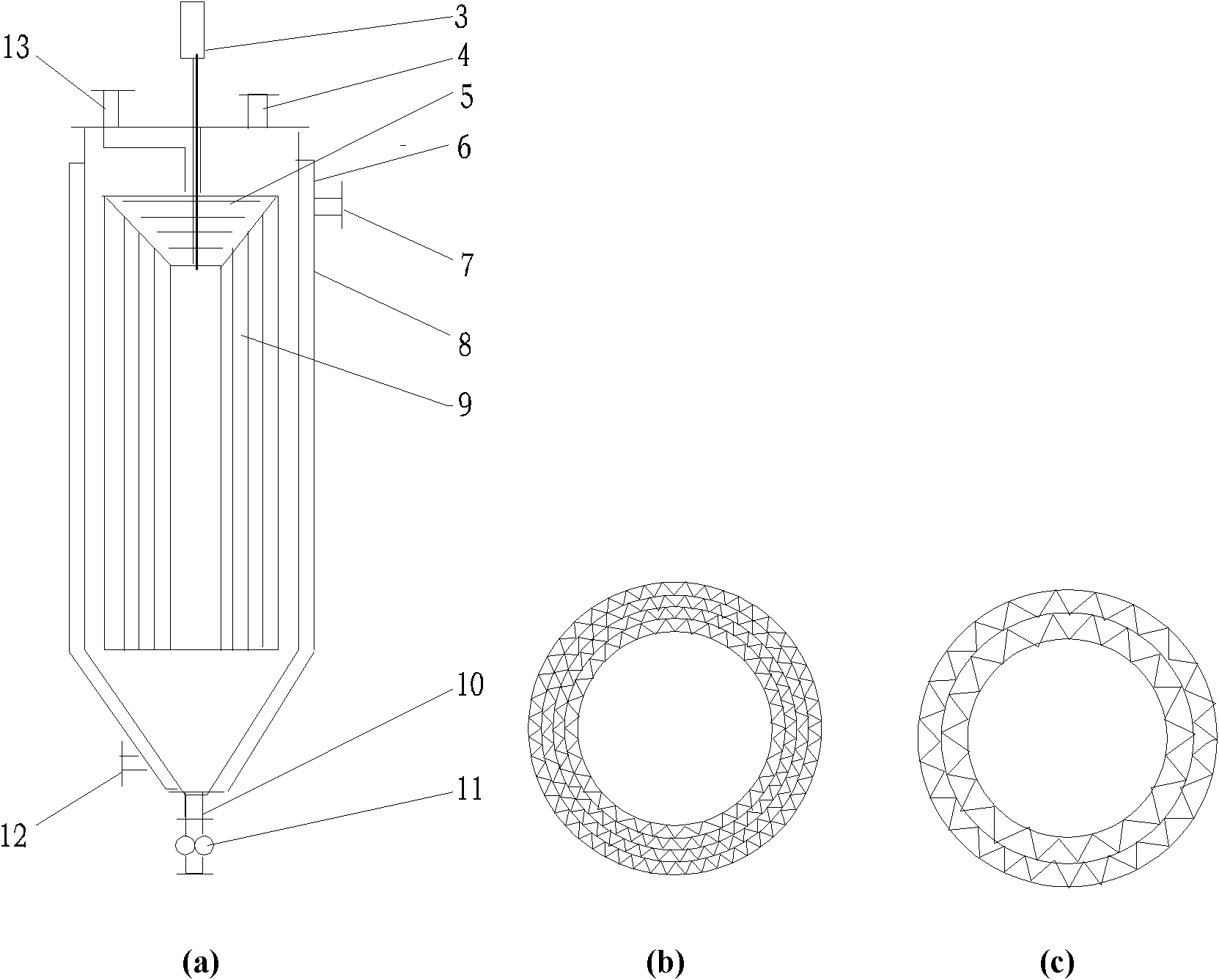

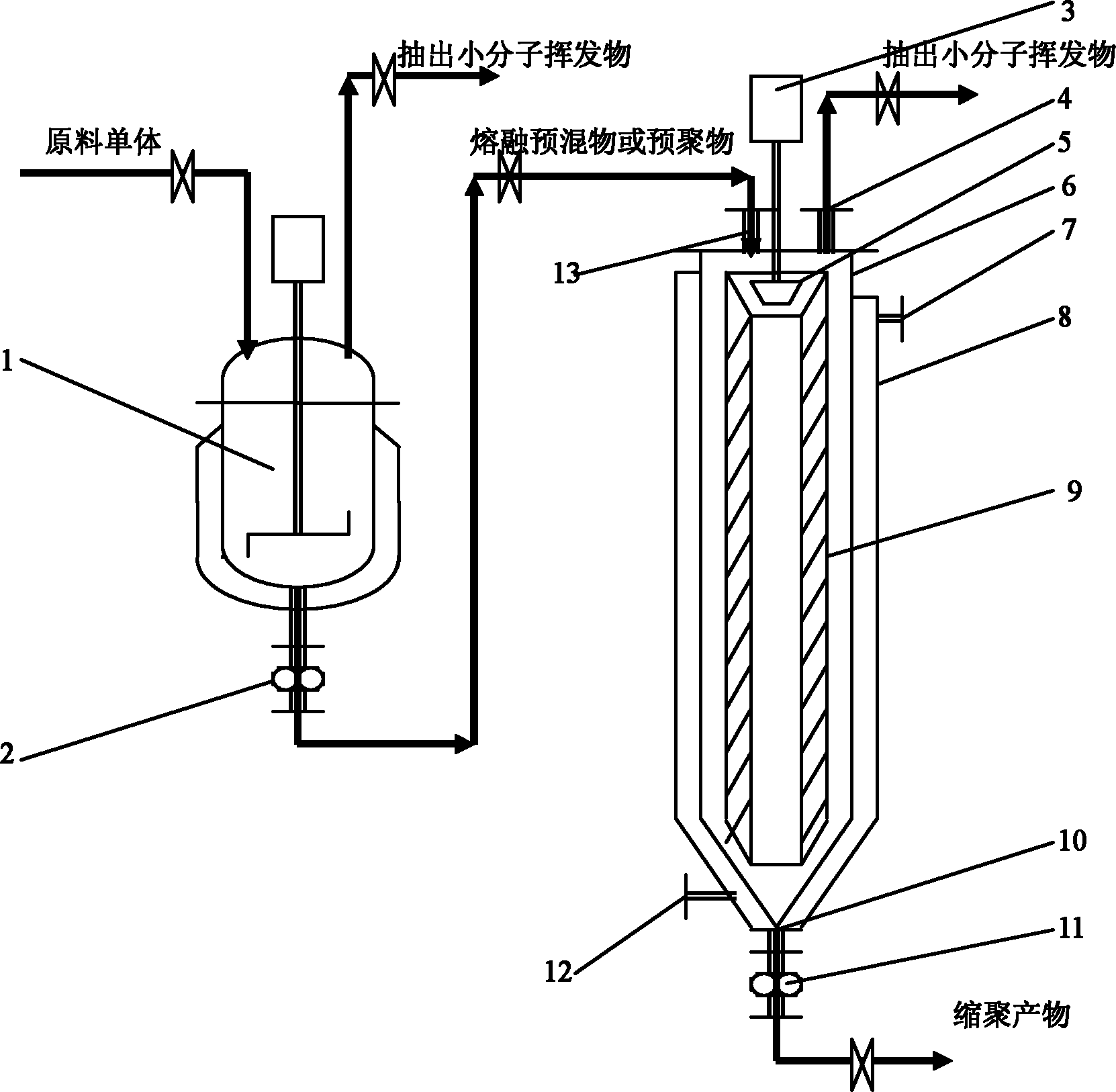

[0035] use as figure 1 As shown in the reaction equipment and flow process for the preparation of high molecular weight polycondensate, the reaction equipment 6 is a vertical cylindrical equipment with a distributor 5 and a network structure 9 inside; the distributor 5 is a horizontally rotating moving part or A distribution head with multiple openings or a combination of the two; the network structure 9 is a vertical hollow cylindrical metal network structure; the distributor 5 and the network structure 9 are separated by a space without contact.

[0036]The network structure 9 is a strip-shaped or tubular, plate-shaped, corrugated plate-shaped or groove-shaped metal member connected by metal materials with a cross-sectional shape of a circle or a rectangle, a ring or a groove, arranged in a crossing, overlapping or parallel manner. composed of methods. The moving parts that rotate horizontally are one or more layers of plane discs or curved discs, and their edges are zigzag...

Embodiment 1

[0038] A mixture of bisphenol A and diphenyl carbonate (the molar ratio of diphenyl carbonate to bisphenol A is 1.07) and tetramethylammonium hydroxide (in terms of per mol of bisphenol A, the amount added is 1.0×10 -4 mol) added to the attached figure 1 In the shown prepolymerization tank 1, under stirring state, the temperature is maintained at 180-240°C and the pressure is 13.3-1.33kPa to carry out the polymerization reaction for 2 hours to obtain a molten prepolymer with a viscosity-average molecular weight (Mv) of 5000. The system was then returned to normal pressure and continued heating to 260°C.

