Electric furnace electrode control system

A control system, electric furnace electrode technology, applied in furnace control devices, electric furnace heating, furnaces, etc., can solve the problems of small reaction area, waste of working time, and inability to independently adjust three-phase electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

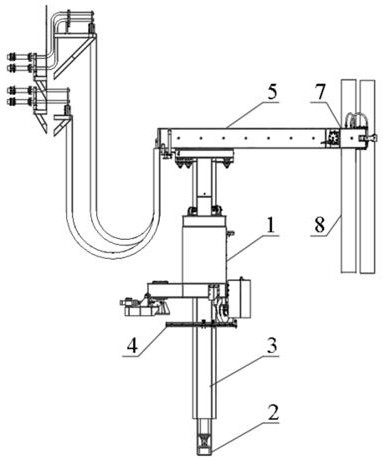

[0053] Such as figure 1 As shown, the electric furnace electrode control system includes a load-bearing shell 1, an installation base 2, a lifting device 3, a station adjustment device 4, a cross arm 5, an electrode circle adjustment device 6, and an electrode clamping device 7. In this embodiment, the load-bearing shell 1 is used as the load-bearing main body and is rotatably installed on the foundation platform through the station adjustment device 4. The foundation platform is a cement platform or a load-bearing bracket. On the base 2, the top of the lifting device 3 is fixed on the bottom of the cross arm 5, the lifting device 3 is used to drive the cross arm 5 to rise and fall, and the station adjustment device 4 is used to drive the load-bearing shell 1, the installation base 2, the lifting device 3 and the cross arm 5 overall rotation.

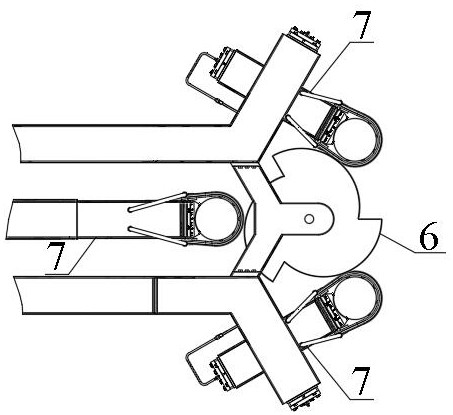

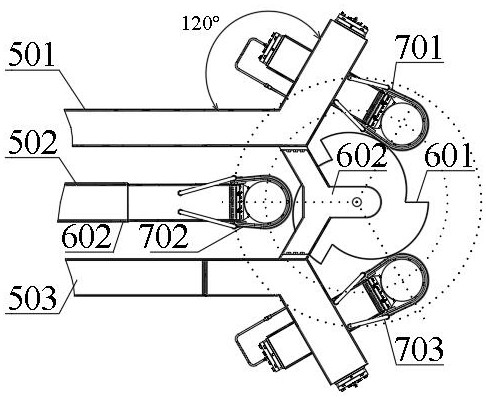

[0054] Such as figure 2 and image 3 As shown, the cross arm 5 is divided into a first cross arm 501, a second cross arm 502 and a...

Embodiment 2

[0061] In this embodiment, the calculation method of the diameter of the electrode circle is as follows:

[0062] D. P =α*Di / K+β*γ*d / cos30°, where D P is the diameter of the electrode circle, Di is the inner diameter of the electric furnace or ladle, K is the empirical coefficient, 2.6≤K≤2.9, d is the electrode diameter, α is the first proportion coefficient, 0.6≤α≤0.65, β is the second proportion coefficient, 0.35≤β≤0.4, γ is the diameter coefficient, 3≤γ≤3.5.

[0063] It should be noted that the electrode circle diameter D P The selection is directly positively related to two factors: the electrode diameter d and the inner diameter Di of the electric furnace or ladle. Specifically, when the electrode diameter d increases, the electrode circle diameter D P Need to increase; when the inner diameter Di of the electric furnace or ladle increases, the diameter of the electrode circle D P also needs to be increased.

[0064] It needs to be further explained that the first pro...

Embodiment 3

[0066] Such as Figure 7 to Figure 9As shown, the electrode clamping device 7 includes a clamping housing 704, an arc-shaped clamping seat 705, a moving clamp 706, a conductive wire 707, a moving groove 708, a transmission plate 709, a clamping connector 710, a clamping cylinder 711 and Roller row 712, in this embodiment, the end of the clamping shell 704 of the electrode clamping device 7 is provided with an arc-shaped clamping seat 705 and a moving clamp 706, and the arc-shaped clamping seat 705 and the moving clamp 706 are used for cooperation On the fixed electrode 8, the outer wall of the movable clamp 706 is in contact with the conductive wire 707, and the two ends of the movable clamp 706 are arranged on the transmission plate 709. 710 is connected to the clamping oil cylinder 711 , and two sets of roller rows 712 are respectively arranged on the upper and lower surfaces of the clamping housing 704 , and cooperate with the chute 505 on the inner wall of the cross arm 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com