An electrode automatic control system

An automatic control and electrode technology, applied in electric heating devices, electrical components, heating by discharge, etc., can solve the problems of unfavorable production, low verticality and strength, and reduce the resistance between electrodes, so as to improve the amount of chemical materials and production, avoid Heat concentration problem, the effect of accurate lifting height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

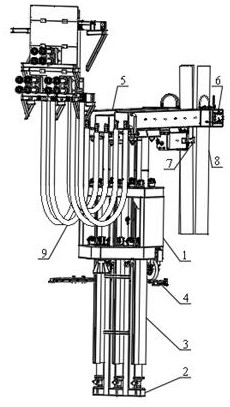

[0051] like Figure 1 to Figure 4 As shown, the electrode automatic control system includes a mobile base frame 1, a base 2, a lifting device 3, a station adjustment device 4, a cross arm 5, an electrode circle adjustment device 6 and an electrode clamping device 7. In this embodiment, the mobile The base frame 1, as a load-bearing body, is rotatably installed on the base table through the station adjustment device 4, the base 2 is horizontally arranged at the bottom of the mobile base frame 1, and the bottom of the lifting device 3 is horizontally fixed on the base 2. The lifting device The top of 3 is fixed on the bottom of the cross arm 5, the lifting device 3 is used to drive the horizontal arm 5 to rise and fall, and the station adjustment device 4 is used to drive the moving base frame 1, the base 2, the lifting device 3 and the horizontal arm 5 to rotate as a whole.

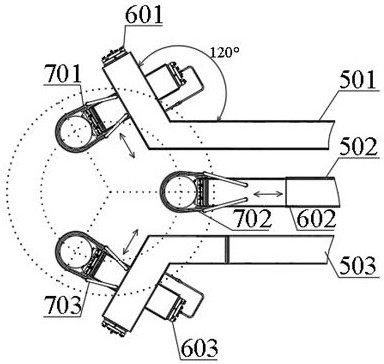

[0052] Specifically, the transverse arm 5 is divided into a first transverse arm 501, a second transver...

Embodiment 2

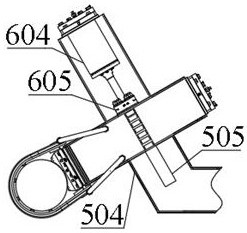

[0056] like Figure 4 and Figure 5 As shown, the electrode clamping device 7 includes a clamping housing 704, an arc-shaped clamping seat 705, a moving clamp 706, a conductive wire 707, a moving groove 708, a transmission plate 709, a clamping connector 710, a clamping oil cylinder 711 and Roller row 712, in this embodiment, the end of the clamping housing 704 of the electrode clamping device 7 is provided with an arc-shaped clamping seat 705 and a movable clamp 706, and the arc-shaped clamping seat 705 and the movable clamp 706 are used for working together In the fixed electrode 8, the outer wall of the movable clamp 706 is in contact with the conductive wire 707, and the two ends of the movable clamp 706 are arranged on the transmission plate 709. 710 is connected to the clamping oil cylinder 711 , and two sets of roller rows 712 are respectively arranged on the upper and lower surfaces of the clamping housing 704 and cooperate with the chute 505 on the inner wall of the ...

Embodiment 3

[0058] like Image 6 and Figure 7 As shown in the figure, the mobile base frame 1 is rotatably installed on the foundation table as the load-bearing main body. The base table is a cement structure or a frame base. The load-bearing plate of the mobile base frame 1 is provided with three upper through holes 101, and the circumference of the upper through holes 101 is symmetrical. A plurality of upper guide wheels 102 are provided, and three lower through holes 103 are correspondingly opened on the lower bearing plate of the mobile base 1 , and a plurality of lower guide wheels 104 are symmetrically arranged around the lower through holes 103 . Specifically, the upper through holes 101 and the lower through holes 103 are correspondingly provided for vertically installing the lifting sleeve 304, and each through hole is configured with four to eight guide wheels, which are symmetrically arranged and used to guide the lifting sleeve 304 vertically. Straight movement, good vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com