[0039] Start the motor 3 to make the distributor 5 rotate at the required speed; start the vacuum pump to extract the gas through the gas outlet 4 to enhance the vacuum in the reactor 5 and maintain it at the required value; the heat from the thermal oil inlet 12 to the reactor Hot oil is passed into the oil jacket 8 and then flows out through the hot oil outlet 7 to maintai...

Embodiment 2

[0044] A mixture of bisphenol A and diphenyl carbonate (the molar ratio of diphenyl carbonate to bisphenol A is 1.07) and tetramethylammonium hydroxide (in terms of per mol of bisphenol A, the amount added is 1.0×10 -4 mol) added to the attached figure 1 In the shown prepolymerization tank 1, the temperature was kept under stirring at 180-250°C and the pressure was 13.3-1.33kPa to carry out the polymerization reaction for 2.5 hours to obtain a molten prepolymer with a viscosity-average molecular weight (Mv) of 7000. The system was then returned to normal pressure and continued heating to 280°C.

[0045] open attached figure 1 The valve on the feed pipeline of the shown reactor 6 starts the discharge pump 2 of the prepolymerization kettle, and feeds the reactor 6 continuously with a flow rate of 40kg / h. Open the valve on the discharge pipe at the bottom of the reactor 6 and start the reactor discharge pump 11 to discharge the polycondensation product.

[0046] The external d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com